87195aba56e1b9691f68cd795c9f2ac3.ppt

- Количество слайдов: 44

An Introduction to Roofing Slate Prepared with the assistance of Dr. I. Sims, Ph. D, CGeol, Stats Consultancy

An Introduction to Roofing Slate Prepared with the assistance of Dr. I. Sims, Ph. D, CGeol, Stats Consultancy

Who are SSQ? § § Founded in 1983 § Specialists in finest quality imported slate § Market leader in UK; exports to Europe and worldwide Producers and exporters of natural slate from Spain, Argentina and Brazil

Who are SSQ? § § Founded in 1983 § Specialists in finest quality imported slate § Market leader in UK; exports to Europe and worldwide Producers and exporters of natural slate from Spain, Argentina and Brazil

Objectives § To explain the geological background of roofing slates § To demonstrate why natural slate makes such good roofing material § To explain the new European Standard for roofing slates § To provide advice on problem free slate specification

Objectives § To explain the geological background of roofing slates § To demonstrate why natural slate makes such good roofing material § To explain the new European Standard for roofing slates § To provide advice on problem free slate specification

Contents § Introduction to slate – geology, extraction and source § § Performance issues The new European Standard & Quality Control Problem-Free Specification Conclusion

Contents § Introduction to slate – geology, extraction and source § § Performance issues The new European Standard & Quality Control Problem-Free Specification Conclusion

An introduction to slate § Definition ‘A smooth fine grained metamorphic rock which can be split into layers. ’ § History § Used since Roman times in Europe § Used for roofing in the UK for over 1000 years

An introduction to slate § Definition ‘A smooth fine grained metamorphic rock which can be split into layers. ’ § History § Used since Roman times in Europe § Used for roofing in the UK for over 1000 years

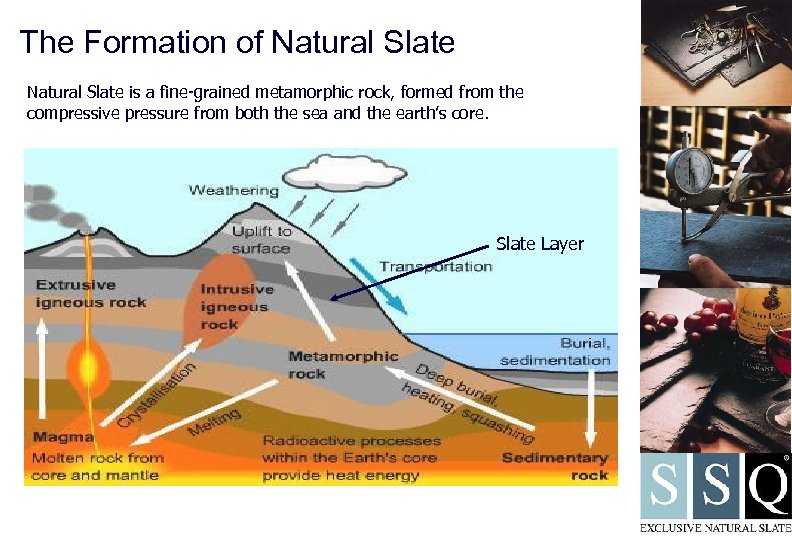

The Formation of Natural Slate is a fine-grained metamorphic rock, formed from the compressive pressure from both the sea and the earth’s core. Slate Layer

The Formation of Natural Slate is a fine-grained metamorphic rock, formed from the compressive pressure from both the sea and the earth’s core. Slate Layer

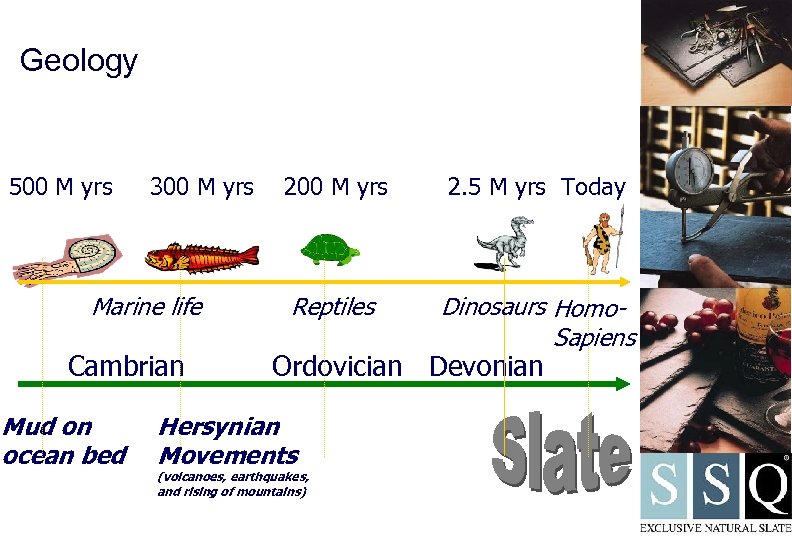

Geology 500 M yrs 300 M yrs Marine life Cambrian Mud on ocean bed 200 M yrs 2. 5 M yrs Today Reptiles Dinosaurs Homo. Sapiens Ordovician Devonian Hersynian Movements (volcanoes, earthquakes, and rising of mountains)

Geology 500 M yrs 300 M yrs Marine life Cambrian Mud on ocean bed 200 M yrs 2. 5 M yrs Today Reptiles Dinosaurs Homo. Sapiens Ordovician Devonian Hersynian Movements (volcanoes, earthquakes, and rising of mountains)

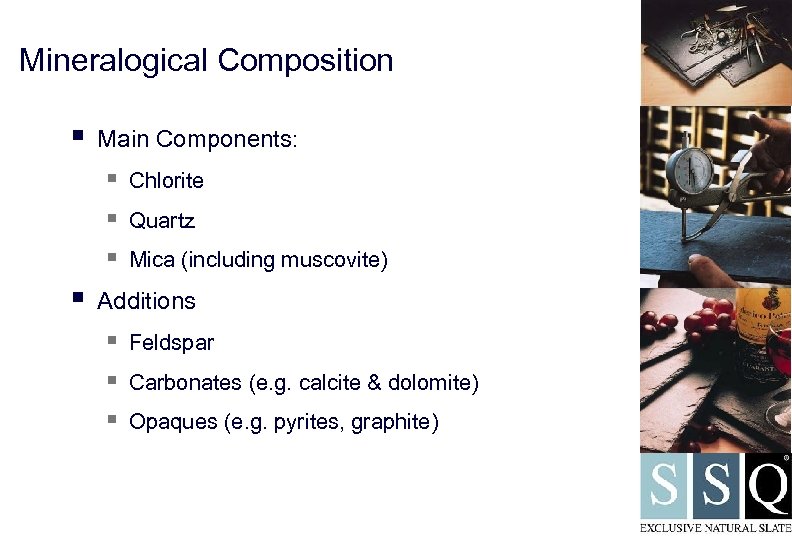

Mineralogical Composition § Main Components: § Chlorite § Quartz § Mica (including muscovite) § Additions § Feldspar § Carbonates (e. g. calcite & dolomite) § Opaques (e. g. pyrites, graphite)

Mineralogical Composition § Main Components: § Chlorite § Quartz § Mica (including muscovite) § Additions § Feldspar § Carbonates (e. g. calcite & dolomite) § Opaques (e. g. pyrites, graphite)

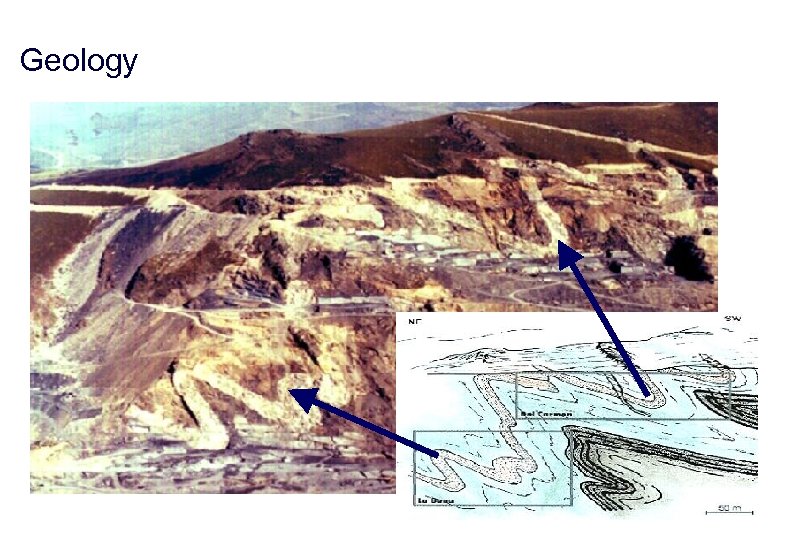

Geology

Geology

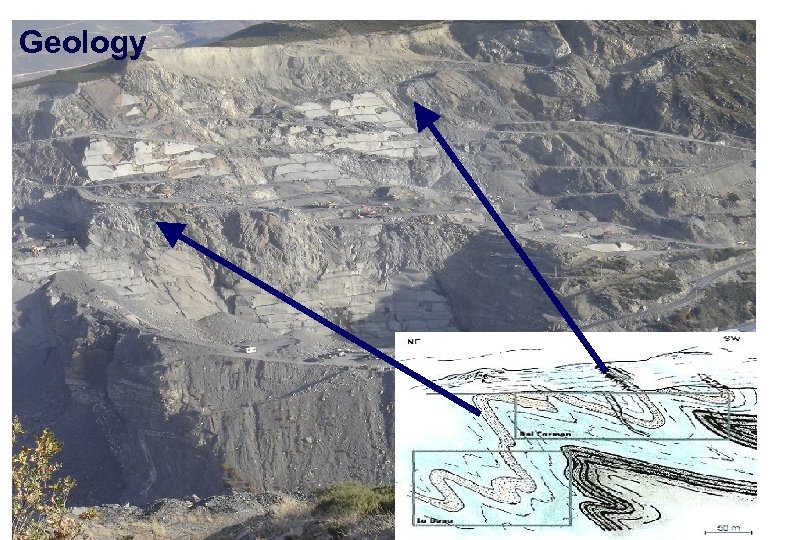

Geology

Geology

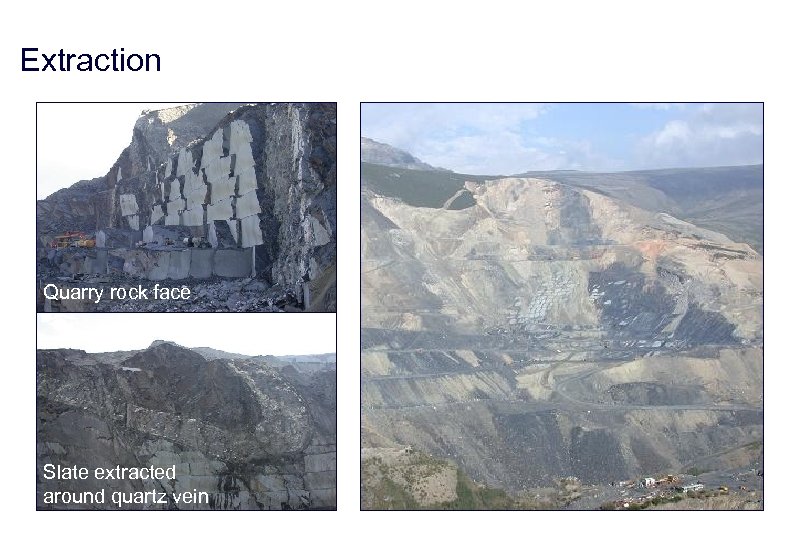

Extraction Quarry rock face Slate extracted around quartz vein

Extraction Quarry rock face Slate extracted around quartz vein

Slate Production /SSQ Slate Production Video

Slate Production /SSQ Slate Production Video

Sources of Slate Used in UK

Sources of Slate Used in UK

Performance Issues

Performance Issues

Advantages of Natural Slates for Roofing § § § Durable § § § Flexible Waterproof Minimum maintenance Non combustible Not susceptible to acid attack thus pollution resistant Natural product Life cycle cost

Advantages of Natural Slates for Roofing § § § Durable § § § Flexible Waterproof Minimum maintenance Non combustible Not susceptible to acid attack thus pollution resistant Natural product Life cycle cost

Properties of a Good Roofing slate Suitability to climatic conditions: § § Resistant to frost Resistant to repeated wetting and drying Suitability for use on a roof: §Flatness §Regular thickness §Square cut §Longitudinal grain

Properties of a Good Roofing slate Suitability to climatic conditions: § § Resistant to frost Resistant to repeated wetting and drying Suitability for use on a roof: §Flatness §Regular thickness §Square cut §Longitudinal grain

Possible Visible Defects of Roofing slates § § § § Non flatness Irregularity in thickness Cracks Transversal grain Non squareness Flaking Delamination

Possible Visible Defects of Roofing slates § § § § Non flatness Irregularity in thickness Cracks Transversal grain Non squareness Flaking Delamination

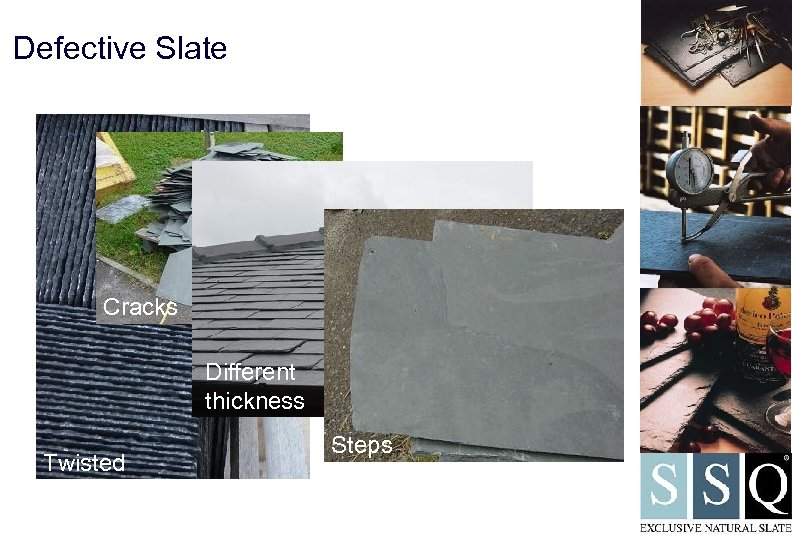

Defective Slate Cracks Different thickness Twisted Steps

Defective Slate Cracks Different thickness Twisted Steps

Possible Invisible Defects in a roofing slate § § § § Inclusions such as oxidising pyrite Water absorption too high Non resistance to acid attack Non resistance to freeze-thaw cycles Inclusions Brittleness/breaking strength too low Pre-existing delamination Calcium carbonate content too high

Possible Invisible Defects in a roofing slate § § § § Inclusions such as oxidising pyrite Water absorption too high Non resistance to acid attack Non resistance to freeze-thaw cycles Inclusions Brittleness/breaking strength too low Pre-existing delamination Calcium carbonate content too high

Defective Slate: Pyrite Leaching and curved slates

Defective Slate: Pyrite Leaching and curved slates

Testing and Standards

Testing and Standards

International Standards § Until recently there were a number of international testing standards, with varying degrees of complexity: § In May 2006 the new BS European Standard (BS EN 12326) was introduced to supersede all other European national standards

International Standards § Until recently there were a number of international testing standards, with varying degrees of complexity: § In May 2006 the new BS European Standard (BS EN 12326) was introduced to supersede all other European national standards

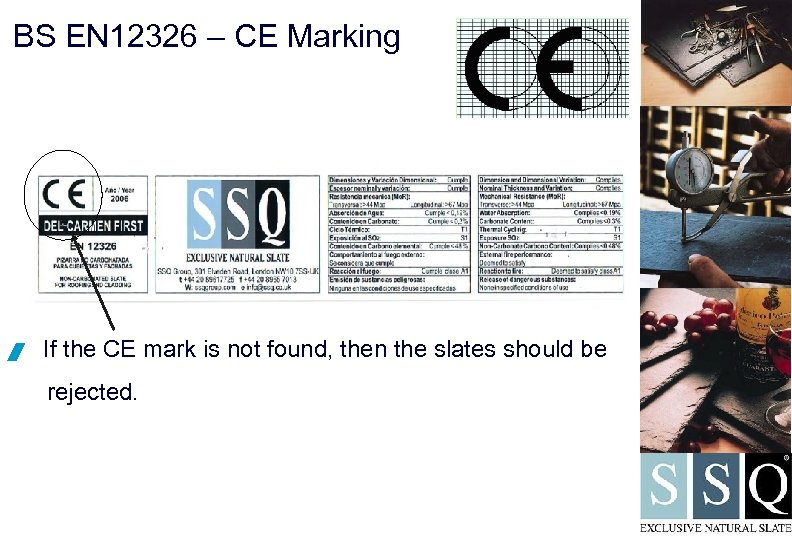

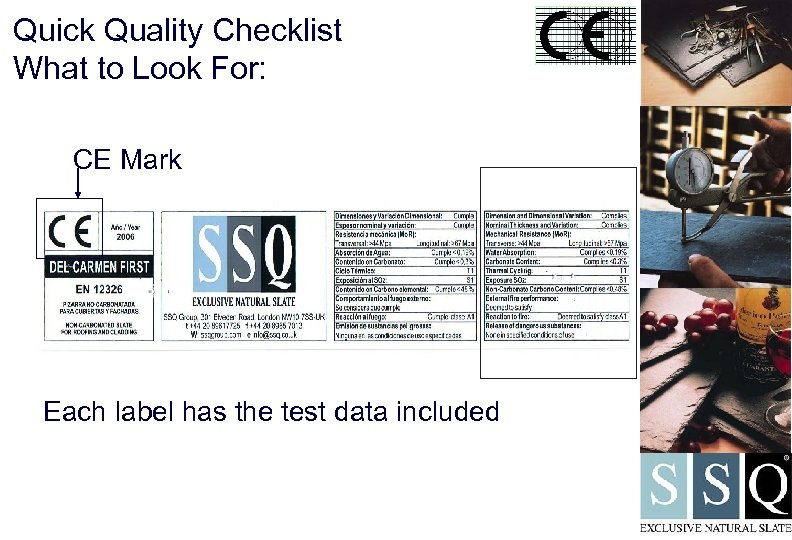

BS EN 12326 – Sample Test Certificate CE Mark

BS EN 12326 – Sample Test Certificate CE Mark

BS EN 12326 – CE Marking / UK building regulations have been modified to ensure that only CE marked roofing products are used. / The CE mark is the manufacturers claim that the slate, has been tested to BS EN 12326 / You can check that slates are tested to the BS EN by looking for the CE marking on packaging and or any documentation accompanying the slates.

BS EN 12326 – CE Marking / UK building regulations have been modified to ensure that only CE marked roofing products are used. / The CE mark is the manufacturers claim that the slate, has been tested to BS EN 12326 / You can check that slates are tested to the BS EN by looking for the CE marking on packaging and or any documentation accompanying the slates.

BS EN 12326 – CE Marking / If the CE mark is not found, then the slates should be rejected.

BS EN 12326 – CE Marking / If the CE mark is not found, then the slates should be rejected.

BS EN 12326 – CE Marking / The CE mark means the slate has been tested in the correct way / CE Marking does not indicate the Quality of the slate

BS EN 12326 – CE Marking / The CE mark means the slate has been tested in the correct way / CE Marking does not indicate the Quality of the slate

European Standard BS EN 12326 § The performance of a slate is measured by various tests, with the most important being: § Dimensional tolerances (deviation from declared length, width, squareness and straightness) § § § Thickness Resistance to flexion Permeability - Water absorption Durability Freeze thaw Thermal cycle test Carbonate content Sulfur dioxide exposure tests Non-carbonate carbon content External fire exposure Release of dangerous substances

European Standard BS EN 12326 § The performance of a slate is measured by various tests, with the most important being: § Dimensional tolerances (deviation from declared length, width, squareness and straightness) § § § Thickness Resistance to flexion Permeability - Water absorption Durability Freeze thaw Thermal cycle test Carbonate content Sulfur dioxide exposure tests Non-carbonate carbon content External fire exposure Release of dangerous substances

European Standard BS EN 12326 § No pass/fail criteria, instead has levels of performance for some tests and values for others § Any tested roofing slate can state compliance with the standard, and show the CE mark no matter what the quality is. § What constitutes a quality slate ?

European Standard BS EN 12326 § No pass/fail criteria, instead has levels of performance for some tests and values for others § Any tested roofing slate can state compliance with the standard, and show the CE mark no matter what the quality is. § What constitutes a quality slate ?

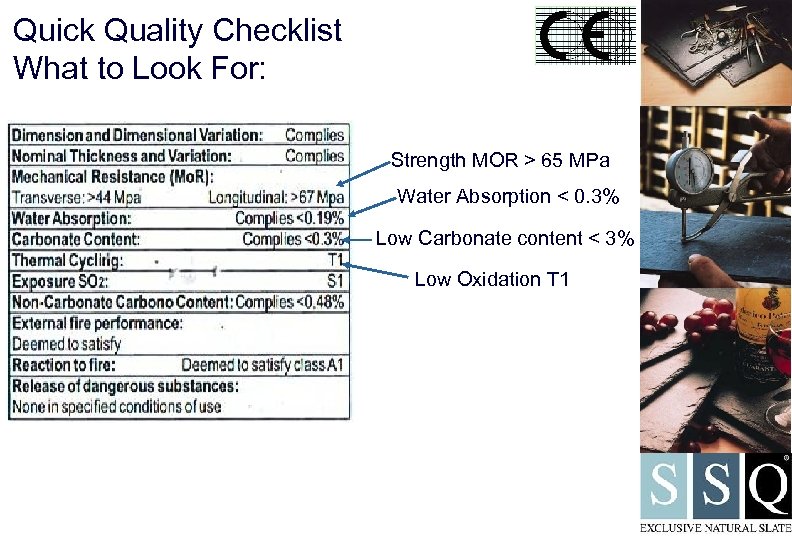

Test Certificate – What to Look For / / Visible: Dimensional and thickness variations Non-visible: STRENGTH Flexural Well performing slates will have : longitudinal Flexural Resistance In excess of 65 MPa

Test Certificate – What to Look For / / Visible: Dimensional and thickness variations Non-visible: STRENGTH Flexural Well performing slates will have : longitudinal Flexural Resistance In excess of 65 MPa

Test Certificate – What to Look For Water Absorption, Permeability & Durability Quality slates have low water absorption Low risk of freeze-thaw damage British standard was <0. 3% New standard: A 1 = <0. 6% ; A 2 = >0. 6% Carbonate Content Differing types of carbonate have different potential for reaction Safe to assume slates with lower carbonate content will weather more slowly unless iron-sulphurs are present Proven quality roofing slates have carbonate content <3%

Test Certificate – What to Look For Water Absorption, Permeability & Durability Quality slates have low water absorption Low risk of freeze-thaw damage British standard was <0. 3% New standard: A 1 = <0. 6% ; A 2 = >0. 6% Carbonate Content Differing types of carbonate have different potential for reaction Safe to assume slates with lower carbonate content will weather more slowly unless iron-sulphurs are present Proven quality roofing slates have carbonate content <3%

Test Certificate – What to Look For Thermal Cycling / Free of Oxidation will occur if reactive iron-sulphur minerals are present (pyrites) Three Classifications: T 1 free of pyrites or of leaching pyrites. Applied to slates that exhibit colour changes that neither affect the structure of the slate nor form runs of discolouration T 2 exhibit pyrites/ leaching pyrites. Applied to slates that form runs of discolouration, but no structural changes T 3 exhibit pyrites/ leaching/oxidising pyrites. Applied to slates that form runs of discolouration and may form holes around inclusions but no structural changes. Well performing slates will have no visible pyrites and be T 1

Test Certificate – What to Look For Thermal Cycling / Free of Oxidation will occur if reactive iron-sulphur minerals are present (pyrites) Three Classifications: T 1 free of pyrites or of leaching pyrites. Applied to slates that exhibit colour changes that neither affect the structure of the slate nor form runs of discolouration T 2 exhibit pyrites/ leaching pyrites. Applied to slates that form runs of discolouration, but no structural changes T 3 exhibit pyrites/ leaching/oxidising pyrites. Applied to slates that form runs of discolouration and may form holes around inclusions but no structural changes. Well performing slates will have no visible pyrites and be T 1

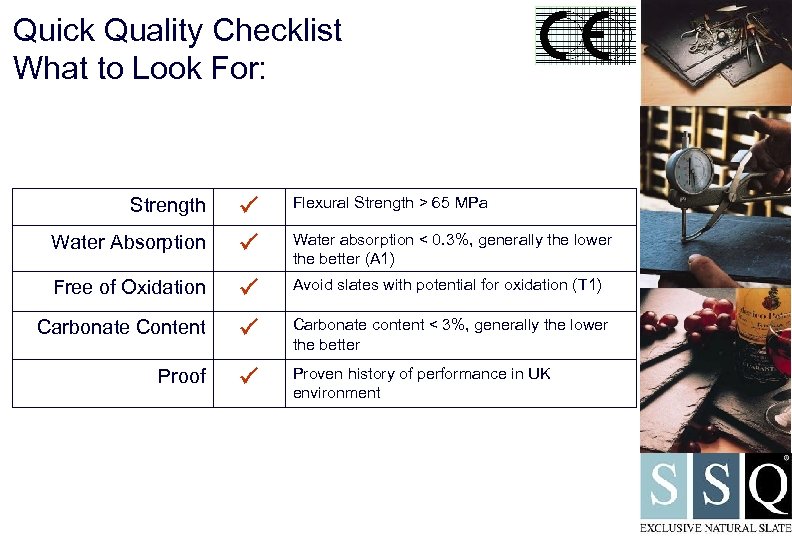

Quick Quality Checklist What to Look For: Flexural Strength > 65 MPa Water Absorption Free of Oxidation Avoid slates with potential for oxidation (T 1) Carbonate Content Carbonate content < 3%, generally the lower the better Proof Proven history of performance in UK environment Strength Water absorption < 0. 3%, generally the lower the better (A 1)

Quick Quality Checklist What to Look For: Flexural Strength > 65 MPa Water Absorption Free of Oxidation Avoid slates with potential for oxidation (T 1) Carbonate Content Carbonate content < 3%, generally the lower the better Proof Proven history of performance in UK environment Strength Water absorption < 0. 3%, generally the lower the better (A 1)

Quick Quality Checklist What to Look For: CE Mark Each label has the test data included

Quick Quality Checklist What to Look For: CE Mark Each label has the test data included

Quick Quality Checklist What to Look For: Strength MOR > 65 MPa Water Absorption < 0. 3% Low Carbonate content < 3% Low Oxidation T 1

Quick Quality Checklist What to Look For: Strength MOR > 65 MPa Water Absorption < 0. 3% Low Carbonate content < 3% Low Oxidation T 1

Specification

Specification

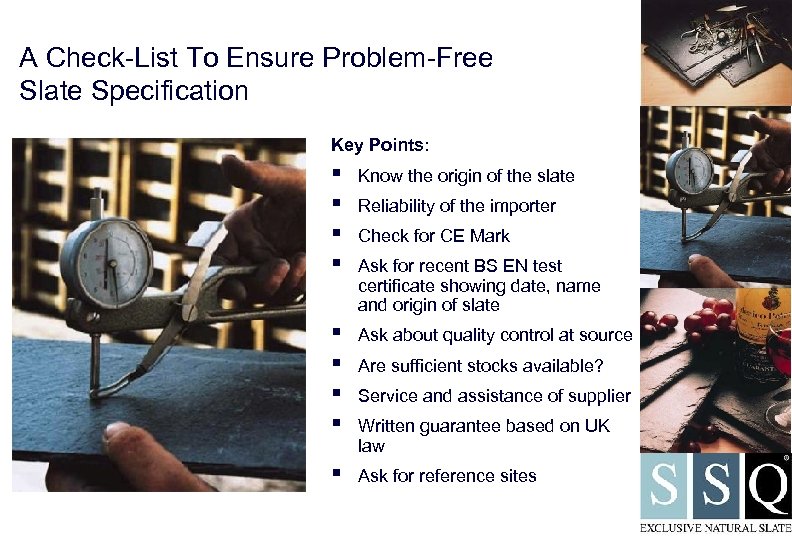

A Check-List To Ensure Problem-Free Slate Specification Key Points: § § Know the origin of the slate § § Ask about quality control at source § Ask for reference sites Reliability of the importer Check for CE Mark Ask for recent BS EN test certificate showing date, name and origin of slate Are sufficient stocks available? Service and assistance of supplier Written guarantee based on UK law

A Check-List To Ensure Problem-Free Slate Specification Key Points: § § Know the origin of the slate § § Ask about quality control at source § Ask for reference sites Reliability of the importer Check for CE Mark Ask for recent BS EN test certificate showing date, name and origin of slate Are sufficient stocks available? Service and assistance of supplier Written guarantee based on UK law

Specifying Slate § Contractual specifications for roofing slates will need to be more sophisticated than in the past § No ‘blanket’ specifications § Ensure CE Marked Slates only § To ensure performance for at least 30 years, request slates with: § > 65 Mo. R, A 1, and T 1 results § Slates with < 65 Mo. R, A 2, and T 3 May comply but may last only a few years on a roof subjected to UK climactic conditions

Specifying Slate § Contractual specifications for roofing slates will need to be more sophisticated than in the past § No ‘blanket’ specifications § Ensure CE Marked Slates only § To ensure performance for at least 30 years, request slates with: § > 65 Mo. R, A 1, and T 1 results § Slates with < 65 Mo. R, A 2, and T 3 May comply but may last only a few years on a roof subjected to UK climactic conditions

Design Possibilities with Slate

Design Possibilities with Slate

Quality Imported Slates in UK § Spanish & Argentinean slates are used on listed buildings § Approved in Snowdonia National Park § Accepted by English Heritage § Some accepted by Historic Scotland

Quality Imported Slates in UK § Spanish & Argentinean slates are used on listed buildings § Approved in Snowdonia National Park § Accepted by English Heritage § Some accepted by Historic Scotland

Applications of Quality Spanish Slate Scotland Slate specially produced for Scottish market: § § equivalent in colour § equivalent in performance to indigenous slate equivalent in texture and size

Applications of Quality Spanish Slate Scotland Slate specially produced for Scottish market: § § equivalent in colour § equivalent in performance to indigenous slate equivalent in texture and size

Conclusion § § Natural slate is the perfect roofing material § Slates may have defects not visible to the naked eye § § Check for the CE Mark on labels & Certificates Natural slate is a low life cycle cost, low maintenance, environmentally friendly material Although the slate may be compliant with the new BS EN 12326 ensure it passes the Quick Quality Checklist

Conclusion § § Natural slate is the perfect roofing material § Slates may have defects not visible to the naked eye § § Check for the CE Mark on labels & Certificates Natural slate is a low life cycle cost, low maintenance, environmentally friendly material Although the slate may be compliant with the new BS EN 12326 ensure it passes the Quick Quality Checklist

/ Visit our website ssqgroup. com

/ Visit our website ssqgroup. com

An Introduction to Roofing Slate Any Questions?

An Introduction to Roofing Slate Any Questions?