c01312371871dd663045cf5cc4285b03.ppt

- Количество слайдов: 38

APAX-5000 PAC Product Introduction CC Lin APAX PSM

APAX-5000 PAC Product Introduction CC Lin APAX PSM

Agenda • Product Overview • Product Position • Product Line Introduction & Application • Competitors Analysis • Product Target Market Reference • Reference Application

Agenda • Product Overview • Product Position • Product Line Introduction & Application • Competitors Analysis • Product Target Market Reference • Reference Application

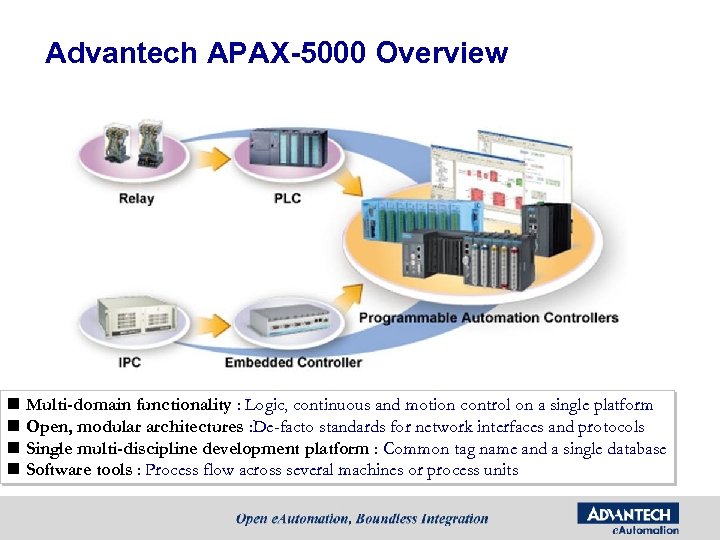

Advantech APAX-5000 Overview n Multi-domain functionality : Logic, continuous and motion control on a single platform n Open, modular architectures : De-facto standards for network interfaces and protocols n Single multi-discipline development platform : Common tag name and a single database n Software tools : Process flow across several machines or process units

Advantech APAX-5000 Overview n Multi-domain functionality : Logic, continuous and motion control on a single platform n Open, modular architectures : De-facto standards for network interfaces and protocols n Single multi-discipline development platform : Common tag name and a single database n Software tools : Process flow across several machines or process units

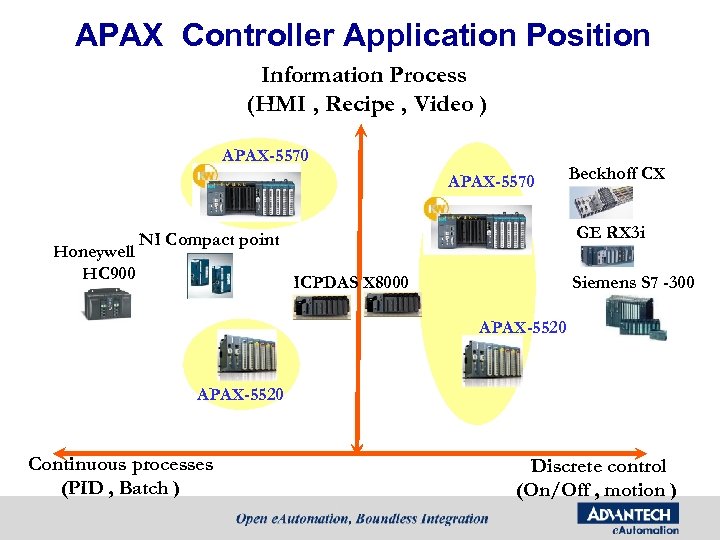

APAX Controller Application Position Information Process (HMI , Recipe , Video ) APAX-5570 Honeywell HC 900 Beckhoff CX GE RX 3 i NI Compact point ICPDAS X 8000 Siemens S 7 -300 APAX-5520 Continuous processes (PID , Batch ) Discrete control (On/Off , motion )

APAX Controller Application Position Information Process (HMI , Recipe , Video ) APAX-5570 Honeywell HC 900 Beckhoff CX GE RX 3 i NI Compact point ICPDAS X 8000 Siemens S 7 -300 APAX-5520 Continuous processes (PID , Batch ) Discrete control (On/Off , motion )

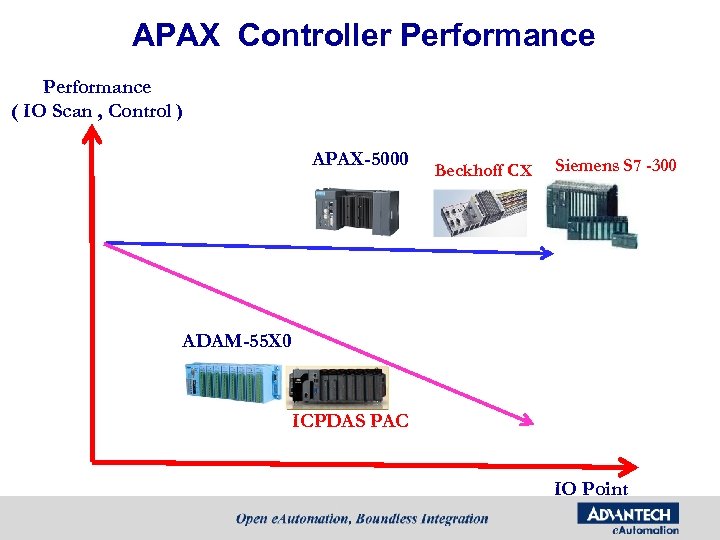

APAX Controller Performance ( IO Scan , Control ) APAX-5000 Beckhoff CX Siemens S 7 -300 ADAM-55 X 0 ICPDAS PAC IO Point

APAX Controller Performance ( IO Scan , Control ) APAX-5000 Beckhoff CX Siemens S 7 -300 ADAM-55 X 0 ICPDAS PAC IO Point

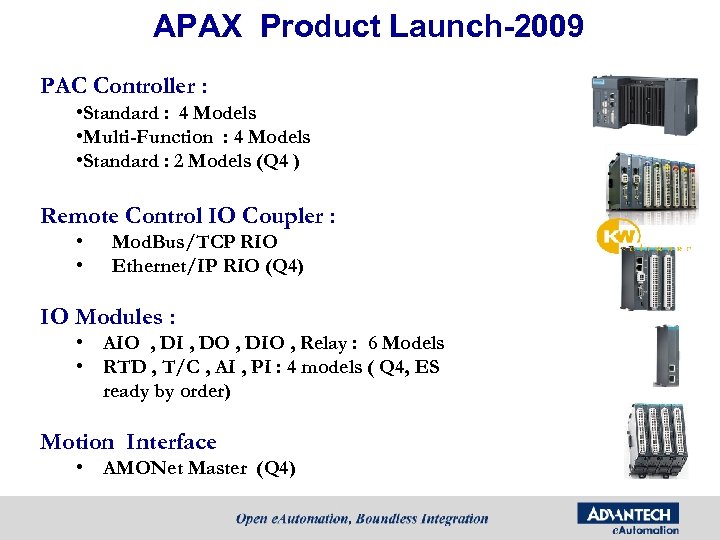

APAX Product Launch-2009 PAC Controller : • Standard : 4 Models • Multi-Function : 4 Models • Standard : 2 Models (Q 4 ) Remote Control IO Coupler : • • Mod. Bus/TCP RIO Ethernet/IP RIO (Q 4) IO Modules : • AIO , DI , DO , DIO , Relay : 6 Models • RTD , T/C , AI , PI : 4 models ( Q 4, ES ready by order) Motion Interface • AMONet Master (Q 4)

APAX Product Launch-2009 PAC Controller : • Standard : 4 Models • Multi-Function : 4 Models • Standard : 2 Models (Q 4 ) Remote Control IO Coupler : • • Mod. Bus/TCP RIO Ethernet/IP RIO (Q 4) IO Modules : • AIO , DI , DO , DIO , Relay : 6 Models • RTD , T/C , AI , PI : 4 models ( Q 4, ES ready by order) Motion Interface • AMONet Master (Q 4)

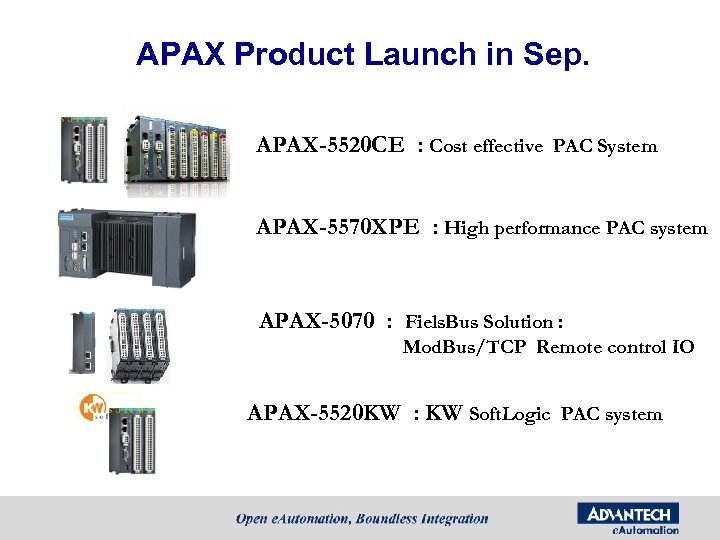

APAX Product Launch in Sep. APAX-5520 CE : Cost effective PAC System APAX-5570 XPE : High performance PAC system APAX-5070 : Fiels. Bus Solution : Mod. Bus/TCP Remote control IO APAX-5520 KW : KW Soft. Logic PAC system

APAX Product Launch in Sep. APAX-5520 CE : Cost effective PAC System APAX-5570 XPE : High performance PAC system APAX-5070 : Fiels. Bus Solution : Mod. Bus/TCP Remote control IO APAX-5520 KW : KW Soft. Logic PAC system

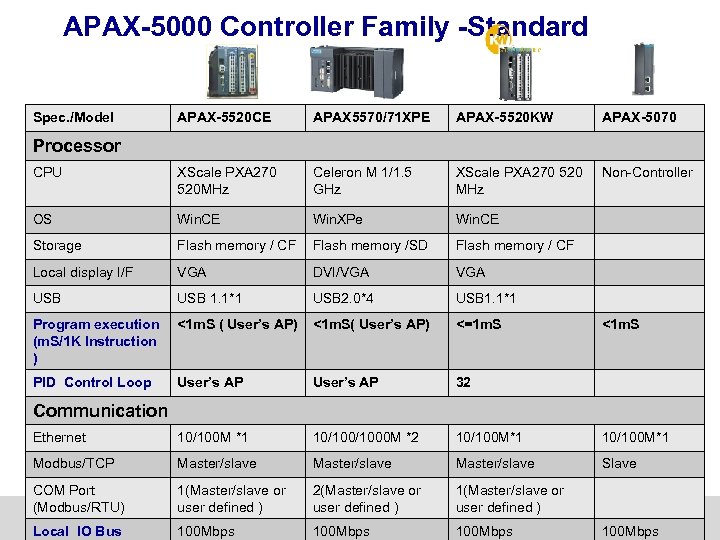

APAX-5000 Controller Family -Standard Spec. /Model APAX-5520 CE APAX 5570/71 XPE APAX-5520 KW APAX-5070 CPU XScale PXA 270 520 MHz Celeron M 1/1. 5 GHz XScale PXA 270 520 MHz Non-Controller OS Win. CE Win. XPe Win. CE Storage Flash memory / CF Flash memory /SD Flash memory / CF Local display I/F VGA DVI/VGA USB 1. 1*1 USB 2. 0*4 USB 1. 1*1 Program execution (m. S/1 K Instruction ) <1 m. S ( User’s AP) <1 m. S( User’s AP) <=1 m. S PID Control Loop User’s AP 32 Ethernet 10/100 M *1 10/1000 M *2 10/100 M*1 Modbus/TCP Master/slave Slave COM Port (Modbus/RTU) 1(Master/slave or user defined ) 2(Master/slave or user defined ) 1(Master/slave or user defined ) Local IO Bus 100 Mbps Processor <1 m. S Communication 100 Mbps

APAX-5000 Controller Family -Standard Spec. /Model APAX-5520 CE APAX 5570/71 XPE APAX-5520 KW APAX-5070 CPU XScale PXA 270 520 MHz Celeron M 1/1. 5 GHz XScale PXA 270 520 MHz Non-Controller OS Win. CE Win. XPe Win. CE Storage Flash memory / CF Flash memory /SD Flash memory / CF Local display I/F VGA DVI/VGA USB 1. 1*1 USB 2. 0*4 USB 1. 1*1 Program execution (m. S/1 K Instruction ) <1 m. S ( User’s AP) <1 m. S( User’s AP) <=1 m. S PID Control Loop User’s AP 32 Ethernet 10/100 M *1 10/1000 M *2 10/100 M*1 Modbus/TCP Master/slave Slave COM Port (Modbus/RTU) 1(Master/slave or user defined ) 2(Master/slave or user defined ) 1(Master/slave or user defined ) Local IO Bus 100 Mbps Processor <1 m. S Communication 100 Mbps

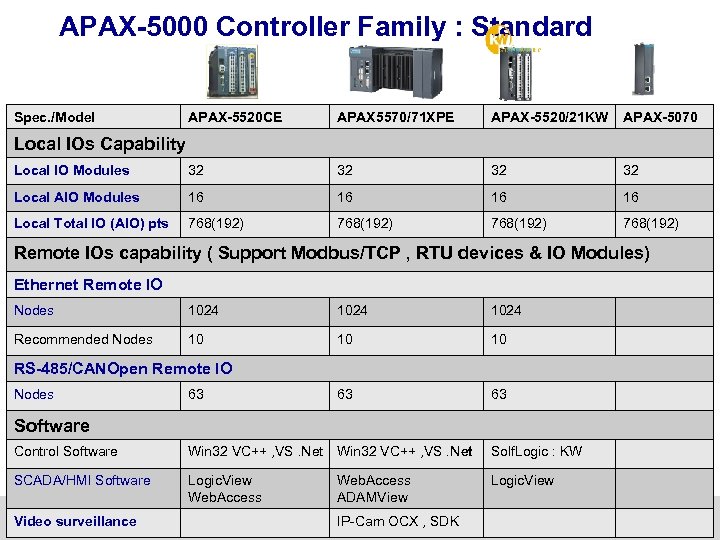

APAX-5000 Controller Family : Standard Spec. /Model APAX-5520 CE APAX 5570/71 XPE APAX-5520/21 KW APAX-5070 Local IO Modules 32 32 Local AIO Modules 16 16 Local Total IO (AIO) pts 768(192) Local IOs Capability Remote IOs capability ( Support Modbus/TCP , RTU devices & IO Modules) Ethernet Remote IO Nodes 1024 Recommended Nodes 10 10 10 63 63 RS-485/CANOpen Remote IO Nodes 63 Software Control Software Win 32 VC++ , VS. Net Solf. Logic : KW SCADA/HMI Software Logic. View Web. Access Logic. View Video surveillance Web. Access ADAMView IP-Cam OCX , SDK

APAX-5000 Controller Family : Standard Spec. /Model APAX-5520 CE APAX 5570/71 XPE APAX-5520/21 KW APAX-5070 Local IO Modules 32 32 Local AIO Modules 16 16 Local Total IO (AIO) pts 768(192) Local IOs Capability Remote IOs capability ( Support Modbus/TCP , RTU devices & IO Modules) Ethernet Remote IO Nodes 1024 Recommended Nodes 10 10 10 63 63 RS-485/CANOpen Remote IO Nodes 63 Software Control Software Win 32 VC++ , VS. Net Solf. Logic : KW SCADA/HMI Software Logic. View Web. Access Logic. View Video surveillance Web. Access ADAMView IP-Cam OCX , SDK

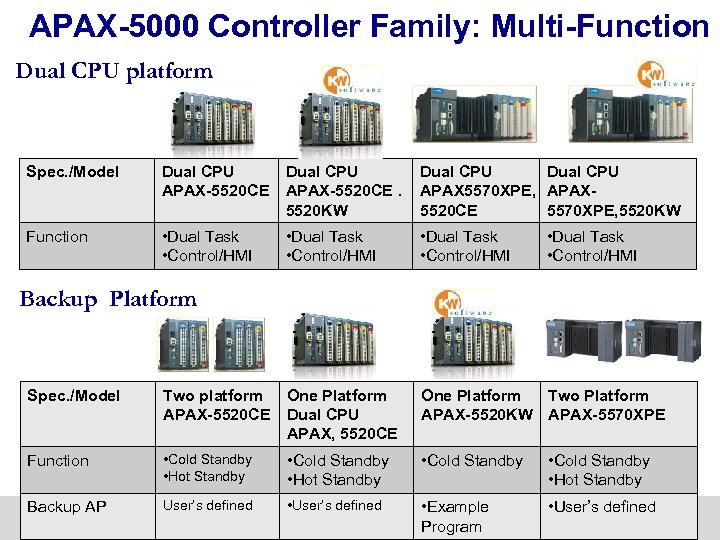

APAX-5000 Controller Family: Multi-Function Dual CPU platform Spec. /Model Dual CPU APAX-5520 CE. 5520 KW Dual CPU APAX 5570 XPE, APAX 5520 CE 5570 XPE, 5520 KW Function • Dual Task • Control/HMI Backup Platform Spec. /Model Two platform APAX-5520 CE One Platform Dual CPU APAX, 5520 CE One Platform Two Platform APAX-5520 KW APAX-5570 XPE Function • Cold Standby • Hot Standby Backup AP User’s defined • Example Program • User’s defined

APAX-5000 Controller Family: Multi-Function Dual CPU platform Spec. /Model Dual CPU APAX-5520 CE. 5520 KW Dual CPU APAX 5570 XPE, APAX 5520 CE 5570 XPE, 5520 KW Function • Dual Task • Control/HMI Backup Platform Spec. /Model Two platform APAX-5520 CE One Platform Dual CPU APAX, 5520 CE One Platform Two Platform APAX-5520 KW APAX-5570 XPE Function • Cold Standby • Hot Standby Backup AP User’s defined • Example Program • User’s defined

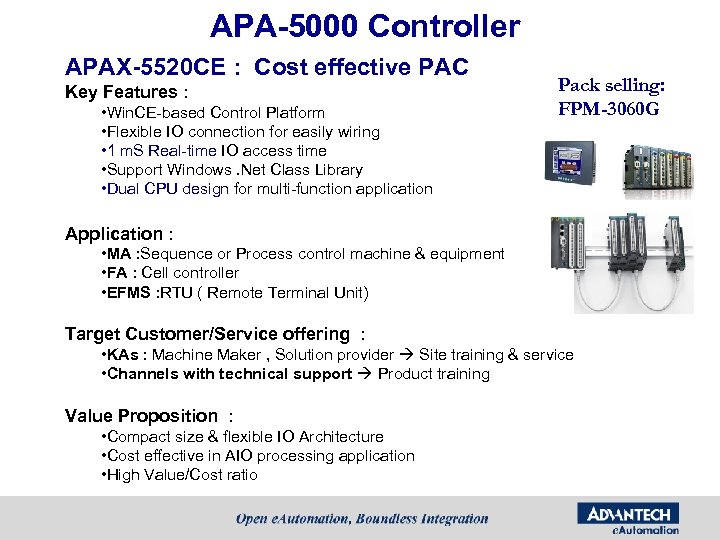

APA-5000 Controller APAX-5520 CE : Cost effective PAC Key Features : • Win. CE-based Control Platform • Flexible IO connection for easily wiring • 1 m. S Real-time IO access time • Support Windows. Net Class Library • Dual CPU design for multi-function application Pack selling: FPM-3060 G Application : • MA : Sequence or Process control machine & equipment • FA : Cell controller • EFMS : RTU ( Remote Terminal Unit) Target Customer/Service offering : • KAs : Machine Maker , Solution provider Site training & service • Channels with technical support Product training Value Proposition : • Compact size & flexible IO Architecture • Cost effective in AIO processing application • High Value/Cost ratio

APA-5000 Controller APAX-5520 CE : Cost effective PAC Key Features : • Win. CE-based Control Platform • Flexible IO connection for easily wiring • 1 m. S Real-time IO access time • Support Windows. Net Class Library • Dual CPU design for multi-function application Pack selling: FPM-3060 G Application : • MA : Sequence or Process control machine & equipment • FA : Cell controller • EFMS : RTU ( Remote Terminal Unit) Target Customer/Service offering : • KAs : Machine Maker , Solution provider Site training & service • Channels with technical support Product training Value Proposition : • Compact size & flexible IO Architecture • Cost effective in AIO processing application • High Value/Cost ratio

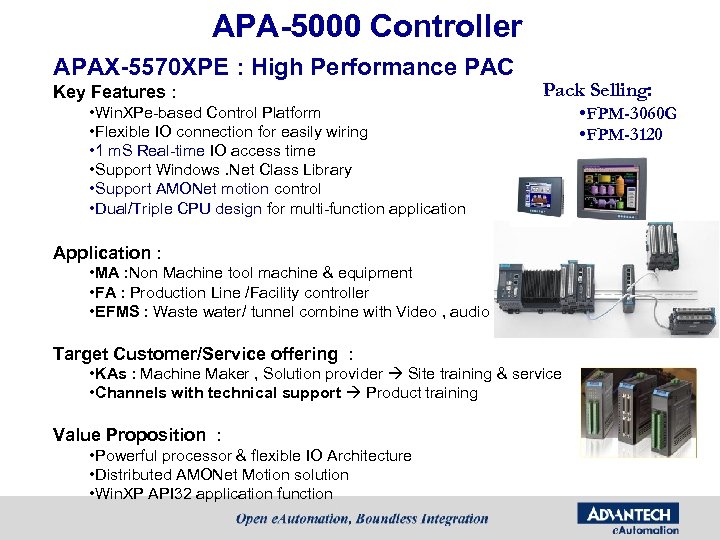

APA-5000 Controller APAX-5570 XPE : High Performance PAC Key Features : Pack Selling: • Win. XPe-based Control Platform • Flexible IO connection for easily wiring • 1 m. S Real-time IO access time • Support Windows. Net Class Library • Support AMONet motion control • Dual/Triple CPU design for multi-function application Application : • MA : Non Machine tool machine & equipment • FA : Production Line /Facility controller • EFMS : Waste water/ tunnel combine with Video , audio Target Customer/Service offering : • KAs : Machine Maker , Solution provider Site training & service • Channels with technical support Product training Value Proposition : • Powerful processor & flexible IO Architecture • Distributed AMONet Motion solution • Win. XP API 32 application function • FPM-3060 G • FPM-3120

APA-5000 Controller APAX-5570 XPE : High Performance PAC Key Features : Pack Selling: • Win. XPe-based Control Platform • Flexible IO connection for easily wiring • 1 m. S Real-time IO access time • Support Windows. Net Class Library • Support AMONet motion control • Dual/Triple CPU design for multi-function application Application : • MA : Non Machine tool machine & equipment • FA : Production Line /Facility controller • EFMS : Waste water/ tunnel combine with Video , audio Target Customer/Service offering : • KAs : Machine Maker , Solution provider Site training & service • Channels with technical support Product training Value Proposition : • Powerful processor & flexible IO Architecture • Distributed AMONet Motion solution • Win. XP API 32 application function • FPM-3060 G • FPM-3120

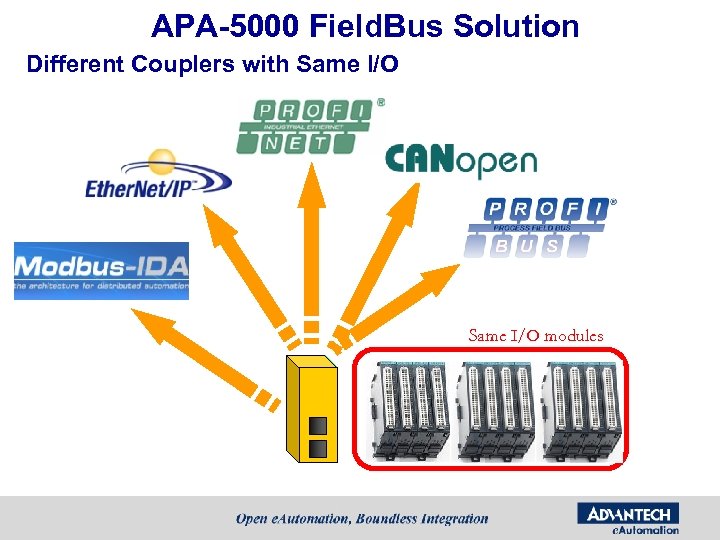

APA-5000 Field. Bus Solution Different Couplers with Same I/O And More …. Same I/O modules can link to different protocol networks

APA-5000 Field. Bus Solution Different Couplers with Same I/O And More …. Same I/O modules can link to different protocol networks

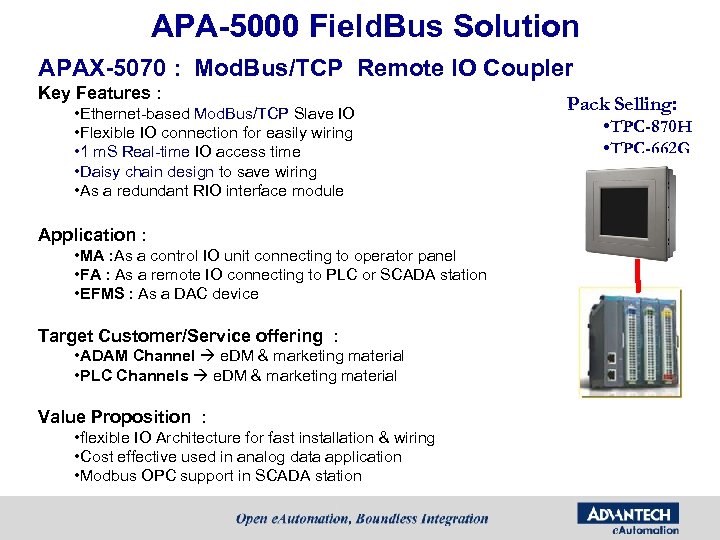

APA-5000 Field. Bus Solution APAX-5070 : Mod. Bus/TCP Remote IO Coupler Key Features : • Ethernet-based Mod. Bus/TCP Slave IO • Flexible IO connection for easily wiring • 1 m. S Real-time IO access time • Daisy chain design to save wiring • As a redundant RIO interface module Application : • MA : As a control IO unit connecting to operator panel • FA : As a remote IO connecting to PLC or SCADA station • EFMS : As a DAC device Target Customer/Service offering : • ADAM Channel e. DM & marketing material • PLC Channels e. DM & marketing material Value Proposition : • flexible IO Architecture for fast installation & wiring • Cost effective used in analog data application • Modbus OPC support in SCADA station Pack Selling: • TPC-870 H • TPC-662 G

APA-5000 Field. Bus Solution APAX-5070 : Mod. Bus/TCP Remote IO Coupler Key Features : • Ethernet-based Mod. Bus/TCP Slave IO • Flexible IO connection for easily wiring • 1 m. S Real-time IO access time • Daisy chain design to save wiring • As a redundant RIO interface module Application : • MA : As a control IO unit connecting to operator panel • FA : As a remote IO connecting to PLC or SCADA station • EFMS : As a DAC device Target Customer/Service offering : • ADAM Channel e. DM & marketing material • PLC Channels e. DM & marketing material Value Proposition : • flexible IO Architecture for fast installation & wiring • Cost effective used in analog data application • Modbus OPC support in SCADA station Pack Selling: • TPC-870 H • TPC-662 G

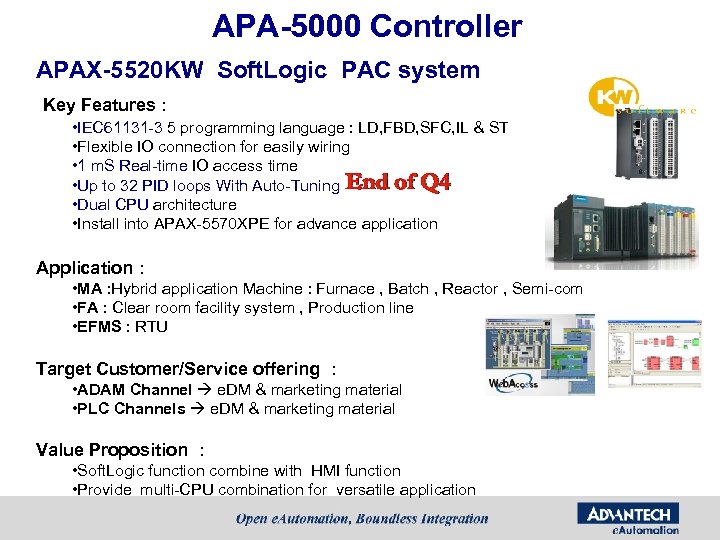

APA-5000 Controller APAX-5520 KW Soft. Logic PAC system Key Features : • IEC 61131 -3 5 programming language : LD, FBD, SFC, IL & ST • Flexible IO connection for easily wiring • 1 m. S Real-time IO access time • Up to 32 PID loops With Auto-Tuning End of Q 4 • Dual CPU architecture • Install into APAX-5570 XPE for advance application Application : • MA : Hybrid application Machine : Furnace , Batch , Reactor , Semi-com • FA : Clear room facility system , Production line • EFMS : RTU Target Customer/Service offering : • ADAM Channel e. DM & marketing material • PLC Channels e. DM & marketing material Value Proposition : • Soft. Logic function combine with HMI function • Provide multi-CPU combination for versatile application

APA-5000 Controller APAX-5520 KW Soft. Logic PAC system Key Features : • IEC 61131 -3 5 programming language : LD, FBD, SFC, IL & ST • Flexible IO connection for easily wiring • 1 m. S Real-time IO access time • Up to 32 PID loops With Auto-Tuning End of Q 4 • Dual CPU architecture • Install into APAX-5570 XPE for advance application Application : • MA : Hybrid application Machine : Furnace , Batch , Reactor , Semi-com • FA : Clear room facility system , Production line • EFMS : RTU Target Customer/Service offering : • ADAM Channel e. DM & marketing material • PLC Channels e. DM & marketing material Value Proposition : • Soft. Logic function combine with HMI function • Provide multi-CPU combination for versatile application

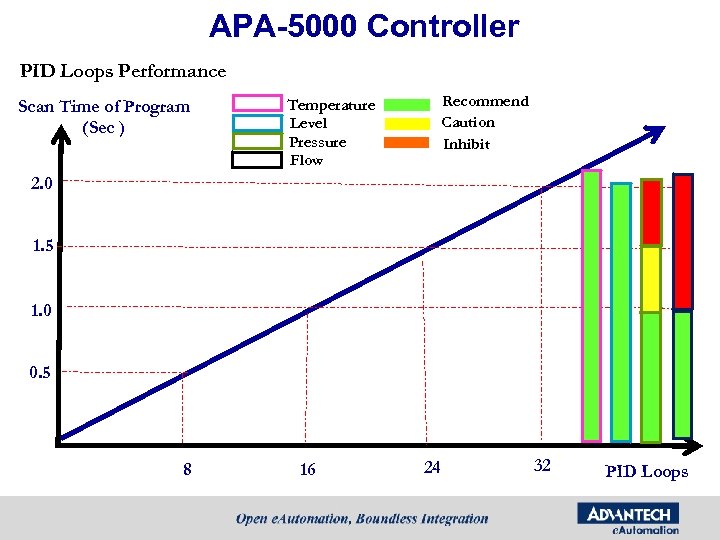

APA-5000 Controller PID Loops Performance Scan Time of Program (Sec ) Recommend Caution Inhibit Temperature Level Pressure Flow 2. 0 1. 5 1. 0 0. 5 8 16 24 32 PID Loops

APA-5000 Controller PID Loops Performance Scan Time of Program (Sec ) Recommend Caution Inhibit Temperature Level Pressure Flow 2. 0 1. 5 1. 0 0. 5 8 16 24 32 PID Loops

APA-5000 Controller End of Q 4 APAX-5521 KW Soft. Logic PAC system w/CANOpen Key Features : • IEC 61131 -3 5 programming language : LD, FBD, SFC, IL & ST • Flexible IO connection for easily wiring • 1 m. S Real-time IO access time • Up to 32 PID loops application • Dual CPU architecture • Install into APAX-5570 XPE for advance application • Support CANOpen for Motion Application : • MA : Motion application Machine : GMC machine Target Customer/Service offering : • KAs : Machine maker CANOpen technical service • Production Equipment Totally solution bundling service Value Proposition : • Soft. Logic function with HMI function together • CANOpen Motion solution ready • Provide multi-CPU combination for versatile application

APA-5000 Controller End of Q 4 APAX-5521 KW Soft. Logic PAC system w/CANOpen Key Features : • IEC 61131 -3 5 programming language : LD, FBD, SFC, IL & ST • Flexible IO connection for easily wiring • 1 m. S Real-time IO access time • Up to 32 PID loops application • Dual CPU architecture • Install into APAX-5570 XPE for advance application • Support CANOpen for Motion Application : • MA : Motion application Machine : GMC machine Target Customer/Service offering : • KAs : Machine maker CANOpen technical service • Production Equipment Totally solution bundling service Value Proposition : • Soft. Logic function with HMI function together • CANOpen Motion solution ready • Provide multi-CPU combination for versatile application

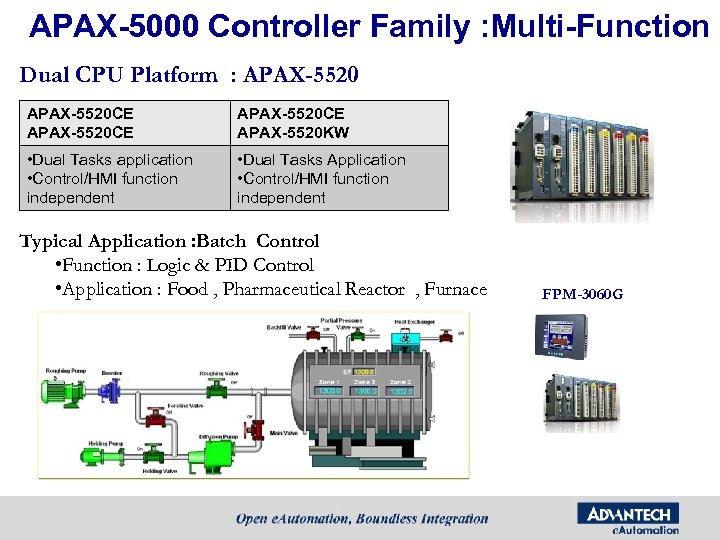

APAX-5000 Controller Family : Multi-Function Dual CPU Platform : APAX-5520 CE APAX-5520 KW • Dual Tasks application • Control/HMI function independent • Dual Tasks Application • Control/HMI function independent Typical Application : Batch Control • Function : Logic & PID Control • Application : Food , Pharmaceutical Reactor , Furnace FPM-3060 G

APAX-5000 Controller Family : Multi-Function Dual CPU Platform : APAX-5520 CE APAX-5520 KW • Dual Tasks application • Control/HMI function independent • Dual Tasks Application • Control/HMI function independent Typical Application : Batch Control • Function : Logic & PID Control • Application : Food , Pharmaceutical Reactor , Furnace FPM-3060 G

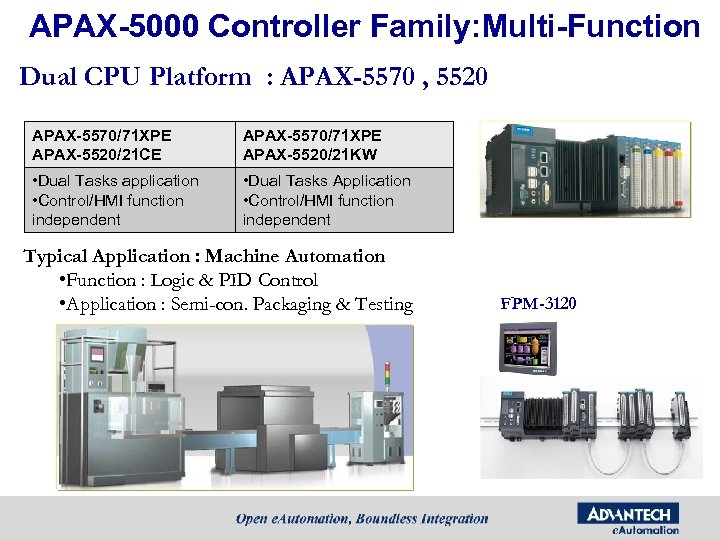

APAX-5000 Controller Family: Multi-Function Dual CPU Platform : APAX-5570 , 5520 APAX-5570/71 XPE APAX-5520/21 CE APAX-5570/71 XPE APAX-5520/21 KW • Dual Tasks application • Control/HMI function independent • Dual Tasks Application • Control/HMI function independent Typical Application : Machine Automation • Function : Logic & PID Control • Application : Semi-con. Packaging & Testing FPM-3120

APAX-5000 Controller Family: Multi-Function Dual CPU Platform : APAX-5570 , 5520 APAX-5570/71 XPE APAX-5520/21 CE APAX-5570/71 XPE APAX-5520/21 KW • Dual Tasks application • Control/HMI function independent • Dual Tasks Application • Control/HMI function independent Typical Application : Machine Automation • Function : Logic & PID Control • Application : Semi-con. Packaging & Testing FPM-3120

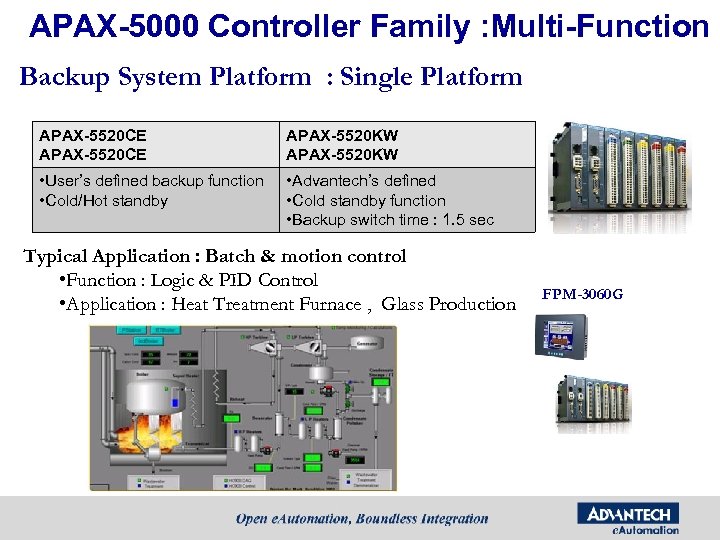

APAX-5000 Controller Family : Multi-Function Backup System Platform : Single Platform APAX-5520 CE APAX-5520 KW • User’s defined backup function • Cold/Hot standby • Advantech’s defined • Cold standby function • Backup switch time : 1. 5 sec Typical Application : Batch & motion control • Function : Logic & PID Control • Application : Heat Treatment Furnace , Glass Production FPM-3060 G

APAX-5000 Controller Family : Multi-Function Backup System Platform : Single Platform APAX-5520 CE APAX-5520 KW • User’s defined backup function • Cold/Hot standby • Advantech’s defined • Cold standby function • Backup switch time : 1. 5 sec Typical Application : Batch & motion control • Function : Logic & PID Control • Application : Heat Treatment Furnace , Glass Production FPM-3060 G

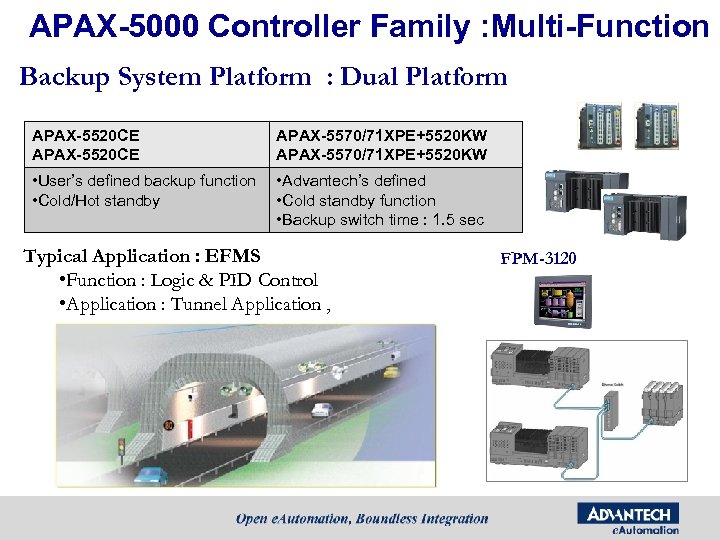

APAX-5000 Controller Family : Multi-Function Backup System Platform : Dual Platform APAX-5520 CE APAX-5570/71 XPE+5520 KW • User’s defined backup function • Cold/Hot standby • Advantech’s defined • Cold standby function • Backup switch time : 1. 5 sec Typical Application : EFMS • Function : Logic & PID Control • Application : Tunnel Application , FPM-3120

APAX-5000 Controller Family : Multi-Function Backup System Platform : Dual Platform APAX-5520 CE APAX-5570/71 XPE+5520 KW • User’s defined backup function • Cold/Hot standby • Advantech’s defined • Cold standby function • Backup switch time : 1. 5 sec Typical Application : EFMS • Function : Logic & PID Control • Application : Tunnel Application , FPM-3120

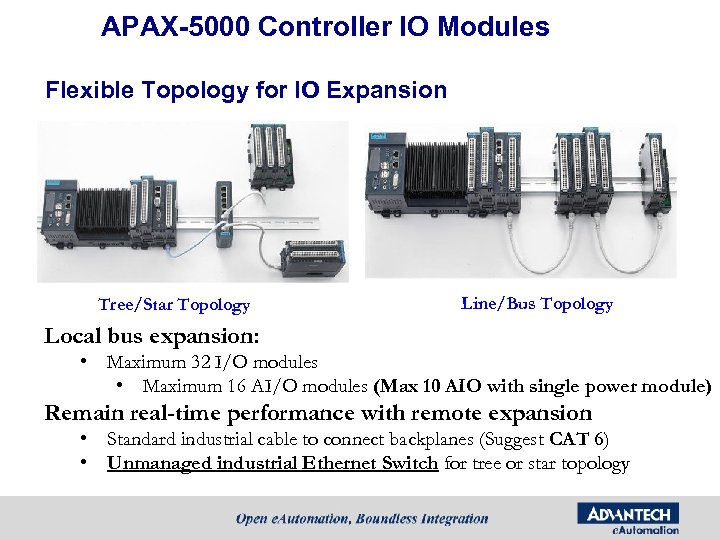

APAX-5000 Controller IO Modules Flexible Topology for IO Expansion Tree/Star Topology Line/Bus Topology Local bus expansion: • Maximum 32 I/O modules • Maximum 16 AI/O modules (Max 10 AIO with single power module) Remain real-time performance with remote expansion • Standard industrial cable to connect backplanes (Suggest CAT 6) • Unmanaged industrial Ethernet Switch for tree or star topology

APAX-5000 Controller IO Modules Flexible Topology for IO Expansion Tree/Star Topology Line/Bus Topology Local bus expansion: • Maximum 32 I/O modules • Maximum 16 AI/O modules (Max 10 AIO with single power module) Remain real-time performance with remote expansion • Standard industrial cable to connect backplanes (Suggest CAT 6) • Unmanaged industrial Ethernet Switch for tree or star topology

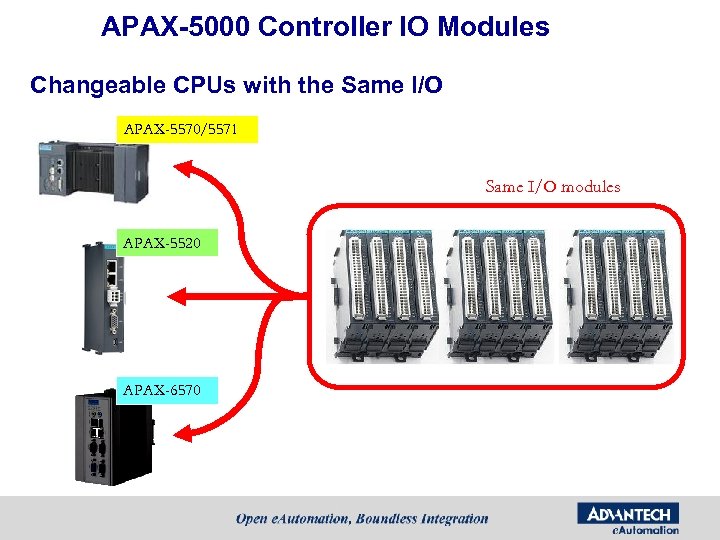

APAX-5000 Controller IO Modules Changeable CPUs with the Same I/O APAX-5570/5571 Same I/O modules APAX-5520 APAX-6570

APAX-5000 Controller IO Modules Changeable CPUs with the Same I/O APAX-5570/5571 Same I/O modules APAX-5520 APAX-6570

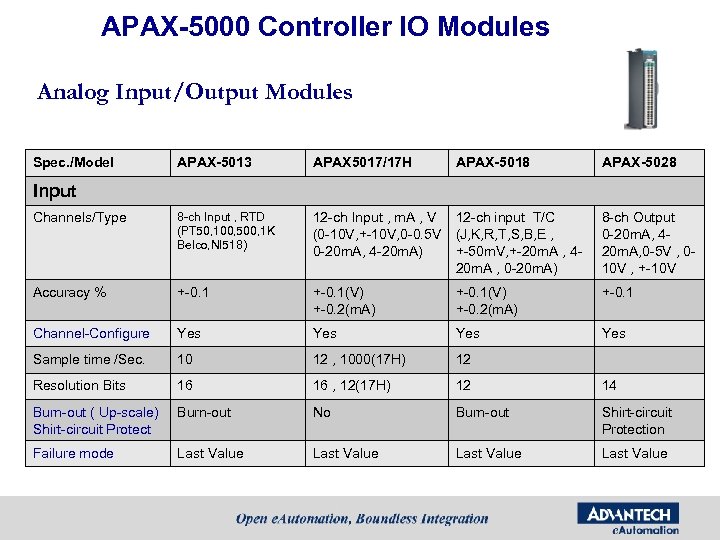

APAX-5000 Controller IO Modules Analog Input/Output Modules Spec. /Model APAX-5013 APAX 5017/17 H APAX-5018 APAX-5028 Channels/Type 8 -ch Input , RTD (PT 50, 100, 500, 1 K Belco, NI 518) 12 -ch Input , m. A , V (0 -10 V, +-10 V, 0 -0. 5 V 0 -20 m. A, 4 -20 m. A) 12 -ch input T/C (J, K, R, T, S, B, E , +-50 m. V, +-20 m. A , 420 m. A , 0 -20 m. A) 8 -ch Output 0 -20 m. A, 420 m. A, 0 -5 V , 010 V , +-10 V Accuracy % +-0. 1(V) +-0. 2(m. A) +-0. 1 Channel-Configure Yes Yes Sample time /Sec. 10 12 , 1000(17 H) 12 Resolution Bits 16 16 , 12(17 H) 12 14 Burn-out ( Up-scale) Shirt-circuit Protect Burn-out No Burn-out Shirt-circuit Protection Failure mode Last Value Input

APAX-5000 Controller IO Modules Analog Input/Output Modules Spec. /Model APAX-5013 APAX 5017/17 H APAX-5018 APAX-5028 Channels/Type 8 -ch Input , RTD (PT 50, 100, 500, 1 K Belco, NI 518) 12 -ch Input , m. A , V (0 -10 V, +-10 V, 0 -0. 5 V 0 -20 m. A, 4 -20 m. A) 12 -ch input T/C (J, K, R, T, S, B, E , +-50 m. V, +-20 m. A , 420 m. A , 0 -20 m. A) 8 -ch Output 0 -20 m. A, 420 m. A, 0 -5 V , 010 V , +-10 V Accuracy % +-0. 1(V) +-0. 2(m. A) +-0. 1 Channel-Configure Yes Yes Sample time /Sec. 10 12 , 1000(17 H) 12 Resolution Bits 16 16 , 12(17 H) 12 14 Burn-out ( Up-scale) Shirt-circuit Protect Burn-out No Burn-out Shirt-circuit Protection Failure mode Last Value Input

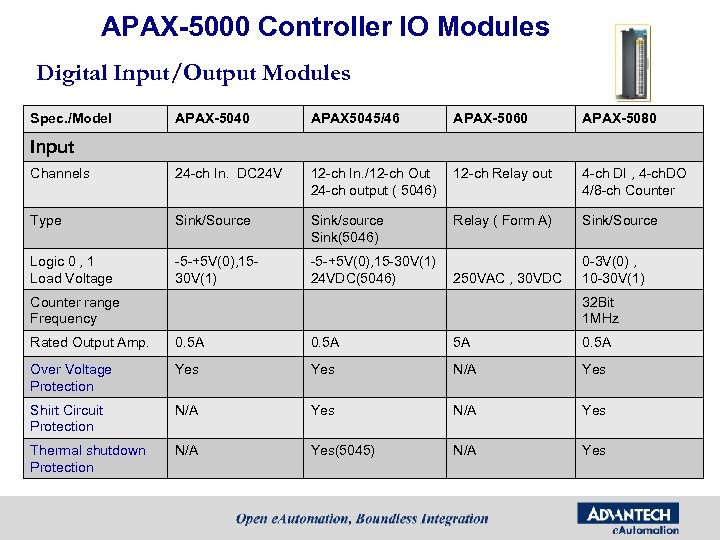

APAX-5000 Controller IO Modules Digital Input/Output Modules Spec. /Model APAX-5040 APAX 5045/46 APAX-5060 APAX-5080 Channels 24 -ch In. DC 24 V 12 -ch In. /12 -ch Out 24 -ch output ( 5046) 12 -ch Relay out 4 -ch DI , 4 -ch. DO 4/8 -ch Counter Type Sink/Source Sink/source Sink(5046) Relay ( Form A) Sink/Source Logic 0 , 1 Load Voltage -5 -+5 V(0), 1530 V(1) -5 -+5 V(0), 15 -30 V(1) 24 VDC(5046) 250 VAC , 30 VDC 0 -3 V(0) , 10 -30 V(1) Input Counter range Frequency 32 Bit 1 MHz Rated Output Amp. 0. 5 A 5 A 0. 5 A Over Voltage Protection Yes N/A Yes Shirt Circuit Protection N/A Yes Thermal shutdown Protection N/A Yes(5045) N/A Yes

APAX-5000 Controller IO Modules Digital Input/Output Modules Spec. /Model APAX-5040 APAX 5045/46 APAX-5060 APAX-5080 Channels 24 -ch In. DC 24 V 12 -ch In. /12 -ch Out 24 -ch output ( 5046) 12 -ch Relay out 4 -ch DI , 4 -ch. DO 4/8 -ch Counter Type Sink/Source Sink/source Sink(5046) Relay ( Form A) Sink/Source Logic 0 , 1 Load Voltage -5 -+5 V(0), 1530 V(1) -5 -+5 V(0), 15 -30 V(1) 24 VDC(5046) 250 VAC , 30 VDC 0 -3 V(0) , 10 -30 V(1) Input Counter range Frequency 32 Bit 1 MHz Rated Output Amp. 0. 5 A 5 A 0. 5 A Over Voltage Protection Yes N/A Yes Shirt Circuit Protection N/A Yes Thermal shutdown Protection N/A Yes(5045) N/A Yes

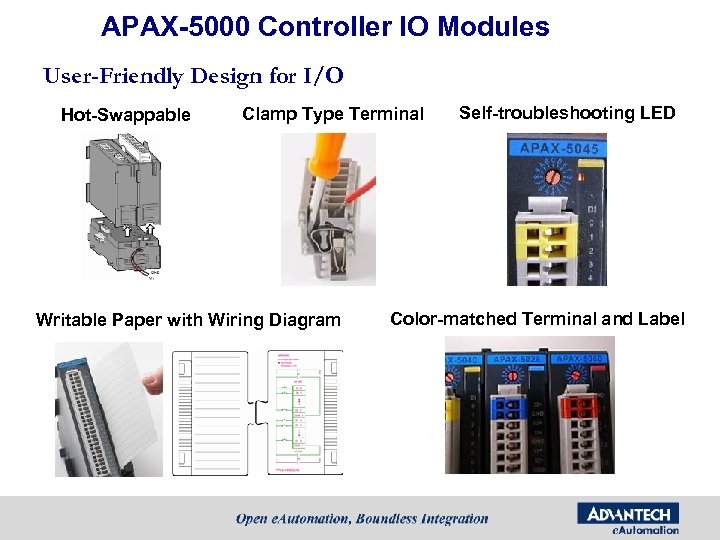

APAX-5000 Controller IO Modules User-Friendly Design for I/O Hot-Swappable Clamp Type Terminal Writable Paper with Wiring Diagram Self-troubleshooting LED Color-matched Terminal and Label

APAX-5000 Controller IO Modules User-Friendly Design for I/O Hot-Swappable Clamp Type Terminal Writable Paper with Wiring Diagram Self-troubleshooting LED Color-matched Terminal and Label

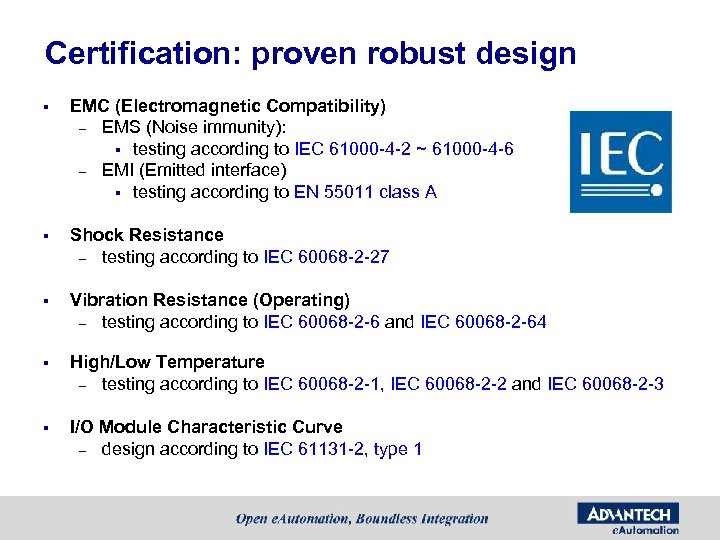

Certification: proven robust design § EMC (Electromagnetic Compatibility) – EMS (Noise immunity): § testing according to IEC 61000 -4 -2 ~ 61000 -4 -6 – EMI (Emitted interface) § testing according to EN 55011 class A § Shock Resistance – testing according to IEC 60068 -2 -27 § Vibration Resistance (Operating) – testing according to IEC 60068 -2 -6 and IEC 60068 -2 -64 § High/Low Temperature – testing according to IEC 60068 -2 -1, IEC 60068 -2 -2 and IEC 60068 -2 -3 § I/O Module Characteristic Curve – design according to IEC 61131 -2, type 1

Certification: proven robust design § EMC (Electromagnetic Compatibility) – EMS (Noise immunity): § testing according to IEC 61000 -4 -2 ~ 61000 -4 -6 – EMI (Emitted interface) § testing according to EN 55011 class A § Shock Resistance – testing according to IEC 60068 -2 -27 § Vibration Resistance (Operating) – testing according to IEC 60068 -2 -6 and IEC 60068 -2 -64 § High/Low Temperature – testing according to IEC 60068 -2 -1, IEC 60068 -2 -2 and IEC 60068 -2 -3 § I/O Module Characteristic Curve – design according to IEC 61131 -2, type 1

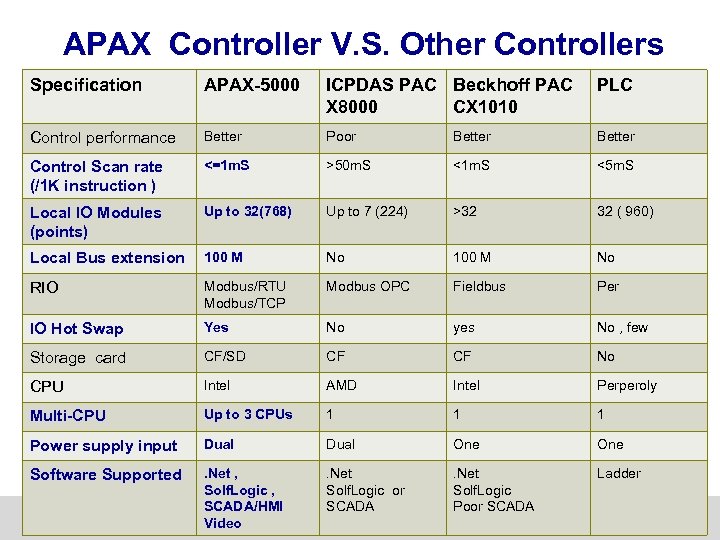

APAX Controller V. S. Other Controllers Specification APAX-5000 ICPDAS PAC Beckhoff PAC X 8000 CX 1010 PLC Control performance Better Poor Better Control Scan rate (/1 K instruction ) <=1 m. S >50 m. S <1 m. S <5 m. S Local IO Modules (points) Up to 32(768) Up to 7 (224) >32 32 ( 960) Local Bus extension 100 M No RIO Modbus/RTU Modbus/TCP Modbus OPC Fieldbus Per IO Hot Swap Yes No yes No , few Storage card CF/SD CF CF No CPU Intel AMD Intel Perperoly Multi-CPU Up to 3 CPUs 1 1 1 Power supply input Dual One Software Supported . Net , Solf. Logic , SCADA/HMI Video . Net Solf. Logic or SCADA . Net Solf. Logic Poor SCADA Ladder

APAX Controller V. S. Other Controllers Specification APAX-5000 ICPDAS PAC Beckhoff PAC X 8000 CX 1010 PLC Control performance Better Poor Better Control Scan rate (/1 K instruction ) <=1 m. S >50 m. S <1 m. S <5 m. S Local IO Modules (points) Up to 32(768) Up to 7 (224) >32 32 ( 960) Local Bus extension 100 M No RIO Modbus/RTU Modbus/TCP Modbus OPC Fieldbus Per IO Hot Swap Yes No yes No , few Storage card CF/SD CF CF No CPU Intel AMD Intel Perperoly Multi-CPU Up to 3 CPUs 1 1 1 Power supply input Dual One Software Supported . Net , Solf. Logic , SCADA/HMI Video . Net Solf. Logic or SCADA . Net Solf. Logic Poor SCADA Ladder

APAX Target Market Reference Machine Automation Factory Automation MA GMC (General Motion) • Semi-con. Testing • Packing • Printing • Production Information • Convey control • Shop flow control • Water treatment • Warehouse MA w/Process • Semi-com Packaging • Plastic • Rubber • Chiller • Chamber • Reactor EFMS • Ultra Pure Water Treatment RTU • Waste water Station RTU • Tunnel facility RTU

APAX Target Market Reference Machine Automation Factory Automation MA GMC (General Motion) • Semi-con. Testing • Packing • Printing • Production Information • Convey control • Shop flow control • Water treatment • Warehouse MA w/Process • Semi-com Packaging • Plastic • Rubber • Chiller • Chamber • Reactor EFMS • Ultra Pure Water Treatment RTU • Waste water Station RTU • Tunnel facility RTU

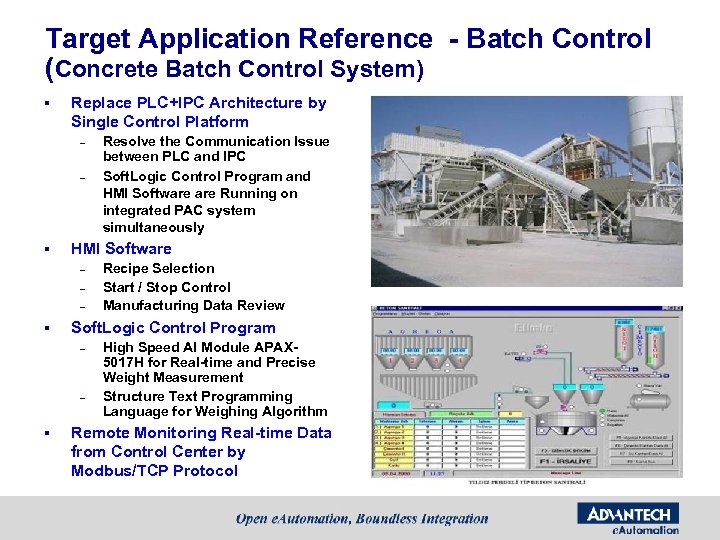

Target Application Reference - Batch Control (Concrete Batch Control System) § Replace PLC+IPC Architecture by Single Control Platform – – § HMI Software – – – § Recipe Selection Start / Stop Control Manufacturing Data Review Soft. Logic Control Program – – § Resolve the Communication Issue between PLC and IPC Soft. Logic Control Program and HMI Software Running on integrated PAC system simultaneously High Speed AI Module APAX 5017 H for Real-time and Precise Weight Measurement Structure Text Programming Language for Weighing Algorithm Remote Monitoring Real-time Data from Control Center by Modbus/TCP Protocol

Target Application Reference - Batch Control (Concrete Batch Control System) § Replace PLC+IPC Architecture by Single Control Platform – – § HMI Software – – – § Recipe Selection Start / Stop Control Manufacturing Data Review Soft. Logic Control Program – – § Resolve the Communication Issue between PLC and IPC Soft. Logic Control Program and HMI Software Running on integrated PAC system simultaneously High Speed AI Module APAX 5017 H for Real-time and Precise Weight Measurement Structure Text Programming Language for Weighing Algorithm Remote Monitoring Real-time Data from Control Center by Modbus/TCP Protocol

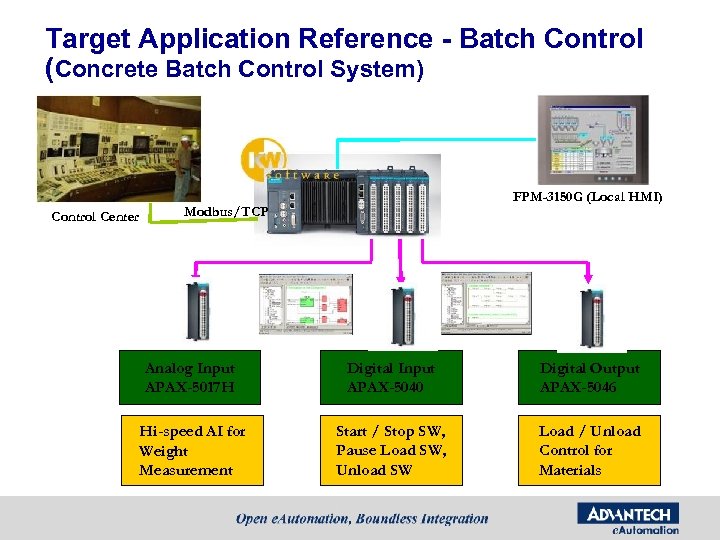

Target Application Reference - Batch Control (Concrete Batch Control System) Control Center FPM-3150 G (Local HMI) Modbus/TCP APAX-5570 XPE+APAX-5520 KW Analog Input APAX-5017 H Digital Input APAX-5040 Digital Output APAX-5046 Hi-speed AI for Weight Measurement Start / Stop SW, Pause Load SW, Unload SW Load / Unload Control for Materials

Target Application Reference - Batch Control (Concrete Batch Control System) Control Center FPM-3150 G (Local HMI) Modbus/TCP APAX-5570 XPE+APAX-5520 KW Analog Input APAX-5017 H Digital Input APAX-5040 Digital Output APAX-5046 Hi-speed AI for Weight Measurement Start / Stop SW, Pause Load SW, Unload SW Load / Unload Control for Materials

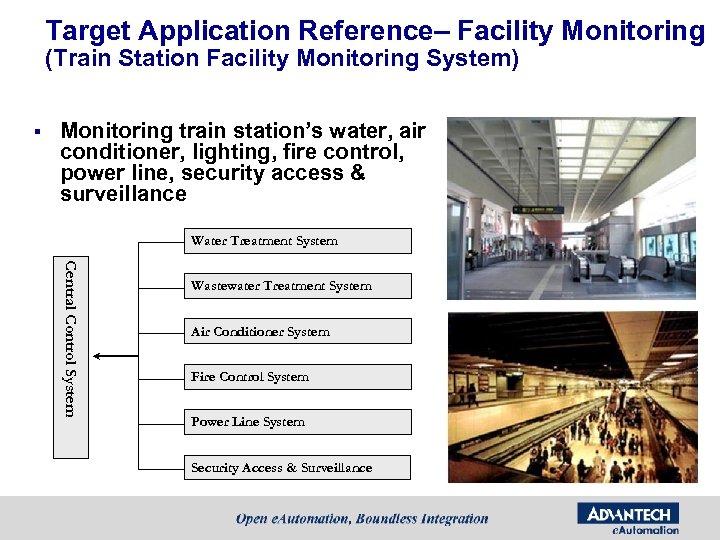

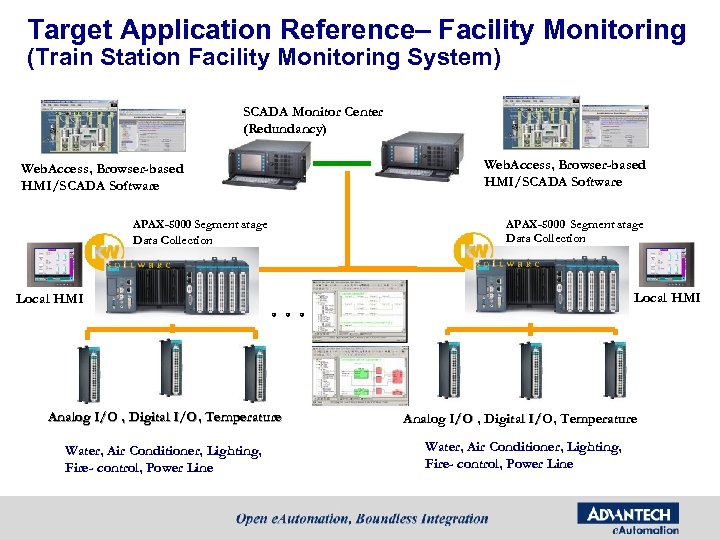

Target Application Reference– Facility Monitoring (Train Station Facility Monitoring System) § Monitoring train station’s water, air conditioner, lighting, fire control, power line, security access & surveillance Water Treatment System Central Control System Wastewater Treatment System Air Conditioner System Fire Control System Power Line System Security Access & Surveillance

Target Application Reference– Facility Monitoring (Train Station Facility Monitoring System) § Monitoring train station’s water, air conditioner, lighting, fire control, power line, security access & surveillance Water Treatment System Central Control System Wastewater Treatment System Air Conditioner System Fire Control System Power Line System Security Access & Surveillance

Target Application Reference– Facility Monitoring (Train Station Facility Monitoring System) SCADA Monitor Center (Redundancy) Web. Access, Browser-based HMI/SCADA Software APAX-5000 Segment stage Data Collection Local HMI 。。。。 Analog I/O , Digital I/O, Temperature Water, Air Conditioner, Lighting, Fire- control, Power Line

Target Application Reference– Facility Monitoring (Train Station Facility Monitoring System) SCADA Monitor Center (Redundancy) Web. Access, Browser-based HMI/SCADA Software APAX-5000 Segment stage Data Collection Local HMI 。。。。 Analog I/O , Digital I/O, Temperature Water, Air Conditioner, Lighting, Fire- control, Power Line

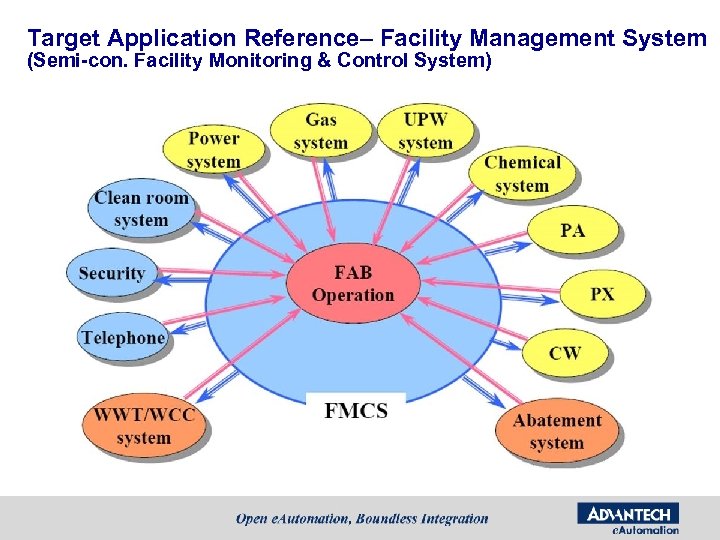

Target Application Reference– Facility Management System (Semi-con. Facility Monitoring & Control System)

Target Application Reference– Facility Management System (Semi-con. Facility Monitoring & Control System)

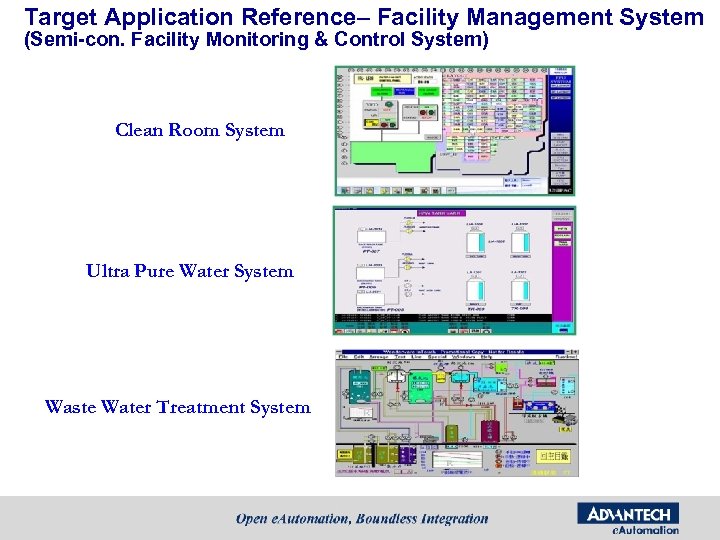

Target Application Reference– Facility Management System (Semi-con. Facility Monitoring & Control System) Clean Room System Ultra Pure Water System Waste Water Treatment System

Target Application Reference– Facility Management System (Semi-con. Facility Monitoring & Control System) Clean Room System Ultra Pure Water System Waste Water Treatment System

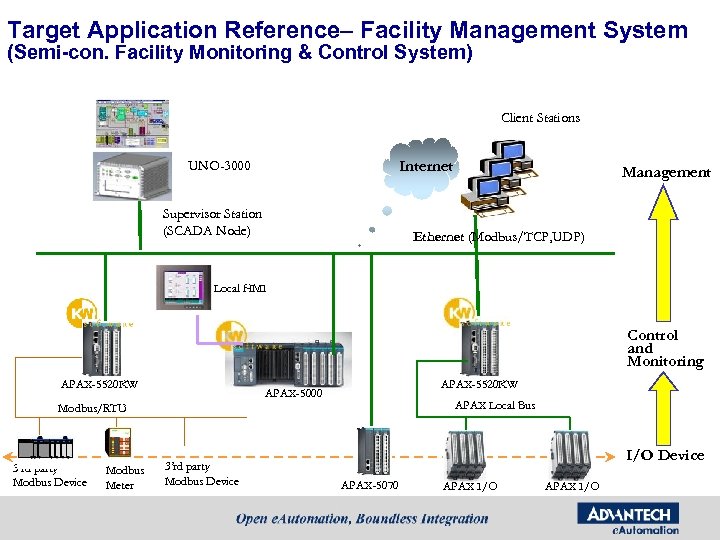

Target Application Reference– Facility Management System (Semi-con. Facility Monitoring & Control System) Client Stations Internet UNO-3000 Supervisor Station (SCADA Node) Management Ethernet (Modbus/TCP, UDP) Local HMI Control and Monitoring APAX-5520 KW APAX-5000 APAX Local Bus Modbus/RTU 3’rd party Modbus Device Modbus Meter 3’rd party Modbus Device I/O Device APAX-5070 APAX I/O

Target Application Reference– Facility Management System (Semi-con. Facility Monitoring & Control System) Client Stations Internet UNO-3000 Supervisor Station (SCADA Node) Management Ethernet (Modbus/TCP, UDP) Local HMI Control and Monitoring APAX-5520 KW APAX-5000 APAX Local Bus Modbus/RTU 3’rd party Modbus Device Modbus Meter 3’rd party Modbus Device I/O Device APAX-5070 APAX I/O

Contact Information CC Lin, PAC Product Sales Manager § VOIP: 511 -2382 § E-mail: cc. lin@advantech. com. tw Sindy Lin, PAC Marketing Communication § VOIP: 511 -2336 § E-mail: sindy. lin@advantech. com. tw Peishan Juan, APAX PD Manager § VOIP: 511 -2175 § E-mail: peishan. juan @advantech. com. tw Kunyu, APAX-5000 series Product Manager § VOIP: 511 -2852 § E-mail: kunyu. lee@advantech. com. tw Alan Su, ADAM-5000/APAX-6000 series Product Manager § VOIP: 511 -2985 § E-mail: alan. su@advantech. com. tw

Contact Information CC Lin, PAC Product Sales Manager § VOIP: 511 -2382 § E-mail: cc. lin@advantech. com. tw Sindy Lin, PAC Marketing Communication § VOIP: 511 -2336 § E-mail: sindy. lin@advantech. com. tw Peishan Juan, APAX PD Manager § VOIP: 511 -2175 § E-mail: peishan. juan @advantech. com. tw Kunyu, APAX-5000 series Product Manager § VOIP: 511 -2852 § E-mail: kunyu. lee@advantech. com. tw Alan Su, ADAM-5000/APAX-6000 series Product Manager § VOIP: 511 -2985 § E-mail: alan. su@advantech. com. tw

Thank you!

Thank you!