3679ed53a1dc549ecd8b2189bce4e200.ppt

- Количество слайдов: 31

An Overview of Building Fire and Smoke Control Systems Design and Commissioning presented to Arkansas ASHRAE – ASHRAE Chapter 62 by Steve Williams, P. E. | Brian Olsen, P. E.

Introduction - General Over 35 years of design experience Support staff of 350 Local Office Wide variety of project types #1 Retail firm in U. S. (based on number of projects and square footage Retail Construction Magazine-2006) Specialty division of Henderson Engineers, Inc. Staff of 30 fire protection professionals Nationwide exposure Significant fire alarm, suppression and code consulting experience HEI - Lowell HEI – Kansas City

Introduction – Presentation Overview – Overview of Smoke Control • Engineered Smoke Control Systems • Stairwell Pressurization • Atrium Smoke Evacuation – Lobbies – Malls • Health Care – Anesthetizing Locations

Introduction – What is Smoke Control – Passive vs. Active • Passive – ‘Smoke Resistant Construction’ – Smoke Barriers – 20 minute rated openings • Active – Pressurization Systems » High-rise of old » Healthcare – Atrium Smoke Exhaust » Makeup Air – Stair Towers » Exhaust » Makeup Air

Introduction – Why Smoke Control – – – Inhalation injury from smoke and the noxious products of combustion in fires may account for as many as 75% of fire-related deaths in the U. S. Key concept - minimize vertical smoke migration. Passive smoke control is known for poor maintenance. Unsealed penetrations, terminations, etc. Basic concept of Smoke Control is to allow occupants to reach a protected means of egress Fire Department Operations Tool (arguable purpose but fire departments will use it this way – fire fighters control panel) Architectural Design Flexibility Atlanta Marriot 47 Story Fire Example

Introduction – Smoke Development

Part 1 Codes – Applicable Codes/Guidelines – – – – 2003 International Building Code (IBC), Section 909 NFPA 101 – Life Safety Code NFPA 92 A – Recommended Practice for Smoke Control Systems NFPA 92 B – Guide for Smoke Management in Malls, Atria, and Large Areas ASHRAE 1999 HVAC Applications, Chapter 51 ASHRAE Principals of Smoke Management Handbook Authority Having Jurisdiction (AHJ) • • Building Inspector Fire Marshall-State and Local

Part 1 Codes – Where Required – – – – Atriums (IBC 404. 4) Enclosed Malls meeting Atrium definition (IBC 402. 9) High-rise Windowless Buildings – Prisons (IBC 408. 8) Smoke Protected Seating (IBC 1024. 6. 2. 1) Healthcare Stair Towers (IBC 1019. 1. 8) • 75 ft above fire department access

Part 1 Codes – Where Required – Atriums (2003 IBC 404. 1. 1/404. 4) • • – “Atrium. An opening connecting two or more stories other than enclosed stairways… [ lists all shaft scenarios]…, which is closed at the top and not defined as mall…” “ 404. 4 Smoke Control. A smoke control system shall be installed in accordance with section 909. ” Stair Towers (2003 IBC 1019. 1. 8) • “ 1019. 1. 8 Smokeproof enclosures. … each of the exits of a building that serves stories where the floor surface is located more than 75 -feet above the lowest level of fire department access or 30 -feet below the level of exit discharge … shall be a smoke proof enclosure or pressurized stairway. ”

Part 1 Codes – Smoke Control Methods – IBC 909 does not specify a specific type of smoke control system. Options include: • Pressurization – • Airflow – • . 05 -inches water gauge across smoke barriers Air Curtain Exhaust – Atriums

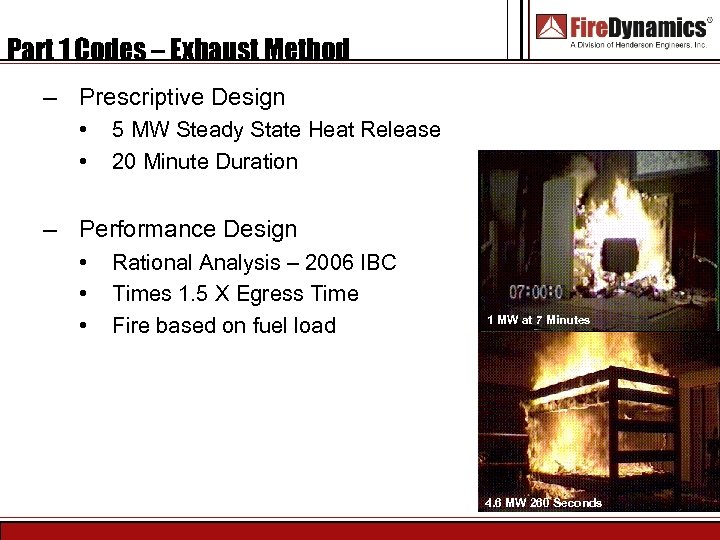

Part 1 Codes – Exhaust Method – Prescriptive Design • • 5 MW Steady State Heat Release 20 Minute Duration – Performance Design • • • Rational Analysis – 2006 IBC Times 1. 5 X Egress Time Fire based on fuel load 1 MW at 7 Minutes 4. 6 MW 260 Seconds

Part 1 Codes – Exhaust Method – Prescriptive Design • 5 MW Steady State Heat Release (IBC 909. 9) – Rather large for some scenarios • 20 Minute Duration (IBC 909. 4. 6) – 20 minute smoke barrier opening protection • Tenability (IBC 909. 8. 1) – 10 -feet smoke interface 2003 IBC – 6 -feet smoke interface 2006 IBC • Exhaust Capacity – Axisymmetric Plume (IBC 909. 8. 2) – Balcony Spill Plume (IBC 909. 8. 3) » In calculations air density must be adjusted for elevation and smoke temperature. See ASHRAE Principals of Smoke Management Handbook

Part I Codes – Exhaust Method Air Movement – Exhaust • • • Stratification Stack Effect Plugholling – Makeup Air • • • Natural or Mechanical 85% total exhaust is rule of thumb 200 fpm maximum velocity towards fire – Distortion of smoke plume • Introduce Below Smoke Layer

Part 1 Codes – Equipment Criteria – UL Listings • • – Fans Smoke Dampers Fire Alarm Control Panel BAS Fire Fighters Smoke Control Panel – – Equipment Temperature Ratings • – Fire Command Center? IBC 909. 10. 1 Initiation as required by Rational Analysis • • • Sprinklers Manual Pull Stations Properly Zoned Sprinkler Waterflow Detection

Part 2 Design – Smoke Control Design Team – – Specialty Engineered System Multidiscipline Effort • • • Architect MEF Authority Having Jurisdiction (AHJ)

Part 2 Design – Architectural Component – – Smoke Control Objective Aesthetics Automatic Door Hardware Owner/Team Communication – Alternatives

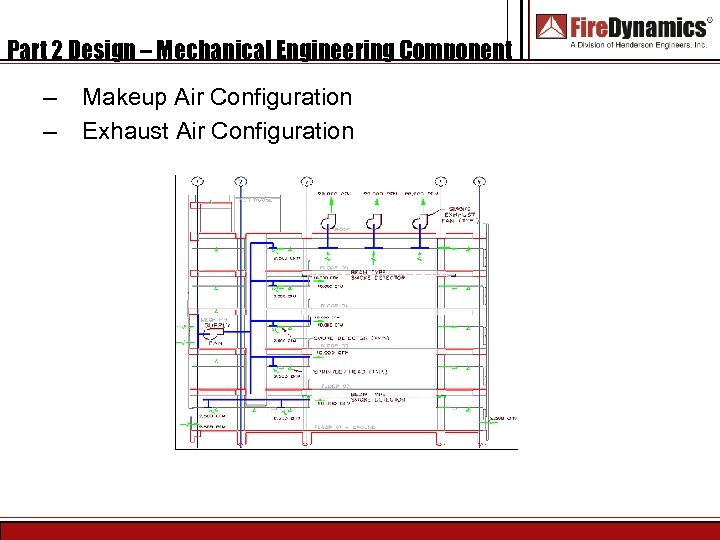

Part 2 Design – Mechanical Engineering Component – – Makeup Air Configuration Exhaust Air Configuration

Part 2 Design – Mechanical Engineering Component – Fan Specification (IBC 909. 10. 5) • • • – Duct Specifications (IBC 909. 10. 2) • • – Omit where air path is instrumental to system operation Fire Damper Approach • – Withstand fire pressures and temperatures Field Tested to 1. 5 X maximum design pressure Smoke Damper Approach • – 1. 5 X Belts Required for Design Duty Minimum 2 Belts Fan Temperature Ratings Higher Temperature Heat Links BAS • Positive Indication of Fan Status

Part 2 Design – Electrical Engineering Component – – Primary Power Secondary Power • • • Dedicated Fire Resistant ATS/Secondary Power Room 60 Second Transfer Time (IBC 909. 11) 15 minute duration UPS for volatile memory BAS (IBC 909. 11. 1).

Part 2 Design – Fire Protection Engineering Component – Design Approach/Rational Analysis • • • Design Fire Stack Effect/Hot Air Stratification Temperature/Wind Effect HVAC System Considerations Plugholling Duration of Operation (Egress Calculations)

Part 2 Design – Fire Protection Engineering Component – Automatic Sprinkler System • Zone Coordination – Fire Alarm and Detection System – Firefighters Smoke Control Panel – Special Inspections

Part 2 Design – Authority Having Jurisdiction Component – Interpretations – Design Approval – Acceptance Criteria

Part 3 Commissioning – General – Why Commission • • – Commissioning Concerns • • – Prove System Functionality Develop Benchmark for Future Testing Outside Normal Services Educate Architects/Contractors/Owners Early Commissioning Team • • Owner Engineers AHJ Air Balance and Test Group

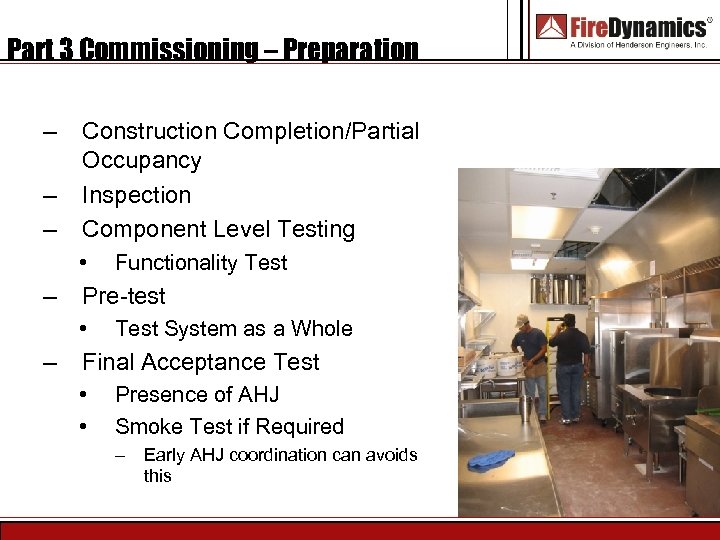

Part 3 Commissioning – Preparation – – – Construction Completion/Partial Occupancy Inspection Component Level Testing • – Pre-test • – Functionality Test System as a Whole Final Acceptance Test • • Presence of AHJ Smoke Test if Required – Early AHJ coordination can avoids this

Part 3 Commissioning – Smoke Testing • • • Subjective - Smoke testing is extremely subjective although it will be required in many jurisdictions. NFPA 92 A discusses smoke testing in detail. NFPA 92 A (2002) Section A. 5. 3. 3. 6. speaks to the limited value of smoke testing. Hot/Cold Smoke Testing Limitations

Part 3 Commissioning – Smoke Testing (con’t) • Smoke Bombs – Superior Smoke » » • Smoke Volume Discharge Time Smoke Generators – Theatrical Units

Part 3 Commissioning – Air Balance Test Reports – Air Balance Contractor • Clear Scope – Exhaust Fans – Makeup Air Inlets • Capability to Adjust Equipment

Part 3 Commissioning – Initiation – Fire Alarm • • • Smoke Detection Manual Alarms Waterflow

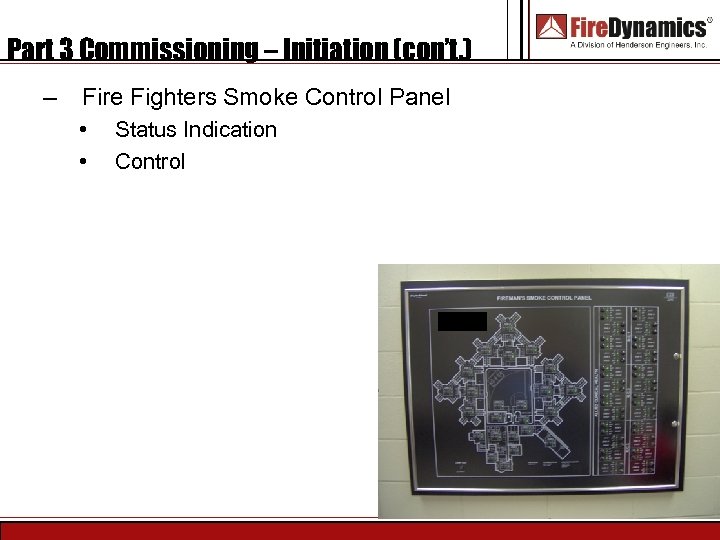

Part 3 Commissioning – Initiation (con’t. ) – Fire Fighters Smoke Control Panel • • Status Indication Control

Part 3 Commissioning – Secondary Power • • Fans Controls – Reboot

Questions? Thank you.

3679ed53a1dc549ecd8b2189bce4e200.ppt