bd06c37e458ad4962360957e2887a789.ppt

- Количество слайдов: 40

Applications of Computational Intelligence Techniques in Engineering B Samanta International Visiting Professor Robert Morris University RMU_Summer 2005_Samanta 1

Presentation Summary n n n n Motivation Computational Intelligence Different CI techniques Applications of CI techniques Recent Work done at RMU Way forward Conclusions RMU_Summer 2005_Samanta 2

Motivation n n n Use of computers for better understanding and interpretation of process/system behavior Use of available information to obtain input-output mapping. Utilization of expert/operator knowledge Ability to use imprecise, uncertain information Integration of knowledge over multiple disciplines Automated machine learning inspired from nature (neuroscience, genetics, behavioral science) Development of models for optimizing the system performance satisfying the inherent system/process constraints. RMU_Summer 2005_Samanta 3

Computational Intelligence (CI) n n Intelligence built in computer programs Covers n n Evolutionary computing Fuzzy computing Neuro-computing Also known as n Soft computing RMU_Summer 2005_Samanta 4

CI Techniques n Artificial Intelligence (AI) n n n n Artificial Neural Networks (ANNs) Fuzzy Logic (FL) Support Vector Machines (SVM) Self Organizing Maps (SOM)- unsupervised Genetic Algorithm (GA) Genetic Programming (GP) Swarm Intelligence/Particle Swarm Optimization (PSO) RMU_Summer 2005_Samanta 5

CI Techniques (contd. ) n ANNs n n Multi-layer Perceptron (MLP) Radial Basis Function (RBF) Probabilistic Neural Network (PNN) Fuzzy Logic + ANN n Adaptive neuro-fuzzy inference system (ANFIS) RMU_Summer 2005_Samanta 6

CI Techniques (contd. ) ANN structure n Input layer n Hidden Layer (s) n Output layer n Number of nodes in each layer n Functions and their parameters Mostly decided on trial and error basis RMU_Summer 2005_Samanta 7

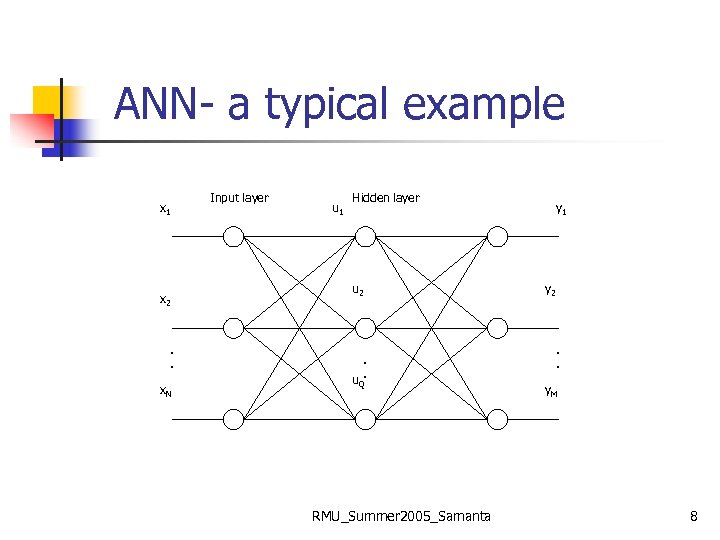

ANN- a typical example x 1 x 2 . . x. N Input layer u 1 Hidden layer u 2 . u. Q RMU_Summer 2005_Samanta y 1 y 2 . . y. M 8

Fuzzy Logic Steps involved n Fuzzification using membership functions (MFs)-input n Generation of rule base n Aggregation n Defuzzification using MFs -output RMU_Summer 2005_Samanta 9

Fuzzy Logic (contd. ) n Input and output MFs n n Number Type Parameters Rule base (experience guided) RMU_Summer 2005_Samanta 10

Neuro-Fuzzy System n n n Combines the advantages of fuzzy logic (FL) and ANNs Starts with an initial FL structure Uses ANN for adapting the FL (MF) parameters and the rule base to the training data RMU_Summer 2005_Samanta 11

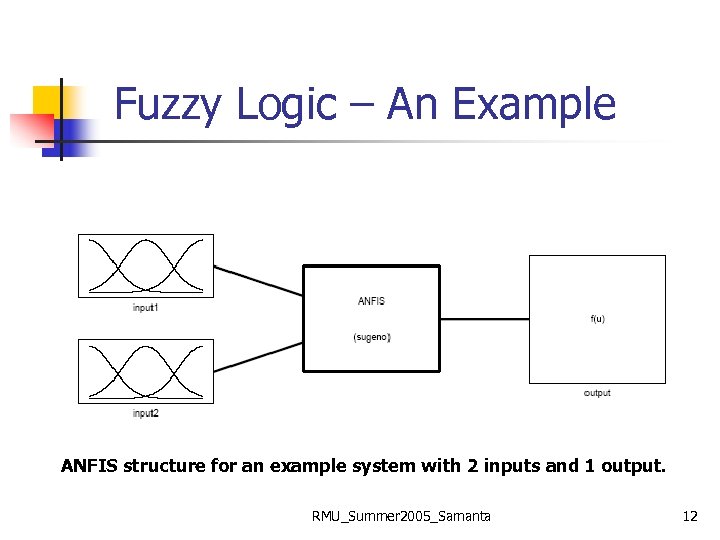

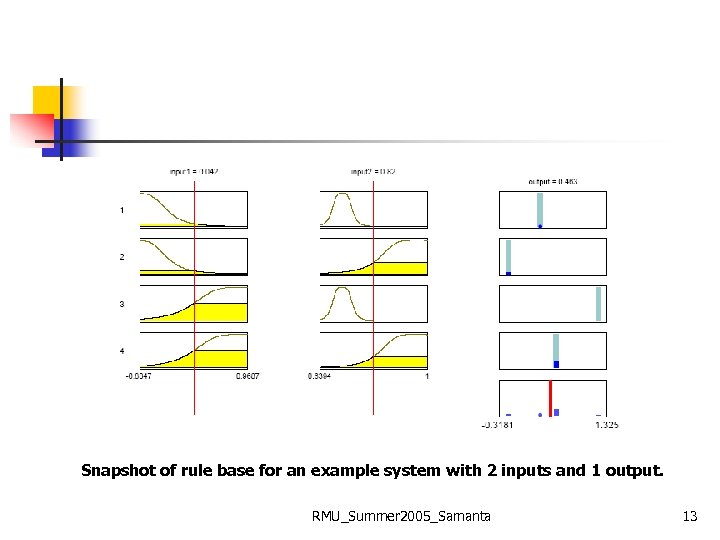

Fuzzy Logic – An Example ANFIS structure for an example system with 2 inputs and 1 output. RMU_Summer 2005_Samanta 12

Snapshot of rule base for an example system with 2 inputs and 1 output. RMU_Summer 2005_Samanta 13

Genetic Algorithms n n n Construction of genome (individual) Generation of initial population (group of individuals) Evaluation of individuals Selection of individuals based on criteria Generation of new individuals n n Mutation Crossover Repetition of the process - generation, evaluation, selection Termination of the process based on max generation no. and/or performance criteria RMU_Summer 2005_Samanta 14

Combinations n n n Combine advantages of GA and other classifiers GA and ANN GA and ANFIS GA and SVM for automatic selection of classifier structure and parameters n n n ANNs -Number of neurons in hidden layer ANFIS - Number of MFs and their parameters SVM – SVM parameters Selection of most important system features from a pool Selection of most important sensors (in the context of on-line condition monitoring and diagnostics)- sensor fusion. RMU_Summer 2005_Samanta 15

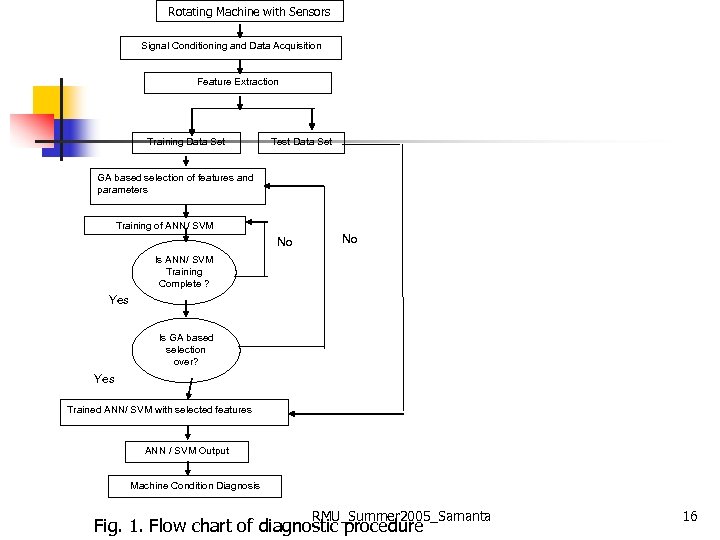

Rotating Machine with Sensors Signal Conditioning and Data Acquisition Feature Extraction Training Data Set Test Data Set GA based selection of features and parameters Training of ANN/ SVM No No Is ANN/ SVM Training Complete ? Yes Is GA based selection over? Yes Trained ANN/ SVM with selected features ANN / SVM Output Machine Condition Diagnosis RMU_Summer 2005_Samanta Fig. 1. Flow chart of diagnostic procedure 16

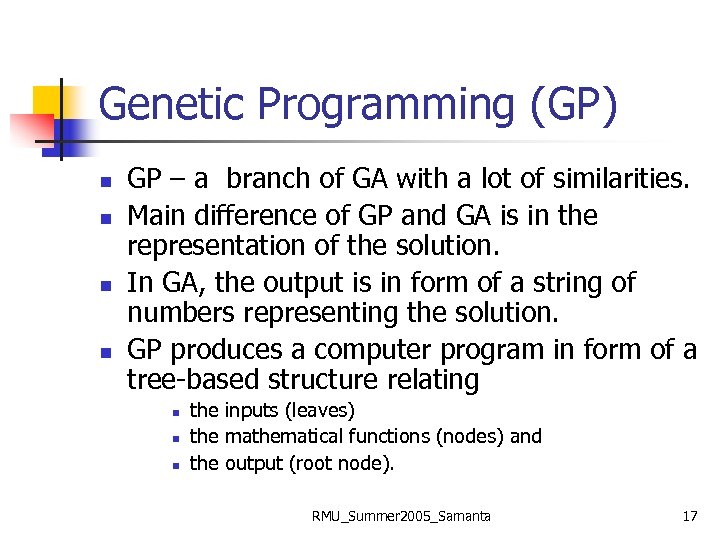

Genetic Programming (GP) n n GP – a branch of GA with a lot of similarities. Main difference of GP and GA is in the representation of the solution. In GA, the output is in form of a string of numbers representing the solution. GP produces a computer program in form of a tree-based structure relating n n n the inputs (leaves) the mathematical functions (nodes) and the output (root node). RMU_Summer 2005_Samanta 17

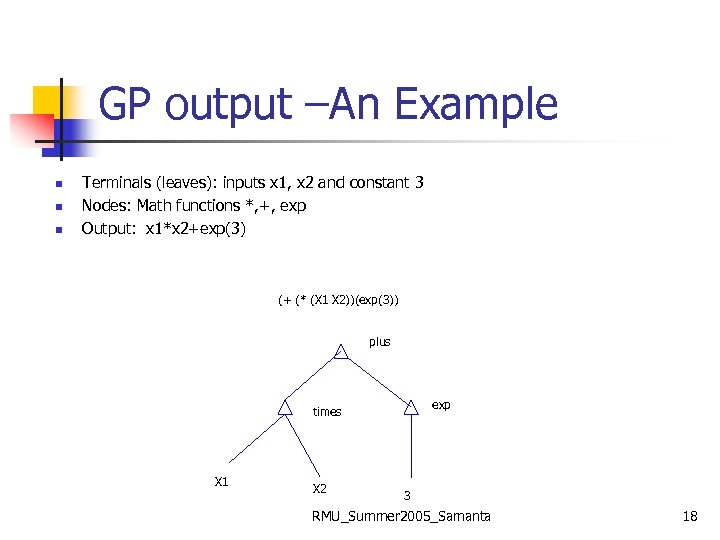

GP output –An Example n n n Terminals (leaves): inputs x 1, x 2 and constant 3 Nodes: Math functions *, +, exp Output: x 1*x 2+exp(3) (+ (* (X 1 X 2))(exp(3)) plus exp times X 1 X 2 3 RMU_Summer 2005_Samanta 18

Applications n Computer Science n n n Mechanical Systems n n Pattern Recognition (PR) Data Mining Knowledge Discovery/ Machine Learning Feature Extraction and Selection Condition monitoring and diagnostics Multiobjective optimization in design Control System Design Manufacturing Systems n n Development of data-driven models Multiobjective optimization of machining parameters RMU_Summer 2005_Samanta 19

Applications (contd. ) n Engineering Management/IE n n n Medicine n n n Inventory management Project selection Facility layout design Scheduling Patient condition monitoring and diagnosis Social Science Business n n Market analysis and forecasting Credit rating RMU_Summer 2005_Samanta 20

Recent Work n Machine Condition Monitoring and Diagnostics using n n n n ANNs-MLP, RBF, PNN SVM ANFIS GA-ANN GA-ANFIS GA-SVM GP Involving signal processing, feature extraction, selection and sensor fusion RMU_Summer 2005_Samanta 21

Recent work (contd. ) n Materials n n ANN based estimation of fatigue life Modeling of material properties in terms of heat treatment parameters Rotordynamics Control System Design RMU_Summer 2005_Samanta 22

Work done at RMU n n Intelligent Manufacturing Systems Development of Tool Wear Model n n n Development of machined surface roughness model n n n ANFIS and GA-ANFIS Genetic Programming (GP) ANFIS and GA Genetic Programming (GP) Mutliobjective optimization of machining parameters n n Minimization of machining cost Minimization of surface roughness Minimization of production time Subject to constraints on n n Operating parameters –speed, feed, depth of cut Cutting Force Power consumption Tested on 5 different data sets Involves different machining operations n n n Milling, turning and Turning of hard material (>Rc 65) RMU_Summer 2005_Samanta 23

Tool Wear Model n Mapping of Inputs and Outputs n Inputs n n n n n Outputs n n n Tool type- geometry, material Work piece Cutting speed (V) Feed rate (f) Depth of cut (d) Vibration (Vx, Vy, Vz) Forces (Fx, Fy, Fz) Cutting Time (t) Tool wear Remaining Tool Life GA/GP based selection of characteristic inputs RMU_Summer 2005_Samanta 24

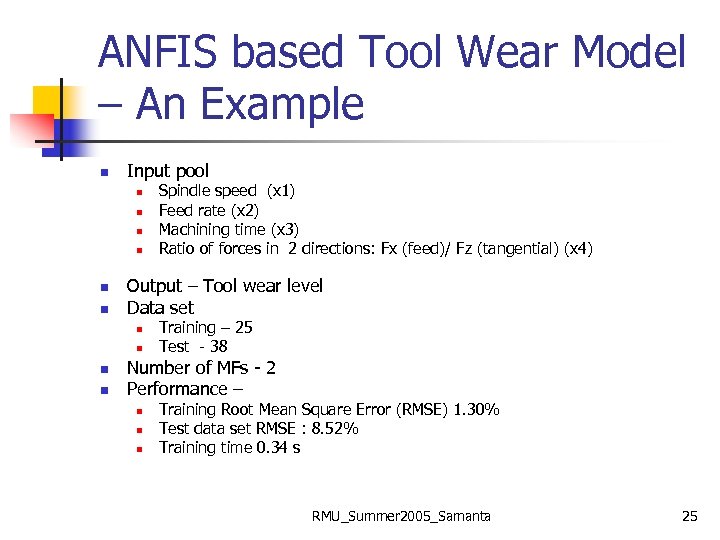

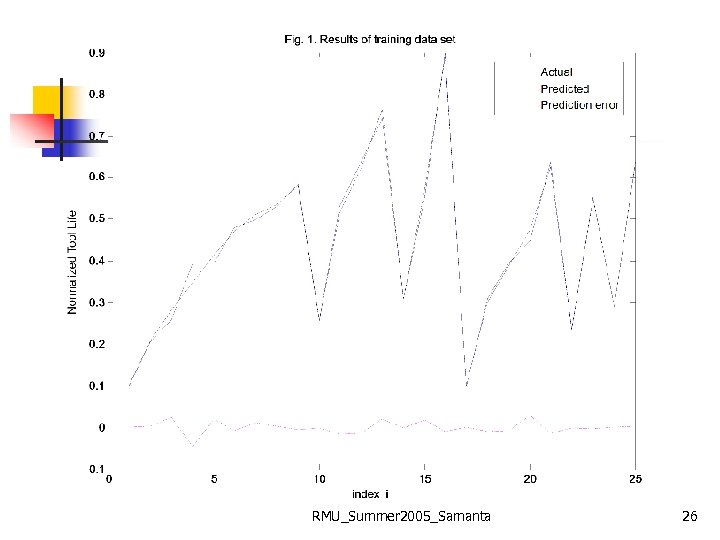

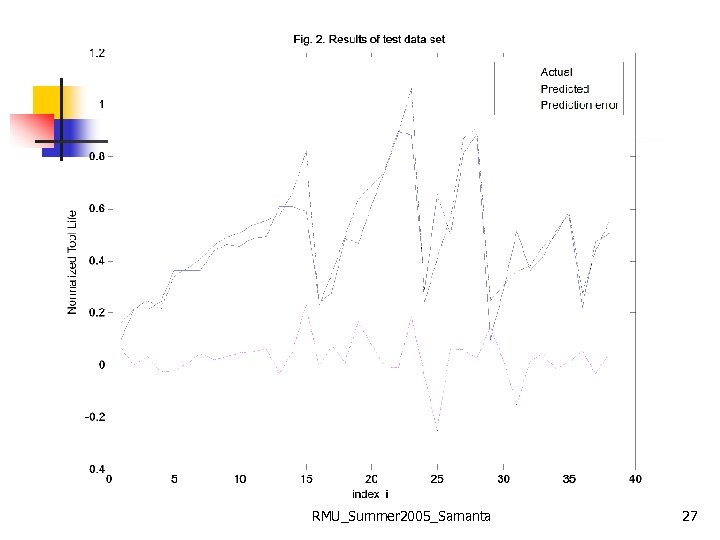

ANFIS based Tool Wear Model – An Example n Input pool n n n Output – Tool wear level Data set n n Spindle speed (x 1) Feed rate (x 2) Machining time (x 3) Ratio of forces in 2 directions: Fx (feed)/ Fz (tangential) (x 4) Training – 25 Test - 38 Number of MFs - 2 Performance – n n n Training Root Mean Square Error (RMSE) 1. 30% Test data set RMSE : 8. 52% Training time 0. 34 s RMU_Summer 2005_Samanta 25

RMU_Summer 2005_Samanta 26

RMU_Summer 2005_Samanta 27

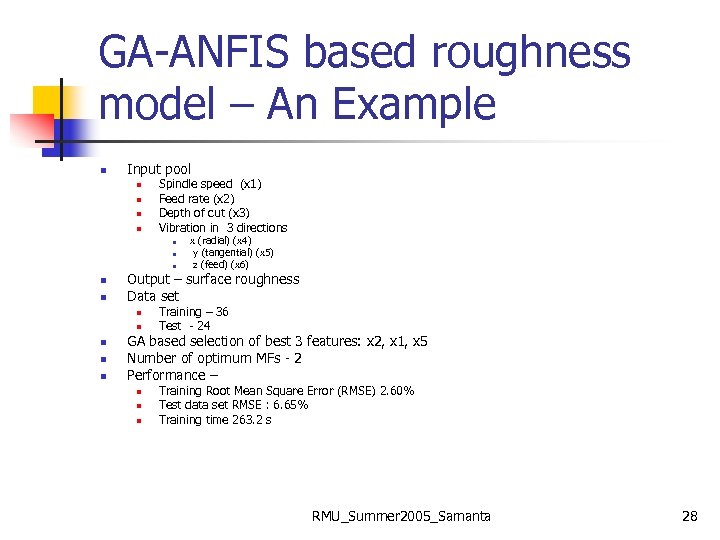

GA-ANFIS based roughness model – An Example n Input pool n n Spindle speed (x 1) Feed rate (x 2) Depth of cut (x 3) Vibration in 3 directions n n n Output – surface roughness Data set n n n x (radial) (x 4) y (tangential) (x 5) z (feed) (x 6) Training – 36 Test - 24 GA based selection of best 3 features: x 2, x 1, x 5 Number of optimum MFs - 2 Performance – n n n Training Root Mean Square Error (RMSE) 2. 60% Test data set RMSE : 6. 65% Training time 263. 2 s RMU_Summer 2005_Samanta 28

RMU_Summer 2005_Samanta 29

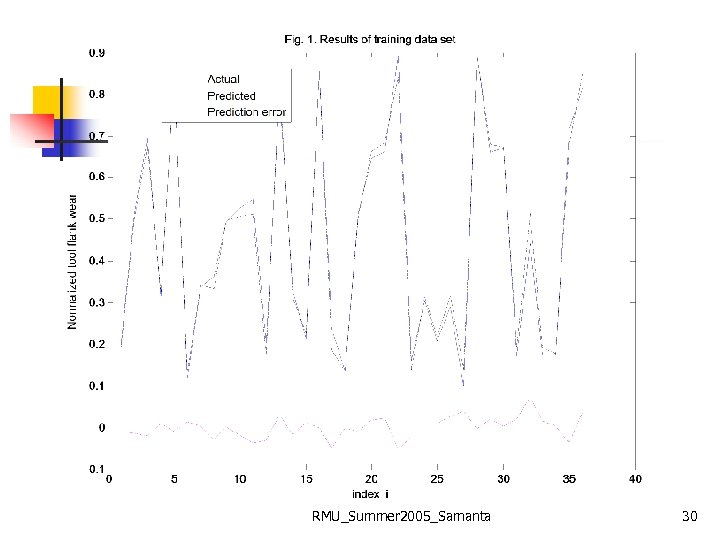

RMU_Summer 2005_Samanta 30

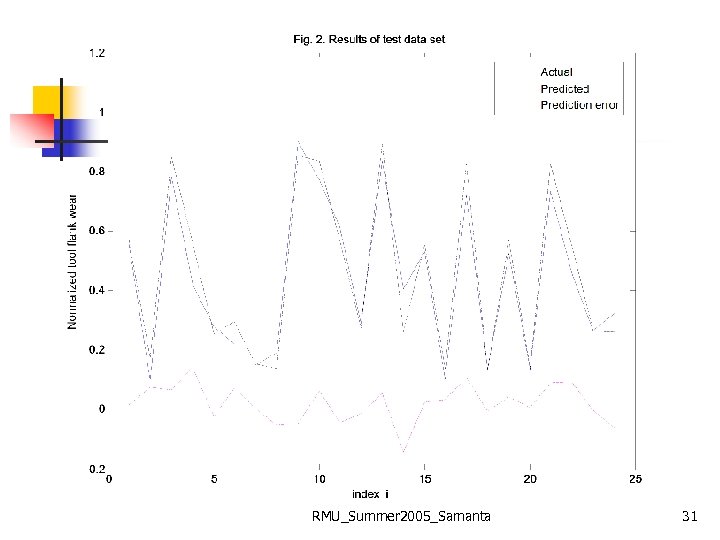

RMU_Summer 2005_Samanta 31

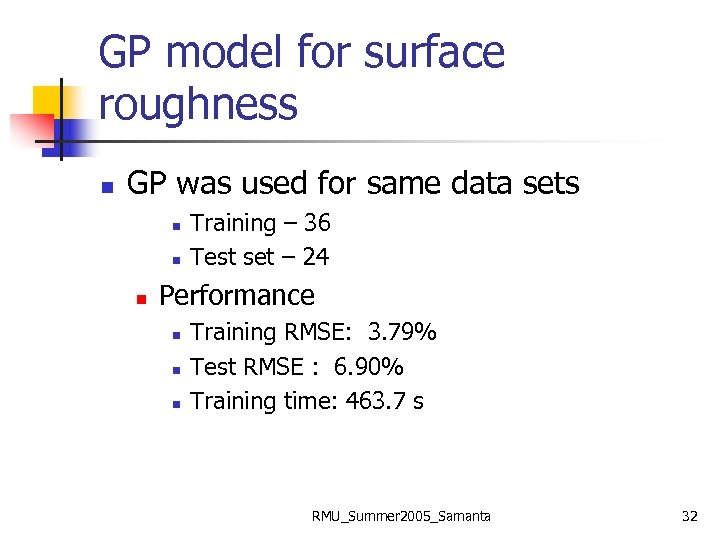

GP model for surface roughness n GP was used for same data sets n n n Training – 36 Test set – 24 Performance n n n Training RMSE: 3. 79% Test RMSE : 6. 90% Training time: 463. 7 s RMU_Summer 2005_Samanta 32

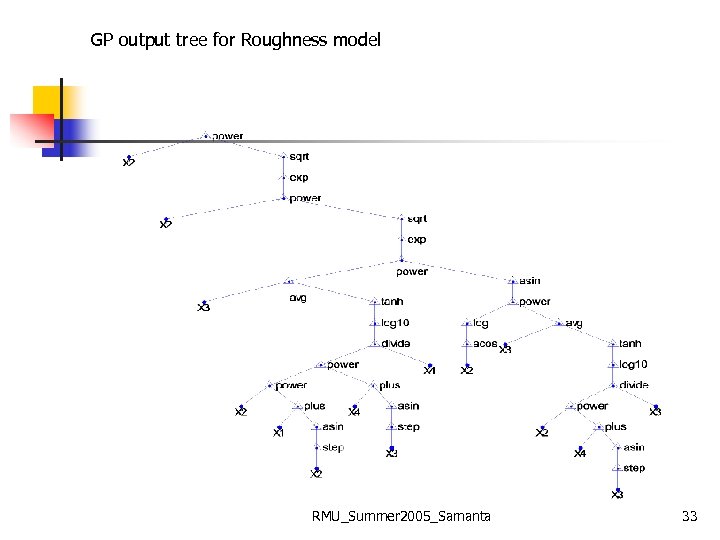

GP output tree for Roughness model RMU_Summer 2005_Samanta 33

Publications Planned n n n Predictive modeling of tool wear in turning using adaptive neuro-fuzzy inference system Modeling and prediction of tool wear in turning using genetic programming Predictive modeling of surface roughness in turning using adaptive neuro-fuzzy inference system and genetic algorithms RMU_Summer 2005_Samanta 34

Publications Planned (contd. ) n n n Modeling and prediction of surface roughness in turning using genetic programming Predictive modeling of surface roughness in milling using adaptive neuro-fuzzy inference system and genetic algorithms Multiobjective evolutionary optimization of a machining process RMU_Summer 2005_Samanta 35

Conferences/Journals n n n North American Manufacturing Research Conference (NAMRC 34 ), NAMRI/SME, May 23 -26, 2006, Milawukee, WI, USA. Flexible Automation and Intelligent Manufacturing (FAIM) June 26 -28, 2006, Univ of Limerick, Ireland. IFAC Symposium on Information Control in Manufacturing (INCOM) May 17 -19, 2006, France. Journal of Manufacturing Systems/SME International Journal of Machine Tools & Manufacture RMU_Summer 2005_Samanta 36

Industry-RMU collaboration Potential n Interest in RMU-EOC research collaboration in the area of Laser machining. n n Development of machining models using CI Multiobjective constrained optimization of machining/laser system parameters Sensor fusion Interest in RMU-Ex. One research collaboration in the areas of 3 D printing n n n process system Design optimization RMU_Summer 2005_Samanta 37

Way Forward n Scope for further collaboration with RMU n n Teaching – Development of new elective or short courses in consultation with Faculty Research – Joint supervision of projects/theses at Senior, MS and Ph. D levels Collaborative work with Faculty Outreach- Industry and Government supported research projects/contracts RMU_Summer 2005_Samanta 38

Conclusions Increasing popularity of CI techniques n Integrating capability over multiple disciplines n Capability of incorporating imprecision and uncertainty n Suitability for hard-to-model processes /systems n Better alternatives to traditional hard computing scenario RMU_Summer 2005_Samanta 39

THANKS Thanks to n RMU Administration n Sponsor of the Program n SEMS/Engineering Faculty, Staff for the support and facilitating the visit Thanks to you all (in audience) n For your time and patience RMU_Summer 2005_Samanta 40

bd06c37e458ad4962360957e2887a789.ppt