0564100c0f264c5df6a775b5d1a78673.ppt

- Количество слайдов: 21

Application of an Advanced Methodology for the Design of a Surfactant Polymer Pilot in Centenario Neuquen EOR workshop - November 2010 P. Moreau 1, M. Morvan 1; B. Bazin 2, F. Douarche 2, J-F. Argillier 2, R. Tabary 2 1 – Rhodia 2 – IFP Energies Nouvelles

Application of an Advanced Methodology for the Design of a Surfactant Polymer Pilot in Centenario Neuquen EOR workshop - November 2010 P. Moreau 1, M. Morvan 1; B. Bazin 2, F. Douarche 2, J-F. Argillier 2, R. Tabary 2 1 – Rhodia 2 – IFP Energies Nouvelles

2 Outline Introduction • Chemical EOR (ASP/SP) – Basics • Rhodia-IFP énergies nouvelles & partners An integrated workflow • Process & material selection • Chemical formulation optimization • Coreflood validation • Simulation An Illustrative Case study Conclusion & Perspectives

2 Outline Introduction • Chemical EOR (ASP/SP) – Basics • Rhodia-IFP énergies nouvelles & partners An integrated workflow • Process & material selection • Chemical formulation optimization • Coreflood validation • Simulation An Illustrative Case study Conclusion & Perspectives

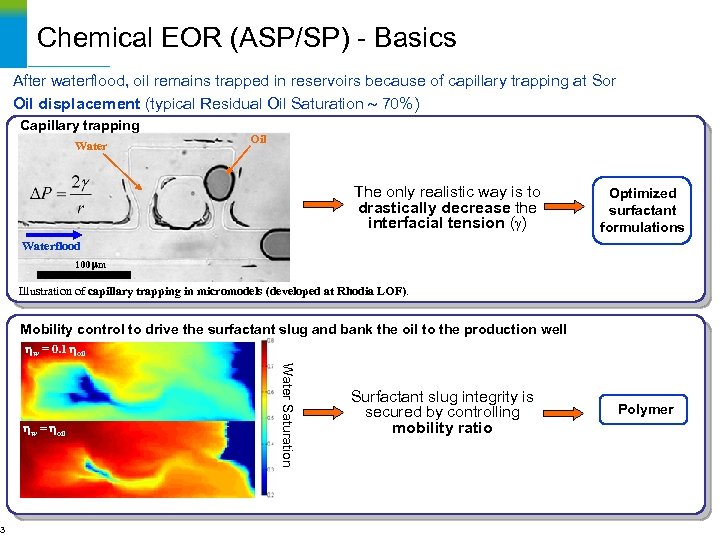

After waterflood, oil remains trapped in reservoirs because of capillary trapping at Sor Oil displacement (typical Residual Oil Saturation 70%) Capillary trapping Water Oil The only realistic way is to drastically decrease the interfacial tension ( ) Optimized surfactant formulations Waterflood 100 m Illustration of capillary trapping in micromodels (developed at Rhodia LOF). Mobility control to drive the surfactant slug and bank the oil to the production well w = 0. 1 oil w = oil Water Saturation 3 Chemical EOR (ASP/SP) - Basics Surfactant slug integrity is secured by controlling mobility ratio Polymer

After waterflood, oil remains trapped in reservoirs because of capillary trapping at Sor Oil displacement (typical Residual Oil Saturation 70%) Capillary trapping Water Oil The only realistic way is to drastically decrease the interfacial tension ( ) Optimized surfactant formulations Waterflood 100 m Illustration of capillary trapping in micromodels (developed at Rhodia LOF). Mobility control to drive the surfactant slug and bank the oil to the production well w = 0. 1 oil w = oil Water Saturation 3 Chemical EOR (ASP/SP) - Basics Surfactant slug integrity is secured by controlling mobility ratio Polymer

4 Bring together the capabilities required for Chemical EOR… World-class geosciences public-sector research Global leader in specialty chemicals and formulation Independant E&P consulting and software editor Polymer technologies for IOR and well performance (IFP subsidiary) 4

4 Bring together the capabilities required for Chemical EOR… World-class geosciences public-sector research Global leader in specialty chemicals and formulation Independant E&P consulting and software editor Polymer technologies for IOR and well performance (IFP subsidiary) 4

5 …With integrated solutions EOR methods screening • Integrated reservoir analysis • Selection of EOR methods Laboratory design • • • Process & Material selection Chemical formulation optimization Coreflood validation Lab-scale simulation Impact on water management Pilot design • Numerical simulation at pilot scale • Pilot economics • Surface facility conceptual design Pilot implementation / Full field extension • Field management and monitoring • Expertise and assistance to operations • Full-field surface facility design Dedicated supply-chains • High-volume logistics • Large-scale manufacturing 5

5 …With integrated solutions EOR methods screening • Integrated reservoir analysis • Selection of EOR methods Laboratory design • • • Process & Material selection Chemical formulation optimization Coreflood validation Lab-scale simulation Impact on water management Pilot design • Numerical simulation at pilot scale • Pilot economics • Surface facility conceptual design Pilot implementation / Full field extension • Field management and monitoring • Expertise and assistance to operations • Full-field surface facility design Dedicated supply-chains • High-volume logistics • Large-scale manufacturing 5

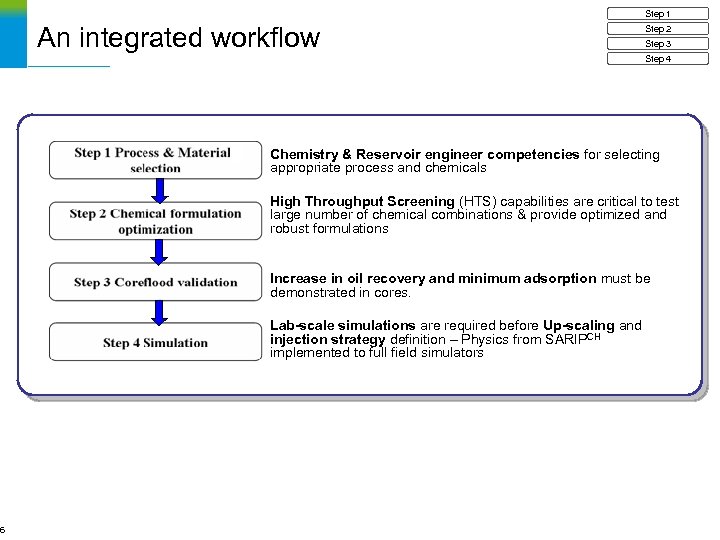

6 Step 1 An integrated workflow Step 2 Step 3 Step 4 Chemistry & Reservoir engineer competencies for selecting appropriate process and chemicals High Throughput Screening (HTS) capabilities are critical to test large number of chemical combinations & provide optimized and robust formulations Increase in oil recovery and minimum adsorption must be demonstrated in cores. Lab-scale simulations are required before Up-scaling and injection strategy definition – Physics from SARIPCH implemented to full field simulators

6 Step 1 An integrated workflow Step 2 Step 3 Step 4 Chemistry & Reservoir engineer competencies for selecting appropriate process and chemicals High Throughput Screening (HTS) capabilities are critical to test large number of chemical combinations & provide optimized and robust formulations Increase in oil recovery and minimum adsorption must be demonstrated in cores. Lab-scale simulations are required before Up-scaling and injection strategy definition – Physics from SARIPCH implemented to full field simulators

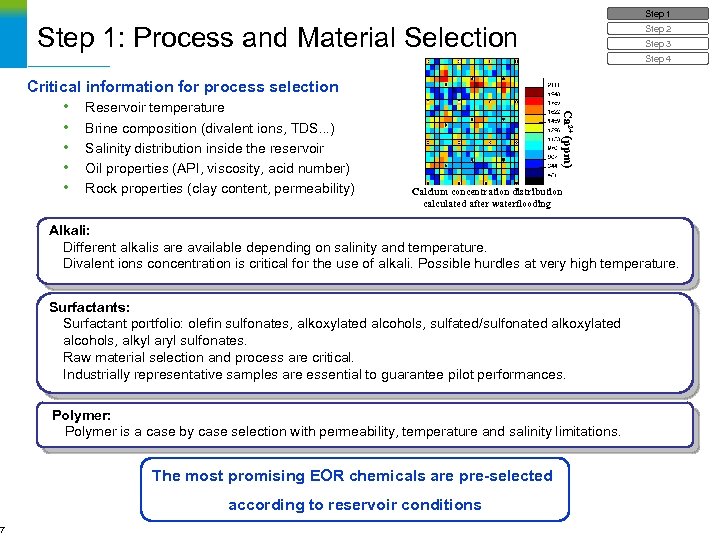

Step 1: Process and Material Selection Step 2 Step 3 Step 4 Critical information for process selection • Reservoir temperature • Brine composition (divalent ions, TDS. . . ) • Salinity distribution inside the reservoir • Oil properties (API, viscosity, acid number) • Rock properties (clay content, permeability) Ca 2+ (ppm) 7 Step 1 Calcium concentration distribution calculated after waterflooding Alkali: Different alkalis are available depending on salinity and temperature. Divalent ions concentration is critical for the use of alkali. Possible hurdles at very high temperature. Surfactants: Surfactant portfolio: olefin sulfonates, alkoxylated alcohols, sulfated/sulfonated alkoxylated alcohols, alkyl aryl sulfonates. Raw material selection and process are critical. Industrially representative samples are essential to guarantee pilot performances. Polymer: Polymer is a case by case selection with permeability, temperature and salinity limitations. The most promising EOR chemicals are pre-selected according to reservoir conditions

Step 1: Process and Material Selection Step 2 Step 3 Step 4 Critical information for process selection • Reservoir temperature • Brine composition (divalent ions, TDS. . . ) • Salinity distribution inside the reservoir • Oil properties (API, viscosity, acid number) • Rock properties (clay content, permeability) Ca 2+ (ppm) 7 Step 1 Calcium concentration distribution calculated after waterflooding Alkali: Different alkalis are available depending on salinity and temperature. Divalent ions concentration is critical for the use of alkali. Possible hurdles at very high temperature. Surfactants: Surfactant portfolio: olefin sulfonates, alkoxylated alcohols, sulfated/sulfonated alkoxylated alcohols, alkyl aryl sulfonates. Raw material selection and process are critical. Industrially representative samples are essential to guarantee pilot performances. Polymer: Polymer is a case by case selection with permeability, temperature and salinity limitations. The most promising EOR chemicals are pre-selected according to reservoir conditions

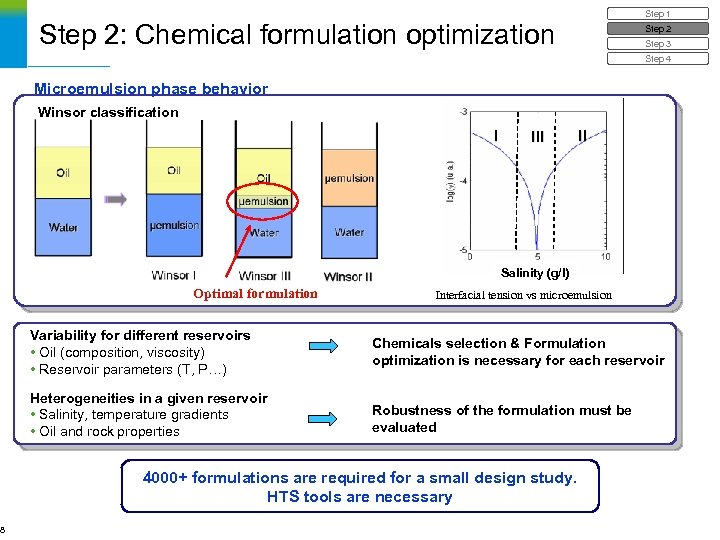

8 Step 1 Step 2: Chemical formulation optimization Step 2 Step 3 Step 4 Microemulsion phase behavior Winsor classification I II Salinity (g/l) Optimal formulation Interfacial tension vs microemulsion Variability for different reservoirs • Oil (composition, viscosity) • Reservoir parameters (T, P…) Chemicals selection & Formulation optimization is necessary for each reservoir Heterogeneities in a given reservoir • Salinity, temperature gradients • Oil and rock properties Robustness of the formulation must be evaluated 4000+ formulations are required for a small design study. HTS tools are necessary

8 Step 1 Step 2: Chemical formulation optimization Step 2 Step 3 Step 4 Microemulsion phase behavior Winsor classification I II Salinity (g/l) Optimal formulation Interfacial tension vs microemulsion Variability for different reservoirs • Oil (composition, viscosity) • Reservoir parameters (T, P…) Chemicals selection & Formulation optimization is necessary for each reservoir Heterogeneities in a given reservoir • Salinity, temperature gradients • Oil and rock properties Robustness of the formulation must be evaluated 4000+ formulations are required for a small design study. HTS tools are necessary

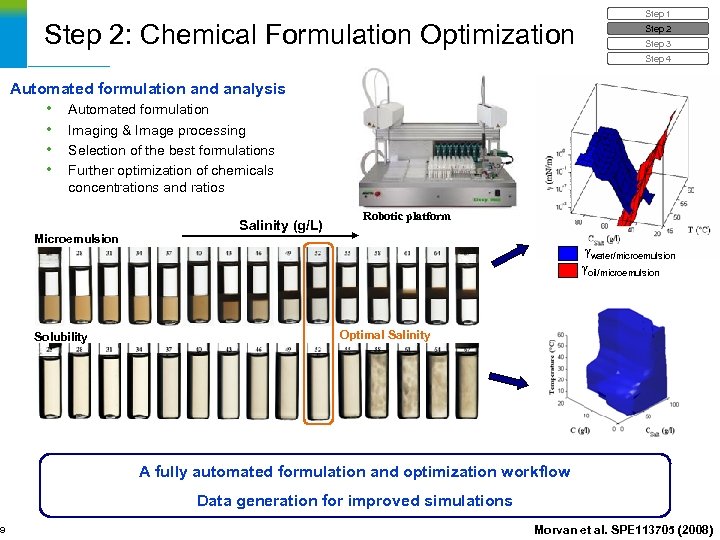

9 Step 2: Chemical Formulation Optimization Step 1 Step 2 Step 3 Step 4 Automated formulation and analysis • Automated formulation • Imaging & Image processing • Selection of the best formulations • Further optimization of chemicals concentrations and ratios Microemulsion Solubility Salinity (g/L) Robotic platform water/microemulsion oil/microemulsion Optimal Salinity A fully automated formulation and optimization workflow Data generation for improved simulations Morvan et al. SPE 113705 (2008)

9 Step 2: Chemical Formulation Optimization Step 1 Step 2 Step 3 Step 4 Automated formulation and analysis • Automated formulation • Imaging & Image processing • Selection of the best formulations • Further optimization of chemicals concentrations and ratios Microemulsion Solubility Salinity (g/L) Robotic platform water/microemulsion oil/microemulsion Optimal Salinity A fully automated formulation and optimization workflow Data generation for improved simulations Morvan et al. SPE 113705 (2008)

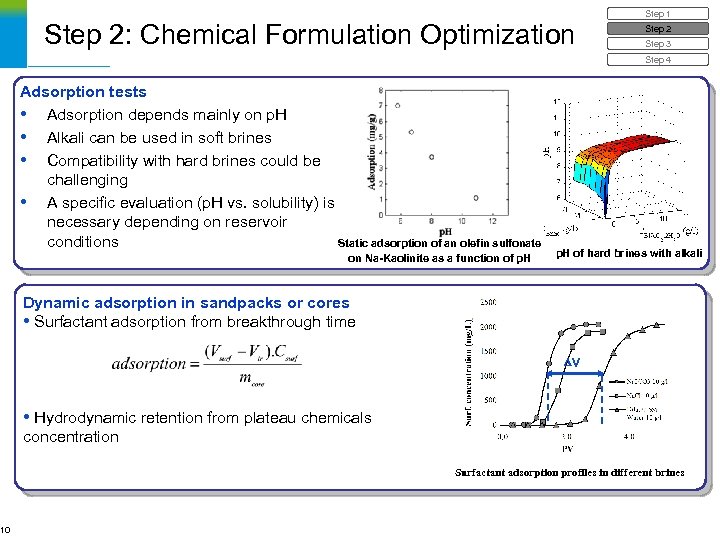

10 Step 2: Chemical Formulation Optimization Step 1 Step 2 Step 3 Step 4 Adsorption tests • Adsorption depends mainly on p. H • Alkali can be used in soft brines • Compatibility with hard brines could be challenging • A specific evaluation (p. H vs. solubility) is necessary depending on reservoir conditions Static adsorption of an olefin sulfonate on Na-Kaolinite as a function of p. H of hard brines with alkali Dynamic adsorption in sandpacks or cores • Surfactant adsorption from breakthrough time DV • Hydrodynamic retention from plateau chemicals concentration Surfactant adsorption profiles in different brines

10 Step 2: Chemical Formulation Optimization Step 1 Step 2 Step 3 Step 4 Adsorption tests • Adsorption depends mainly on p. H • Alkali can be used in soft brines • Compatibility with hard brines could be challenging • A specific evaluation (p. H vs. solubility) is necessary depending on reservoir conditions Static adsorption of an olefin sulfonate on Na-Kaolinite as a function of p. H of hard brines with alkali Dynamic adsorption in sandpacks or cores • Surfactant adsorption from breakthrough time DV • Hydrodynamic retention from plateau chemicals concentration Surfactant adsorption profiles in different brines

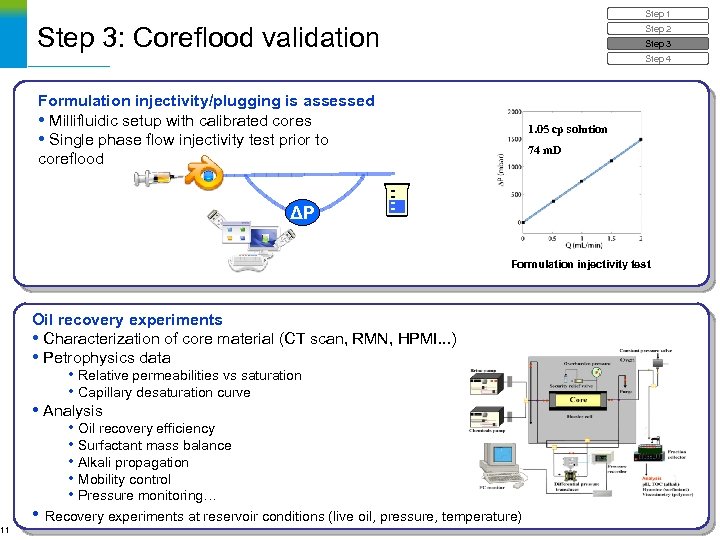

11 Step 3: Coreflood validation Step 2 Step 3 Step 4 Formulation injectivity/plugging is assessed • Millifluidic setup with calibrated cores • Single phase flow injectivity test prior to coreflood 1. 05 cp solution 74 m. D ΔP Formulation injectivity test Oil recovery experiments • Characterization of core material (CT scan, RMN, HPMI. . . ) • Petrophysics data • Relative permeabilities vs saturation • Capillary desaturation curve • Analysis • Oil recovery efficiency • Surfactant mass balance • Alkali propagation • Mobility control • Pressure monitoring… • Recovery experiments at reservoir conditions (live oil, pressure, temperature)

11 Step 3: Coreflood validation Step 2 Step 3 Step 4 Formulation injectivity/plugging is assessed • Millifluidic setup with calibrated cores • Single phase flow injectivity test prior to coreflood 1. 05 cp solution 74 m. D ΔP Formulation injectivity test Oil recovery experiments • Characterization of core material (CT scan, RMN, HPMI. . . ) • Petrophysics data • Relative permeabilities vs saturation • Capillary desaturation curve • Analysis • Oil recovery efficiency • Surfactant mass balance • Alkali propagation • Mobility control • Pressure monitoring… • Recovery experiments at reservoir conditions (live oil, pressure, temperature)

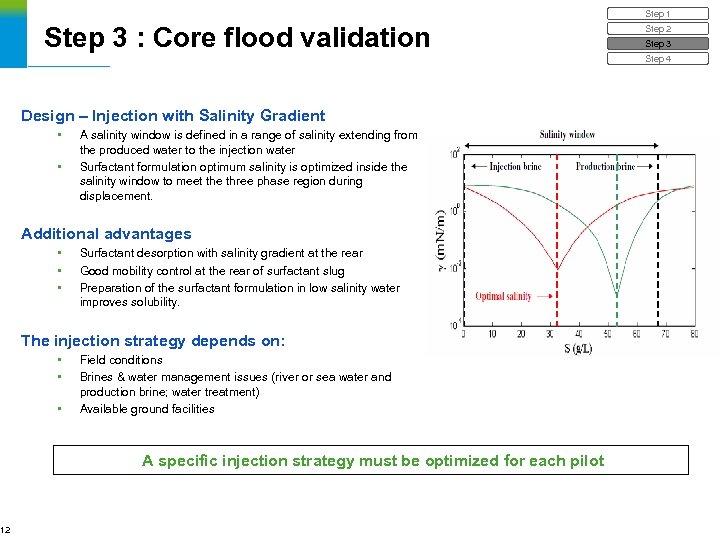

12 Step 1 Step 3 : Core flood validation Step 2 Step 3 Step 4 Design – Injection with Salinity Gradient • • A salinity window is defined in a range of salinity extending from the produced water to the injection water Surfactant formulation optimum salinity is optimized inside the salinity window to meet the three phase region during displacement. Additional advantages • • • Surfactant desorption with salinity gradient at the rear Good mobility control at the rear of surfactant slug Preparation of the surfactant formulation in low salinity water improves solubility. The injection strategy depends on: • • • Field conditions Brines & water management issues (river or sea water and production brine; water treatment) Available ground facilities A specific injection strategy must be optimized for each pilot

12 Step 1 Step 3 : Core flood validation Step 2 Step 3 Step 4 Design – Injection with Salinity Gradient • • A salinity window is defined in a range of salinity extending from the produced water to the injection water Surfactant formulation optimum salinity is optimized inside the salinity window to meet the three phase region during displacement. Additional advantages • • • Surfactant desorption with salinity gradient at the rear Good mobility control at the rear of surfactant slug Preparation of the surfactant formulation in low salinity water improves solubility. The injection strategy depends on: • • • Field conditions Brines & water management issues (river or sea water and production brine; water treatment) Available ground facilities A specific injection strategy must be optimized for each pilot

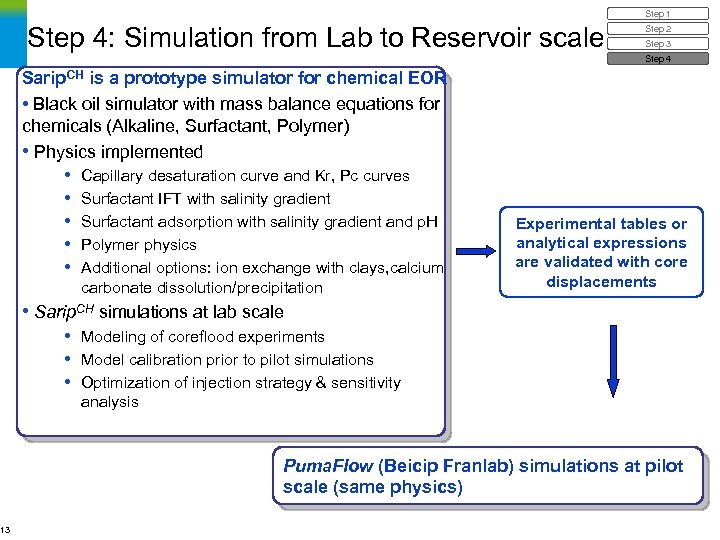

13 Step 1 Step 4: Simulation from Lab to Reservoir scale Step 2 Step 3 Step 4 Sarip. CH is a prototype simulator for chemical EOR • Black oil simulator with mass balance equations for chemicals (Alkaline, Surfactant, Polymer) • Physics implemented • • • Capillary desaturation curve and Kr, Pc curves Surfactant IFT with salinity gradient Surfactant adsorption with salinity gradient and p. H Polymer physics Additional options: ion exchange with clays, calcium Cumulative oil carbonate dissolution/precipitation • Sarip. CH simulations at lab scale Experimental tables or analytical expressions are validated with core displacements Oil cut • Modeling of coreflood experiments • Model calibration prior to pilot simulations • Optimization of injection strategy & sensitivity analysis Puma. Flow (Beicip Franlab) simulations at pilot scale (same physics)

13 Step 1 Step 4: Simulation from Lab to Reservoir scale Step 2 Step 3 Step 4 Sarip. CH is a prototype simulator for chemical EOR • Black oil simulator with mass balance equations for chemicals (Alkaline, Surfactant, Polymer) • Physics implemented • • • Capillary desaturation curve and Kr, Pc curves Surfactant IFT with salinity gradient Surfactant adsorption with salinity gradient and p. H Polymer physics Additional options: ion exchange with clays, calcium Cumulative oil carbonate dissolution/precipitation • Sarip. CH simulations at lab scale Experimental tables or analytical expressions are validated with core displacements Oil cut • Modeling of coreflood experiments • Model calibration prior to pilot simulations • Optimization of injection strategy & sensitivity analysis Puma. Flow (Beicip Franlab) simulations at pilot scale (same physics)

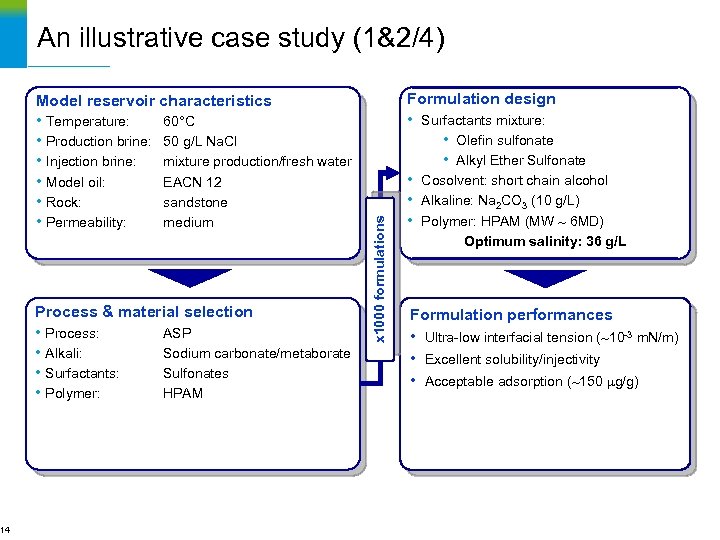

14 An illustrative case study (1&2/4) Formulation design • Temperature: • Production brine: • Injection brine: • Model oil: • Rock: • Permeability: • Surfactants mixture: • Olefin sulfonate • Alkyl Ether Sulfonate • Cosolvent: short chain alcohol • Alkaline: Na 2 CO 3 (10 g/L) • Polymer: HPAM (MW 6 MD) 60°C 50 g/L Na. Cl mixture production/fresh water EACN 12 sandstone medium Process & material selection • Process: • Alkali: • Surfactants: • Polymer: ASP Sodium carbonate/metaborate Sulfonates HPAM x 1000 formulations Model reservoir characteristics Optimum salinity: 36 g/L Formulation performances • Ultra-low interfacial tension ( 10 -3 m. N/m) • Excellent solubility/injectivity • Acceptable adsorption ( 150 g/g)

14 An illustrative case study (1&2/4) Formulation design • Temperature: • Production brine: • Injection brine: • Model oil: • Rock: • Permeability: • Surfactants mixture: • Olefin sulfonate • Alkyl Ether Sulfonate • Cosolvent: short chain alcohol • Alkaline: Na 2 CO 3 (10 g/L) • Polymer: HPAM (MW 6 MD) 60°C 50 g/L Na. Cl mixture production/fresh water EACN 12 sandstone medium Process & material selection • Process: • Alkali: • Surfactants: • Polymer: ASP Sodium carbonate/metaborate Sulfonates HPAM x 1000 formulations Model reservoir characteristics Optimum salinity: 36 g/L Formulation performances • Ultra-low interfacial tension ( 10 -3 m. N/m) • Excellent solubility/injectivity • Acceptable adsorption ( 150 g/g)

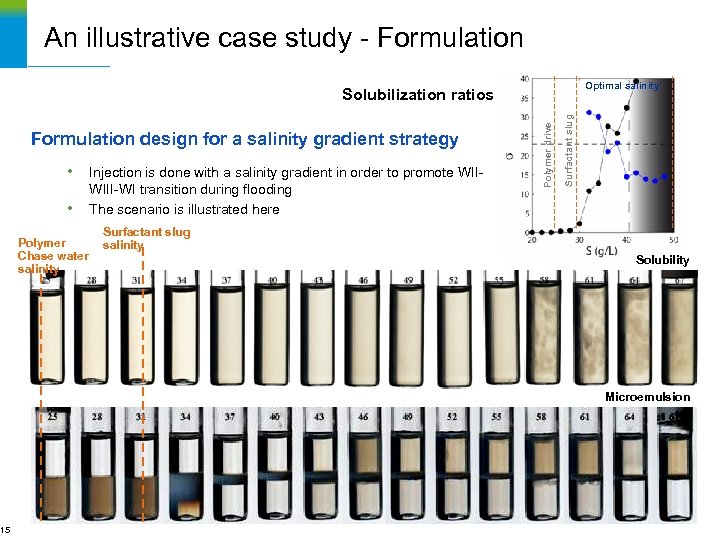

15 An illustrative case study - Formulation • Polymer Chase water salinity Injection is done with a salinity gradient in order to promote WIIWIII-WI transition during flooding The scenario is illustrated here Surfactant slug salinity Surfactant slug • Polymer drive Formulation design for a salinity gradient strategy Formation brine Optimal salinity Solubilization ratios Solubility Salinity Microemulsion

15 An illustrative case study - Formulation • Polymer Chase water salinity Injection is done with a salinity gradient in order to promote WIIWIII-WI transition during flooding The scenario is illustrated here Surfactant slug salinity Surfactant slug • Polymer drive Formulation design for a salinity gradient strategy Formation brine Optimal salinity Solubilization ratios Solubility Salinity Microemulsion

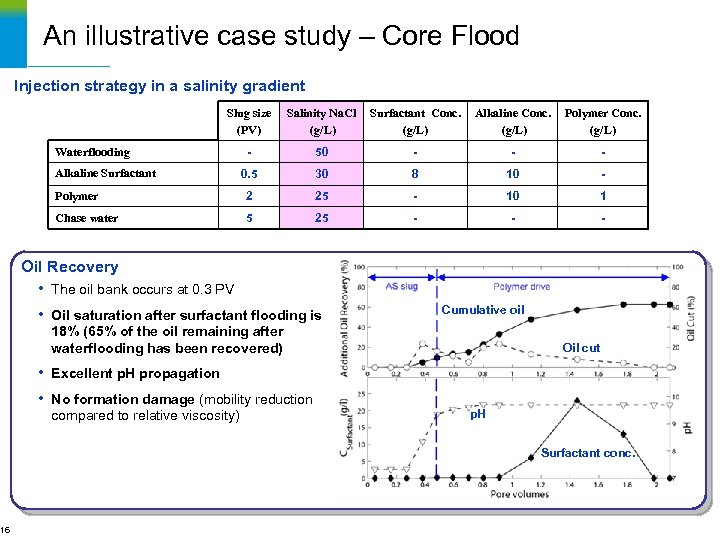

16 An illustrative case study – Core Flood Injection strategy in a salinity gradient Slug size (PV) Salinity Na. Cl (g/L) Surfactant Conc. (g/L) Alkaline Conc. (g/L) Polymer Conc. (g/L) - 50 - - - 0. 5 30 8 10 - Polymer 2 25 - 10 1 Chase water 5 25 - - - Waterflooding Alkaline Surfactant Oil Recovery • The oil bank occurs at 0. 3 PV • Oil saturation after surfactant flooding is Cumulative oil 18% (65% of the oil remaining after waterflooding has been recovered) Oil cut • Excellent p. H propagation • No formation damage (mobility reduction compared to relative viscosity) p. H Surfactant conc.

16 An illustrative case study – Core Flood Injection strategy in a salinity gradient Slug size (PV) Salinity Na. Cl (g/L) Surfactant Conc. (g/L) Alkaline Conc. (g/L) Polymer Conc. (g/L) - 50 - - - 0. 5 30 8 10 - Polymer 2 25 - 10 1 Chase water 5 25 - - - Waterflooding Alkaline Surfactant Oil Recovery • The oil bank occurs at 0. 3 PV • Oil saturation after surfactant flooding is Cumulative oil 18% (65% of the oil remaining after waterflooding has been recovered) Oil cut • Excellent p. H propagation • No formation damage (mobility reduction compared to relative viscosity) p. H Surfactant conc.

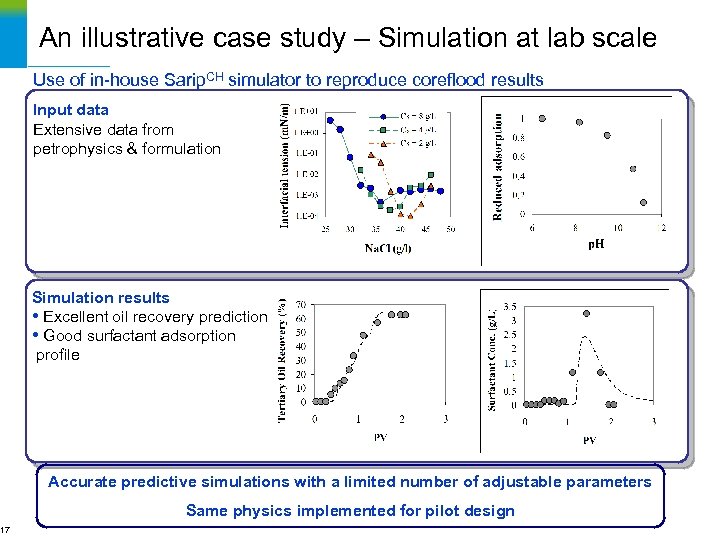

17 An illustrative case study – Simulation at lab scale Use of in-house Sarip. CH simulator to reproduce coreflood results Input data Extensive data from petrophysics & formulation Simulation results • Excellent oil recovery prediction • Good surfactant adsorption profile IFT = f (Composition) Accurate predictive simulations with a limited number of adjustable parameters Same physics implemented for pilot design

17 An illustrative case study – Simulation at lab scale Use of in-house Sarip. CH simulator to reproduce coreflood results Input data Extensive data from petrophysics & formulation Simulation results • Excellent oil recovery prediction • Good surfactant adsorption profile IFT = f (Composition) Accurate predictive simulations with a limited number of adjustable parameters Same physics implemented for pilot design

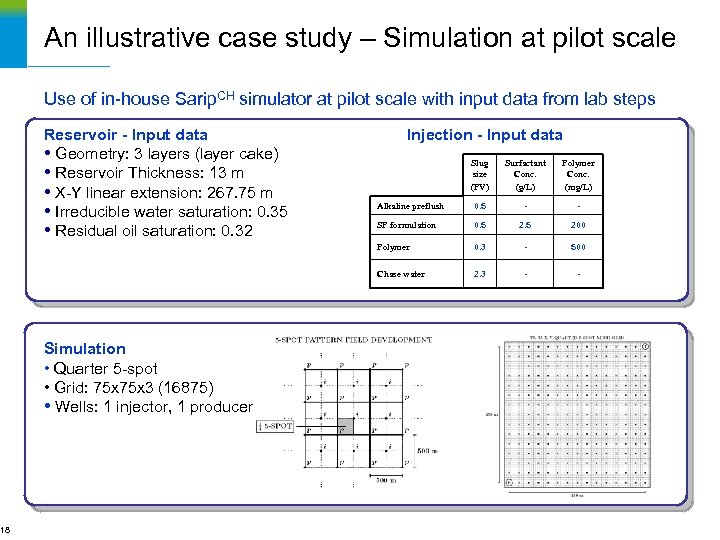

18 An illustrative case study – Simulation at pilot scale Use of in-house Sarip. CH simulator at pilot scale with input data from lab steps Reservoir - Input data • Geometry: 3 layers (layer cake) • Reservoir Thickness: 13 m • X-Y linear extension: 267. 75 m • Irreducible water saturation: 0. 35 • Residual oil saturation: 0. 32 Injection - Input data Surfactant Conc. (g/L) Polymer Conc. (mg/L) Alkaline preflush 0. 5 - - SP formulation 0. 5 2. 5 200 Polymer 0. 3 - 500 Chase water Simulation • Quarter 5 -spot • Grid: 75 x 3 (16875) • Wells: 1 injector, 1 producer Slug size (PV) 2. 3 - -

18 An illustrative case study – Simulation at pilot scale Use of in-house Sarip. CH simulator at pilot scale with input data from lab steps Reservoir - Input data • Geometry: 3 layers (layer cake) • Reservoir Thickness: 13 m • X-Y linear extension: 267. 75 m • Irreducible water saturation: 0. 35 • Residual oil saturation: 0. 32 Injection - Input data Surfactant Conc. (g/L) Polymer Conc. (mg/L) Alkaline preflush 0. 5 - - SP formulation 0. 5 2. 5 200 Polymer 0. 3 - 500 Chase water Simulation • Quarter 5 -spot • Grid: 75 x 3 (16875) • Wells: 1 injector, 1 producer Slug size (PV) 2. 3 - -

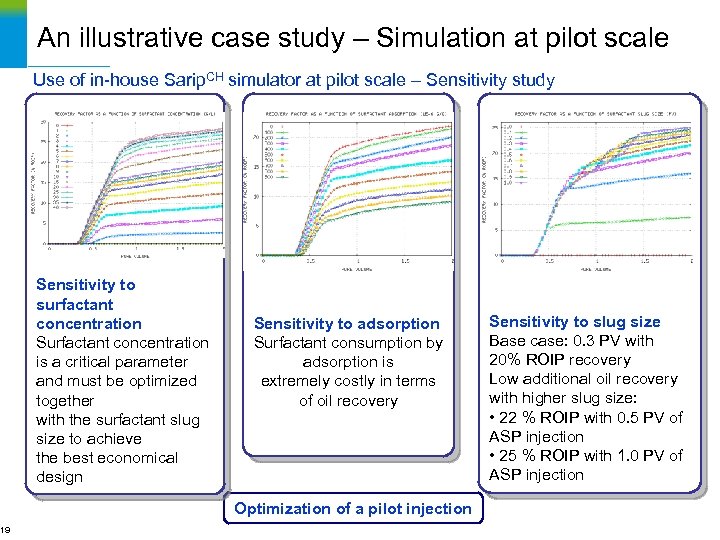

19 An illustrative case study – Simulation at pilot scale Use of in-house Sarip. CH simulator at pilot scale – Sensitivity study Sensitivity to surfactant concentration Surfactant concentration is a critical parameter and must be optimized together with the surfactant slug size to achieve the best economical design Sensitivity to adsorption IFT = f (Composition) Surfactant consumption by adsorption is extremely costly in terms of oil recovery Optimization of a pilot injection Sensitivity to slug size Base case: 0. 3 PV with 20% ROIP recovery Low additional oil recovery with higher slug size: • 22 % ROIP with 0. 5 PV of ASP injection • 25 % ROIP with 1. 0 PV of ASP injection

19 An illustrative case study – Simulation at pilot scale Use of in-house Sarip. CH simulator at pilot scale – Sensitivity study Sensitivity to surfactant concentration Surfactant concentration is a critical parameter and must be optimized together with the surfactant slug size to achieve the best economical design Sensitivity to adsorption IFT = f (Composition) Surfactant consumption by adsorption is extremely costly in terms of oil recovery Optimization of a pilot injection Sensitivity to slug size Base case: 0. 3 PV with 20% ROIP recovery Low additional oil recovery with higher slug size: • 22 % ROIP with 0. 5 PV of ASP injection • 25 % ROIP with 1. 0 PV of ASP injection

20 Conclusions The integrated workflow presented here is based on: • • A fast identification of the best chemicals for given field conditions • • An extensive optimization study thanks to robotized techniques • • Core flood experiments for adsorption and oil recovery determination • • Optimization at pilot scale with simulations using extensive experimental input data Methodology deployed for multiple customers worldwide Next step: development at reservoir scale • Chemical reservoir model available (Puma. Flow) • Sensitivity analysis • Optimization of injection strategy

20 Conclusions The integrated workflow presented here is based on: • • A fast identification of the best chemicals for given field conditions • • An extensive optimization study thanks to robotized techniques • • Core flood experiments for adsorption and oil recovery determination • • Optimization at pilot scale with simulations using extensive experimental input data Methodology deployed for multiple customers worldwide Next step: development at reservoir scale • Chemical reservoir model available (Puma. Flow) • Sensitivity analysis • Optimization of injection strategy

Thank you for your attention

Thank you for your attention