1ea01bde79f6ba9a56bfc86eed2f4b68.ppt

- Количество слайдов: 34

Appsworld 2003 Integrating the Supply Chain in Process Industries Cesare Kim 26 June 2003

Appsworld 2003 Integrating the Supply Chain in Process Industries Cesare Kim 26 June 2003

Oraplus Background “We leverage Oracle technology in order to achieve major cost reductions and provide strategic advantage to our clients” – – – – Founded in 1997 Offices in Italy, France, USA and the UK Specialised in the implementation of Oracle based solutions Vast repository of technical and functional expertise Participation in over 40 major projects in 8 countries in 3 continents Oracle Certified Partner Extensive experience in Remote Oracle Support and Hosting – Certified ISO 9001 EN: 2000 for the design, development, management and support of solutions based on Oracle Technology www. oraplus. com

Oraplus Background “We leverage Oracle technology in order to achieve major cost reductions and provide strategic advantage to our clients” – – – – Founded in 1997 Offices in Italy, France, USA and the UK Specialised in the implementation of Oracle based solutions Vast repository of technical and functional expertise Participation in over 40 major projects in 8 countries in 3 continents Oracle Certified Partner Extensive experience in Remote Oracle Support and Hosting – Certified ISO 9001 EN: 2000 for the design, development, management and support of solutions based on Oracle Technology www. oraplus. com

Agenda Introduction The OPM Solution The Oracle APS Solution ASCP and Manufacturing Scheduler Integration Case Study for a Bio-Chemical Company Q&A www. oraplus. com

Agenda Introduction The OPM Solution The Oracle APS Solution ASCP and Manufacturing Scheduler Integration Case Study for a Bio-Chemical Company Q&A www. oraplus. com

Introduction

Introduction

Third-party APS systems • OPM has traditionally integrated with i 2 and other packages such as Manugistics • Different look and feel for the different modules • Three points of failure – OPM – Links – Third-party APS system • Different vendors with different support policies • Different vendors with different upgrade and technology stategies www. oraplus. com

Third-party APS systems • OPM has traditionally integrated with i 2 and other packages such as Manugistics • Different look and feel for the different modules • Three points of failure – OPM – Links – Third-party APS system • Different vendors with different support policies • Different vendors with different upgrade and technology stategies www. oraplus. com

An Integrated Solution • • • Same look and feel Single sign-on Single-vendor interface Integrated support/upgrade strategy No need for customization/data cleaning due to architectural differences • Lower TCO www. oraplus. com

An Integrated Solution • • • Same look and feel Single sign-on Single-vendor interface Integrated support/upgrade strategy No need for customization/data cleaning due to architectural differences • Lower TCO www. oraplus. com

The OPM Solution

The OPM Solution

Native Planning Capabilities • Static lead-time and standard lot size definition – Identification of standard procurement leadtimes and lot sizes – Auto-calculation of standard leadtimes for manufactured goods • Quick single planning run – OPM MRP runs can be multi-warehouse and are very quick to produce a single MPS/MRP • Infinite Capacity Planning – Infinite Capacity capability only. – Graphical drag and drop interface allows quick manual leveling • Inter-organization transfer capability – Creation of an internal distribution network with specific transfer rules www. oraplus. com

Native Planning Capabilities • Static lead-time and standard lot size definition – Identification of standard procurement leadtimes and lot sizes – Auto-calculation of standard leadtimes for manufactured goods • Quick single planning run – OPM MRP runs can be multi-warehouse and are very quick to produce a single MPS/MRP • Infinite Capacity Planning – Infinite Capacity capability only. – Graphical drag and drop interface allows quick manual leveling • Inter-organization transfer capability – Creation of an internal distribution network with specific transfer rules www. oraplus. com

Modelling Considerations • Model creation based on simplification – Occam’s razor – Identify critical processes – Identify critical resources • Model creation based on standard Client processes – Pareto Principle (80% of the issues are resolved with 20% of the effort) • Model by increasing complexity – Initial model should be limited to simple processes to enhance Client understanding of OPM – As processes and resources increase, so do their interactions, and a model that approaches reality is developed collaboratively www. oraplus. com

Modelling Considerations • Model creation based on simplification – Occam’s razor – Identify critical processes – Identify critical resources • Model creation based on standard Client processes – Pareto Principle (80% of the issues are resolved with 20% of the effort) • Model by increasing complexity – Initial model should be limited to simple processes to enhance Client understanding of OPM – As processes and resources increase, so do their interactions, and a model that approaches reality is developed collaboratively www. oraplus. com

Bio-Chemical Process Modelling • Chemical and Biological synthesis processes are different for assembling and mixing processes • Reactor planning requires fixed leadtimes - resource capacities have different meanings • The interaction between different operations can be very complex as constraints are not fixed but depend on the interaction of all processes www. oraplus. com

Bio-Chemical Process Modelling • Chemical and Biological synthesis processes are different for assembling and mixing processes • Reactor planning requires fixed leadtimes - resource capacities have different meanings • The interaction between different operations can be very complex as constraints are not fixed but depend on the interaction of all processes www. oraplus. com

The Oracle APS Solution

The Oracle APS Solution

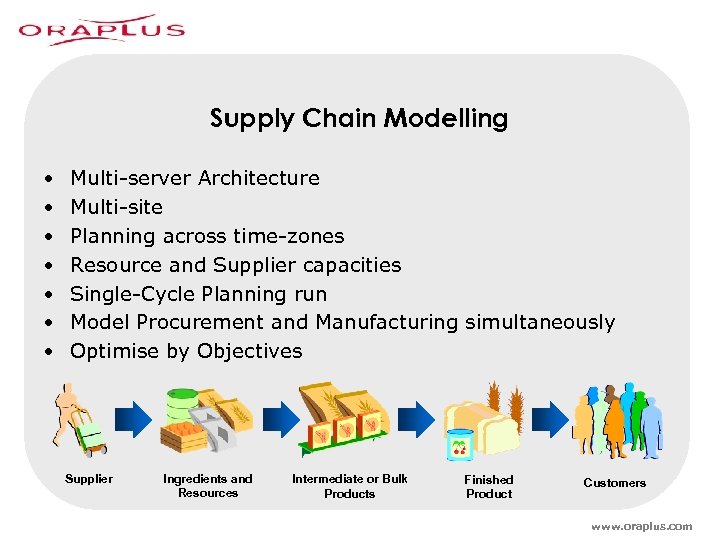

Supply Chain Modelling • • Multi-server Architecture Multi-site Planning across time-zones Resource and Supplier capacities Single-Cycle Planning run Model Procurement and Manufacturing simultaneously Optimise by Objectives Supplier Ingredients and Resources Intermediate or Bulk Products Finished Product Customers www. oraplus. com

Supply Chain Modelling • • Multi-server Architecture Multi-site Planning across time-zones Resource and Supplier capacities Single-Cycle Planning run Model Procurement and Manufacturing simultaneously Optimise by Objectives Supplier Ingredients and Resources Intermediate or Bulk Products Finished Product Customers www. oraplus. com

Manufacturing Scheduling • • Modelling environment on top of Transactional System Capacity-constrained fine scheduling Setup optimization Resource rather than Material-centric www. oraplus. com

Manufacturing Scheduling • • Modelling environment on top of Transactional System Capacity-constrained fine scheduling Setup optimization Resource rather than Material-centric www. oraplus. com

ASCP & Manufacturing Scheduler Integration with OPM

ASCP & Manufacturing Scheduler Integration with OPM

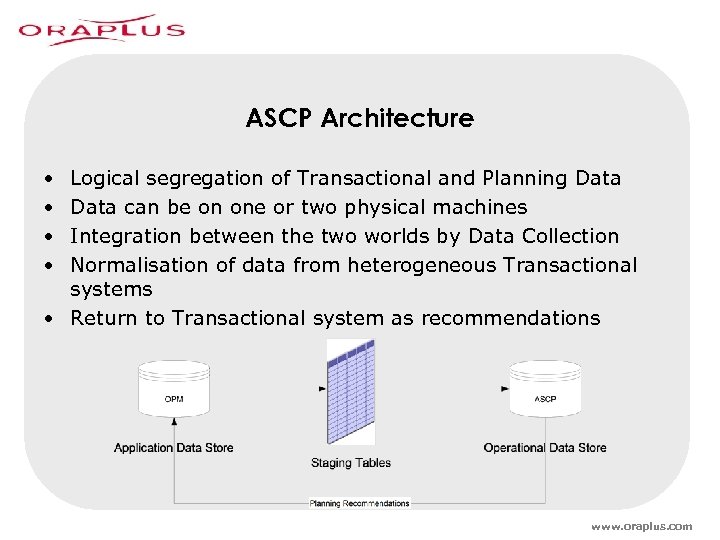

ASCP Architecture • • Logical segregation of Transactional and Planning Data can be on one or two physical machines Integration between the two worlds by Data Collection Normalisation of data from heterogeneous Transactional systems • Return to Transactional system as recommendations www. oraplus. com

ASCP Architecture • • Logical segregation of Transactional and Planning Data can be on one or two physical machines Integration between the two worlds by Data Collection Normalisation of data from heterogeneous Transactional systems • Return to Transactional system as recommendations www. oraplus. com

ASCP OPM Integration • Model Formulas and Routings from OPM • Model Effectivities using OPM Recipes • Model Resource Capacities using OPM • Model Suppliers using Supply Chain Planning www. oraplus. com

ASCP OPM Integration • Model Formulas and Routings from OPM • Model Effectivities using OPM Recipes • Model Resource Capacities using OPM • Model Suppliers using Supply Chain Planning www. oraplus. com

ASCP OPM Integration Limits • Cannot model charges • Powerful but delicate sinergy • Information is distributed over many modules • Significantly more maintenance at the technical level www. oraplus. com

ASCP OPM Integration Limits • Cannot model charges • Powerful but delicate sinergy • Information is distributed over many modules • Significantly more maintenance at the technical level www. oraplus. com

Manufacturing Scheduling OPM Integration • • Take a snapshot of current jobs Calculate resource availabilities Manually level resources by drag and drop Automatically schedule using optimization objectives and constraints www. oraplus. com

Manufacturing Scheduling OPM Integration • • Take a snapshot of current jobs Calculate resource availabilities Manually level resources by drag and drop Automatically schedule using optimization objectives and constraints www. oraplus. com

Case Study

Case Study

Common Bio-Chem Requirements Need to: – Plan reactors – Coordinate extremely long and complicated routings with significant resource overlaps – Manage maintenance – Manage cleaning and setups – Schedule operations over inactive periods – Plan across a very long horizon for procurement www. oraplus. com

Common Bio-Chem Requirements Need to: – Plan reactors – Coordinate extremely long and complicated routings with significant resource overlaps – Manage maintenance – Manage cleaning and setups – Schedule operations over inactive periods – Plan across a very long horizon for procurement www. oraplus. com

Modelling Reactors • Chemical and biological synthesis processes are quantity independent – The reactor volumetric capacity will only dictate maximum quantity – Reaction time is based on process not quantity • Charge functionality partially addresses issue – Reactor volumetric capacity is modelled but this is often insufficient – Many companies manage different levels of detail for planning and fabbrication modelling www. oraplus. com

Modelling Reactors • Chemical and biological synthesis processes are quantity independent – The reactor volumetric capacity will only dictate maximum quantity – Reaction time is based on process not quantity • Charge functionality partially addresses issue – Reactor volumetric capacity is modelled but this is often insufficient – Many companies manage different levels of detail for planning and fabbrication modelling www. oraplus. com

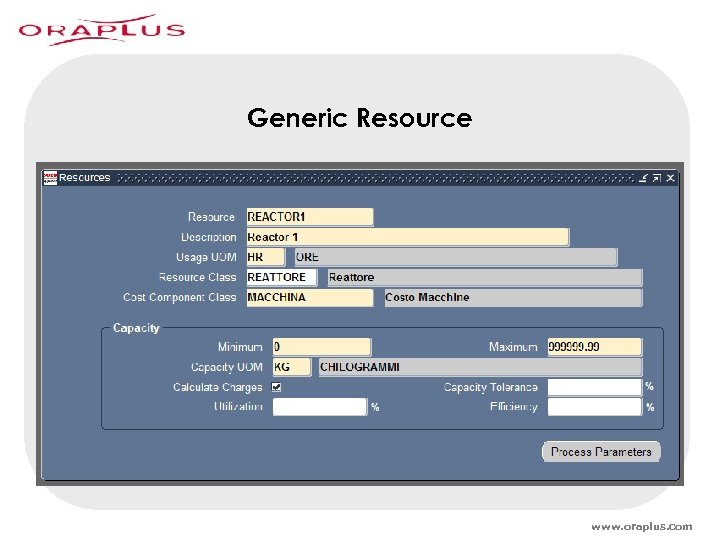

Generic Resource www. oraplus. com

Generic Resource www. oraplus. com

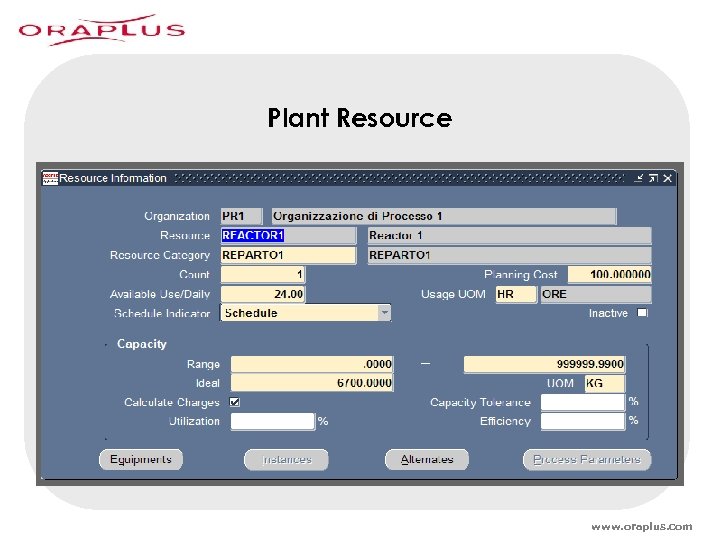

Plant Resource www. oraplus. com

Plant Resource www. oraplus. com

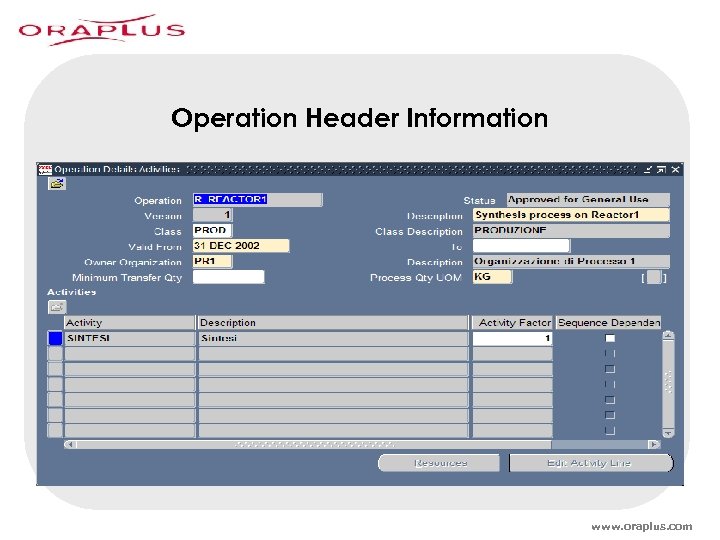

Operation Header Information www. oraplus. com

Operation Header Information www. oraplus. com

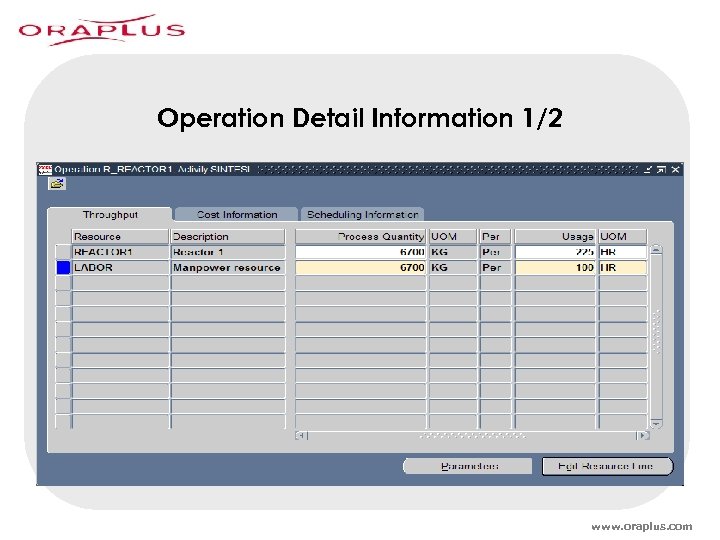

Operation Detail Information 1/2 www. oraplus. com

Operation Detail Information 1/2 www. oraplus. com

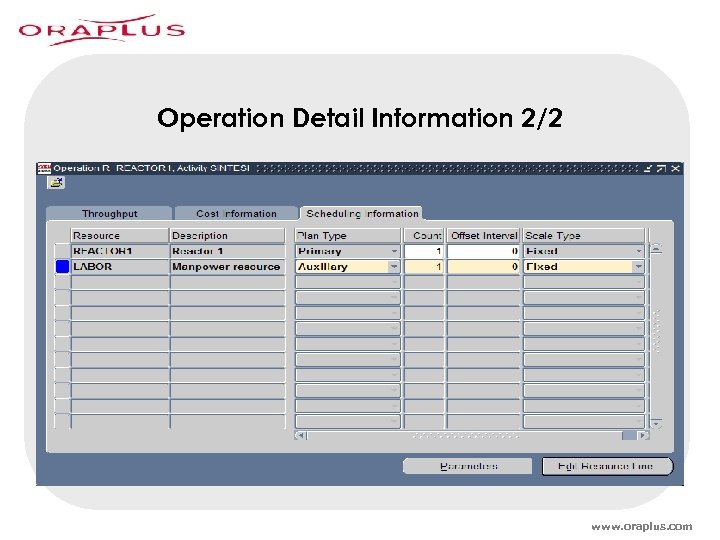

Operation Detail Information 2/2 www. oraplus. com

Operation Detail Information 2/2 www. oraplus. com

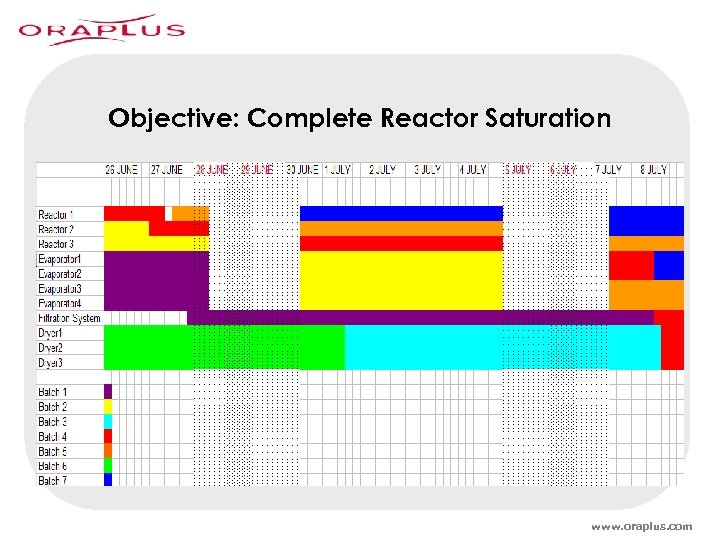

Objective: Complete Reactor Saturation www. oraplus. com

Objective: Complete Reactor Saturation www. oraplus. com

Maintenance Management • Can use Resource Exceptions for basic scheduled maintenance • Enterprise Asset Management will be interfaced with ASCP to have a completely integrated Management suite www. oraplus. com

Maintenance Management • Can use Resource Exceptions for basic scheduled maintenance • Enterprise Asset Management will be interfaced with ASCP to have a completely integrated Management suite www. oraplus. com

Manage Reactor Cleaning and Setup • Cleaning operations and setups depending on the material processed in the previous batch • Modelling different recipes is a possible solution • Manually inserting downtimes is another possibility • Using Manufacturing Scheduler for fine scheduling is probably the best solution www. oraplus. com

Manage Reactor Cleaning and Setup • Cleaning operations and setups depending on the material processed in the previous batch • Modelling different recipes is a possible solution • Manually inserting downtimes is another possibility • Using Manufacturing Scheduler for fine scheduling is probably the best solution www. oraplus. com

Break Management • Special cleaning processes may be required if reactors are inactive for too long • Some operations may not be interrupted • Model operations for minimum length to complete operations www. oraplus. com

Break Management • Special cleaning processes may be required if reactors are inactive for too long • Some operations may not be interrupted • Model operations for minimum length to complete operations www. oraplus. com

Procurement • Many tipologies of ingredients can be purchased at cheaper rates in relatively distant countries • Need to plan for long procurement cycles • Use ASCP long-term Procument Planning www. oraplus. com

Procurement • Many tipologies of ingredients can be purchased at cheaper rates in relatively distant countries • Need to plan for long procurement cycles • Use ASCP long-term Procument Planning www. oraplus. com

Prototype Solution • Use ASCP to develop a long-term infinite capacity plan • Actuate mid-term finite capacity procurement and manufacturing • Fine schedule using Manufacturing Scheduler • Minimal level of detail necessary to schedule and plan • Complete automation is difficult using a simplified model so a graphical drag and a drop interface becomes crucial for planners www. oraplus. com

Prototype Solution • Use ASCP to develop a long-term infinite capacity plan • Actuate mid-term finite capacity procurement and manufacturing • Fine schedule using Manufacturing Scheduler • Minimal level of detail necessary to schedule and plan • Complete automation is difficult using a simplified model so a graphical drag and a drop interface becomes crucial for planners www. oraplus. com

Lessons learned • Stay up to date with latest rollups during implementation • ASCP is an integrating force • Include a heavy patch installation and testing contingency • Unexpected results are often due to setup issues • Profile Options! www. oraplus. com

Lessons learned • Stay up to date with latest rollups during implementation • ASCP is an integrating force • Include a heavy patch installation and testing contingency • Unexpected results are often due to setup issues • Profile Options! www. oraplus. com

Q&A www. oraplus. com

Q&A www. oraplus. com