0fc64fd91d85d9279ec21d6c23b89cc1.ppt

- Количество слайдов: 19

API Q 1 and ISO/TS 29001 A Case Study in Successful Collaboration Stacey Hagen, Drilling Materials Sr. QA Advisor – OCTG Lead Chair, API Subcommittee on Quality 1

API Q 1 and ISO/TS 29001 A Case Study in Successful Collaboration Stacey Hagen, Drilling Materials Sr. QA Advisor – OCTG Lead Chair, API Subcommittee on Quality 1

Overview • Exxon. Mobil Background • Exxon. Mobil’s standards strategy • API Q 1/ISO 29001 Case Study • Conclusions 2

Overview • Exxon. Mobil Background • Exxon. Mobil’s standards strategy • API Q 1/ISO 29001 Case Study • Conclusions 2

Company Background • Formed in 2000 as the result of the merger of Exxon and Mobil corporations • Now the world’s largest publicly owned oil company • 2006 net income of $39 billion US: – Total liquid and gas production available for sale was 4. 2 million oil-equivalent barrels per day – Refinery throughput of 5. 6 million barrels per day • On March 30, 2007 announced participation in China’s first fully integrated refining, petrochemical and fuels marketing joint venture with foreign participation – Agreement between Sinopec, Fuijan Province, Exxon. Mobil and Saudi Aramco 3

Company Background • Formed in 2000 as the result of the merger of Exxon and Mobil corporations • Now the world’s largest publicly owned oil company • 2006 net income of $39 billion US: – Total liquid and gas production available for sale was 4. 2 million oil-equivalent barrels per day – Refinery throughput of 5. 6 million barrels per day • On March 30, 2007 announced participation in China’s first fully integrated refining, petrochemical and fuels marketing joint venture with foreign participation – Agreement between Sinopec, Fuijan Province, Exxon. Mobil and Saudi Aramco 3

Standards Strategy • Exxon. Mobil has long been active in national and international standardization – Member of the American Petroleum Institute (API), the leading oil industry standards developing organization since 1919 – Chairman and CEO Rex Tillerson currently serves as Chairman of the API Board – Involvement in ISO activities since 1947, providing the chair of TC 28, “Petroleum Products and Lubricants” since its inception and holding a variety of other positions in TC 28 as well as TC 67, “Oilfield Equipment, Materials, and Offshore Structures” and TC 193, “Natural Gas” 4

Standards Strategy • Exxon. Mobil has long been active in national and international standardization – Member of the American Petroleum Institute (API), the leading oil industry standards developing organization since 1919 – Chairman and CEO Rex Tillerson currently serves as Chairman of the API Board – Involvement in ISO activities since 1947, providing the chair of TC 28, “Petroleum Products and Lubricants” since its inception and holding a variety of other positions in TC 28 as well as TC 67, “Oilfield Equipment, Materials, and Offshore Structures” and TC 193, “Natural Gas” 4

Standards Strategy • Participation is based on business / industry need – Resource cost assessed against standards added value – Standards value – combination of business benefits, priority, and spend – Provide leadership where Exxon. Mobil has resources and expertise • Standardization – vehicle to improved performance – Improved safety – Improved reliability – Reduce costs and enhanced supplier base 5

Standards Strategy • Participation is based on business / industry need – Resource cost assessed against standards added value – Standards value – combination of business benefits, priority, and spend – Provide leadership where Exxon. Mobil has resources and expertise • Standardization – vehicle to improved performance – Improved safety – Improved reliability – Reduce costs and enhanced supplier base 5

Standards Strategy • Exxon. Mobil participation in Upstream oil & gas – 50 technical professionals actively participate on API/ISO committees – Annual prioritization of standards activities and proposals – Steering team reviews accomplishments and forward plans 6

Standards Strategy • Exxon. Mobil participation in Upstream oil & gas – 50 technical professionals actively participate on API/ISO committees – Annual prioritization of standards activities and proposals – Steering team reviews accomplishments and forward plans 6

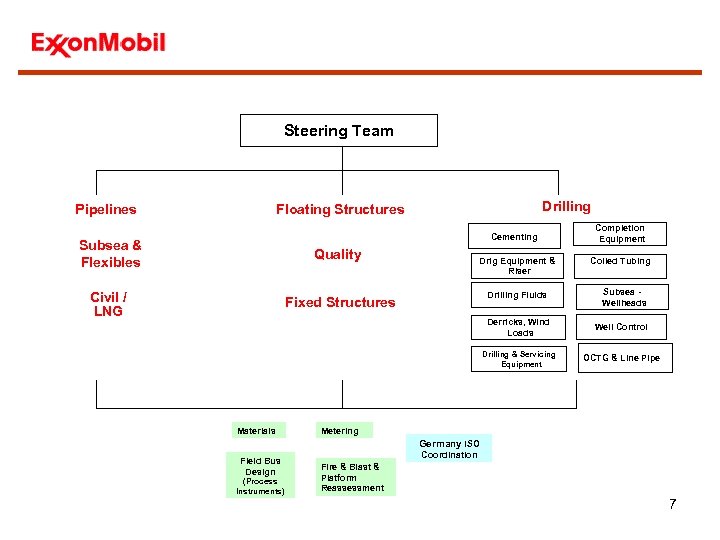

Steering Team Pipelines Drilling Floating Structures Cementing Subsea & Flexibles Quality Civil / LNG Fixed Structures Drlg Equipment & Riser Completion Equipment Coiled Tubing Subsea Wellheads Derricks, Wind Loads Well Control Drilling & Servicing Equipment Materials Drilling Fluids OCTG & Line Pipe Metering Germany ISO Field Bus Design (Process Instruments) Coordination Fire & Blast & Platform Reassessment 7

Steering Team Pipelines Drilling Floating Structures Cementing Subsea & Flexibles Quality Civil / LNG Fixed Structures Drlg Equipment & Riser Completion Equipment Coiled Tubing Subsea Wellheads Derricks, Wind Loads Well Control Drilling & Servicing Equipment Materials Drilling Fluids OCTG & Line Pipe Metering Germany ISO Field Bus Design (Process Instruments) Coordination Fire & Blast & Platform Reassessment 7

API Q 1/ISO TS 29001 Case Study • API has been developing standards since 1923 and is recognized as “de facto” international standards 1 • Industry undergoes tremendous transformation and growth: – 1970’s North Sea Discoveries, 1980’s frontier areas including China, Africa, Middle East • TC 67 reactivated in 1989, API assumes secretariat on behalf of ANSI in 1995 1 “Standards & Competitiveness: Coordination for Results removing Standards-Related Trade Barriers Through Effective Collaboration”, US DOC report, May 2004. 8

API Q 1/ISO TS 29001 Case Study • API has been developing standards since 1923 and is recognized as “de facto” international standards 1 • Industry undergoes tremendous transformation and growth: – 1970’s North Sea Discoveries, 1980’s frontier areas including China, Africa, Middle East • TC 67 reactivated in 1989, API assumes secretariat on behalf of ANSI in 1995 1 “Standards & Competitiveness: Coordination for Results removing Standards-Related Trade Barriers Through Effective Collaboration”, US DOC report, May 2004. 8

API Q 1/ISO TS 29001 Case Study • API Q 1, “Specifications for Quality Systems” first published in 1985, two years prior to initial publication of ISO 9000 series • API Q 1 and API product specifications form the basis of API’s Monogram Program – API Monogram Program is the leading industry conformity assessment program, with 2120 licensed facilities worldwide – China has largest number of licenses issued to date, 560 9

API Q 1/ISO TS 29001 Case Study • API Q 1, “Specifications for Quality Systems” first published in 1985, two years prior to initial publication of ISO 9000 series • API Q 1 and API product specifications form the basis of API’s Monogram Program – API Monogram Program is the leading industry conformity assessment program, with 2120 licensed facilities worldwide – China has largest number of licenses issued to date, 560 9

API Q 1/ISO TS 29001 Case Study • Why does oil and gas industry need more than ISO 9001: 2000? – Failure of goods and services can have severe consequences – Need for consistency in manufacturing • API Q 1 contains 9001 text in its entirety and 45 additional requirements – Control Features – Independent Design Review – Final Acceptance Inspection 10

API Q 1/ISO TS 29001 Case Study • Why does oil and gas industry need more than ISO 9001: 2000? – Failure of goods and services can have severe consequences – Need for consistency in manufacturing • API Q 1 contains 9001 text in its entirety and 45 additional requirements – Control Features – Independent Design Review – Final Acceptance Inspection 10

API Q 1/ISO TS 29001 Case Study • Oil industry determined need for a sector-specific solution similar to automotive – Standard to be developed in liaison with the TC 176 to ensure harmonization • Q 1 was recognized as model for an international sectorspecific document so that final API and ISO standards would be identical 11

API Q 1/ISO TS 29001 Case Study • Oil industry determined need for a sector-specific solution similar to automotive – Standard to be developed in liaison with the TC 176 to ensure harmonization • Q 1 was recognized as model for an international sectorspecific document so that final API and ISO standards would be identical 11

API Q 1/ISO TS 29001 Case Study • How best to align API Q 1 and ISO as a sector specific quality standard? – API’s Subcommittee on Quality proposed a NWI to align a revision of API Q 1 and the development of sector specific quality requirements in March, 2002 – Draft Technical Specification January 2003 – Publication June 2003 12

API Q 1/ISO TS 29001 Case Study • How best to align API Q 1 and ISO as a sector specific quality standard? – API’s Subcommittee on Quality proposed a NWI to align a revision of API Q 1 and the development of sector specific quality requirements in March, 2002 – Draft Technical Specification January 2003 – Publication June 2003 12

API Q 1/ISO TS 29001 Case Study • One standard accepted globally • One assessment / certification body accepted globally – Ensures consistency in audits – Eliminates variances in interpretations • Prerequisite for doing business 13

API Q 1/ISO TS 29001 Case Study • One standard accepted globally • One assessment / certification body accepted globally – Ensures consistency in audits – Eliminates variances in interpretations • Prerequisite for doing business 13

API Q 1/ISO TS 29001 Case Study • Conclusions: – API and ISO can work together successfully if the vision and commitment is agreed at the project’s onset – Exxon. Mobil and the international Oil and Gas industry will continue to push frontier boundaries in the search for oil and gas, requiring more stringent quality assurance requirements – API Q 1/ISO TS 29001 will continue to help the oil and gas industry ensure consistency in manufacturing and reliability of products. 14

API Q 1/ISO TS 29001 Case Study • Conclusions: – API and ISO can work together successfully if the vision and commitment is agreed at the project’s onset – Exxon. Mobil and the international Oil and Gas industry will continue to push frontier boundaries in the search for oil and gas, requiring more stringent quality assurance requirements – API Q 1/ISO TS 29001 will continue to help the oil and gas industry ensure consistency in manufacturing and reliability of products. 14

Xie (Thank you) Contact Information: Stacey Hagen Drilling Materials Sr. QA Advisor – OCTG Lead Exxon. Mobil Global Service Company 16945 Northchase Dr Houston, TX 77060 stacey. w. hagen@exxonmobil. com API – www. api. org, standards@api. org ISO – www. iso. org, central@iso. org 15

Xie (Thank you) Contact Information: Stacey Hagen Drilling Materials Sr. QA Advisor – OCTG Lead Exxon. Mobil Global Service Company 16945 Northchase Dr Houston, TX 77060 stacey. w. hagen@exxonmobil. com API – www. api. org, standards@api. org ISO – www. iso. org, central@iso. org 15

Back-Up Slide Definitions: API Spec Q 1 Specification for Quality Programs for the Petroleum, Petrochemical and Natural Gas Industry ISO TS 29001 Petroleum, Petrochemical and Natural Gas Industries – Sector Specific Quality Management Systems – Requirements for Product and Service Supply Organizations NWI New Work Item TC Technical Committee 16

Back-Up Slide Definitions: API Spec Q 1 Specification for Quality Programs for the Petroleum, Petrochemical and Natural Gas Industry ISO TS 29001 Petroleum, Petrochemical and Natural Gas Industries – Sector Specific Quality Management Systems – Requirements for Product and Service Supply Organizations NWI New Work Item TC Technical Committee 16

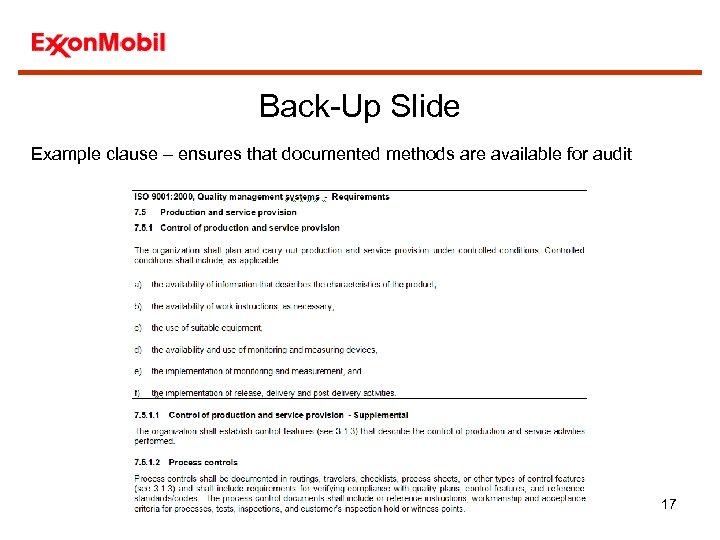

Back-Up Slide Example clause – ensures that documented methods are available for audit 17

Back-Up Slide Example clause – ensures that documented methods are available for audit 17

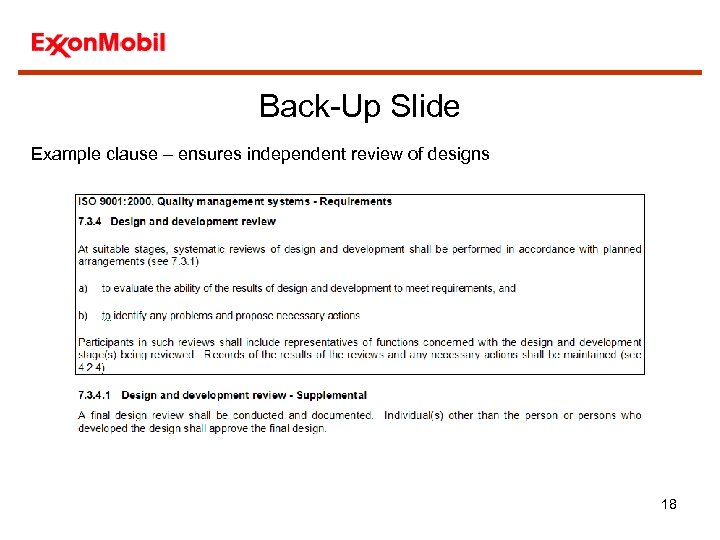

Back-Up Slide Example clause – ensures independent review of designs 18

Back-Up Slide Example clause – ensures independent review of designs 18

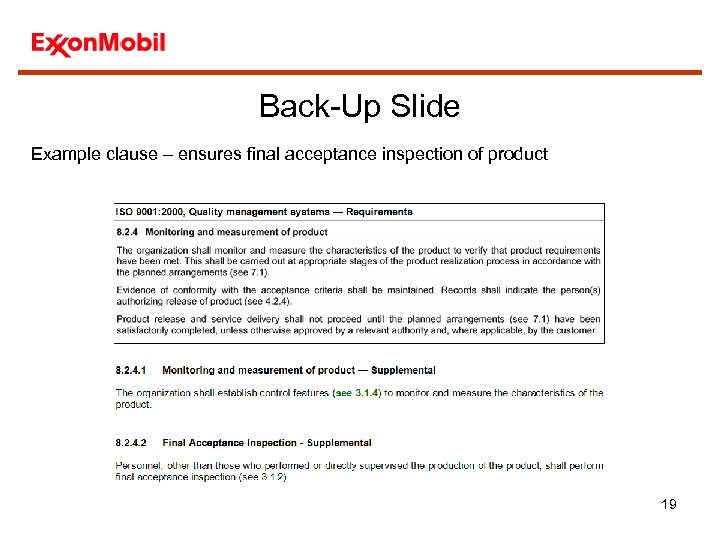

Back-Up Slide Example clause – ensures final acceptance inspection of product 19

Back-Up Slide Example clause – ensures final acceptance inspection of product 19