46ccb02045f6ab34c7ece47966ee19c1.ppt

- Количество слайдов: 43

Americas Cavity and Cryomodule R&D Shekhar Mishra Fermilab 2007 DOE/NSF review 3/17/2018 Global design effort 1

Outline Americas • Technical Goals • FY 06 -07 – Cavity Fabrication (1. 3 and 3. 9 GHz) – Cavity Processing • Jlab • Cornell – Cryomodule • Fabrication Plan • T 4 CM Design – Industrial Development • Plans for FY 08 -09 • International Collaboration • Summary 2007 DOE/NSF review 3/17/2018 Global design effort 2

Technical Goals Americas • Demonstrate the basic ILC Main Linac technology – Develop cavity processing parameters for a reproducible cavity gradient of 35 MV/m; improve the yield of 9 -cell cavities for gradient of 35 MV/m in vertical tests (S 0. 1). – Carry out parallel/coupled R&D on cavity material, fabrication, and processing to identify paths to success (S 0. 2). – Assemble and test several cryomodules with average gradient > 31. 5 MV/m (S 1). – Build and test one or more ILC rf units at ILC beam parameters, high gradient, and full pulse rep rate (S 2. 1). – Carry out Key Alternate Design R&D item • GDE wants a “forward looking” approach • Improve ILC performance, reduce cost • Install Sufficient Infrastructure to support these activities 2007 DOE/NSF review 3/17/2018 Global design effort 3

US Cavity Americas 1/3 of the Global Need With focus on getting US Industry involved • FY 05 – 4 Cavities from ACCEL • FY 06 – – 4 Cavities from AES 4 Jlab (2 Fine, 2 Large) 9 Cavities from ACCEL 6 Cavities from AES • FY 07 – 16 Cavities • FY 08 -09 – 24 & 60 Cavities (Proposed) 2007 DOE/NSF review 3/17/2018 Global design effort 4

US SRF Infrastructure Strength Americas • Cavity Processing and Vertical Testing R&D Facility – – Jlab (30 FY 07, 40 FY 08, 50 FY 09) cycles/yr ANL/FNAL ( 10 -20 FY 07, 30 FY 08, 40 FY 09) cycles/yr Cornell 12 cycles/yr VTS @FNAL 45 cycles/yr (08) • Horizontal Test Stand – FNAL 24 cavities/yr • Cavity Dressing and Cryomodule Assembly – FNAL 4/yr (FY 07) • Limited cavity fabrication capability in US industry 2007 DOE/NSF review 3/17/2018 Global design effort 5

Cavity Fabrication: 1. 3 GHz Americas • Four DESY TTF style cavities with asymmetric beam tubes (Type III+) were purchased from ACCEL in FY 05. – Two of these cavities have undergone EP processing and vertical testing at TJNL. – The remaining two cavities are being processed and tested at Cornell • Four additional Type III+ cavities ordered from AES in FY 06 were recently completed. – Three of these were shipped to TJNL: processing and vertical testing is in progress. – The fourth cavity was shipped to FNAL for mechanical and RF measurements. From there it will go to TJNL for processing and vertical testing. • All the cavities listed above were fabricated from fine grain niobium. 2007 DOE/NSF review 3/17/2018 Global design effort 6

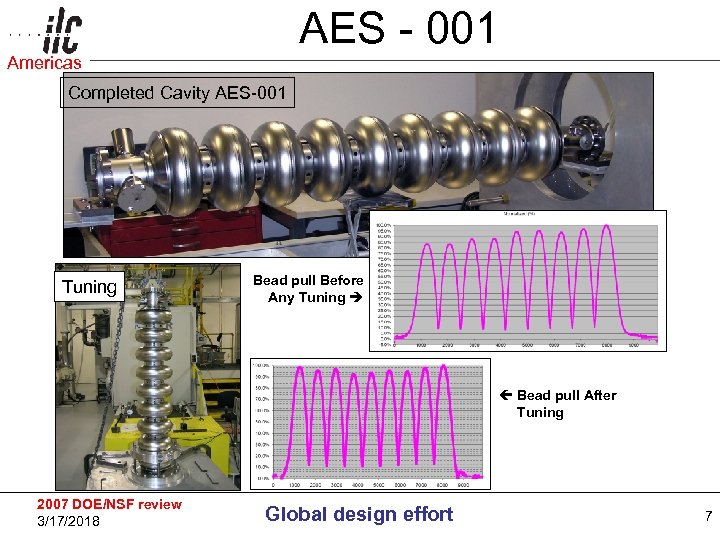

AES - 001 Americas Completed Cavity AES-001 Tuning Bead pull Before Any Tuning Bead pull After Tuning 2007 DOE/NSF review 3/17/2018 Global design effort 7

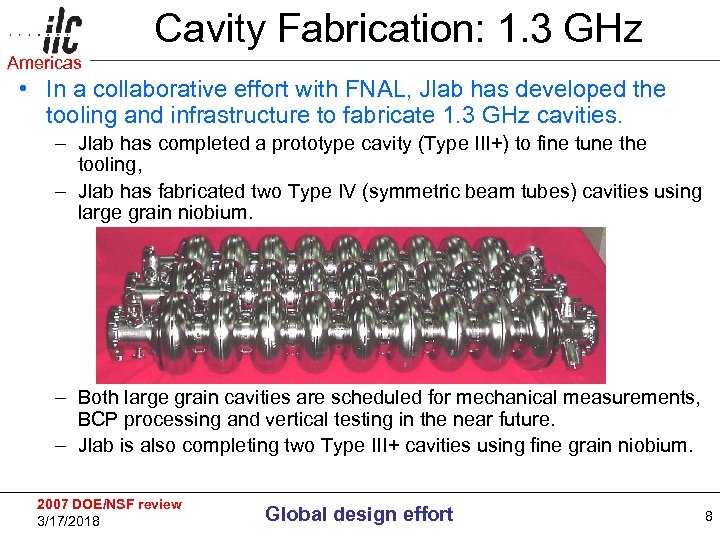

Cavity Fabrication: 1. 3 GHz Americas • In a collaborative effort with FNAL, Jlab has developed the tooling and infrastructure to fabricate 1. 3 GHz cavities. – Jlab has completed a prototype cavity (Type III+) to fine tune the tooling, – Jlab has fabricated two Type IV (symmetric beam tubes) cavities using large grain niobium. – Both large grain cavities are scheduled for mechanical measurements, BCP processing and vertical testing in the near future. – Jlab is also completing two Type III+ cavities using fine grain niobium. 2007 DOE/NSF review 3/17/2018 Global design effort 8

Cavity Fabrication & Industry Development Americas • Purchase orders were issued for fourteen additional Type IV cavities, six from AES and eight from ACCEL. – ACCEL has acquired all necessary material and has shipped the halfcell blanks to FNAL for eddy current scanning. – Material for AES is currently in Inspection at FNAL to verify conformance with the FNAL niobium specification. • Delivery date for these cavities is projected to be during the fourth quarter of FY 2007. • First step toward developing additional US Cavity vendors for cavity fabrication, – Phase I of multi-phase program is funded with Roark Engineering. Roark is building three 3. 9 GHz single-cell cavities to develop expertise in niobium machining, forming and EB welding. Tooling forming the half-cells was provided by FNAL. – Fermilab is working with Roark and Niowave in developing a collaborative venture 2007 DOE/NSF review 3/17/2018 Global design effort 9

Cavity Fabrication Plan Americas • Goals and plans for the remainder of FY 2007 and beyond – Solicit bids from industry for six or twelve Type IV cavities (plus options for four additional cavities). • FNAL will evaluate all positive responses based on technical merit, proposed schedule and cost. – Roark/Niowave collaboration with the goal of fabricating a single-cell 1. 3 GHz cavity, followed by one or two nine-cell Type IV cavities. – FNAL and Jlab will continue collaborative efforts to develop additional US vendors for cavity fabrication. – In FY 2008/09 the plan is to issue purchase requisitions for 24/60 Type IV cavities. 2007 DOE/NSF review 3/17/2018 Global design effort 10

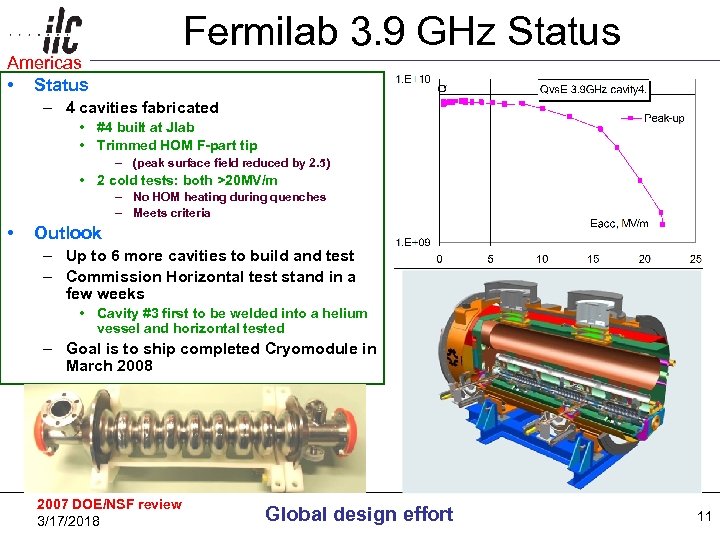

Fermilab 3. 9 GHz Status Americas • Status – 4 cavities fabricated • #4 built at Jlab • Trimmed HOM F-part tip – (peak surface field reduced by 2. 5) • 2 cold tests: both >20 MV/m – No HOM heating during quenches – Meets criteria • Outlook – Up to 6 more cavities to build and test – Commission Horizontal test stand in a few weeks • Cavity #3 first to be welded into a helium vessel and horizontal tested – Goal is to ship completed Cryomodule in March 2008 2007 DOE/NSF review 3/17/2018 Global design effort 11

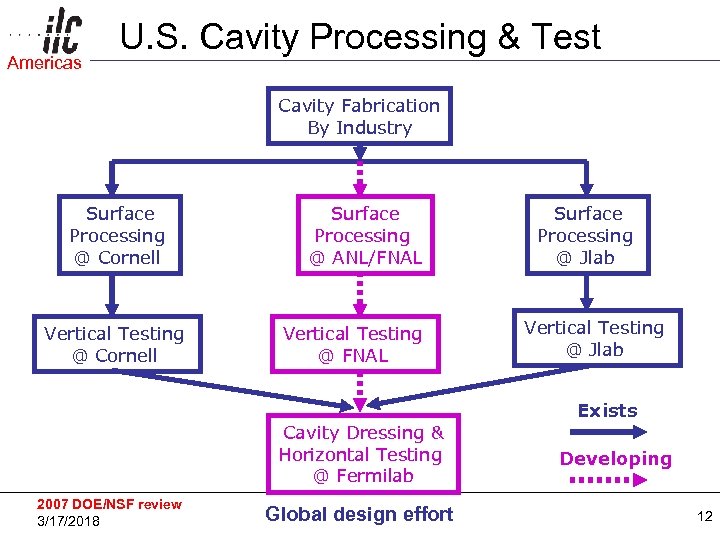

Americas U. S. Cavity Processing & Test Cavity Fabrication By Industry Surface Processing @ Cornell Vertical Testing @ Cornell Surface Processing @ ANL/FNAL Vertical Testing @ FNAL Cavity Dressing & Horizontal Testing @ Fermilab 2007 DOE/NSF review 3/17/2018 Global design effort Surface Processing @ Jlab Vertical Testing @ Jlab Exists Developing 12

Jlab: ILC Electro-polish and Vertical Test Americas • Production Like Process Established – – 12 Vertical RF Test completed 5 Bulk chemistries and 11 final chemistries completed 2 Cavities qualified for S 0 program Rate of 50 processes/year achieved with 3 FTEs • Current Issues – Production rate is limited by tooling sets and facility availability • Cavity Performance – – Quench limits reached in all but 1 RF test Field emission no problem below 30 MV/m A 7 Reached 42 MV/m on 2 nd Qualify Test AES built cavities testing started: 18 MV/m so far • 1 - Single cell baseline test completed – Easily reach the 10 planned tests for FY 07 2007 DOE/NSF review 3/17/2018 Global design effort 13

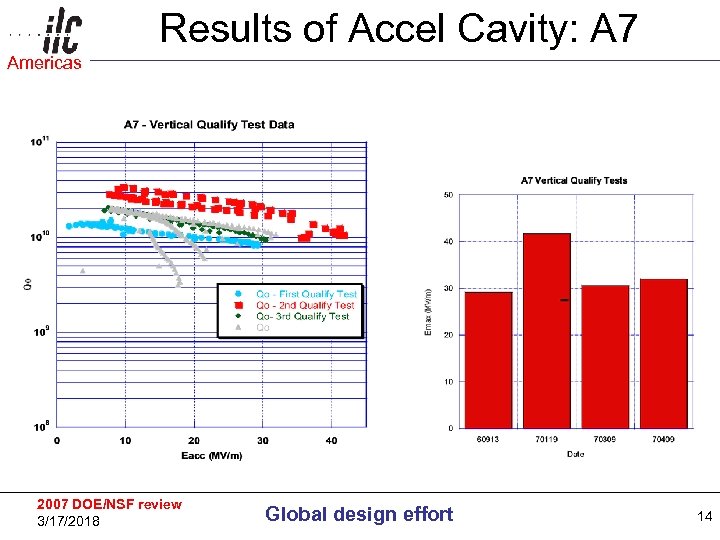

Results of Accel Cavity: A 7 Americas 2007 DOE/NSF review 3/17/2018 Global design effort 14

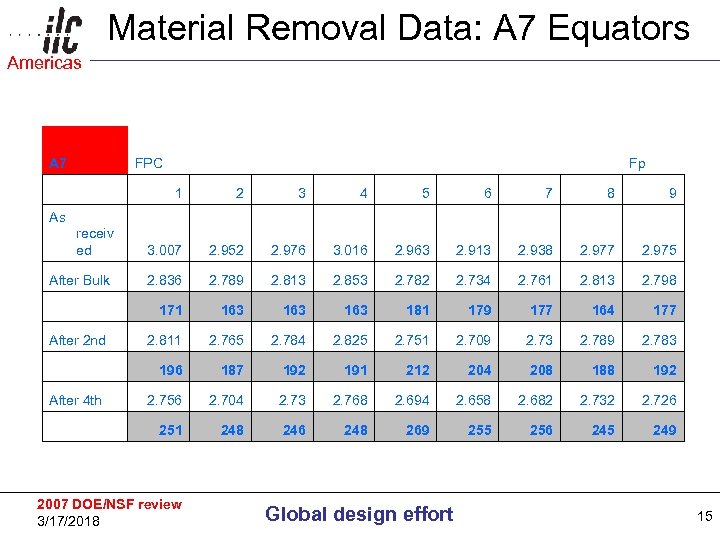

Material Removal Data: A 7 Equators Americas A 7 FPC Fp 1 2 3 4 5 6 7 8 9 receiv ed 3. 007 2. 952 2. 976 3. 016 2. 963 2. 913 2. 938 2. 977 2. 975 After Bulk 2. 836 2. 789 2. 813 2. 853 2. 782 2. 734 2. 761 2. 813 2. 798 171 163 163 181 179 177 164 177 2. 811 2. 765 2. 784 2. 825 2. 751 2. 709 2. 73 2. 789 2. 783 196 187 192 191 212 204 208 188 192 2. 756 2. 704 2. 73 2. 768 2. 694 2. 658 2. 682 2. 732 2. 726 251 248 246 248 269 255 256 245 249 As After 2 nd After 4 th 2007 DOE/NSF review 3/17/2018 Global design effort 15

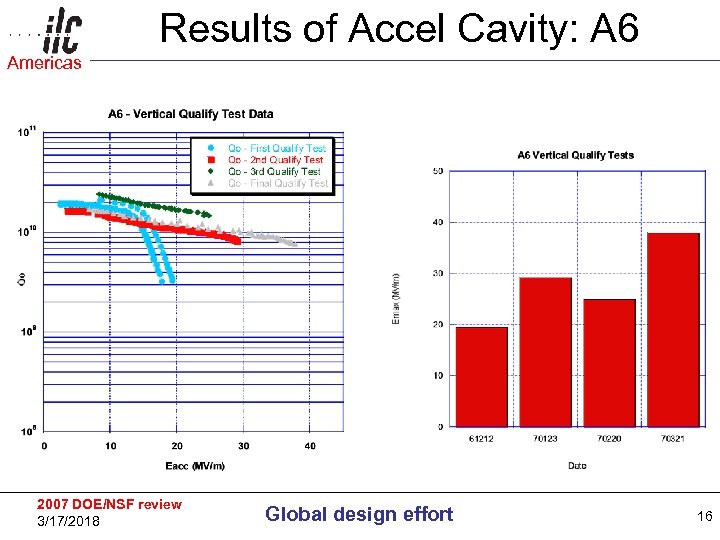

Results of Accel Cavity: A 6 Americas 2007 DOE/NSF review 3/17/2018 Global design effort 16

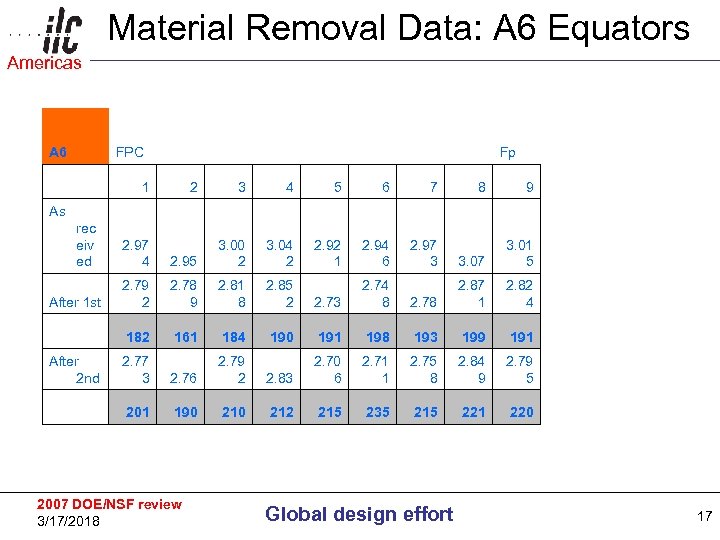

Material Removal Data: A 6 Equators Americas A 6 FPC Fp 1 2 3 4 5 6 7 8 9 2. 97 4 2. 95 3. 00 2 3. 04 2 2. 92 1 2. 94 6 2. 97 3 3. 07 3. 01 5 After 1 st 2. 79 2 2. 78 9 2. 81 8 2. 85 2 2. 73 2. 74 8 2. 78 2. 87 1 2. 82 4 182 161 184 190 191 198 193 199 191 After 2 nd 2. 77 3 2. 76 2. 79 2 2. 83 2. 70 6 2. 71 1 2. 75 8 2. 84 9 2. 79 5 201 190 212 215 235 215 221 220 As rec eiv ed 2007 DOE/NSF review 3/17/2018 Global design effort 17

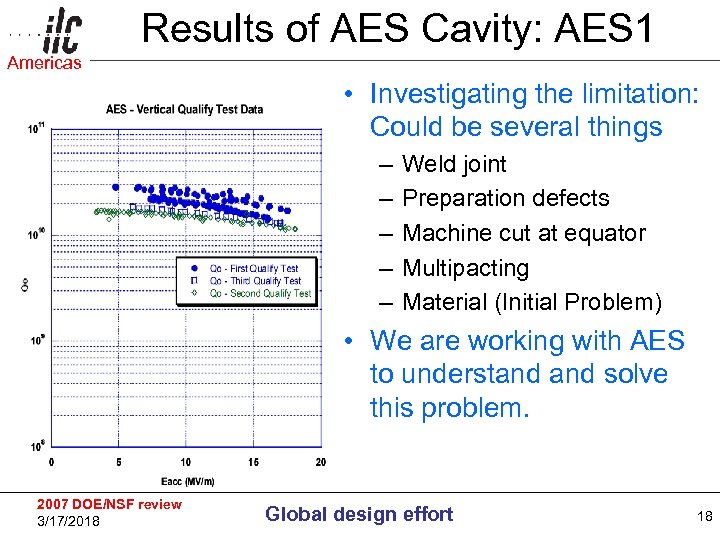

Results of AES Cavity: AES 1 Americas • Investigating the limitation: Could be several things – – – Weld joint Preparation defects Machine cut at equator Multipacting Material (Initial Problem) • We are working with AES to understand solve this problem. 2007 DOE/NSF review 3/17/2018 Global design effort 18

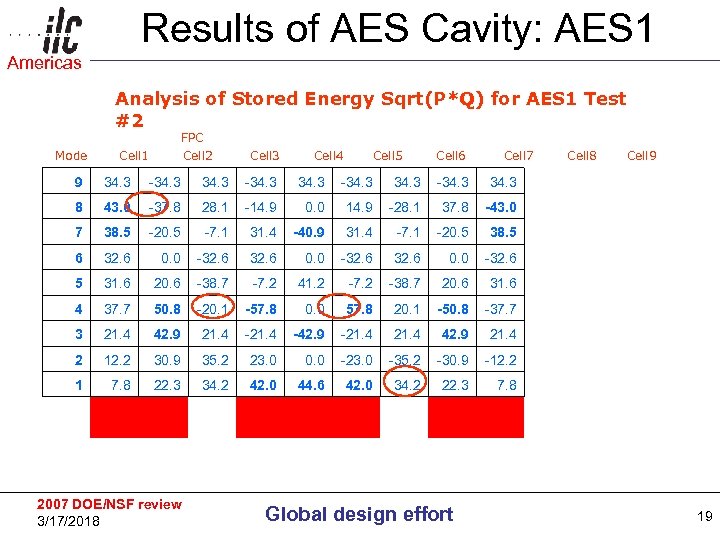

Results of AES Cavity: AES 1 Americas Analysis of Stored Energy Sqrt(P*Q) for AES 1 Test #2 Mode FPC Cell 2 Cell 1 Cell 3 Cell 4 Cell 5 Cell 6 Cell 7 9 34. 3 -34. 3 43. 0 -37. 8 28. 1 -14. 9 0. 0 14. 9 -28. 1 37. 8 -43. 0 7 38. 5 -20. 5 -7. 1 31. 4 -40. 9 31. 4 -7. 1 -20. 5 38. 5 6 32. 6 0. 0 -32. 6 5 31. 6 20. 6 -38. 7 -7. 2 41. 2 -7. 2 -38. 7 20. 6 31. 6 4 37. 7 50. 8 -20. 1 -57. 8 0. 0 57. 8 20. 1 -50. 8 -37. 7 3 21. 4 42. 9 21. 4 -42. 9 -21. 4 42. 9 21. 4 2 12. 2 30. 9 35. 2 23. 0 0. 0 -23. 0 -35. 2 -30. 9 -12. 2 1 7. 8 22. 3 34. 2 42. 0 44. 6 42. 0 34. 2 22. 3 Cell 9 34. 3 8 Cell 8 7. 8 2007 DOE/NSF review 3/17/2018 Global design effort 19

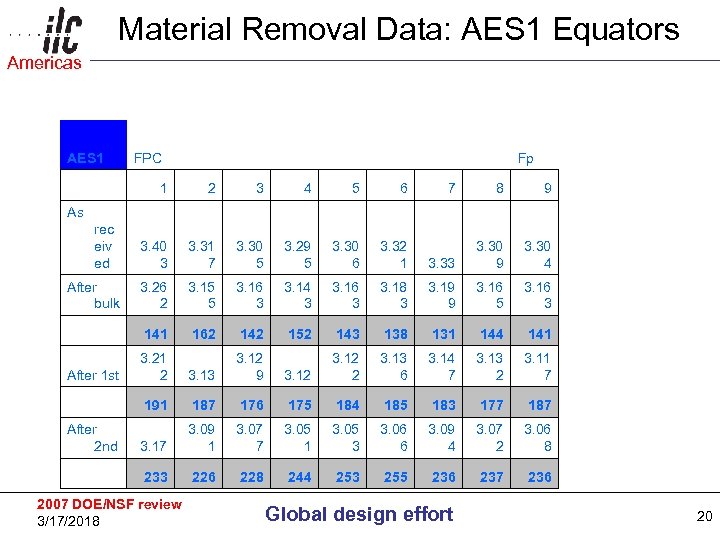

Material Removal Data: AES 1 Equators Americas AES 1 FPC Fp 1 2 3 4 5 6 7 8 9 3. 40 3 3. 31 7 3. 30 5 3. 29 5 3. 30 6 3. 32 1 3. 33 3. 30 9 3. 30 4 After bulk 3. 26 2 3. 15 5 3. 16 3 3. 14 3 3. 16 3 3. 18 3 3. 19 9 3. 16 5 3. 16 3 141 162 142 152 143 138 131 144 141 After 1 st 3. 21 2 3. 13 3. 12 9 3. 12 2 3. 13 6 3. 14 7 3. 13 2 3. 11 7 191 187 176 175 184 185 183 177 187 After 2 nd 3. 17 3. 09 1 3. 07 7 3. 05 1 3. 05 3 3. 06 6 3. 09 4 3. 07 2 3. 06 8 233 226 228 244 253 255 236 237 236 As rec eiv ed 2007 DOE/NSF review 3/17/2018 Global design effort 20

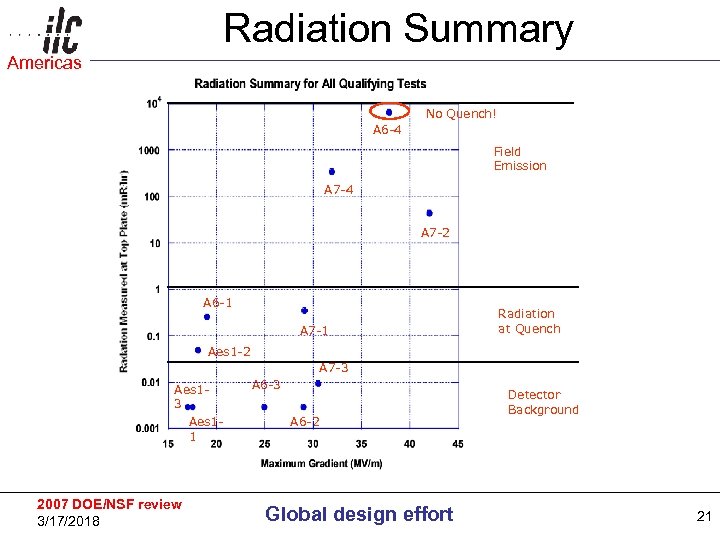

Radiation Summary Americas No Quench! A 6 -4 Field Emission A 7 -4 A 7 -2 A 6 -1 A 7 -1 Radiation at Quench Aes 1 -2 A 7 -3 Aes 11 2007 DOE/NSF review 3/17/2018 A 6 -3 A 6 -2 Global design effort Detector Background 21

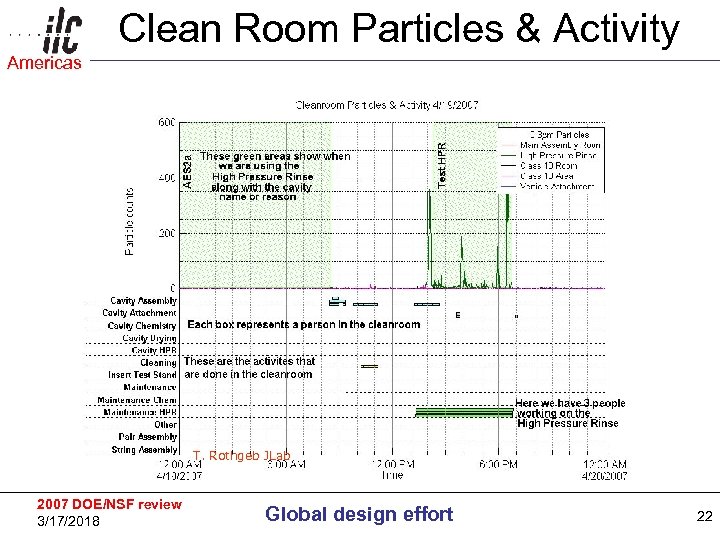

Clean Room Particles & Activity Americas T. Rothgeb JLab 2007 DOE/NSF review 3/17/2018 Global design effort 22

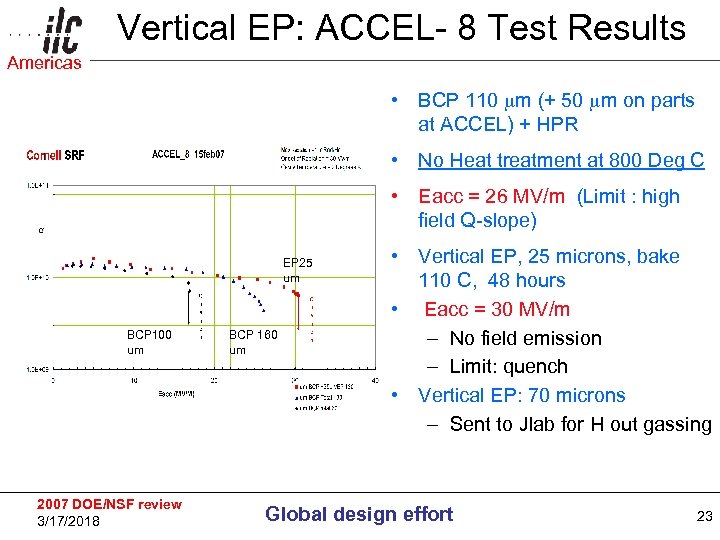

Vertical EP: ACCEL- 8 Test Results Americas • BCP 110 m (+ 50 m on parts at ACCEL) + HPR • No Heat treatment at 800 Deg C • Eacc = 26 MV/m (Limit : high field Q-slope) EP 25 um BCP 100 um 2007 DOE/NSF review 3/17/2018 BCP 160 um • Vertical EP, 25 microns, bake 110 C, 48 hours • Eacc = 30 MV/m – No field emission – Limit: quench • Vertical EP: 70 microns – Sent to Jlab for H out gassing Global design effort 23

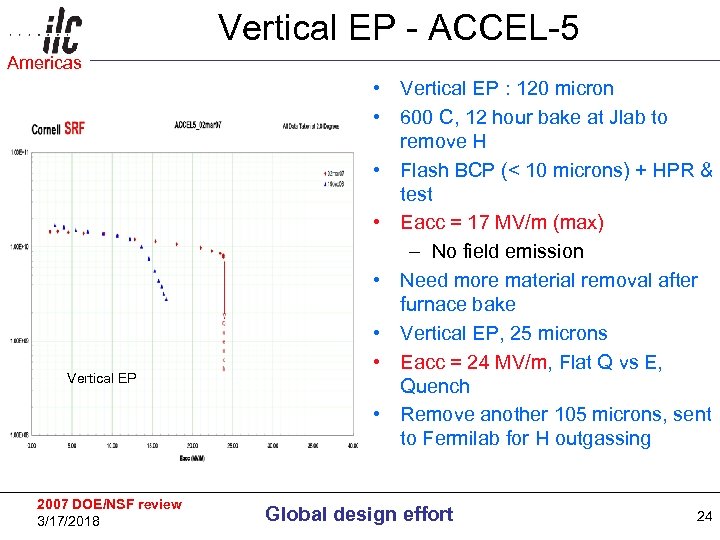

Vertical EP - ACCEL-5 Americas Vertical EP 2007 DOE/NSF review 3/17/2018 • Vertical EP : 120 micron • 600 C, 12 hour bake at Jlab to remove H • Flash BCP (< 10 microns) + HPR & test • Eacc = 17 MV/m (max) – No field emission • Need more material removal after furnace bake • Vertical EP, 25 microns • Eacc = 24 MV/m, Flat Q vs E, Quench • Remove another 105 microns, sent to Fermilab for H outgassing Global design effort 24

Cryomodule Fabrication Americas • Fermilab plans to assemble 1 st cryomodule using a kit from DESY in CY 07. – 2 cavities of this kit is here at Fermilab – Another 2 are ready for shipment, Rest is awaiting horizontal test at DESY – The cold mass is getting ready to be shipped. • Fermilab plans to assemble 2 nd cryomodule using – – – Cavity purchased and processed in US ( 10 cavities ) The cold mass has been ordered through INFN from Zenon The tuner and associated parts have been ordered through INFN Couplers have been bought from CPI and will be processed at SLAC We plan to assemble this cryomodule in mid FY 08. • Cryomodule 3 and 4 (Type-IV) – Proposed to be ordered by FNAL in FY 08 2007 DOE/NSF review 3/17/2018 Global design effort 25

T 4 CM Design Americas • Fermilab is leading an international effort in design of the ILC T 4 CM, with INFN (Milan and Pisa), KEK and CREN. • A detailed plan of who is working on what and co-ordination between groups exits. • Two cryomodules will be designed: Ø 9 cavities w/o magnet Ø 8 cavities w/ magnet package. • The deadline for completing a drawing package for the first cryomodule has been set by Fermilab to be October 1, 2007 DOE/NSF review 3/17/2018 Global design effort 26

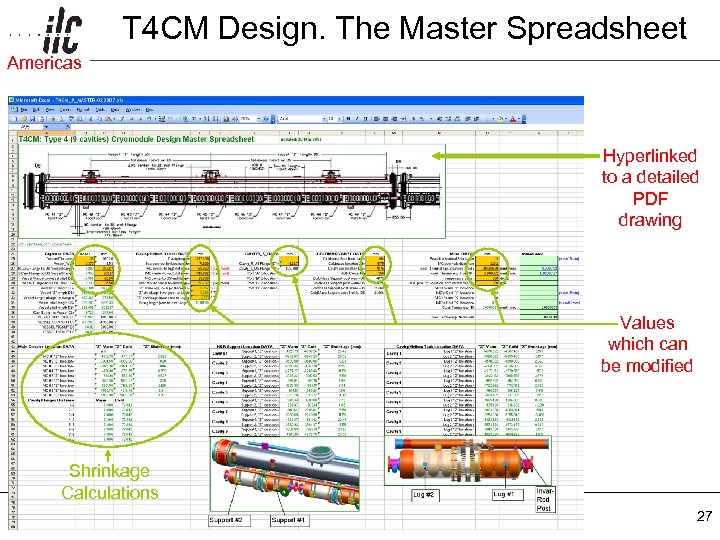

T 4 CM Design. The Master Spreadsheet Americas Hyperlinked to a detailed PDF drawing Values which can be modified Shrinkage Calculations 2007 DOE/NSF review 3/17/2018 Global design effort 27

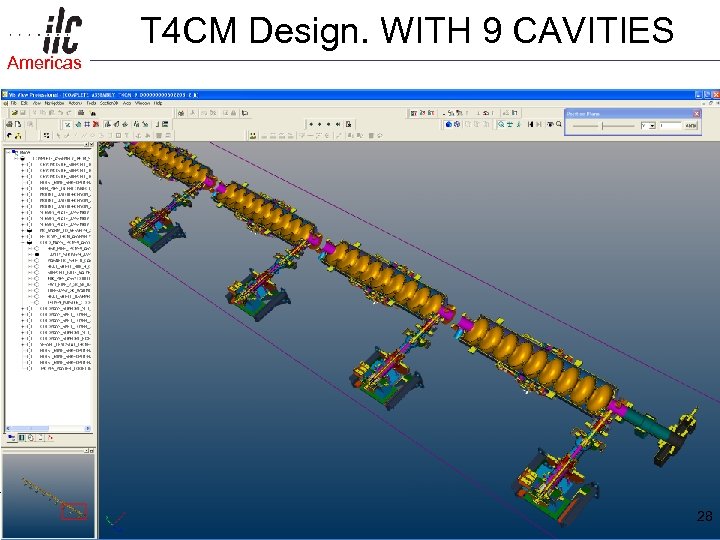

T 4 CM Design. WITH 9 CAVITIES Americas 2007 DOE/NSF review 3/17/2018 Global design effort 28

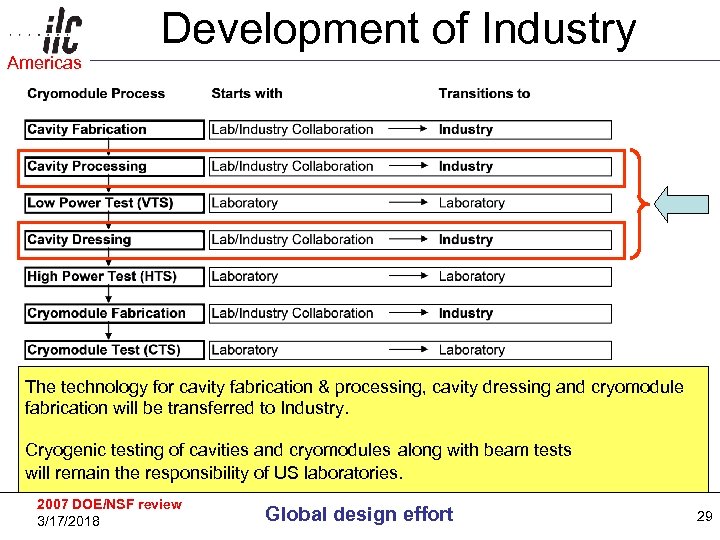

Development of Industry Americas The technology for cavity fabrication & processing, cavity dressing and cryomodule fabrication will be transferred to Industry. Cryogenic testing of cavities and cryomodules along with beam tests will remain the responsibility of US laboratories. 2007 DOE/NSF review 3/17/2018 Global design effort 29

Industrial Development Americas • We plan to work with US industry technology transfer to Dressed and tested Cavity Fabrication – The qualified US vendor will fabricate Cavity, Coupler, He Vessel, Tuner in Industry – The cavity vendor could work with a processing industry and Fermilab to process and vertical test the cavity – The coupler and He vessel industry could work with Fermilab in dressing and horizontal testing of cavities. 2007 DOE/NSF review 3/17/2018 Global design effort 30

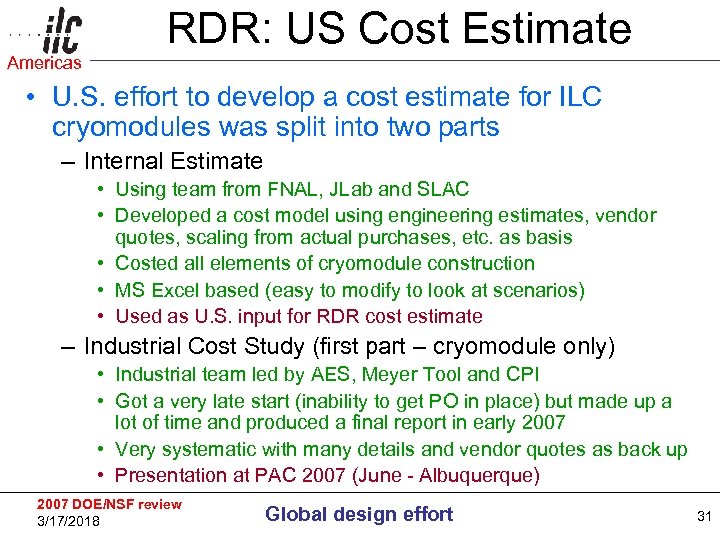

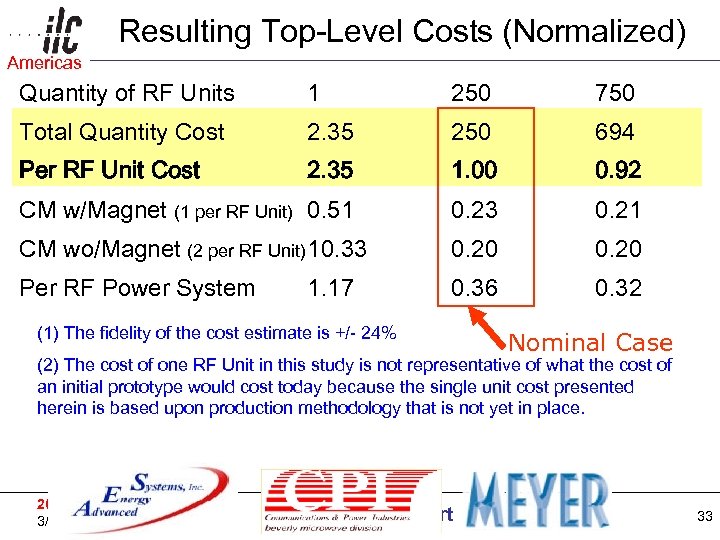

RDR: US Cost Estimate Americas • U. S. effort to develop a cost estimate for ILC cryomodules was split into two parts – Internal Estimate • Using team from FNAL, JLab and SLAC • Developed a cost model using engineering estimates, vendor quotes, scaling from actual purchases, etc. as basis • Costed all elements of cryomodule construction • MS Excel based (easy to modify to look at scenarios) • Used as U. S. input for RDR cost estimate – Industrial Cost Study (first part – cryomodule only) • Industrial team led by AES, Meyer Tool and CPI • Got a very late start (inability to get PO in place) but made up a lot of time and produced a final report in early 2007 • Very systematic with many details and vendor quotes as back up • Presentation at PAC 2007 (June - Albuquerque) 2007 DOE/NSF review 3/17/2018 Global design effort 31

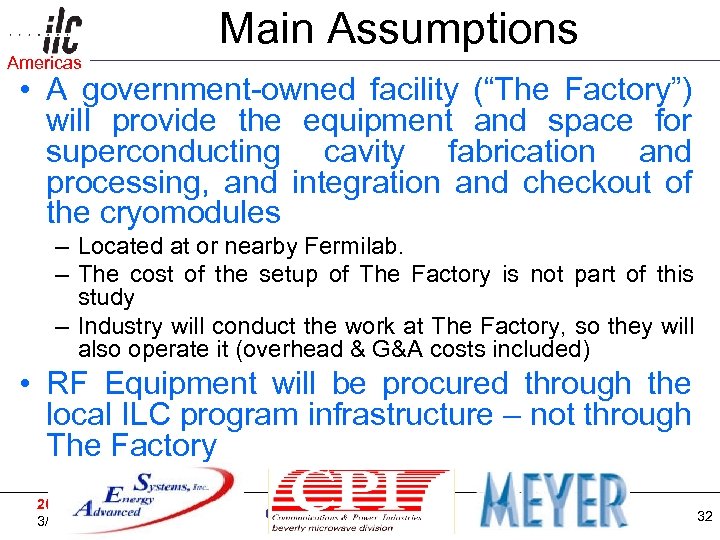

Main Assumptions Americas • A government-owned facility (“The Factory”) will provide the equipment and space for superconducting cavity fabrication and processing, and integration and checkout of the cryomodules – Located at or nearby Fermilab. – The cost of the setup of The Factory is not part of this study – Industry will conduct the work at The Factory, so they will also operate it (overhead & G&A costs included) • RF Equipment will be procured through the local ILC program infrastructure – not through The Factory 2007 DOE/NSF review 3/17/2018 Global design effort 32

Resulting Top-Level Costs (Normalized) Americas Quantity of RF Units 1 250 750 Total Quantity Cost 2. 35 250 694 Per RF Unit Cost 2. 35 1. 00 0. 92 CM w/Magnet (1 per RF Unit) 0. 51 0. 23 0. 21 CM wo/Magnet (2 per RF Unit) 10. 33 0. 20 Per RF Power System 0. 36 0. 32 1. 17 (1) The fidelity of the cost estimate is +/- 24% Nominal Case (2) The cost of one RF Unit in this study is not representative of what the cost of an initial prototype would cost today because the single unit cost presented herein is based upon production methodology that is not yet in place. 2007 DOE/NSF review 3/17/2018 Global design effort 33

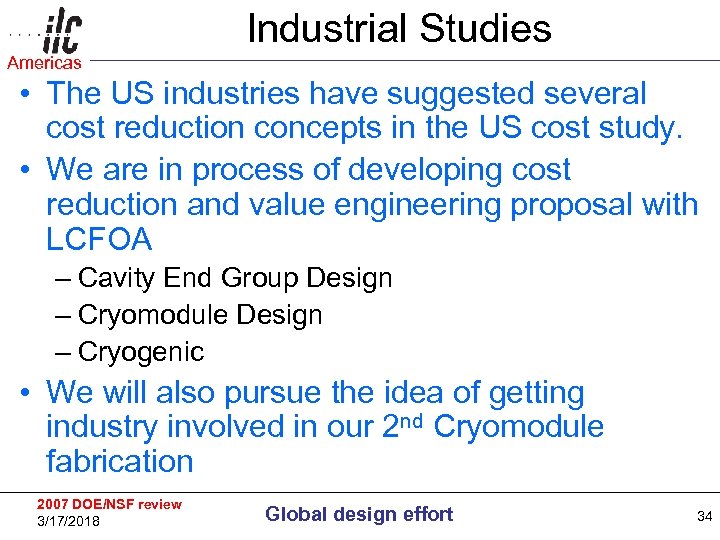

Industrial Studies Americas • The US industries have suggested several cost reduction concepts in the US cost study. • We are in process of developing cost reduction and value engineering proposal with LCFOA – Cavity End Group Design – Cryomodule Design – Cryogenic • We will also pursue the idea of getting industry involved in our 2 nd Cryomodule fabrication 2007 DOE/NSF review 3/17/2018 Global design effort 34

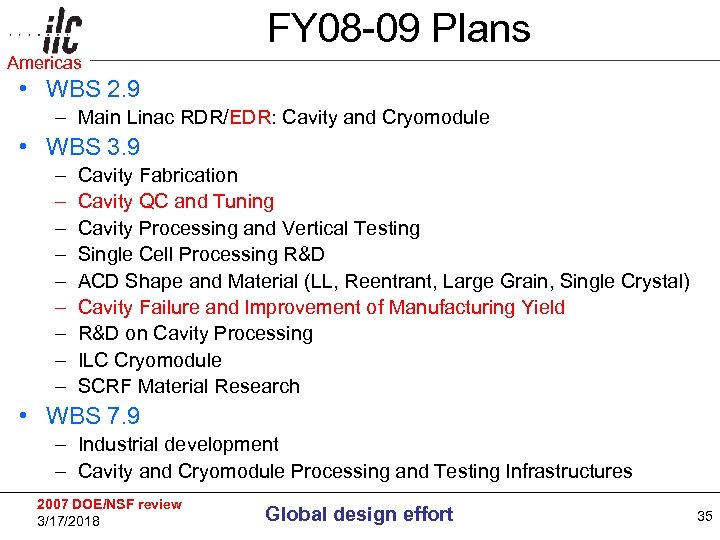

FY 08 -09 Plans Americas • WBS 2. 9 – Main Linac RDR/EDR: Cavity and Cryomodule • WBS 3. 9 – – – – – Cavity Fabrication Cavity QC and Tuning Cavity Processing and Vertical Testing Single Cell Processing R&D ACD Shape and Material (LL, Reentrant, Large Grain, Single Crystal) Cavity Failure and Improvement of Manufacturing Yield R&D on Cavity Processing ILC Cryomodule SCRF Material Research • WBS 7. 9 – Industrial development – Cavity and Cryomodule Processing and Testing Infrastructures 2007 DOE/NSF review 3/17/2018 Global design effort 35

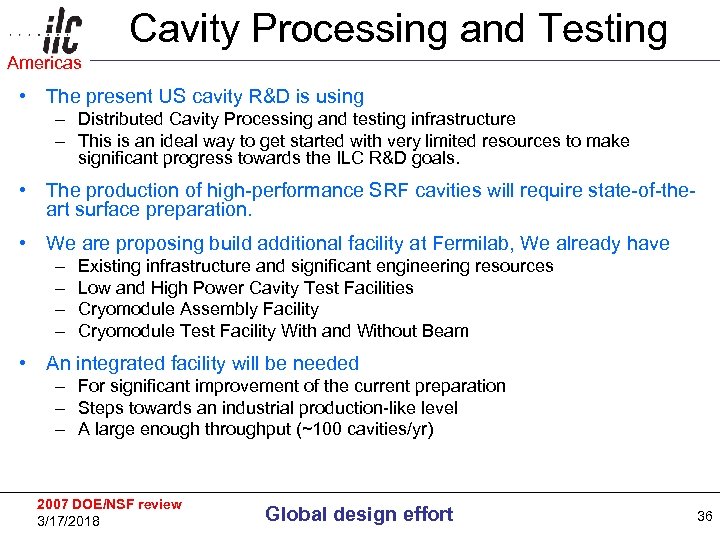

Cavity Processing and Testing Americas • The present US cavity R&D is using – Distributed Cavity Processing and testing infrastructure – This is an ideal way to get started with very limited resources to make significant progress towards the ILC R&D goals. • The production of high-performance SRF cavities will require state-of-theart surface preparation. • We are proposing build additional facility at Fermilab, We already have – – Existing infrastructure and significant engineering resources Low and High Power Cavity Test Facilities Cryomodule Assembly Facility Cryomodule Test Facility With and Without Beam • An integrated facility will be needed – For significant improvement of the current preparation – Steps towards an industrial production-like level – A large enough throughput (~100 cavities/yr) 2007 DOE/NSF review 3/17/2018 Global design effort 36

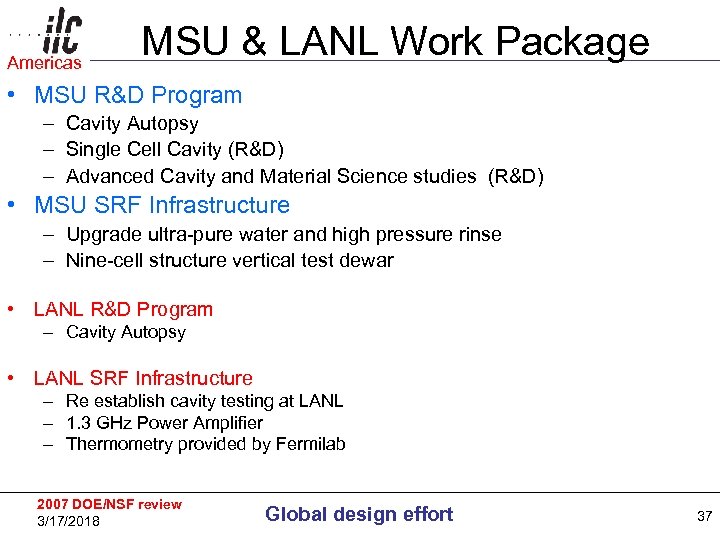

Americas MSU & LANL Work Package • MSU R&D Program – Cavity Autopsy – Single Cell Cavity (R&D) – Advanced Cavity and Material Science studies (R&D) • MSU SRF Infrastructure – Upgrade ultra-pure water and high pressure rinse – Nine-cell structure vertical test dewar • LANL R&D Program – Cavity Autopsy • LANL SRF Infrastructure – Re establish cavity testing at LANL – 1. 3 GHz Power Amplifier – Thermometry provided by Fermilab 2007 DOE/NSF review 3/17/2018 Global design effort 37

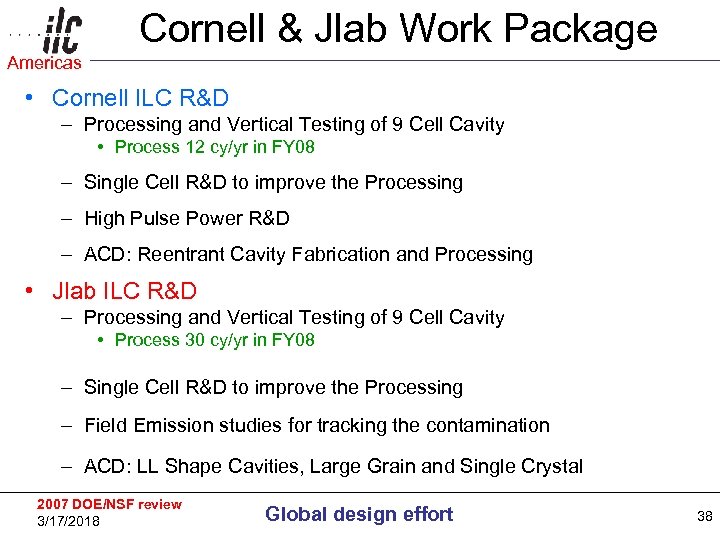

Cornell & Jlab Work Package Americas • Cornell ILC R&D – Processing and Vertical Testing of 9 Cell Cavity • Process 12 cy/yr in FY 08 – Single Cell R&D to improve the Processing – High Pulse Power R&D – ACD: Reentrant Cavity Fabrication and Processing • Jlab ILC R&D – Processing and Vertical Testing of 9 Cell Cavity • Process 30 cy/yr in FY 08 – Single Cell R&D to improve the Processing – Field Emission studies for tracking the contamination – ACD: LL Shape Cavities, Large Grain and Single Crystal 2007 DOE/NSF review 3/17/2018 Global design effort 38

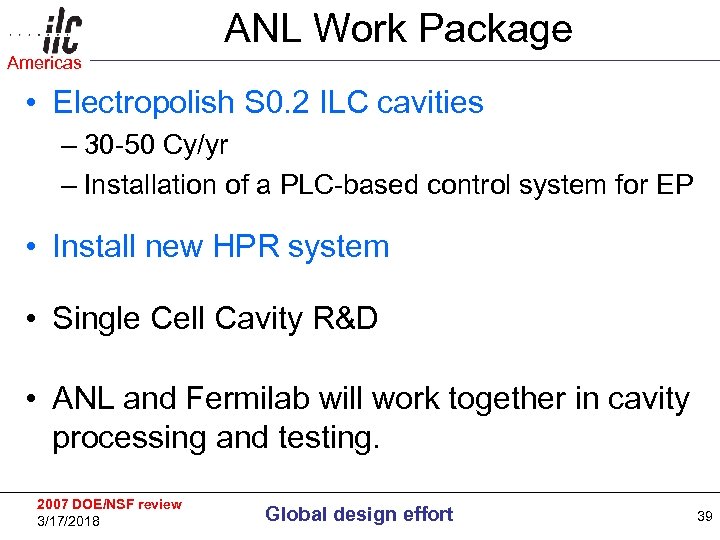

ANL Work Package Americas • Electropolish S 0. 2 ILC cavities – 30 -50 Cy/yr – Installation of a PLC-based control system for EP • Install new HPR system • Single Cell Cavity R&D • ANL and Fermilab will work together in cavity processing and testing. 2007 DOE/NSF review 3/17/2018 Global design effort 39

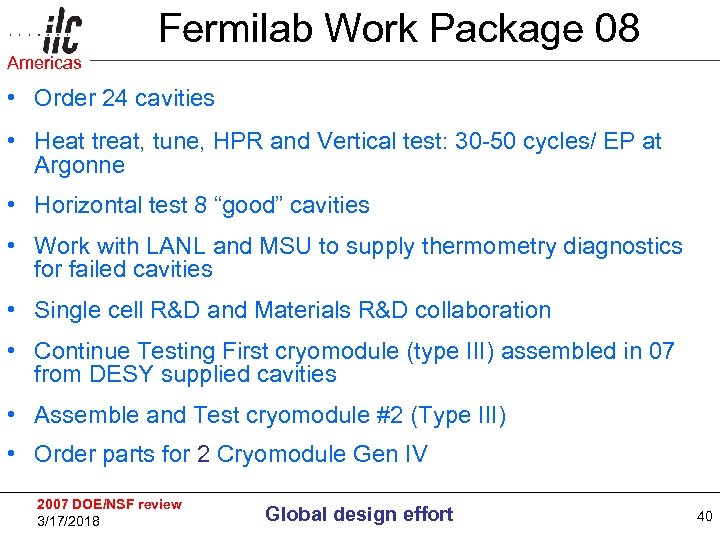

Fermilab Work Package 08 Americas • Order 24 cavities • Heat treat, tune, HPR and Vertical test: 30 -50 cycles/ EP at Argonne • Horizontal test 8 “good” cavities • Work with LANL and MSU to supply thermometry diagnostics for failed cavities • Single cell R&D and Materials R&D collaboration • Continue Testing First cryomodule (type III) assembled in 07 from DESY supplied cavities • Assemble and Test cryomodule #2 (Type III) • Order parts for 2 Cryomodule Gen IV 2007 DOE/NSF review 3/17/2018 Global design effort 40

Fermilab Work Package 08 Americas • Continue Next Generation CM design, manufacturability, transportability, cost reduction • Cavity Tuning Machine • Involve industry in fabrication of Dress Cavities activities • Start Next Generation and Pre-Production cavity processing • Vertical Test Stand to increase Capacity • RF unit infrastructure 2007 DOE/NSF review 3/17/2018 Global design effort 41

International Collaboration Americas • American Regional Team is collaborating on ILC Cavity and Cryomodule R&D. – We are participating in the S 0, S 1 and S 2 R&D programs – US purchased/produced cavities will go to KEK and DESY for “Tight Loop” S 0 processing – KEK and DESY cavities will come to US for processing. • We are coordinating the ILC Cryomodule Design effort • We collaborate with INFN in development and testing of Tuner • We are developing new collaboration – India (RRCAT, BARC, IUAC, UD) joined TTC • Detailed MOU is in preparation that could lead to an RF unit fabrication • India is fabricating Cavity fabrication tooling • Two scientists from India will spend time at Fermilab and coordinate work at Indian laboratories. – TRIUMF • Cavity fabrication • Tuner 2007 DOE/NSF review 3/17/2018 Global design effort 42

Summary Americas • We have made considerable progress in building US infrastructure for cavity fabrication, processing and testing. • We are ready to play a significant role in cavity and cryomodule R&D – Cavity Processing (> 30 Mv/m) – Cryomodule design and fabrication • The initial plan for FY 08 -09 is in place – This uses the developed strength of the US laboratories in cavity processing – We are developing significant infrastructure at Fermilab – We will work with US industry • International Collaboration 2007 DOE/NSF review 3/17/2018 Global design effort 43

46ccb02045f6ab34c7ece47966ee19c1.ppt