fa0eed38004b86f531c0e6977ec9f251.ppt

- Количество слайдов: 57

AMCA International Technical Seminar 2009 AIRFLOW IN A SYSTEM Presented by: Bill Howarth, Illinois Blower, Inc.

AMCA International Technical Seminar 2009 AIRFLOW IN A SYSTEM Presented by: Bill Howarth, Illinois Blower, Inc.

The Air Movement and Control Association International (AMCA), has met the standards and requirements of the Registered Continuing Education Providers Program. Credit earned on completion of this program will be reported to the RCEPP. A certificate of completion will be issued to each participant. As such, it does not include content that may be deemed or construed to be an approval or endorsement by NCEES or RCEPP.

The Air Movement and Control Association International (AMCA), has met the standards and requirements of the Registered Continuing Education Providers Program. Credit earned on completion of this program will be reported to the RCEPP. A certificate of completion will be issued to each participant. As such, it does not include content that may be deemed or construed to be an approval or endorsement by NCEES or RCEPP.

Learning Objectives • • • Describe the elements of an air system Know the physical properties of air Describe the effects of system components on airflow Understand the concept of pressure Understand how the conservation of energy relates to airflow Understand an air systems operating point

Learning Objectives • • • Describe the elements of an air system Know the physical properties of air Describe the effects of system components on airflow Understand the concept of pressure Understand how the conservation of energy relates to airflow Understand an air systems operating point

MOVING AIR Air at “A” Air at “B”

MOVING AIR Air at “A” Air at “B”

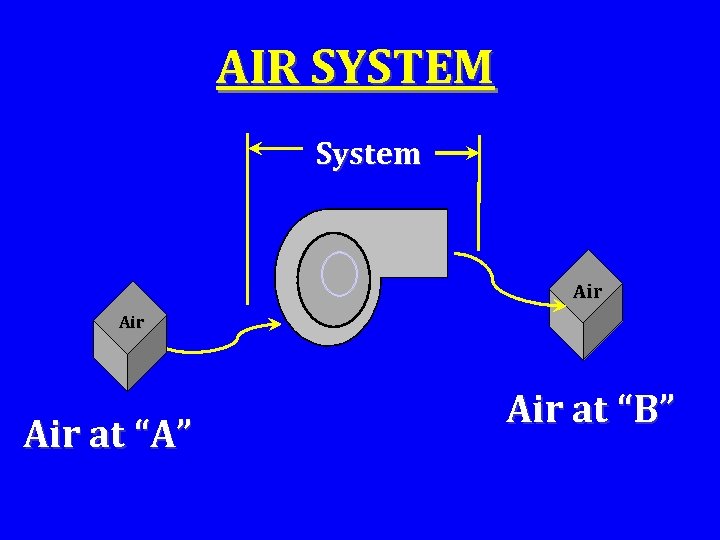

AIR SYSTEM System Air Air at “A” Air at “B”

AIR SYSTEM System Air Air at “A” Air at “B”

AIR SYSTEM DESIGN PARAMETERS • Properties of Air • Conservation of Energy • Friction And Friction Losses • Fan Characteristics

AIR SYSTEM DESIGN PARAMETERS • Properties of Air • Conservation of Energy • Friction And Friction Losses • Fan Characteristics

PROPERTIES OF AIR • Standard Air • Density • Pressure • Temperature

PROPERTIES OF AIR • Standard Air • Density • Pressure • Temperature

STANDARD AIR The Reference Gas for Air System Design

STANDARD AIR The Reference Gas for Air System Design

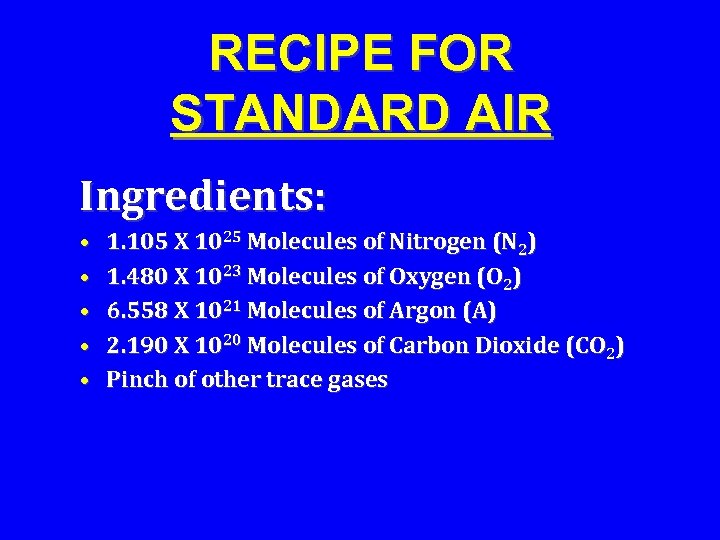

RECIPE FOR STANDARD AIR Ingredients: • • • 1. 105 X 1025 Molecules of Nitrogen (N 2) 1. 480 X 1023 Molecules of Oxygen (O 2) 6. 558 X 1021 Molecules of Argon (A) 2. 190 X 1020 Molecules of Carbon Dioxide (CO 2) Pinch of other trace gases

RECIPE FOR STANDARD AIR Ingredients: • • • 1. 105 X 1025 Molecules of Nitrogen (N 2) 1. 480 X 1023 Molecules of Oxygen (O 2) 6. 558 X 1021 Molecules of Argon (A) 2. 190 X 1020 Molecules of Carbon Dioxide (CO 2) Pinch of other trace gases

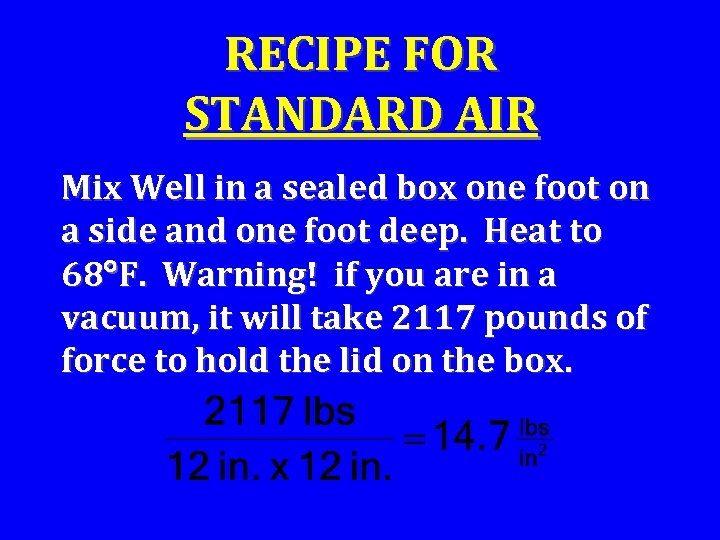

RECIPE FOR STANDARD AIR Mix Well in a sealed box one foot on a side and one foot deep. Heat to 68 F. Warning! if you are in a vacuum, it will take 2117 pounds of force to hold the lid on the box.

RECIPE FOR STANDARD AIR Mix Well in a sealed box one foot on a side and one foot deep. Heat to 68 F. Warning! if you are in a vacuum, it will take 2117 pounds of force to hold the lid on the box.

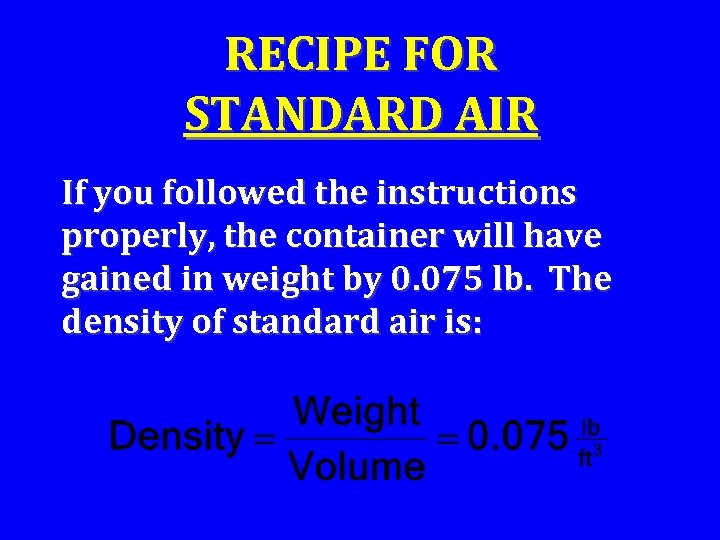

RECIPE FOR STANDARD AIR If you followed the instructions properly, the container will have gained in weight by 0. 075 lb. The density of standard air is:

RECIPE FOR STANDARD AIR If you followed the instructions properly, the container will have gained in weight by 0. 075 lb. The density of standard air is:

STANDARD AIR DEVIATIONS Due To: • Change In Pressure • Change in Temperature • Addition of other Component(s), such as Water

STANDARD AIR DEVIATIONS Due To: • Change In Pressure • Change in Temperature • Addition of other Component(s), such as Water

STANDARD AIR Pressure

STANDARD AIR Pressure

PRESSURE 1 Cubic Foot at 68 F. Air molecules are in continuous random motion. The average impact of the molecules against the sides of a container result in the phenomenon known as pressure.

PRESSURE 1 Cubic Foot at 68 F. Air molecules are in continuous random motion. The average impact of the molecules against the sides of a container result in the phenomenon known as pressure.

PRESSURE 1 Cubic Foot at 68 F. Forcing the same number of molecules to occupy a smaller volume (compressing the air) will increase the frequency of the molecular impacts, which is an increase in pressure.

PRESSURE 1 Cubic Foot at 68 F. Forcing the same number of molecules to occupy a smaller volume (compressing the air) will increase the frequency of the molecular impacts, which is an increase in pressure.

PRESSURE 1 Cubic Foot at 600 F. Increasing energy raises the random motion and the temperature. Pressure also increases. But; a cubic foot of air at 600 F and 14. 7 lb/in 2 has fewer molecules - It is less dense.

PRESSURE 1 Cubic Foot at 600 F. Increasing energy raises the random motion and the temperature. Pressure also increases. But; a cubic foot of air at 600 F and 14. 7 lb/in 2 has fewer molecules - It is less dense.

BAROMETRIC PRESSURE AIR The weight of our atmosphere compresses air to a pressure of 14. 7 lb/in 2 or 29. 92 in. Hg (average at sea level with 50% relative humidity).

BAROMETRIC PRESSURE AIR The weight of our atmosphere compresses air to a pressure of 14. 7 lb/in 2 or 29. 92 in. Hg (average at sea level with 50% relative humidity).

PRESSURE • Absolute Pressure • Any Pressure referenced to absolute zero pressure. • Barometric Pressure is an absolute pressure.

PRESSURE • Absolute Pressure • Any Pressure referenced to absolute zero pressure. • Barometric Pressure is an absolute pressure.

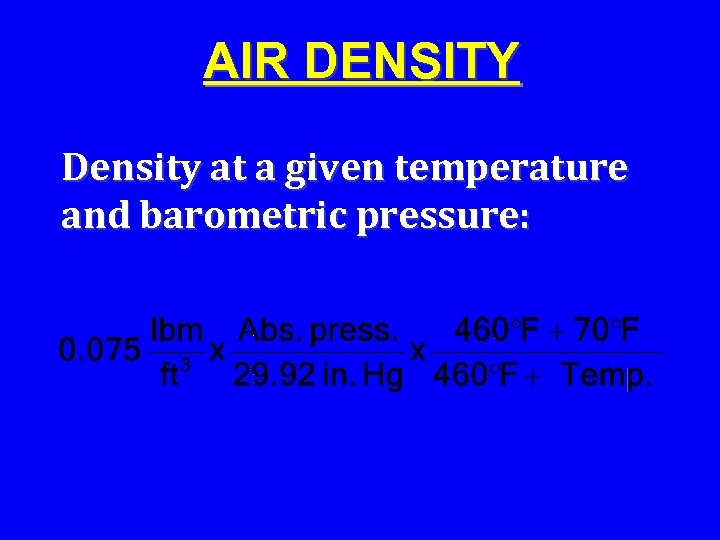

AIR DENSITY Density at a given temperature and barometric pressure:

AIR DENSITY Density at a given temperature and barometric pressure:

EFFECT OF HUMIDITY The addition of water vapor to air will decrease the density of the air.

EFFECT OF HUMIDITY The addition of water vapor to air will decrease the density of the air.

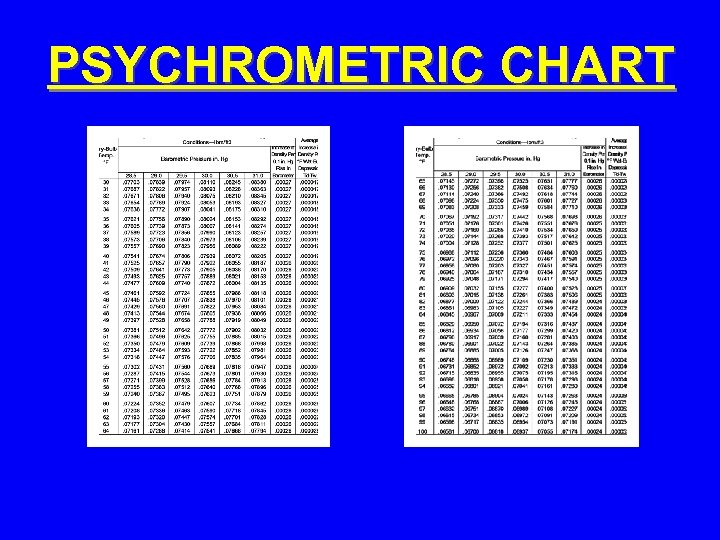

PSYCHROMETRIC CHART

PSYCHROMETRIC CHART

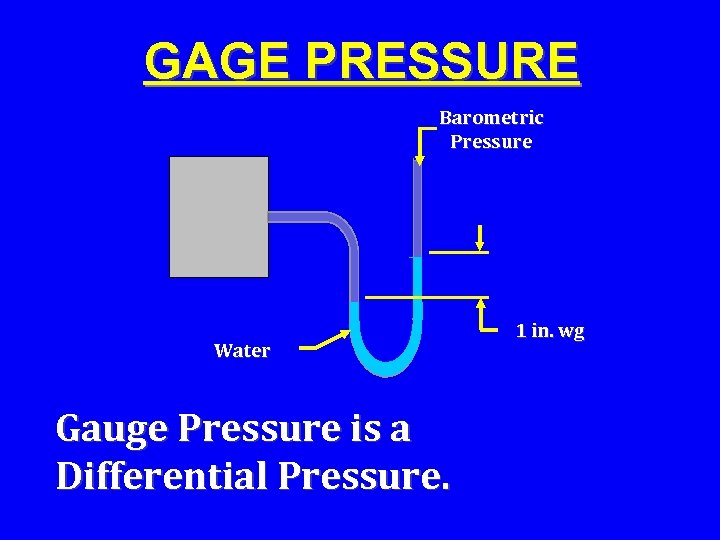

GAGE PRESSURE Barometric Pressure Water Gauge Pressure is a Differential Pressure. 1 in. wg

GAGE PRESSURE Barometric Pressure Water Gauge Pressure is a Differential Pressure. 1 in. wg

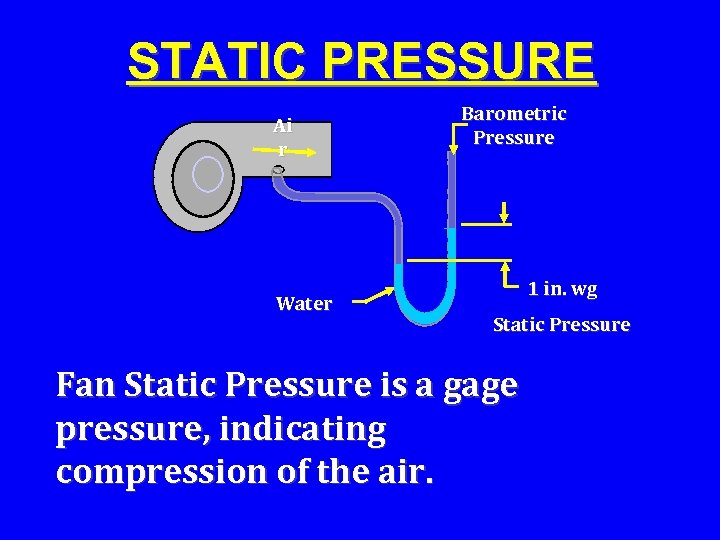

STATIC PRESSURE Ai r Water Barometric Pressure 1 in. wg Static Pressure Fan Static Pressure is a gage pressure, indicating compression of the air.

STATIC PRESSURE Ai r Water Barometric Pressure 1 in. wg Static Pressure Fan Static Pressure is a gage pressure, indicating compression of the air.

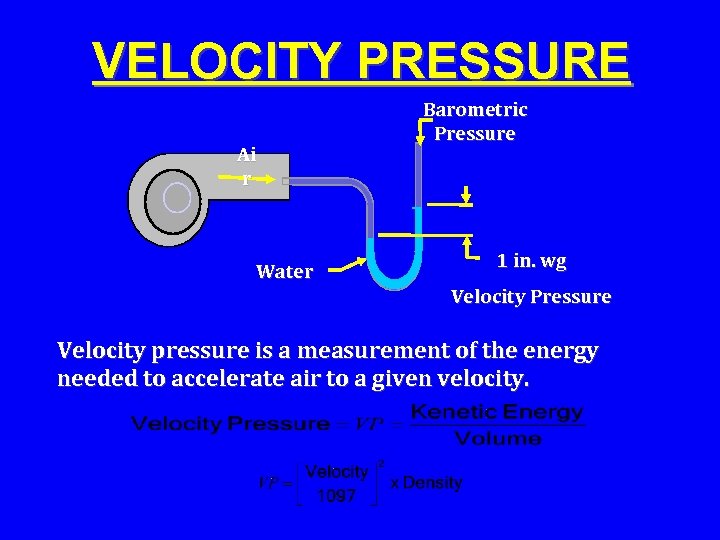

VELOCITY PRESSURE Ai r Water Barometric Pressure 1 in. wg Velocity Pressure Velocity pressure is a measurement of the energy needed to accelerate air to a given velocity.

VELOCITY PRESSURE Ai r Water Barometric Pressure 1 in. wg Velocity Pressure Velocity pressure is a measurement of the energy needed to accelerate air to a given velocity.

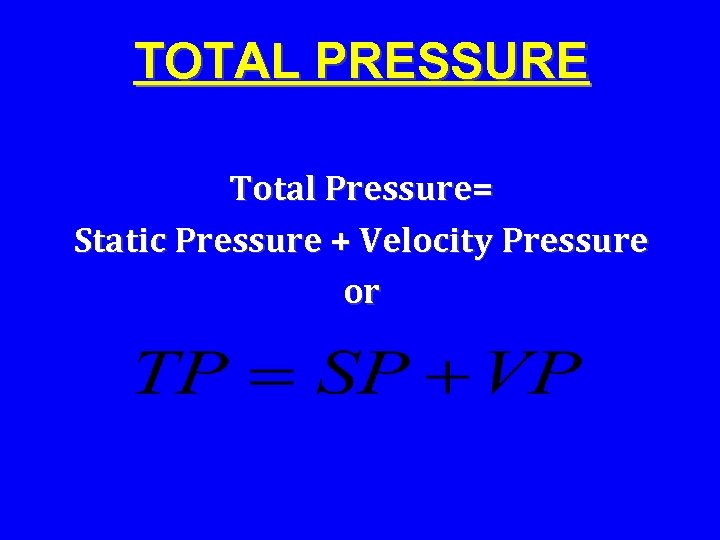

TOTAL PRESSURE Total Pressure= Static Pressure + Velocity Pressure or

TOTAL PRESSURE Total Pressure= Static Pressure + Velocity Pressure or

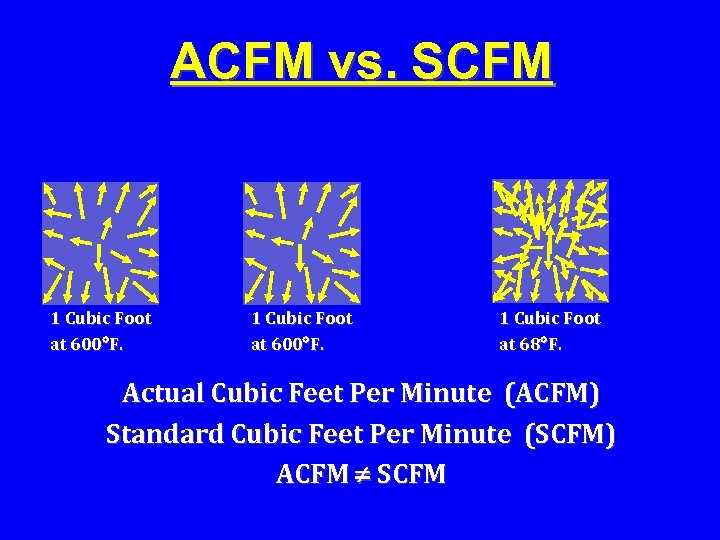

ACFM vs. SCFM 1 Cubic Foot at 600 F. 1 Cubic Foot at 68 F. Actual Cubic Feet Per Minute (ACFM) Standard Cubic Feet Per Minute (SCFM) ACFM SCFM

ACFM vs. SCFM 1 Cubic Foot at 600 F. 1 Cubic Foot at 68 F. Actual Cubic Feet Per Minute (ACFM) Standard Cubic Feet Per Minute (SCFM) ACFM SCFM

CONSERVATION OF ENERGY

CONSERVATION OF ENERGY

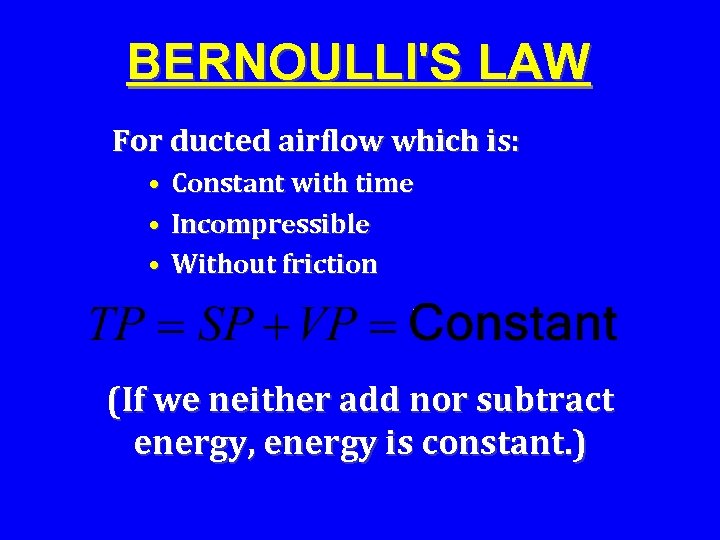

BERNOULLI'S LAW For ducted airflow which is: • Constant with time • Incompressible • Without friction (If we neither add nor subtract energy, energy is constant. )

BERNOULLI'S LAW For ducted airflow which is: • Constant with time • Incompressible • Without friction (If we neither add nor subtract energy, energy is constant. )

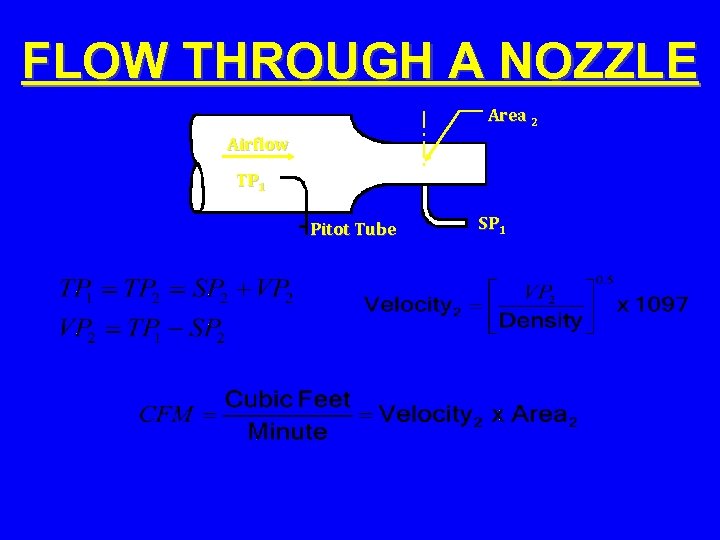

FLOW THROUGH A NOZZLE Area 2 Airflow TP 1 Pitot Tube SP 1

FLOW THROUGH A NOZZLE Area 2 Airflow TP 1 Pitot Tube SP 1

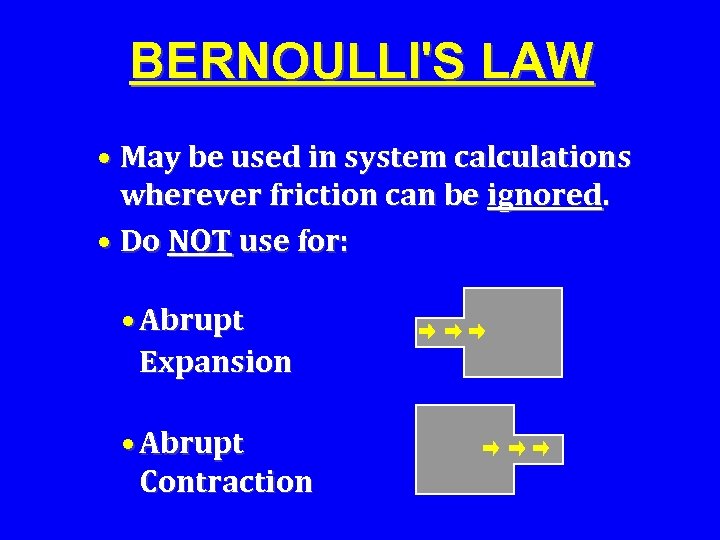

BERNOULLI'S LAW • May be used in system calculations wherever friction can be ignored. • Do NOT use for: • Abrupt Expansion • Abrupt Contraction

BERNOULLI'S LAW • May be used in system calculations wherever friction can be ignored. • Do NOT use for: • Abrupt Expansion • Abrupt Contraction

FRICTION AND FRICTION LOSSES

FRICTION AND FRICTION LOSSES

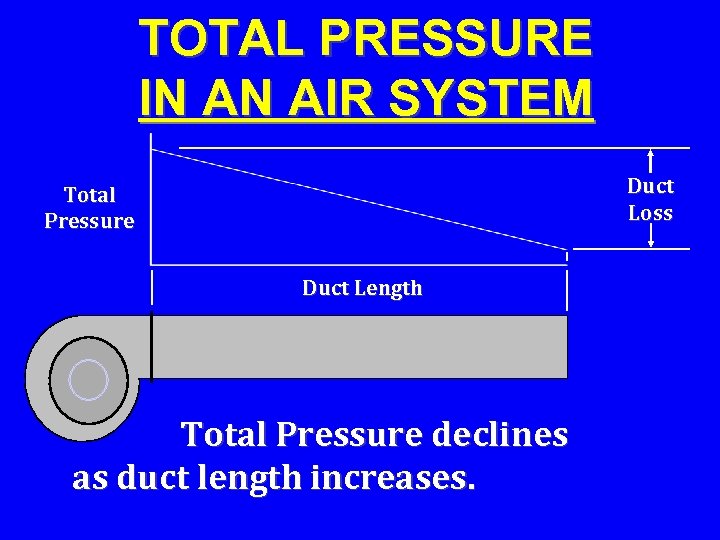

TOTAL PRESSURE IN AN AIR SYSTEM Duct Loss Total Pressure Duct Length Total Pressure declines as duct length increases.

TOTAL PRESSURE IN AN AIR SYSTEM Duct Loss Total Pressure Duct Length Total Pressure declines as duct length increases.

FRICTION LOSS • Caused by non-uniform velocities across the ductwork, coupled with the viscosity of air. • Always results in the conversion of Total Pressure to Heat • Turbulence (irregular or chaotic air flow) will amplify the friction loss.

FRICTION LOSS • Caused by non-uniform velocities across the ductwork, coupled with the viscosity of air. • Always results in the conversion of Total Pressure to Heat • Turbulence (irregular or chaotic air flow) will amplify the friction loss.

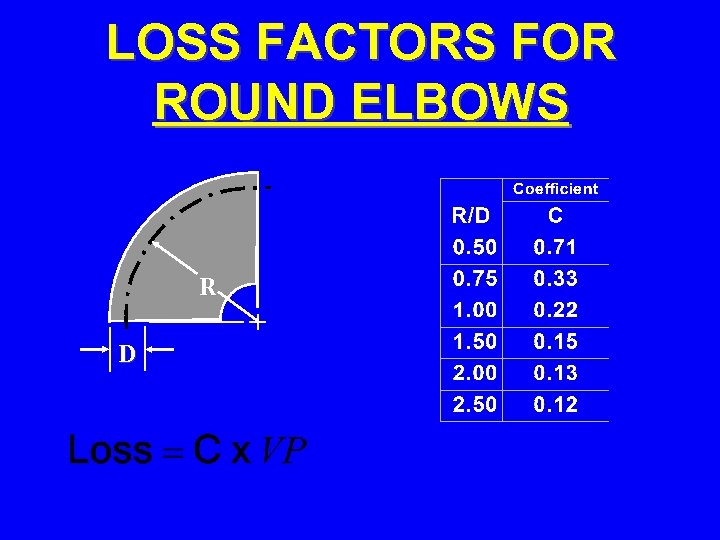

LOSS FACTORS FOR ROUND ELBOWS R D

LOSS FACTORS FOR ROUND ELBOWS R D

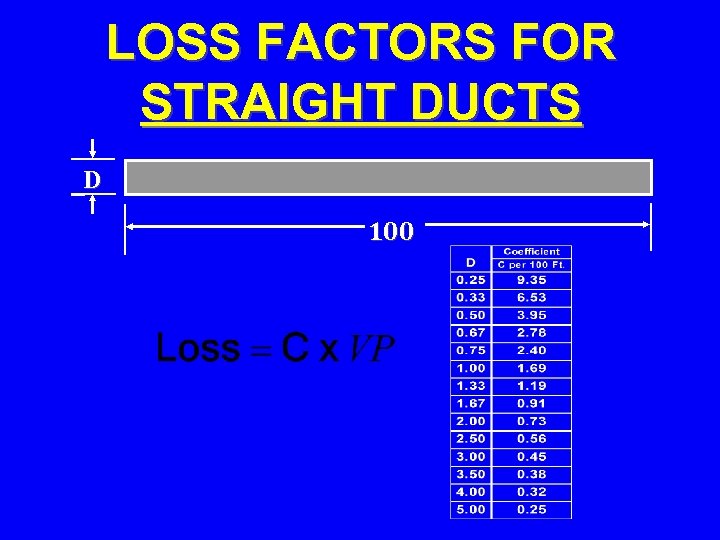

LOSS FACTORS FOR STRAIGHT DUCTS D 100

LOSS FACTORS FOR STRAIGHT DUCTS D 100

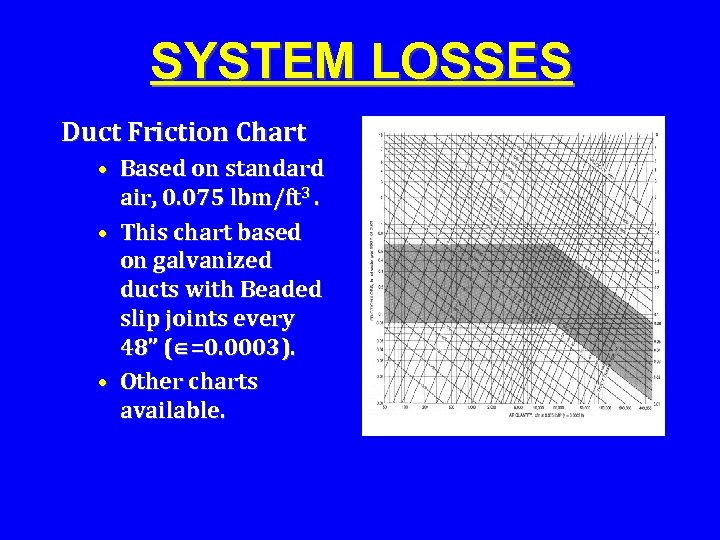

SYSTEM LOSSES Duct Friction Chart • Based on standard air, 0. 075 lbm/ft 3. • This chart based on galvanized ducts with Beaded slip joints every 48” ( =0. 0003). • Other charts available.

SYSTEM LOSSES Duct Friction Chart • Based on standard air, 0. 075 lbm/ft 3. • This chart based on galvanized ducts with Beaded slip joints every 48” ( =0. 0003). • Other charts available.

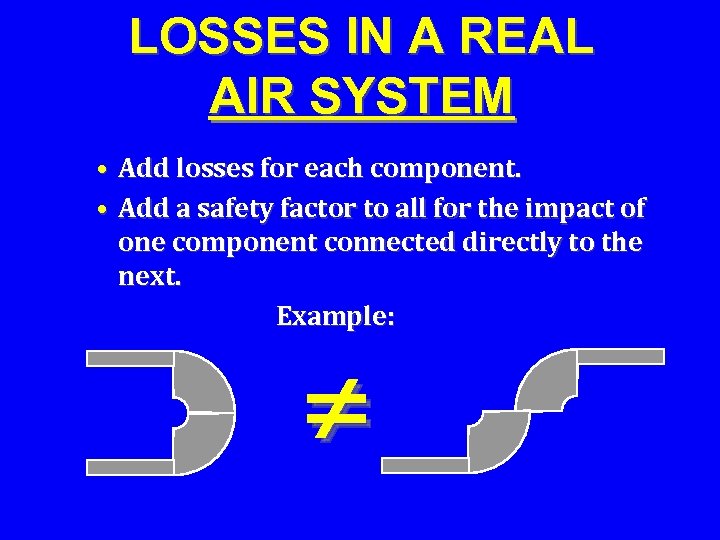

LOSSES IN A REAL AIR SYSTEM • Add losses for each component. • Add a safety factor to all for the impact of one component connected directly to the next. Example:

LOSSES IN A REAL AIR SYSTEM • Add losses for each component. • Add a safety factor to all for the impact of one component connected directly to the next. Example:

AIR SYSTEMS Basis for development of an Air System • Ventilation Rate • Air Changes/Hour • Face Velocity • Exhaust Requirements • References: • Fan Application Manual • ASHRAE Handbooks • Industrial Ventilation Guide

AIR SYSTEMS Basis for development of an Air System • Ventilation Rate • Air Changes/Hour • Face Velocity • Exhaust Requirements • References: • Fan Application Manual • ASHRAE Handbooks • Industrial Ventilation Guide

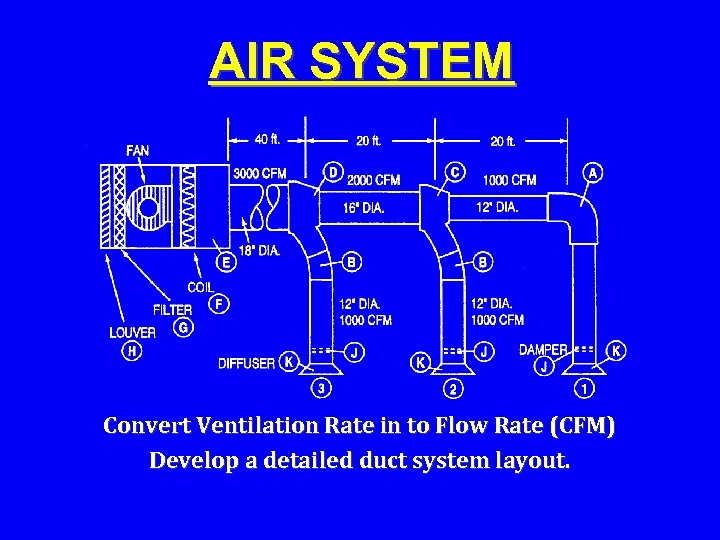

AIR SYSTEM Convert Ventilation Rate in to Flow Rate (CFM) Develop a detailed duct system layout.

AIR SYSTEM Convert Ventilation Rate in to Flow Rate (CFM) Develop a detailed duct system layout.

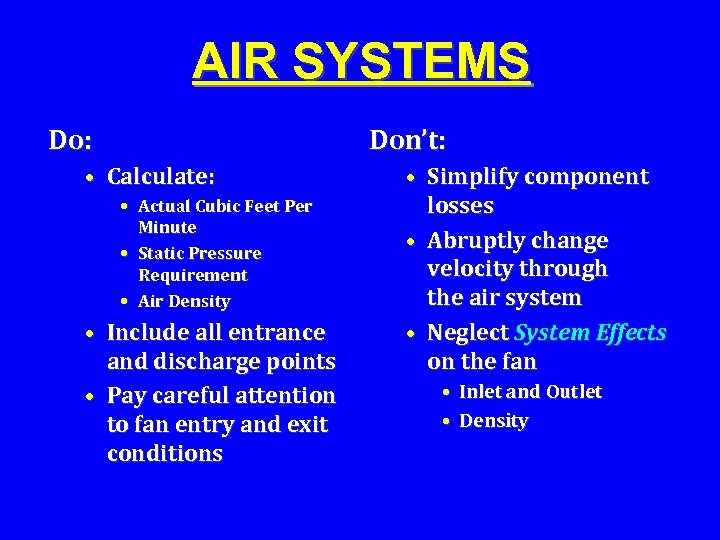

AIR SYSTEMS Do: Don’t: • Calculate: • Actual Cubic Feet Per Minute • Static Pressure Requirement • Air Density • Include all entrance and discharge points • Pay careful attention to fan entry and exit conditions • Simplify component losses • Abruptly change velocity through the air system • Neglect System Effects on the fan • Inlet and Outlet • Density

AIR SYSTEMS Do: Don’t: • Calculate: • Actual Cubic Feet Per Minute • Static Pressure Requirement • Air Density • Include all entrance and discharge points • Pay careful attention to fan entry and exit conditions • Simplify component losses • Abruptly change velocity through the air system • Neglect System Effects on the fan • Inlet and Outlet • Density

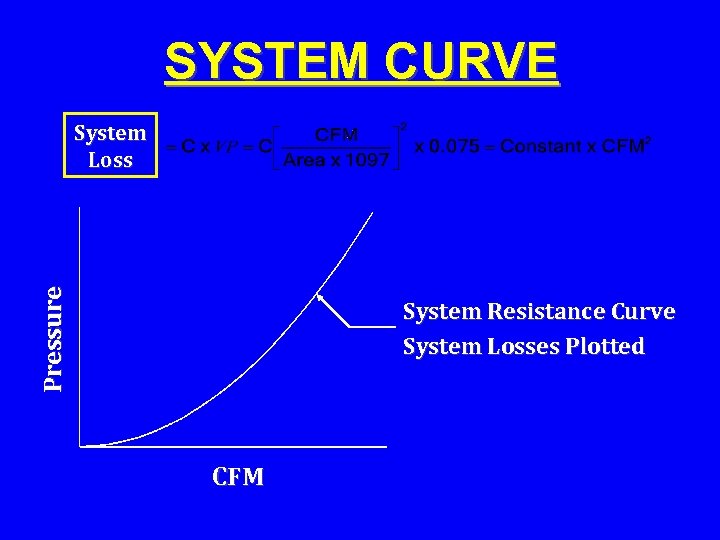

SYSTEM CURVE Pressure System Loss System Resistance Curve System Losses Plotted CFM

SYSTEM CURVE Pressure System Loss System Resistance Curve System Losses Plotted CFM

THE FAN’S JOB The purpose of a fan is to supply an air system with energy (in the form of pressure) necessary to maintain airflow.

THE FAN’S JOB The purpose of a fan is to supply an air system with energy (in the form of pressure) necessary to maintain airflow.

FAN CHARACTERISTICS

FAN CHARACTERISTICS

FANS • There are many types of fans. • For each type, there may be many sizes. • All fans have one thing in common: Accurate prediction of aerodynamic performance requires a test.

FANS • There are many types of fans. • For each type, there may be many sizes. • All fans have one thing in common: Accurate prediction of aerodynamic performance requires a test.

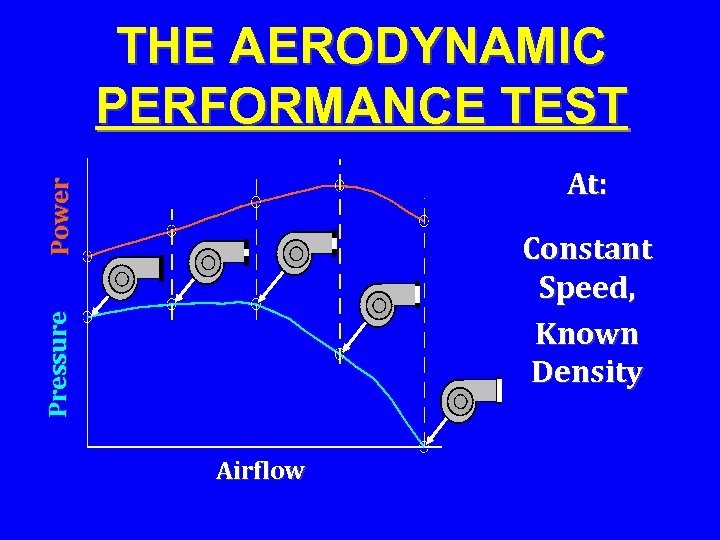

THE AERODYNAMIC PERFORMANCE TEST Power At: Pressure Constant Speed, Known Density Airflow

THE AERODYNAMIC PERFORMANCE TEST Power At: Pressure Constant Speed, Known Density Airflow

THE FAN LAWS • Are used to calculate fan performance at: • Other Speeds • Other Densities • Other Fan Sizes

THE FAN LAWS • Are used to calculate fan performance at: • Other Speeds • Other Densities • Other Fan Sizes

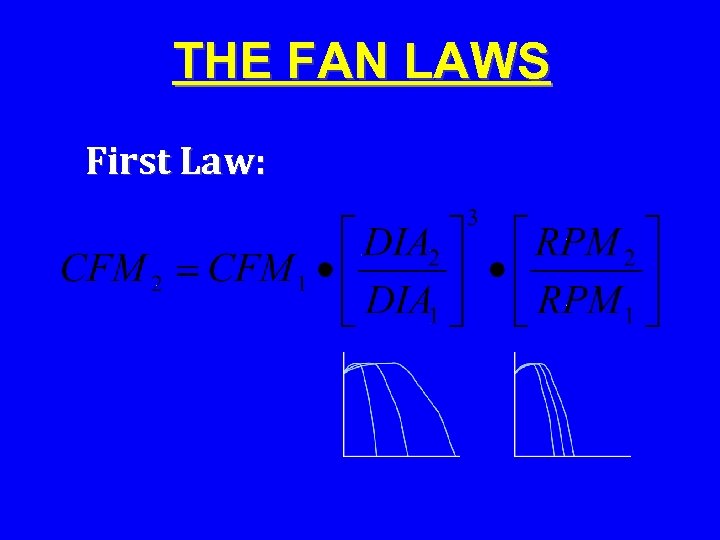

THE FAN LAWS First Law:

THE FAN LAWS First Law:

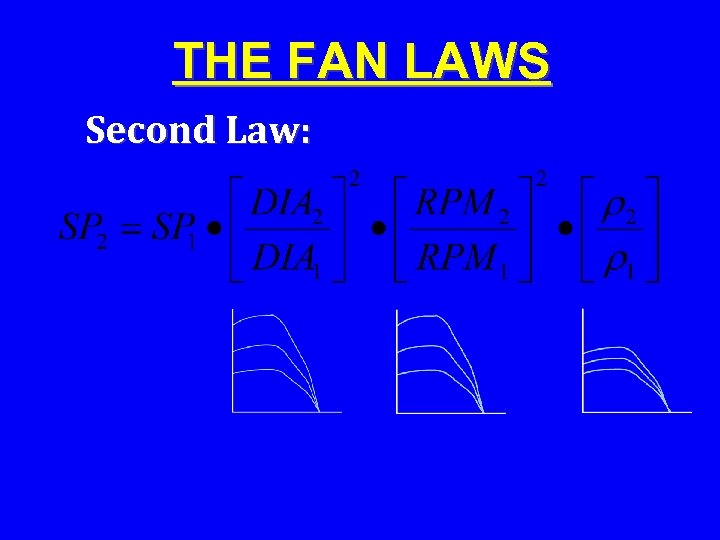

THE FAN LAWS Second Law:

THE FAN LAWS Second Law:

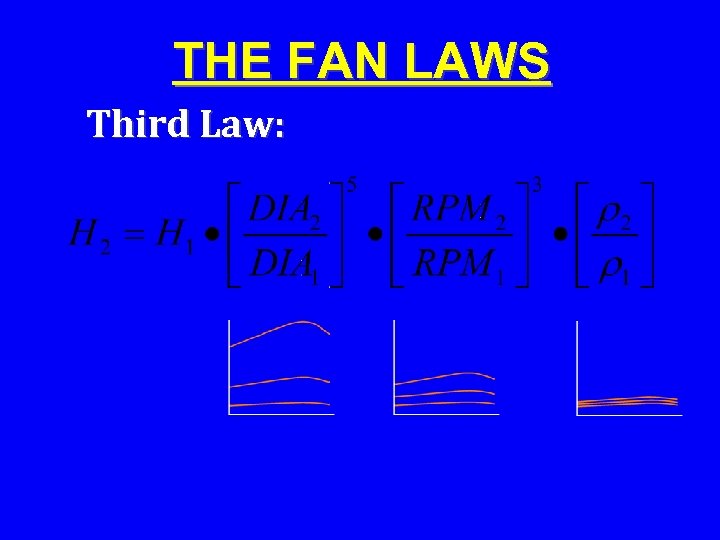

THE FAN LAWS Third Law:

THE FAN LAWS Third Law:

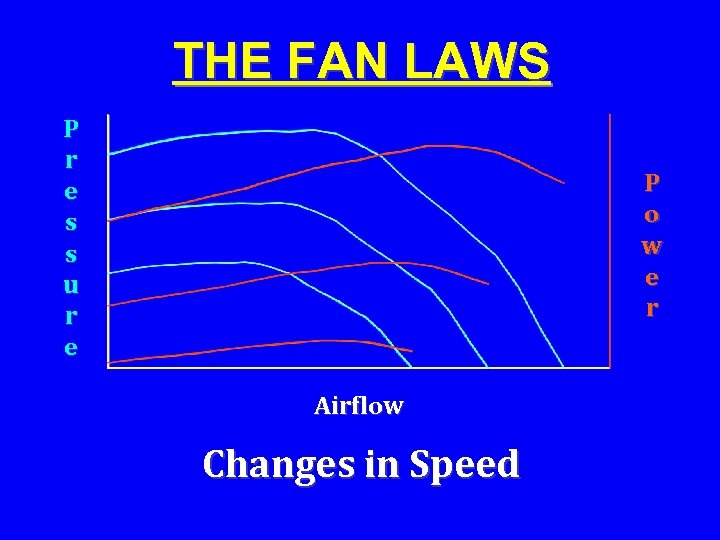

THE FAN LAWS P r e s s u r e P o w e r Airflow Changes in Speed

THE FAN LAWS P r e s s u r e P o w e r Airflow Changes in Speed

FAN SELECTION Airflow Desired CFM Select a fan which will generate the required pressure at the desired airflow.

FAN SELECTION Airflow Desired CFM Select a fan which will generate the required pressure at the desired airflow.

FAN SELECTION • There is only one intersection between the fan curve and system curve. • Fans are load matching devices. • Fans handle ACFM only.

FAN SELECTION • There is only one intersection between the fan curve and system curve. • Fans are load matching devices. • Fans handle ACFM only.

OPERATING POINT Fan - Air System Interaction

OPERATING POINT Fan - Air System Interaction

FAN SELECTION COROLLARIES • Any air system fan which generates the required system pressure will also deliver the required airflow. • If an air system fan generates the specified static pressure but not the desired airflow, the system resistance has been mis-calculated.

FAN SELECTION COROLLARIES • Any air system fan which generates the required system pressure will also deliver the required airflow. • If an air system fan generates the specified static pressure but not the desired airflow, the system resistance has been mis-calculated.

FAN PERFORMANCE TOLERANCES • Account for: • Test Uncertainty • Manufacturing Imperfections

FAN PERFORMANCE TOLERANCES • Account for: • Test Uncertainty • Manufacturing Imperfections

AMCA TOLERANCES • The fan must perform within 2. 5% of its air performance rating and within 5% of its power rating. • To meet rated performance, the fan RPM might have to be increased up to 2. 5%, and the power increased up to 5% of the rated power. • The AMCA Tolerances DO NOT account for System Effect or for errors in the system calculations.

AMCA TOLERANCES • The fan must perform within 2. 5% of its air performance rating and within 5% of its power rating. • To meet rated performance, the fan RPM might have to be increased up to 2. 5%, and the power increased up to 5% of the rated power. • The AMCA Tolerances DO NOT account for System Effect or for errors in the system calculations.

Questions?

Questions?