d9208935ef4c6be3394091abf3292bd9.ppt

- Количество слайдов: 31

Anti-Lock Brake System Control Using An Innovative Intelligent Tire-Vehicle Integrated Dynamic Friction Estimation Technique Kanwar Bharat Singh, Graduate Student Saied Taheri, Associate Professor Mechanical Engineering Department Center for Vehicle Systems and Safety Intelligent Transportation Laboratory Virginia Tech 1

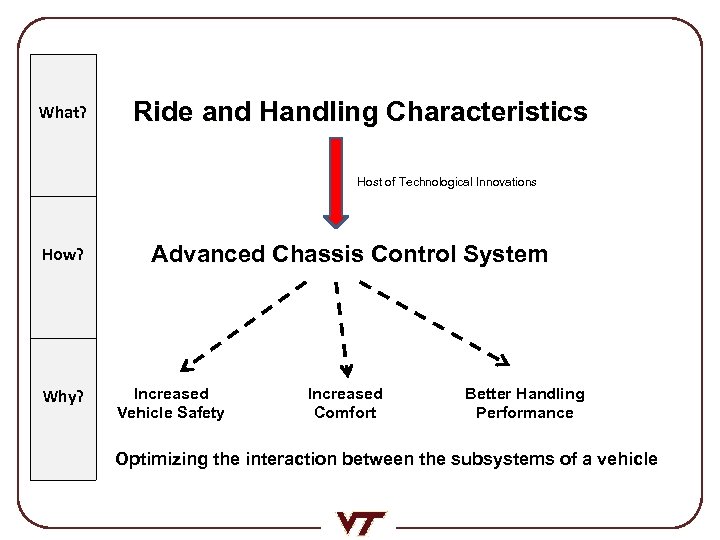

State of the art - Modern Day Chassis Control Systems Masterpiece Of Both Technological Innovation And Impeccable Design Vehicle With On-board Sensors Driver Input What? Wheel Speed Sensors Vehicle State Estimator Ride and Handling Characteristics IMU (6 axis) Host of Technological Innovations Control Inputs How? Steering Wheel Angle Sensor Advanced Chassis Control System On-line Measurements Of The State-of-the Vehicle Controller Optimizes The Tire Usage Estimated States ABS CMD Why? Increased AFS CMD Vehicle Safety Increased Integrated Chassis Comfort Controller Better Handling Performance Estimated tire forces and tire– road friction coefficient Critical Input For The Tire Controller Optimizing the interaction between the subsystems of a vehicle CDC CMD Knowledge Of Current Force Utilization Level And Handling Limits 2

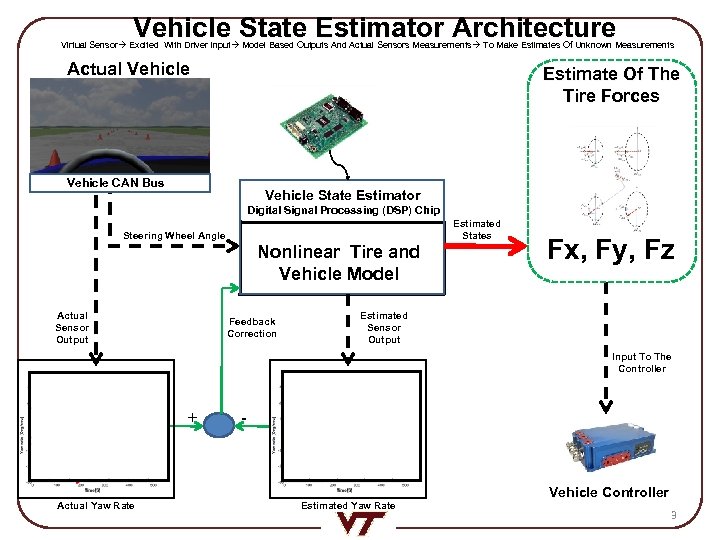

Vehicle State Estimator Architecture Virtual Sensor Excited With Driver Input Model Based Outputs And Actual Sensors Measurements To Make Estimates Of Unknown Measurements Actual Vehicle Estimate Of The Tire Forces Vehicle CAN Bus Vehicle State Estimator Digital Signal Processing (DSP) Chip Estimated States Steering Wheel Angle Nonlinear Tire and Vehicle Model Actual Sensor Output Feedback Correction Fx, Fy, Fz Estimated Sensor Output Input To The Controller + Actual Yaw Rate - Estimated Yaw Rate Vehicle Controller 3

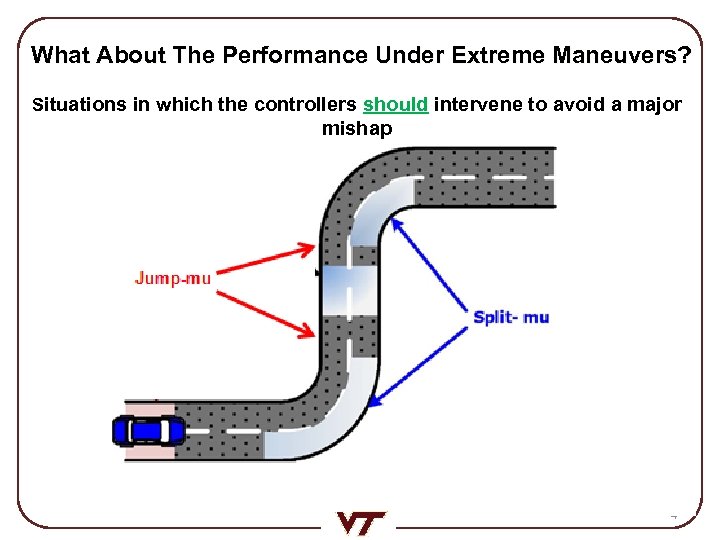

Tire-Force Estimator Performance What About The Performance Under Tire Force Estimates Extreme Maneuvers? Situations in which the controllers should intervene to avoid a major mishap Vehicle CAN Bus 4 Tire Force Estimator Architecture Implemented A Nonlinear State Estimator Using A High Fidelity Vehicle Dynamics Model 4

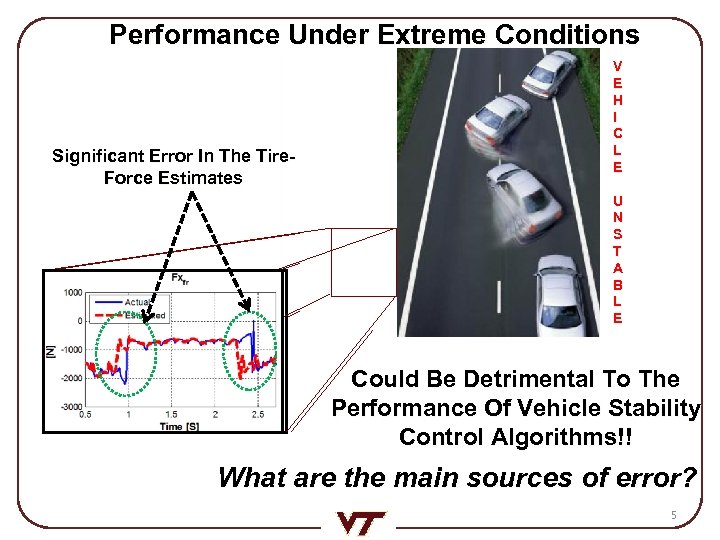

Performance Under Extreme Conditions V E H I C L E Significant Error In The Tire. Force Estimates Tire Force Estimates U N S T A B L E Could Be Detrimental To The Performance Of Vehicle Stability Control Algorithms!! What are the main sources of error? 5

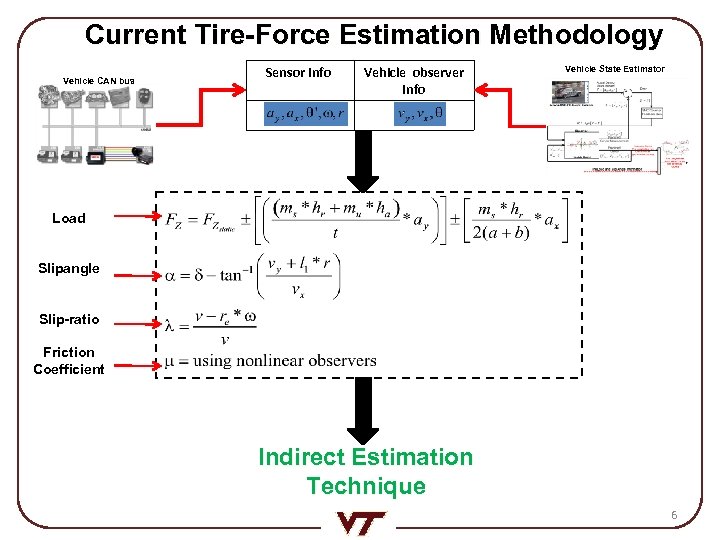

Current Tire-Force Estimation Methodology Vehicle CAN bus Vehicle State. Vehicle observer Estimator Sensor Info Vehicle State Estimator Info Tire Model Vehicle Model Load Slip-ratio Slipangle Friction Coefficient Slip-ratio Inputs Variables For A Typical Tire Model Friction Coefficient How exactly do we estimate these variables? Indirect Estimation Technique 6

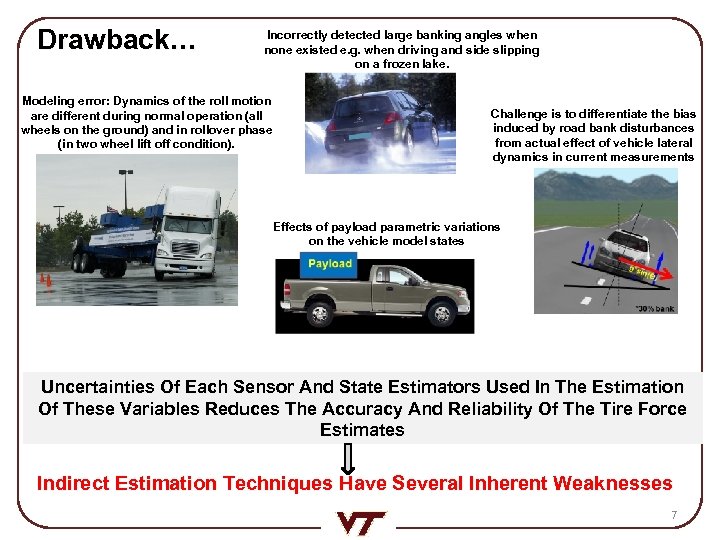

Drawback… Incorrectly detected large banking angles when none existed e. g. when driving and side slipping on a frozen lake. Modeling error: Dynamics of the roll motion are different during normal operation (all wheels on the ground) and in rollover phase (in two wheel lift off condition). Challenge is to differentiate the bias induced by road bank disturbances from actual effect of vehicle lateral dynamics in current measurements Effects of payload parametric variations on the vehicle model states Uncertainties Of Each Sensor And State Estimators Used In The Estimation Of These Variables Reduces The Accuracy And Reliability Of The Tire Force effects of payload parametric variations on the LWV states Estimates Indirect Estimation Techniques Have Several Inherent Weaknesses 7

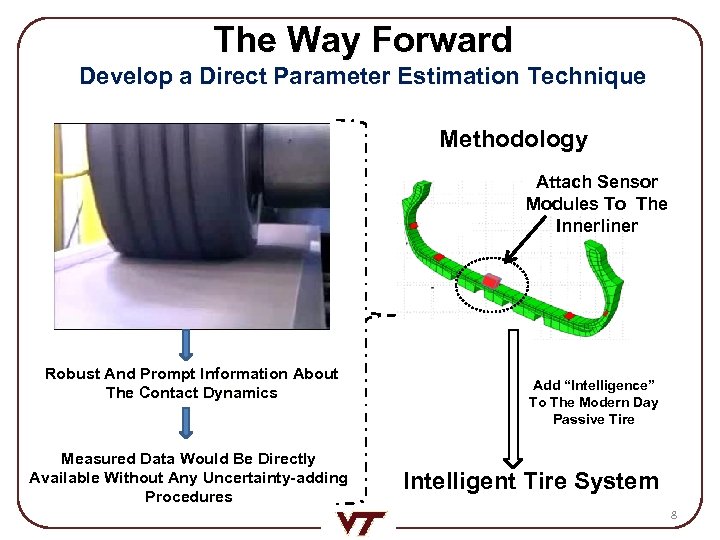

The Way Forward Develop a Direct Parameter Estimation Technique Methodology Attach Sensor Modules To The Innerliner Direct Estimation Technique Robust And Prompt Information About The Contact Dynamics Measured Data Would Be Directly Available Without Any Uncertainty-adding Procedures Add “Intelligence” To The Modern Day Passive Tire Intelligent Tire System 8

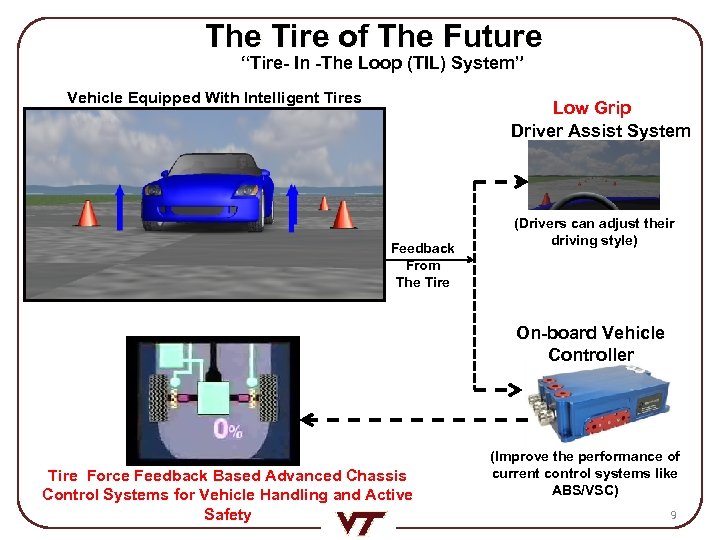

The Tire of The Future “Tire- In -The Loop (TIL) System” Vehicle Equipped With Intelligent Tires Low Grip Driver Assist System Feedback From The Tire (Drivers can adjust their driving style) On-board Vehicle Controller Tire Force Feedback Based Advanced Chassis Control Systems for Vehicle Handling and Active Safety (Improve the performance of current control systems like ABS/VSC) 9

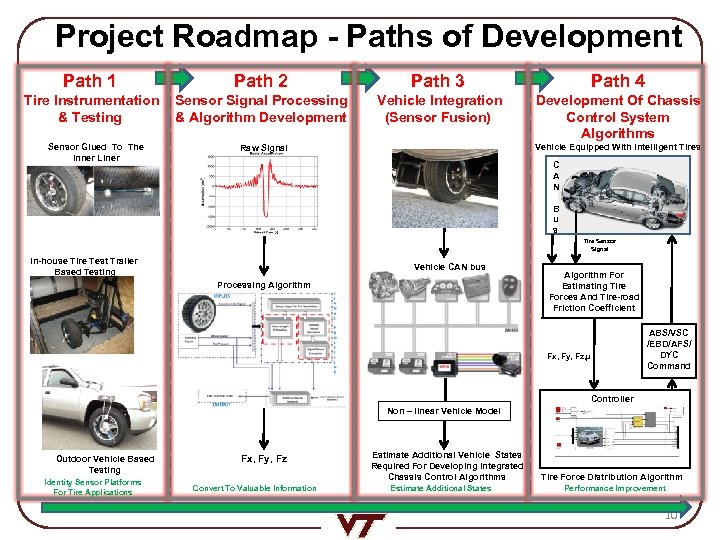

Project Roadmap - Paths of Development Path 1 Path 2 Path 3 Path 4 Tire Instrumentation & Testing Sensor Signal Processing & Algorithm Development Vehicle Integration (Sensor Fusion) Development Of Chassis Control System Algorithms Sensor Glued To The Inner Liner Vehicle Equipped With Intelligent Tires Raw Signal C A N B u s Tire Sensor Signal In-house Tire Test Trailer Based Testing Vehicle CAN bus Processing Algorithm For Estimating Tire Forces And Tire-road Friction Coefficient ABS/VSC /EBD/AFS/ DYC Command Fx, Fy, Fz, µ Controller Non – linear Vehicle Model Outdoor Vehicle Based Testing Identity Sensor Platforms For Tire Applications Fx, Fy, Fz Convert To Valuable Information Estimate Additional Vehicle States Required For Developing Integrated Chassis Control Algorithms Estimate Additional States Tire Force Distribution Algorithm Performance Improvement 10

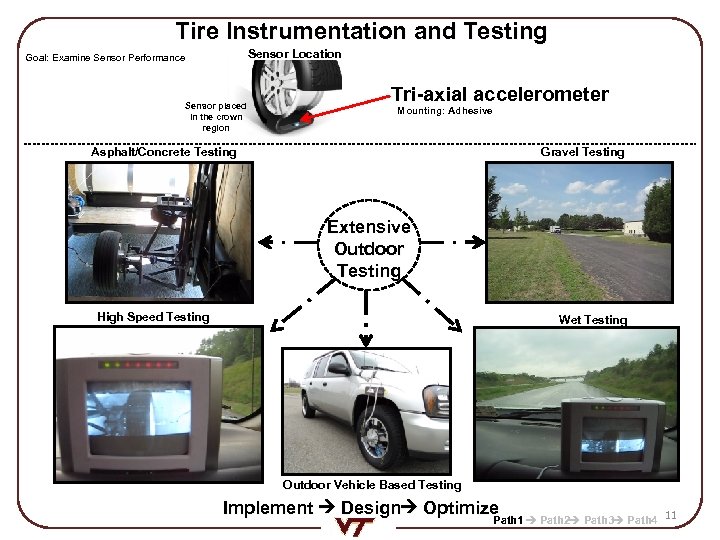

Tire Instrumentation and Testing Sensor Location Goal: Examine Sensor Performance Sensor placed in the crown region Tri-axial accelerometer Mounting: Adhesive Asphalt/Concrete Testing Gravel Testing Extensive Outdoor Testing High Speed Testing Wet Testing Outdoor Vehicle Based Testing Evaluate the system Design real Optimize Implement performance in world conditions Path 1 Path 2 Path 3 Path 4 11

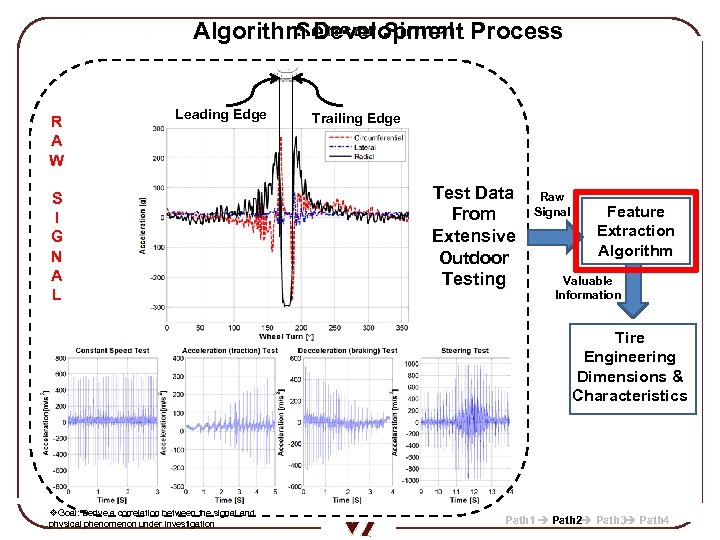

Algorithm Development Process Sensor Signal R A W Leading Edge Trailing Edge Sensor Signal for One Tire Rotation S I G N A L X Y Z v. Goal: Derive a correlation between the signal and physical phenomenon under investigation D Y N Test Data Raw Signal Feature A From Extraction. M Extensive Algorithm. I Outdoor C Valuable Testing Information P Tire H Engineering. E Dimensions & N Characteristics M E N O N Linked to 12 Path 1 Path 2 Path 3 Path 4

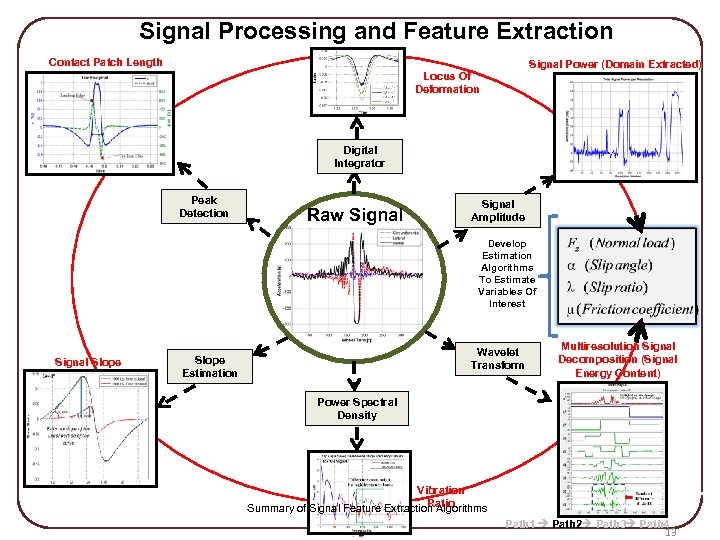

Signal Processing and Feature Extraction Contact Patch Length Signal Power (Domain Extracted) Locus Of Deformation Digital Integrator Peak Detection Raw Signal Amplitude Develop Estimation Algorithms To Estimate Variables Of Interest Signal Slope Wavelet Transform Slope Estimation Multiresolution Signal Decomposition (Signal Energy Content) Power Spectral Density Vibration Ratio Summary of Signal Feature Extraction Algorithms Path 1 Path 2 Path 3 Path 4 13

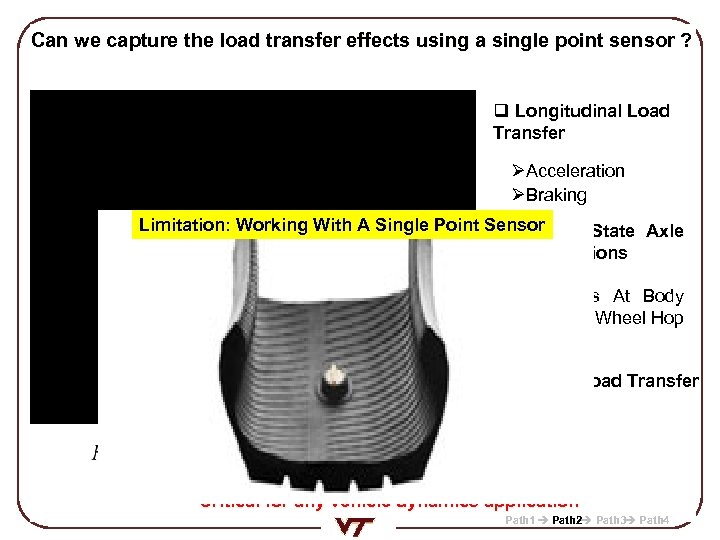

Load (Fz) Estimation Algorithm Fz Can we capture the load transfer effects using a single point sensor ? Features: Footprint length Radial Deformation Inputs q Longitudinal Load Transfer Output ØAcceleration ØBraking Artificial Neural Network (ANN) Based Parameter Estimation Algorithm Limitation: Working With A Single Point Sensor q Steady State Axle Load Variations ØOscillations At Body Bounce And Wheel Hop Frequencies q Lateral Load Transfer Critical for any vehicle dynamics application Path 1 Path 2 Path 3 Path 4 14

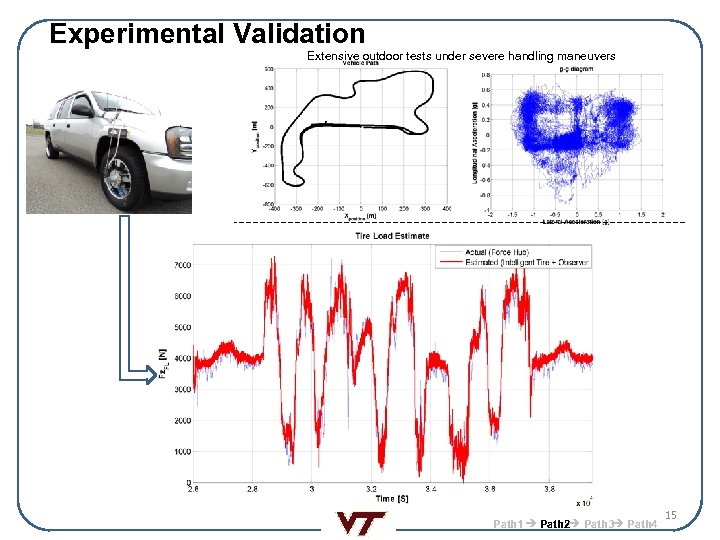

Dynamic Tire Load Estimation Algorithm Experimental Validation Developed A Sensor Fusion Approach Intelligent tire + Vehicle CAN Bus Extensive outdoor tests under severe handling maneuvers C A N Vehicle Equipped With Intelligent Tires B U S Information from an intelligent tire Load Transfer Ratio (LTR) Adaptive Load Transfer Ratio (ALTR) Estimation (adaptive parameter estimation) Roll angle Roll Angle Estimate (bank angle compensated) Kalman Filter (Observer) Roll rate Static normal load Dynamic Tire Load Estimation Algorithm Parameter Adaptation Path 1 Path 2 Path 3 Path 4 15 Path 1 Path 2 Path 3 Path 4

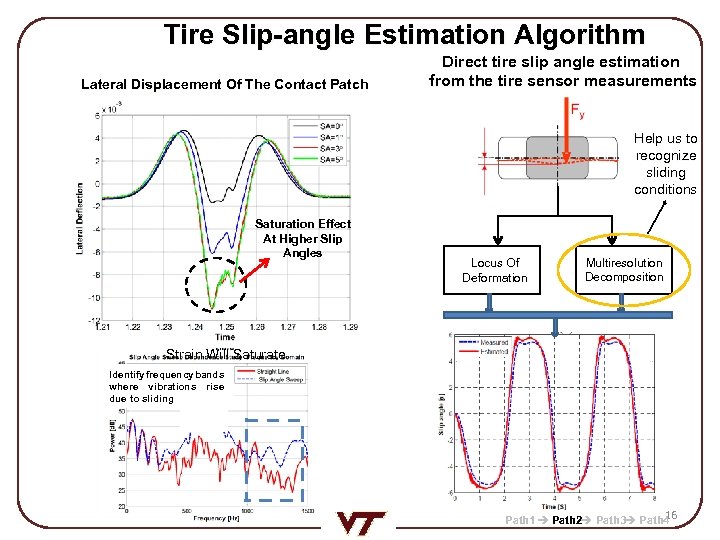

Tire Slip-angle Estimation Algorithm Lateral Displacement Of The Contact Patch Direct tire slip angle estimation from the tire sensor measurements Help us to recognize sliding conditions Saturation Effect At Higher Slip Angles Locus Of Deformation Multiresolution Decomposition Strain Will Saturate Identify frequency bands where vibrations rise due to sliding Leading Edge Trailing Edge 16 Path 1 Path 2 Path 3 Path 4

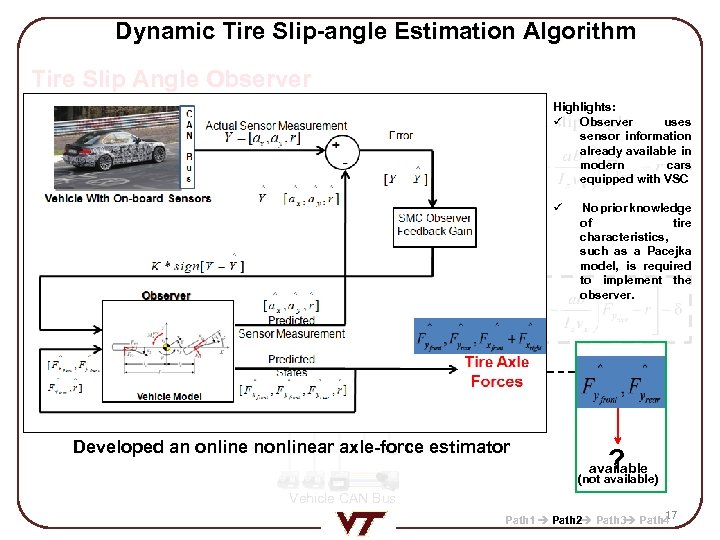

Dynamic Tire Slip-angle Estimation Algorithm Tire Slip Angle Observer Highlights: ü Observer uses sensor information already available in modern cars equipped with VSC Single-track model ü Dynamics of slip angle Developed an online nonlinear axle-force estimator No prior knowledge of tire characteristics, such as a Pacejka model, is required to implement the observer. ? available (not available) Vehicle CAN Bus 17 Path 1 Path 2 Path 3 Path 4

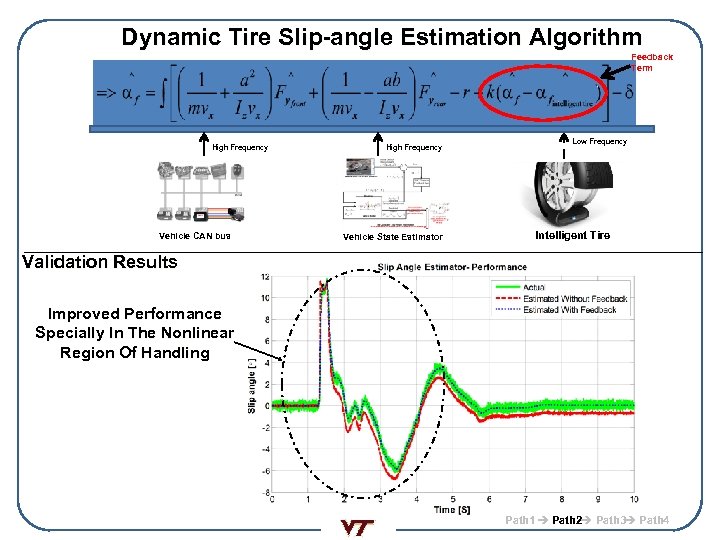

Tire-Axle Force Estimator Performance Dynamic Tire Slip-angle Estimation Algorithm *Evaluated performance using the Feedback commercial software Term CARSIM Estimation Results Vehicle CAN Bus High Frequency Nonlinear Observer – Vehicle CAN bus Tire-Axle Force Estimator High Frequency Vehicle State Estimator Low Frequency Intelligent Tire Validation Results Improved Performance Longitudinal Force Estimator Specially In The Nonlinear – Per Wheel Region Of Handling Vehicle equipped with VSC controller 18 Path 1 Path 2 Path 3 Path 4

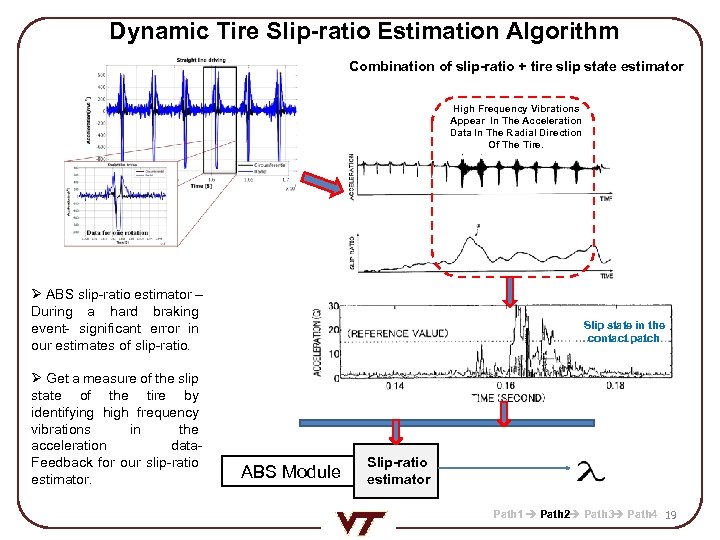

Dynamic Tire Slip-ratio Estimation Algorithm Combination of slip-ratio + tire slip state estimator High Frequency Vibrations Appear In The Acceleration Data In The Radial Direction Of The Tire. Ø ABS slip-ratio estimator – During a hard braking event- significant error in our estimates of slip-ratio. Ø Get a measure of the slip state of the tire by identifying high frequency vibrations in the acceleration data. Feedback for our slip-ratio estimator. Slip state in the contact patch ABS Module Slip-ratio estimator Path 1 Path 2 Path 3 Path 4 19

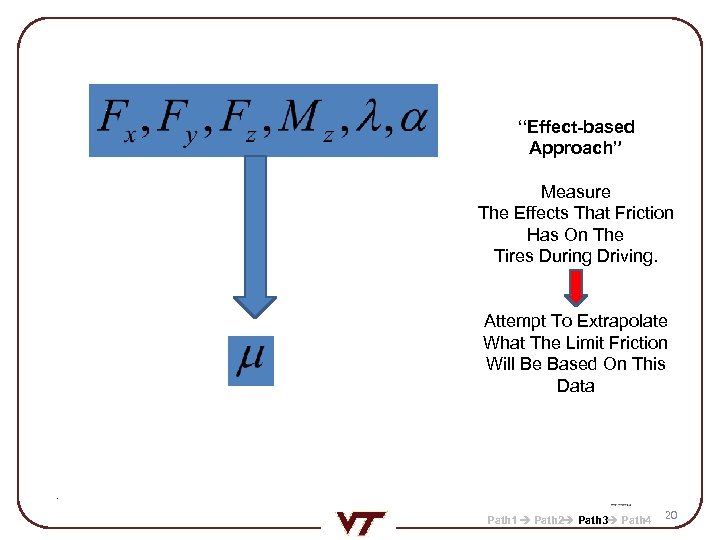

Dynamic Tire Force Estimation Self Aligning Torque Observer Vehicle CAN Bus Input steering wheel angle S E N S O Observer R Low Frequency F U S I O N High Frequency (reliable) ‘‘Effect-based Approach” Measure The Effects That Friction Observer Performance Has On The Tires During Driving. Vehicle & Tire Model Attempt To Extrapolate What The Limit Friction Will Be Based On This Data v Electric power steering (EPS) is becoming common in modern day cars. . Intelligent Tire v. Linear disturbance observer enables us to extract self aligning torque from steering torque measurements. Path 1 Path 2 Path 3 Path 4 20

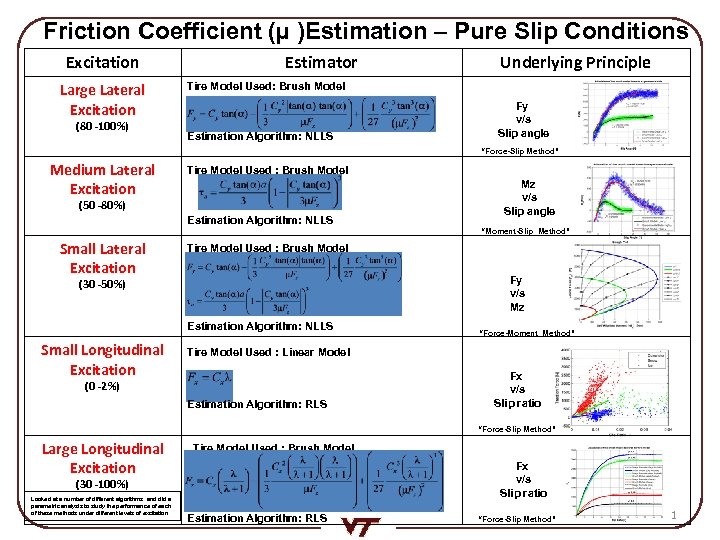

Friction Coefficient (µ )Estimation – Pure Slip Conditions Excitation Large Lateral Excitation (80 -100%) Estimator Underlying Principle Tire Model Used: Brush Model Estimation Algorithm: NLLS Fy v/s Slip angle “Force-Slip Method” Medium Lateral Excitation Tire Model Used : Brush Model (50 -80%) Estimation Algorithm: NLLS Mz v/s Slip angle “Moment-Slip Method” Small Lateral Excitation Tire Model Used : Brush Model Fy v/s Mz (30 -50%) Estimation Algorithm: NLLS Small Longitudinal Excitation “Force-Moment Method” Tire Model Used : Linear Model (0 -2%) Estimation Algorithm: RLS Fx v/s Slip ratio “Force-Slip Method” Large Longitudinal Excitation Tire Model Used : Brush Model Fx v/s Slip ratio (30 -100%) Looked at a number of different algorithms and did a parametric analysis to study the performance of each of these methods under different levels of excitation Estimation Algorithm: RLS “Force-Slip Method” 21

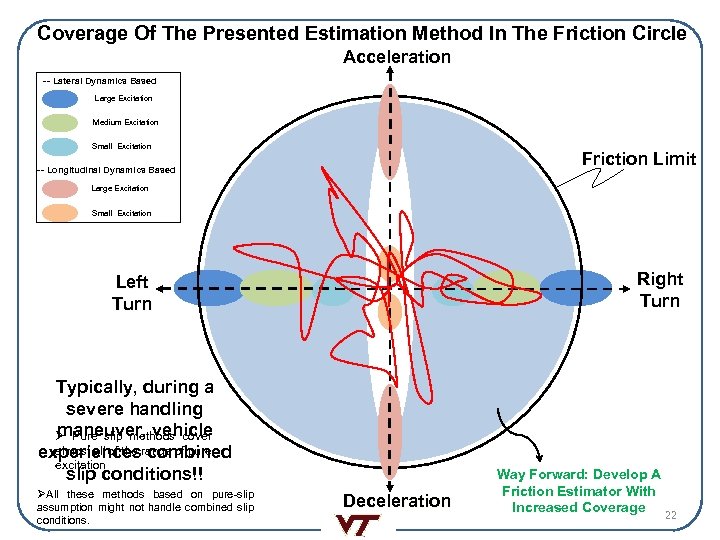

Coverage Of The Presented Estimation Method In The Friction Circle Acceleration -- Lateral Dynamics Based Large Excitation Medium Excitation Small Excitation Friction Limit -- Longitudinal Dynamics Based Large Excitation Small Excitation Right Turn Left Turn Typically, during a severe handling maneuver, vehicle Ø Pure slip methods cover almost all of the combined experiencesrange of pure excitation slip conditions!! ØAll these methods based on pure-slip assumption might not handle combined slip conditions. Deceleration Way Forward: Develop A Friction Estimator With Increased Coverage 22

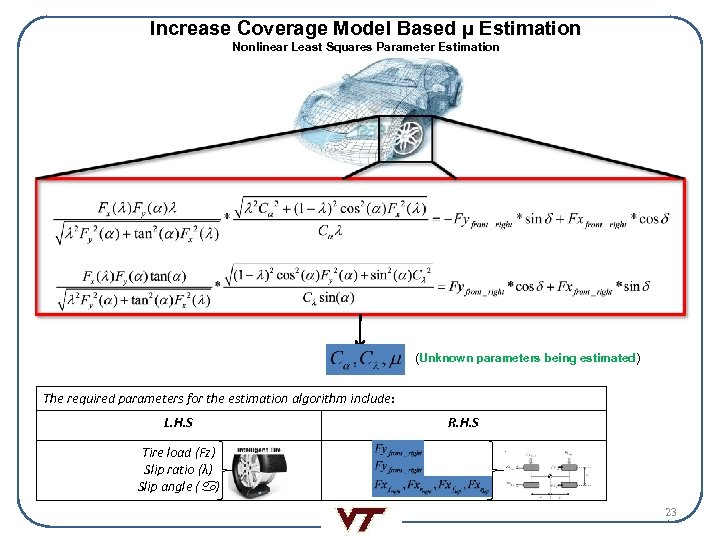

Increase Coverage Model Based µ Estimation Nonlinear Least Squares Parameter Estimation (Unknown parameters being estimated) The required parameters for the estimation algorithm include: L. H. S R. H. S Tire load (Fz) Slip ratio (λ) Slip angle ( ) 23

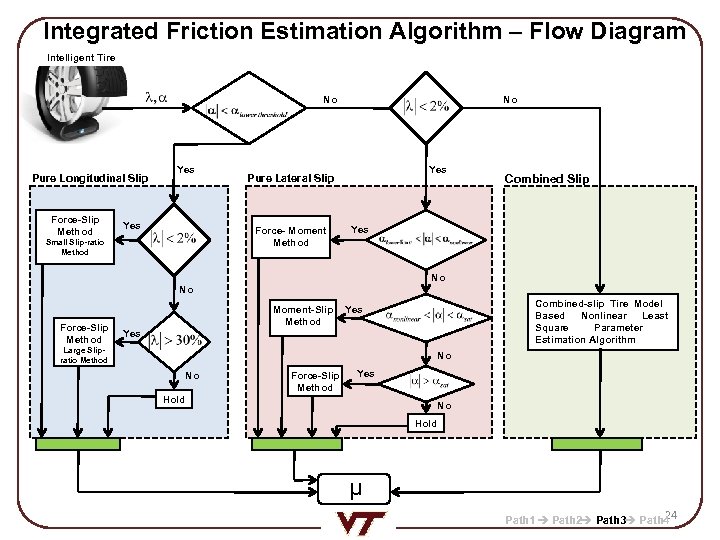

Integrated Friction Estimation Algorithm – Flow Diagram Intelligent Tire No Pure Longitudinal Slip Force-Slip Method Yes Yes Pure Lateral Slip Force- Moment Method Small Slip-ratio Method No Combined Slip Yes No No Force-Slip Method Moment-Slip Method Combined-slip Tire Model Based Nonlinear Least Square Parameter Estimation Algorithm Yes Large Slipratio Method No No Force-Slip Method Yes Hold No Hold µ 24 Path 1 Path 2 Path 3 Path 4

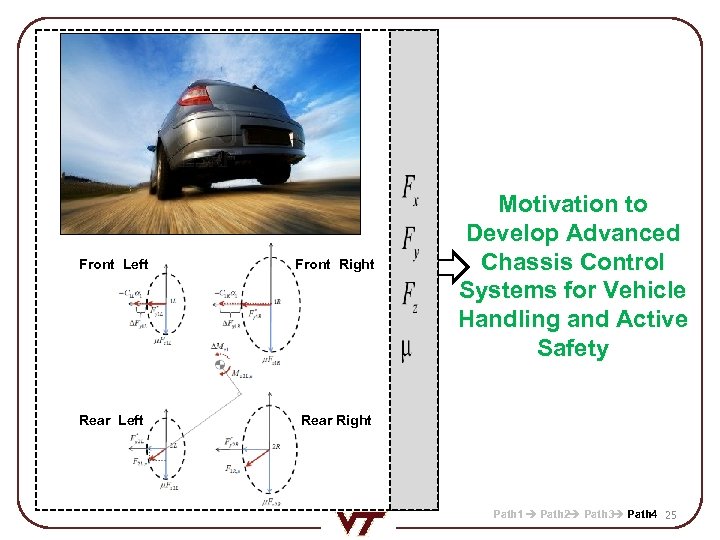

Front Left Front Right Rear Left Motivation to Develop Advanced Chassis Control Systems for Vehicle Handling and Active Safety Rear Right Path 1 Path 2 Path 3 Path 4 25

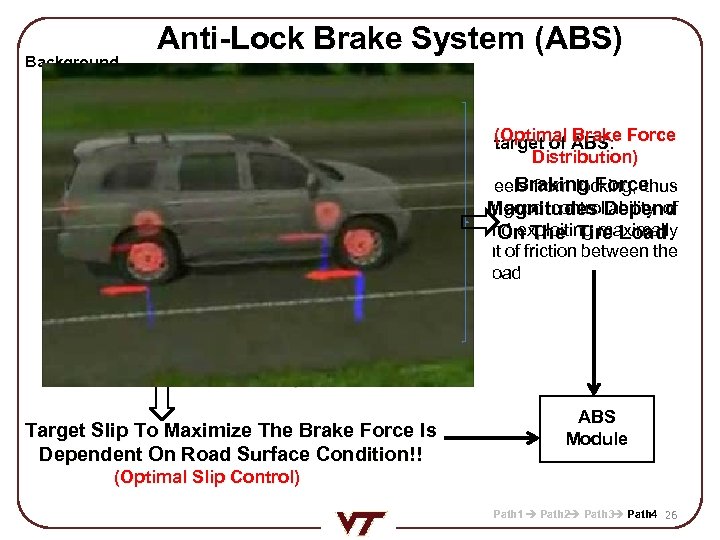

Background Anti-Lock Brake System (ABS) (Optimal Brake The control target of ABS: Force Distribution) Braking Force Keep the wheels from locking, thus guaranteeing good controllability of Magnitudes Depend the vehicle and exploiting maximally On The Tire Load the coefficient of friction between the tire and the road Target Slip To Maximize The Brake Force Is Dependent On Road Surface Condition!! ABS Module (Optimal Slip Control) Path 1 Path 2 Path 3 Path 4 26

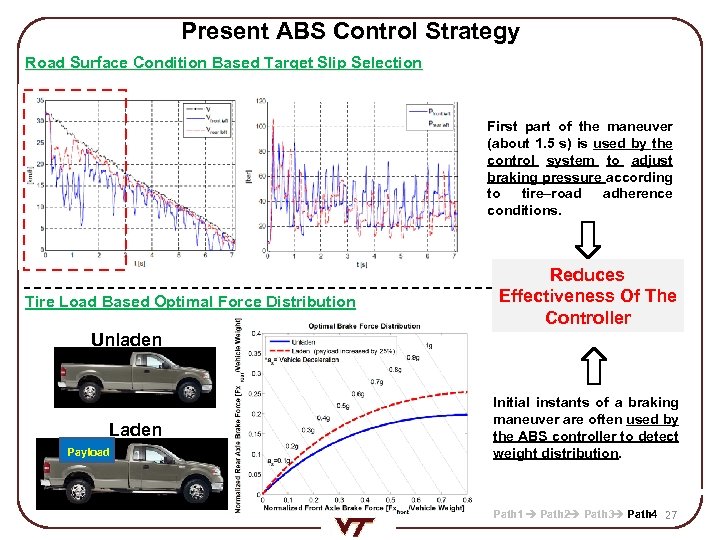

Present ABS Control Strategy Road Surface Condition Based Target Slip Selection First part of the maneuver (about 1. 5 s) is used by the control system to adjust braking pressure according to tire–road adherence conditions. v Tire Load Based Optimal Force Distribution Reduces Effectiveness Of The Controller Unladen v Laden Payload Initial instants of a braking maneuver are often used by the ABS controller to detect weight distribution. Path 1 Path 2 Path 3 Path 4 27

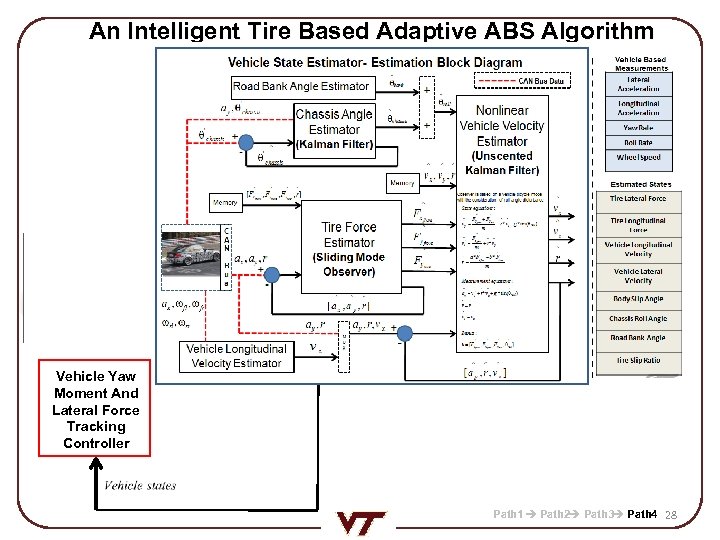

An Intelligent Tire Based Adaptive ABS Algorithm Brake Command Driver ABS Module Fuzzy/Sliding mode/Proportional Integral (Fuzzy-SMC-PI (FSP)) control + Intelligent Tire Emulator Optimal Slip Selector Brake Preconditioning Module Vehicle Yaw Moment And Lateral Force Tracking Controller Optimal Force Distribution Algorithm DYC Braking Command AFS Command A F S M O D U L E Path 1 Path 2 Path 3 Path 4 28

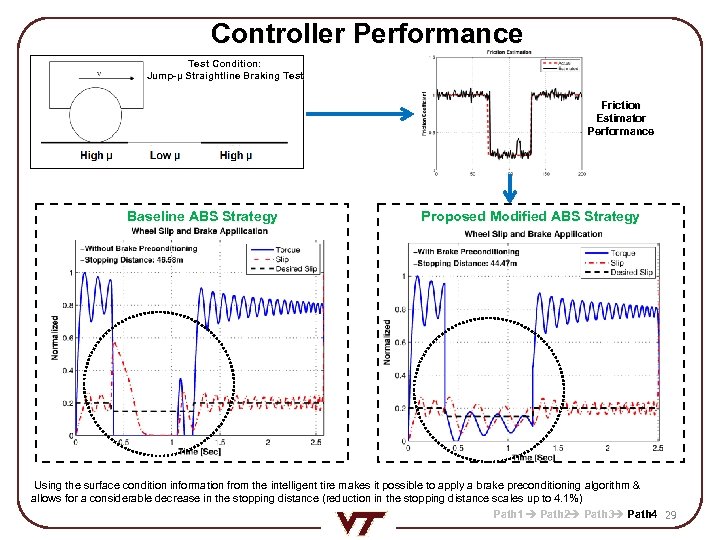

Controller Performance Test Condition: Jump-μ Straightline Braking Test Jump-μ Friction Estimator Performance Baseline ABS Strategy Proposed Modified ABS Strategy Using the surface condition information from the intelligent tire makes it possible to apply a brake preconditioning algorithm & allows for a considerable decrease in the stopping distance (reduction in the stopping distance scales up to 4. 1%) Path 1 Path 2 Path 3 Path 4 29

Conclusion Ø This work focuses on the possibility of enhancing the performance of the ABS (Antilock Braking System)/EBD (electronic braking distribution) control system by using the additional information provided by intelligent tires. ØWe expect the intelligent tire system to stimulate the development of a new generation of traction, braking and stability control systems for improving vehicle safety and performances. Ø Major challenge: Meeting the power supply needs of all the electronic components of an intelligent tire system. Future Work Ø Validate controller performance via hardware-in-the-loop (HIL) simulations. HIL Setup, Intelligent Transportation Laboratory Virginia Tech 30

Thank You… Questions? 31

d9208935ef4c6be3394091abf3292bd9.ppt