4f647dd82b8f60dafbdffb59868fbcc9.ppt

- Количество слайдов: 12

ANTICORROSION COATINGS

ANTICORROSION COATINGS

INTRODUCTION Company WCS General Trading F. Z. C. is a manufacturer of anticorrosion coatings. Stable product quality is achieved using only high quality raw materials and implementation of quality control system according to ISO 9001. Proven and reliable equipment, which are equipped with our production sites in Russia and abroad, provides stable quality characteristics of each batch of each product. Manufacturing facilities also have R&D departments, which gives BIURS the ability, if necessary, either change the characteristics of existing products or to design a new product in a short period of time to meet clients’ requirements.

INTRODUCTION Company WCS General Trading F. Z. C. is a manufacturer of anticorrosion coatings. Stable product quality is achieved using only high quality raw materials and implementation of quality control system according to ISO 9001. Proven and reliable equipment, which are equipped with our production sites in Russia and abroad, provides stable quality characteristics of each batch of each product. Manufacturing facilities also have R&D departments, which gives BIURS the ability, if necessary, either change the characteristics of existing products or to design a new product in a short period of time to meet clients’ requirements.

SYSTEM OF ANTICORROSION COATING “BIURS” System of anti-corrosion coating (hereinafter referred as SAC) “BIURS” designed for insulation of underground and overhead oil and/or gas pipelines and for protection of fittings and valves at pumps and compressors stations. SAC “BIURS” meets main requirements of “Technical requirements of OJSC “Gazprom” to external coatings based on thermoset materials for anticorrosive protection of pipes, joining parts, valves and mounting units of pipelines with operational temperatures ranging from – 20 o. C to +100 o. C” as well as requirements of “Technical requirements of JSC “Transneft” to the coatings of shaped joining parts and latches of trunk pipelines” and GOST # P 51164 -98 “Trunk steel pipelines”. Protective coating is a system consisted of quick-setting primer named “Primer MB” and protective mastix named “BIUR” which have to be put sequentially onto prepared pipeline surface. Preparation of a pipeline (metal) surface means removing rust residues and making surface rough to required extent by using sand-blasting or grit-blasting methods: at field conditions – 2 according to GOST 9. 402 or not less than St 3 according to ISO 8501 -1 with roughness of surface R z 30 -100 micrometers at factory (base) conditions – 1 according to GOST 9. 402 or not less than St 2 according to ISO 8501 -1 with roughness of surface R z 60 -150 micrometers A pipeline surface should be degreased and clear from dust prior application of putting SAC “BIURS”. Primer “Primer MB” is a two-component system based on epoxy resin. The components of it are base and hardener. Before using the primer both its components have to be carefully mixed together by a mixer. Application of the primer can be done either manually (by a brush, a roller etc) or mechanically by using vacuum sputtering unit at temperatures from +5 o. C to +50 o. C. Important parameter in putting the primer is primer’s layer drying extent. It should be rested till “dry touch”. Meeting these conditions provides creating of chemical links between the primer and the mastix. The thickness of primer’s layer varies from 50 to 150 micrometers depending on operational conditions.

SYSTEM OF ANTICORROSION COATING “BIURS” System of anti-corrosion coating (hereinafter referred as SAC) “BIURS” designed for insulation of underground and overhead oil and/or gas pipelines and for protection of fittings and valves at pumps and compressors stations. SAC “BIURS” meets main requirements of “Technical requirements of OJSC “Gazprom” to external coatings based on thermoset materials for anticorrosive protection of pipes, joining parts, valves and mounting units of pipelines with operational temperatures ranging from – 20 o. C to +100 o. C” as well as requirements of “Technical requirements of JSC “Transneft” to the coatings of shaped joining parts and latches of trunk pipelines” and GOST # P 51164 -98 “Trunk steel pipelines”. Protective coating is a system consisted of quick-setting primer named “Primer MB” and protective mastix named “BIUR” which have to be put sequentially onto prepared pipeline surface. Preparation of a pipeline (metal) surface means removing rust residues and making surface rough to required extent by using sand-blasting or grit-blasting methods: at field conditions – 2 according to GOST 9. 402 or not less than St 3 according to ISO 8501 -1 with roughness of surface R z 30 -100 micrometers at factory (base) conditions – 1 according to GOST 9. 402 or not less than St 2 according to ISO 8501 -1 with roughness of surface R z 60 -150 micrometers A pipeline surface should be degreased and clear from dust prior application of putting SAC “BIURS”. Primer “Primer MB” is a two-component system based on epoxy resin. The components of it are base and hardener. Before using the primer both its components have to be carefully mixed together by a mixer. Application of the primer can be done either manually (by a brush, a roller etc) or mechanically by using vacuum sputtering unit at temperatures from +5 o. C to +50 o. C. Important parameter in putting the primer is primer’s layer drying extent. It should be rested till “dry touch”. Meeting these conditions provides creating of chemical links between the primer and the mastix. The thickness of primer’s layer varies from 50 to 150 micrometers depending on operational conditions.

SYSTEM OF ANTICORROSION COATING “BIURS” “Primer MB” can be used as independent coating against corrosion of steel surfaces which contact with oil, distillates, fresh and sea water, as well as a protective coating for main pipelines and internal surfaces of oil and fuel tanks. Protective mastix “BUIR” should be applied only upon primer ”Primer MB” and works as a protection of the primer from mechanical damages while doing different operations with an object to be protected (such as moving, setting up, ripping-up and covering of a ditch). The mastix is based on modified polyurethane. Application of the mastix is done by using hot vacuum spraying method with separate components feeding. The thickness of mastix’s layer varies 2 -2. 5 millimeters as per GOST 51164 -98 Time of ageing the coating before covering protected object into ground shouldn’t be less than 6 -8 hours at +20 o. C. Full hardening is achieved within 144 -192 hours. Lifetime of the coating is at least 20 years (in case all technical requirements are observed)

SYSTEM OF ANTICORROSION COATING “BIURS” “Primer MB” can be used as independent coating against corrosion of steel surfaces which contact with oil, distillates, fresh and sea water, as well as a protective coating for main pipelines and internal surfaces of oil and fuel tanks. Protective mastix “BUIR” should be applied only upon primer ”Primer MB” and works as a protection of the primer from mechanical damages while doing different operations with an object to be protected (such as moving, setting up, ripping-up and covering of a ditch). The mastix is based on modified polyurethane. Application of the mastix is done by using hot vacuum spraying method with separate components feeding. The thickness of mastix’s layer varies 2 -2. 5 millimeters as per GOST 51164 -98 Time of ageing the coating before covering protected object into ground shouldn’t be less than 6 -8 hours at +20 o. C. Full hardening is achieved within 144 -192 hours. Lifetime of the coating is at least 20 years (in case all technical requirements are observed)

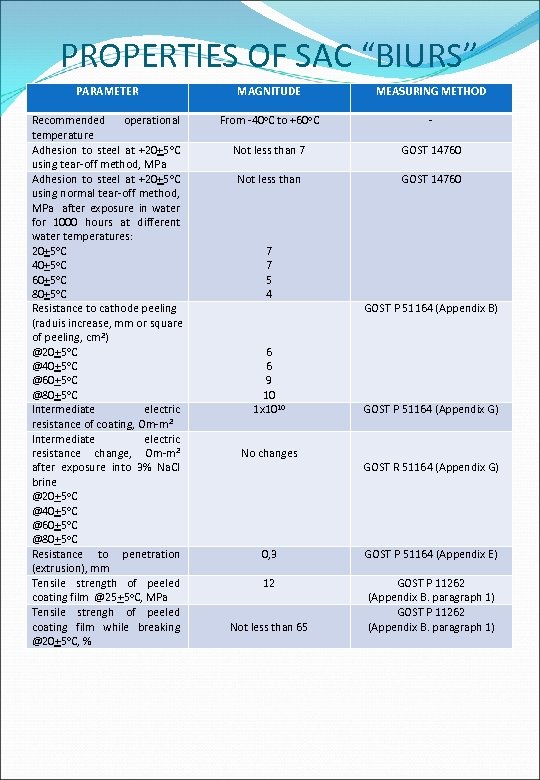

PROPERTIES OF SAC “BIURS” PARAMETER MAGNITUDE MEASURING METHOD Recommended operational temperature Adhesion to steel at +20+5 o. C using tear-off method, MPa Adhesion to steel at +20+5 o. C using normal tear-off method, MPa after exposure in water for 1000 hours at different water temperatures: 20+5 o. C 40+5 o. C 60+5 o. C 80+5 o. C Resistance to cathode peeling (raduis increase, mm or square of peeling, cm 2) @20+5 o. C @40+5 o. C @60+5 o. C @80+5 o. C Intermediate electric resistance of coating, Om-m 2 Intermediate electric resistance change, Om-m 2 after exposure into 3% Na. Cl brine @20+5 o. C @40+5 o. C @60+5 o. C @80+5 o. C Resistance to penetration (extrusion), mm Tensile strength of peeled coating film @25+5 o. C, MPa Tensile strengh of peeled coating film while breaking @20+5 o. C, % From -40 o. C to +60 o. C - Not less than 7 GOST 14760 Not less than GOST 14760 7 7 5 4 6 6 9 10 1 x 1010 No changes GOST P 51164 (Appendix B) GOST P 51164 (Appendix G) GOST R 51164 (Appendix G) 0, 3 GOST P 51164 (Appendix E) 12 GOST P 11262 (Appendix B. paragraph 1) Not less than 65

PROPERTIES OF SAC “BIURS” PARAMETER MAGNITUDE MEASURING METHOD Recommended operational temperature Adhesion to steel at +20+5 o. C using tear-off method, MPa Adhesion to steel at +20+5 o. C using normal tear-off method, MPa after exposure in water for 1000 hours at different water temperatures: 20+5 o. C 40+5 o. C 60+5 o. C 80+5 o. C Resistance to cathode peeling (raduis increase, mm or square of peeling, cm 2) @20+5 o. C @40+5 o. C @60+5 o. C @80+5 o. C Intermediate electric resistance of coating, Om-m 2 Intermediate electric resistance change, Om-m 2 after exposure into 3% Na. Cl brine @20+5 o. C @40+5 o. C @60+5 o. C @80+5 o. C Resistance to penetration (extrusion), mm Tensile strength of peeled coating film @25+5 o. C, MPa Tensile strengh of peeled coating film while breaking @20+5 o. C, % From -40 o. C to +60 o. C - Not less than 7 GOST 14760 Not less than GOST 14760 7 7 5 4 6 6 9 10 1 x 1010 No changes GOST P 51164 (Appendix B) GOST P 51164 (Appendix G) GOST R 51164 (Appendix G) 0, 3 GOST P 51164 (Appendix E) 12 GOST P 11262 (Appendix B. paragraph 1) Not less than 65

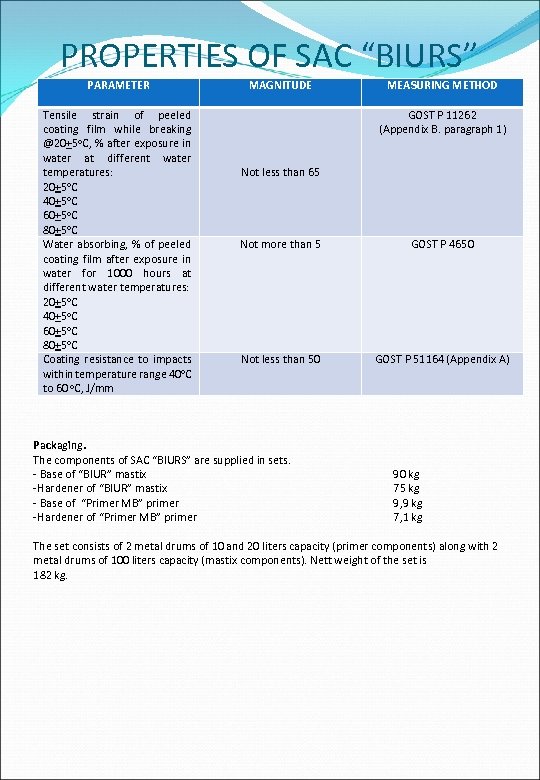

PROPERTIES OF SAC “BIURS” PARAMETER Tensile strain of peeled coating film while breaking @20+5 o. C, % after exposure in water at different water temperatures: 20+5 o. C 40+5 o. C 60+5 o. C 80+5 o. C Water absorbing, % of peeled coating film after exposure in water for 1000 hours at different water temperatures: 20+5 o. C 40+5 o. C 60+5 o. C 80+5 o. C Coating resistance to impacts within temperature range 40 o. C to 60 o. C, J/mm MAGNITUDE MEASURING METHOD GOST P 11262 (Appendix B. paragraph 1) Not less than 65 Not more than 5 GOST P 4650 Not less than 50 GOST P 51164 (Appendix A) Packaging. The components of SAC “BIURS” are supplied in sets. - Base of “BIUR” mastix -Hardener of “BIUR” mastix - Base of “Primer MB” primer -Hardener of “Primer MB” primer 90 kg 75 kg 9, 9 kg 7, 1 kg The set consists of 2 metal drums of 10 and 20 liters capacity (primer components) along with 2 metal drums of 100 liters capacity (mastix components). Nett weight of the set is 182 kg.

PROPERTIES OF SAC “BIURS” PARAMETER Tensile strain of peeled coating film while breaking @20+5 o. C, % after exposure in water at different water temperatures: 20+5 o. C 40+5 o. C 60+5 o. C 80+5 o. C Water absorbing, % of peeled coating film after exposure in water for 1000 hours at different water temperatures: 20+5 o. C 40+5 o. C 60+5 o. C 80+5 o. C Coating resistance to impacts within temperature range 40 o. C to 60 o. C, J/mm MAGNITUDE MEASURING METHOD GOST P 11262 (Appendix B. paragraph 1) Not less than 65 Not more than 5 GOST P 4650 Not less than 50 GOST P 51164 (Appendix A) Packaging. The components of SAC “BIURS” are supplied in sets. - Base of “BIUR” mastix -Hardener of “BIUR” mastix - Base of “Primer MB” primer -Hardener of “Primer MB” primer 90 kg 75 kg 9, 9 kg 7, 1 kg The set consists of 2 metal drums of 10 and 20 liters capacity (primer components) along with 2 metal drums of 100 liters capacity (mastix components). Nett weight of the set is 182 kg.

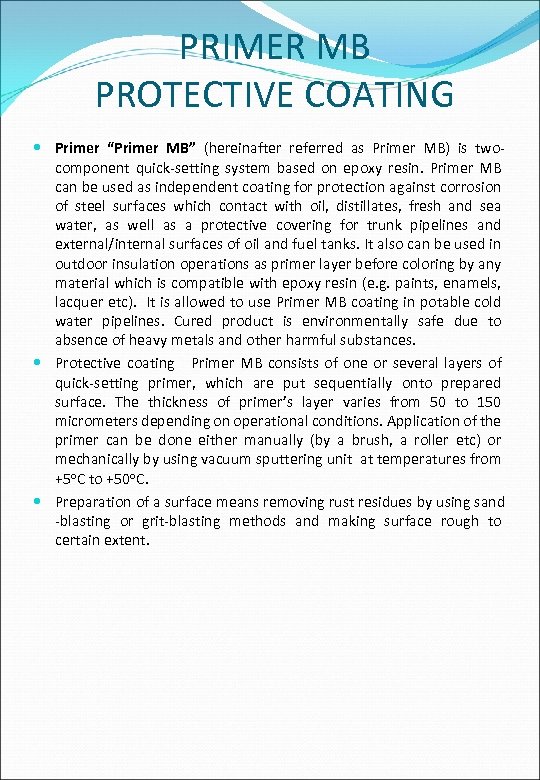

PRIMER MB PROTECTIVE COATING Primer “Primer MB” (hereinafter referred as Primer MB) is twocomponent quick-setting system based on epoxy resin. Primer MB can be used as independent coating for protection against corrosion of steel surfaces which contact with oil, distillates, fresh and sea water, as well as a protective covering for trunk pipelines and external/internal surfaces of oil and fuel tanks. It also can be used in outdoor insulation operations as primer layer before coloring by any material which is compatible with epoxy resin (e. g. paints, enamels, lacquer etc). It is allowed to use Primer MB coating in potable cold water pipelines. Cured product is environmentally safe due to absence of heavy metals and other harmful substances. Protective coating Primer MB consists of one or several layers of quick-setting primer, which are put sequentially onto prepared surface. The thickness of primer’s layer varies from 50 to 150 micrometers depending on operational conditions. Application of the primer can be done either manually (by a brush, a roller etc) or mechanically by using vacuum sputtering unit at temperatures from +5 o. C to +50 o. C. Preparation of a surface means removing rust residues by using sand -blasting or grit-blasting methods and making surface rough to certain extent.

PRIMER MB PROTECTIVE COATING Primer “Primer MB” (hereinafter referred as Primer MB) is twocomponent quick-setting system based on epoxy resin. Primer MB can be used as independent coating for protection against corrosion of steel surfaces which contact with oil, distillates, fresh and sea water, as well as a protective covering for trunk pipelines and external/internal surfaces of oil and fuel tanks. It also can be used in outdoor insulation operations as primer layer before coloring by any material which is compatible with epoxy resin (e. g. paints, enamels, lacquer etc). It is allowed to use Primer MB coating in potable cold water pipelines. Cured product is environmentally safe due to absence of heavy metals and other harmful substances. Protective coating Primer MB consists of one or several layers of quick-setting primer, which are put sequentially onto prepared surface. The thickness of primer’s layer varies from 50 to 150 micrometers depending on operational conditions. Application of the primer can be done either manually (by a brush, a roller etc) or mechanically by using vacuum sputtering unit at temperatures from +5 o. C to +50 o. C. Preparation of a surface means removing rust residues by using sand -blasting or grit-blasting methods and making surface rough to certain extent.

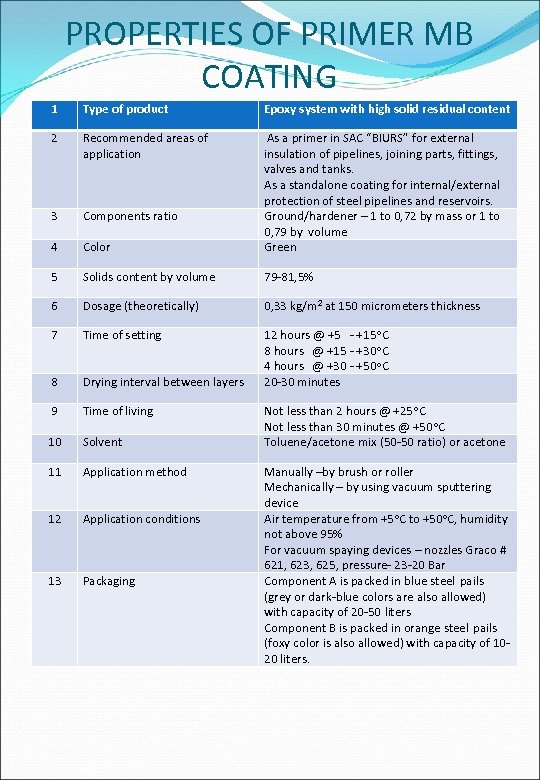

PROPERTIES OF PRIMER MB COATING 1 Type of product Epoxy system with high solid residual content 2 Recommended areas of application 3 Components ratio 4 Color As a primer in SAC “BIURS” for external insulation of pipelines, joining parts, fittings, valves and tanks. As a standalone coating for internal/external protection of steel pipelines and reservoirs. Ground/hardener – 1 to 0, 72 by mass or 1 to 0, 79 by volume Green 5 Solids content by volume 79 -81, 5% 6 Dosage (theoretically) 0, 33 kg/m 2 at 150 micrometers thickness 7 Time of setting 8 Drying interval between layers 12 hours @ +5 - +15 o. C 8 hours @ +15 - +30 o. C 4 hours @ +30 - +50 o. C 20 -30 minutes 9 Time of living 10 Solvent 11 Application method 12 Application conditions 13 Packaging Not less than 2 hours @ +25 o. C Not less than 30 minutes @ +50 o. C Toluene/acetone mix (50 -50 ratio) or acetone Manually –by brush or roller Mechanically – by using vacuum sputtering device Air temperature from +5 o. C to +50 o. C, humidity not above 95% For vacuum spaying devices – nozzles Graco # 621, 623, 625, pressure- 23 -20 Bar Component A is packed in blue steel pails (grey or dark-blue colors are also allowed) with capacity of 20 -50 liters Component B is packed in orange steel pails (foxy color is also allowed) with capacity of 1020 liters.

PROPERTIES OF PRIMER MB COATING 1 Type of product Epoxy system with high solid residual content 2 Recommended areas of application 3 Components ratio 4 Color As a primer in SAC “BIURS” for external insulation of pipelines, joining parts, fittings, valves and tanks. As a standalone coating for internal/external protection of steel pipelines and reservoirs. Ground/hardener – 1 to 0, 72 by mass or 1 to 0, 79 by volume Green 5 Solids content by volume 79 -81, 5% 6 Dosage (theoretically) 0, 33 kg/m 2 at 150 micrometers thickness 7 Time of setting 8 Drying interval between layers 12 hours @ +5 - +15 o. C 8 hours @ +15 - +30 o. C 4 hours @ +30 - +50 o. C 20 -30 minutes 9 Time of living 10 Solvent 11 Application method 12 Application conditions 13 Packaging Not less than 2 hours @ +25 o. C Not less than 30 minutes @ +50 o. C Toluene/acetone mix (50 -50 ratio) or acetone Manually –by brush or roller Mechanically – by using vacuum sputtering device Air temperature from +5 o. C to +50 o. C, humidity not above 95% For vacuum spaying devices – nozzles Graco # 621, 623, 625, pressure- 23 -20 Bar Component A is packed in blue steel pails (grey or dark-blue colors are also allowed) with capacity of 20 -50 liters Component B is packed in orange steel pails (foxy color is also allowed) with capacity of 1020 liters.

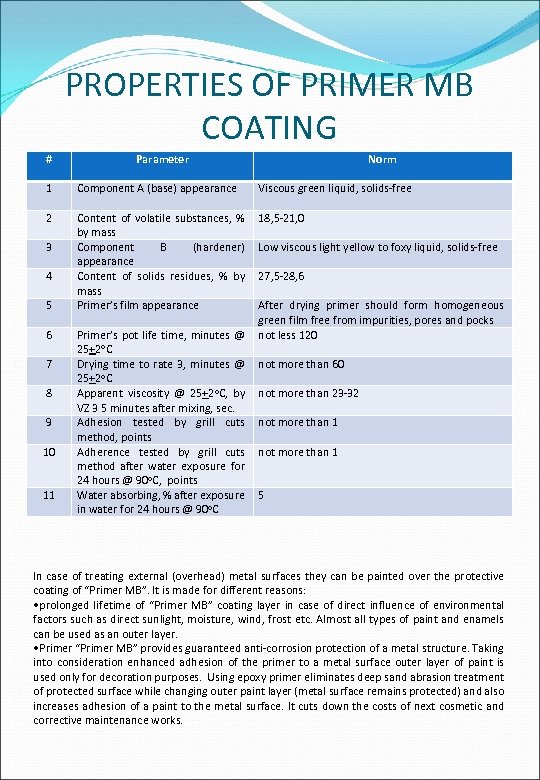

PROPERTIES OF PRIMER MB COATING # Parameter Norm 1 Component A (base) appearance Viscous green liquid, solids-free 2 Content of volatile substances, % by mass Component B (hardener) appearance Content of solids residues, % by mass Primer’s film appearance 18, 5 -21, 0 3 4 5 6 7 8 9 10 11 Low viscous light yellow to foxy liquid, solids-free 27, 5 -28, 6 After drying primer should form homogeneous green film free from impurities, pores and pocks Primer’s pot life time, minutes @ not less 120 25+2 o. C Drying time to rate 3, minutes @ not more than 60 25+2 o. C Apparent viscosity @ 25+2 o. C, by not more than 23 -32 VZ 3 5 minutes after mixing, sec. Adhesion tested by grill cuts not more than 1 method, points Adherence tested by grill cuts not more than 1 method after water exposure for 24 hours @ 90 o. C, points Water absorbing, % after exposure 5 in water for 24 hours @ 90 o. C In case of treating external (overhead) metal surfaces they can be painted over the protective coating of “Primer MB”. It is made for different reasons: • prolonged lifetime of “Primer MB” coating layer in case of direct influence of environmental factors such as direct sunlight, moisture, wind, frost etc. Almost all types of paint and enamels can be used as an outer layer. • Primer “Primer MB” provides guaranteed anti-corrosion protection of a metal structure. Taking into consideration enhanced adhesion of the primer to a metal surface outer layer of paint is used only for decoration purposes. Using epoxy primer eliminates deep sand abrasion treatment of protected surface while changing outer paint layer (metal surface remains protected) and also increases adhesion of a paint to the metal surface. It cuts down the costs of next cosmetic and corrective maintenance works.

PROPERTIES OF PRIMER MB COATING # Parameter Norm 1 Component A (base) appearance Viscous green liquid, solids-free 2 Content of volatile substances, % by mass Component B (hardener) appearance Content of solids residues, % by mass Primer’s film appearance 18, 5 -21, 0 3 4 5 6 7 8 9 10 11 Low viscous light yellow to foxy liquid, solids-free 27, 5 -28, 6 After drying primer should form homogeneous green film free from impurities, pores and pocks Primer’s pot life time, minutes @ not less 120 25+2 o. C Drying time to rate 3, minutes @ not more than 60 25+2 o. C Apparent viscosity @ 25+2 o. C, by not more than 23 -32 VZ 3 5 minutes after mixing, sec. Adhesion tested by grill cuts not more than 1 method, points Adherence tested by grill cuts not more than 1 method after water exposure for 24 hours @ 90 o. C, points Water absorbing, % after exposure 5 in water for 24 hours @ 90 o. C In case of treating external (overhead) metal surfaces they can be painted over the protective coating of “Primer MB”. It is made for different reasons: • prolonged lifetime of “Primer MB” coating layer in case of direct influence of environmental factors such as direct sunlight, moisture, wind, frost etc. Almost all types of paint and enamels can be used as an outer layer. • Primer “Primer MB” provides guaranteed anti-corrosion protection of a metal structure. Taking into consideration enhanced adhesion of the primer to a metal surface outer layer of paint is used only for decoration purposes. Using epoxy primer eliminates deep sand abrasion treatment of protected surface while changing outer paint layer (metal surface remains protected) and also increases adhesion of a paint to the metal surface. It cuts down the costs of next cosmetic and corrective maintenance works.

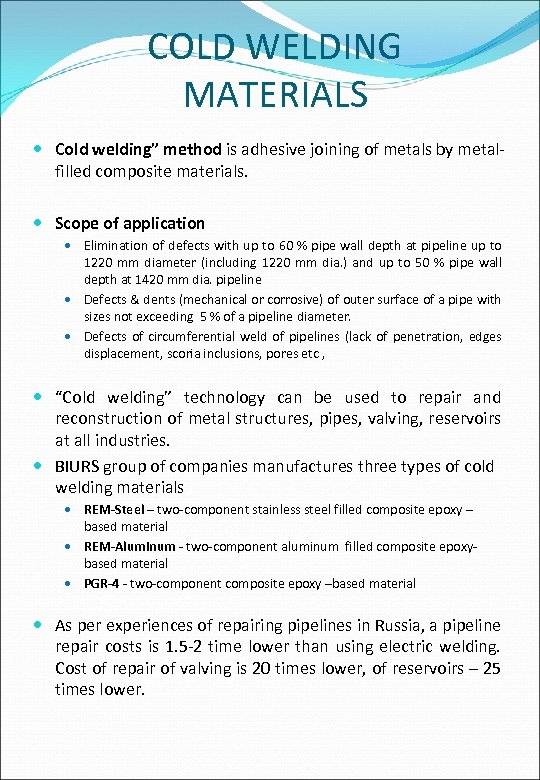

COLD WELDING MATERIALS Cold welding” method is adhesive joining of metals by metalfilled composite materials. Scope of application Elimination of defects with up to 60 % pipe wall depth at pipeline up to 1220 mm diameter (including 1220 mm dia. ) and up to 50 % pipe wall depth at 1420 mm dia. pipeline Defects & dents (mechanical or corrosive) of outer surface of a pipe with sizes not exceeding 5 % of a pipeline diameter. Defects of circumferential weld of pipelines (lack of penetration, edges displacement, scoria inclusions, pores etc , “Cold welding” technology can be used to repair and reconstruction of metal structures, pipes, valving, reservoirs at all industries. BIURS group of companies manufactures three types of cold welding materials REM-Steel – two-component stainless steel filled composite epoxy – based material REM-Aluminum - two-component aluminum filled composite epoxybased material PGR-4 - two-component composite epoxy –based material As per experiences of repairing pipelines in Russia, a pipeline repair costs is 1. 5 -2 time lower than using electric welding. Cost of repair of valving is 20 times lower, of reservoirs – 25 times lower.

COLD WELDING MATERIALS Cold welding” method is adhesive joining of metals by metalfilled composite materials. Scope of application Elimination of defects with up to 60 % pipe wall depth at pipeline up to 1220 mm diameter (including 1220 mm dia. ) and up to 50 % pipe wall depth at 1420 mm dia. pipeline Defects & dents (mechanical or corrosive) of outer surface of a pipe with sizes not exceeding 5 % of a pipeline diameter. Defects of circumferential weld of pipelines (lack of penetration, edges displacement, scoria inclusions, pores etc , “Cold welding” technology can be used to repair and reconstruction of metal structures, pipes, valving, reservoirs at all industries. BIURS group of companies manufactures three types of cold welding materials REM-Steel – two-component stainless steel filled composite epoxy – based material REM-Aluminum - two-component aluminum filled composite epoxybased material PGR-4 - two-component composite epoxy –based material As per experiences of repairing pipelines in Russia, a pipeline repair costs is 1. 5 -2 time lower than using electric welding. Cost of repair of valving is 20 times lower, of reservoirs – 25 times lower.

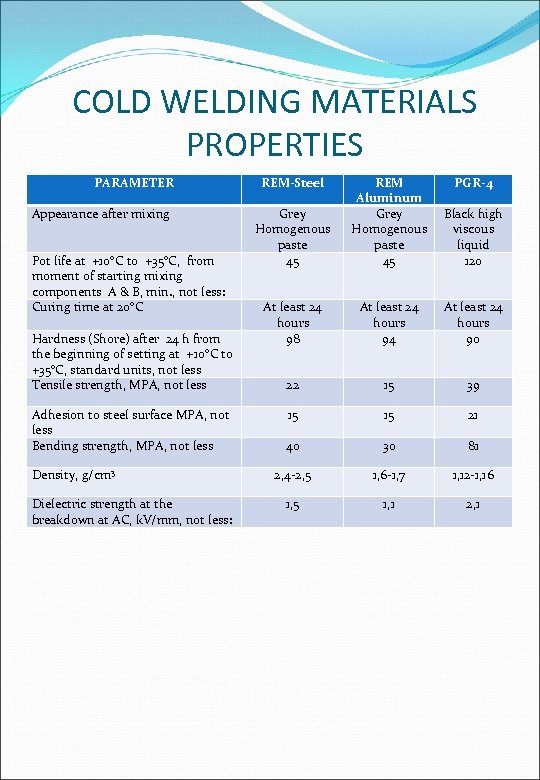

COLD WELDING MATERIALS PROPERTIES PARAMETER Appearance after mixing Pot life at +10°С to +35°С, from moment of starting mixing components А & B, min. , not less: Curing time at 20°С Hardness (Shore) after 24 h from the beginning of setting at +10°С to +35°С, standard units, not less Tensile strength, MPA, not less Adhesion to steel surface MPA, not less Bending strength, MPA, not less Density, g/cm 3 Dielectric strength at the breakdown at AC, k. V/mm, not less: REM-Steel Grey Homogenous paste 45 REM Aluminum Grey Homogenous paste 45 PGR-4 Black high viscous liquid 120 At least 24 hours 98 At least 24 hours 94 At least 24 hours 90 22 15 39 15 15 21 40 30 81 2, 4 -2, 5 1, 6 -1, 7 1, 12 -1, 16 1, 5 1, 1 2, 1

COLD WELDING MATERIALS PROPERTIES PARAMETER Appearance after mixing Pot life at +10°С to +35°С, from moment of starting mixing components А & B, min. , not less: Curing time at 20°С Hardness (Shore) after 24 h from the beginning of setting at +10°С to +35°С, standard units, not less Tensile strength, MPA, not less Adhesion to steel surface MPA, not less Bending strength, MPA, not less Density, g/cm 3 Dielectric strength at the breakdown at AC, k. V/mm, not less: REM-Steel Grey Homogenous paste 45 REM Aluminum Grey Homogenous paste 45 PGR-4 Black high viscous liquid 120 At least 24 hours 98 At least 24 hours 94 At least 24 hours 90 22 15 39 15 15 21 40 30 81 2, 4 -2, 5 1, 6 -1, 7 1, 12 -1, 16 1, 5 1, 1 2, 1

CONTACTS Head Office Ajman Free Zone Ajman United Arab Emirates SM-Office B 1 -613 C Office in Russia Address : ul. Reshetnikova, 17 korp. 4 A Saint-Petersburg, Russia 196105 Phonefax: +7 -812 -495 -69 -60, 495 -69 -62 E-mail: info@wcsbiurs. ru Website: www. wcsbiurs. ru www. wcsenergy. ru

CONTACTS Head Office Ajman Free Zone Ajman United Arab Emirates SM-Office B 1 -613 C Office in Russia Address : ul. Reshetnikova, 17 korp. 4 A Saint-Petersburg, Russia 196105 Phonefax: +7 -812 -495 -69 -60, 495 -69 -62 E-mail: info@wcsbiurs. ru Website: www. wcsbiurs. ru www. wcsenergy. ru