ff2ac7ef536b8edd604d290d186cb910.ppt

- Количество слайдов: 93

AMCA International Technical Seminar 2009 Energy Efficiency Classification for Fans John Cermak, Ph. D. , P. Eng. , M. Sc. Executive Vice President ACME Engineering and Manufacturing Corp.

AMCA International Technical Seminar 2009 Energy Efficiency Classification for Fans John Cermak, Ph. D. , P. Eng. , M. Sc. Executive Vice President ACME Engineering and Manufacturing Corp.

The Air Movement and Control Association International (AMCA), has met the standards and requirements of the Registered Continuing Education Providers Program. Credit earned on completion of this program will be reported to the RCEPP. A certificate of completion will be issued to each participant. As such, it does not include content that may be deemed or construed to be an approval or endorsement by NCEES or RCEPP.

The Air Movement and Control Association International (AMCA), has met the standards and requirements of the Registered Continuing Education Providers Program. Credit earned on completion of this program will be reported to the RCEPP. A certificate of completion will be issued to each participant. As such, it does not include content that may be deemed or construed to be an approval or endorsement by NCEES or RCEPP.

Learning Objectives • • • Learn about the current actions in fan industry leading to immediate and long term improvement in energy consumption by fans Understand the choices of the corner stones for building the AMCA Int’l initiative in ASHRAE and ISO Learn about importance of fan total pressure for finding energy savings Understand how fan selection impacts energy consumption of fans Understand how knowledge of the fan discharge energy contributes to successful fan selection from energy consumption point Learn about standardization of fan energy efficiency for better usage of energy by fans

Learning Objectives • • • Learn about the current actions in fan industry leading to immediate and long term improvement in energy consumption by fans Understand the choices of the corner stones for building the AMCA Int’l initiative in ASHRAE and ISO Learn about importance of fan total pressure for finding energy savings Understand how fan selection impacts energy consumption of fans Understand how knowledge of the fan discharge energy contributes to successful fan selection from energy consumption point Learn about standardization of fan energy efficiency for better usage of energy by fans

Fan Industry Energy Consumption Challenge

Fan Industry Energy Consumption Challenge

What is Happening? 5

What is Happening? 5

What is happening ASHRAE – 90. 1 Standard (revision 2010) – TC 5. 1 Fans - ad hoc WG 90. 1 6

What is happening ASHRAE – 90. 1 Standard (revision 2010) – TC 5. 1 Fans - ad hoc WG 90. 1 6

What is happening AMCA International – Mid-year and annual meetings 08 – Fan Committee – SC for AMCA 205 – AMCA Standard 205 “Energy Efficiency Classification for Fans” 7

What is happening AMCA International – Mid-year and annual meetings 08 – Fan Committee – SC for AMCA 205 – AMCA Standard 205 “Energy Efficiency Classification for Fans” 7

What is happening ISO/TC 117 Fans – WG 11 Fan Efficiency – DIS 12759 Energy Classification for fans 8

What is happening ISO/TC 117 Fans – WG 11 Fan Efficiency – DIS 12759 Energy Classification for fans 8

What is happening AMCA International active in ASHRAE ANSI ISO 9

What is happening AMCA International active in ASHRAE ANSI ISO 9

Purpose

Purpose

Purpose AMCA International supporting Legislative bodies Regulatory bodies in U. S. A. as well as in other countries 11

Purpose AMCA International supporting Legislative bodies Regulatory bodies in U. S. A. as well as in other countries 11

Purpose Establishing ways and goals to achieve significant energy savings in usage of fans 12

Purpose Establishing ways and goals to achieve significant energy savings in usage of fans 12

Purpose Making the application of fans fitting the energy consumption goals without making it difficult 13

Purpose Making the application of fans fitting the energy consumption goals without making it difficult 13

Corner Stones

Corner Stones

Corner Stones Fan energy efficiency based on fan total pressure 15

Corner Stones Fan energy efficiency based on fan total pressure 15

Corner Stones Tool for regulative bodies 16

Corner Stones Tool for regulative bodies 16

Corner Stones Support fan manufacturers’ effort to improve the energy efficiency of their products 17

Corner Stones Support fan manufacturers’ effort to improve the energy efficiency of their products 17

Corner Stones As much as possible keep one series in one efficiency grade 18

Corner Stones As much as possible keep one series in one efficiency grade 18

Corner Stones Fan peak total efficiency of a fan series is dependent on fan size 19

Corner Stones Fan peak total efficiency of a fan series is dependent on fan size 19

Corner Stones Defining areas of responsibility for: Fan manufacturer Motor manufacturer HVAC system designer 20

Corner Stones Defining areas of responsibility for: Fan manufacturer Motor manufacturer HVAC system designer 20

Fan Total Pressure Why?

Fan Total Pressure Why?

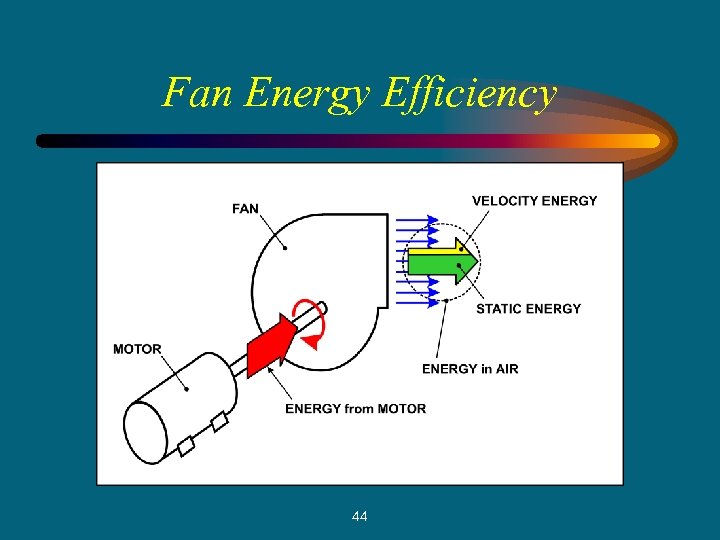

Total or Static? Fan creates pressures: dynamic (velocity) and static 22

Total or Static? Fan creates pressures: dynamic (velocity) and static 22

Total or Static Both pressures are also specific energies a unit of flow exerted into the air by a fan 23

Total or Static Both pressures are also specific energies a unit of flow exerted into the air by a fan 23

Total or Static? • Fan is a device to create air flow as its primary function • The motion of the air carries dynamic (velocity) energy 24

Total or Static? • Fan is a device to create air flow as its primary function • The motion of the air carries dynamic (velocity) energy 24

Total or Static? Fan total pressure is sum of dynamic (velocity) pressure and static pressure 25

Total or Static? Fan total pressure is sum of dynamic (velocity) pressure and static pressure 25

Answer For fan selection are needed at least two from the three fan pressures: total and velocity static and velocity total and static 26

Answer For fan selection are needed at least two from the three fan pressures: total and velocity static and velocity total and static 26

Fan Selection 27

Fan Selection 27

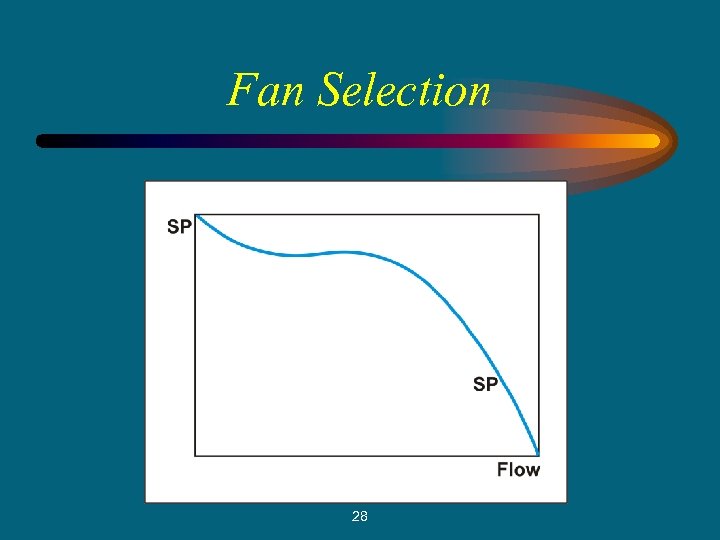

Fan Selection 28

Fan Selection 28

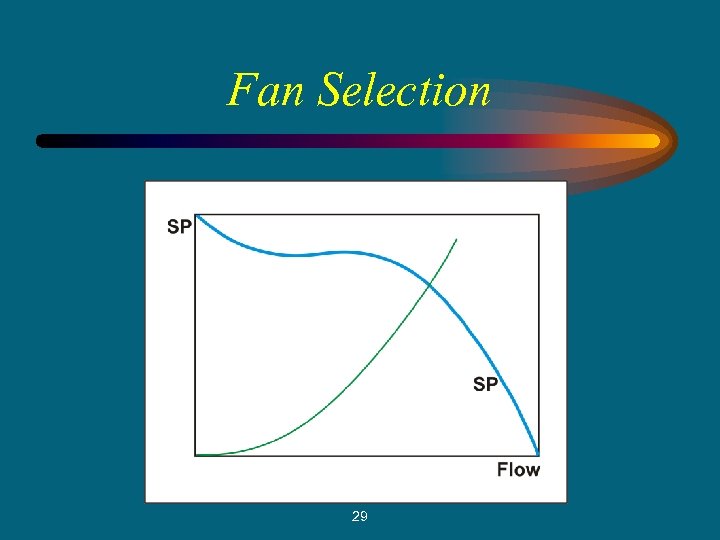

Fan Selection 29

Fan Selection 29

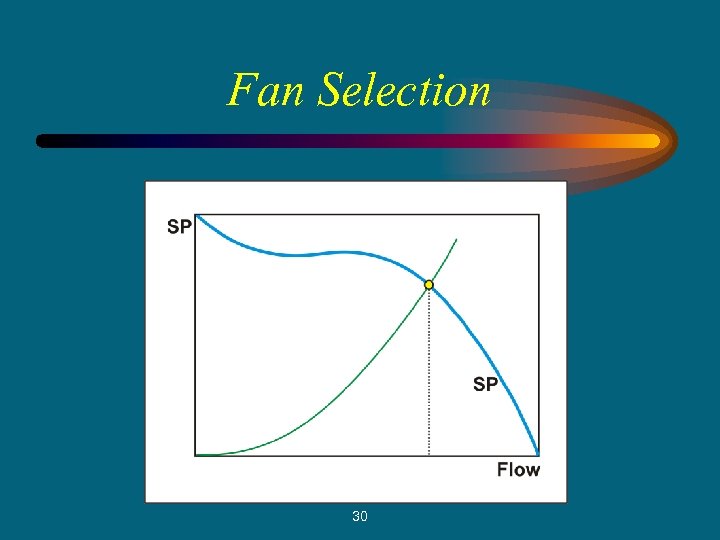

Fan Selection 30

Fan Selection 30

Fan Selection • Matching the pressure drop across the system against fan static pressure does not give the correct flow, fan size and power 31

Fan Selection • Matching the pressure drop across the system against fan static pressure does not give the correct flow, fan size and power 31

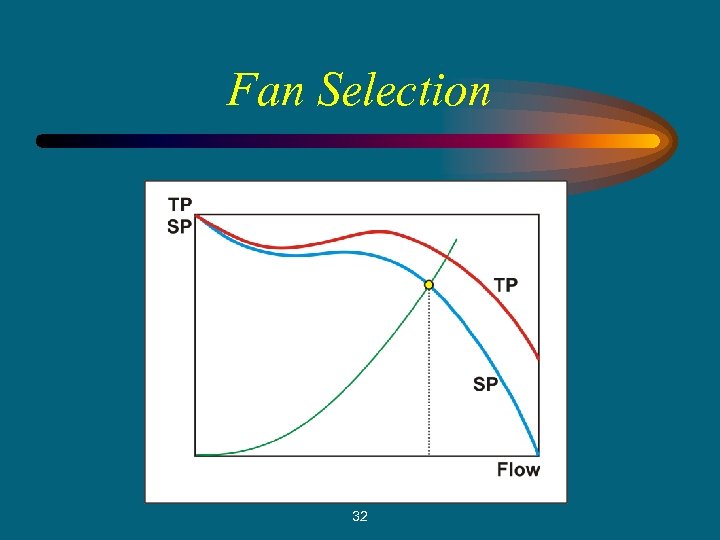

Fan Selection 32

Fan Selection 32

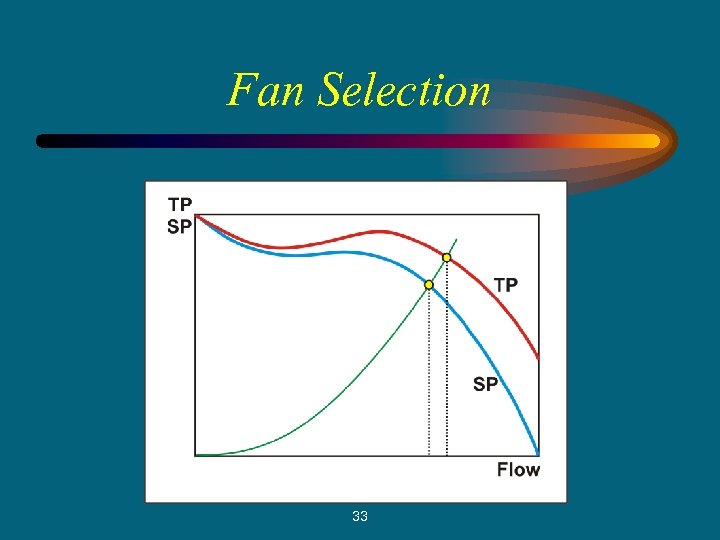

Fan Selection 33

Fan Selection 33

Using Fan Discharge Energy 34

Using Fan Discharge Energy 34

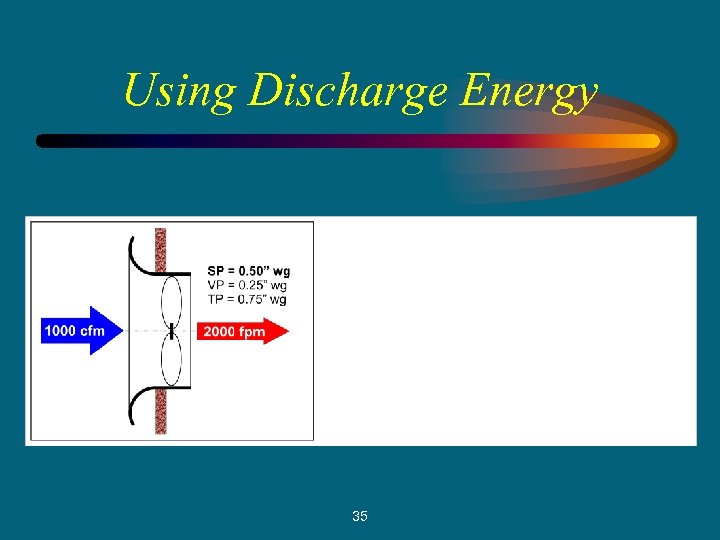

Using Discharge Energy 35

Using Discharge Energy 35

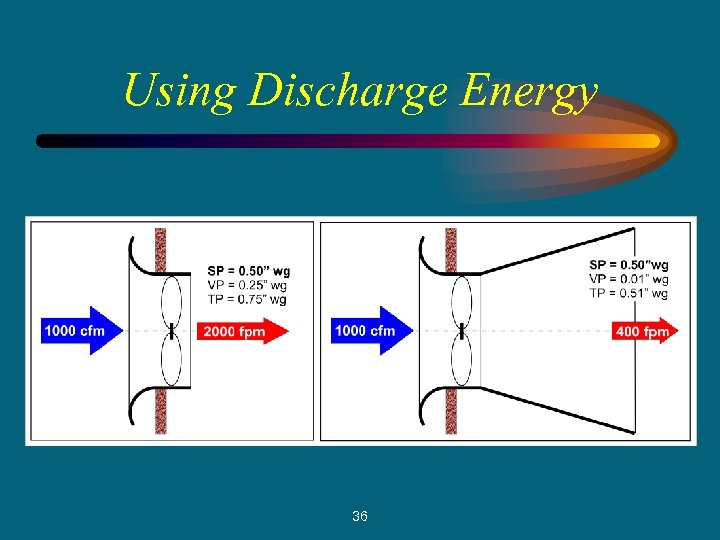

Using Discharge Energy 36

Using Discharge Energy 36

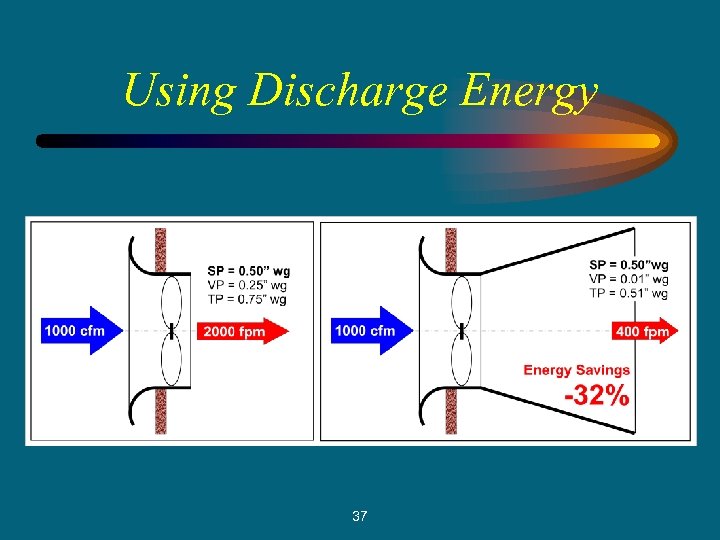

Using Discharge Energy 37

Using Discharge Energy 37

Fan Characteristics 38

Fan Characteristics 38

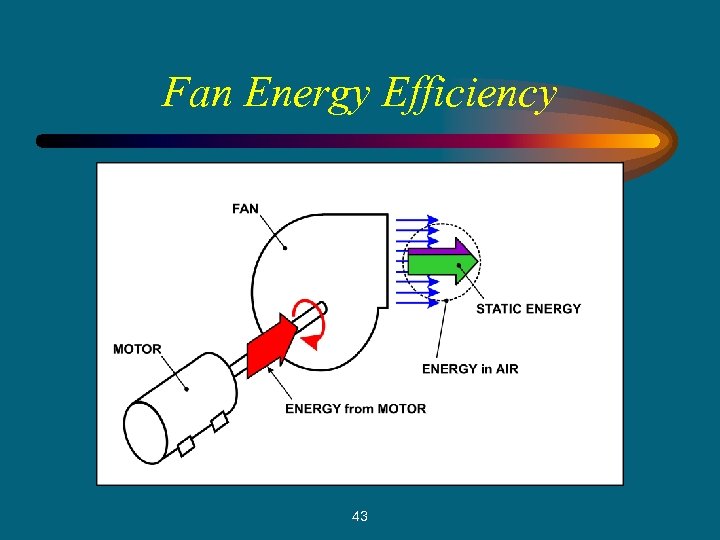

Fan Energy Efficiency • Fan is a device creating air flow and transferring energy from the motor into the air • Fan Total Pressure is the total energy exerted into air by fan 39

Fan Energy Efficiency • Fan is a device creating air flow and transferring energy from the motor into the air • Fan Total Pressure is the total energy exerted into air by fan 39

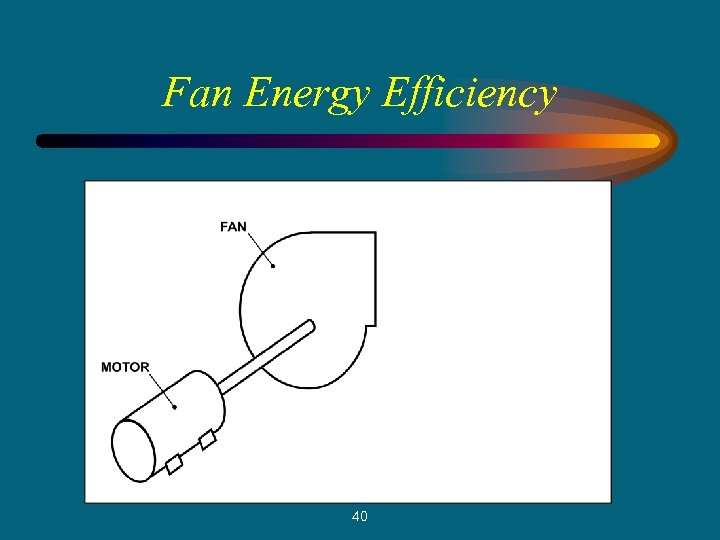

Fan Energy Efficiency 40

Fan Energy Efficiency 40

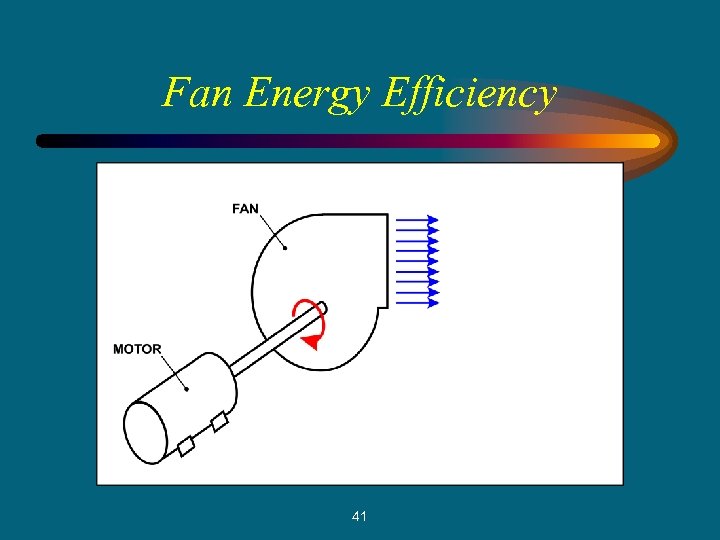

Fan Energy Efficiency 41

Fan Energy Efficiency 41

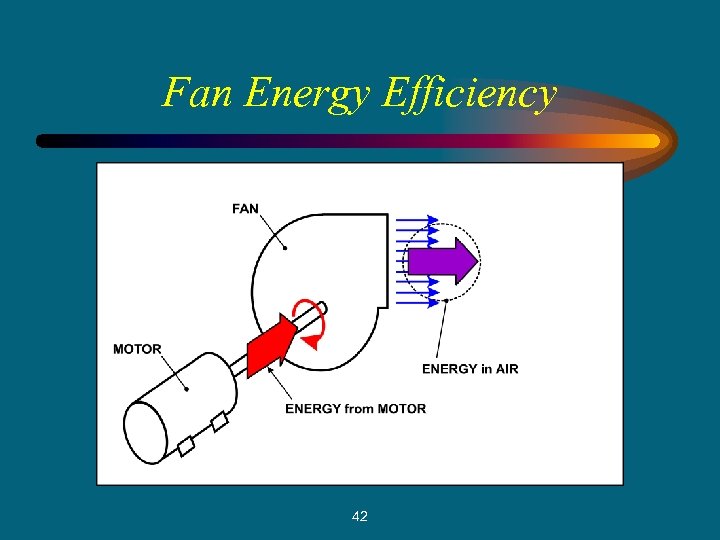

Fan Energy Efficiency 42

Fan Energy Efficiency 42

Fan Energy Efficiency 43

Fan Energy Efficiency 43

Fan Energy Efficiency 44

Fan Energy Efficiency 44

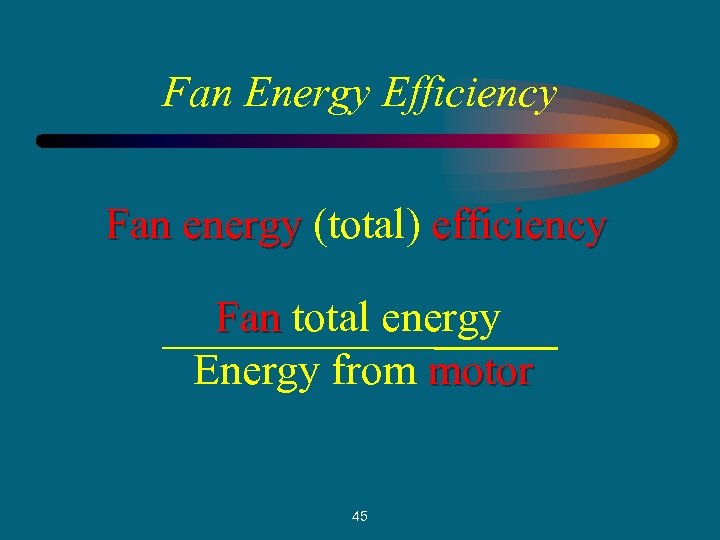

Fan Energy Efficiency Fan energy (total) efficiency Fan total energy Energy from motor 45

Fan Energy Efficiency Fan energy (total) efficiency Fan total energy Energy from motor 45

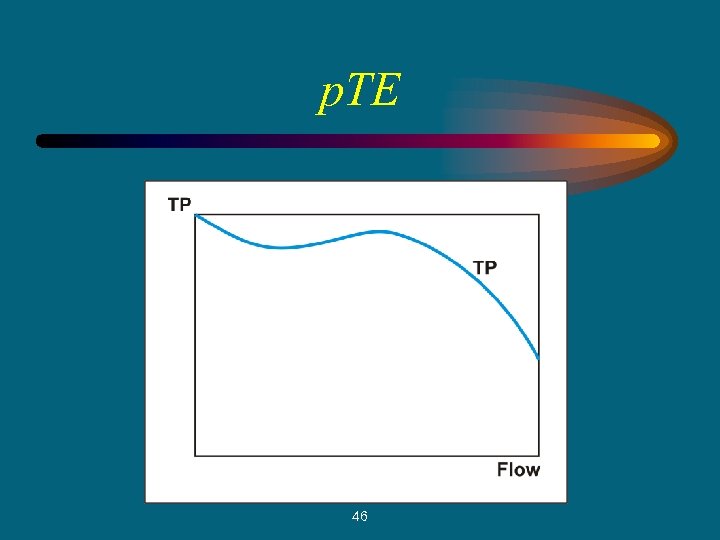

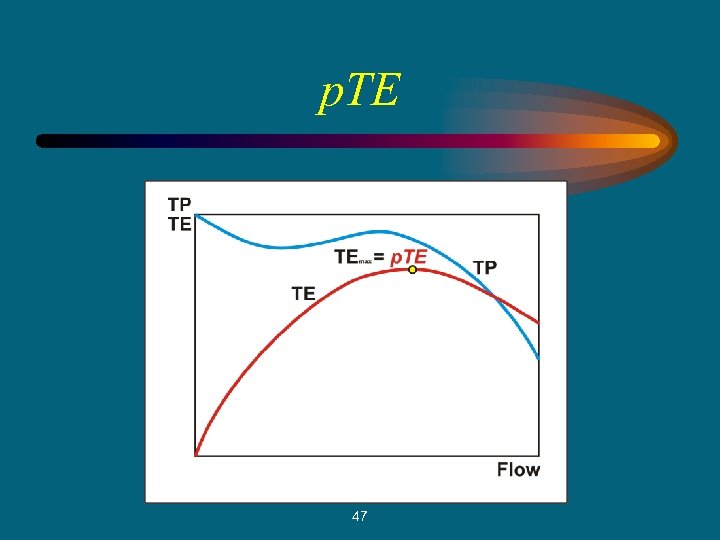

p. TE 46

p. TE 46

p. TE 47

p. TE 47

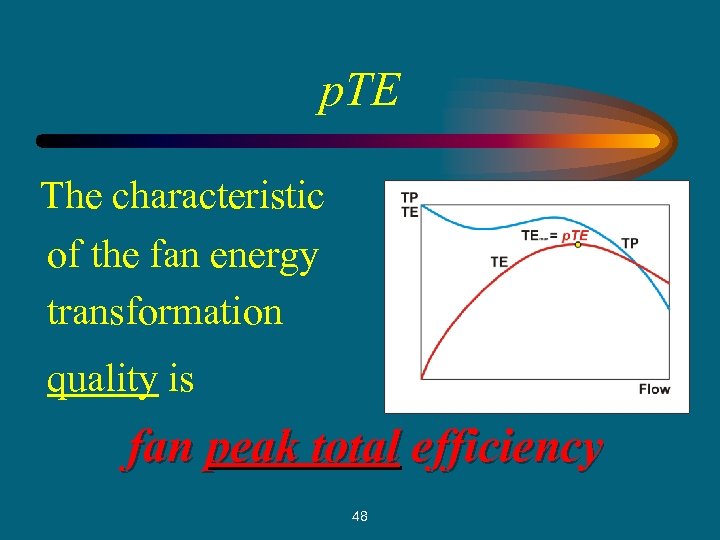

p. TE The characteristic of the fan energy transformation quality is fan peak total efficiency 48

p. TE The characteristic of the fan energy transformation quality is fan peak total efficiency 48

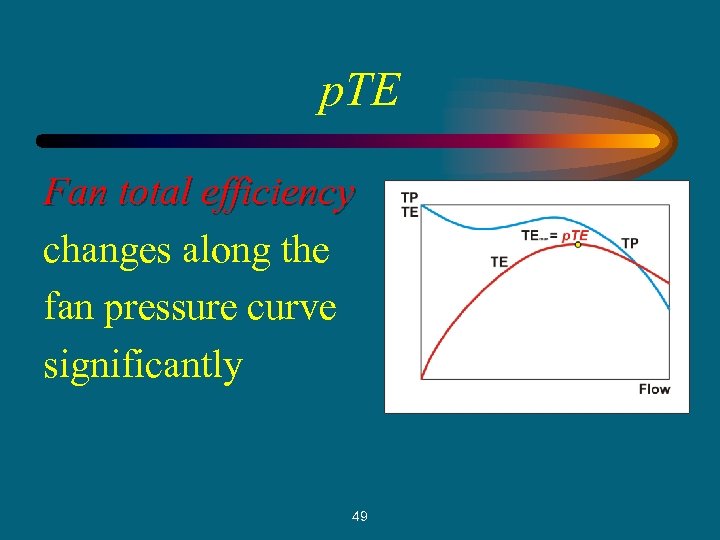

p. TE Fan total efficiency changes along the fan pressure curve significantly 49

p. TE Fan total efficiency changes along the fan pressure curve significantly 49

Fan size and p. TE 50

Fan size and p. TE 50

p. TE At constant tip speed the fan p. TE of a fan Series changes with the fan size 51

p. TE At constant tip speed the fan p. TE of a fan Series changes with the fan size 51

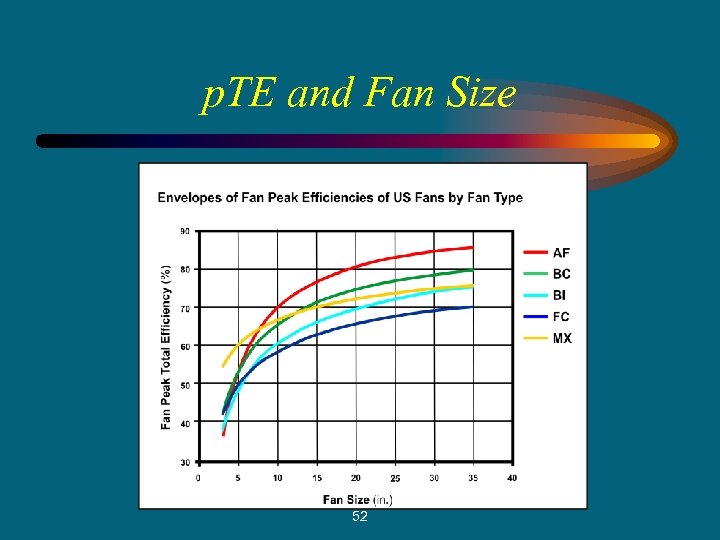

p. TE and Fan Size 52

p. TE and Fan Size 52

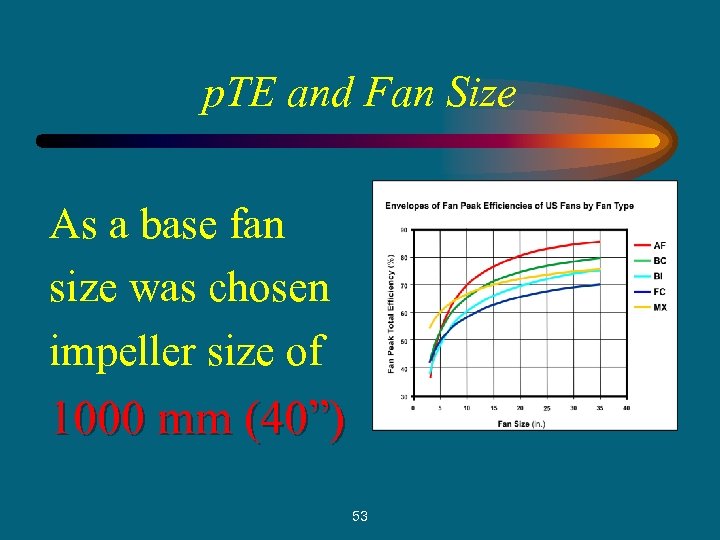

p. TE and Fan Size As a base fan size was chosen impeller size of 1000 mm (40”) 53

p. TE and Fan Size As a base fan size was chosen impeller size of 1000 mm (40”) 53

Fan Size Effect The Size Effect includes effects – Reynolds number – changes in flow pattern – impact of volumetric and mechanical losses 54

Fan Size Effect The Size Effect includes effects – Reynolds number – changes in flow pattern – impact of volumetric and mechanical losses 54

Fan Size Effect The Size Effect includes effects – deviations from geometrical similarity from size to size 55

Fan Size Effect The Size Effect includes effects – deviations from geometrical similarity from size to size 55

Fan Size Effect The character of the Size Effect changes from one fan Series to another 56

Fan Size Effect The character of the Size Effect changes from one fan Series to another 56

Design of FEG System FEG = Fan Efficiency Grade

Design of FEG System FEG = Fan Efficiency Grade

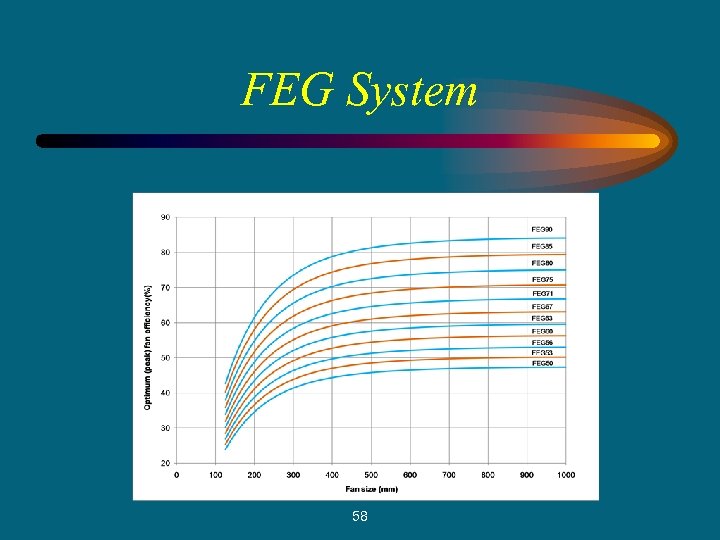

FEG System 58

FEG System 58

FEG System • Grade labels in preferred numbers e. g. FEG 80, 71, 63 etc. 80 • Layer thickness is 6% 59

FEG System • Grade labels in preferred numbers e. g. FEG 80, 71, 63 etc. 80 • Layer thickness is 6% 59

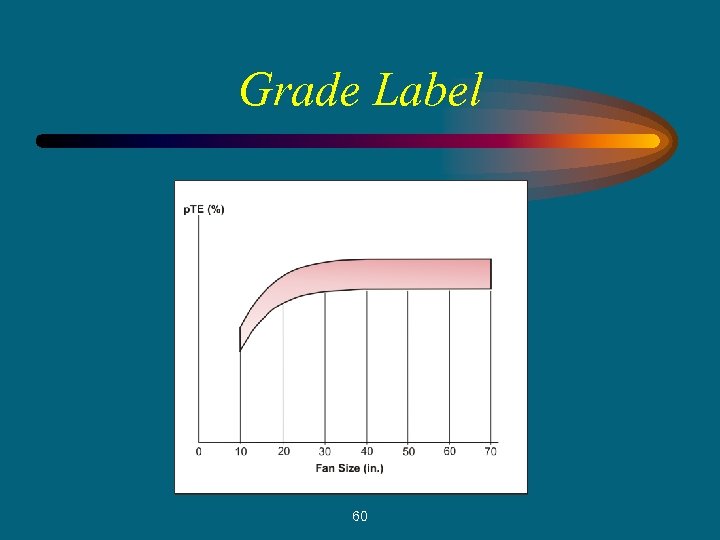

Grade Label 60

Grade Label 60

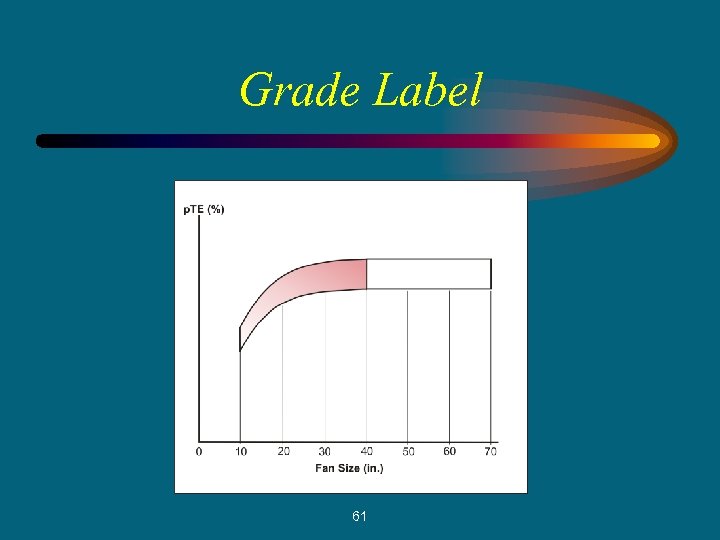

Grade Label 61

Grade Label 61

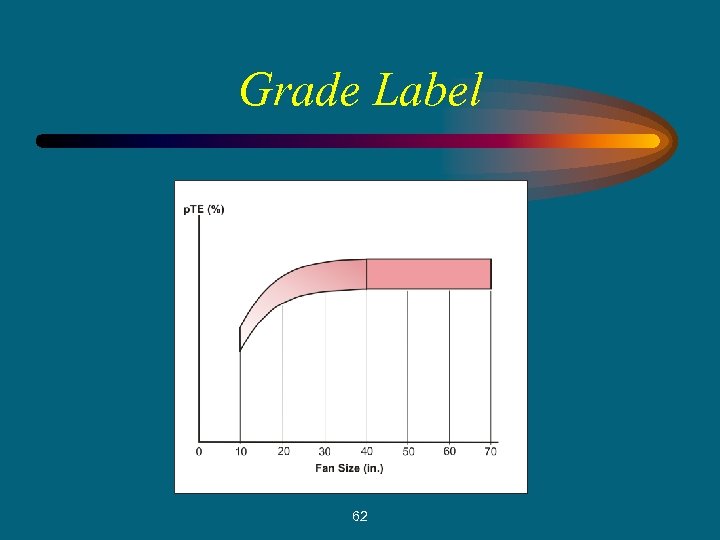

Grade Label 62

Grade Label 62

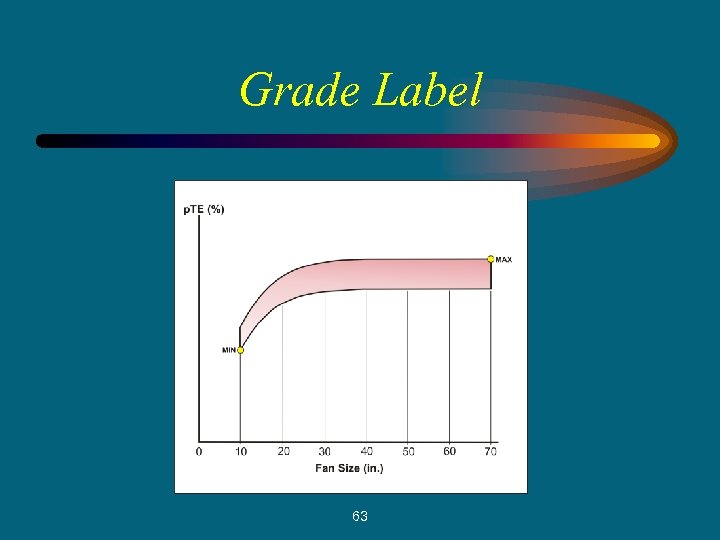

Grade Label 63

Grade Label 63

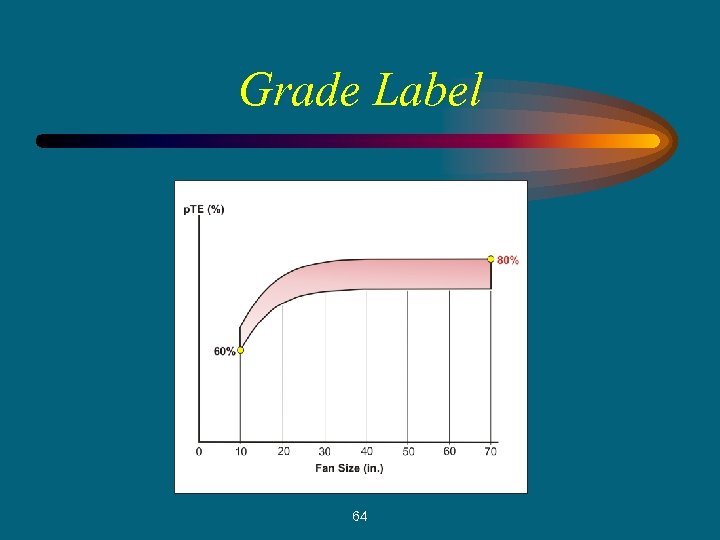

Grade Label 64

Grade Label 64

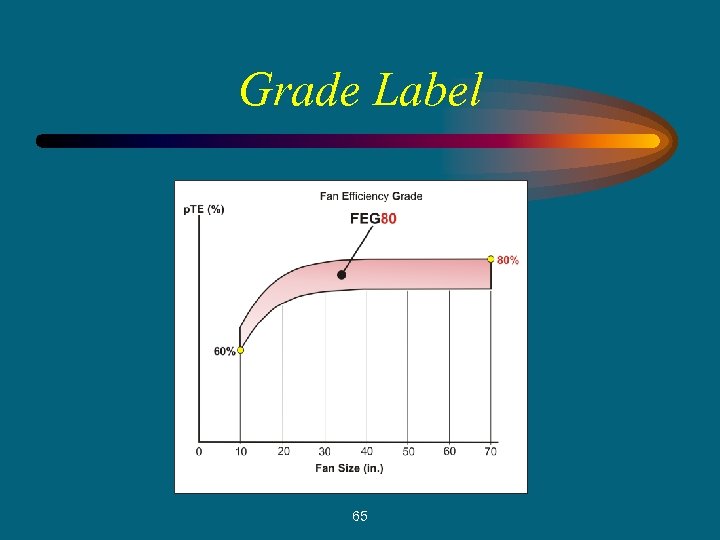

Grade Label 65

Grade Label 65

Attached Conditions Using these conditions would yield the fastest energy savings

Attached Conditions Using these conditions would yield the fastest energy savings

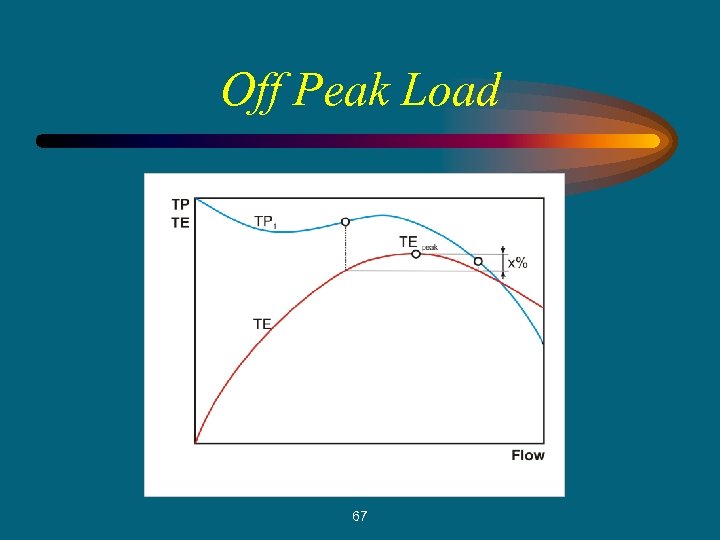

Off Peak Load 67

Off Peak Load 67

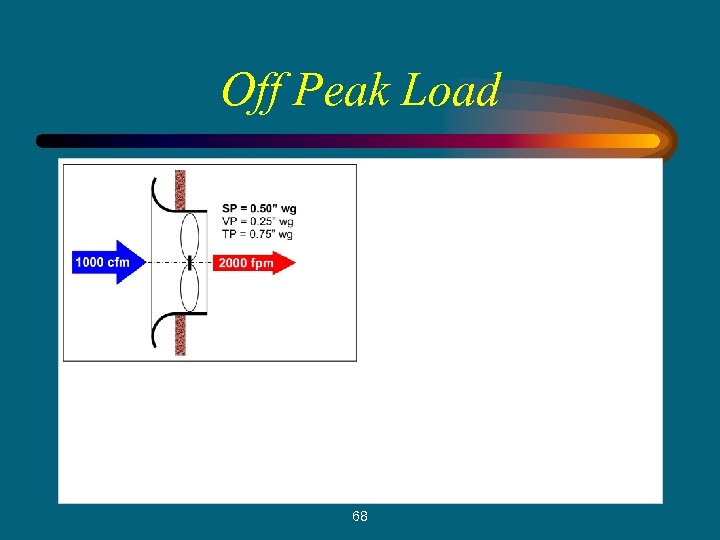

Off Peak Load 68

Off Peak Load 68

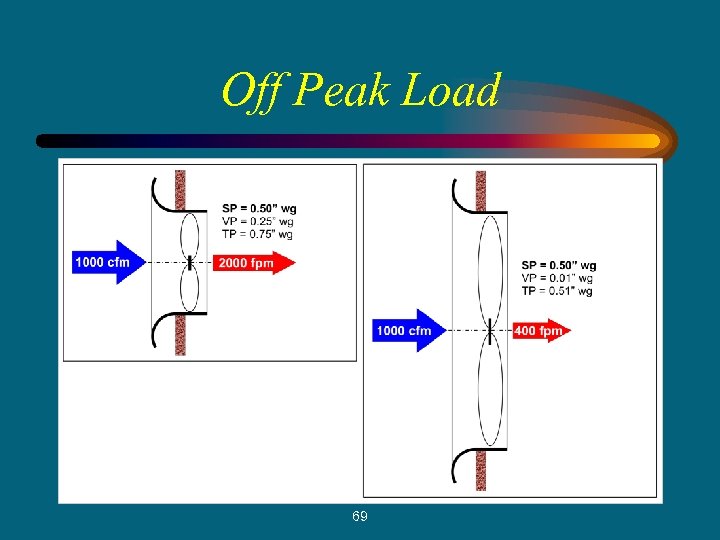

Off Peak Load 69

Off Peak Load 69

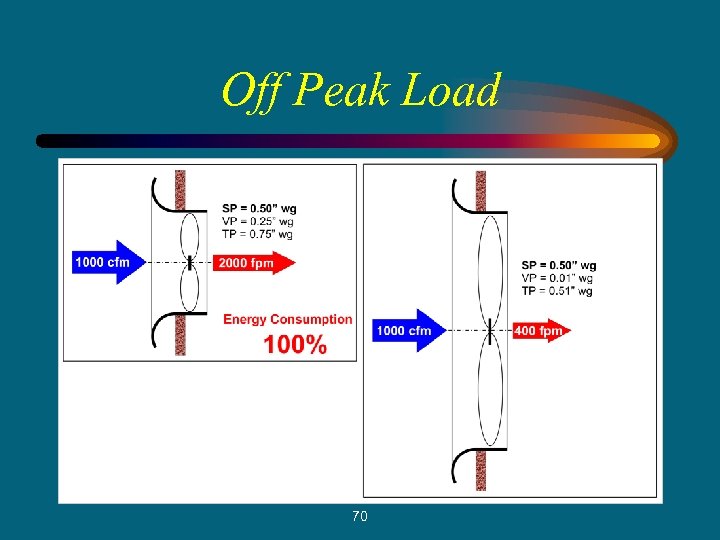

Off Peak Load 70

Off Peak Load 70

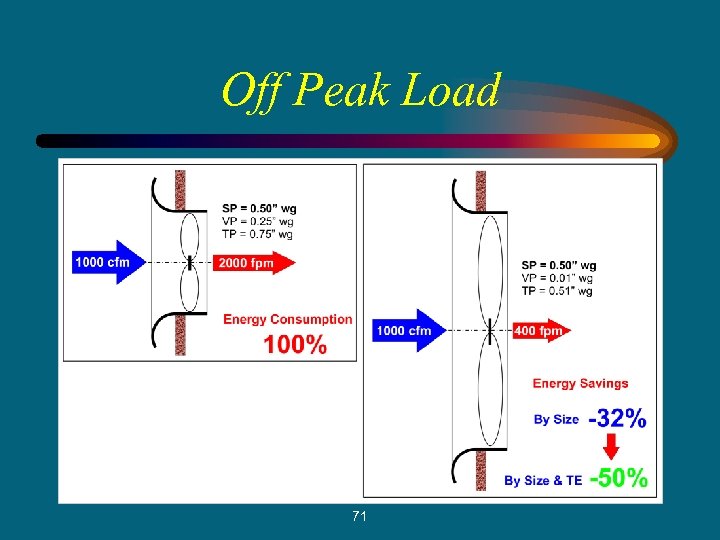

Off Peak Load 71

Off Peak Load 71

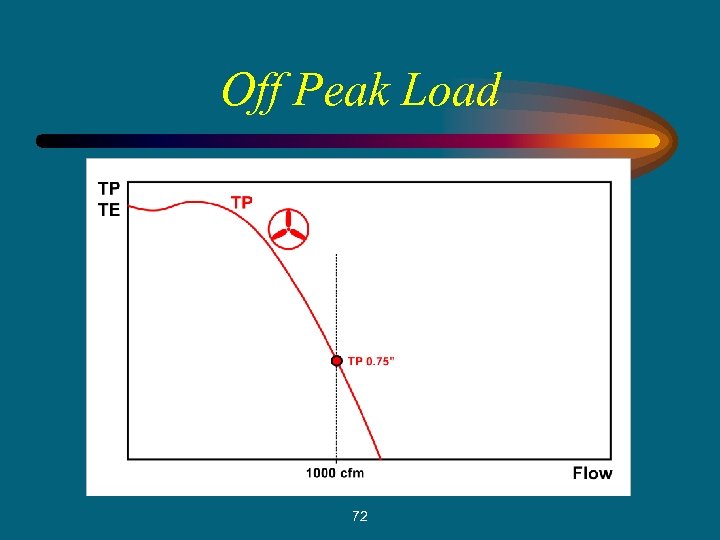

Off Peak Load 72

Off Peak Load 72

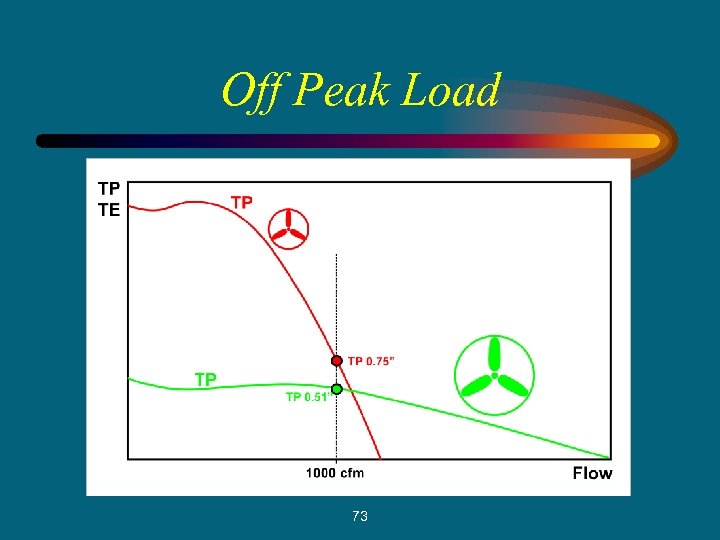

Off Peak Load 73

Off Peak Load 73

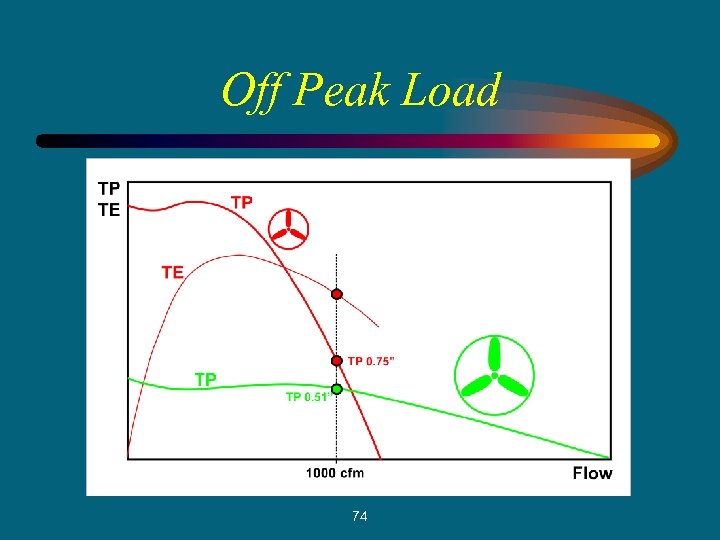

Off Peak Load 74

Off Peak Load 74

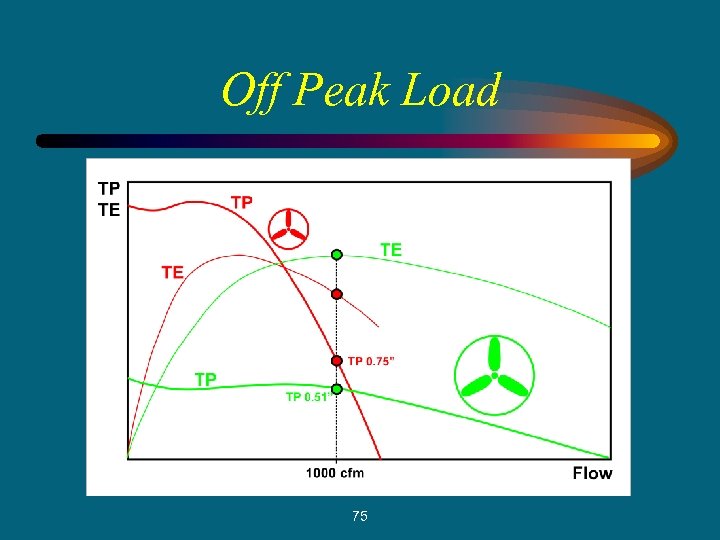

Off Peak Load 75

Off Peak Load 75

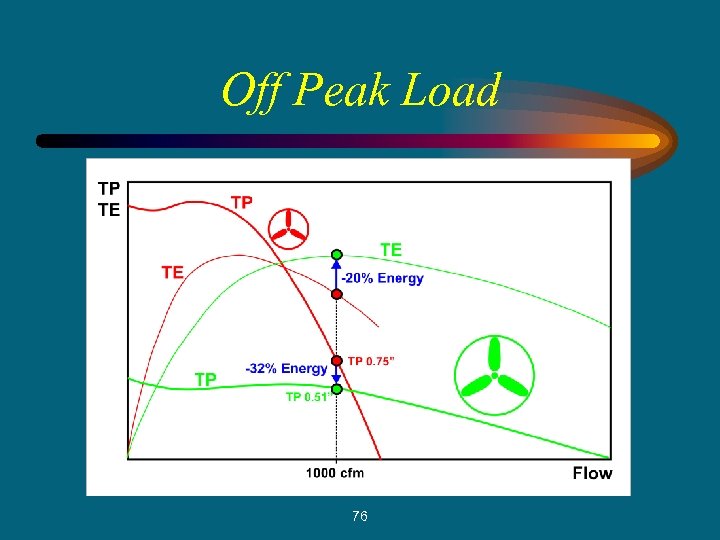

Off Peak Load 76

Off Peak Load 76

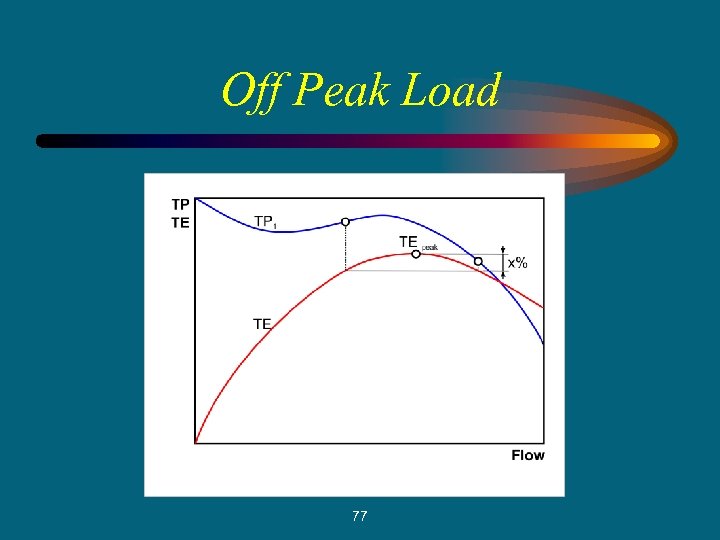

Off Peak Load 77

Off Peak Load 77

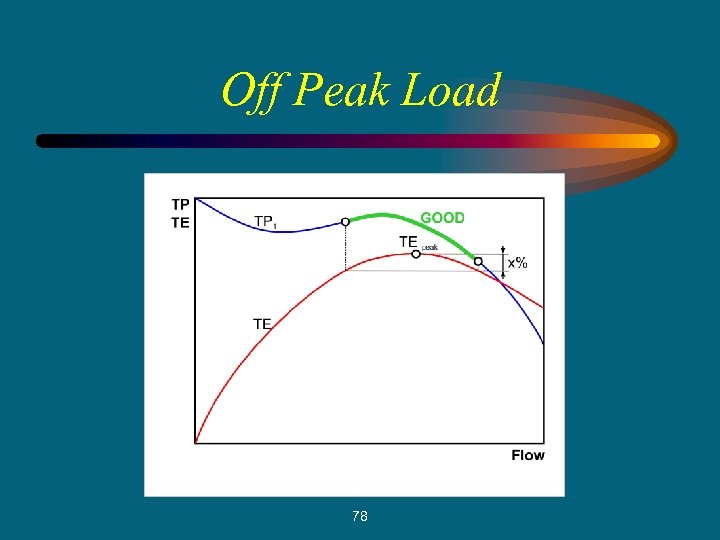

Off Peak Load 78

Off Peak Load 78

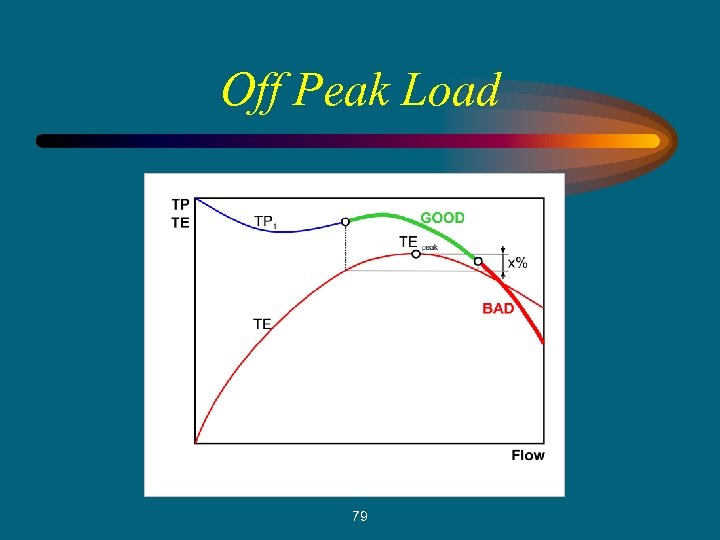

Off Peak Load 79

Off Peak Load 79

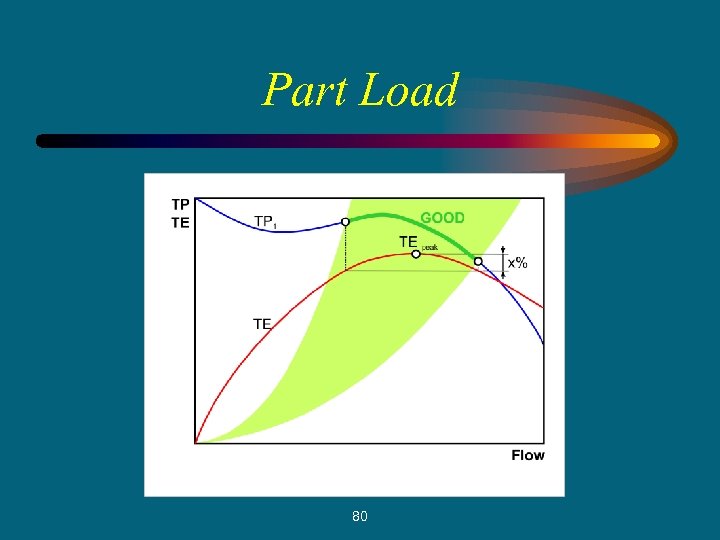

Part Load 80

Part Load 80

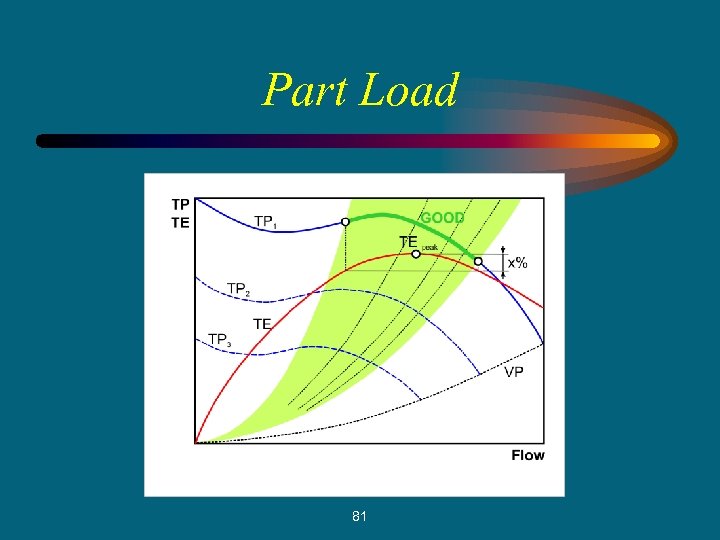

Part Load 81

Part Load 81

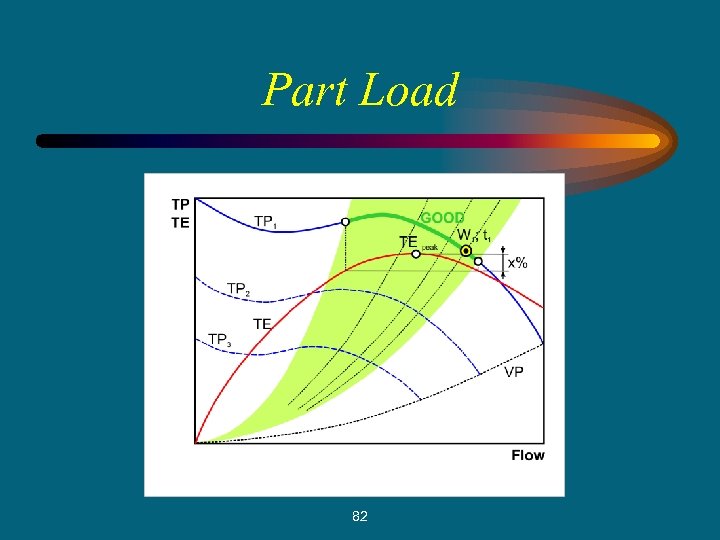

Part Load 82

Part Load 82

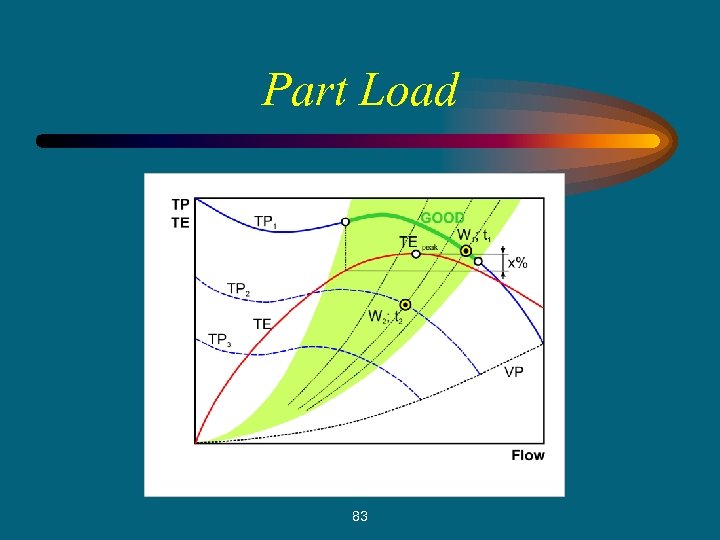

Part Load 83

Part Load 83

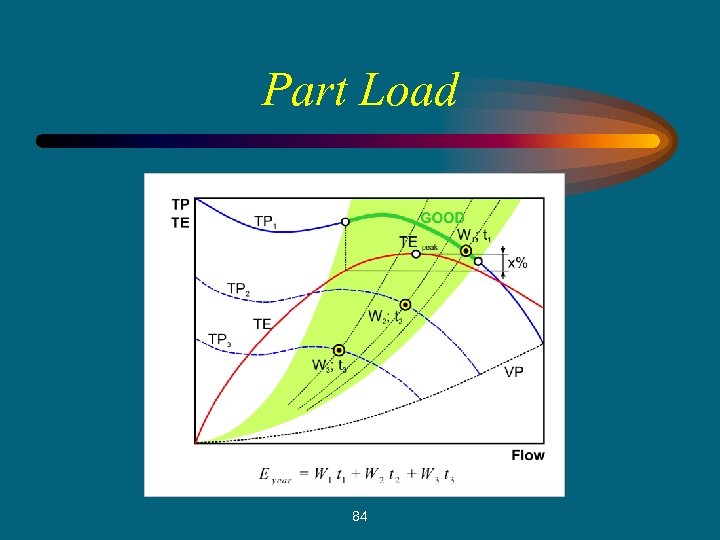

Part Load 84

Part Load 84

System Effects Restrictions on usage of “system effects” 85

System Effects Restrictions on usage of “system effects” 85

Result Defined Areas of Responsibility

Result Defined Areas of Responsibility

Areas of Responsibility Fan manufacturer Offers fans with the highest p. TE now at least FEG 67 later 71 and direct driven units 87

Areas of Responsibility Fan manufacturer Offers fans with the highest p. TE now at least FEG 67 later 71 and direct driven units 87

Areas of Responsibility Motor manufacturer Offer motors with highest p. Eff and smart units 88

Areas of Responsibility Motor manufacturer Offer motors with highest p. Eff and smart units 88

Areas of Responsibility HVAC system designer desi Optimizes use of the selection of the fan and the motor incl. drive package) 89

Areas of Responsibility HVAC system designer desi Optimizes use of the selection of the fan and the motor incl. drive package) 89

Areas of Responsibility What is missing? User of HVAC 90

Areas of Responsibility What is missing? User of HVAC 90

Questions?

Questions?

Thank You

Thank You

93

93