6383038411e24353844e2c249fd9befd.ppt

- Количество слайдов: 30

APPI 03/10/2005 Status of ILC Activity in KEK H. Hayano, KEK

APPI 03/10/2005 Status of ILC Activity in KEK H. Hayano, KEK

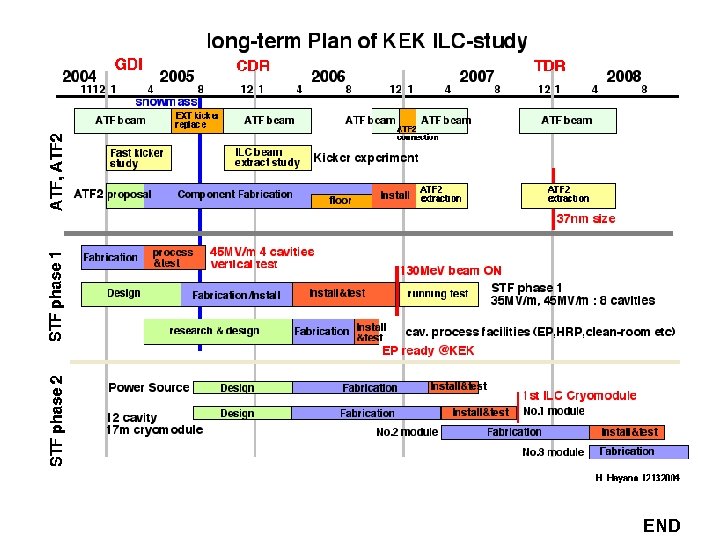

Official Time Schedule of ILC 2005. 8 Decide the director and location of Central GDI Establish Regional GDIs Decide the design outline in Snowmass Workshop (acc. gradient, 1 or 2 tunnel, dogbone/small DR, e+generation etc) 2005 end Complete CDR with rough cost/schedule 2007 end Complete TDR, role of regions, start site selection 2008 Decide the site, budget approval 2009 Ground breaking 2014 Commissioning starts

Official Time Schedule of ILC 2005. 8 Decide the director and location of Central GDI Establish Regional GDIs Decide the design outline in Snowmass Workshop (acc. gradient, 1 or 2 tunnel, dogbone/small DR, e+generation etc) 2005 end Complete CDR with rough cost/schedule 2007 end Complete TDR, role of regions, start site selection 2008 Decide the site, budget approval 2009 Ground breaking 2014 Commissioning starts

Asian Organization for ILC Research ● LC Office in Japan F. Takasaki, K. Yokoya, H. Hayano, N. Toge, S. Yamashita ● Working groups in Asian region WG 1 WG 2 WG 3 WG 4 WG 5 ? ? Overall design (K. Kubo) Main Linac (H. Hayano) Injectors (M. Kuriki) Beam Delivery System (T. Sanuki) HG Cavities (K. Saito) Facility (A. Enomoto) Site (R. Sugawara)

Asian Organization for ILC Research ● LC Office in Japan F. Takasaki, K. Yokoya, H. Hayano, N. Toge, S. Yamashita ● Working groups in Asian region WG 1 WG 2 WG 3 WG 4 WG 5 ? ? Overall design (K. Kubo) Main Linac (H. Hayano) Injectors (M. Kuriki) Beam Delivery System (T. Sanuki) HG Cavities (K. Saito) Facility (A. Enomoto) Site (R. Sugawara)

Critical Research Areas Establishment of the technology for accelerating gradient 35 MV/m ● . Technologies for cost reduction. Technologies for mass production ● Pursuit of possible higher accelerating gradient. Larger operational margin of gradient. Wider possibility of site selection ● Beam technology development using KEK-ATF. Unique storage ring to reach ILC emittance. Make full use of ATF capabilities

Critical Research Areas Establishment of the technology for accelerating gradient 35 MV/m ● . Technologies for cost reduction. Technologies for mass production ● Pursuit of possible higher accelerating gradient. Larger operational margin of gradient. Wider possibility of site selection ● Beam technology development using KEK-ATF. Unique storage ring to reach ILC emittance. Make full use of ATF capabilities

Guiding Principle Global Point of View ● Time line ● Low cost design ● Effective use of R&D budget by global coordination Regional Point of View ● Establish the leadership in leading areas ● Promote industrial level Time Scale ● Snowmass issues (Aug. 2005) ● CDR issues (End of 2005) ● TDR issues (End of 2007)

Guiding Principle Global Point of View ● Time line ● Low cost design ● Effective use of R&D budget by global coordination Regional Point of View ● Establish the leadership in leading areas ● Promote industrial level Time Scale ● Snowmass issues (Aug. 2005) ● CDR issues (End of 2005) ● TDR issues (End of 2007)

Development of 45 MV/m High Gradient Cavity Single-cell test in Dec 2004 - Mar 2005 ● Individual vertical test of four 9 -cell cavities by Sep. 2005. Just in time for CDR completion. In existing facilities (AR east). If expected performance not obtained, ⇒ change to slower plan for ILC 2 nd stage ● Cryomodule test by end of 2006 ⇒ STF Phase 1 ● Industrial design by TDR ●

Development of 45 MV/m High Gradient Cavity Single-cell test in Dec 2004 - Mar 2005 ● Individual vertical test of four 9 -cell cavities by Sep. 2005. Just in time for CDR completion. In existing facilities (AR east). If expected performance not obtained, ⇒ change to slower plan for ILC 2 nd stage ● Cryomodule test by end of 2006 ⇒ STF Phase 1 ● Industrial design by TDR ●

Superconducting RF Test Facility Comprehensive Test Facility dedicated to ILC SC-RF R&D 1. Superconducting Cavity; fabrication, surface treatment, installation, vertical test / horizontal test, system test with beam 2. Cryomodule; cavity installation, alignment, cryostat operation, heat cycle test, input coupler R&D, tuner mechanism R&D 3. Power source; modulator development, klystron development, WG components 4. He plant; High efficiency cryogenic system 5. Beam Instrumentation; ILC beam generation, BPM, HOM, Low-Level RF control 6. Cavity Surface Treatment Facility; BCP, EP, HPR, clean room

Superconducting RF Test Facility Comprehensive Test Facility dedicated to ILC SC-RF R&D 1. Superconducting Cavity; fabrication, surface treatment, installation, vertical test / horizontal test, system test with beam 2. Cryomodule; cavity installation, alignment, cryostat operation, heat cycle test, input coupler R&D, tuner mechanism R&D 3. Power source; modulator development, klystron development, WG components 4. He plant; High efficiency cryogenic system 5. Beam Instrumentation; ILC beam generation, BPM, HOM, Low-Level RF control 6. Cavity Surface Treatment Facility; BCP, EP, HPR, clean room

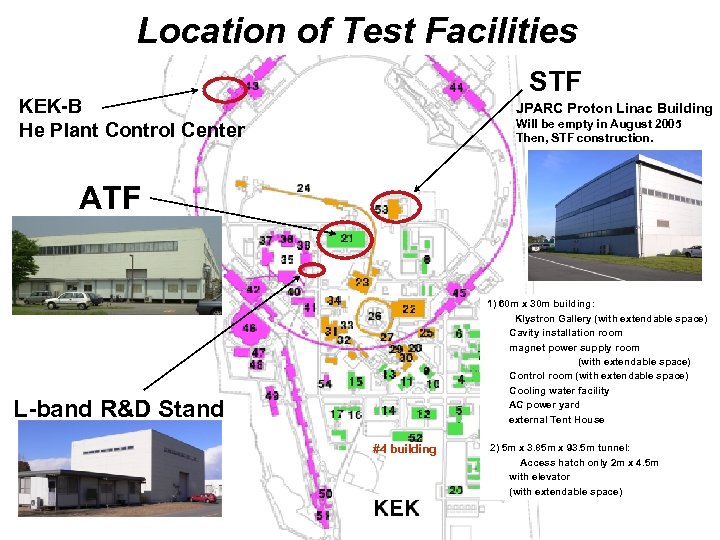

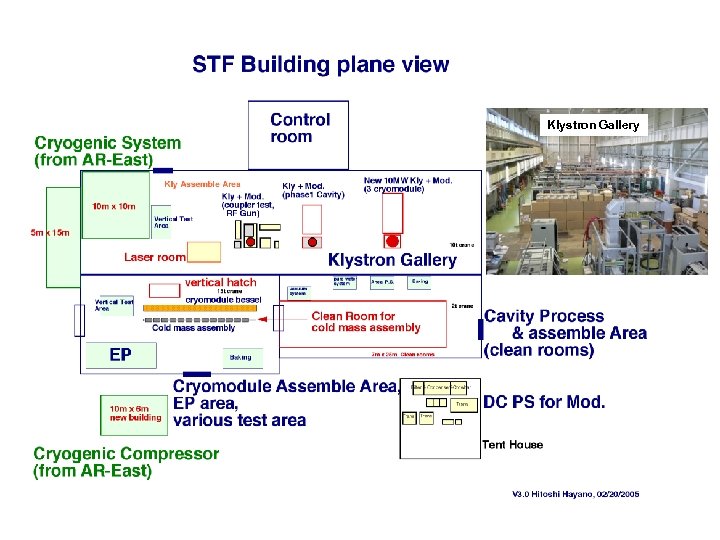

Location of Test Facilities STF KEK-B He Plant Control Center JPARC Proton Linac Building Will be empty in August 2005 Then, STF construction. ATF 1) 60 m x 30 m building: Klystron Gallery (with extendable space) Cavity installation room magnet power supply room (with extendable space) Control room (with extendable space) Cooling water facility AC power yard external Tent House L-band R&D Stand #4 building 2) 5 m x 3. 85 m x 93. 5 m tunnel: Access hatch only 2 m x 4. 5 m with elevator (with extendable space)

Location of Test Facilities STF KEK-B He Plant Control Center JPARC Proton Linac Building Will be empty in August 2005 Then, STF construction. ATF 1) 60 m x 30 m building: Klystron Gallery (with extendable space) Cavity installation room magnet power supply room (with extendable space) Control room (with extendable space) Cooling water facility AC power yard external Tent House L-band R&D Stand #4 building 2) 5 m x 3. 85 m x 93. 5 m tunnel: Access hatch only 2 m x 4. 5 m with elevator (with extendable space)

Purpose of STF ● Establish industrial design of Linac unit (35 MV/m and 45 MV/m) Promote Asian/Japanese industrial level for ILC component production ● ● Form Asian base for international collaboration ● Enlist/educate new comers

Purpose of STF ● Establish industrial design of Linac unit (35 MV/m and 45 MV/m) Promote Asian/Japanese industrial level for ILC component production ● ● Form Asian base for international collaboration ● Enlist/educate new comers

Klystron Gallery

Klystron Gallery

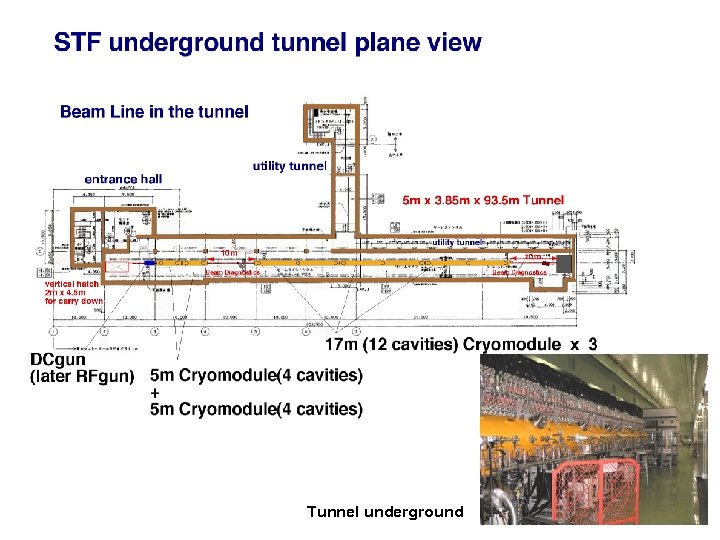

Tunnel underground

Tunnel underground

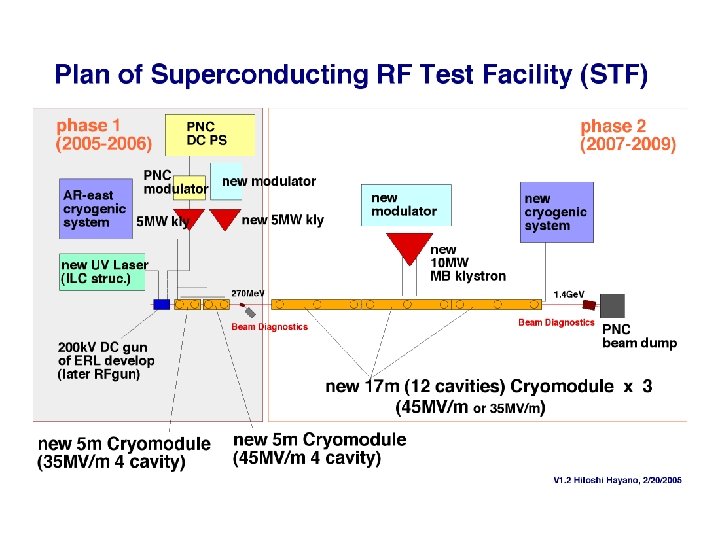

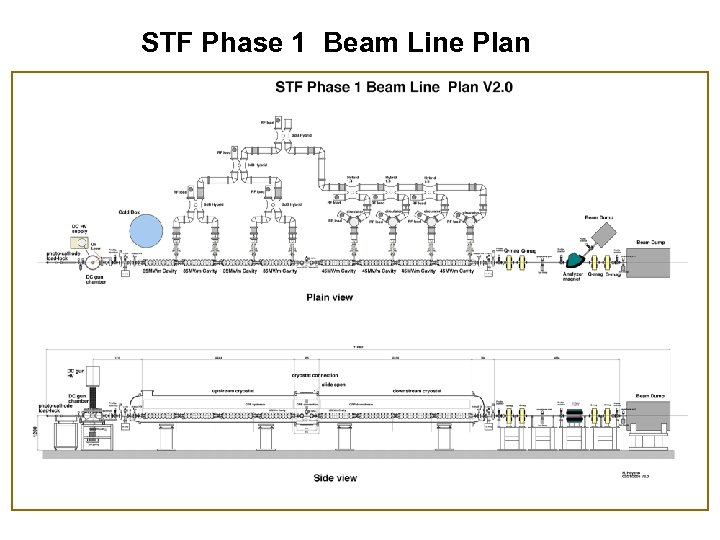

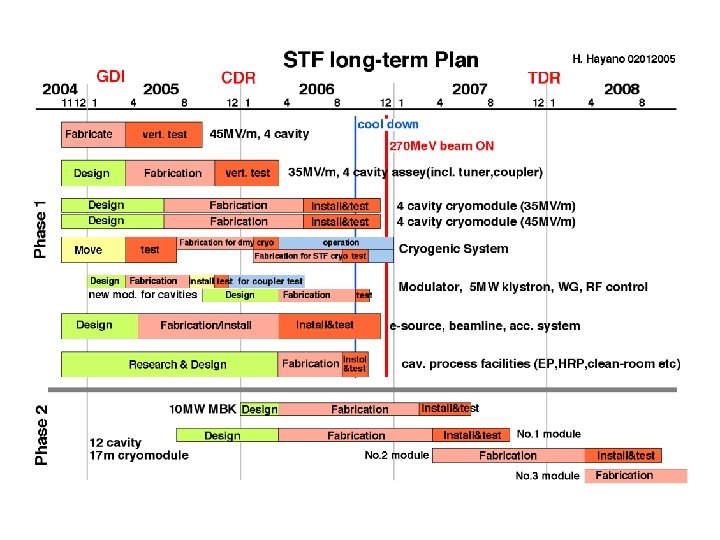

STF Phase 1 (2005 -2006) ● Cryomodule for 4 45 MV/m cavities ● Cryomodule for 4 35 MV/m cavities ● RF source and cryogenic system (mostly recycled) ● Electron beam and its diagnostics system ● Synthetic test of 35 MV/m & 45 MV/m cryomodules with beam Other items in parallel ● Electro-polishing Facility. Can electro-polish cavities to be used overseas ● Cost reduction of cavity fabrication (Nb/Cu-clad, seamless)

STF Phase 1 (2005 -2006) ● Cryomodule for 4 45 MV/m cavities ● Cryomodule for 4 35 MV/m cavities ● RF source and cryogenic system (mostly recycled) ● Electron beam and its diagnostics system ● Synthetic test of 35 MV/m & 45 MV/m cryomodules with beam Other items in parallel ● Electro-polishing Facility. Can electro-polish cavities to be used overseas ● Cost reduction of cavity fabrication (Nb/Cu-clad, seamless)

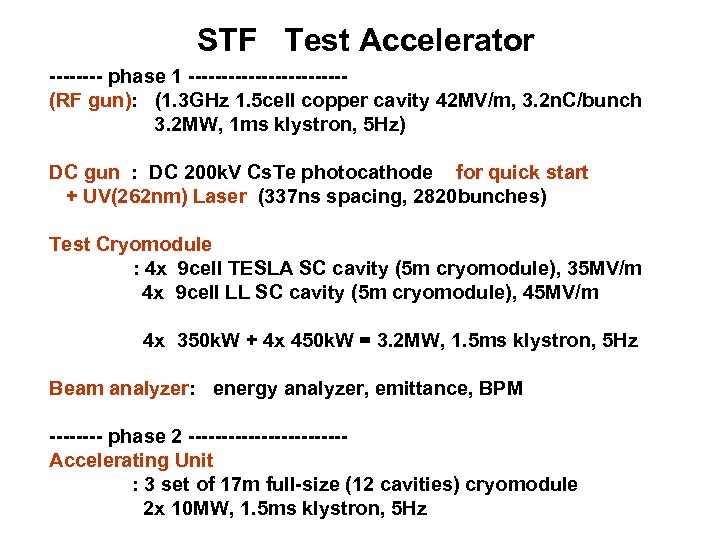

STF Test Accelerator ---- phase 1 ------------(RF gun): (1. 3 GHz 1. 5 cell copper cavity 42 MV/m, 3. 2 n. C/bunch 3. 2 MW, 1 ms klystron, 5 Hz) DC gun : DC 200 k. V Cs. Te photocathode for quick start + UV(262 nm) Laser (337 ns spacing, 2820 bunches) Test Cryomodule : 4 x 9 cell TESLA SC cavity (5 m cryomodule), 35 MV/m 4 x 9 cell LL SC cavity (5 m cryomodule), 45 MV/m 4 x 350 k. W + 4 x 450 k. W = 3. 2 MW, 1. 5 ms klystron, 5 Hz Beam analyzer: energy analyzer, emittance, BPM ---- phase 2 ------------Accelerating Unit : 3 set of 17 m full-size (12 cavities) cryomodule 2 x 10 MW, 1. 5 ms klystron, 5 Hz

STF Test Accelerator ---- phase 1 ------------(RF gun): (1. 3 GHz 1. 5 cell copper cavity 42 MV/m, 3. 2 n. C/bunch 3. 2 MW, 1 ms klystron, 5 Hz) DC gun : DC 200 k. V Cs. Te photocathode for quick start + UV(262 nm) Laser (337 ns spacing, 2820 bunches) Test Cryomodule : 4 x 9 cell TESLA SC cavity (5 m cryomodule), 35 MV/m 4 x 9 cell LL SC cavity (5 m cryomodule), 45 MV/m 4 x 350 k. W + 4 x 450 k. W = 3. 2 MW, 1. 5 ms klystron, 5 Hz Beam analyzer: energy analyzer, emittance, BPM ---- phase 2 ------------Accelerating Unit : 3 set of 17 m full-size (12 cavities) cryomodule 2 x 10 MW, 1. 5 ms klystron, 5 Hz

STF Infra-structure EP: build new EP(Electro chemical Polishing) facility HPR : move High Pressure Rinse from L-band test stand Clean room : build new clean room for cavity assemble Vertical Test Stand : build new stand, deep enough for superstructure cavity Coupler Test Stand : 5 MW, 1. 5 ms klystron, 5 Hz (switch use between Test Cryomodule ) He Plant : 600 W at 4 K plant moving from AR-East building (adding new 2 K system )

STF Infra-structure EP: build new EP(Electro chemical Polishing) facility HPR : move High Pressure Rinse from L-band test stand Clean room : build new clean room for cavity assemble Vertical Test Stand : build new stand, deep enough for superstructure cavity Coupler Test Stand : 5 MW, 1. 5 ms klystron, 5 Hz (switch use between Test Cryomodule ) He Plant : 600 W at 4 K plant moving from AR-East building (adding new 2 K system )

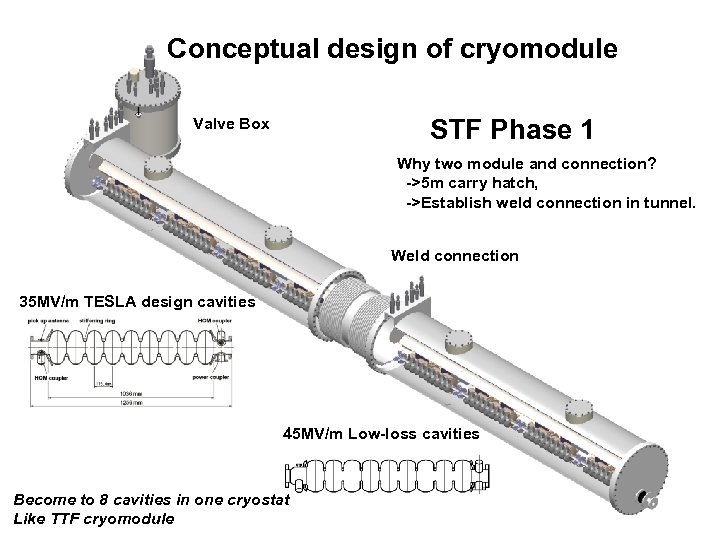

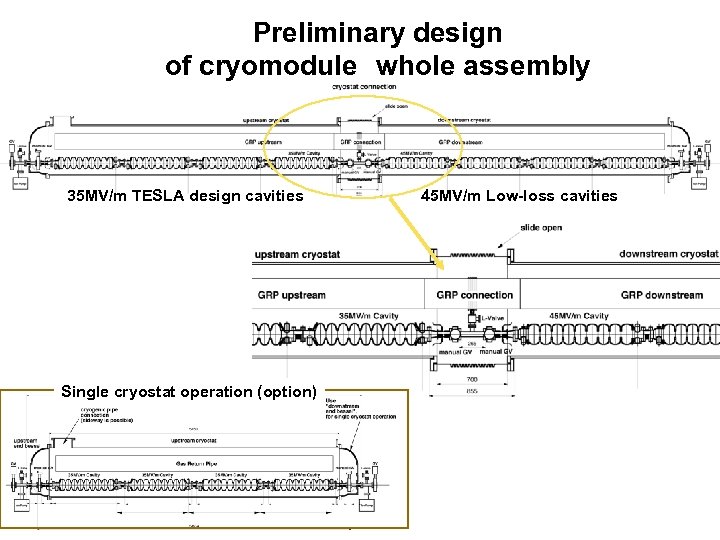

Conceptual design of cryomodule STF Phase 1 Valve Box Why two module and connection? ->5 m carry hatch, ->Establish weld connection in tunnel. Weld connection 35 MV/m TESLA design cavities 45 MV/m Low-loss cavities Become to 8 cavities in one cryostat Like TTF cryomodule

Conceptual design of cryomodule STF Phase 1 Valve Box Why two module and connection? ->5 m carry hatch, ->Establish weld connection in tunnel. Weld connection 35 MV/m TESLA design cavities 45 MV/m Low-loss cavities Become to 8 cavities in one cryostat Like TTF cryomodule

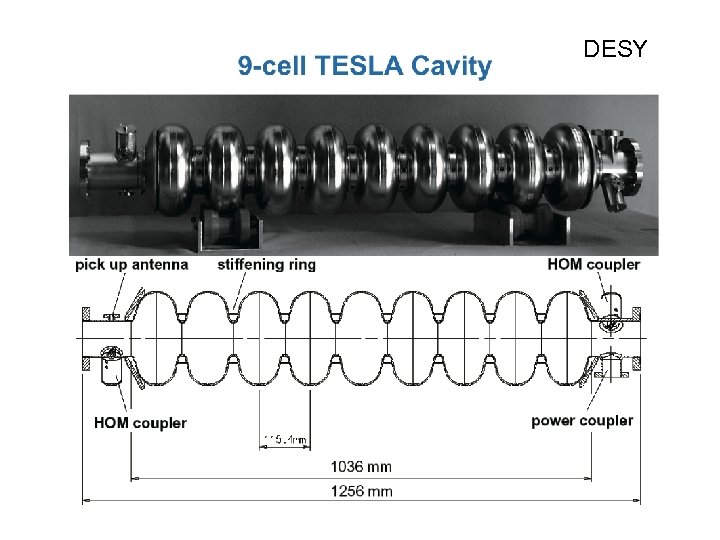

DESY

DESY

Preliminary design of cryomodule whole assembly 35 MV/m TESLA design cavities Single cryostat operation (option) 45 MV/m Low-loss cavities

Preliminary design of cryomodule whole assembly 35 MV/m TESLA design cavities Single cryostat operation (option) 45 MV/m Low-loss cavities

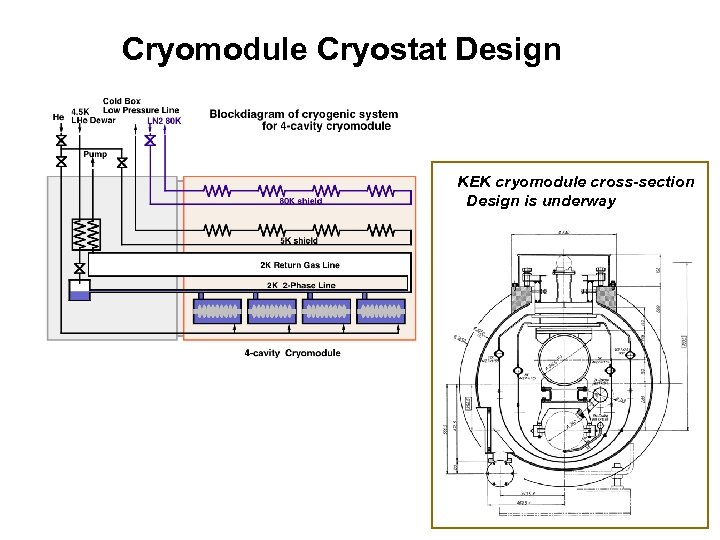

Cryomodule Cryostat Design KEK cryomodule cross-section Design is underway

Cryomodule Cryostat Design KEK cryomodule cross-section Design is underway

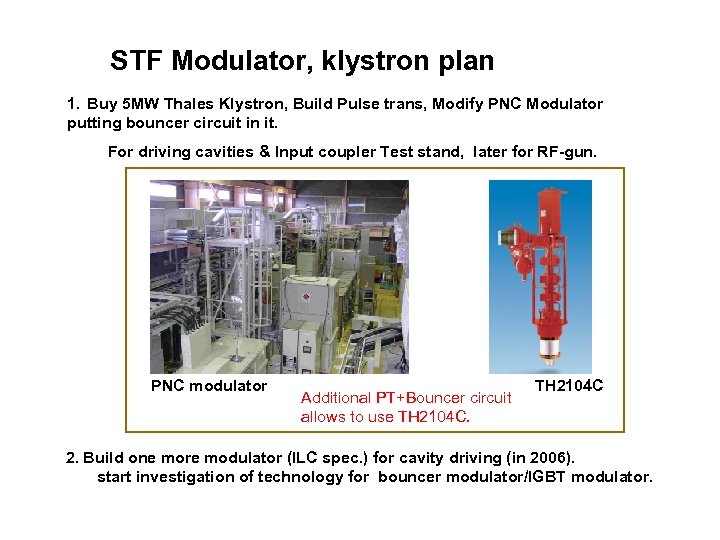

STF Modulator, klystron plan 1. Buy 5 MW Thales Klystron, Build Pulse trans, Modify PNC Modulator putting bouncer circuit in it. For driving cavities & Input coupler Test stand, later for RF-gun. PNC modulator Additional PT+Bouncer circuit allows to use TH 2104 C 2. Build one more modulator (ILC spec. ) for cavity driving (in 2006). start investigation of technology for bouncer modulator/IGBT modulator.

STF Modulator, klystron plan 1. Buy 5 MW Thales Klystron, Build Pulse trans, Modify PNC Modulator putting bouncer circuit in it. For driving cavities & Input coupler Test stand, later for RF-gun. PNC modulator Additional PT+Bouncer circuit allows to use TH 2104 C 2. Build one more modulator (ILC spec. ) for cavity driving (in 2006). start investigation of technology for bouncer modulator/IGBT modulator.

STF Phase 1 Beam Line Plan

STF Phase 1 Beam Line Plan

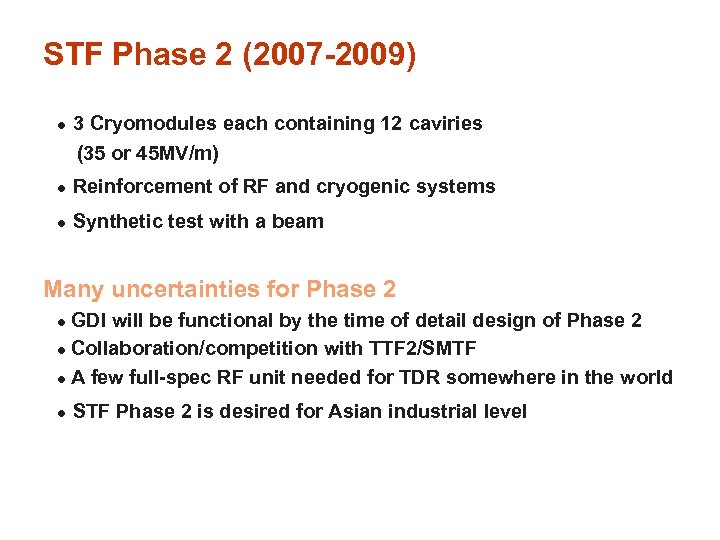

STF Phase 2 (2007 -2009) ● 3 Cryomodules each containing 12 caviries (35 or 45 MV/m) ● Reinforcement of RF and cryogenic systems ● Synthetic test with a beam Many uncertainties for Phase 2 ● GDI will be functional by the time of detail design of Phase 2 ● Collaboration/competition with TTF 2/SMTF ● A few full-spec RF unit needed for TDR somewhere in the world ● STF Phase 2 is desired for Asian industrial level

STF Phase 2 (2007 -2009) ● 3 Cryomodules each containing 12 caviries (35 or 45 MV/m) ● Reinforcement of RF and cryogenic systems ● Synthetic test with a beam Many uncertainties for Phase 2 ● GDI will be functional by the time of detail design of Phase 2 ● Collaboration/competition with TTF 2/SMTF ● A few full-spec RF unit needed for TDR somewhere in the world ● STF Phase 2 is desired for Asian industrial level

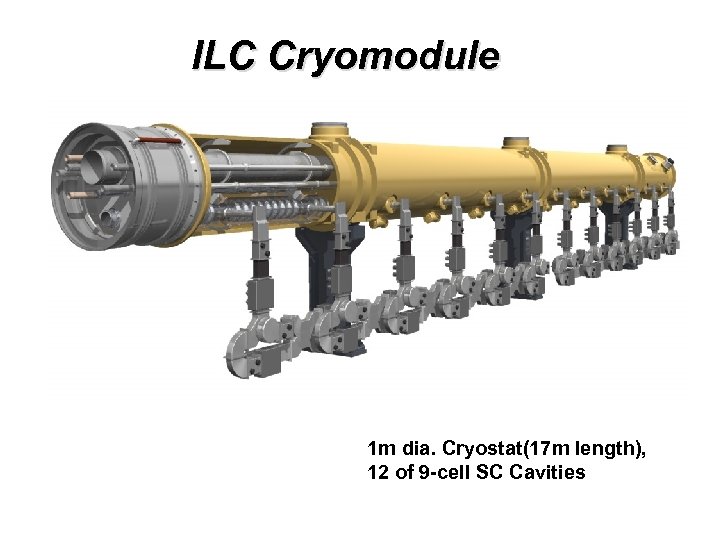

ILC Cryomodule 1 m dia. Cryostat(17 m length), 12 of 9 -cell SC Cavities

ILC Cryomodule 1 m dia. Cryostat(17 m length), 12 of 9 -cell SC Cavities

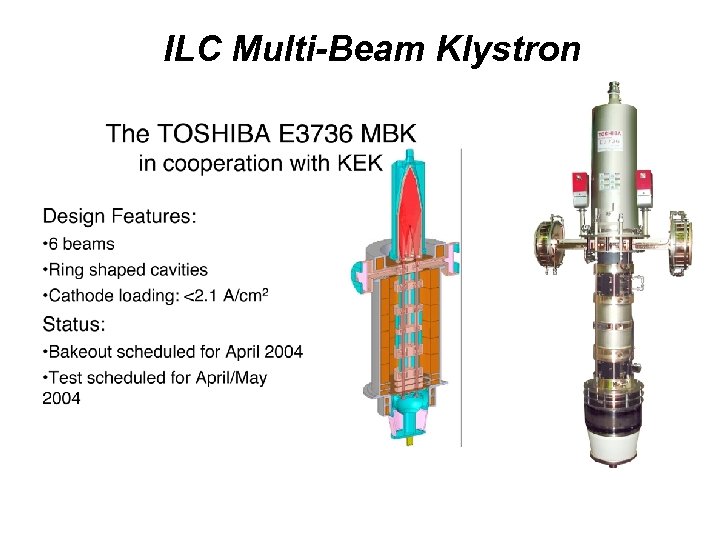

ILC Multi-Beam Klystron

ILC Multi-Beam Klystron

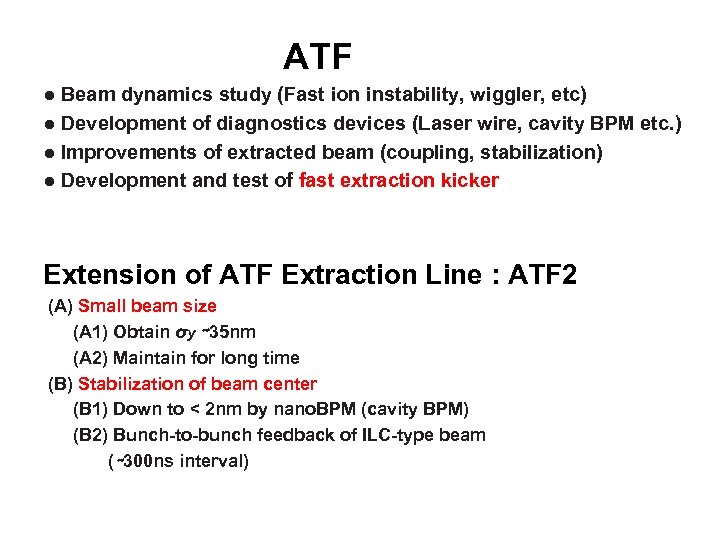

ATF ● Beam dynamics study (Fast ion instability, wiggler, etc) ● Development of diagnostics devices (Laser wire, cavity BPM etc. ) ● Improvements of extracted beam (coupling, stabilization) ● Development and test of fast extraction kicker Extension of ATF Extraction Line : ATF 2 (A) Small beam size (A 1) Obtain σy ∼ 35 nm (A 2) Maintain for long time (B) Stabilization of beam center (B 1) Down to < 2 nm by nano. BPM (cavity BPM) (B 2) Bunch-to-bunch feedback of ILC-type beam (∼ 300 ns interval)

ATF ● Beam dynamics study (Fast ion instability, wiggler, etc) ● Development of diagnostics devices (Laser wire, cavity BPM etc. ) ● Improvements of extracted beam (coupling, stabilization) ● Development and test of fast extraction kicker Extension of ATF Extraction Line : ATF 2 (A) Small beam size (A 1) Obtain σy ∼ 35 nm (A 2) Maintain for long time (B) Stabilization of beam center (B 1) Down to < 2 nm by nano. BPM (cavity BPM) (B 2) Bunch-to-bunch feedback of ILC-type beam (∼ 300 ns interval)

ATF Mission: generation&confirmation of LC low emittance e- beam ATF emittance goal was set to X emit=2. 5 E-6( at 0 intensity) Y emit=2. 5 E-8( at 0 intensity) 1% from X

ATF Mission: generation&confirmation of LC low emittance e- beam ATF emittance goal was set to X emit=2. 5 E-6( at 0 intensity) Y emit=2. 5 E-8( at 0 intensity) 1% from X

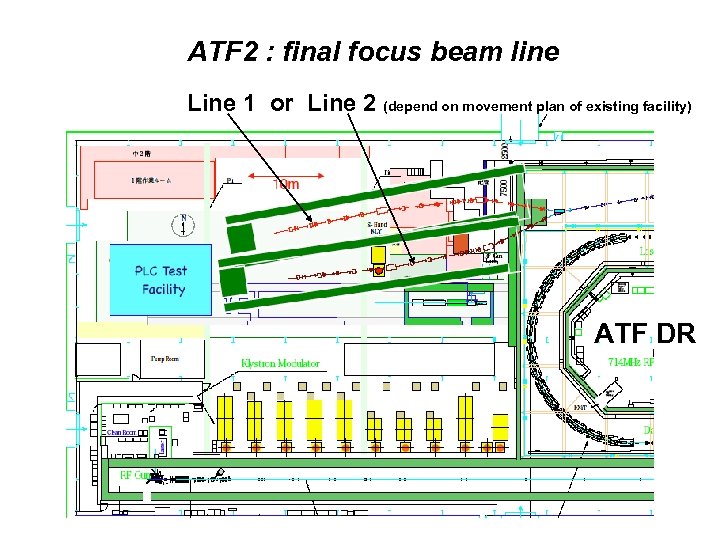

ATF 2 : final focus beam line Line 1 or Line 2 (depend on movement plan of existing facility) ATF DR

ATF 2 : final focus beam line Line 1 or Line 2 (depend on movement plan of existing facility) ATF DR

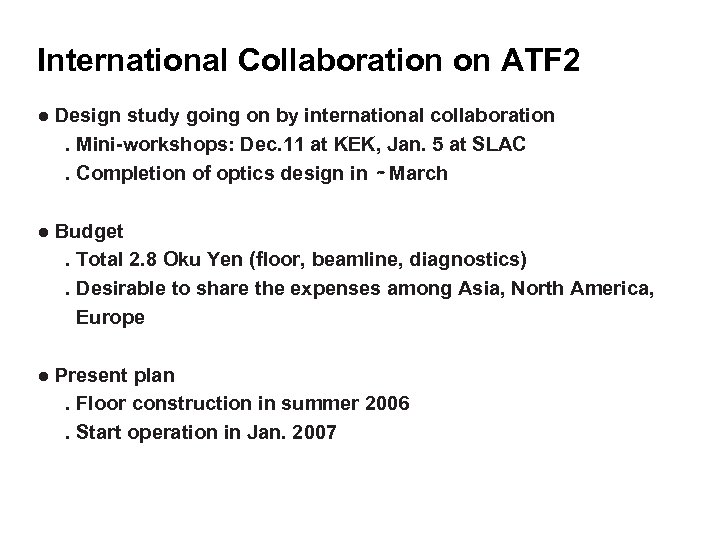

International Collaboration on ATF 2 ● Design study going on by international collaboration. Mini-workshops: Dec. 11 at KEK, Jan. 5 at SLAC. Completion of optics design in ∼ March ● Budget. Total 2. 8 Oku Yen (floor, beamline, diagnostics). Desirable to share the expenses among Asia, North America, Europe ● Present plan. Floor construction in summer 2006. Start operation in Jan. 2007

International Collaboration on ATF 2 ● Design study going on by international collaboration. Mini-workshops: Dec. 11 at KEK, Jan. 5 at SLAC. Completion of optics design in ∼ March ● Budget. Total 2. 8 Oku Yen (floor, beamline, diagnostics). Desirable to share the expenses among Asia, North America, Europe ● Present plan. Floor construction in summer 2006. Start operation in Jan. 2007

END

END