08772d79c8b36e5517729c32ec55ce90.ppt

- Количество слайдов: 30

Applications Cutting Tools Machining 1 © Iscar Seminar 2001 Conditions

Applications Cutting Tools Machining 1 © Iscar Seminar 2001 Conditions

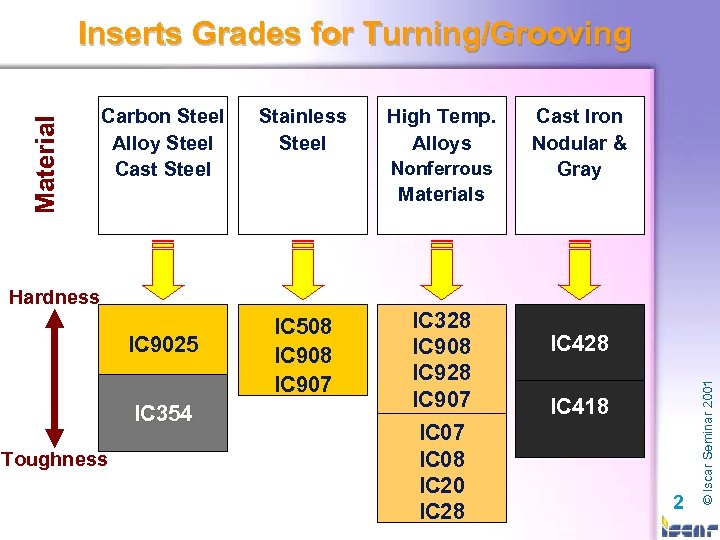

Carbon Steel Alloy Steel Cast Steel Stainless Steel Nonferrous Cast Iron Nodular & Gray Materials Hardness IC 9025 IC 354 Toughness High Temp. Alloys IC 508 IC 907 IC 328 IC 908 IC 928 IC 907 IC 08 IC 20 IC 28 IC 418 2 © Iscar Seminar 2001 Material Inserts Grades for Turning/Grooving

Carbon Steel Alloy Steel Cast Steel Stainless Steel Nonferrous Cast Iron Nodular & Gray Materials Hardness IC 9025 IC 354 Toughness High Temp. Alloys IC 508 IC 907 IC 328 IC 908 IC 928 IC 907 IC 08 IC 20 IC 28 IC 418 2 © Iscar Seminar 2001 Material Inserts Grades for Turning/Grooving

GRIP Inserts with Positive Rake for Machining High Temp. Alloys Submicron Grade for Exotic Materials PVD Coating of Ti. Al. N © Iscar Seminar 2001 GIPA 3 -6

GRIP Inserts with Positive Rake for Machining High Temp. Alloys Submicron Grade for Exotic Materials PVD Coating of Ti. Al. N © Iscar Seminar 2001 GIPA 3 -6

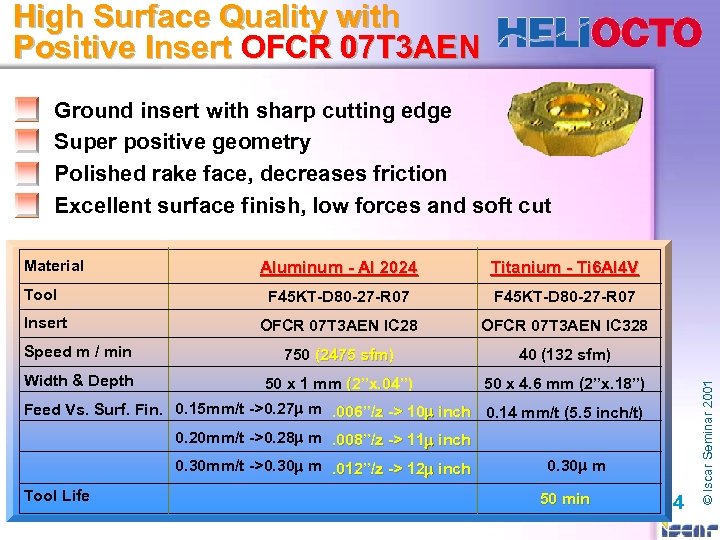

High Surface Quality with Positive Insert OFCR 07 T 3 AEN Ground insert with sharp cutting edge Super positive geometry Polished rake face, decreases friction Excellent surface finish, low forces and soft cut Material Titanium - Ti 6 Al 4 V F 45 KT-D 80 -27 -R 07 OFCR 07 T 3 AEN IC 28 OFCR 07 T 3 AEN IC 328 Speed m / min 750 (2475 sfm) 40 (132 sfm) Width & Depth 50 x 1 mm (2”x. 04”) 50 x 4. 6 mm (2”x. 18”) Tool Insert Feed Vs. Surf. Fin. 0. 15 mm/t ->0. 27 m m. 006”/z -> 10 m inch 0. 14 mm/t (5. 5 inch/t) 0. 20 mm/t ->0. 28 m m. 008”/z -> 11 m inch 0. 30 mm/t ->0. 30 m m. 012”/z -> 12 m inch Tool Life 0. 30 m m 50 min 4 © Iscar Seminar 2001 Aluminum - Al 2024

High Surface Quality with Positive Insert OFCR 07 T 3 AEN Ground insert with sharp cutting edge Super positive geometry Polished rake face, decreases friction Excellent surface finish, low forces and soft cut Material Titanium - Ti 6 Al 4 V F 45 KT-D 80 -27 -R 07 OFCR 07 T 3 AEN IC 28 OFCR 07 T 3 AEN IC 328 Speed m / min 750 (2475 sfm) 40 (132 sfm) Width & Depth 50 x 1 mm (2”x. 04”) 50 x 4. 6 mm (2”x. 18”) Tool Insert Feed Vs. Surf. Fin. 0. 15 mm/t ->0. 27 m m. 006”/z -> 10 m inch 0. 14 mm/t (5. 5 inch/t) 0. 20 mm/t ->0. 28 m m. 008”/z -> 11 m inch 0. 30 mm/t ->0. 30 m m. 012”/z -> 12 m inch Tool Life 0. 30 m m 50 min 4 © Iscar Seminar 2001 Aluminum - Al 2024

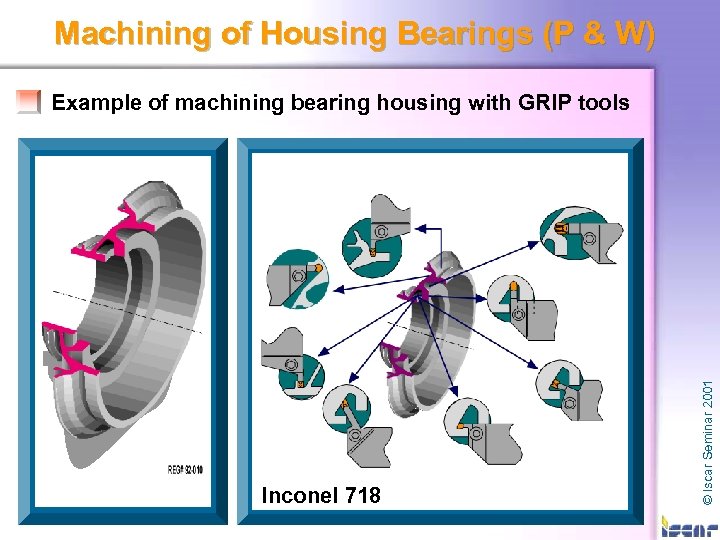

Machining of Housing Bearings (P & W) Inconel 718 © Iscar Seminar 2001 Example of machining bearing housing with GRIP tools

Machining of Housing Bearings (P & W) Inconel 718 © Iscar Seminar 2001 Example of machining bearing housing with GRIP tools

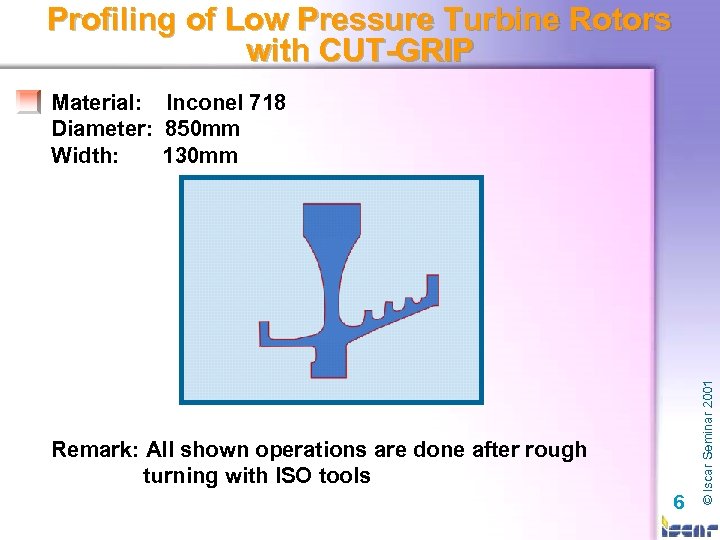

Profiling of Low Pressure Turbine Rotors with CUT-GRIP Remark: All shown operations are done after rough turning with ISO tools 6 © Iscar Seminar 2001 Material: Inconel 718 Diameter: 850 mm Width: 130 mm

Profiling of Low Pressure Turbine Rotors with CUT-GRIP Remark: All shown operations are done after rough turning with ISO tools 6 © Iscar Seminar 2001 Material: Inconel 718 Diameter: 850 mm Width: 130 mm

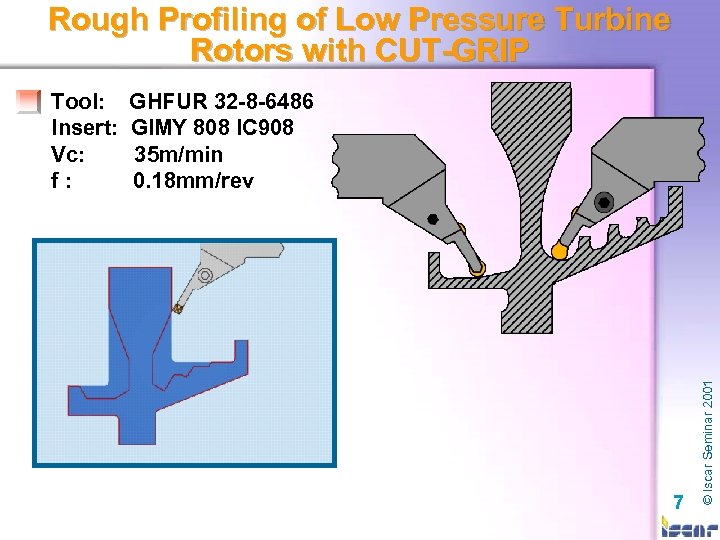

Rough Profiling of Low Pressure Turbine Rotors with CUT-GRIP GHFUR 32 -8 -6486 GIMY 808 IC 908 35 m/min 0. 18 mm/rev 7 © Iscar Seminar 2001 Tool: Insert: Vc: f:

Rough Profiling of Low Pressure Turbine Rotors with CUT-GRIP GHFUR 32 -8 -6486 GIMY 808 IC 908 35 m/min 0. 18 mm/rev 7 © Iscar Seminar 2001 Tool: Insert: Vc: f:

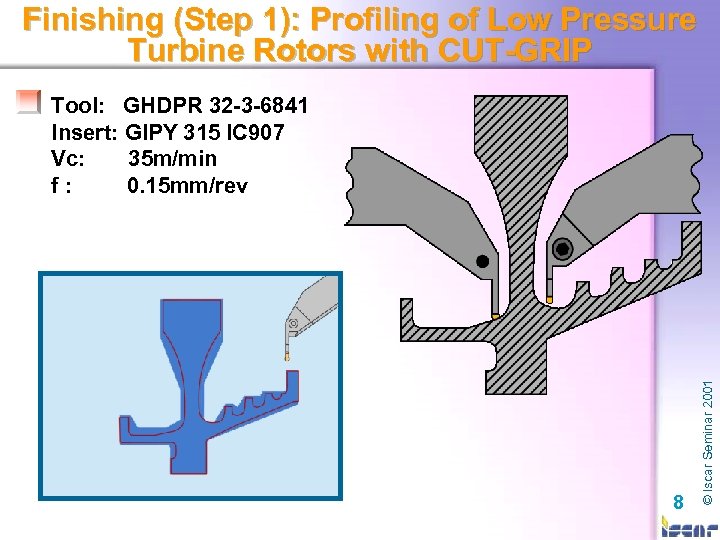

Finishing (Step 1): Profiling of Low Pressure Turbine Rotors with CUT-GRIP 8 © Iscar Seminar 2001 Tool: GHDPR 32 -3 -6841 Insert: GIPY 315 IC 907 Vc: 35 m/min f: 0. 15 mm/rev

Finishing (Step 1): Profiling of Low Pressure Turbine Rotors with CUT-GRIP 8 © Iscar Seminar 2001 Tool: GHDPR 32 -3 -6841 Insert: GIPY 315 IC 907 Vc: 35 m/min f: 0. 15 mm/rev

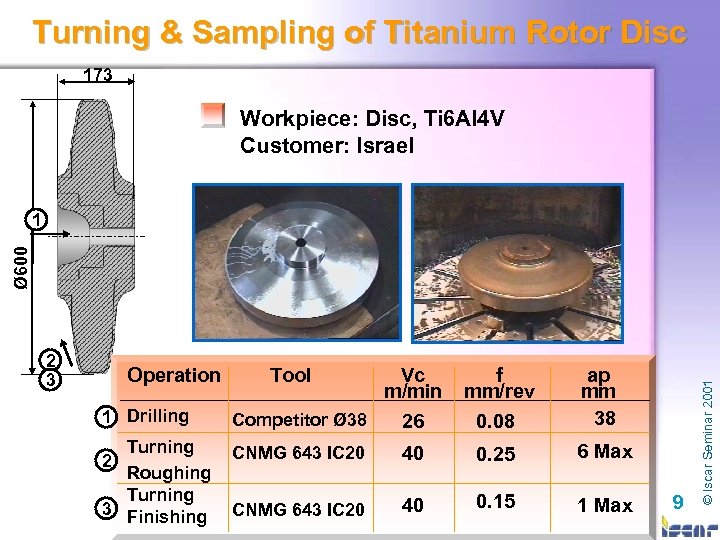

Turning & Sampling of Titanium Rotor Disc 173 Workpiece: Disc, Ti 6 Al 4 V Customer: Israel 2 3 Operation 1 Drilling Competitor Ø 38 26 0. 08 ap mm 38 Turning Roughing Turning 3 Finishing CNMG 643 IC 20 40 0. 25 6 Max CNMG 643 IC 20 40 0. 15 1 Max 2 Tool Vc m/min f mm/rev 9 © Iscar Seminar 2001 Ø 600 1

Turning & Sampling of Titanium Rotor Disc 173 Workpiece: Disc, Ti 6 Al 4 V Customer: Israel 2 3 Operation 1 Drilling Competitor Ø 38 26 0. 08 ap mm 38 Turning Roughing Turning 3 Finishing CNMG 643 IC 20 40 0. 25 6 Max CNMG 643 IC 20 40 0. 15 1 Max 2 Tool Vc m/min f mm/rev 9 © Iscar Seminar 2001 Ø 600 1

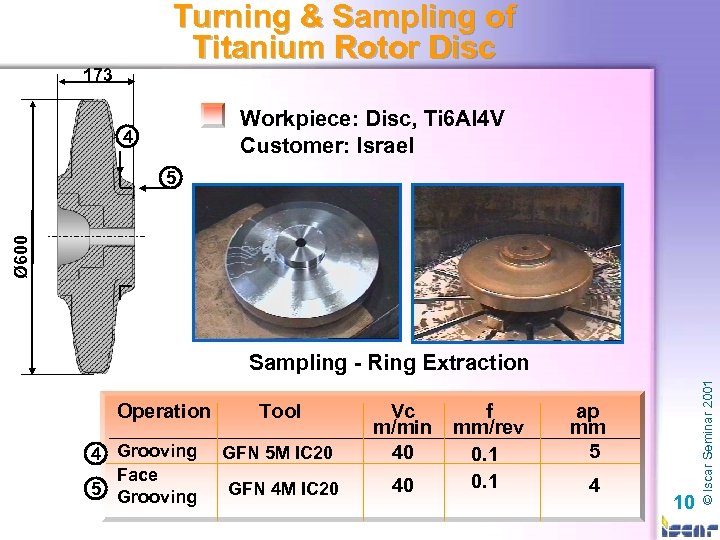

Turning & Sampling of Titanium Rotor Disc 173 Workpiece: Disc, Ti 6 Al 4 V Customer: Israel 4 Ø 600 5 Operation 4 Grooving Face 5 Grooving Tool GFN 5 M IC 20 GFN 4 M IC 20 Vc m/min 40 40 f mm/rev 0. 1 ap mm 5 4 10 © Iscar Seminar 2001 Sampling - Ring Extraction

Turning & Sampling of Titanium Rotor Disc 173 Workpiece: Disc, Ti 6 Al 4 V Customer: Israel 4 Ø 600 5 Operation 4 Grooving Face 5 Grooving Tool GFN 5 M IC 20 GFN 4 M IC 20 Vc m/min 40 40 f mm/rev 0. 1 ap mm 5 4 10 © Iscar Seminar 2001 Sampling - Ring Extraction

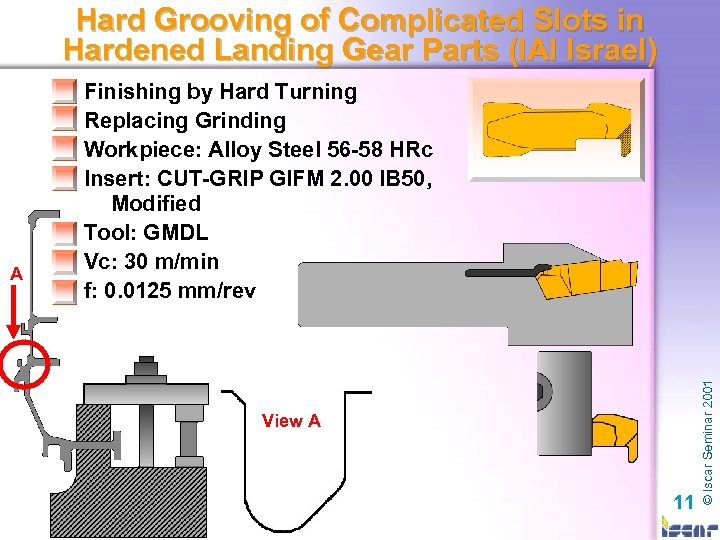

Hard Grooving of Complicated Slots in Hardened Landing Gear Parts (IAI Israel) View A 11 © Iscar Seminar 2001 A Finishing by Hard Turning Replacing Grinding Workpiece: Alloy Steel 56 -58 HRc Insert: CUT-GRIP GIFM 2. 00 IB 50, Modified Tool: GMDL Vc: 30 m/min f: 0. 0125 mm/rev

Hard Grooving of Complicated Slots in Hardened Landing Gear Parts (IAI Israel) View A 11 © Iscar Seminar 2001 A Finishing by Hard Turning Replacing Grinding Workpiece: Alloy Steel 56 -58 HRc Insert: CUT-GRIP GIFM 2. 00 IB 50, Modified Tool: GMDL Vc: 30 m/min f: 0. 0125 mm/rev

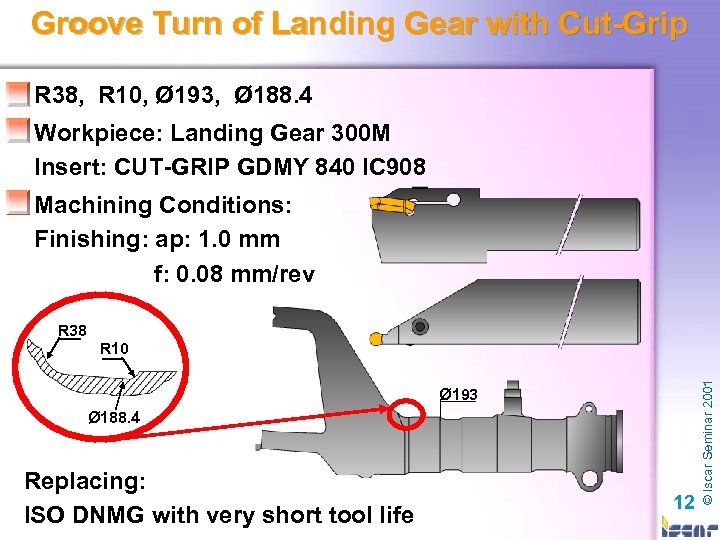

Groove Turn of Landing Gear with Cut-Grip R 38, R 10, Ø 193, Ø 188. 4 Workpiece: Landing Gear 300 M Insert: CUT-GRIP GDMY 840 IC 908 Machining Conditions: Finishing: ap: 1. 0 mm f: 0. 08 mm/rev R 38 Ø 193 Ø 188. 4 Replacing: ISO DNMG with very short tool life 12 © Iscar Seminar 2001 R 10

Groove Turn of Landing Gear with Cut-Grip R 38, R 10, Ø 193, Ø 188. 4 Workpiece: Landing Gear 300 M Insert: CUT-GRIP GDMY 840 IC 908 Machining Conditions: Finishing: ap: 1. 0 mm f: 0. 08 mm/rev R 38 Ø 193 Ø 188. 4 Replacing: ISO DNMG with very short tool life 12 © Iscar Seminar 2001 R 10

Extended-Length Endmills with Steel or Carbide Shanks for Machining Engine Rotors Max Length: 500 mm Max Length: 250 mm D: 32 mm Shank: DIN 69871 13 © Iscar Seminar 2001 HELIBALL Inserts

Extended-Length Endmills with Steel or Carbide Shanks for Machining Engine Rotors Max Length: 500 mm Max Length: 250 mm D: 32 mm Shank: DIN 69871 13 © Iscar Seminar 2001 HELIBALL Inserts

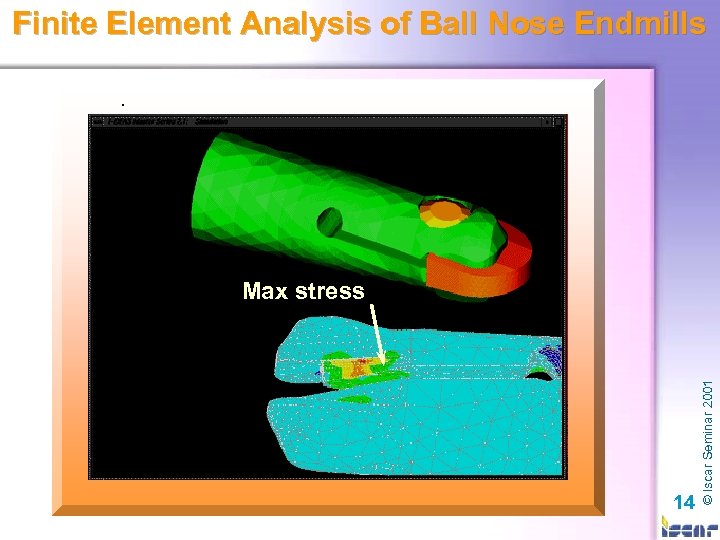

Finite Element Analysis of Ball Nose Endmills 14 © Iscar Seminar 2001 Max stress

Finite Element Analysis of Ball Nose Endmills 14 © Iscar Seminar 2001 Max stress

High-Performance Cutting of Aircraft Wings (Honeycomb) 1: Facing 2: Shouldering 3: Slotting 4: Ramp Down a =22 o 4 3 1 15 © Iscar Seminar 2001 2

High-Performance Cutting of Aircraft Wings (Honeycomb) 1: Facing 2: Shouldering 3: Slotting 4: Ramp Down a =22 o 4 3 1 15 © Iscar Seminar 2001 2

High Speed Machining of Aluminum Wings (AIRBUS & Boeing & Subcontractors ) Holders: HM 90 -EAL-D… Inserts: HM 90 APCR 1605… 16 © Iscar Seminar 2001 0. 4 £ R £ 6. 0 mm

High Speed Machining of Aluminum Wings (AIRBUS & Boeing & Subcontractors ) Holders: HM 90 -EAL-D… Inserts: HM 90 APCR 1605… 16 © Iscar Seminar 2001 0. 4 £ R £ 6. 0 mm

High Speed Machining (Darmstadt, Germany) 17 © Iscar Seminar 2001 Testing of Milling Cutters at Very High Speeds for the Evaluation of Speed Limit

High Speed Machining (Darmstadt, Germany) 17 © Iscar Seminar 2001 Testing of Milling Cutters at Very High Speeds for the Evaluation of Speed Limit

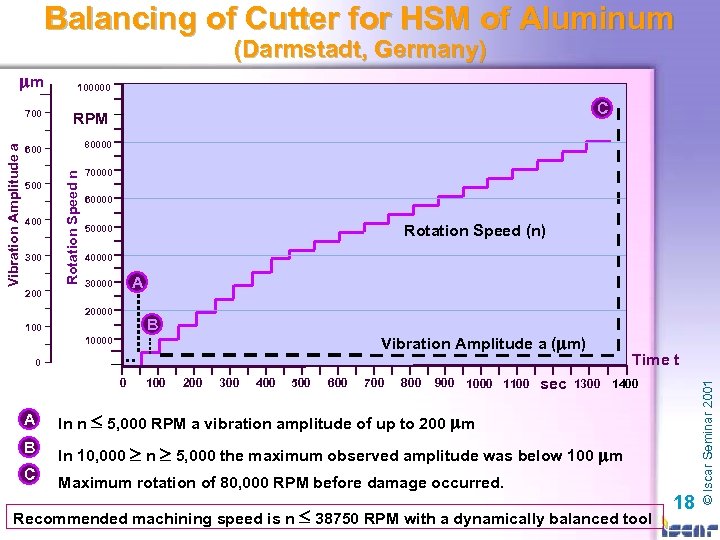

Balancing of Cutter for HSM of Aluminum (Darmstadt, Germany) 80000 600 500 400 300 200 C RPM Rotation Speed n Vibration Amplitude a 700 100000 70000 60000 Rotation Speed (n) 50000 40000 A 30000 20000 B 100 Vibration Amplitude a (mm) 10000 0 0 100 200 300 400 500 600 700 800 900 1000 1100 sec Time t 1300 1400 A In n £ 5, 000 RPM a vibration amplitude of up to 200 mm B In 10, 000 ³ n ³ 5, 000 the maximum observed amplitude was below 100 mm C Maximum rotation of 80, 000 RPM before damage occurred. Recommended machining speed is n £ 38750 RPM with a dynamically balanced tool 18 © Iscar Seminar 2001 mm

Balancing of Cutter for HSM of Aluminum (Darmstadt, Germany) 80000 600 500 400 300 200 C RPM Rotation Speed n Vibration Amplitude a 700 100000 70000 60000 Rotation Speed (n) 50000 40000 A 30000 20000 B 100 Vibration Amplitude a (mm) 10000 0 0 100 200 300 400 500 600 700 800 900 1000 1100 sec Time t 1300 1400 A In n £ 5, 000 RPM a vibration amplitude of up to 200 mm B In 10, 000 ³ n ³ 5, 000 the maximum observed amplitude was below 100 mm C Maximum rotation of 80, 000 RPM before damage occurred. Recommended machining speed is n £ 38750 RPM with a dynamically balanced tool 18 © Iscar Seminar 2001 mm

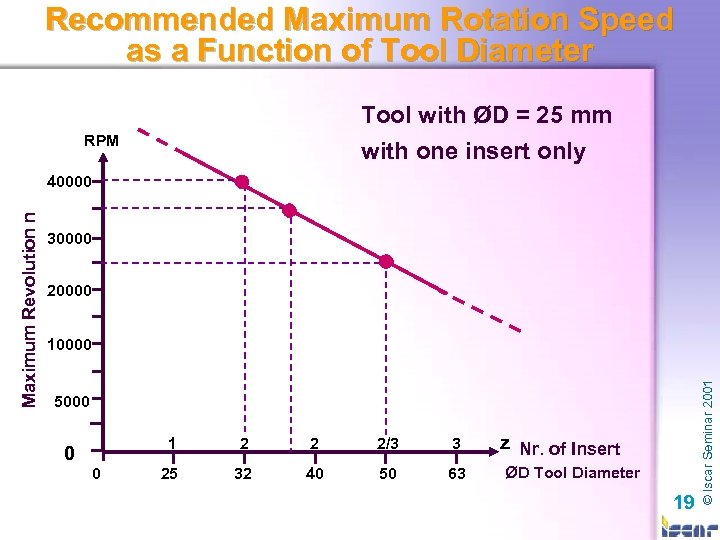

Recommended Maximum Rotation Speed as a Function of Tool Diameter Tool with ØD = 25 mm with one insert only RPM 30000 20000 10000 5000 0 1 0 2 2 2/3 3 25 32 40 50 63 z Nr. of Insert ØD Tool Diameter 19 © Iscar Seminar 2001 Maximum Revolution n 40000

Recommended Maximum Rotation Speed as a Function of Tool Diameter Tool with ØD = 25 mm with one insert only RPM 30000 20000 10000 5000 0 1 0 2 2 2/3 3 25 32 40 50 63 z Nr. of Insert ØD Tool Diameter 19 © Iscar Seminar 2001 Maximum Revolution n 40000

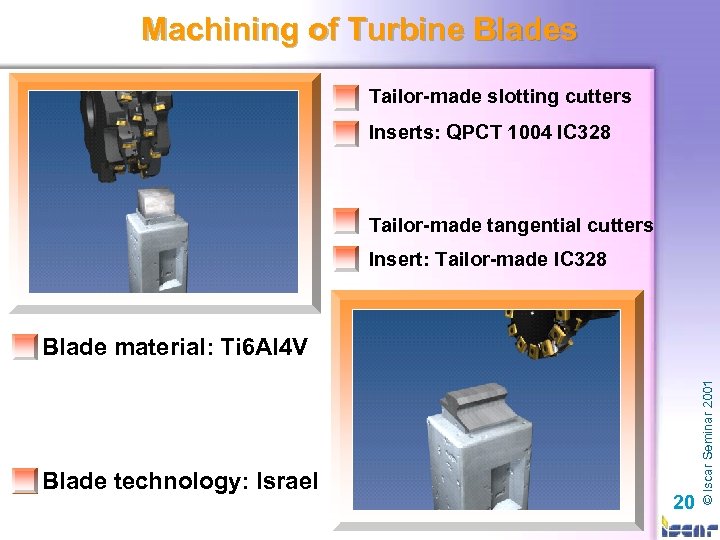

Machining of Turbine Blades Tailor-made slotting cutters Inserts: QPCT 1004 IC 328 Tailor-made tangential cutters Insert: Tailor-made IC 328 Blade technology: Israel 20 © Iscar Seminar 2001 Blade material: Ti 6 Al 4 V

Machining of Turbine Blades Tailor-made slotting cutters Inserts: QPCT 1004 IC 328 Tailor-made tangential cutters Insert: Tailor-made IC 328 Blade technology: Israel 20 © Iscar Seminar 2001 Blade material: Ti 6 Al 4 V

High Speed Machining of Stinger (Wing Beams) Tool: ETS-D 4. 4 -1. 0 -R 17 Tailor-made Radial insert adjustment 21 © Iscar Seminar 2001 Fine sensitivity (10 mm)

High Speed Machining of Stinger (Wing Beams) Tool: ETS-D 4. 4 -1. 0 -R 17 Tailor-made Radial insert adjustment 21 © Iscar Seminar 2001 Fine sensitivity (10 mm)

High Speed Machining of Stinger (Wing Beams) Tool: ETS-D 4. 4 -1. 0 -R 17 Tailor-made Axial insert adjustment Fine sensitivity (10 mm) Adjustable screw 22 © Iscar Seminar 2001 Clamping screw

High Speed Machining of Stinger (Wing Beams) Tool: ETS-D 4. 4 -1. 0 -R 17 Tailor-made Axial insert adjustment Fine sensitivity (10 mm) Adjustable screw 22 © Iscar Seminar 2001 Clamping screw

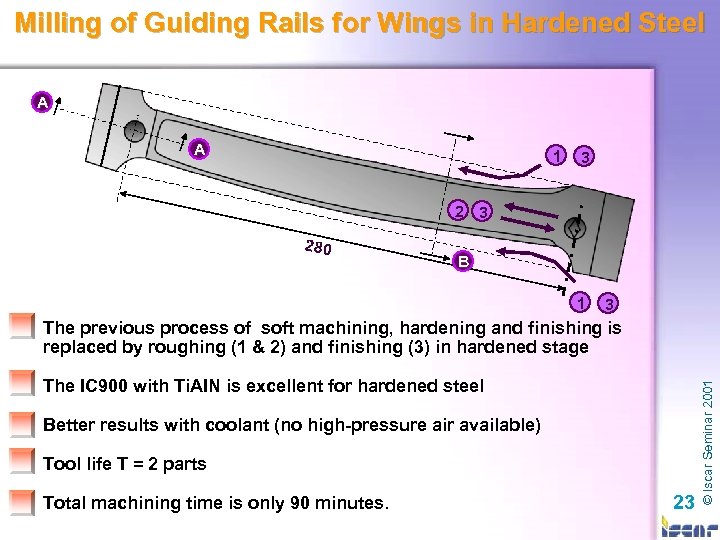

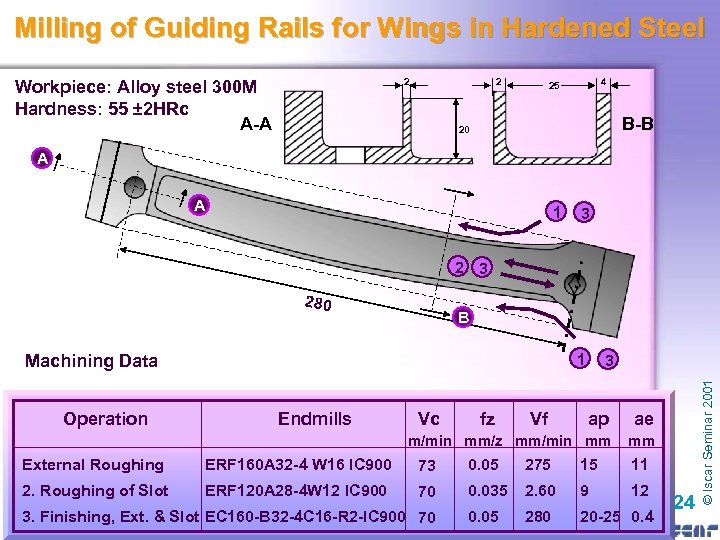

Milling of Guiding Rails for Wings in Hardened Steel A A 1 3 280 B 1 3 The IC 900 with Ti. AIN is excellent for hardened steel Better results with coolant (no high-pressure air available) Tool life T = 2 parts Total machining time is only 90 minutes. 23 © Iscar Seminar 2001 The previous process of soft machining, hardening and finishing is replaced by roughing (1 & 2) and finishing (3) in hardened stage

Milling of Guiding Rails for Wings in Hardened Steel A A 1 3 280 B 1 3 The IC 900 with Ti. AIN is excellent for hardened steel Better results with coolant (no high-pressure air available) Tool life T = 2 parts Total machining time is only 90 minutes. 23 © Iscar Seminar 2001 The previous process of soft machining, hardening and finishing is replaced by roughing (1 & 2) and finishing (3) in hardened stage

Milling of Guiding Rails for Wings in Hardened Steel 2 Workpiece: Alloy steel 300 M Hardness: 55 ± 2 HRc A-A 2 4 25 B-B 20 A A 1 3 280 B Operation 1 Endmills Vc fz Vf 3 ap ae m/min mm/z mm/min mm mm External Roughing ERF 160 A 32 -4 W 16 IC 900 73 0. 05 275 15 11 2. Roughing of Slot ERF 120 A 28 -4 W 12 IC 900 70 0. 035 2. 60 9 12 0. 05 280 20 -25 0. 4 3. Finishing, Ext. & Slot EC 160 -B 32 -4 C 16 -R 2 -IC 900 70 24 © Iscar Seminar 2001 Machining Data

Milling of Guiding Rails for Wings in Hardened Steel 2 Workpiece: Alloy steel 300 M Hardness: 55 ± 2 HRc A-A 2 4 25 B-B 20 A A 1 3 280 B Operation 1 Endmills Vc fz Vf 3 ap ae m/min mm/z mm/min mm mm External Roughing ERF 160 A 32 -4 W 16 IC 900 73 0. 05 275 15 11 2. Roughing of Slot ERF 120 A 28 -4 W 12 IC 900 70 0. 035 2. 60 9 12 0. 05 280 20 -25 0. 4 3. Finishing, Ext. & Slot EC 160 -B 32 -4 C 16 -R 2 -IC 900 70 24 © Iscar Seminar 2001 Machining Data

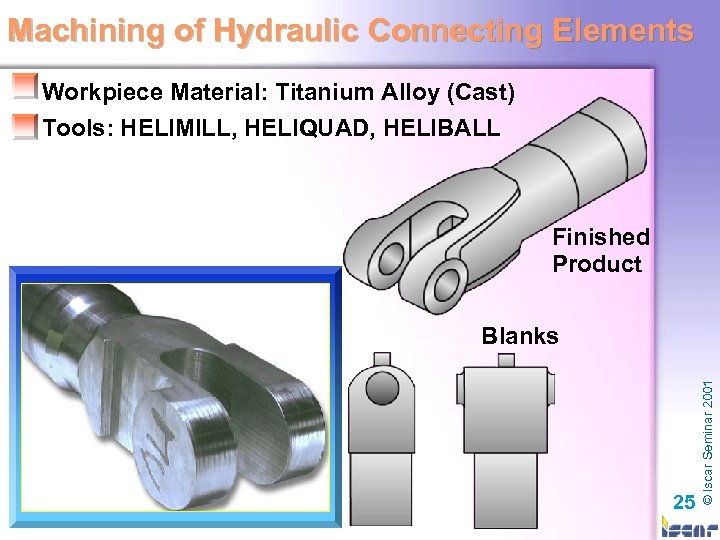

Machining of Hydraulic Connecting Elements Workpiece Material: Titanium Alloy (Cast) Tools: HELIMILL, HELIQUAD, HELIBALL Finished Product 25 © Iscar Seminar 2001 Blanks

Machining of Hydraulic Connecting Elements Workpiece Material: Titanium Alloy (Cast) Tools: HELIMILL, HELIQUAD, HELIBALL Finished Product 25 © Iscar Seminar 2001 Blanks

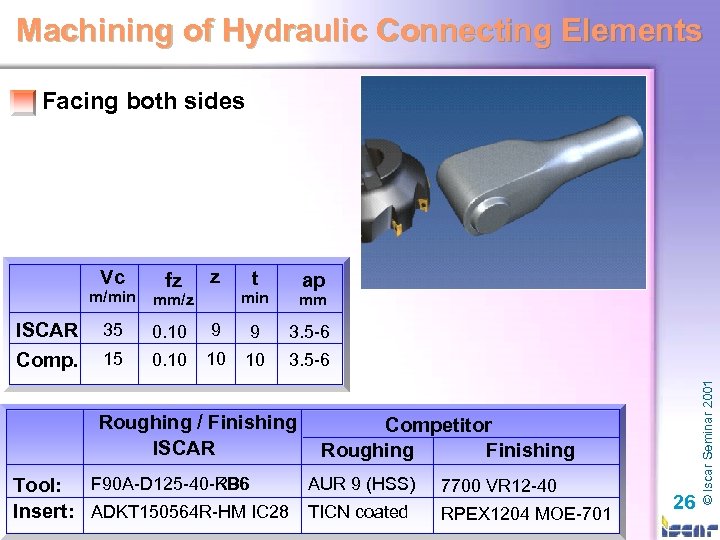

Machining of Hydraulic Connecting Elements Facing both sides z m/min fz mm/z ISCAR 35 0. 10 Comp. 15 0. 10 t ap min mm 9 9 3. 5 -6 10 10 3. 5 -6 Roughing / Finishing ISCAR Competitor Roughing Finishing F 90 A-D 125 -40 -RB 6 AUR 9 (HSS) Tool: F 90 A-D 125 -40 -KB 6 Insert: ADKT 150564 R-HM IC 28 TICN coated 7700 VR 12 -40 RPEX 1204 MOE-701 26 © Iscar Seminar 2001 Vc

Machining of Hydraulic Connecting Elements Facing both sides z m/min fz mm/z ISCAR 35 0. 10 Comp. 15 0. 10 t ap min mm 9 9 3. 5 -6 10 10 3. 5 -6 Roughing / Finishing ISCAR Competitor Roughing Finishing F 90 A-D 125 -40 -RB 6 AUR 9 (HSS) Tool: F 90 A-D 125 -40 -KB 6 Insert: ADKT 150564 R-HM IC 28 TICN coated 7700 VR 12 -40 RPEX 1204 MOE-701 26 © Iscar Seminar 2001 Vc

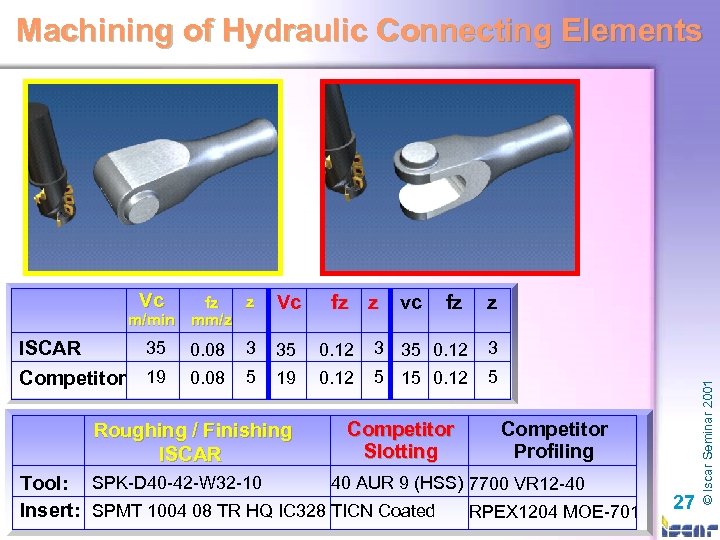

Machining of Hydraulic Connecting Elements z fz m/min mm/z ISCAR Vc fz z 35 0. 08 3 35 0. 12 Competitor 19 0. 08 5 19 0. 12 Roughing / Finishing ISCAR vc fz 3 35 0. 12 5 15 0. 12 Competitor Slotting z 3 5 Competitor Profiling 40 AUR 9 (HSS) 7700 VR 12 -40 Tool: SPK-D 40 -42 -W 32 -10 Insert: SPMT 1004 08 TR HQ IC 328 TICN Coated RPEX 1204 MOE-701 27 © Iscar Seminar 2001 Vc

Machining of Hydraulic Connecting Elements z fz m/min mm/z ISCAR Vc fz z 35 0. 08 3 35 0. 12 Competitor 19 0. 08 5 19 0. 12 Roughing / Finishing ISCAR vc fz 3 35 0. 12 5 15 0. 12 Competitor Slotting z 3 5 Competitor Profiling 40 AUR 9 (HSS) 7700 VR 12 -40 Tool: SPK-D 40 -42 -W 32 -10 Insert: SPMT 1004 08 TR HQ IC 328 TICN Coated RPEX 1204 MOE-701 27 © Iscar Seminar 2001 Vc

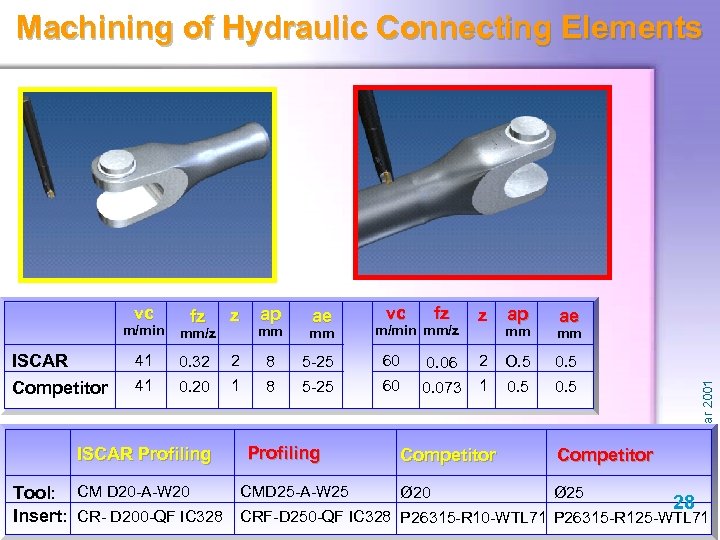

Machining of Hydraulic Connecting Elements m/min fz z mm/z ISCAR 41 0. 32 Competitor 41 0. 20 ap ae vc fz m/min mm/z mm mm 2 8 5 -25 60 0. 06 1 8 5 -25 60 0. 073 Rouging / Finishing Competitor Profiling ISCAR Profiling Roughing ISCAR z ap ae mm mm 2 O. 5 0. 5 1 0. 5 Competitor Finishing Competitor © Iscar Seminar 2001 vc CM D 20 -A-W 20 AUR 9 (HHS) Ø 20 Ø 25 Tool: F 90 A-D 125 -40 -KB 6 CMD 25 -A-W 25 7700 VR 12 -40 28 CR- D 200 -QF IC 328 CRF-D 250 -QF RPEX 1204 MOE-701 Insert: ADKT 150564 R-HM IC 28 TICN couted. IC 328 P 26315 -R 10 -WTL 71 P 26315 -R 125 -WTL 71

Machining of Hydraulic Connecting Elements m/min fz z mm/z ISCAR 41 0. 32 Competitor 41 0. 20 ap ae vc fz m/min mm/z mm mm 2 8 5 -25 60 0. 06 1 8 5 -25 60 0. 073 Rouging / Finishing Competitor Profiling ISCAR Profiling Roughing ISCAR z ap ae mm mm 2 O. 5 0. 5 1 0. 5 Competitor Finishing Competitor © Iscar Seminar 2001 vc CM D 20 -A-W 20 AUR 9 (HHS) Ø 20 Ø 25 Tool: F 90 A-D 125 -40 -KB 6 CMD 25 -A-W 25 7700 VR 12 -40 28 CR- D 200 -QF IC 328 CRF-D 250 -QF RPEX 1204 MOE-701 Insert: ADKT 150564 R-HM IC 28 TICN couted. IC 328 P 26315 -R 10 -WTL 71 P 26315 -R 125 -WTL 71

29 © Iscar Seminar 2001 Always look ahead. . .

29 © Iscar Seminar 2001 Always look ahead. . .

© Iscar Seminar 2001 30

© Iscar Seminar 2001 30