f3fabe943fa959f2d039f3718945504d.ppt

- Количество слайдов: 34

Alternative evaporative cooling and naturally ventilated double roof system for environmental controlled dairy barn located in tropical and subtropical regions Wei Fang, Ph. D. , Professor Dept. of Bio-Industrial Mechatronics Engineering National Taiwan University

Part I. Alternative evaporative cooling

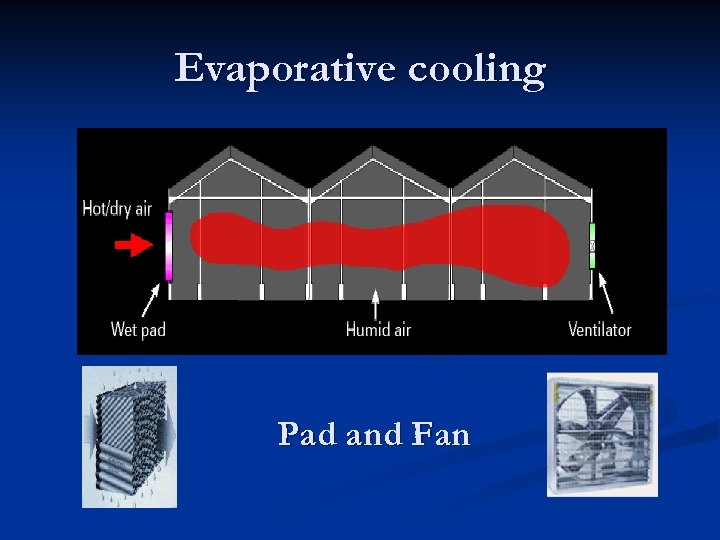

Evaporative cooling Pad and Fan

Pad and Fan system is Powerful But it require proper design, proper installation and proper maintenance.

Poor design/install/maintenance

Poor design/install/maintenance

Electrolysis

Coated Pad

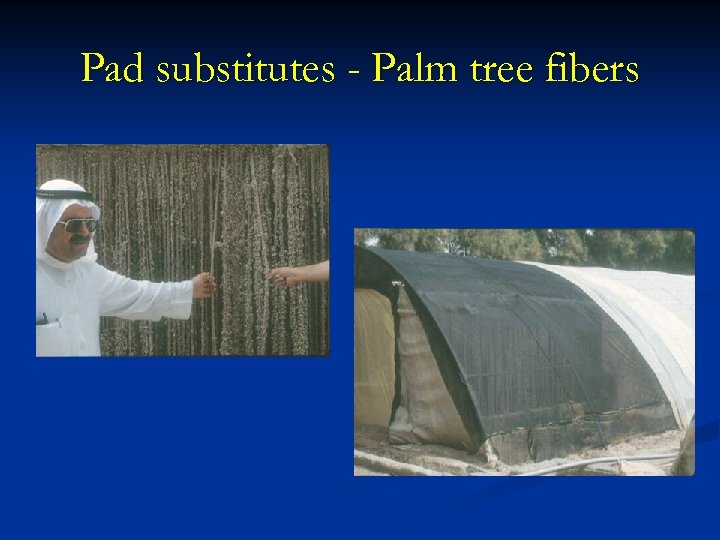

Pad substitutes - Palm tree fibers

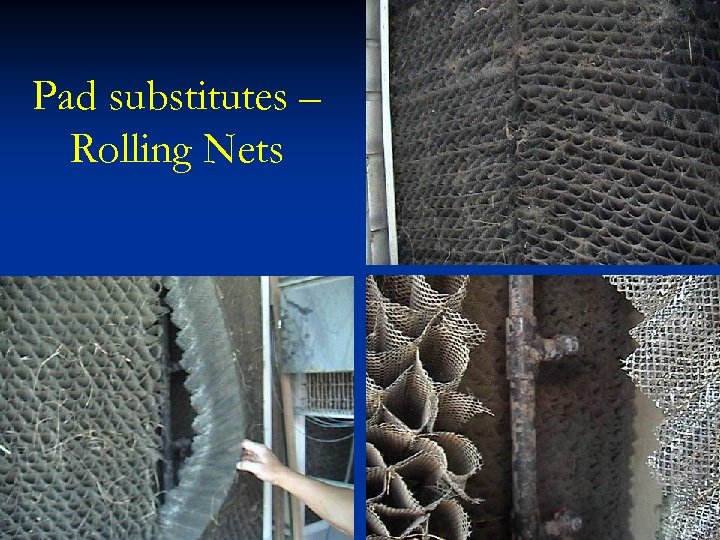

Pad substitutes – Rolling Nets

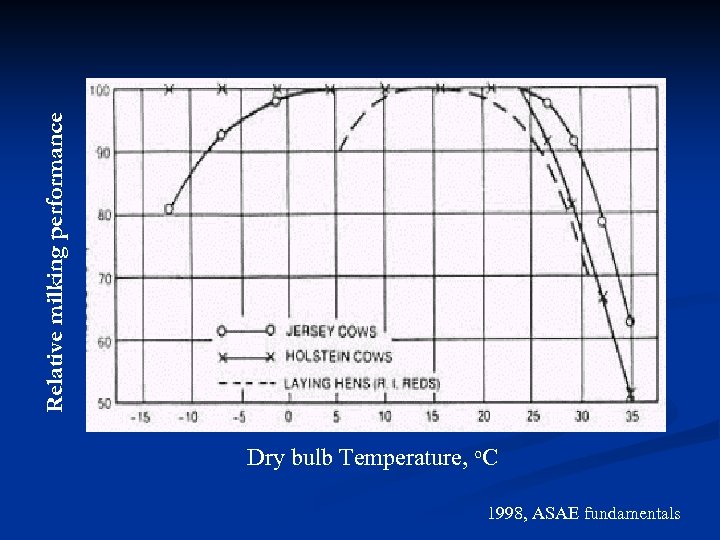

Relative milking performance Dry bulb Temperature, o. C 1998, ASAE fundamentals

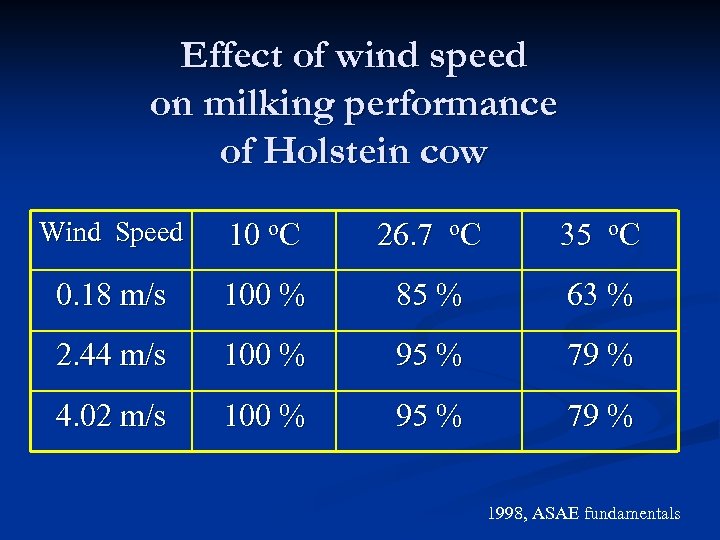

Effect of wind speed on milking performance of Holstein cow Wind Speed 10 o. C 26. 7 o. C 35 o. C 0. 18 m/s 100 % 85 % 63 % 2. 44 m/s 100 % 95 % 79 % 4. 02 m/s 100 % 95 % 79 % 1998, ASAE fundamentals

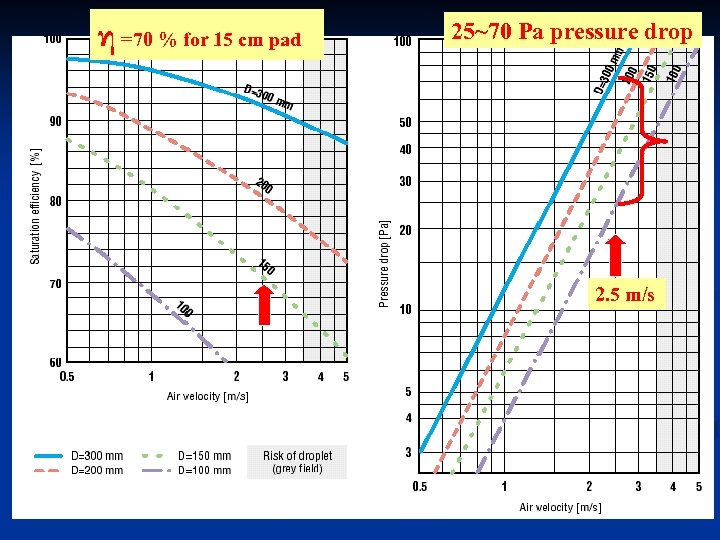

η =70 % for 15 cm pad 25~70 Pa pressure drop 2. 5 m/s

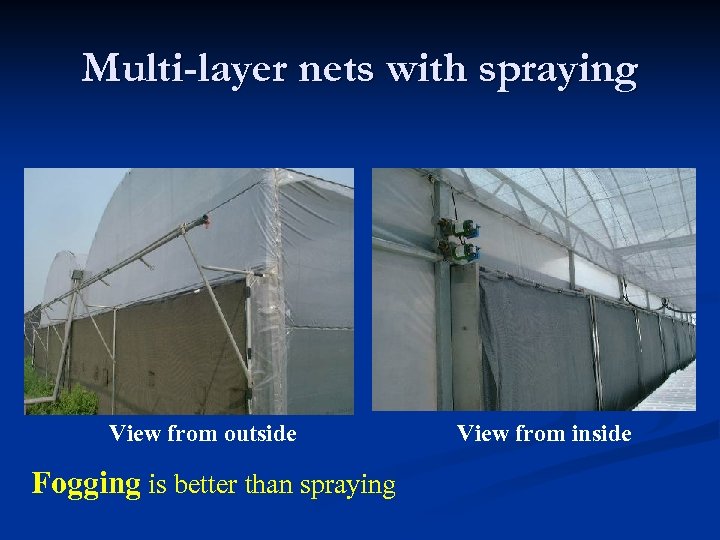

Multi-layer nets with spraying View from outside Fogging is better than spraying View from inside

Multi-layer nets with fogging

Multi-layer nets with fogging

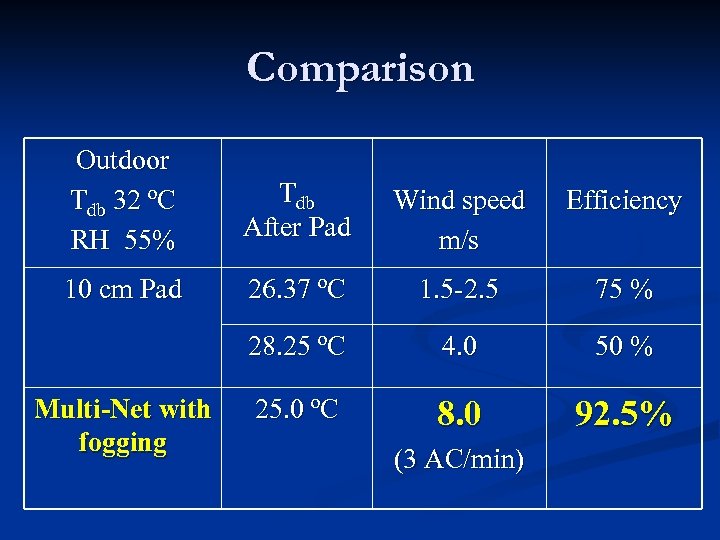

Comparison Outdoor Tdb 32 o. C RH 55% Tdb After Pad Wind speed m/s Efficiency 10 cm Pad 26. 37 o. C 1. 5 -2. 5 75 % 28. 25 o. C 4. 0 50 % 25. 0 o. C 8. 0 92. 5% Multi-Net with fogging (3 AC/min)

Part II. Naturally ventilated double roof system

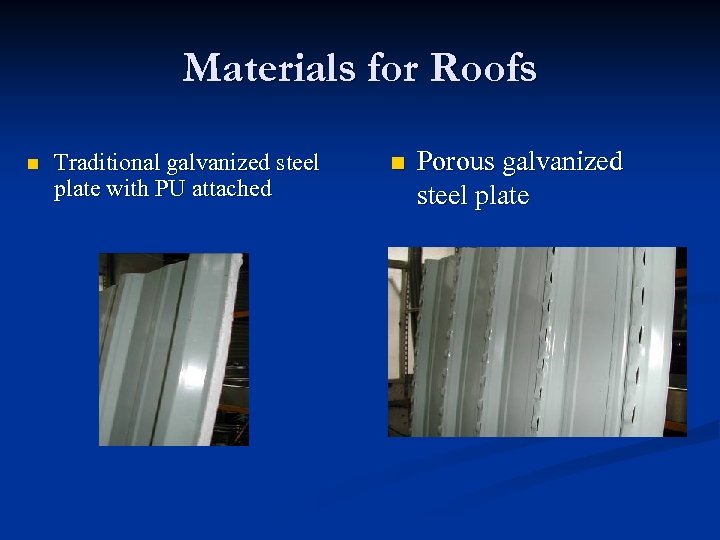

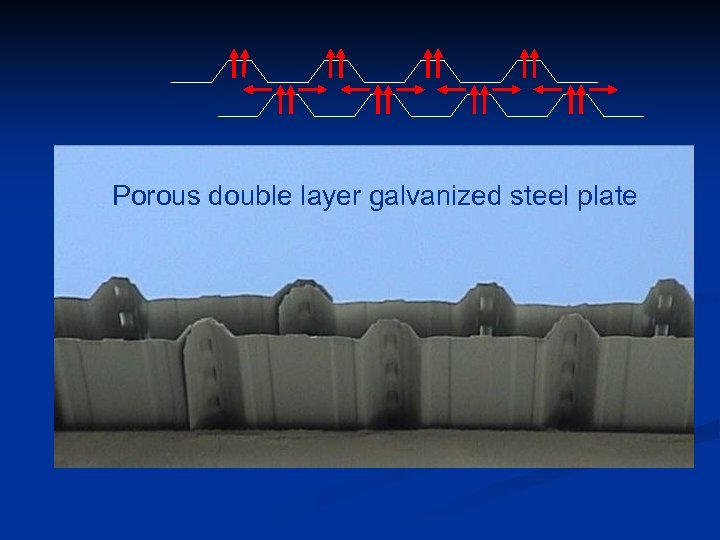

Materials for Roofs n Traditional galvanized steel plate with PU attached n Porous galvanized steel plate

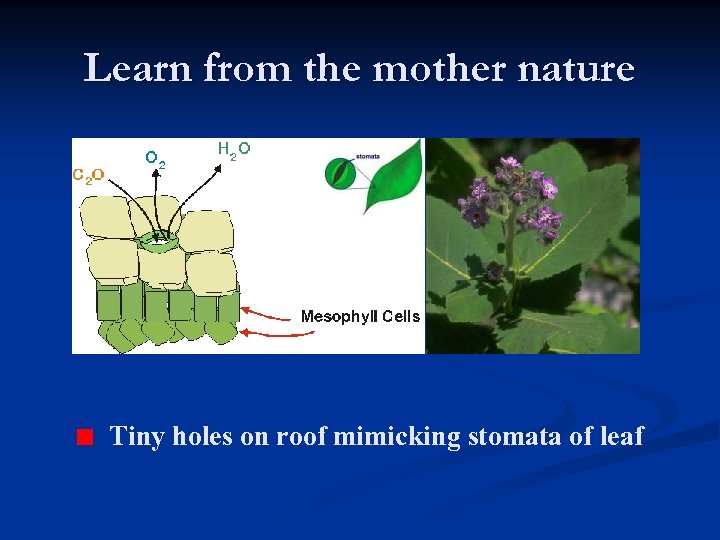

Learn from the mother nature Tiny holes on roof mimicking stomata of leaf

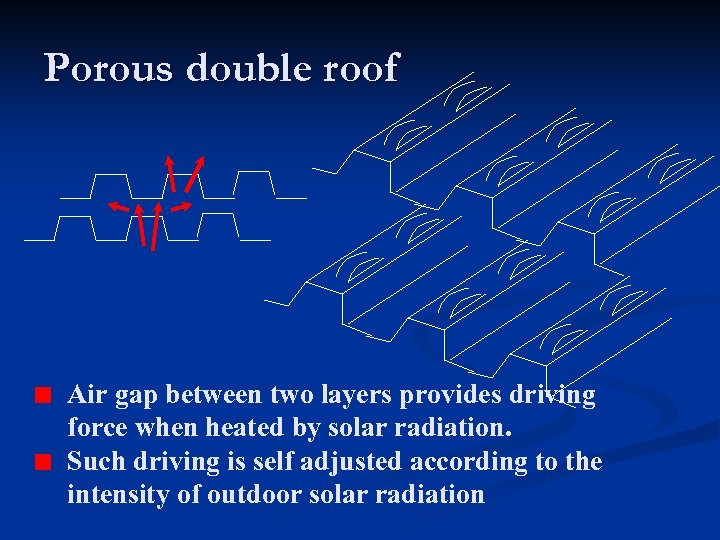

Porous double roof Air gap between two layers provides driving force when heated by solar radiation. Such driving is self adjusted according to the intensity of outdoor solar radiation

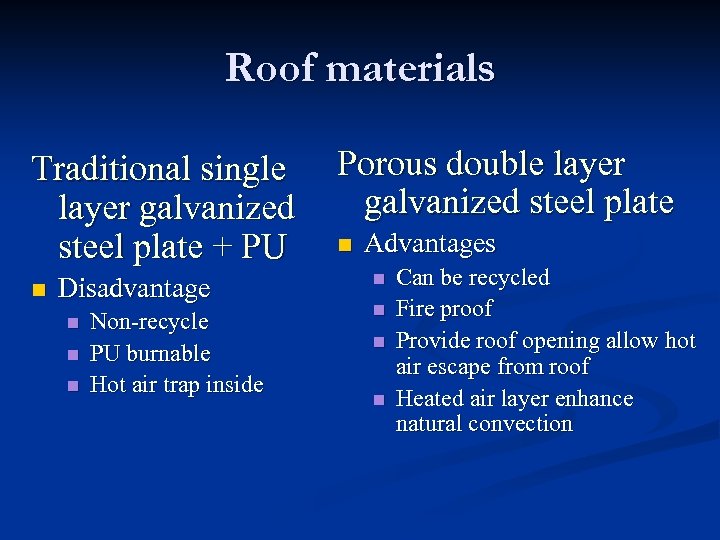

Roof materials Traditional single layer galvanized steel plate + PU n Disadvantage n n n Non-recycle PU burnable Hot air trap inside Porous double layer galvanized steel plate n Advantages n n Can be recycled Fire proof Provide roof opening allow hot air escape from roof Heated air layer enhance natural convection

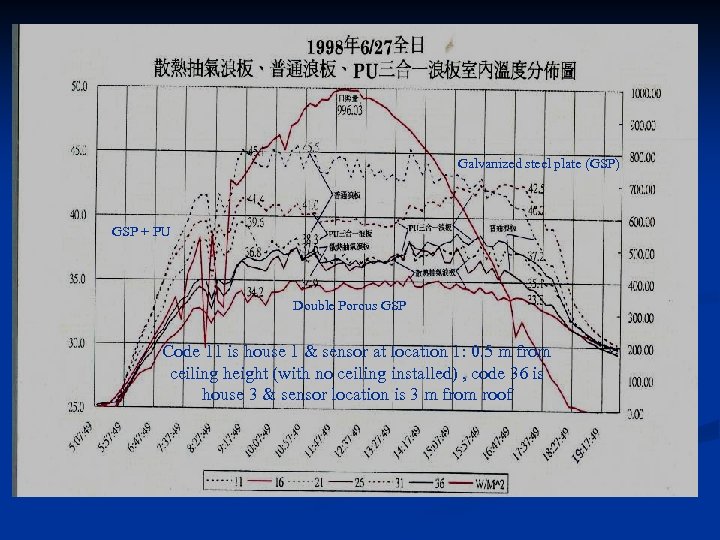

Galvanized steel plate (GSP) GSP + PU Double Porous GSP Code 11 is house 1 & sensor at location 1: 0. 5 m from ceiling height (with no ceiling installed) , code 36 is house 3 & sensor location is 3 m from roof

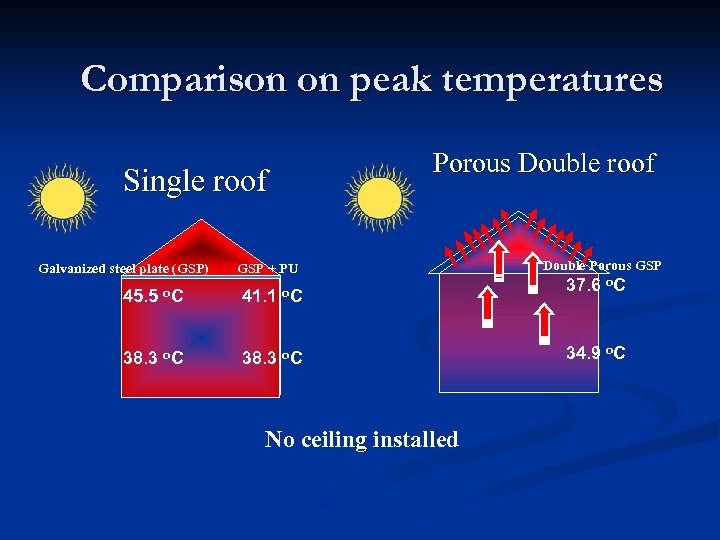

Comparison on peak temperatures Porous Double roof Single roof Galvanized steel plate (GSP) 45. 5 o. C 38. 3 o. C GSP + PU 41. 1 o. C 38. 3 o. C No ceiling installed Double Porous GSP 37. 6 o. C 34. 9 o. C

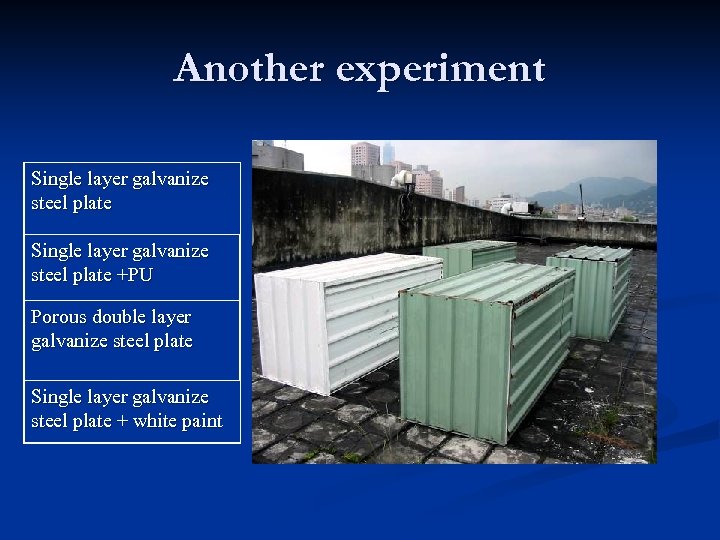

Another experiment Single layer galvanize steel plate +PU Porous double layer galvanize steel plate Single layer galvanize steel plate + white paint

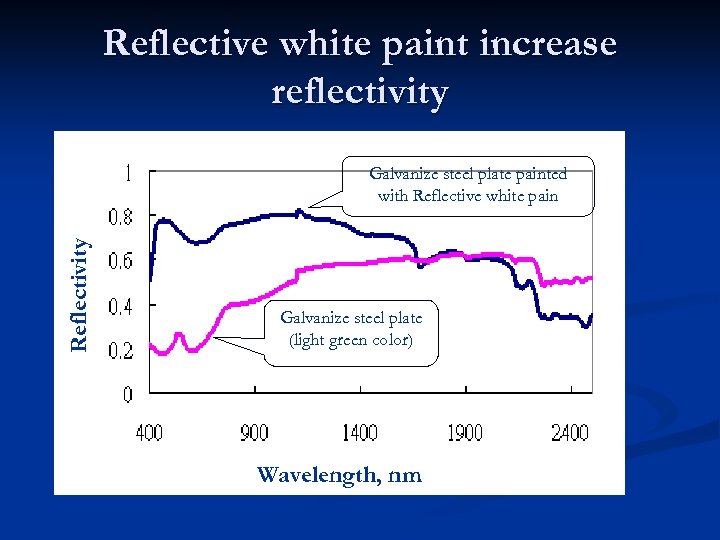

Reflective white paint increase reflectivity Reflectivity Galvanize steel plate painted with Reflective white pain Galvanize steel plate (light green color) Wavelength, nm

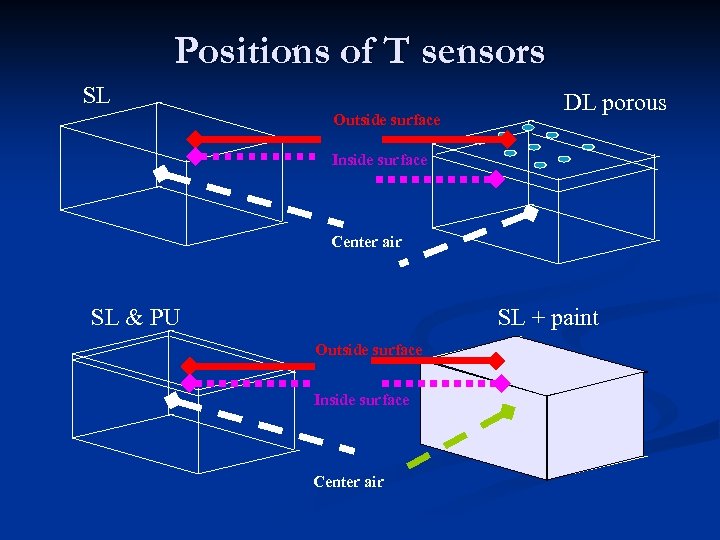

Positions of T sensors SL Outside surface DL porous Inside surface Center air SL & PU SL + paint Outside surface Inside surface Center air

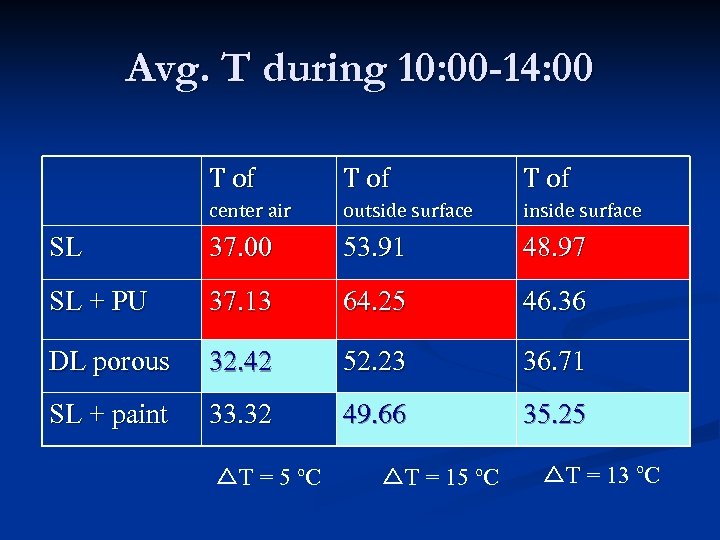

Avg. T during 10: 00 -14: 00 T of center air outside surface inside surface SL 37. 00 53. 91 48. 97 SL + PU 37. 13 64. 25 46. 36 DL porous 32. 42 52. 23 36. 71 SL + paint 33. 32 49. 66 35. 25 △T = 5 o. C △T = 13 o. C

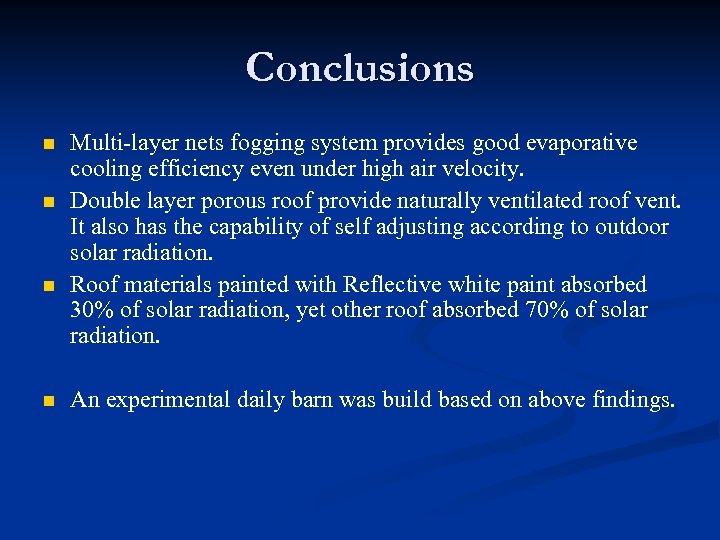

Conclusions n n Multi-layer nets fogging system provides good evaporative cooling efficiency even under high air velocity. Double layer porous roof provide naturally ventilated roof vent. It also has the capability of self adjusting according to outdoor solar radiation. Roof materials painted with Reflective white paint absorbed 30% of solar radiation, yet other roof absorbed 70% of solar radiation. An experimental daily barn was build based on above findings.

50 m x 15 m x 2. 5 m, cows 50 Wind speed 2. 5 m/s Air exchange 2 times/min

Porous double layer galvanized steel plate

Thank you for your attention

f3fabe943fa959f2d039f3718945504d.ppt