ccbe1eecaed892cde606f5641c16ce34.ppt

- Количество слайдов: 40

An Introduction to Uhde Oil & Gas Thyssen. Krupp Uhde - Engineering with Ideas.

An Introduction to Uhde Oil & Gas Thyssen. Krupp Uhde - Engineering with Ideas.

Agenda: ¡ Welcome and Introduction ¡ Corporate Overview ¡ Uhde Oil and Gas Business Line ¡ Uhde Group Resources ¡ Technology ¡ Downstream Capability ¡ Upstream Capability ¡ Key Clients

Agenda: ¡ Welcome and Introduction ¡ Corporate Overview ¡ Uhde Oil and Gas Business Line ¡ Uhde Group Resources ¡ Technology ¡ Downstream Capability ¡ Upstream Capability ¡ Key Clients

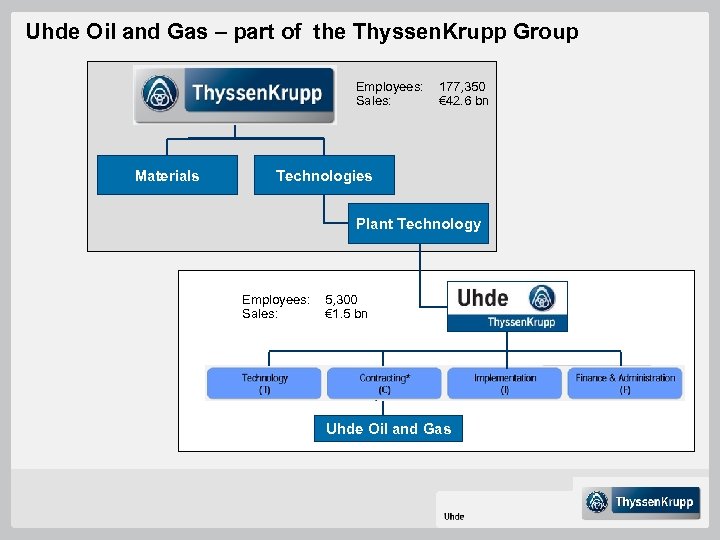

Uhde Oil and Gas – part of the Thyssen. Krupp Group Employees: Sales: Materials 177, 350 € 42. 6 bn Technologies Plant Technology Employees: Sales: 5, 300 € 1. 5 bn Uhde Oil and Gas

Uhde Oil and Gas – part of the Thyssen. Krupp Group Employees: Sales: Materials 177, 350 € 42. 6 bn Technologies Plant Technology Employees: Sales: 5, 300 € 1. 5 bn Uhde Oil and Gas

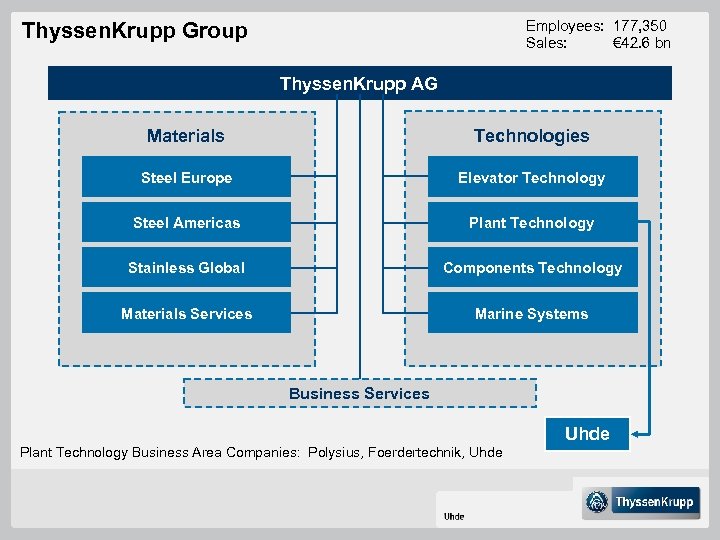

Thyssen. Krupp Group Employees: 177, 350 Sales: € 42. 6 bn Thyssen. Krupp AG Materials Technologies Steel Europe Elevator Technology Steel Americas Plant Technology Stainless Global Components Technology Materials Services Marine Systems Business Services Uhde Plant Technology Business Area Companies: Polysius, Foerdertechnik, Uhde

Thyssen. Krupp Group Employees: 177, 350 Sales: € 42. 6 bn Thyssen. Krupp AG Materials Technologies Steel Europe Elevator Technology Steel Americas Plant Technology Stainless Global Components Technology Materials Services Marine Systems Business Services Uhde Plant Technology Business Area Companies: Polysius, Foerdertechnik, Uhde

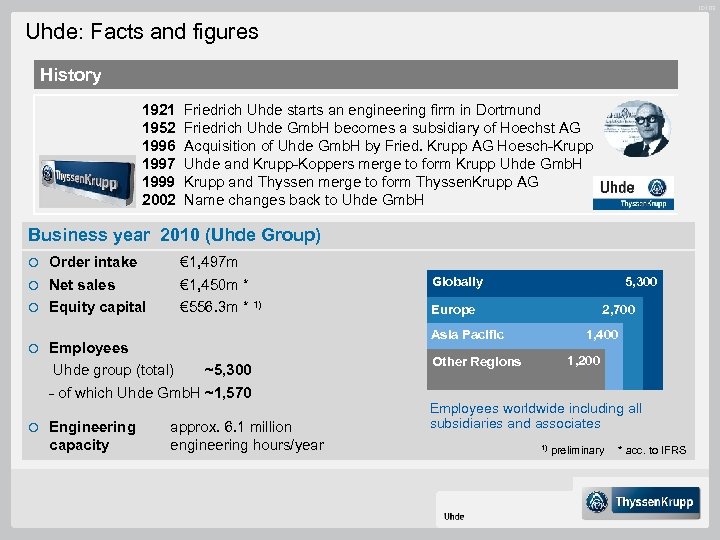

ID 103 Uhde: Facts and figures History 1921 1952 1996 1997 1999 2002 Friedrich Uhde starts an engineering firm in Dortmund Friedrich Uhde Gmb. H becomes a subsidiary of Hoechst AG Acquisition of Uhde Gmb. H by Fried. Krupp AG Hoesch-Krupp Uhde and Krupp-Koppers merge to form Krupp Uhde Gmb. H Krupp and Thyssen merge to form Thyssen. Krupp AG Name changes back to Uhde Gmb. H Business year 2010 (Uhde Group) Order intake ¡ Net sales ¡ Equity capital ¡ ¡ ¡ € 1, 497 m € 1, 450 m * € 556. 3 m * 1) Employees Uhde group (total) ~5, 300 - of which Uhde Gmb. H ~1, 570 Engineering capacity approx. 6. 1 million engineering hours/year 5, 300 Globally Europe Asia Pacific Other Regions 2, 700 1, 400 1, 200 Employees worldwide including all subsidiaries and associates 1) preliminary * acc. to IFRS

ID 103 Uhde: Facts and figures History 1921 1952 1996 1997 1999 2002 Friedrich Uhde starts an engineering firm in Dortmund Friedrich Uhde Gmb. H becomes a subsidiary of Hoechst AG Acquisition of Uhde Gmb. H by Fried. Krupp AG Hoesch-Krupp Uhde and Krupp-Koppers merge to form Krupp Uhde Gmb. H Krupp and Thyssen merge to form Thyssen. Krupp AG Name changes back to Uhde Gmb. H Business year 2010 (Uhde Group) Order intake ¡ Net sales ¡ Equity capital ¡ ¡ ¡ € 1, 497 m € 1, 450 m * € 556. 3 m * 1) Employees Uhde group (total) ~5, 300 - of which Uhde Gmb. H ~1, 570 Engineering capacity approx. 6. 1 million engineering hours/year 5, 300 Globally Europe Asia Pacific Other Regions 2, 700 1, 400 1, 200 Employees worldwide including all subsidiaries and associates 1) preliminary * acc. to IFRS

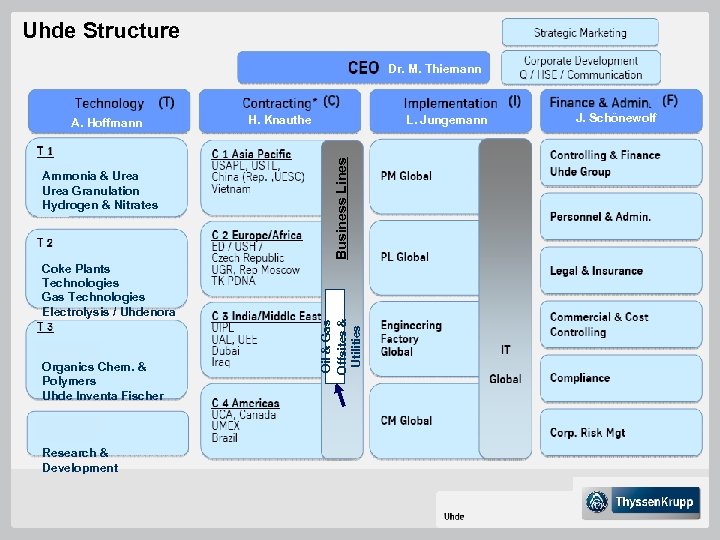

Structure Uhde Group Organisation L. Jungemann A. Hoffmann Ammonia & Urea Granulation Hydrogen & Nitrates Coke Plants Technologies Gas Technologies Electrolysis / Uhdenora Organics Chem. & Polymers Uhde Inventa Fischer Research & Development A. Hoffmann H. Knauthe Dr. M. Thiemann L. Jungemann Business Lines Business Segments and Product Divisions Dr. M. Thiemann (Chairman) Oil & Gas Offsites & Utilities Executive Board J. Schönewolf

Structure Uhde Group Organisation L. Jungemann A. Hoffmann Ammonia & Urea Granulation Hydrogen & Nitrates Coke Plants Technologies Gas Technologies Electrolysis / Uhdenora Organics Chem. & Polymers Uhde Inventa Fischer Research & Development A. Hoffmann H. Knauthe Dr. M. Thiemann L. Jungemann Business Lines Business Segments and Product Divisions Dr. M. Thiemann (Chairman) Oil & Gas Offsites & Utilities Executive Board J. Schönewolf

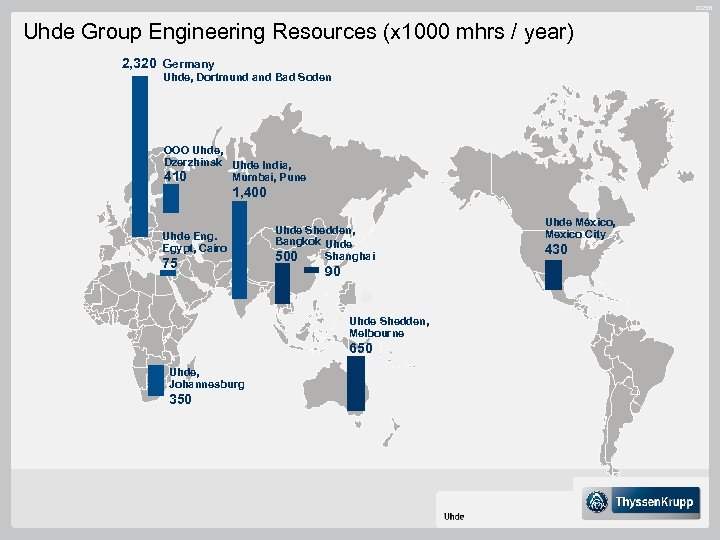

ID 258 Uhde Group Engineering Resources (x 1000 mhrs / year) 2, 320 Germany Uhde, Dortmund and Bad Soden OOO Uhde, Dzerzhinsk Uhde India, Mumbai, Pune 410 1, 400 Uhde Eng. Egypt, Cairo 75 Uhde Shedden, Bangkok Uhde Shanghai 500 90 Uhde Shedden, Melbourne 650 Uhde, Johannesburg 350 Uhde México, Mexico City 430

ID 258 Uhde Group Engineering Resources (x 1000 mhrs / year) 2, 320 Germany Uhde, Dortmund and Bad Soden OOO Uhde, Dzerzhinsk Uhde India, Mumbai, Pune 410 1, 400 Uhde Eng. Egypt, Cairo 75 Uhde Shedden, Bangkok Uhde Shanghai 500 90 Uhde Shedden, Melbourne 650 Uhde, Johannesburg 350 Uhde México, Mexico City 430

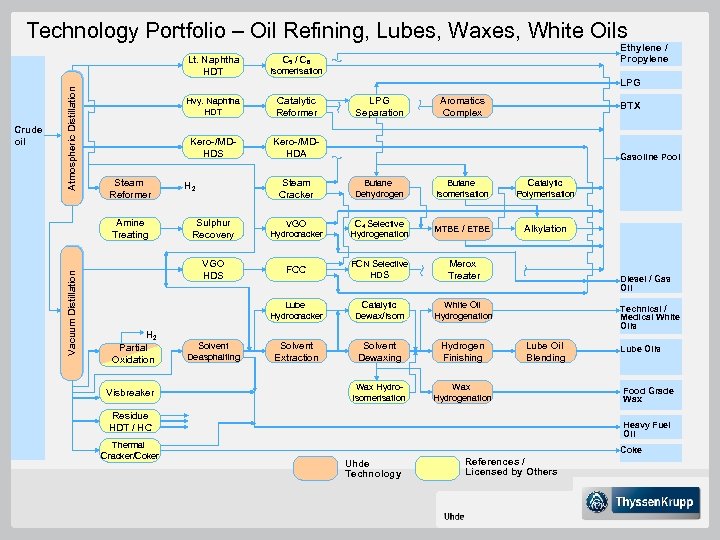

Technology Portfolio – Oil Refining, Lubes, Waxes, White Oils Kero-/MDHDS Steam Reformer Catalytic Reformer Ethylene / Propylene C 5 / C 6 Isomerisation Hvy. Naphtha HDT Kero-/MDHDA LPG Separation Aromatics Complex BTX Gasoline Pool Visbreaker Butane Dehydrogen Butane Isomerisation Catalytic Polymerisation Sulphur Recovery VGO Hydrocracker C 4 Selective Hydrogenation MTBE / ETBE Alkylation FCC FCN Selective HDS Merox Treater Lube Hydrocracker H 2 Partial Oxidation Steam Cracker VGO HDS Amine Treating Vacuum Distillation Crude oil Atmospheric Distillation Lt. Naphtha HDT Catalytic Dewax/Isom White Oil Hydrogenation Solvent Extraction Solvent Dewaxing Hydrogen Finishing Wax Hydroisomerisation Wax Hydrogenation H 2 Solvent Deasphalting Diesel / Gas Oil Technical / Medical White Oils Lube Oil Blending Residue HDT / HC Thermal Cracker/Coker Lube Oils Food Grade Wax Heavy Fuel Oil Coke Uhde Technology References / Licensed by Others

Technology Portfolio – Oil Refining, Lubes, Waxes, White Oils Kero-/MDHDS Steam Reformer Catalytic Reformer Ethylene / Propylene C 5 / C 6 Isomerisation Hvy. Naphtha HDT Kero-/MDHDA LPG Separation Aromatics Complex BTX Gasoline Pool Visbreaker Butane Dehydrogen Butane Isomerisation Catalytic Polymerisation Sulphur Recovery VGO Hydrocracker C 4 Selective Hydrogenation MTBE / ETBE Alkylation FCC FCN Selective HDS Merox Treater Lube Hydrocracker H 2 Partial Oxidation Steam Cracker VGO HDS Amine Treating Vacuum Distillation Crude oil Atmospheric Distillation Lt. Naphtha HDT Catalytic Dewax/Isom White Oil Hydrogenation Solvent Extraction Solvent Dewaxing Hydrogen Finishing Wax Hydroisomerisation Wax Hydrogenation H 2 Solvent Deasphalting Diesel / Gas Oil Technical / Medical White Oils Lube Oil Blending Residue HDT / HC Thermal Cracker/Coker Lube Oils Food Grade Wax Heavy Fuel Oil Coke Uhde Technology References / Licensed by Others

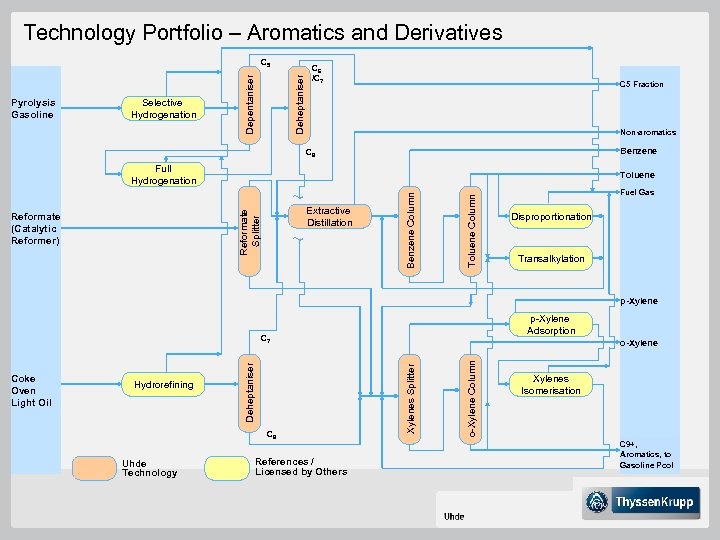

Technology Portfolio – Aromatics and Derivatives Selective Hydrogenation Depentaniser Pyrolysis Gasoline Deheptaniser C 5 C 6 /C 7 C 5 Fraction Non-aromatics Benzene C 8 Full Hydrogenation Toluene Column Extractive Distillation Reformate Splitter Reformate (Catalytic Reformer) Benzene Column Toluene Fuel Gas Disproportionation Transalkylation p-Xylene Adsorption C 8 Uhde Technology References / Licensed by Others o-Xylene Column Hydrorefining o-Xylenes Splitter Coke Oven Light Oil Deheptaniser C 7 Xylenes Isomerisation C 9+, Aromatics, to Gasoline Pool

Technology Portfolio – Aromatics and Derivatives Selective Hydrogenation Depentaniser Pyrolysis Gasoline Deheptaniser C 5 C 6 /C 7 C 5 Fraction Non-aromatics Benzene C 8 Full Hydrogenation Toluene Column Extractive Distillation Reformate Splitter Reformate (Catalytic Reformer) Benzene Column Toluene Fuel Gas Disproportionation Transalkylation p-Xylene Adsorption C 8 Uhde Technology References / Licensed by Others o-Xylene Column Hydrorefining o-Xylenes Splitter Coke Oven Light Oil Deheptaniser C 7 Xylenes Isomerisation C 9+, Aromatics, to Gasoline Pool

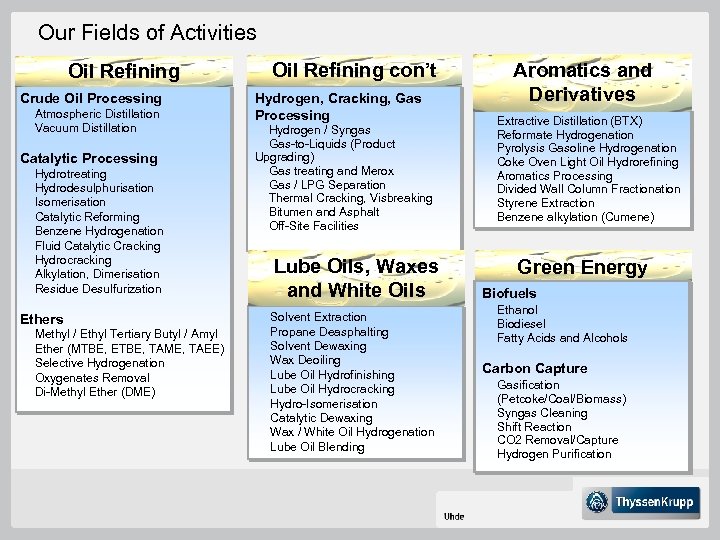

Our Fields of Activities Oil Refining Crude Oil Processing Atmospheric Distillation Vacuum Distillation Catalytic Processing Hydrotreating Hydrodesulphurisation Isomerisation Catalytic Reforming Benzene Hydrogenation Fluid Catalytic Cracking Hydrocracking Alkylation, Dimerisation Residue Desulfurization Ethers Methyl / Ethyl Tertiary Butyl / Amyl Ether (MTBE, ETBE, TAME, TAEE) Selective Hydrogenation Oxygenates Removal Di-Methyl Ether (DME) Oil Refining con’t Hydrogen, Cracking, Gas Processing Hydrogen / Syngas Gas-to-Liquids (Product Upgrading) Gas treating and Merox Gas / LPG Separation Thermal Cracking, Visbreaking Bitumen and Asphalt Off-Site Facilities Lube Oils, Waxes and White Oils Solvent Extraction Propane Deasphalting Solvent Dewaxing Wax Deoiling Lube Oil Hydrofinishing Lube Oil Hydrocracking Hydro-Isomerisation Catalytic Dewaxing Wax / White Oil Hydrogenation Lube Oil Blending Aromatics and Derivatives Extractive Distillation (BTX) Reformate Hydrogenation Pyrolysis Gasoline Hydrogenation Coke Oven Light Oil Hydrorefining Aromatics Processing Divided Wall Column Fractionation Styrene Extraction Benzene alkylation (Cumene) Green Energy Biofuels Ethanol Biodiesel Fatty Acids and Alcohols Carbon Capture Gasification (Petcoke/Coal/Biomass) Syngas Cleaning Shift Reaction CO 2 Removal/Capture Hydrogen Purification

Our Fields of Activities Oil Refining Crude Oil Processing Atmospheric Distillation Vacuum Distillation Catalytic Processing Hydrotreating Hydrodesulphurisation Isomerisation Catalytic Reforming Benzene Hydrogenation Fluid Catalytic Cracking Hydrocracking Alkylation, Dimerisation Residue Desulfurization Ethers Methyl / Ethyl Tertiary Butyl / Amyl Ether (MTBE, ETBE, TAME, TAEE) Selective Hydrogenation Oxygenates Removal Di-Methyl Ether (DME) Oil Refining con’t Hydrogen, Cracking, Gas Processing Hydrogen / Syngas Gas-to-Liquids (Product Upgrading) Gas treating and Merox Gas / LPG Separation Thermal Cracking, Visbreaking Bitumen and Asphalt Off-Site Facilities Lube Oils, Waxes and White Oils Solvent Extraction Propane Deasphalting Solvent Dewaxing Wax Deoiling Lube Oil Hydrofinishing Lube Oil Hydrocracking Hydro-Isomerisation Catalytic Dewaxing Wax / White Oil Hydrogenation Lube Oil Blending Aromatics and Derivatives Extractive Distillation (BTX) Reformate Hydrogenation Pyrolysis Gasoline Hydrogenation Coke Oven Light Oil Hydrorefining Aromatics Processing Divided Wall Column Fractionation Styrene Extraction Benzene alkylation (Cumene) Green Energy Biofuels Ethanol Biodiesel Fatty Acids and Alcohols Carbon Capture Gasification (Petcoke/Coal/Biomass) Syngas Cleaning Shift Reaction CO 2 Removal/Capture Hydrogen Purification

Uhde Refining Group - Technology Partners

Uhde Refining Group - Technology Partners

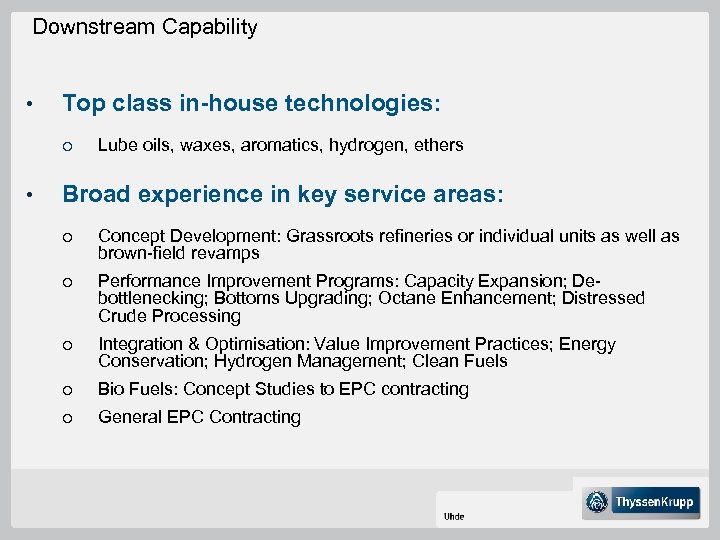

Downstream Capability • Top class in-house technologies: ¡ • Lube oils, waxes, aromatics, hydrogen, ethers Broad experience in key service areas: ¡ Concept Development: Grassroots refineries or individual units as well as brown-field revamps ¡ Performance Improvement Programs: Capacity Expansion; Debottlenecking; Bottoms Upgrading; Octane Enhancement; Distressed Crude Processing ¡ Integration & Optimisation: Value Improvement Practices; Energy Conservation; Hydrogen Management; Clean Fuels ¡ Bio Fuels: Concept Studies to EPC contracting ¡ General EPC Contracting

Downstream Capability • Top class in-house technologies: ¡ • Lube oils, waxes, aromatics, hydrogen, ethers Broad experience in key service areas: ¡ Concept Development: Grassroots refineries or individual units as well as brown-field revamps ¡ Performance Improvement Programs: Capacity Expansion; Debottlenecking; Bottoms Upgrading; Octane Enhancement; Distressed Crude Processing ¡ Integration & Optimisation: Value Improvement Practices; Energy Conservation; Hydrogen Management; Clean Fuels ¡ Bio Fuels: Concept Studies to EPC contracting ¡ General EPC Contracting

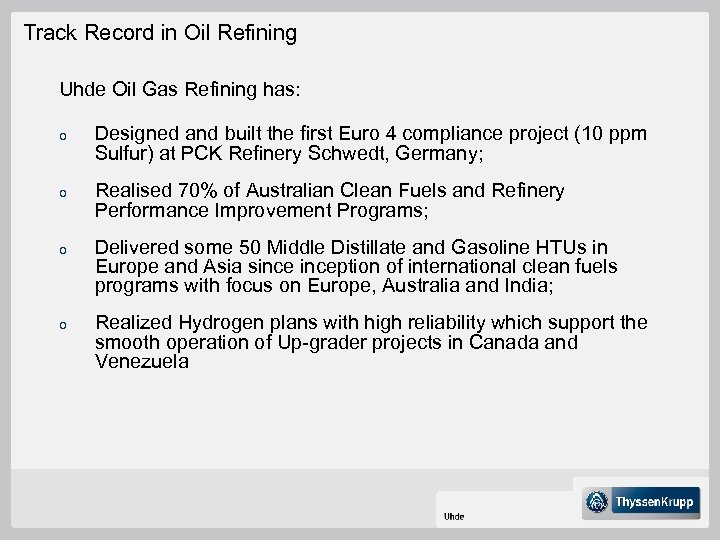

Track Record in Oil Refining Uhde Oil Gas Refining has: o Designed and built the first Euro 4 compliance project (10 ppm Sulfur) at PCK Refinery Schwedt, Germany; o Realised 70% of Australian Clean Fuels and Refinery Performance Improvement Programs; o Delivered some 50 Middle Distillate and Gasoline HTUs in Europe and Asia sinception of international clean fuels programs with focus on Europe, Australia and India; o Realized Hydrogen plans with high reliability which support the smooth operation of Up-grader projects in Canada and Venezuela

Track Record in Oil Refining Uhde Oil Gas Refining has: o Designed and built the first Euro 4 compliance project (10 ppm Sulfur) at PCK Refinery Schwedt, Germany; o Realised 70% of Australian Clean Fuels and Refinery Performance Improvement Programs; o Delivered some 50 Middle Distillate and Gasoline HTUs in Europe and Asia sinception of international clean fuels programs with focus on Europe, Australia and India; o Realized Hydrogen plans with high reliability which support the smooth operation of Up-grader projects in Canada and Venezuela

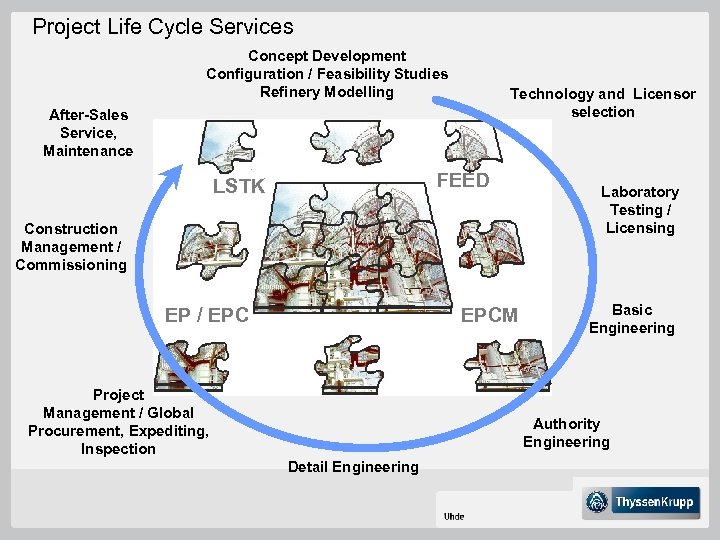

Project Life Cycle Services Concept Development Configuration / Feasibility Studies Refinery Modelling Technology and Licensor selection After-Sales Service, Maintenance FEED LSTK Construction Management / Commissioning EP / EPCM Project Management / Global Procurement, Expediting, Inspection Laboratory Testing / Licensing Basic Engineering Authority Engineering Detail Engineering

Project Life Cycle Services Concept Development Configuration / Feasibility Studies Refinery Modelling Technology and Licensor selection After-Sales Service, Maintenance FEED LSTK Construction Management / Commissioning EP / EPCM Project Management / Global Procurement, Expediting, Inspection Laboratory Testing / Licensing Basic Engineering Authority Engineering Detail Engineering

Uhde Global Refining – Selected Recent References • • Crude Oil Processing and Refining Clean Fuels Hydrogen Aromatics Lube Oil & Waxes Ethers Bio Fuels Revamps

Uhde Global Refining – Selected Recent References • • Crude Oil Processing and Refining Clean Fuels Hydrogen Aromatics Lube Oil & Waxes Ethers Bio Fuels Revamps

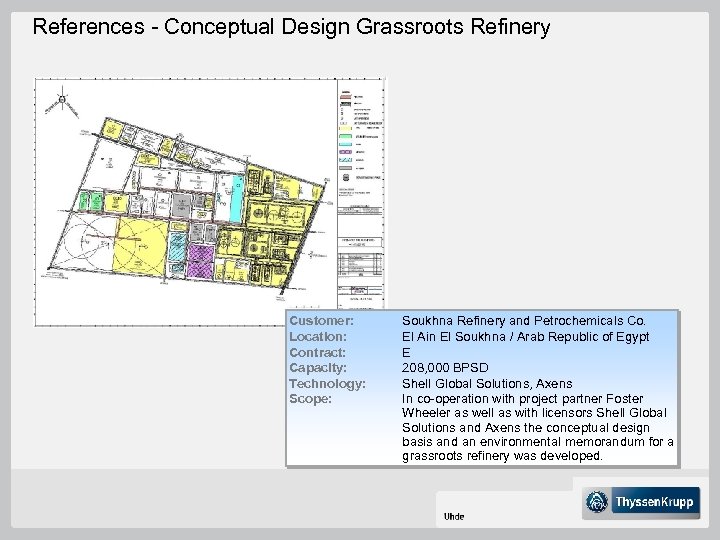

References - Conceptual Design Grassroots Refinery Customer: Location: Contract: Capacity: Technology: Scope: Soukhna Refinery and Petrochemicals Co. El Ain El Soukhna / Arab Republic of Egypt E 208, 000 BPSD Shell Global Solutions, Axens In co-operation with project partner Foster Wheeler as well as with licensors Shell Global Solutions and Axens the conceptual design basis and an environmental memorandum for a grassroots refinery was developed.

References - Conceptual Design Grassroots Refinery Customer: Location: Contract: Capacity: Technology: Scope: Soukhna Refinery and Petrochemicals Co. El Ain El Soukhna / Arab Republic of Egypt E 208, 000 BPSD Shell Global Solutions, Axens In co-operation with project partner Foster Wheeler as well as with licensors Shell Global Solutions and Axens the conceptual design basis and an environmental memorandum for a grassroots refinery was developed.

References - Refinery Expansion Feasibility study Synfuels Growth Project Customer: Location: Contract: Capacity: Technology: Scope: Sasol Secunda, South Africa E Axens, Uhde, Badger Debottlenecking studies for Temane gas plant, Mozambique. Extended basic engineering for Cumene plant, reducing benzene in gasoline. Uhde as Sasol’s engineering partner of the Sasol Growth Programme undertakes to revamp the two Secunda refineries and to engineer additional new clean fuels units.

References - Refinery Expansion Feasibility study Synfuels Growth Project Customer: Location: Contract: Capacity: Technology: Scope: Sasol Secunda, South Africa E Axens, Uhde, Badger Debottlenecking studies for Temane gas plant, Mozambique. Extended basic engineering for Cumene plant, reducing benzene in gasoline. Uhde as Sasol’s engineering partner of the Sasol Growth Programme undertakes to revamp the two Secunda refineries and to engineer additional new clean fuels units.

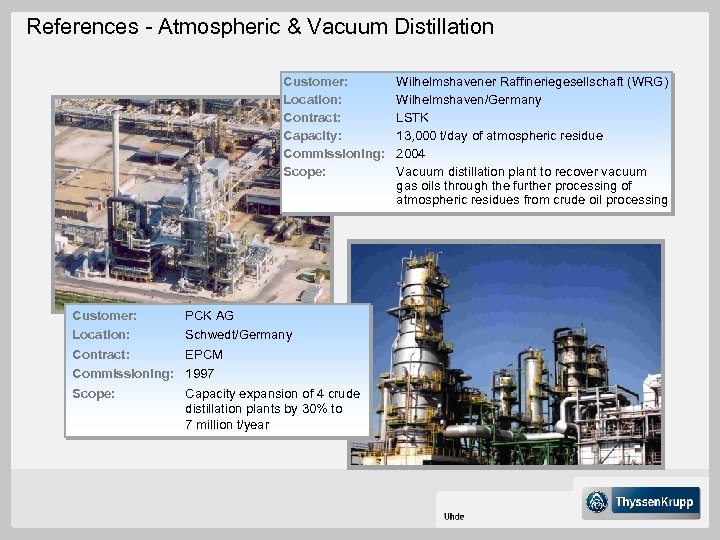

References - Atmospheric & Vacuum Distillation Customer: Location: Contract: Capacity: Commissioning: Scope: Customer: PCK AG Location: Schwedt/Germany Contract: EPCM Commissioning: 1997 Scope: Capacity expansion of 4 crude distillation plants by 30% to 7 million t/year Wilhelmshavener Raffineriegesellschaft (WRG) Wilhelmshaven/Germany LSTK 13, 000 t/day of atmospheric residue 2004 Vacuum distillation plant to recover vacuum gas oils through the further processing of atmospheric residues from crude oil processing

References - Atmospheric & Vacuum Distillation Customer: Location: Contract: Capacity: Commissioning: Scope: Customer: PCK AG Location: Schwedt/Germany Contract: EPCM Commissioning: 1997 Scope: Capacity expansion of 4 crude distillation plants by 30% to 7 million t/year Wilhelmshavener Raffineriegesellschaft (WRG) Wilhelmshaven/Germany LSTK 13, 000 t/day of atmospheric residue 2004 Vacuum distillation plant to recover vacuum gas oils through the further processing of atmospheric residues from crude oil processing

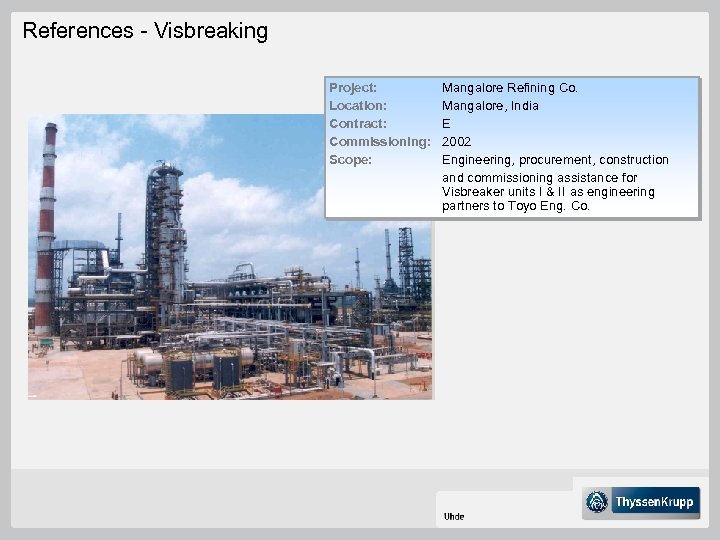

References - Visbreaking Project: Location: Contract: Commissioning: Scope: Mangalore Refining Co. Mangalore, India E 2002 Engineering, procurement, construction and commissioning assistance for Visbreaker units I & II as engineering partners to Toyo Eng. Co.

References - Visbreaking Project: Location: Contract: Commissioning: Scope: Mangalore Refining Co. Mangalore, India E 2002 Engineering, procurement, construction and commissioning assistance for Visbreaker units I & II as engineering partners to Toyo Eng. Co.

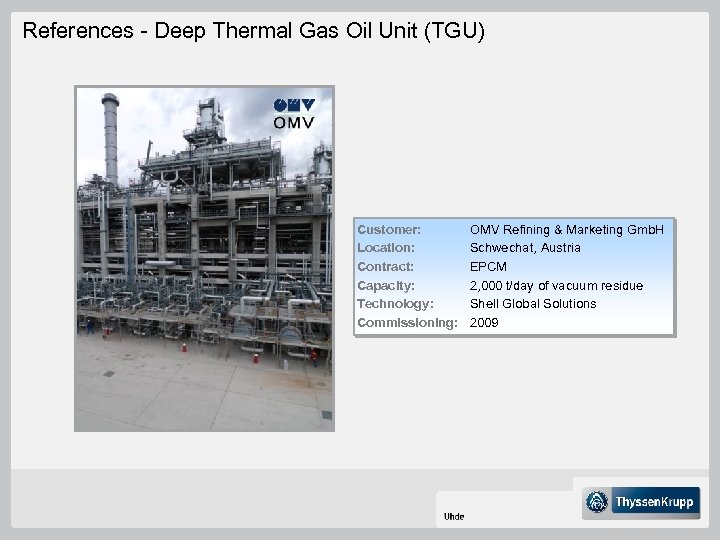

References - Deep Thermal Gas Oil Unit (TGU) Customer: Location: Contract: Capacity: Technology: Commissioning: OMV Refining & Marketing Gmb. H Schwechat, Austria EPCM 2, 000 t/day of vacuum residue Shell Global Solutions 2009

References - Deep Thermal Gas Oil Unit (TGU) Customer: Location: Contract: Capacity: Technology: Commissioning: OMV Refining & Marketing Gmb. H Schwechat, Austria EPCM 2, 000 t/day of vacuum residue Shell Global Solutions 2009

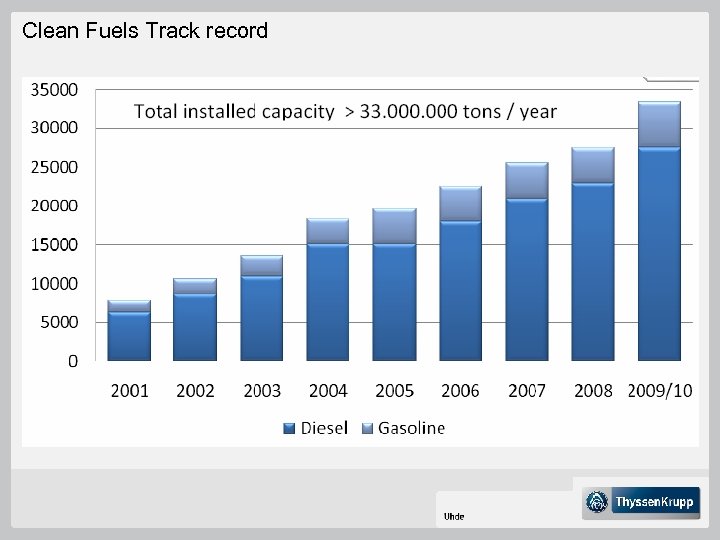

Clean Fuels Track record

Clean Fuels Track record

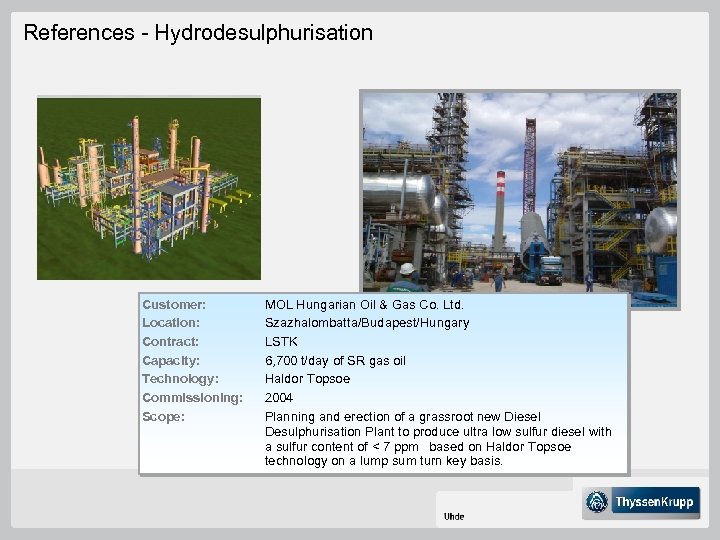

References - Hydrodesulphurisation Customer: Location: Contract: Capacity: Technology: Commissioning: Scope: MOL Hungarian Oil & Gas Co. Ltd. Szazhalombatta/Budapest/Hungary LSTK 6, 700 t/day of SR gas oil Haldor Topsoe 2004 Planning and erection of a grassroot new Diesel Desulphurisation Plant to produce ultra low sulfur diesel with a sulfur content of < 7 ppm based on Haldor Topsoe technology on a lump sum turn key basis.

References - Hydrodesulphurisation Customer: Location: Contract: Capacity: Technology: Commissioning: Scope: MOL Hungarian Oil & Gas Co. Ltd. Szazhalombatta/Budapest/Hungary LSTK 6, 700 t/day of SR gas oil Haldor Topsoe 2004 Planning and erection of a grassroot new Diesel Desulphurisation Plant to produce ultra low sulfur diesel with a sulfur content of < 7 ppm based on Haldor Topsoe technology on a lump sum turn key basis.

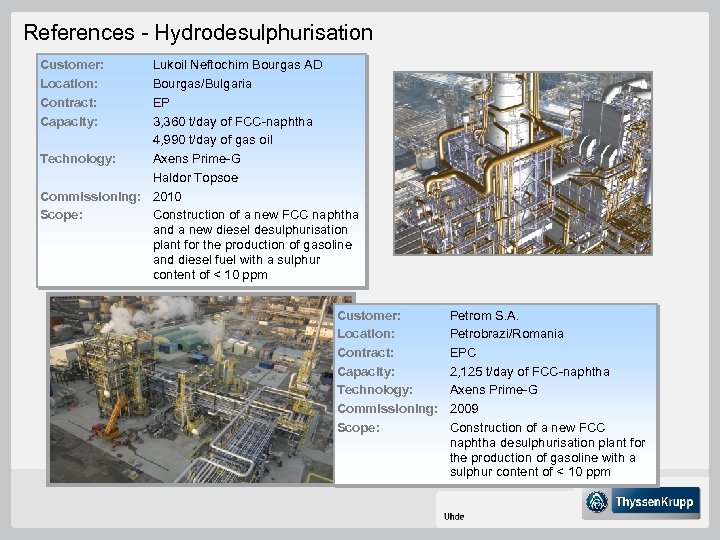

References - Hydrodesulphurisation Customer: Location: Contract: Capacity: Lukoil Neftochim Bourgas AD Bourgas/Bulgaria EP 3, 360 t/day of FCC-naphtha 4, 990 t/day of gas oil Technology: Axens Prime-G Haldor Topsoe Commissioning: 2010 Scope: Construction of a new FCC naphtha and a new diesel desulphurisation plant for the production of gasoline and diesel fuel with a sulphur content of < 10 ppm Customer: Location: Contract: Capacity: Technology: Commissioning: Scope: Petrom S. A. Petrobrazi/Romania EPC 2, 125 t/day of FCC-naphtha Axens Prime-G 2009 Construction of a new FCC naphtha desulphurisation plant for the production of gasoline with a sulphur content of < 10 ppm

References - Hydrodesulphurisation Customer: Location: Contract: Capacity: Lukoil Neftochim Bourgas AD Bourgas/Bulgaria EP 3, 360 t/day of FCC-naphtha 4, 990 t/day of gas oil Technology: Axens Prime-G Haldor Topsoe Commissioning: 2010 Scope: Construction of a new FCC naphtha and a new diesel desulphurisation plant for the production of gasoline and diesel fuel with a sulphur content of < 10 ppm Customer: Location: Contract: Capacity: Technology: Commissioning: Scope: Petrom S. A. Petrobrazi/Romania EPC 2, 125 t/day of FCC-naphtha Axens Prime-G 2009 Construction of a new FCC naphtha desulphurisation plant for the production of gasoline with a sulphur content of < 10 ppm

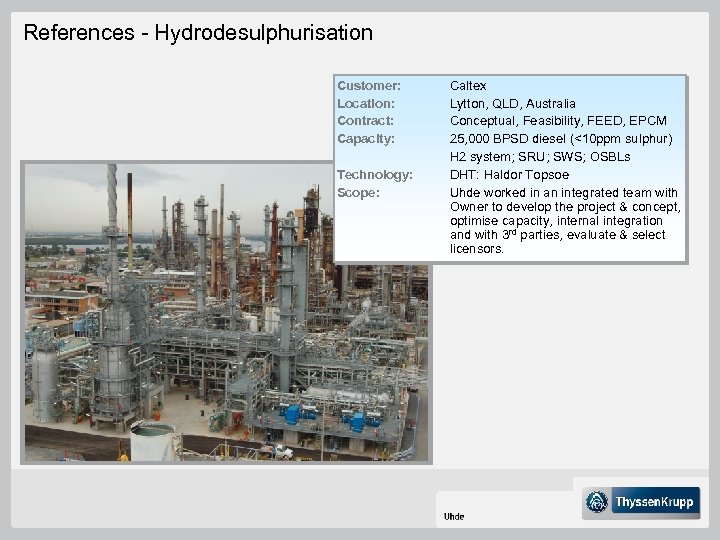

References - Hydrodesulphurisation Customer: Location: Contract: Capacity: Technology: Scope: Caltex Lytton, QLD, Australia Conceptual, Feasibility, FEED, EPCM 25, 000 BPSD diesel (<10 ppm sulphur) H 2 system; SRU; SWS; OSBLs DHT: Haldor Topsoe Uhde worked in an integrated team with Owner to develop the project & concept, optimise capacity, internal integration and with 3 rd parties, evaluate & select licensors.

References - Hydrodesulphurisation Customer: Location: Contract: Capacity: Technology: Scope: Caltex Lytton, QLD, Australia Conceptual, Feasibility, FEED, EPCM 25, 000 BPSD diesel (<10 ppm sulphur) H 2 system; SRU; SWS; OSBLs DHT: Haldor Topsoe Uhde worked in an integrated team with Owner to develop the project & concept, optimise capacity, internal integration and with 3 rd parties, evaluate & select licensors.

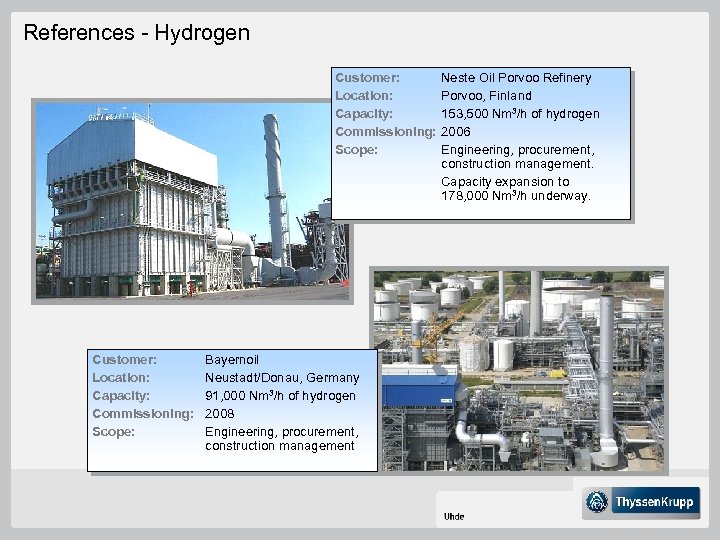

References - Hydrogen Customer: Neste Oil Porvoo Refinery Location: Porvoo, Finland Capacity: 153, 500 Nm 3/h of hydrogen Commissioning: 2006 Scope: Engineering, procurement, construction management. Capacity expansion to 178, 000 Nm 3/h underway. Customer: Location: Capacity: Commissioning: Scope: Bayernoil Neustadt/Donau, Germany 91, 000 Nm 3/h of hydrogen 2008 Engineering, procurement, construction management

References - Hydrogen Customer: Neste Oil Porvoo Refinery Location: Porvoo, Finland Capacity: 153, 500 Nm 3/h of hydrogen Commissioning: 2006 Scope: Engineering, procurement, construction management. Capacity expansion to 178, 000 Nm 3/h underway. Customer: Location: Capacity: Commissioning: Scope: Bayernoil Neustadt/Donau, Germany 91, 000 Nm 3/h of hydrogen 2008 Engineering, procurement, construction management

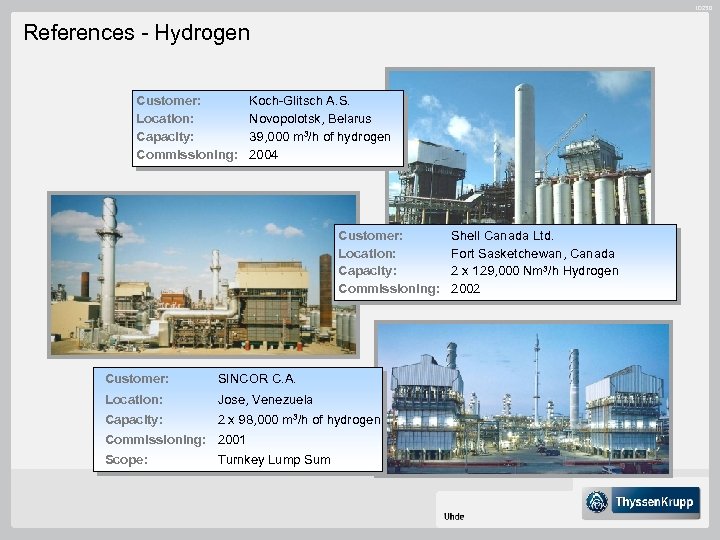

ID 230 References - Hydrogen Customer: Location: Capacity: Commissioning: Koch-Glitsch A. S. Novopolotsk, Belarus 39, 000 m 3/h of hydrogen 2004 Customer: Location: Capacity: Commissioning: Customer: SINCOR C. A. Location: Jose, Venezuela Capacity: 2 x 98, 000 m 3/h of hydrogen Commissioning: 2001 Scope: Turnkey Lump Sum Shell Canada Ltd. Fort Sasketchewan, Canada 2 x 129, 000 Nm 3/h Hydrogen 2002

ID 230 References - Hydrogen Customer: Location: Capacity: Commissioning: Koch-Glitsch A. S. Novopolotsk, Belarus 39, 000 m 3/h of hydrogen 2004 Customer: Location: Capacity: Commissioning: Customer: SINCOR C. A. Location: Jose, Venezuela Capacity: 2 x 98, 000 m 3/h of hydrogen Commissioning: 2001 Scope: Turnkey Lump Sum Shell Canada Ltd. Fort Sasketchewan, Canada 2 x 129, 000 Nm 3/h Hydrogen 2002

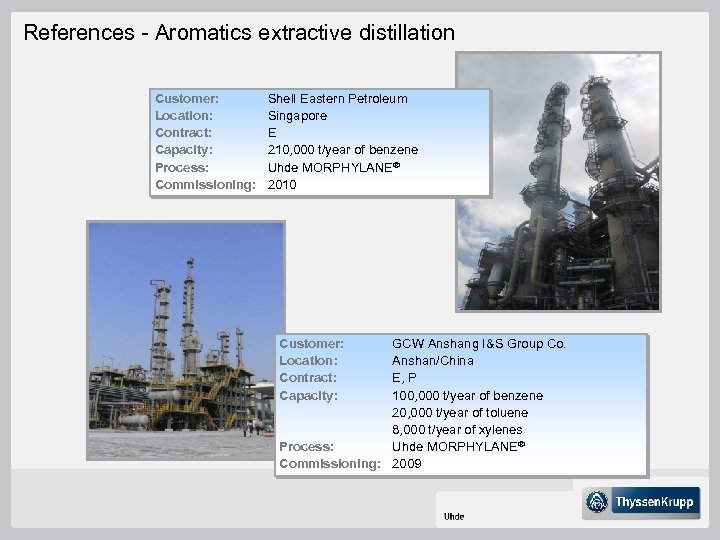

References - Aromatics extractive distillation Customer: Location: Contract: Capacity: Process: Commissioning: Shell Eastern Petroleum Singapore E 210, 000 t/year of benzene Uhde MORPHYLANE® 2010 Customer: Location: Contract: Capacity: GCW Anshang I&S Group Co. Anshan/China E, P 100, 000 t/year of benzene 20, 000 t/year of toluene 8, 000 t/year of xylenes Process: Uhde MORPHYLANE® Commissioning: 2009

References - Aromatics extractive distillation Customer: Location: Contract: Capacity: Process: Commissioning: Shell Eastern Petroleum Singapore E 210, 000 t/year of benzene Uhde MORPHYLANE® 2010 Customer: Location: Contract: Capacity: GCW Anshang I&S Group Co. Anshan/China E, P 100, 000 t/year of benzene 20, 000 t/year of toluene 8, 000 t/year of xylenes Process: Uhde MORPHYLANE® Commissioning: 2009

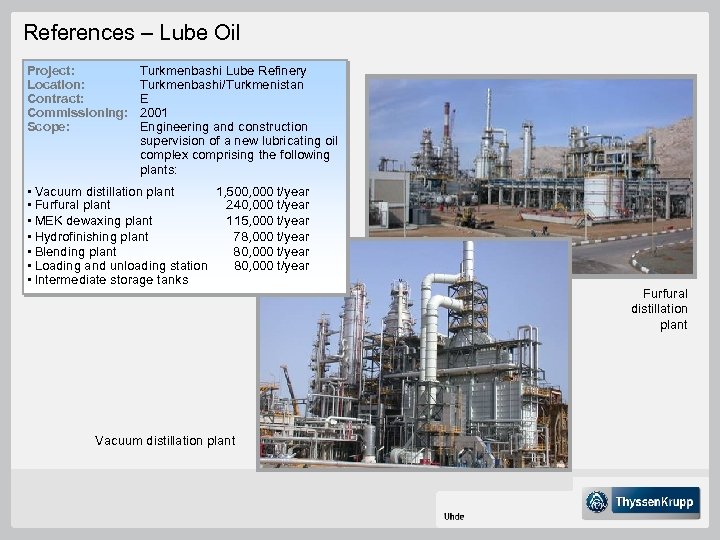

References – Lube Oil Project: Location: Contract: Commissioning: Scope: Turkmenbashi Lube Refinery Turkmenbashi/Turkmenistan E 2001 Engineering and construction supervision of a new lubricating oil complex comprising the following plants: • Vacuum distillation plant • Furfural plant • MEK dewaxing plant • Hydrofinishing plant • Blending plant • Loading and unloading station • Intermediate storage tanks 1, 500, 000 t/year 240, 000 t/year 115, 000 t/year 78, 000 t/year 80, 000 t/year Vacuum distillation plant Furfural distillation plant

References – Lube Oil Project: Location: Contract: Commissioning: Scope: Turkmenbashi Lube Refinery Turkmenbashi/Turkmenistan E 2001 Engineering and construction supervision of a new lubricating oil complex comprising the following plants: • Vacuum distillation plant • Furfural plant • MEK dewaxing plant • Hydrofinishing plant • Blending plant • Loading and unloading station • Intermediate storage tanks 1, 500, 000 t/year 240, 000 t/year 115, 000 t/year 78, 000 t/year 80, 000 t/year Vacuum distillation plant Furfural distillation plant

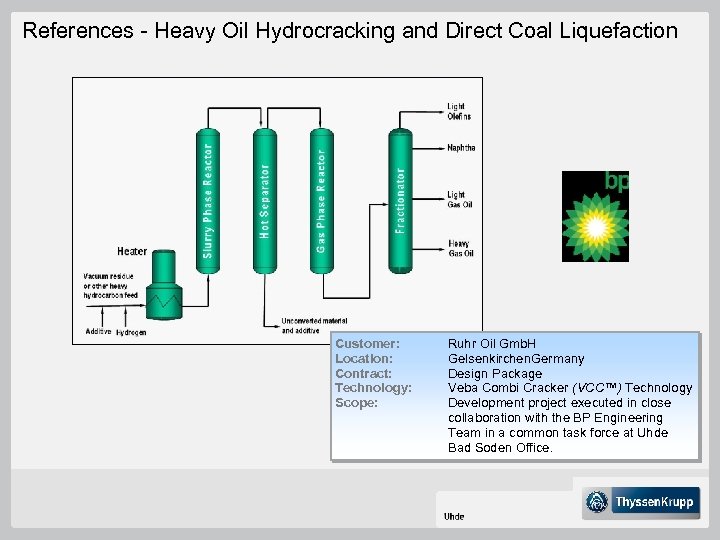

References - Heavy Oil Hydrocracking and Direct Coal Liquefaction Customer: Location: Contract: Technology: Scope: Ruhr Oil Gmb. H Gelsenkirchen. Germany Design Package Veba Combi Cracker (VCC™) Technology Development project executed in close collaboration with the BP Engineering Team in a common task force at Uhde Bad Soden Office.

References - Heavy Oil Hydrocracking and Direct Coal Liquefaction Customer: Location: Contract: Technology: Scope: Ruhr Oil Gmb. H Gelsenkirchen. Germany Design Package Veba Combi Cracker (VCC™) Technology Development project executed in close collaboration with the BP Engineering Team in a common task force at Uhde Bad Soden Office.

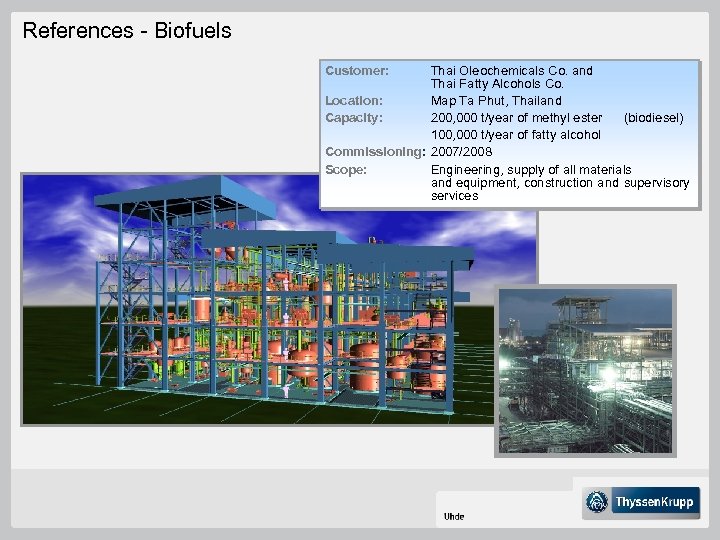

References - Biofuels Customer: Thai Oleochemicals Co. and Thai Fatty Alcohols Co. Location: Map Ta Phut, Thailand Capacity: 200, 000 t/year of methyl ester (biodiesel) 100, 000 t/year of fatty alcohol Commissioning: 2007/2008 Scope: Engineering, supply of all materials and equipment, construction and supervisory services

References - Biofuels Customer: Thai Oleochemicals Co. and Thai Fatty Alcohols Co. Location: Map Ta Phut, Thailand Capacity: 200, 000 t/year of methyl ester (biodiesel) 100, 000 t/year of fatty alcohol Commissioning: 2007/2008 Scope: Engineering, supply of all materials and equipment, construction and supervisory services

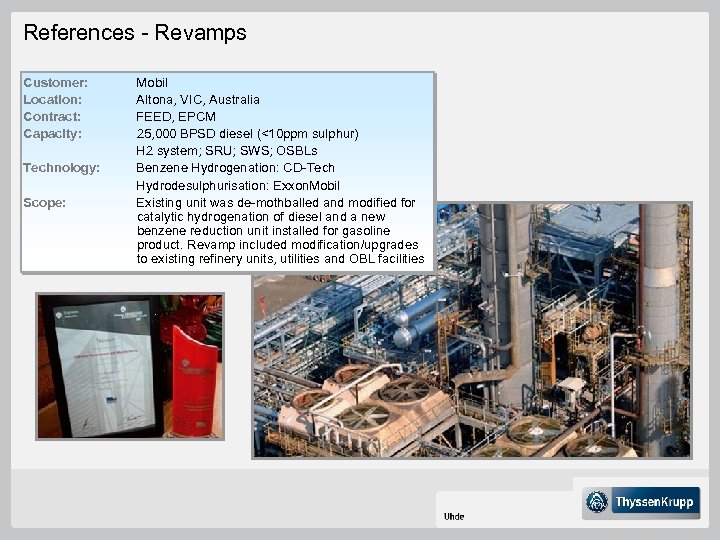

References - Revamps Customer: Location: Contract: Capacity: Technology: Scope: Mobil Altona, VIC, Australia FEED, EPCM 25, 000 BPSD diesel (<10 ppm sulphur) H 2 system; SRU; SWS; OSBLs Benzene Hydrogenation: CD-Tech Hydrodesulphurisation: Exxon. Mobil Existing unit was de-mothballed and modified for catalytic hydrogenation of diesel and a new benzene reduction unit installed for gasoline product. Revamp included modification/upgrades to existing refinery units, utilities and OBL facilities

References - Revamps Customer: Location: Contract: Capacity: Technology: Scope: Mobil Altona, VIC, Australia FEED, EPCM 25, 000 BPSD diesel (<10 ppm sulphur) H 2 system; SRU; SWS; OSBLs Benzene Hydrogenation: CD-Tech Hydrodesulphurisation: Exxon. Mobil Existing unit was de-mothballed and modified for catalytic hydrogenation of diesel and a new benzene reduction unit installed for gasoline product. Revamp included modification/upgrades to existing refinery units, utilities and OBL facilities

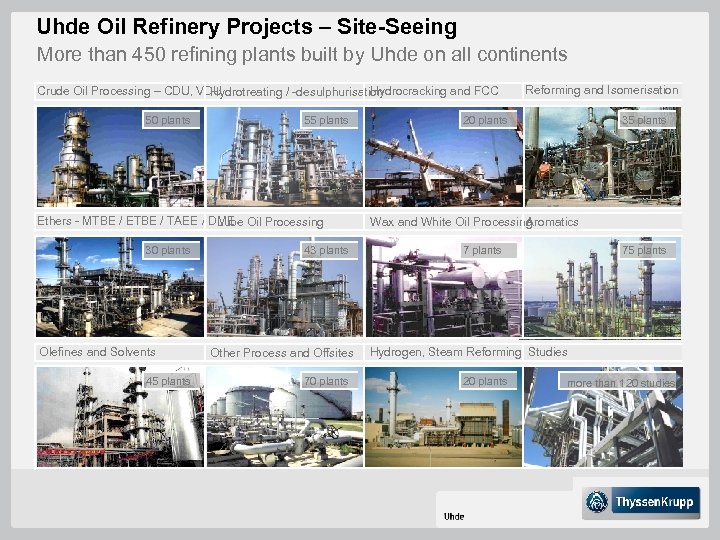

Uhde Oil Refinery Projects – Site-Seeing More than 450 refining plants built by Uhde on all continents Crude Oil Processing – CDU, VDU Hydrocracking and FCC Hydrotreating / -desulphurisation 50 plants 55 plants Ethers - MTBE / ETBE / TAEE / DME Lube Oil Processing 30 plants Olefines and Solvents 45 plants 43 plants Other Process and Offsites 70 plants Reforming and Isomerisation 20 plants 35 plants Wax and White Oil Processing romatics A 7 plants 75 plants Hydrogen, Steam Reforming Studies 20 plants more than 120 studies

Uhde Oil Refinery Projects – Site-Seeing More than 450 refining plants built by Uhde on all continents Crude Oil Processing – CDU, VDU Hydrocracking and FCC Hydrotreating / -desulphurisation 50 plants 55 plants Ethers - MTBE / ETBE / TAEE / DME Lube Oil Processing 30 plants Olefines and Solvents 45 plants 43 plants Other Process and Offsites 70 plants Reforming and Isomerisation 20 plants 35 plants Wax and White Oil Processing romatics A 7 plants 75 plants Hydrogen, Steam Reforming Studies 20 plants more than 120 studies

Uhde‘s Refinery BDH Technology The route to acid-free alkylation Alkylation Plant Replacement goals • HF acid carries many HSE issues and costs • H 2 SO 4 better, but only a matter of degree! • Need a non-acid route to 98 RONC gasoline • Oligomerisation can’t convert butane, isobutane • New refinery applications to avoid acid alkylation process • Existing refinery retro-fits to replace acid alkylation units • Existing refinery gasoline pool octane uplift

Uhde‘s Refinery BDH Technology The route to acid-free alkylation Alkylation Plant Replacement goals • HF acid carries many HSE issues and costs • H 2 SO 4 better, but only a matter of degree! • Need a non-acid route to 98 RONC gasoline • Oligomerisation can’t convert butane, isobutane • New refinery applications to avoid acid alkylation process • Existing refinery retro-fits to replace acid alkylation units • Existing refinery gasoline pool octane uplift

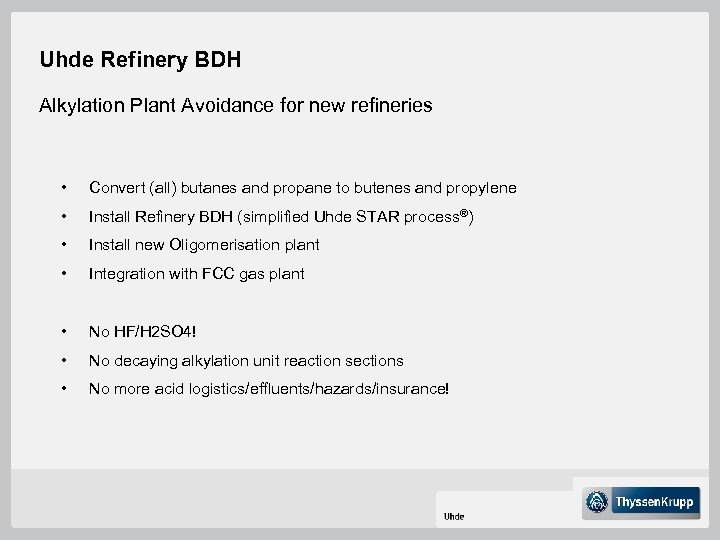

Uhde Refinery BDH Alkylation Plant Avoidance for new refineries • Convert (all) butanes and propane to butenes and propylene • Install Refinery BDH (simplified Uhde STAR process®) • Install new Oligomerisation plant • Integration with FCC gas plant • No HF/H 2 SO 4! • No decaying alkylation unit reaction sections • No more acid logistics/effluents/hazards/insurance!

Uhde Refinery BDH Alkylation Plant Avoidance for new refineries • Convert (all) butanes and propane to butenes and propylene • Install Refinery BDH (simplified Uhde STAR process®) • Install new Oligomerisation plant • Integration with FCC gas plant • No HF/H 2 SO 4! • No decaying alkylation unit reaction sections • No more acid logistics/effluents/hazards/insurance!

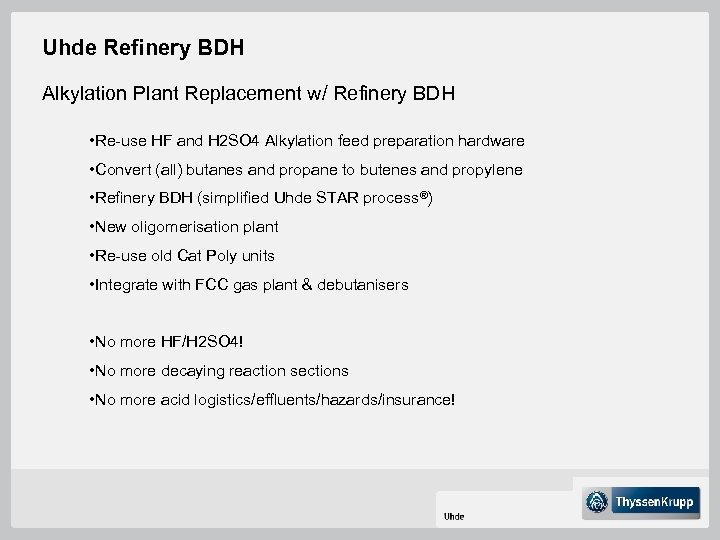

Uhde Refinery BDH Alkylation Plant Replacement w/ Refinery BDH • Re-use HF and H 2 SO 4 Alkylation feed preparation hardware • Convert (all) butanes and propane to butenes and propylene • Refinery BDH (simplified Uhde STAR process®) • New oligomerisation plant • Re-use old Cat Poly units • Integrate with FCC gas plant & debutanisers • No more HF/H 2 SO 4! • No more decaying reaction sections • No more acid logistics/effluents/hazards/insurance!

Uhde Refinery BDH Alkylation Plant Replacement w/ Refinery BDH • Re-use HF and H 2 SO 4 Alkylation feed preparation hardware • Convert (all) butanes and propane to butenes and propylene • Refinery BDH (simplified Uhde STAR process®) • New oligomerisation plant • Re-use old Cat Poly units • Integrate with FCC gas plant & debutanisers • No more HF/H 2 SO 4! • No more decaying reaction sections • No more acid logistics/effluents/hazards/insurance!

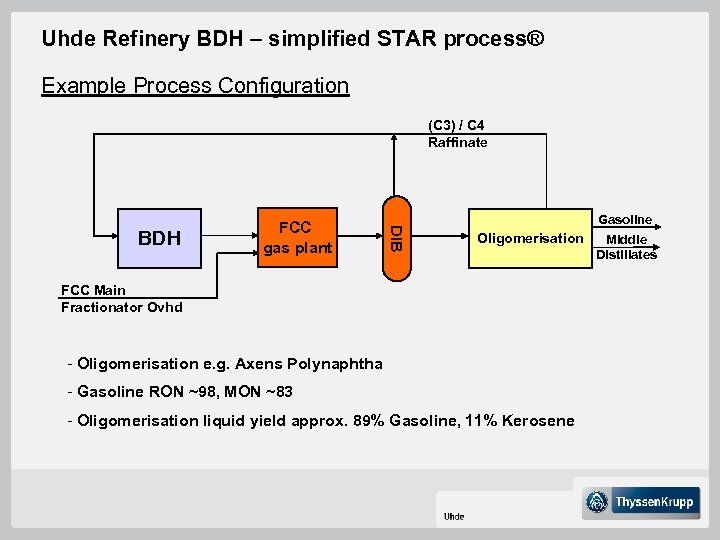

Uhde Refinery BDH – simplified STAR process® Example Process Configuration (C 3) / C 4 Raffinate DIB BDH FCC gas plant Gasoline Oligomerisation FCC Main Fractionator Ovhd - Oligomerisation e. g. Axens Polynaphtha - Gasoline RON ~98, MON ~83 - Oligomerisation liquid yield approx. 89% Gasoline, 11% Kerosene Middle Distillates

Uhde Refinery BDH – simplified STAR process® Example Process Configuration (C 3) / C 4 Raffinate DIB BDH FCC gas plant Gasoline Oligomerisation FCC Main Fractionator Ovhd - Oligomerisation e. g. Axens Polynaphtha - Gasoline RON ~98, MON ~83 - Oligomerisation liquid yield approx. 89% Gasoline, 11% Kerosene Middle Distillates

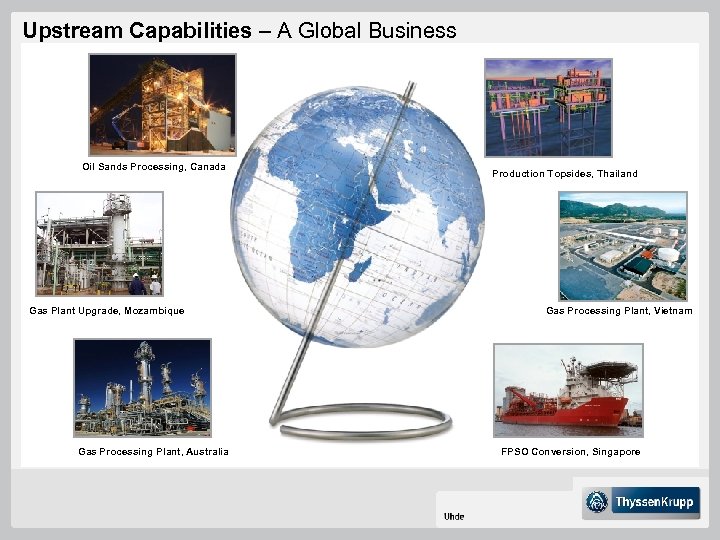

Upstream Capabilities – A Global Business Oil Sands Processing, Canada Gas Plant Upgrade, Mozambique Gas Processing Plant, Australia Production Topsides, Thailand Gas Processing Plant, Vietnam FPSO Conversion, Singapore

Upstream Capabilities – A Global Business Oil Sands Processing, Canada Gas Plant Upgrade, Mozambique Gas Processing Plant, Australia Production Topsides, Thailand Gas Processing Plant, Vietnam FPSO Conversion, Singapore

Upstream Capabilities – From Planning to Production Field Development Planning Concept Studies Front End Design Project Delivery

Upstream Capabilities – From Planning to Production Field Development Planning Concept Studies Front End Design Project Delivery

Key Clients

Key Clients

Thank You

Thank You