2f5bdf9599996257956022ba51d1c6b1.ppt

- Количество слайдов: 40

An Engineer Dive in the Bio and Medical Devices World Presentation by: Amer El-Hage 11/20/2006 Beeston Engineering Consulting 1

Outline A bit about myself, Beeston Engineering and this industry What my Engineering education missed! What is Art, Science and what is Engineering? Common Engineering issues Project management! Summary Beeston Engineering Consulting 2

My Qualifications 25 years in scientific instrument development at Beckman, Varian, LJL Biosystems and Molecular Devices Over 30 product development programs experience. Several products carried from concept to full production Directed product development projects in meeting their specification, budget and schedule goals Involved in several instrument designs (fifteen issued patents), product validation and risk assessment programs Developed at Varian, LJL and MDC their product development process ASME Silicon Valley volunteer for over five years, chair 2006 U. C. Berkeley M. S. 1980, Mechanical Engineering- Design and Automation Beeston Engineering Consulting 3

Beeston Engineering Consulting Independent evaluation of product or devices at any stage in the development cycle n n n Identify necessary technical skills and tools to execute a product development project successfully Program Management: Develop tasks, budget, and resources Develop plans to validate prototypes to relevant standards and regulatory systems Draft engineering, quality and processes to efficiently transfer or release your product to manufacturing Beeston Engineering Consulting 4

California and Bay area Bio -Space Some Statistics and Graphs Beeston Engineering Consulting 5

Defining the Industry The Biotech & Biomedical (Life-science) Industry in California is comprised of many sectors, with employment today exceeding 250, 000. Employment breaks down as follows: Biopharmaceuticals (34%) Medical devices, instruments and diagnostics (33%) Academic research (18%) Laboratory services (12%) Other (3%) Source: CHI, California’s Biomedical Industry, 2004 Beeston Engineering Consulting 6

A Few Figures for California Total biomedical companies: 2, 600 (90% founded since 1980 and 80% privately owned) Total world-wide revenues: $32. 3 billion Total employment: 230, 100 (This exceeds the number employed by the computer industry in the same time frame!) Total wages and salaries paid: $14 billion These companies serve as powerful economic drivers in the 7 regional clusters in which they are located. Source: CHI, California’s Biomedical Industry, 2004 Beeston Engineering Consulting 7

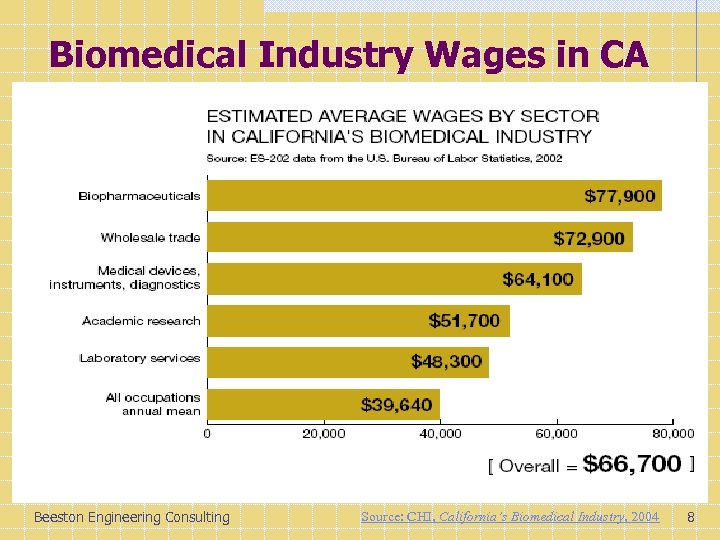

Biomedical Industry Wages in CA Beeston Engineering Consulting Source: CHI, California’s Biomedical Industry, 2004 8

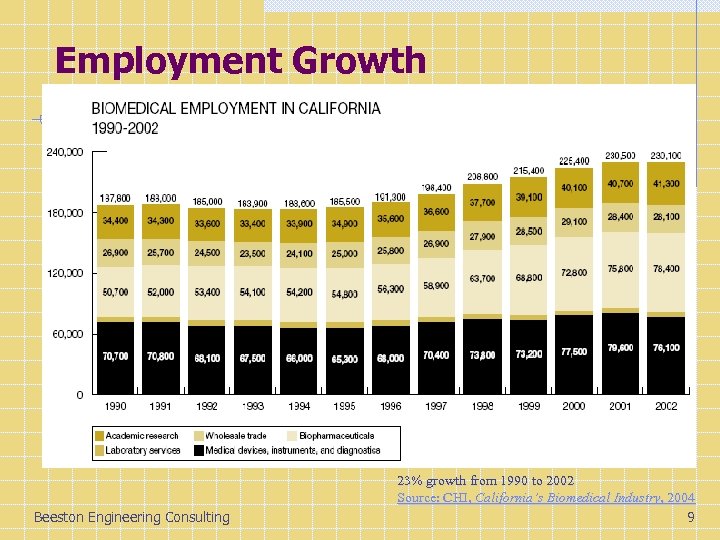

Employment Growth Beeston Engineering Consulting 23% growth from 1990 to 2002 Source: CHI, California’s Biomedical Industry, 2004 9

Some of my Instrumentations and Medical Devices Experience Chemical and Immunodiagnostics – Design audit, Project planning and transfer to manufacturing Combinatorial Chemistry systems DNA, HIV and other detection systems Biology and cell based assays Pulmonary drug delivery device – Plastic molding Glaucoma, Bone density - Technical reviews and project development for medical devices measurement, Insulin inhaling device Catheters and Stents – SLA models, and coating processes Quality Engineering, Design Control and process validation Beeston Engineering Consulting 10

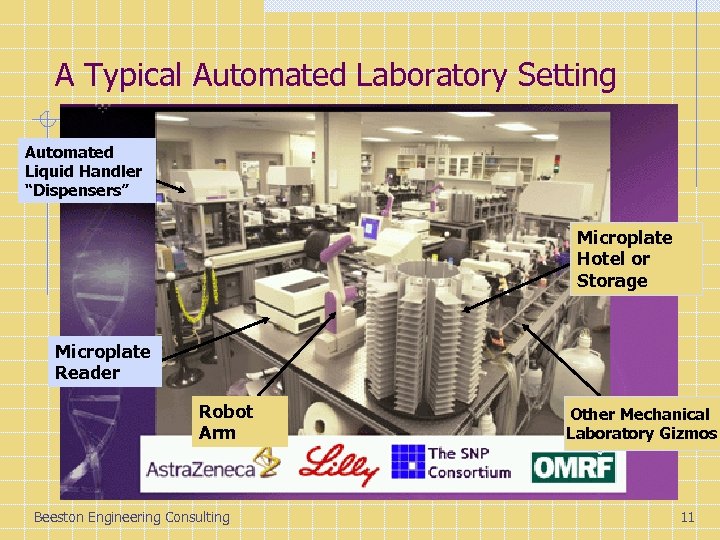

A Typical Automated Laboratory Setting Automated Liquid Handler “Dispensers” Microplate Hotel or Storage Microplate Reader Robot Arm Beeston Engineering Consulting Other Mechanical Laboratory Gizmos 11

Microtubes Moved Into 96 Well Microplates Beeston Engineering Consulting 12

Beeston Engineering Consulting 13

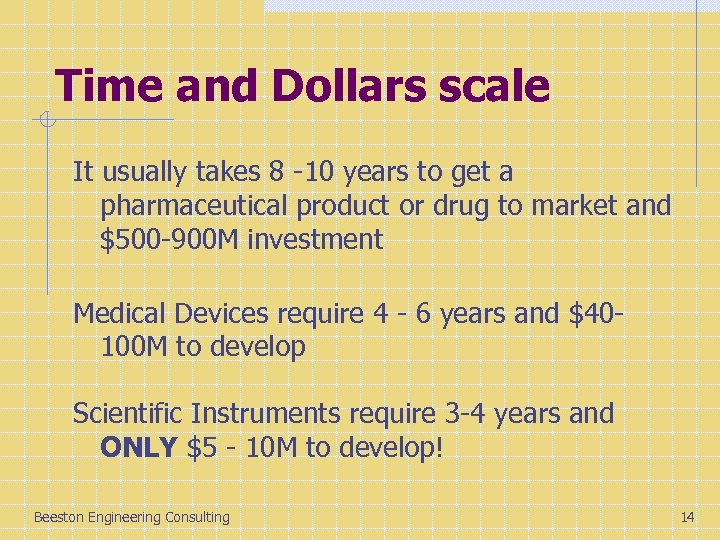

Time and Dollars scale It usually takes 8 -10 years to get a pharmaceutical product or drug to market and $500 -900 M investment Medical Devices require 4 - 6 years and $40100 M to develop Scientific Instruments require 3 -4 years and ONLY $5 - 10 M to develop! Beeston Engineering Consulting 14

What about the Bay Area? 750+ companies * 86, 000+ employees 30+ academic and research institutions The Bay Area has the largest concentration of medical device start-ups in the U. S. , and the largest concentration of companies bought out by medical device giants. * Excludes the 98 companies and 5, 000 employees in the Sacramento area Source: CHI, California’s Biomedical Industry , 2004 Beeston Engineering Consulting 15

Example of some Scientific and medical Devices companies Beeston Engineering Consulting 16

BD Biosciences Division of Becton Dickinson Company Medical Device company - Regulated industry Parent company well established > 100 yrs n n IVD products Research products Approximately 15, 000 employees (1, 000 BA) Revenue of $4 B ($300 -400 M) per year Figures in (parenthesis) are my estimates Beeston Engineering Consulting 17

A BD Diagnostic Instrument Made Possible by “Engineers” Beeston Engineering Consulting 18

Molecular Devices Corp. Scientific and Bio-analytical solution company – Non Regulated (yet!) Company well established > 20 yrs n n Drug discovery tools, includes reagents Research, and Analytical instruments Approximately 600 employees Revenue of $160 -200 M per year n n Wide portfolio, steady growth mostly by acquisitions Operate several independent companies worldwide Beeston Engineering Consulting 19

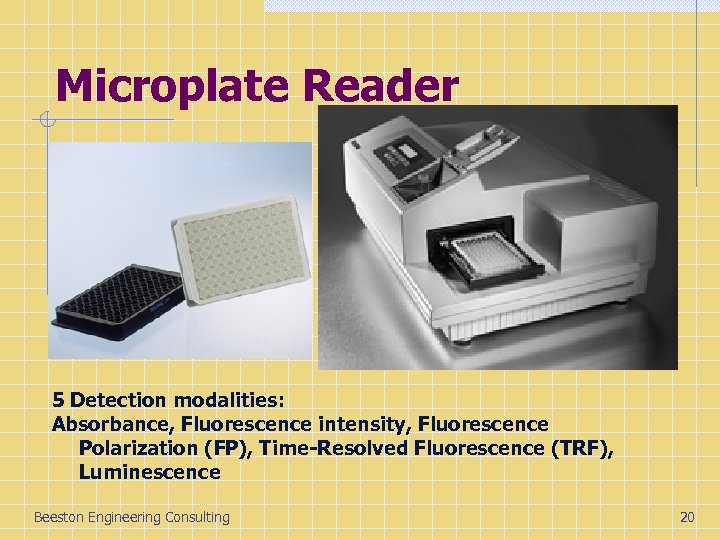

Microplate Reader 5 Detection modalities: Absorbance, Fluorescence intensity, Fluorescence Polarization (FP), Time-Resolved Fluorescence (TRF), Luminescence Beeston Engineering Consulting 20

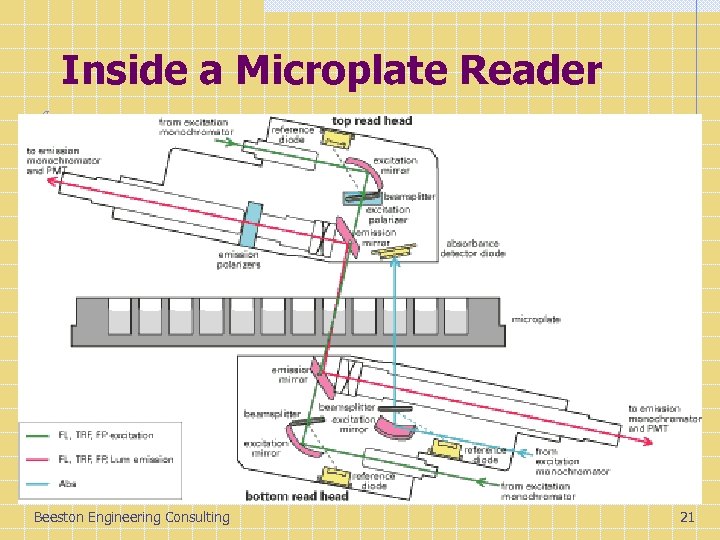

Inside a Microplate Reader Beeston Engineering Consulting 21

Predicant Biosciences Medical Device company- will have to be FDA regulated Startup - about 3 yrs old n IVD products w System that analyzes protein patterns in blood to correlate with disease state. Approximately 40 employees No revenue…yet Beeston Engineering Consulting 22

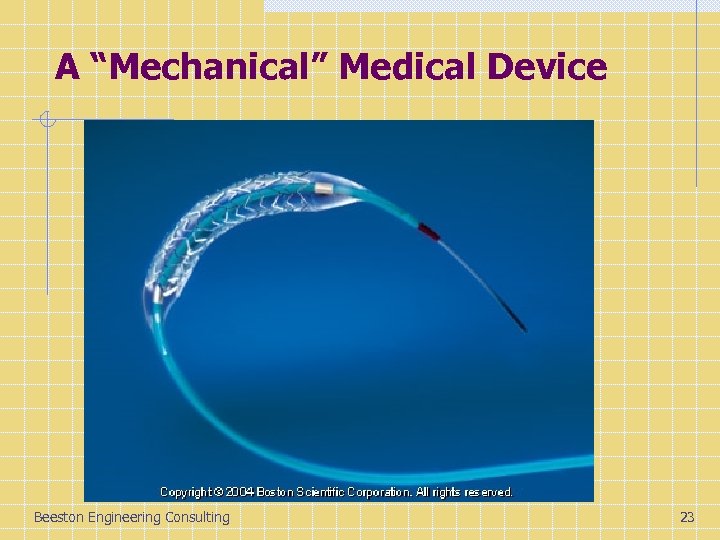

A “Mechanical” Medical Device Beeston Engineering Consulting 23

Areas that I learned something about after graduation… Program and Project management Instruments, device design – Mechanical, fluidics, and opto-mechanical Plastics, labware and consumables – Co-chair SBS/ANSI Microplate Standards Quality, Audit, QMS and Regulatory (CE and ISO, too) MEMS and special processes – Member on SEMI Fluid Interface Task force Beeston Engineering Consulting 24

What my Berkeley Education missed! All data is NOT created EQUAL! n n How to design “in-tolerance”… and promote probabilities The problems with diversity and dependencies, DOE Freedom of choice is great… ” as long as it is my choice!” Write your processes or you’re Left with regulators Do not create every design… buy the wheel! Talking and making friends with business Beeston Engineering Consulting 25

What is Art and What is Science? This stuff is organic… and it really stinks! What’s the matter with this material? Polymers and the slippery, sticky, and non-linear stuff… Give Precision to the Scientist, and leave the Accuracy to the Gods. . . Lab-On-A-Chip, Microfluids, MEMS, and the uncharted murky nano-waters Time, Temperature, and Temper of Biological entities large and small. Beeston Engineering Consulting 26

Errors !!! Random or Systematic n Deviation from the mean (DFM) is used to define or distinguish the type False Negatives: Appearance of a negative value or “No result” when a positive or some value is expected. False Positives: Appearance of a positive value or result when a negative value is expected. Beeston Engineering Consulting 27

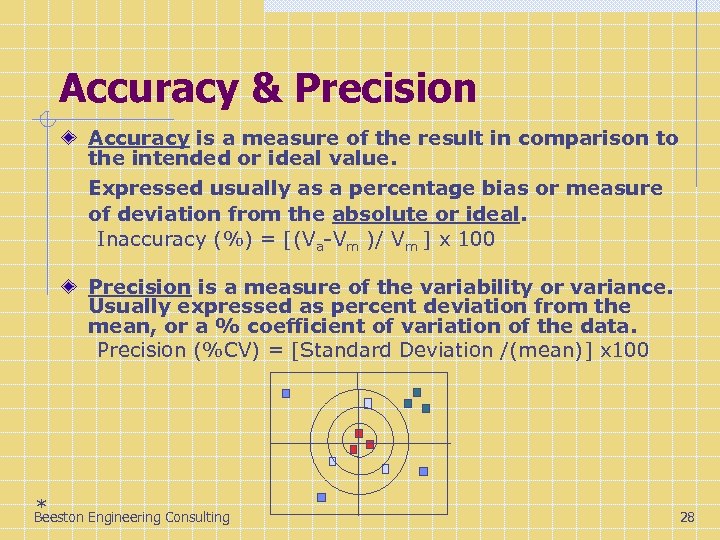

Accuracy & Precision Accuracy is a measure of the result in comparison to the intended or ideal value. Expressed usually as a percentage bias or measure of deviation from the absolute or ideal. Inaccuracy (%) = [(Va-Vm )/ Vm ] x 100 Precision is a measure of the variability or variance. Usually expressed as percent deviation from the mean, or a % coefficient of variation of the data. Precision (%CV) = [Standard Deviation /(mean)] x 100 * Beeston Engineering Consulting 28

What’s Art and What’s Engineering Rules of Thumb (ROT) and fundamentals are always helpful, but watch the unexpected in MEMS and living entities Tiny Mechanical gadgets nothing . . that can do (work) on Optics Galore – Not just Snell your Beer’s law? Fluidics… Reynolds and the Junk n n There will be always a bubble or a leak Carryover, cross contamination… How do you clean this Attomole junk? CAD-CAM, SLA, RPT and other fine acronyms Beeston Engineering Consulting 29

Common Engineering Issues Fluid dynamics (not what you learned at your Alta Mater) Material properties (not only Stainless) n n n Galvanic (ions are everywhere) Polymers Adhesives Surface Chemistry ( especially when things get smaller and need to be sensitive) Manufacturing and cost issues Packaging and Sterility Beeston Engineering Consulting 30

Schedules and Projects from Hell ! § Get the requirements first, the specs (speck-less) and agreed on early! § Typical project equation = 2 t x 2$<spec/2 § Watch for Creeping Elegance § The many distinct Phases of Product Development - Three times (min. ) is a charm… Beeston Engineering Consulting 31

Responsibilities and Contributors Phase 0 - R&D and Business Development Phase 1 – R&D, Marketing, and QA Phase 2 - Engineering, Marketing and R&D Phase 3 - Engineering, Marketing, QA and Manufacturing Phase 4 - Manufacturing, QA/QC, service and sales support Phase 5 – Operation, QC and Production Beeston Engineering Consulting 32

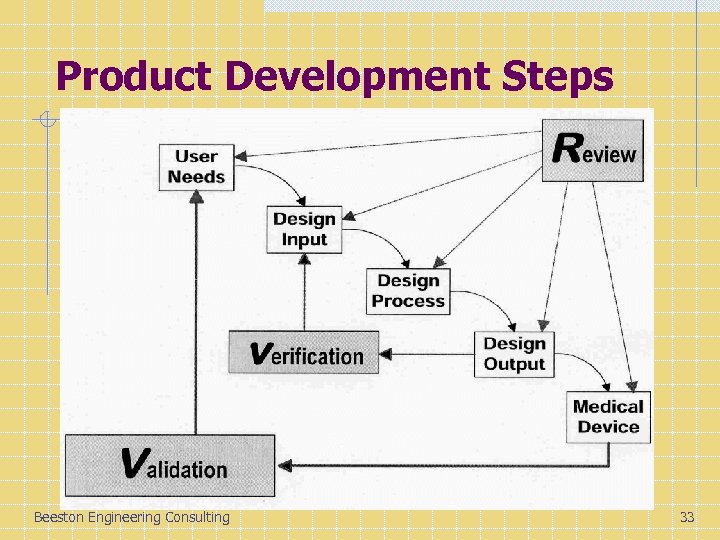

Product Development Steps Beeston Engineering Consulting 33

Summary High Level Areas Interaction with Biological matrix and the nature of small and “large living species” QSR regulatory and FDA – QA is part of Development Management types: Optimistic (marketing driven) or conservative and inefficient (Scientific and technical driven) Collaborations, Finance, VC, IP and legal issues Discipline and focus Beeston Engineering Consulting 34

Conclusions Biomedical Device Engineering is a true multidisciplinary activity It is the best “continuous learning” career Creativity is not bounded by the laws of Physics, but by the laws of Business! Driven by desire to do products for industry, society’s health and its patients (self interest) Beeston Engineering Consulting 35

Q&A Contact: amerhaj@Netzero. net Beeston Engineering Consulting 36

Supporting slides Beeston Engineering Consulting 37

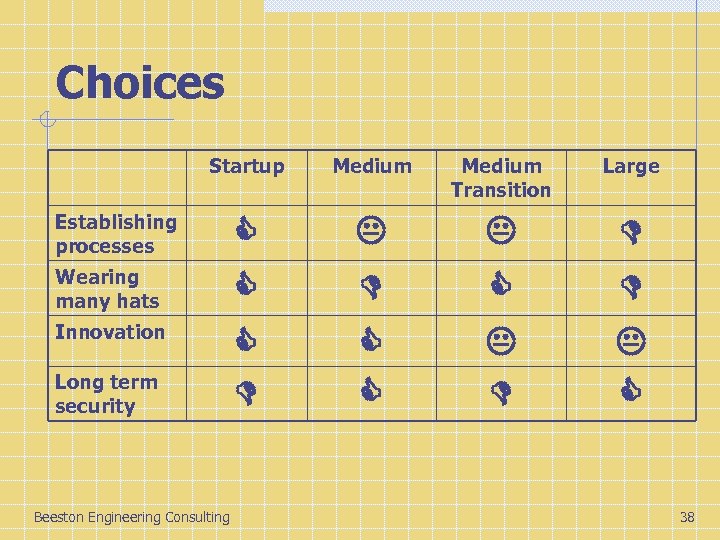

Choices Startup Medium Transition Large Establishing processes Wearing many hats Innovation Long term security Beeston Engineering Consulting 38

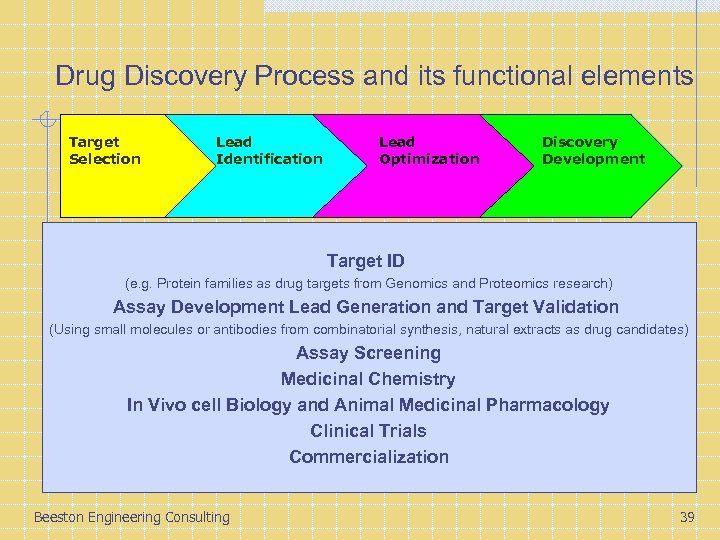

Drug Discovery Process and its functional elements Target Selection Lead Identification Lead Optimization Discovery Development Target ID (e. g. Protein families as drug targets from Genomics and Proteomics research) Assay Development Lead Generation and Target Validation (Using small molecules or antibodies from combinatorial synthesis, natural extracts as drug candidates) Assay Screening Medicinal Chemistry In Vivo cell Biology and Animal Medicinal Pharmacology Clinical Trials Commercialization Beeston Engineering Consulting 39

SBS and the Microplate Standards History First annual meeting held in Philadelphia, Sept. 1995 n Working Groups formed to address variety of issues relevant to its members w A group was to address issues where standardization would improve performance of automation w Top on the list of issues was standardizing the 96 well microplate In 1998, SBS Board re-opened the standard w Email List. Serv started in March 1998 w First meeting held in Boston in August 1998 The Microplate Standards Development Committee Became an Accredited ANSI Standards Developer in July, 2002 4 Standards submitted and approved by ANSI in Jan 2004 Beeston Engineering Consulting 40

2f5bdf9599996257956022ba51d1c6b1.ppt