8069badf30555873281bf3c795106d30.ppt

- Количество слайдов: 29

Application of Ne. SSI to Fundamental Measurements for Modeling and Process Development Michelle J. Cohn uop LLC © 2004 UOP LLC. All Rights Reserved.

Application of Ne. SSI to Fundamental Measurements for Modeling and Process Development Michelle J. Cohn uop LLC © 2004 UOP LLC. All Rights Reserved.

UOP LLC Who We Are n n n Global company with 11 manufacturing sites and offices in 25 countries More than 3, 000 highly trained employees 90 years of innovative solutions for the hydrocarbon processing industry UOP’s customers are located in more than 200 countries. World’s largest supplier of molecular sieve adsorbents

UOP LLC Who We Are n n n Global company with 11 manufacturing sites and offices in 25 countries More than 3, 000 highly trained employees 90 years of innovative solutions for the hydrocarbon processing industry UOP’s customers are located in more than 200 countries. World’s largest supplier of molecular sieve adsorbents

What We Do n n Develop technology that provides solutions to problems License, design, engineer, and service process technology Develop and manufacture catalysts, molecular sieves, adsorbents, and specialized equipment Transfer technology to customers who achieve high yield of high quality products

What We Do n n Develop technology that provides solutions to problems License, design, engineer, and service process technology Develop and manufacture catalysts, molecular sieves, adsorbents, and specialized equipment Transfer technology to customers who achieve high yield of high quality products

Some Process Development Needs - Reaction Kinetics Needs for Fundamental Understanding. Decision for Process Intensification • Reaction mechanism/pathways • Kinetic constants - adsorption constant - activation energy - heats of adsorption - pre-exponentials

Some Process Development Needs - Reaction Kinetics Needs for Fundamental Understanding. Decision for Process Intensification • Reaction mechanism/pathways • Kinetic constants - adsorption constant - activation energy - heats of adsorption - pre-exponentials

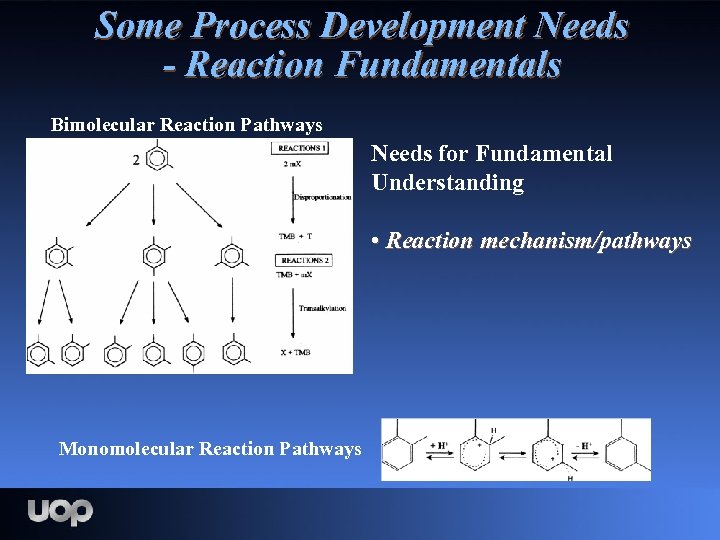

Some Process Development Needs - Reaction Fundamentals Bimolecular Reaction Pathways Needs for Fundamental Understanding • Reaction mechanism/pathways Monomolecular Reaction Pathways

Some Process Development Needs - Reaction Fundamentals Bimolecular Reaction Pathways Needs for Fundamental Understanding • Reaction mechanism/pathways Monomolecular Reaction Pathways

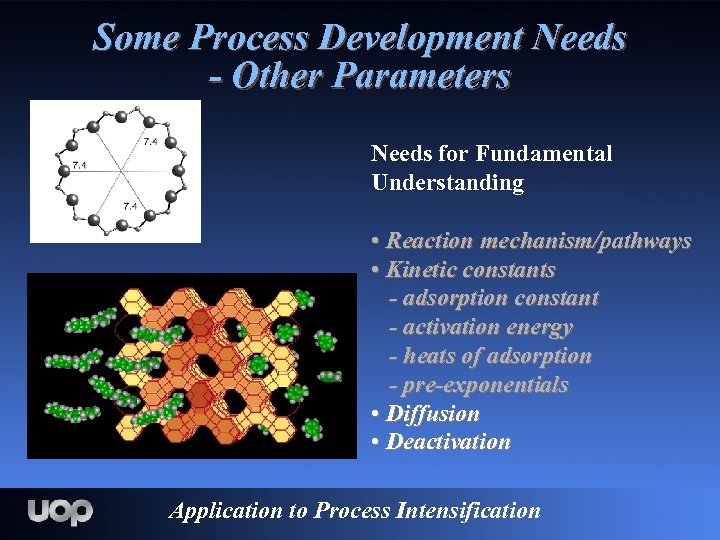

Some Process Development Needs - Other Parameters Needs for Fundamental Understanding • Reaction mechanism/pathways • Kinetic constants - adsorption constant - activation energy - heats of adsorption - pre-exponentials • Diffusion • Deactivation Application to Process Intensification

Some Process Development Needs - Other Parameters Needs for Fundamental Understanding • Reaction mechanism/pathways • Kinetic constants - adsorption constant - activation energy - heats of adsorption - pre-exponentials • Diffusion • Deactivation Application to Process Intensification

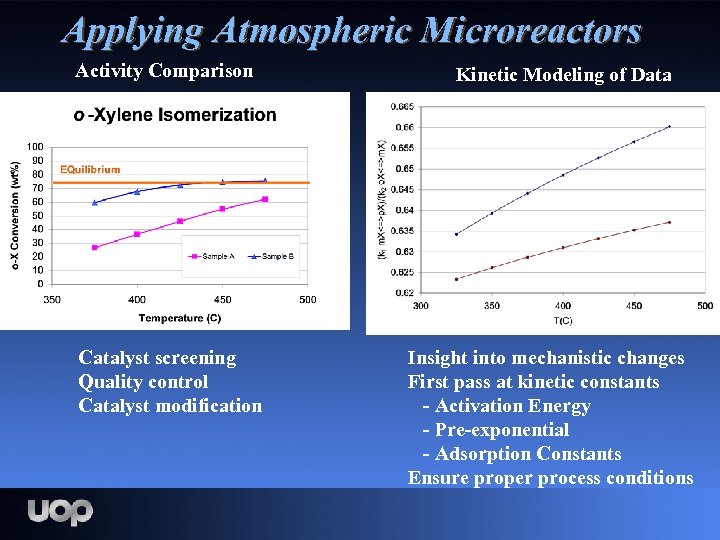

Applying Atmospheric Microreactors Activity Comparison Catalyst screening Quality control Catalyst modification Kinetic Modeling of Data Insight into mechanistic changes First pass at kinetic constants - Activation Energy - Pre-exponential - Adsorption Constants Ensure proper process conditions

Applying Atmospheric Microreactors Activity Comparison Catalyst screening Quality control Catalyst modification Kinetic Modeling of Data Insight into mechanistic changes First pass at kinetic constants - Activation Energy - Pre-exponential - Adsorption Constants Ensure proper process conditions

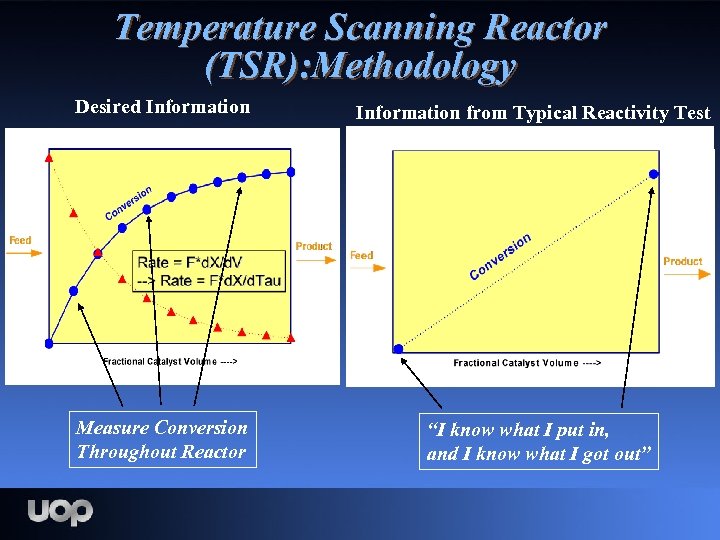

Temperature Scanning Reactor (TSR): Methodology Desired Information from Typical Reactivity Test Measure Conversion Throughout Reactor “I know what I put in, and I know what I got out”

Temperature Scanning Reactor (TSR): Methodology Desired Information from Typical Reactivity Test Measure Conversion Throughout Reactor “I know what I put in, and I know what I got out”

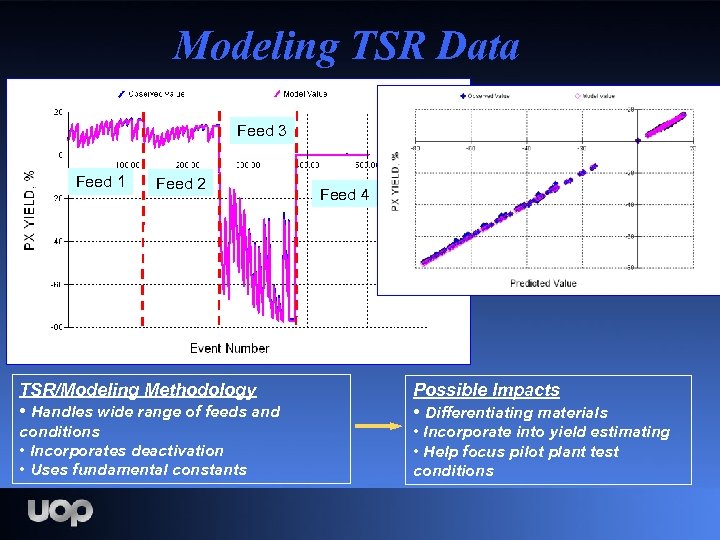

Modeling TSR Data Feed 3 Feed 1 Feed 2 Feed 4 TSR/Modeling Methodology • Handles wide range of feeds and Possible Impacts • Differentiating materials conditions • Incorporates deactivation • Uses fundamental constants • Incorporate into yield estimating • Help focus pilot plant test conditions

Modeling TSR Data Feed 3 Feed 1 Feed 2 Feed 4 TSR/Modeling Methodology • Handles wide range of feeds and Possible Impacts • Differentiating materials conditions • Incorporates deactivation • Uses fundamental constants • Incorporate into yield estimating • Help focus pilot plant test conditions

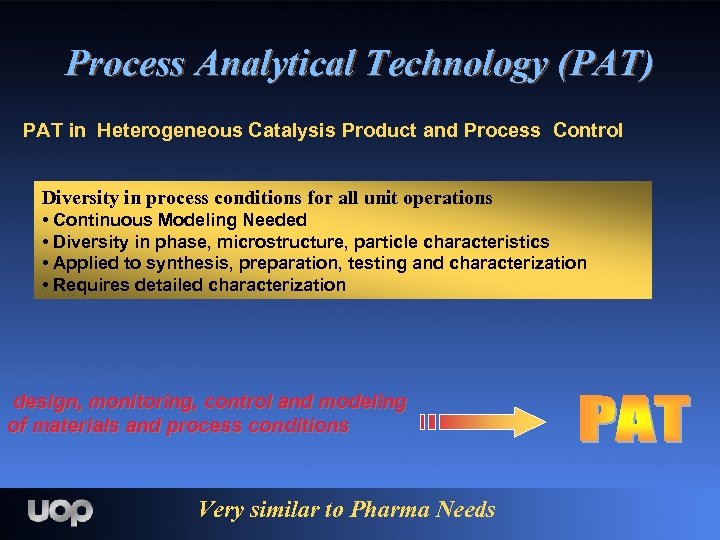

Process Analytical Technology (PAT) PAT in Heterogeneous Catalysis Product and Process Control Diversity in process conditions for all unit operations • Continuous Modeling Needed • Diversity in phase, microstructure, particle characteristics • Applied to synthesis, preparation, testing and characterization • Requires detailed characterization design, monitoring, control and modeling of materials and process conditions Very similar to Pharma Needs

Process Analytical Technology (PAT) PAT in Heterogeneous Catalysis Product and Process Control Diversity in process conditions for all unit operations • Continuous Modeling Needed • Diversity in phase, microstructure, particle characteristics • Applied to synthesis, preparation, testing and characterization • Requires detailed characterization design, monitoring, control and modeling of materials and process conditions Very similar to Pharma Needs

Enablers for PAT T Sensor Reactor Time Model Building Data Analysis Feedback Control Sampling ü ü ü Online Process Analytics P ü ü QMS ü RAMAN ü GC ü NIR FTIR Ultrasound LAMIMS Micro-calorimetry FTIR Etc. NESSI V T A P. S. NESSI

Enablers for PAT T Sensor Reactor Time Model Building Data Analysis Feedback Control Sampling ü ü ü Online Process Analytics P ü ü QMS ü RAMAN ü GC ü NIR FTIR Ultrasound LAMIMS Micro-calorimetry FTIR Etc. NESSI V T A P. S. NESSI

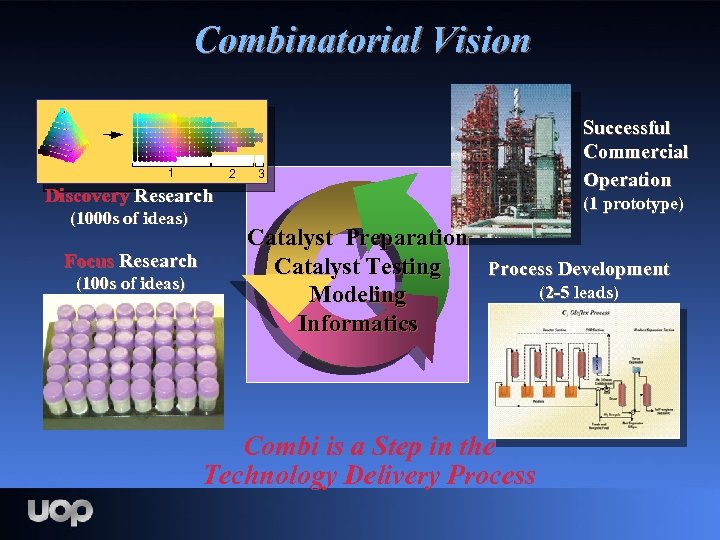

Combinatorial Vision 1 2 3 Discovery Research (1000 s of ideas) Focus Research (100 s of ideas) Successful Commercial Operation (1 prototype) Catalyst Preparation Catalyst Testing Process Development (2 -5 leads) Modeling Informatics Combi is a Step in the Technology Delivery Process

Combinatorial Vision 1 2 3 Discovery Research (1000 s of ideas) Focus Research (100 s of ideas) Successful Commercial Operation (1 prototype) Catalyst Preparation Catalyst Testing Process Development (2 -5 leads) Modeling Informatics Combi is a Step in the Technology Delivery Process

Enablers of Combinatorial Chemistry Efficient ways of materials synthesis q Parallel preparation of experimental catalysts q Availability and development of high-speed characterization tools q Parallel and high throughput testing of catalytic properties q Data analysis techniques - informatics q q Accelerated processes of discovery and technology delivery

Enablers of Combinatorial Chemistry Efficient ways of materials synthesis q Parallel preparation of experimental catalysts q Availability and development of high-speed characterization tools q Parallel and high throughput testing of catalytic properties q Data analysis techniques - informatics q q Accelerated processes of discovery and technology delivery

High Throughput Characterization Tools HT SEM Morphology, Particle Size HT XRD IR Thermography Structural, TPD, Adsorption Phase ID HT Adsorption HT XRF Goals Surface Area, Pore Element Size Distribution n Full spectrum of tools Analysis n Ultra-fast collection times HT Raman LAMIMS n 100’s to 1000’s samples /day Active Site, Reactivity Characterization is Key to Success Phase ID From Data Structure/Function Models = Knowledge

High Throughput Characterization Tools HT SEM Morphology, Particle Size HT XRD IR Thermography Structural, TPD, Adsorption Phase ID HT Adsorption HT XRF Goals Surface Area, Pore Element Size Distribution n Full spectrum of tools Analysis n Ultra-fast collection times HT Raman LAMIMS n 100’s to 1000’s samples /day Active Site, Reactivity Characterization is Key to Success Phase ID From Data Structure/Function Models = Knowledge

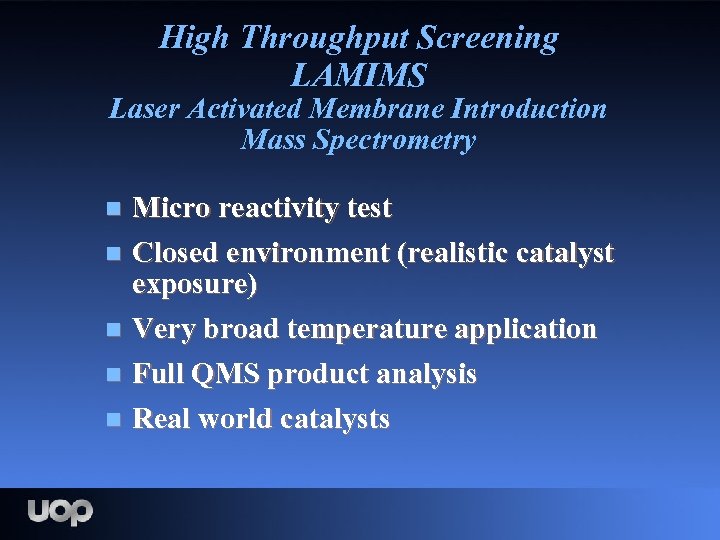

High Throughput Screening LAMIMS Laser Activated Membrane Introduction Mass Spectrometry Micro reactivity test n Closed environment (realistic catalyst exposure) n Very broad temperature application n Full QMS product analysis n Real world catalysts n

High Throughput Screening LAMIMS Laser Activated Membrane Introduction Mass Spectrometry Micro reactivity test n Closed environment (realistic catalyst exposure) n Very broad temperature application n Full QMS product analysis n Real world catalysts n

The LAMIMS Screening System n n n System Components LAMIMS reactant delivery system A 25 watt CO 2 barcode writing laser LAMIMS reactor Quadrupole mass spectrometer (QMS) Ne. SSI reactant feed system

The LAMIMS Screening System n n n System Components LAMIMS reactant delivery system A 25 watt CO 2 barcode writing laser LAMIMS reactor Quadrupole mass spectrometer (QMS) Ne. SSI reactant feed system

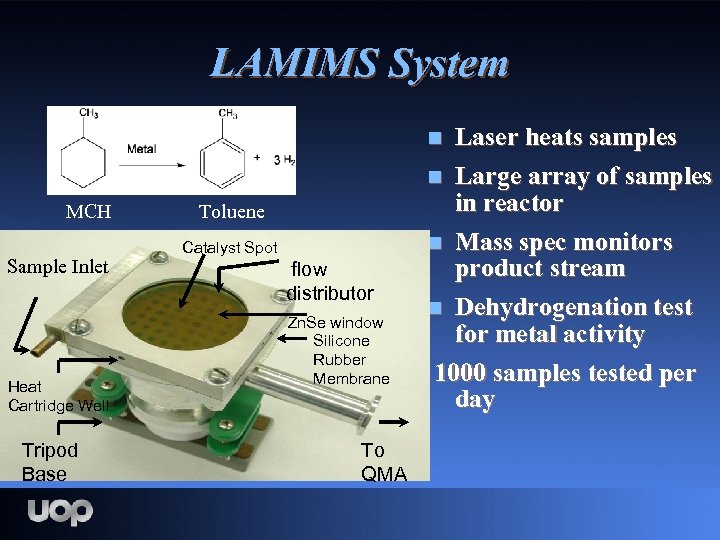

LAMIMS System Laser heats samples n Large array of samples in reactor n Mass spec monitors product stream n Dehydrogenation test for metal activity 1000 samples tested per day n MCH Sample Inlet Heat Cartridge Well Tripod Base Toluene Catalyst Spot flow distributor Zn. Se window Silicone Rubber Membrane To QMA

LAMIMS System Laser heats samples n Large array of samples in reactor n Mass spec monitors product stream n Dehydrogenation test for metal activity 1000 samples tested per day n MCH Sample Inlet Heat Cartridge Well Tripod Base Toluene Catalyst Spot flow distributor Zn. Se window Silicone Rubber Membrane To QMA

Data from Reactor System 45 samples

Data from Reactor System 45 samples

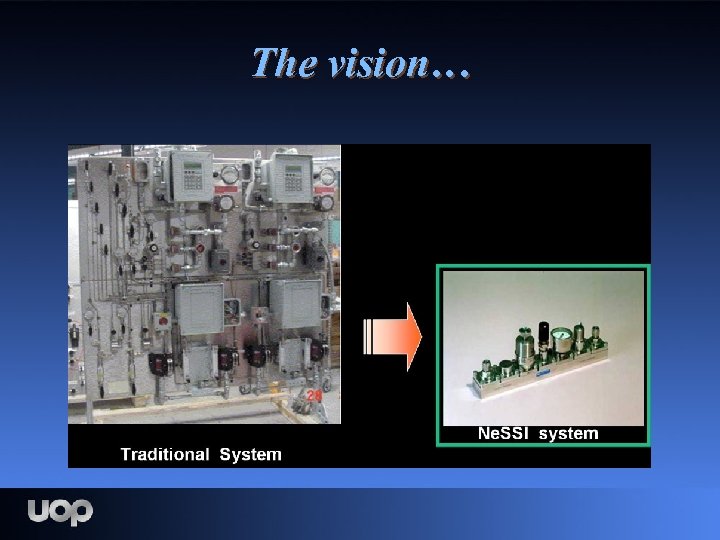

The vision…

The vision…

Applying Ne. SSI Technology n n n Honeywell sensors Parker Hannifin Intraflow substrate and components GO pressure regulators Parker valves and actuators Brooks mass flow controllers Used Ethernet and Device. Net networks and commercially available Gen I Lab. View software on PC for configuration, control, data and diagnostics Proved the need for low power small size actuators and valves Exceptional diagnostic, control, and data collection capabilities Remote monitoring and control via standard internet tools Fast and easy configuration using Lab. View

Applying Ne. SSI Technology n n n Honeywell sensors Parker Hannifin Intraflow substrate and components GO pressure regulators Parker valves and actuators Brooks mass flow controllers Used Ethernet and Device. Net networks and commercially available Gen I Lab. View software on PC for configuration, control, data and diagnostics Proved the need for low power small size actuators and valves Exceptional diagnostic, control, and data collection capabilities Remote monitoring and control via standard internet tools Fast and easy configuration using Lab. View

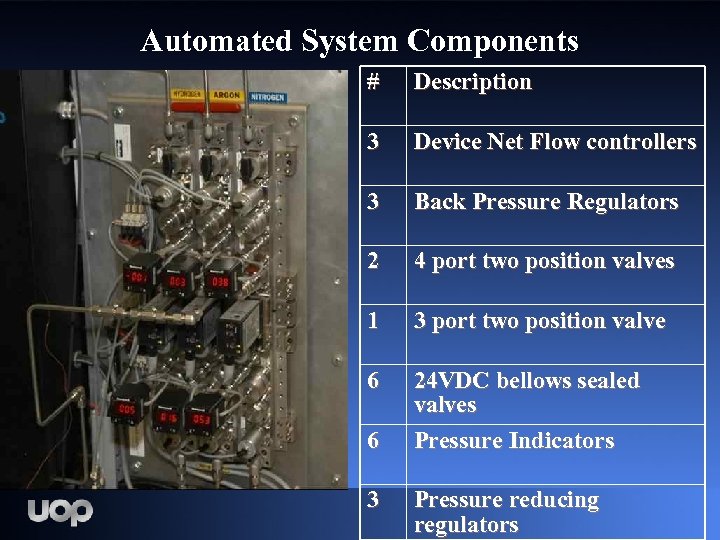

Automated System Components # Description 3 Device Net Flow controllers 3 Back Pressure Regulators 2 4 port two position valves 1 3 port two position valve 6 24 VDC bellows sealed valves Pressure Indicators 6 3 Pressure reducing regulators

Automated System Components # Description 3 Device Net Flow controllers 3 Back Pressure Regulators 2 4 port two position valves 1 3 port two position valve 6 24 VDC bellows sealed valves Pressure Indicators 6 3 Pressure reducing regulators

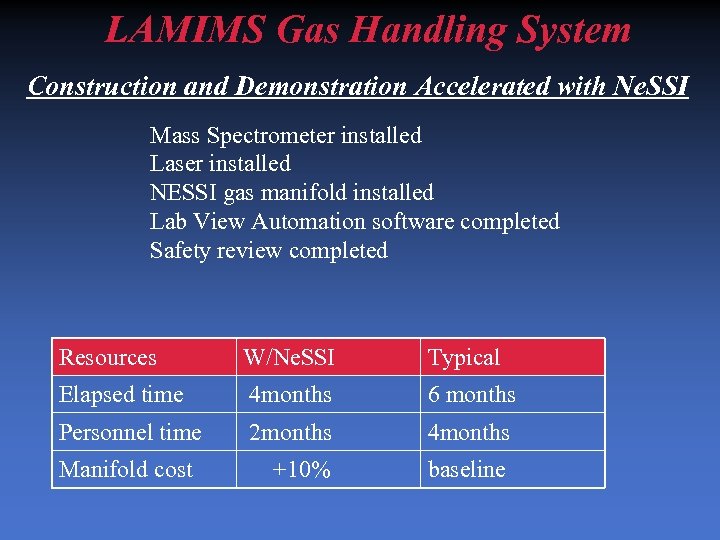

LAMIMS Gas Handling System Construction and Demonstration Accelerated with Ne. SSI Mass Spectrometer installed Laser installed NESSI gas manifold installed Lab View Automation software completed Safety review completed Resources W/Ne. SSI Typical Elapsed time 4 months 6 months Personnel time 2 months 4 months +10% baseline Manifold cost

LAMIMS Gas Handling System Construction and Demonstration Accelerated with Ne. SSI Mass Spectrometer installed Laser installed NESSI gas manifold installed Lab View Automation software completed Safety review completed Resources W/Ne. SSI Typical Elapsed time 4 months 6 months Personnel time 2 months 4 months +10% baseline Manifold cost

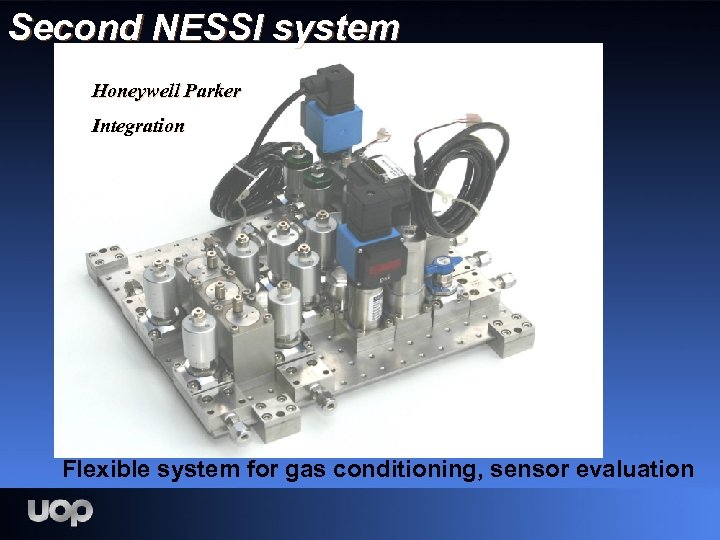

Second NESSI system Honeywell Parker Integration Flexible system for gas conditioning, sensor evaluation

Second NESSI system Honeywell Parker Integration Flexible system for gas conditioning, sensor evaluation

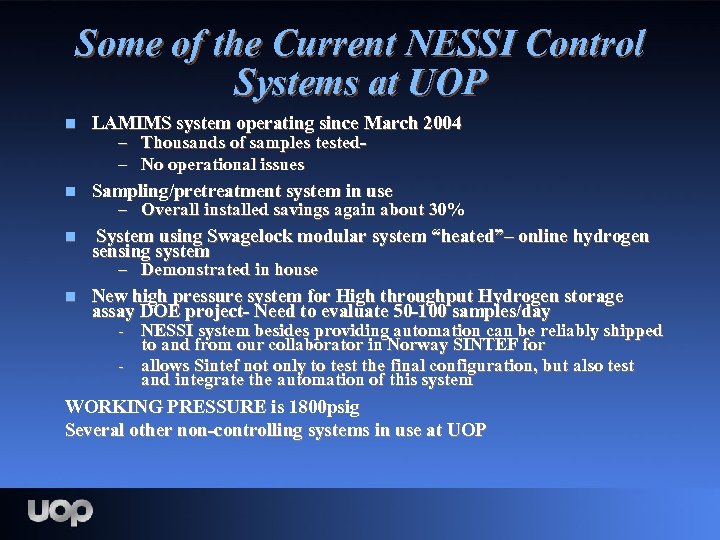

Some of the Current NESSI Control Systems at UOP n n LAMIMS system operating since March 2004 – Thousands of samples tested– No operational issues Sampling/pretreatment system in use – Overall installed savings again about 30% System using Swagelock modular system “heated”– online hydrogen sensing system – Demonstrated in house New high pressure system for High throughput Hydrogen storage assay DOE project- Need to evaluate 50 -100 samples/day - NESSI system besides providing automation can be reliably shipped to and from our collaborator in Norway SINTEF for - allows Sintef not only to test the final configuration, but also test and integrate the automation of this system WORKING PRESSURE is 1800 psig Several other non-controlling systems in use at UOP

Some of the Current NESSI Control Systems at UOP n n LAMIMS system operating since March 2004 – Thousands of samples tested– No operational issues Sampling/pretreatment system in use – Overall installed savings again about 30% System using Swagelock modular system “heated”– online hydrogen sensing system – Demonstrated in house New high pressure system for High throughput Hydrogen storage assay DOE project- Need to evaluate 50 -100 samples/day - NESSI system besides providing automation can be reliably shipped to and from our collaborator in Norway SINTEF for - allows Sintef not only to test the final configuration, but also test and integrate the automation of this system WORKING PRESSURE is 1800 psig Several other non-controlling systems in use at UOP

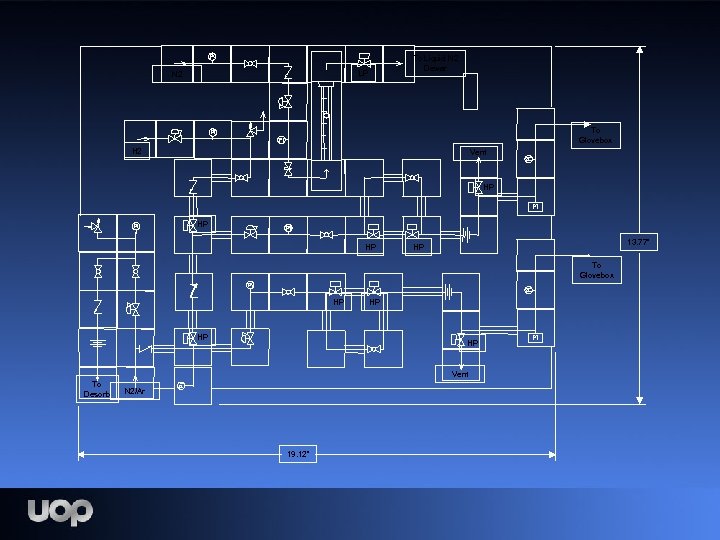

To Liquid N 2 Dewar LP N 2 To Glovebox H 2 Vent HP HP HP 13. 77” HP To Glovebox HP HP Vent To Desorb N 2/Ar 19. 12”

To Liquid N 2 Dewar LP N 2 To Glovebox H 2 Vent HP HP HP 13. 77” HP To Glovebox HP HP Vent To Desorb N 2/Ar 19. 12”

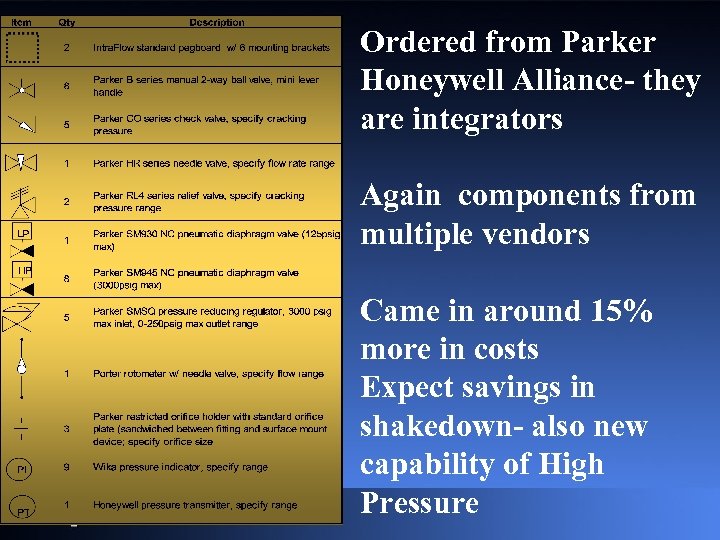

Ordered from Parker Honeywell Alliance- they are integrators Again components from multiple vendors Came in around 15% more in costs Expect savings in shakedown- also new capability of High Pressure

Ordered from Parker Honeywell Alliance- they are integrators Again components from multiple vendors Came in around 15% more in costs Expect savings in shakedown- also new capability of High Pressure

PAT Summary n Technology and industry needs are converging for PAT and NESSI – – n n In-situ measurements Sensor integration Computational capacity and models Understanding of mechanisms Demonstrated success in refining and petrochemicals Opportunities for cross-industry fertilization

PAT Summary n Technology and industry needs are converging for PAT and NESSI – – n n In-situ measurements Sensor integration Computational capacity and models Understanding of mechanisms Demonstrated success in refining and petrochemicals Opportunities for cross-industry fertilization

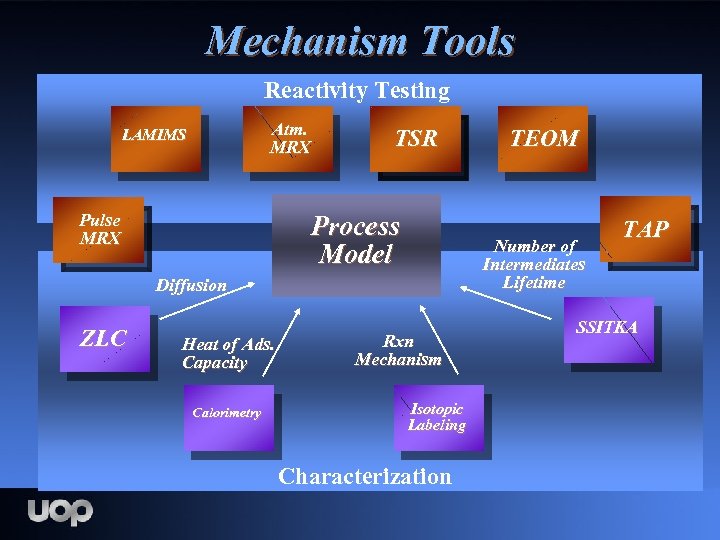

Mechanism Tools Reactivity Testing Atm. MRX LAMIMS Pulse MRX TSR Process Model Number of Intermediates Lifetime Diffusion ZLC Heat of Ads. Capacity Calorimetry TEOM Rxn Mechanism Isotopic Labeling Characterization TAP SSITKA

Mechanism Tools Reactivity Testing Atm. MRX LAMIMS Pulse MRX TSR Process Model Number of Intermediates Lifetime Diffusion ZLC Heat of Ads. Capacity Calorimetry TEOM Rxn Mechanism Isotopic Labeling Characterization TAP SSITKA

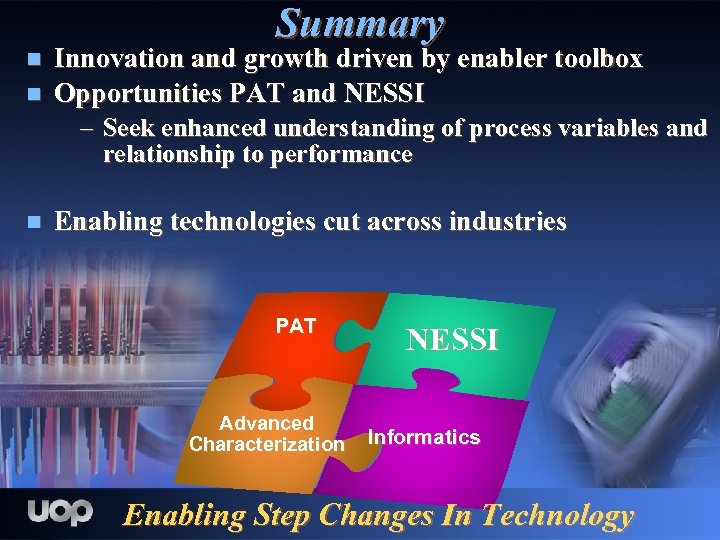

Summary n n Innovation and growth driven by enabler toolbox Opportunities PAT and NESSI – Seek enhanced understanding of process variables and relationship to performance n Enabling technologies cut across industries PAT Advanced Characterization NESSI Informatics Enabling Step Changes In Technology

Summary n n Innovation and growth driven by enabler toolbox Opportunities PAT and NESSI – Seek enhanced understanding of process variables and relationship to performance n Enabling technologies cut across industries PAT Advanced Characterization NESSI Informatics Enabling Step Changes In Technology