241bd56a8b5a39df186e93e3afce035f.ppt

- Количество слайдов: 44

Alternative Aviation Fuels Tim Edwards Propulsion Directorate 88 ABW-2009 -4026

Alternative Aviation Fuels Tim Edwards Propulsion Directorate 88 ABW-2009 -4026

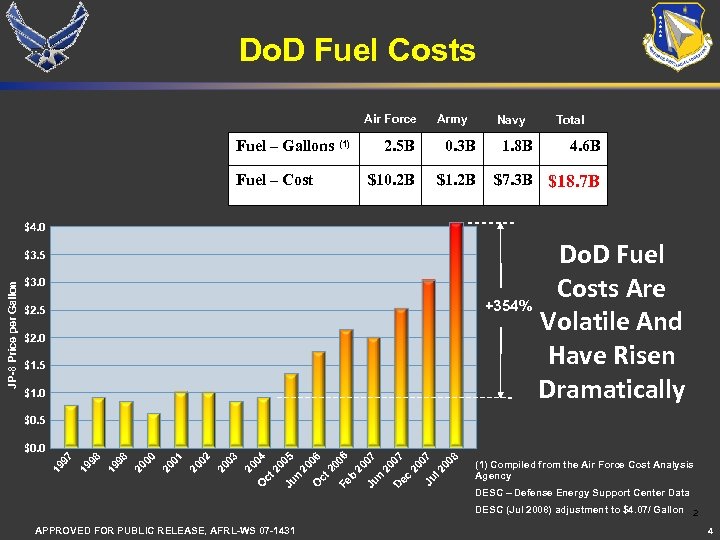

Do. D Fuel Costs Air Force Fuel – Gallons (1) Fuel – Cost Army Navy 2. 5 B 0. 3 B $10. 2 B $1. 2 B 1. 8 B Total 4. 6 B $7. 3 B $18. 7 B $4. 0 Do. D Fuel Costs Are +354% Volatile And Have Risen Dramatically $3. 0 $2. 5 $2. 0 $1. 5 $1. 0 $0. 5 $0. 0 19 97 19 98 20 00 20 01 20 02 20 03 20 04 O ct 20 Ju 05 n 20 06 O ct 20 Fe 06 b 20 Ju 07 n 20 0 D ec 7 20 07 Ju l 2 00 8 JP-8 Price per Gallon $3. 5 (1) Compiled from the Air Force Cost Analysis Agency DESC – Defense Energy Support Center Data DESC (Jul 2008) adjustment to $4. 07/ Gallon 2 APPROVED FOR PUBLIC RELEASE, AFRL-WS 07 -1431 4

Do. D Fuel Costs Air Force Fuel – Gallons (1) Fuel – Cost Army Navy 2. 5 B 0. 3 B $10. 2 B $1. 2 B 1. 8 B Total 4. 6 B $7. 3 B $18. 7 B $4. 0 Do. D Fuel Costs Are +354% Volatile And Have Risen Dramatically $3. 0 $2. 5 $2. 0 $1. 5 $1. 0 $0. 5 $0. 0 19 97 19 98 20 00 20 01 20 02 20 03 20 04 O ct 20 Ju 05 n 20 06 O ct 20 Fe 06 b 20 Ju 07 n 20 0 D ec 7 20 07 Ju l 2 00 8 JP-8 Price per Gallon $3. 5 (1) Compiled from the Air Force Cost Analysis Agency DESC – Defense Energy Support Center Data DESC (Jul 2008) adjustment to $4. 07/ Gallon 2 APPROVED FOR PUBLIC RELEASE, AFRL-WS 07 -1431 4

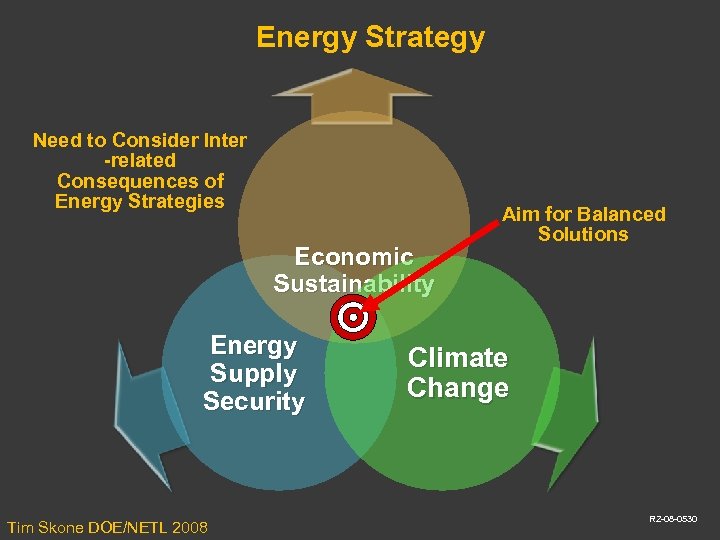

Energy Strategy Need to Consider Inter -related Consequences of Energy Strategies Economic Sustainability Energy Supply Security Tim Skone DOE/NETL 2008 Aim for Balanced Solutions Climate Change RZ-08 -0530

Energy Strategy Need to Consider Inter -related Consequences of Energy Strategies Economic Sustainability Energy Supply Security Tim Skone DOE/NETL 2008 Aim for Balanced Solutions Climate Change RZ-08 -0530

U. S. Air Force Energy Approach Vision: Make Energy A Consideration In All We Do Strategy: Reduce Demand Increase Supply Change the Culture 4

U. S. Air Force Energy Approach Vision: Make Energy A Consideration In All We Do Strategy: Reduce Demand Increase Supply Change the Culture 4

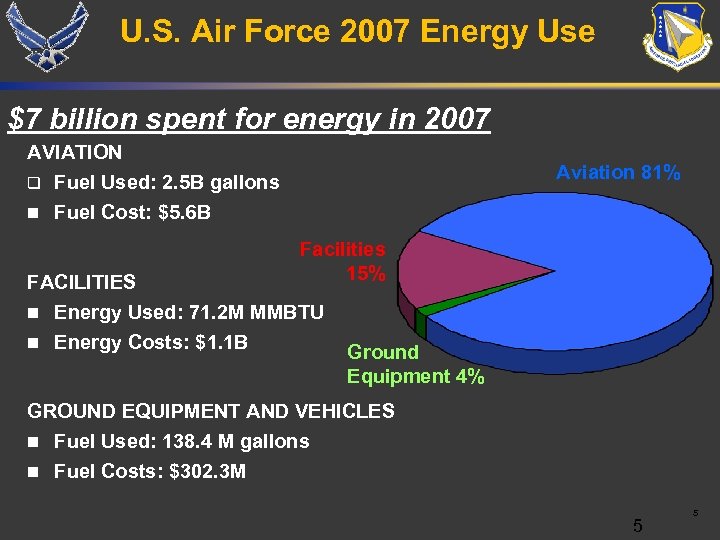

U. S. Air Force 2007 Energy Use $7 billion spent for energy in 2007 AVIATION q Fuel Used: 2. 5 B gallons n Aviation 81% Fuel Cost: $5. 6 B Facilities 15% FACILITIES n Energy Used: 71. 2 M MMBTU n Energy Costs: $1. 1 B Ground Equipment 4% GROUND EQUIPMENT AND VEHICLES n Fuel Used: 138. 4 M gallons n Fuel Costs: $302. 3 M 5 5

U. S. Air Force 2007 Energy Use $7 billion spent for energy in 2007 AVIATION q Fuel Used: 2. 5 B gallons n Aviation 81% Fuel Cost: $5. 6 B Facilities 15% FACILITIES n Energy Used: 71. 2 M MMBTU n Energy Costs: $1. 1 B Ground Equipment 4% GROUND EQUIPMENT AND VEHICLES n Fuel Used: 138. 4 M gallons n Fuel Costs: $302. 3 M 5 5

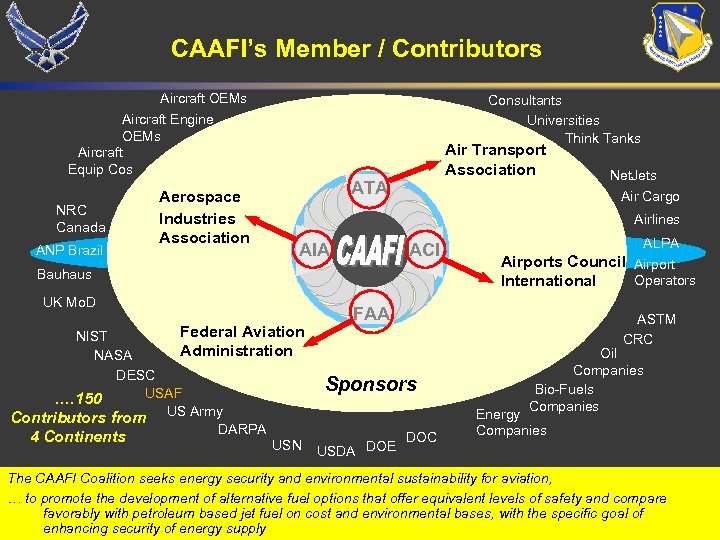

CAAFI’s Member / Contributors Aircraft OEMs Aircraft Engine OEMs Aircraft Equip Cos NRC Canada ANP Brazil Aerospace Industries Association Consultants Universities Think Tanks Air Transport Association ATA Air Cargo Airlines ACI AIA Bauhaus UK Mo. D Net. Jets ALPA Airports Council Airport Operators International FAA Federal Aviation NIST Administration NASA DESC Sponsors USAF …. 150 Contributors from US Army DARPA 4 Continents DOC USN USDA DOE ASTM CRC Oil Companies Bio-Fuels Companies Energy Companies The CAAFI Coalition seeks energy security and environmental sustainability for aviation, … to promote the development of alternative fuel options that offer equivalent levels of safety and compare favorably with petroleum based jet fuel on cost and environmental bases, with the specific goal of enhancing security of energy supply 6

CAAFI’s Member / Contributors Aircraft OEMs Aircraft Engine OEMs Aircraft Equip Cos NRC Canada ANP Brazil Aerospace Industries Association Consultants Universities Think Tanks Air Transport Association ATA Air Cargo Airlines ACI AIA Bauhaus UK Mo. D Net. Jets ALPA Airports Council Airport Operators International FAA Federal Aviation NIST Administration NASA DESC Sponsors USAF …. 150 Contributors from US Army DARPA 4 Continents DOC USN USDA DOE ASTM CRC Oil Companies Bio-Fuels Companies Energy Companies The CAAFI Coalition seeks energy security and environmental sustainability for aviation, … to promote the development of alternative fuel options that offer equivalent levels of safety and compare favorably with petroleum based jet fuel on cost and environmental bases, with the specific goal of enhancing security of energy supply 6

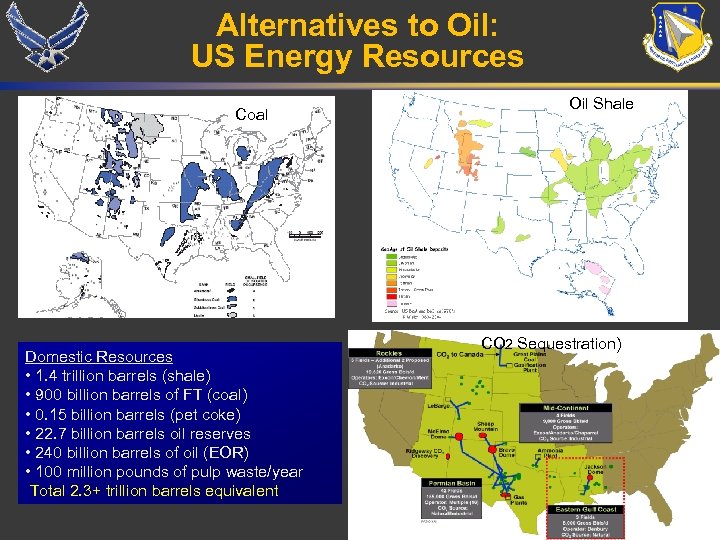

Alternatives to Oil: US Energy Resources Oil Shale Coal Domestic Resources • 1. 4 trillion barrels (shale) • 900 billion barrels of FT (coal) • 0. 15 billion barrels (pet coke) • 22. 7 billion barrels oil reserves • 240 billion barrels of oil (EOR) • 100 million pounds of pulp waste/year Total 2. 3+ trillion barrels equivalent CO 2 Sequestration) 7 7

Alternatives to Oil: US Energy Resources Oil Shale Coal Domestic Resources • 1. 4 trillion barrels (shale) • 900 billion barrels of FT (coal) • 0. 15 billion barrels (pet coke) • 22. 7 billion barrels oil reserves • 240 billion barrels of oil (EOR) • 100 million pounds of pulp waste/year Total 2. 3+ trillion barrels equivalent CO 2 Sequestration) 7 7

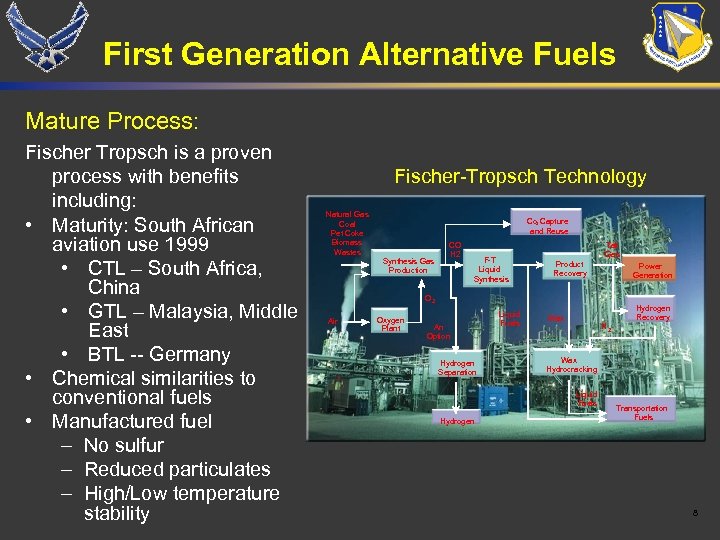

First Generation Alternative Fuels Mature Process: Fischer Tropsch is a proven process with benefits including: • Maturity: South African aviation use 1999 • CTL – South Africa, China • GTL – Malaysia, Middle East • BTL -- Germany • Chemical similarities to conventional fuels • Manufactured fuel – No sulfur – Reduced particulates – High/Low temperature stability Fischer-Tropsch Technology Natural Gas Coal Pet Coke Biomass Wastes Co 2 Capture and Reuse Synthesis Gas Production CO H 2 F-T Liquid Synthesis Tail Gas Product Recovery Power Generation O 2 Air Oxygen Plant An Option Hydrogen Separation Liquid Fuels Wax H 2 Wax Hydrocracking Liquid Fuels Hydrogen Recovery Transportation Fuels 8

First Generation Alternative Fuels Mature Process: Fischer Tropsch is a proven process with benefits including: • Maturity: South African aviation use 1999 • CTL – South Africa, China • GTL – Malaysia, Middle East • BTL -- Germany • Chemical similarities to conventional fuels • Manufactured fuel – No sulfur – Reduced particulates – High/Low temperature stability Fischer-Tropsch Technology Natural Gas Coal Pet Coke Biomass Wastes Co 2 Capture and Reuse Synthesis Gas Production CO H 2 F-T Liquid Synthesis Tail Gas Product Recovery Power Generation O 2 Air Oxygen Plant An Option Hydrogen Separation Liquid Fuels Wax H 2 Wax Hydrocracking Liquid Fuels Hydrogen Recovery Transportation Fuels 8

Fuels From Alternate Sources We Could Be the New Middle East 2. 3+ Trillion Barrels Old Middle East Saudi Arabia: Iraq: UAE: Kuwait: Iran: Qatar: Oman: Yemen: Syria: TOTAL Domestic Sources 261. 8 Billion Barrels Coal and Shale 112. 5 Billion Barrels Appalachian States 0. 9+ T Bbls 97. 8 Billion Barrels 96. 5 Billion Barrels Western States 1. 4+ T Bbls 89. 7 Billion Barrels TOTAL: 2. 3+ T Bbls 15. 2 Billion Barrels 5. 5 Billion Barrels Indiana Coal: 20 B Bbls 4. 0 Billion Barrels 2. 5 Billion Barrels 685. 5 Billion Barrels TOTAL 2. 3+ T Bbls Equivalent

Fuels From Alternate Sources We Could Be the New Middle East 2. 3+ Trillion Barrels Old Middle East Saudi Arabia: Iraq: UAE: Kuwait: Iran: Qatar: Oman: Yemen: Syria: TOTAL Domestic Sources 261. 8 Billion Barrels Coal and Shale 112. 5 Billion Barrels Appalachian States 0. 9+ T Bbls 97. 8 Billion Barrels 96. 5 Billion Barrels Western States 1. 4+ T Bbls 89. 7 Billion Barrels TOTAL: 2. 3+ T Bbls 15. 2 Billion Barrels 5. 5 Billion Barrels Indiana Coal: 20 B Bbls 4. 0 Billion Barrels 2. 5 Billion Barrels 685. 5 Billion Barrels TOTAL 2. 3+ T Bbls Equivalent

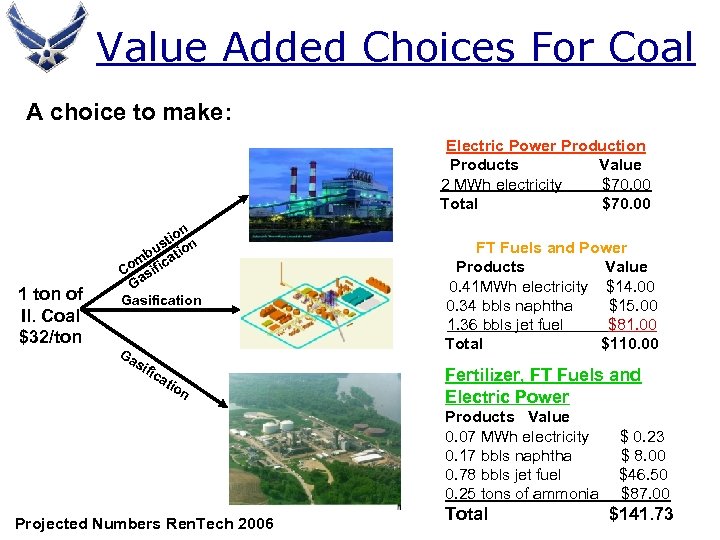

Value Added Choices For Coal A choice to make: Electric Power Production Products Value 2 MWh electricity $70. 00 Total $70. 00 1 ton of Il. Coal $32/ton n tio n s bu atio m c Co sifi Ga Gasification Ga sif ica tio n FT Fuels and Power Products Value 0. 41 MWh electricity $14. 00 0. 34 bbls naphtha $15. 00 1. 36 bbls jet fuel $81. 00 Total $110. 00 Fertilizer, FT Fuels and Electric Power Products Value 0. 07 MWh electricity 0. 17 bbls naphtha 0. 78 bbls jet fuel 0. 25 tons of ammonia Projected Numbers Ren. Tech 2006 Total $ 0. 23 $ 8. 00 $46. 50 $87. 00 $141. 73

Value Added Choices For Coal A choice to make: Electric Power Production Products Value 2 MWh electricity $70. 00 Total $70. 00 1 ton of Il. Coal $32/ton n tio n s bu atio m c Co sifi Ga Gasification Ga sif ica tio n FT Fuels and Power Products Value 0. 41 MWh electricity $14. 00 0. 34 bbls naphtha $15. 00 1. 36 bbls jet fuel $81. 00 Total $110. 00 Fertilizer, FT Fuels and Electric Power Products Value 0. 07 MWh electricity 0. 17 bbls naphtha 0. 78 bbls jet fuel 0. 25 tons of ammonia Projected Numbers Ren. Tech 2006 Total $ 0. 23 $ 8. 00 $46. 50 $87. 00 $141. 73

Franz Fischer and Hans Tropsch Franz Fisher Hans Tropsch 11

Franz Fischer and Hans Tropsch Franz Fisher Hans Tropsch 11

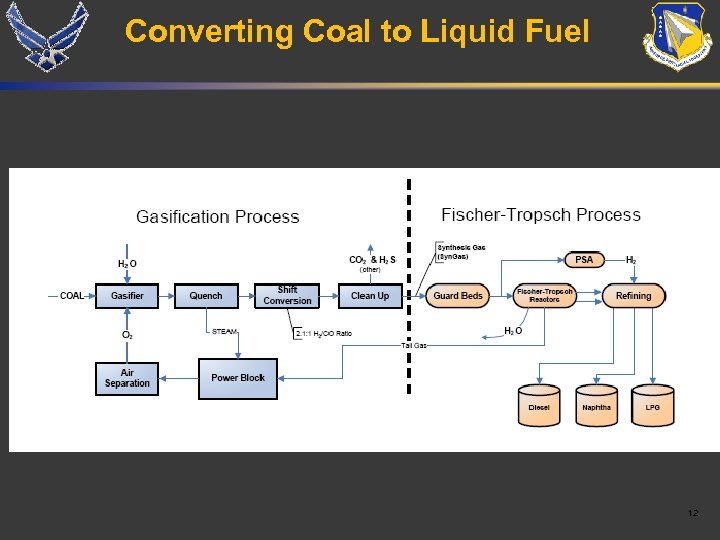

Converting Coal to Liquid Fuel 12

Converting Coal to Liquid Fuel 12

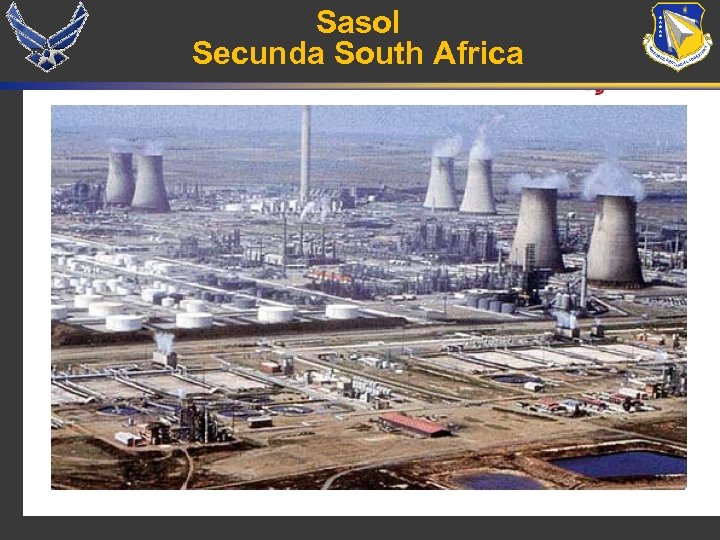

Sasol Secunda South Africa 13

Sasol Secunda South Africa 13

B-52 Certified for 50/50 Blend! 8 Aug 2007 14 14

B-52 Certified for 50/50 Blend! 8 Aug 2007 14 14

Alternative Fuels Certification Office Certification Process Execution • MIL-HDBK-510 – used for fuel approval • Specification – used for fuel procurement Process Owner Coordinates Single Managers Execute Single Managers Knowledge Gaps Tech Data Handbook Sustaining Engineering Identify Gaps (System/Class) Fills Gaps No Gaps – Performs “Like” JP-8 Evaluation/ Risk Analysis Fuel Approved “Unrestricted” Fuel Approved “Restricted” Fuel Approved “Unrestricted” Fuel Rejected Process owner: ASC • Coordinates gap analysis • Coordinates sustaining engineering • Ensures data flow between SMs • Updates MIL-Handbook with lessons learned • Revise Specification (if req’d) B-52/C-17 approach consistent with this process 15 15

Alternative Fuels Certification Office Certification Process Execution • MIL-HDBK-510 – used for fuel approval • Specification – used for fuel procurement Process Owner Coordinates Single Managers Execute Single Managers Knowledge Gaps Tech Data Handbook Sustaining Engineering Identify Gaps (System/Class) Fills Gaps No Gaps – Performs “Like” JP-8 Evaluation/ Risk Analysis Fuel Approved “Unrestricted” Fuel Approved “Restricted” Fuel Approved “Unrestricted” Fuel Rejected Process owner: ASC • Coordinates gap analysis • Coordinates sustaining engineering • Ensures data flow between SMs • Updates MIL-Handbook with lessons learned • Revise Specification (if req’d) B-52/C-17 approach consistent with this process 15 15

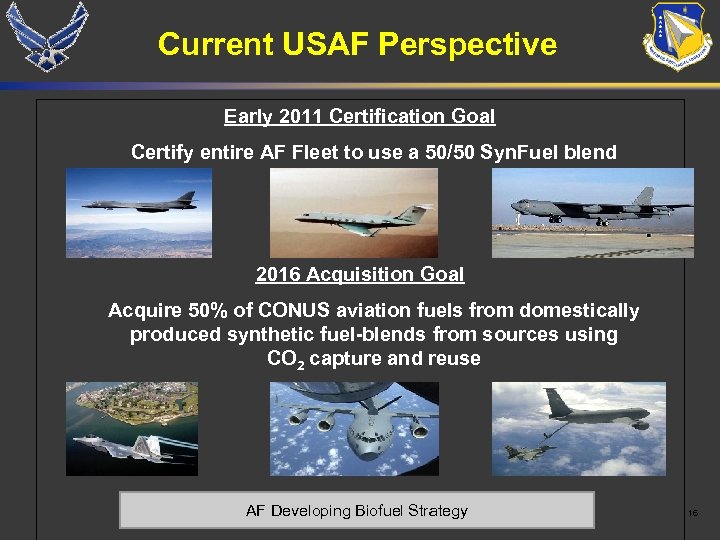

Current USAF Perspective Early 2011 Certification Goal Certify entire AF Fleet to use a 50/50 Syn. Fuel blend 2016 Acquisition Goal Acquire 50% of CONUS aviation fuels from domestically produced synthetic fuel-blends from sources using CO 2 capture and reuse AF Developing Biofuel Strategy 16

Current USAF Perspective Early 2011 Certification Goal Certify entire AF Fleet to use a 50/50 Syn. Fuel blend 2016 Acquisition Goal Acquire 50% of CONUS aviation fuels from domestically produced synthetic fuel-blends from sources using CO 2 capture and reuse AF Developing Biofuel Strategy 16

Alternative Fuels Certification Office FT-Blend Summary Certification Schedule/Status Maximizing War-winning Capabilities For… Every Airman…Every Aircraft B-52 FY 08 FY 09 FY 10 FY 11 Today B-1 B-2 Engine Test C-17 Cert Complete KC-135 All Transports Flight Complete F-15 F-16 F-22 All Fighter/ Attack Excludes F-35 Trainers Heli /Special GSE / ESOH / Infrastructure Excludes CV-22 All USAF Systems NOTIONAL Gap Analysis Cert. Completion FSE 25 Nov 09

Alternative Fuels Certification Office FT-Blend Summary Certification Schedule/Status Maximizing War-winning Capabilities For… Every Airman…Every Aircraft B-52 FY 08 FY 09 FY 10 FY 11 Today B-1 B-2 Engine Test C-17 Cert Complete KC-135 All Transports Flight Complete F-15 F-16 F-22 All Fighter/ Attack Excludes F-35 Trainers Heli /Special GSE / ESOH / Infrastructure Excludes CV-22 All USAF Systems NOTIONAL Gap Analysis Cert. Completion FSE 25 Nov 09

AFRL Major Thrusts • High level goals: – 2011 – 50/50 F-T blend certification for all systems (Alternative Fuel Certification Office (AFCO)) – 2016 – 50% of domestic consumption contains synthetics (F-T + ? ) (~400 M gal), “greener” than petroleum, cost-competitive • AFRL major efforts (joint w/ AFPET) (coord w/ CAAFI) – F-T certification support (properties, mat’l compatibility, toxicology) – Aviation biofuel certification – Key parameters • • • Performance (“drop-in”) Cost (“competitive”) Production potential (“significant”) Lifecycle greenhouse gas footprint (“less than petroleum”) Sustainability (“? ”) 18

AFRL Major Thrusts • High level goals: – 2011 – 50/50 F-T blend certification for all systems (Alternative Fuel Certification Office (AFCO)) – 2016 – 50% of domestic consumption contains synthetics (F-T + ? ) (~400 M gal), “greener” than petroleum, cost-competitive • AFRL major efforts (joint w/ AFPET) (coord w/ CAAFI) – F-T certification support (properties, mat’l compatibility, toxicology) – Aviation biofuel certification – Key parameters • • • Performance (“drop-in”) Cost (“competitive”) Production potential (“significant”) Lifecycle greenhouse gas footprint (“less than petroleum”) Sustainability (“? ”) 18

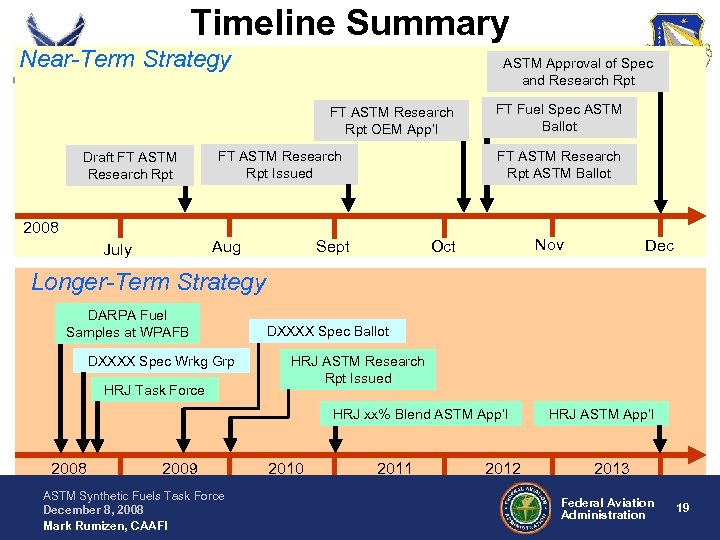

Timeline Summary Near-Term Strategy ASTM Approval of Spec and Research Rpt FT ASTM Research Rpt OEM App’l Draft FT ASTM Research Rpt Issued FT Fuel Spec ASTM Ballot FT ASTM Research Rpt ASTM Ballot 2008 Aug July Sept Nov Oct Dec Longer-Term Strategy DARPA Fuel Samples at WPAFB DXXXX Spec Wrkg Grp HRJ Task Force DXXXX Spec Ballot HRJ ASTM Research Rpt Issued HRJ xx% Blend ASTM App’l 2008 2009 ASTM Synthetic Fuels Task Force December 8, 2008 Mark Rumizen, CAAFI 2010 2011 2012 HRJ ASTM App’l 2013 Federal Aviation Administration 19 19

Timeline Summary Near-Term Strategy ASTM Approval of Spec and Research Rpt FT ASTM Research Rpt OEM App’l Draft FT ASTM Research Rpt Issued FT Fuel Spec ASTM Ballot FT ASTM Research Rpt ASTM Ballot 2008 Aug July Sept Nov Oct Dec Longer-Term Strategy DARPA Fuel Samples at WPAFB DXXXX Spec Wrkg Grp HRJ Task Force DXXXX Spec Ballot HRJ ASTM Research Rpt Issued HRJ xx% Blend ASTM App’l 2008 2009 ASTM Synthetic Fuels Task Force December 8, 2008 Mark Rumizen, CAAFI 2010 2011 2012 HRJ ASTM App’l 2013 Federal Aviation Administration 19 19

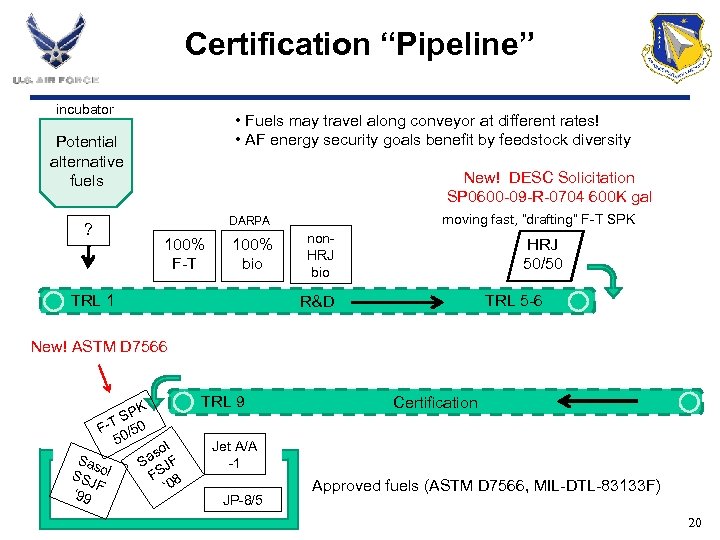

Certification “Pipeline” incubator • Fuels may travel along conveyor at different rates! • AF energy security goals benefit by feedstock diversity Potential alternative fuels New! DESC Solicitation SP 0600 -09 -R-0704 600 K gal moving fast, “drafting” F-T SPK DARPA ? 100% F-T 100% bio TRL 1 non. HRJ bio HRJ 50/50 TRL 5 -6 R&D New! ASTM D 7566 PK TS 0 F- 0/5 5 Sas SSJ ol F ‘ 99 ol as F S J FS 8 ‘ 0 TRL 9 Certification Jet A/A -1 JP-8/5 Approved fuels (ASTM D 7566, MIL-DTL-83133 F) 20

Certification “Pipeline” incubator • Fuels may travel along conveyor at different rates! • AF energy security goals benefit by feedstock diversity Potential alternative fuels New! DESC Solicitation SP 0600 -09 -R-0704 600 K gal moving fast, “drafting” F-T SPK DARPA ? 100% F-T 100% bio TRL 1 non. HRJ bio HRJ 50/50 TRL 5 -6 R&D New! ASTM D 7566 PK TS 0 F- 0/5 5 Sas SSJ ol F ‘ 99 ol as F S J FS 8 ‘ 0 TRL 9 Certification Jet A/A -1 JP-8/5 Approved fuels (ASTM D 7566, MIL-DTL-83133 F) 20

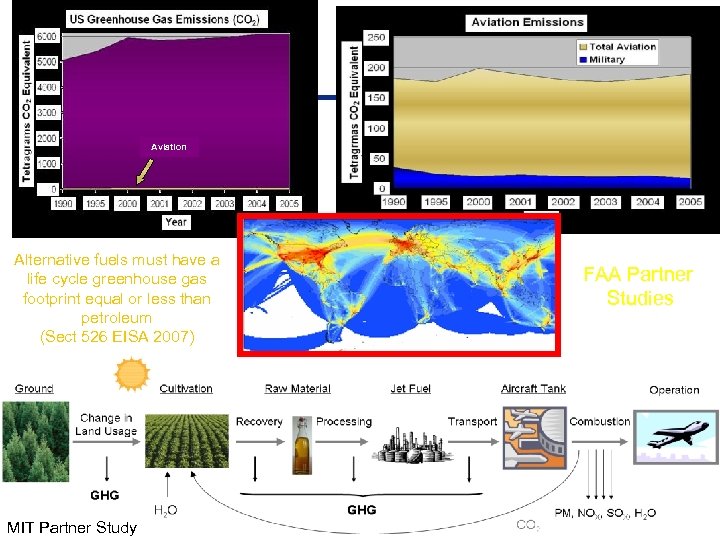

Aviation Alternative fuels must have a life cycle greenhouse gas footprint equal or less than petroleum (Sect 526 EISA 2007) MIT Partner Study FAA Partner Studies

Aviation Alternative fuels must have a life cycle greenhouse gas footprint equal or less than petroleum (Sect 526 EISA 2007) MIT Partner Study FAA Partner Studies

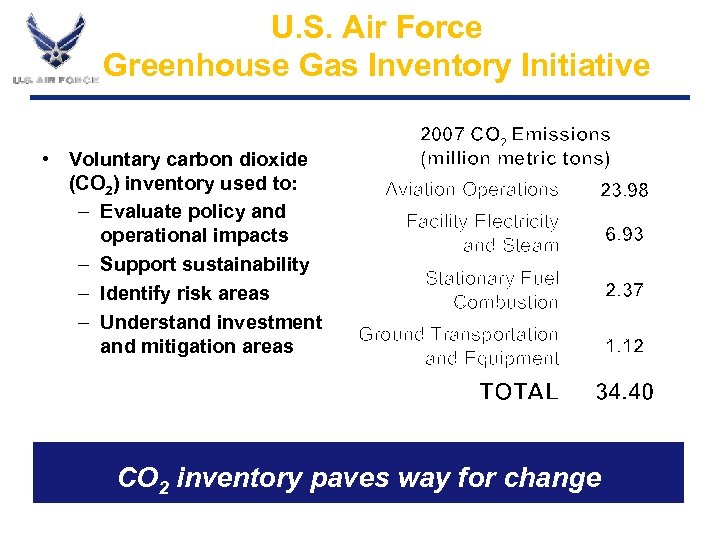

U. S. Air Force Greenhouse Gas Inventory Initiative • Voluntary carbon dioxide (CO 2) inventory used to: – Evaluate policy and operational impacts – Support sustainability – Identify risk areas – Understand investment and mitigation areas 2007 CO 2 Emissions (million metric tons) Aviation Operations 23. 98 Facility Electricity and Steam 6. 93 Stationary Fuel Combustion 2. 37 Ground Transportation and Equipment 1. 12 TOTAL 34. 40 CO 2 inventory paves way for change 22

U. S. Air Force Greenhouse Gas Inventory Initiative • Voluntary carbon dioxide (CO 2) inventory used to: – Evaluate policy and operational impacts – Support sustainability – Identify risk areas – Understand investment and mitigation areas 2007 CO 2 Emissions (million metric tons) Aviation Operations 23. 98 Facility Electricity and Steam 6. 93 Stationary Fuel Combustion 2. 37 Ground Transportation and Equipment 1. 12 TOTAL 34. 40 CO 2 inventory paves way for change 22

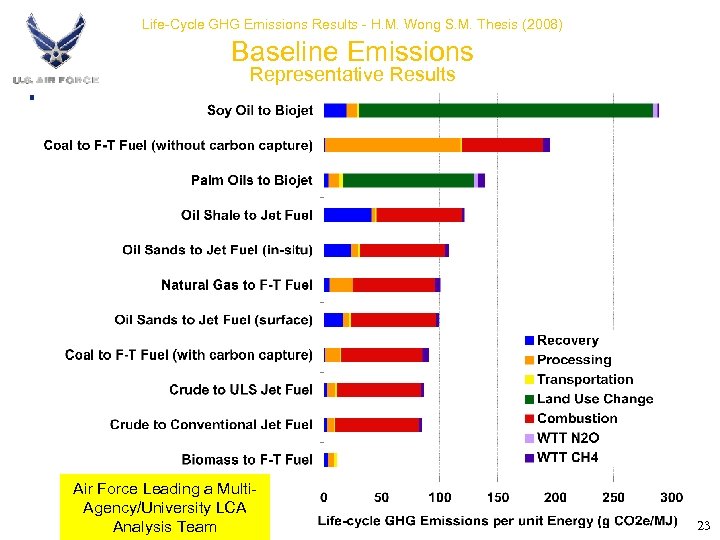

Life-Cycle GHG Emissions Results - H. M. Wong S. M. Thesis (2008) Baseline Emissions Representative Results Air Force Leading a Multi. Agency/University LCA Analysis Team 23

Life-Cycle GHG Emissions Results - H. M. Wong S. M. Thesis (2008) Baseline Emissions Representative Results Air Force Leading a Multi. Agency/University LCA Analysis Team 23

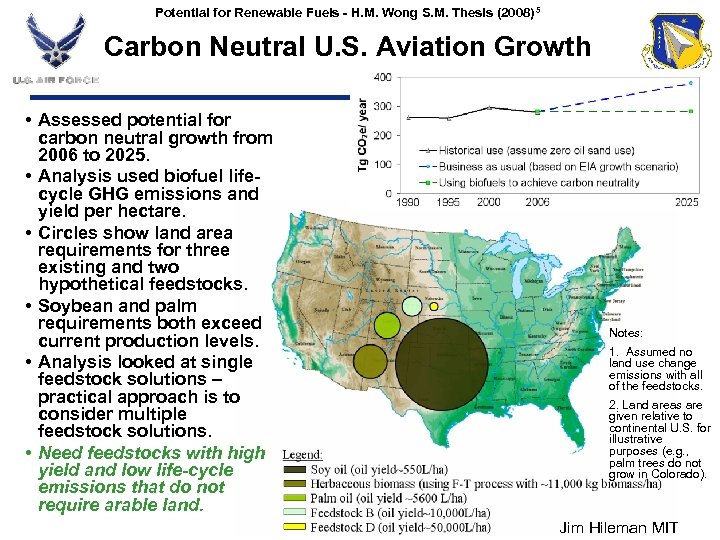

Potential for Renewable Fuels - H. M. Wong S. M. Thesis (2008) 5 Carbon Neutral U. S. Aviation Growth • Assessed potential for carbon neutral growth from 2006 to 2025. • Analysis used biofuel lifecycle GHG emissions and yield per hectare. • Circles show land area requirements for three existing and two hypothetical feedstocks. • Soybean and palm requirements both exceed current production levels. • Analysis looked at single feedstock solutions – practical approach is to consider multiple feedstock solutions. • Need feedstocks with high yield and low life-cycle emissions that do not require arable land. Notes: 1. Assumed no land use change emissions with all of the feedstocks. 2. Land areas are given relative to continental U. S. for illustrative purposes (e. g. , palm trees do not grow in Colorado). Jim Hileman MIT

Potential for Renewable Fuels - H. M. Wong S. M. Thesis (2008) 5 Carbon Neutral U. S. Aviation Growth • Assessed potential for carbon neutral growth from 2006 to 2025. • Analysis used biofuel lifecycle GHG emissions and yield per hectare. • Circles show land area requirements for three existing and two hypothetical feedstocks. • Soybean and palm requirements both exceed current production levels. • Analysis looked at single feedstock solutions – practical approach is to consider multiple feedstock solutions. • Need feedstocks with high yield and low life-cycle emissions that do not require arable land. Notes: 1. Assumed no land use change emissions with all of the feedstocks. 2. Land areas are given relative to continental U. S. for illustrative purposes (e. g. , palm trees do not grow in Colorado). Jim Hileman MIT

Sustainability • Need to develop an aviation consensus view – Environmental sustainability • • • Water usage Water pollution Local air quality Global air quality Land use changes – Business sustainability • Aviation sector performance is closely linked to fuel costs 25

Sustainability • Need to develop an aviation consensus view – Environmental sustainability • • • Water usage Water pollution Local air quality Global air quality Land use changes – Business sustainability • Aviation sector performance is closely linked to fuel costs 25

Quantifying Well-to-Wake Benefits - Hileman et al. (2008)5 Assessing Uncertainties: Land use change scenarios: 1. Use Marginal Land or Waste Product • Process efficiency 2. Conversion of Brazilian Cerrado • Carbon capture efficiency 3. Wide-Spread Agricultural Changes 4. Destruction of Peatland Rain Forest • Feedstock variation Jim Hileman MIT

Quantifying Well-to-Wake Benefits - Hileman et al. (2008)5 Assessing Uncertainties: Land use change scenarios: 1. Use Marginal Land or Waste Product • Process efficiency 2. Conversion of Brazilian Cerrado • Carbon capture efficiency 3. Wide-Spread Agricultural Changes 4. Destruction of Peatland Rain Forest • Feedstock variation Jim Hileman MIT

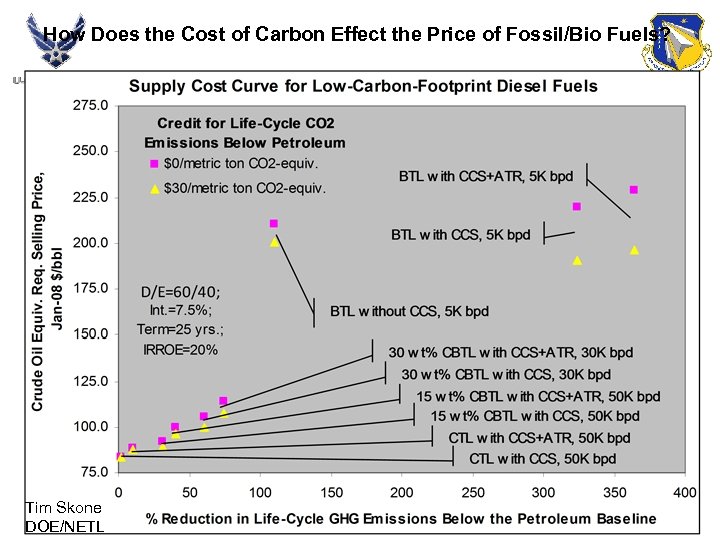

How Does the Cost of Carbon Effect the Price of Fossil/Bio Fuels? Tim Skone DOE/NETL

How Does the Cost of Carbon Effect the Price of Fossil/Bio Fuels? Tim Skone DOE/NETL

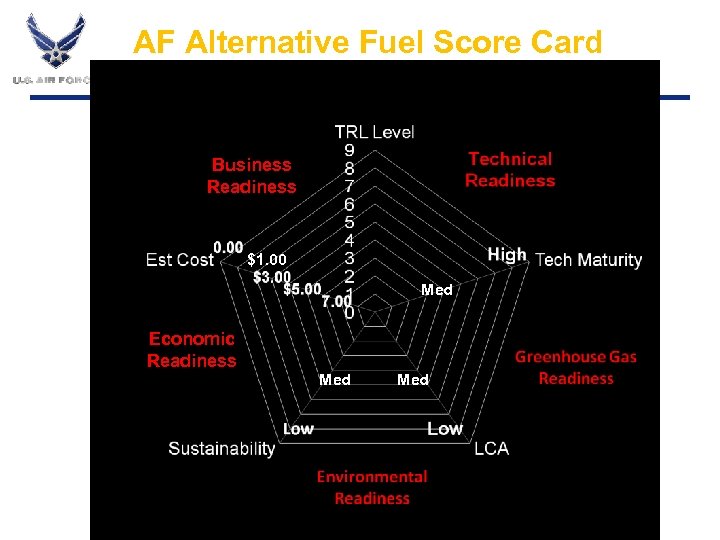

AF Alternative Fuel Score Card Business Readiness $1. 00 Med Economic Readiness Med

AF Alternative Fuel Score Card Business Readiness $1. 00 Med Economic Readiness Med

Summary • Alternative fuels offer potential to reduce green house gases and particulate emissions • Air Force will certify its entire fleet by 2011 to use a 50/50 blend of FT fuels • FT fuels can be produced from coal, biomass, natural gas as well as coal and biomass • Sect 526 EISA 2007 governs Do. D purchases of alternative fuels • Coal derived FT fuels could be produced with a CO 2 footprint equal to or less than petroleum • Developing assessment “rules and tools” to compare alternative fuels

Summary • Alternative fuels offer potential to reduce green house gases and particulate emissions • Air Force will certify its entire fleet by 2011 to use a 50/50 blend of FT fuels • FT fuels can be produced from coal, biomass, natural gas as well as coal and biomass • Sect 526 EISA 2007 governs Do. D purchases of alternative fuels • Coal derived FT fuels could be produced with a CO 2 footprint equal to or less than petroleum • Developing assessment “rules and tools” to compare alternative fuels

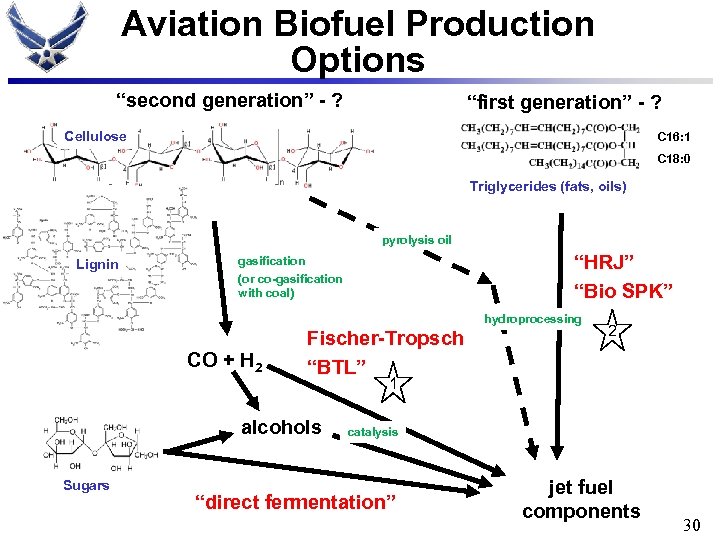

Aviation Biofuel Production Options “second generation” - ? “first generation” - ? Cellulose C 16: 1 C 18: 0 Triglycerides (fats, oils) pyrolysis oil Lignin “HRJ” “Bio SPK” gasification (or co-gasification with coal) hydroprocessing CO + H 2 Fischer-Tropsch “BTL” alcohols Sugars 2 1 catalysis “direct fermentation” jet fuel components 30

Aviation Biofuel Production Options “second generation” - ? “first generation” - ? Cellulose C 16: 1 C 18: 0 Triglycerides (fats, oils) pyrolysis oil Lignin “HRJ” “Bio SPK” gasification (or co-gasification with coal) hydroprocessing CO + H 2 Fischer-Tropsch “BTL” alcohols Sugars 2 1 catalysis “direct fermentation” jet fuel components 30

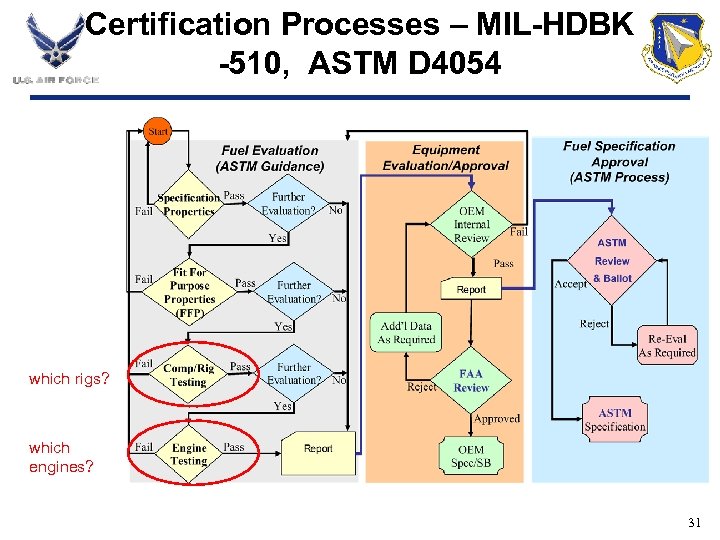

Certification Processes – MIL-HDBK -510, ASTM D 4054 which rigs? which engines? 31

Certification Processes – MIL-HDBK -510, ASTM D 4054 which rigs? which engines? 31

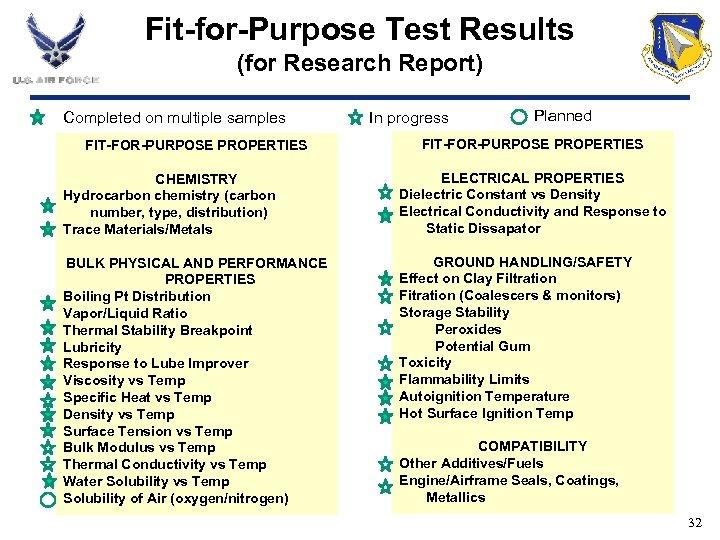

Fit-for-Purpose Test Results (for Research Report) Completed on multiple samples FIT-FOR-PURPOSE PROPERTIES In progress Planned FIT-FOR-PURPOSE PROPERTIES CHEMISTRY Hydrocarbon chemistry (carbon number, type, distribution) Trace Materials/Metals ELECTRICAL PROPERTIES Dielectric Constant vs Density Electrical Conductivity and Response to Static Dissapator BULK PHYSICAL AND PERFORMANCE PROPERTIES Boiling Pt Distribution Vapor/Liquid Ratio Thermal Stability Breakpoint Lubricity Response to Lube Improver Viscosity vs Temp Specific Heat vs Temp Density vs Temp Surface Tension vs Temp Bulk Modulus vs Temp Thermal Conductivity vs Temp Water Solubility vs Temp Solubility of Air (oxygen/nitrogen) GROUND HANDLING/SAFETY Effect on Clay Filtration Fitration (Coalescers & monitors) Storage Stability Peroxides Potential Gum Toxicity Flammability Limits Autoignition Temperature Hot Surface Ignition Temp COMPATIBILITY Other Additives/Fuels Engine/Airframe Seals, Coatings, Metallics 32

Fit-for-Purpose Test Results (for Research Report) Completed on multiple samples FIT-FOR-PURPOSE PROPERTIES In progress Planned FIT-FOR-PURPOSE PROPERTIES CHEMISTRY Hydrocarbon chemistry (carbon number, type, distribution) Trace Materials/Metals ELECTRICAL PROPERTIES Dielectric Constant vs Density Electrical Conductivity and Response to Static Dissapator BULK PHYSICAL AND PERFORMANCE PROPERTIES Boiling Pt Distribution Vapor/Liquid Ratio Thermal Stability Breakpoint Lubricity Response to Lube Improver Viscosity vs Temp Specific Heat vs Temp Density vs Temp Surface Tension vs Temp Bulk Modulus vs Temp Thermal Conductivity vs Temp Water Solubility vs Temp Solubility of Air (oxygen/nitrogen) GROUND HANDLING/SAFETY Effect on Clay Filtration Fitration (Coalescers & monitors) Storage Stability Peroxides Potential Gum Toxicity Flammability Limits Autoignition Temperature Hot Surface Ignition Temp COMPATIBILITY Other Additives/Fuels Engine/Airframe Seals, Coatings, Metallics 32

Research Reports • Used to support commercial specifications (data also used for military certification) • Addresses whether “drop-in” fuels fall within experience base 33

Research Reports • Used to support commercial specifications (data also used for military certification) • Addresses whether “drop-in” fuels fall within experience base 33

Experience Base • World Fuel Survey • PQIS database • Newly developed data NIST 34

Experience Base • World Fuel Survey • PQIS database • Newly developed data NIST 34

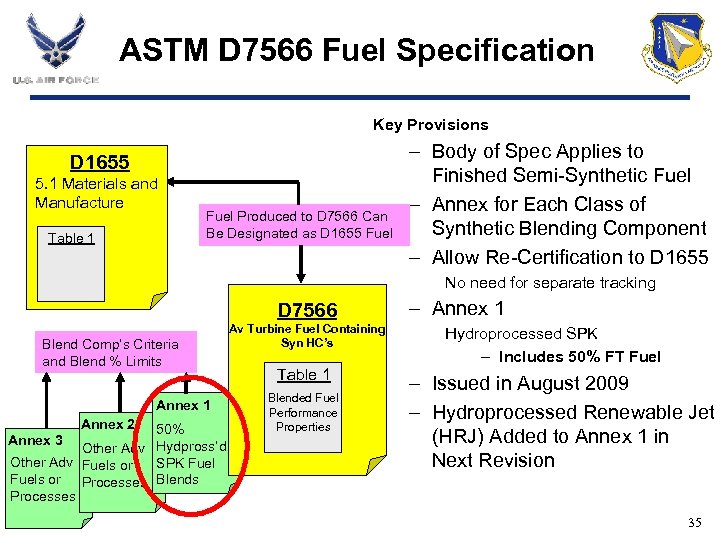

ASTM D 7566 Fuel Specification Key Provisions D 1655 5. 1 Materials and Manufacture Table 1 Fuel Produced to D 7566 Can Be Designated as D 1655 Fuel – Body of Spec Applies to Finished Semi-Synthetic Fuel – Annex for Each Class of Synthetic Blending Component – Allow Re-Certification to D 1655 No need for separate tracking D 7566 Blend Comp’s Criteria and Blend % Limits Annex 1 Annex 2 50% Other Adv Hydpross’d Other Adv Fuels or SPK Fuels or Processes Blends Processes Annex 3 Av Turbine Fuel Containing Syn HC’s Table 1 Blended Fuel Performance Properties – Annex 1 Hydroprocessed SPK – Includes 50% FT Fuel – Issued in August 2009 – Hydroprocessed Renewable Jet (HRJ) Added to Annex 1 in Next Revision 35

ASTM D 7566 Fuel Specification Key Provisions D 1655 5. 1 Materials and Manufacture Table 1 Fuel Produced to D 7566 Can Be Designated as D 1655 Fuel – Body of Spec Applies to Finished Semi-Synthetic Fuel – Annex for Each Class of Synthetic Blending Component – Allow Re-Certification to D 1655 No need for separate tracking D 7566 Blend Comp’s Criteria and Blend % Limits Annex 1 Annex 2 50% Other Adv Hydpross’d Other Adv Fuels or SPK Fuels or Processes Blends Processes Annex 3 Av Turbine Fuel Containing Syn HC’s Table 1 Blended Fuel Performance Properties – Annex 1 Hydroprocessed SPK – Includes 50% FT Fuel – Issued in August 2009 – Hydroprocessed Renewable Jet (HRJ) Added to Annex 1 in Next Revision 35

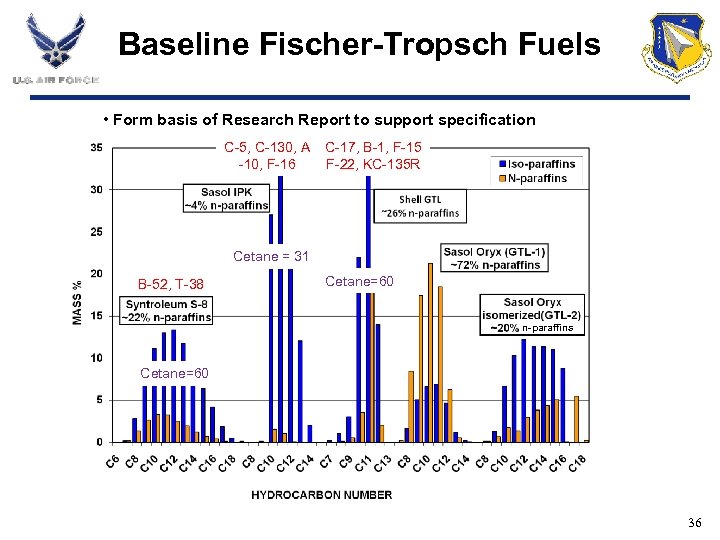

Baseline Fischer-Tropsch Fuels • Form basis of Research Report to support specification C-5, C-130, A -10, F-16 C-17, B-1, F-15 F-22, KC-135 R Cetane = 31 B-52, T-38 Cetane=60 n-paraffins Cetane=60 36

Baseline Fischer-Tropsch Fuels • Form basis of Research Report to support specification C-5, C-130, A -10, F-16 C-17, B-1, F-15 F-22, KC-135 R Cetane = 31 B-52, T-38 Cetane=60 n-paraffins Cetane=60 36

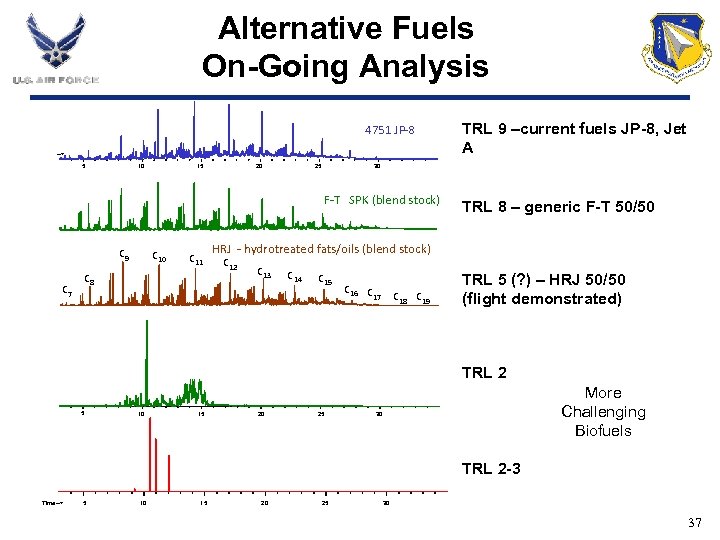

Alternative Fuels On-Going Analysis 4751 JP-8 --> 5 10 15 20 25 30 F-T SPK (blend stock) C 9 C 7 C 10 C 11 C 8 TRL 9 –current fuels JP-8, Jet A TRL 8 – generic F-T 50/50 HRJ - hydrotreated fats/oils (blend stock) C 12 C 13 C 14 C 15 C 16 C 17 C 18 C 19 TRL 5 (? ) – HRJ 50/50 (flight demonstrated) TRL 2 5 10 15 20 25 More Challenging Biofuels 30 TRL 2 -3 Time--> 5 10 15 20 25 30 37

Alternative Fuels On-Going Analysis 4751 JP-8 --> 5 10 15 20 25 30 F-T SPK (blend stock) C 9 C 7 C 10 C 11 C 8 TRL 9 –current fuels JP-8, Jet A TRL 8 – generic F-T 50/50 HRJ - hydrotreated fats/oils (blend stock) C 12 C 13 C 14 C 15 C 16 C 17 C 18 C 19 TRL 5 (? ) – HRJ 50/50 (flight demonstrated) TRL 2 5 10 15 20 25 More Challenging Biofuels 30 TRL 2 -3 Time--> 5 10 15 20 25 30 37

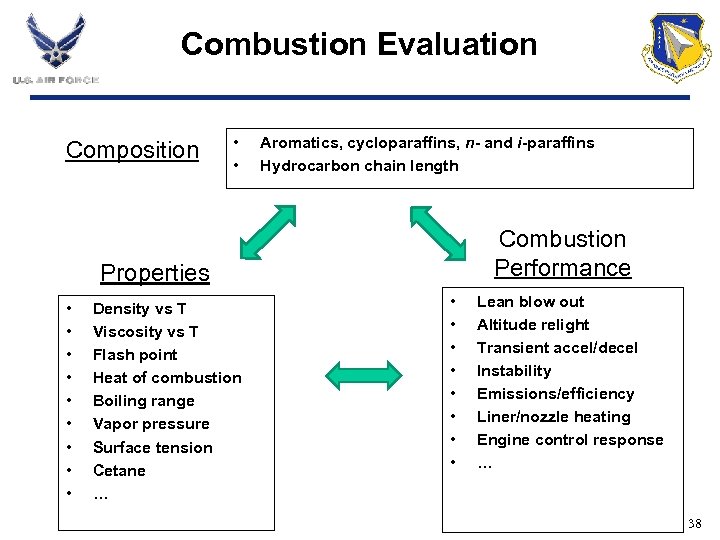

Combustion Evaluation Composition • • Aromatics, cycloparaffins, n- and i-paraffins Hydrocarbon chain length Combustion Performance Properties • • • Density vs T Viscosity vs T Flash point Heat of combustion Boiling range Vapor pressure Surface tension Cetane … • • Lean blow out Altitude relight Transient accel/decel Instability Emissions/efficiency Liner/nozzle heating Engine control response … 38

Combustion Evaluation Composition • • Aromatics, cycloparaffins, n- and i-paraffins Hydrocarbon chain length Combustion Performance Properties • • • Density vs T Viscosity vs T Flash point Heat of combustion Boiling range Vapor pressure Surface tension Cetane … • • Lean blow out Altitude relight Transient accel/decel Instability Emissions/efficiency Liner/nozzle heating Engine control response … 38

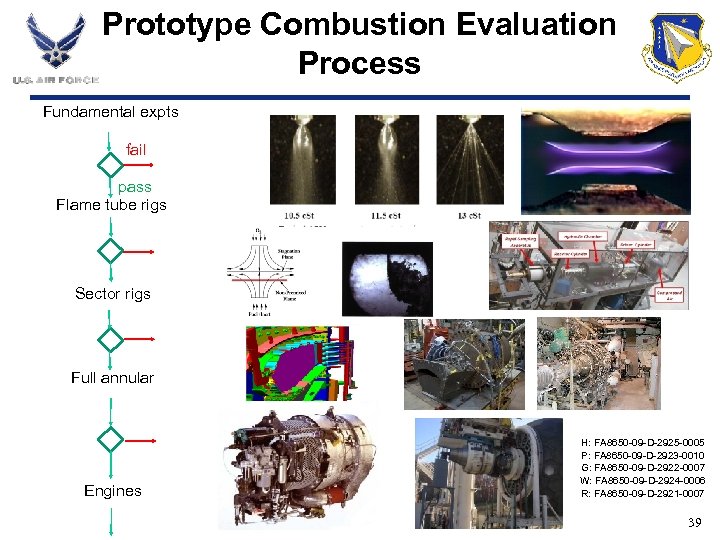

Prototype Combustion Evaluation Process Fundamental expts fail pass Flame tube rigs Sector rigs Full annular Engines H: FA 8650 -09 -D-2925 -0005 P: FA 8650 -09 -D-2923 -0010 G: FA 8650 -09 -D-2922 -0007 W: FA 8650 -09 -D-2924 -0006 R: FA 8650 -09 -D-2921 -0007 39

Prototype Combustion Evaluation Process Fundamental expts fail pass Flame tube rigs Sector rigs Full annular Engines H: FA 8650 -09 -D-2925 -0005 P: FA 8650 -09 -D-2923 -0010 G: FA 8650 -09 -D-2922 -0007 W: FA 8650 -09 -D-2924 -0006 R: FA 8650 -09 -D-2921 -0007 39

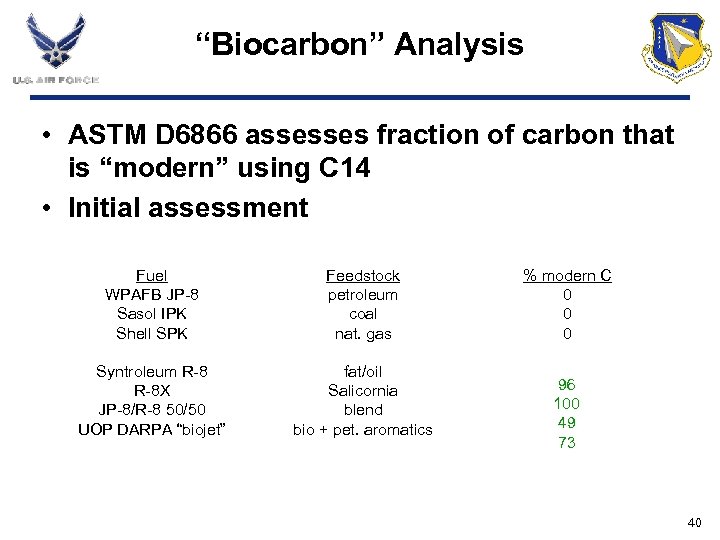

“Biocarbon” Analysis • ASTM D 6866 assesses fraction of carbon that is “modern” using C 14 • Initial assessment Fuel WPAFB JP-8 Sasol IPK Shell SPK Feedstock petroleum coal nat. gas Syntroleum R-8 X JP-8/R-8 50/50 UOP DARPA “biojet” fat/oil Salicornia blend bio + pet. aromatics % modern C 0 0 0 96 100 49 73 40

“Biocarbon” Analysis • ASTM D 6866 assesses fraction of carbon that is “modern” using C 14 • Initial assessment Fuel WPAFB JP-8 Sasol IPK Shell SPK Feedstock petroleum coal nat. gas Syntroleum R-8 X JP-8/R-8 50/50 UOP DARPA “biojet” fat/oil Salicornia blend bio + pet. aromatics % modern C 0 0 0 96 100 49 73 40

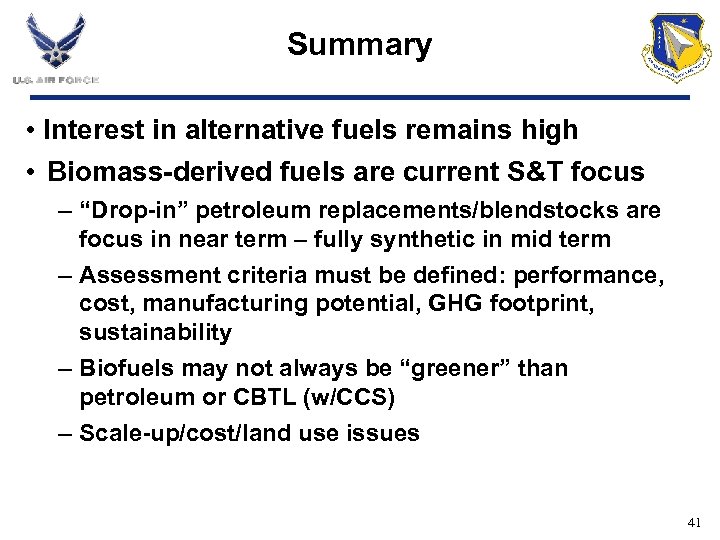

Summary • Interest in alternative fuels remains high • Biomass-derived fuels are current S&T focus – “Drop-in” petroleum replacements/blendstocks are focus in near term – fully synthetic in mid term – Assessment criteria must be defined: performance, cost, manufacturing potential, GHG footprint, sustainability – Biofuels may not always be “greener” than petroleum or CBTL (w/CCS) – Scale-up/cost/land use issues 41

Summary • Interest in alternative fuels remains high • Biomass-derived fuels are current S&T focus – “Drop-in” petroleum replacements/blendstocks are focus in near term – fully synthetic in mid term – Assessment criteria must be defined: performance, cost, manufacturing potential, GHG footprint, sustainability – Biofuels may not always be “greener” than petroleum or CBTL (w/CCS) – Scale-up/cost/land use issues 41

SECNAV Energy Goals At the Naval Energy Forum, the Honorable Ray Mabus expressed support for President Obama’s goal to reduce consumption of fuel and water and reduce overall greenhouse gas emissions. He announced five DON Energy Goals: New Requirements for Acquisition Processes • Mandatory evaluation factors used when awarding contracts for platforms, weapon systems, and buildings will include: – Lifecycle energy costs – Fully-burdened cost of fuel – Contractor energy footprint Sail the “Great Green Fleet” • DON will demonstrate a Green Strike Group in local operations by 2012 and sail it by 2016 – Nuclear ships – Surface combatants using biofuels with hybrid electric power systems – Aircraft flying on biofuels Reduce Petroleum Use in Non-Tactical Vehicles • By 2015, DON will reduce petroleum use in the commercial fleet by 50 percent – Flex fuel vehicles – Hybrid electric vehicles – Neighborhood electric vehicles Increase Alternative Energy Ashore • By 2020, DON will produce at least 50 percent of shore-based energy requirements from alternative sources – Solar, Wind, Ocean, Geothermal Increase Alternative Energy Use Navy-wide • By 2020, 50 percent of total DON energy consumption will come from alternative sources 42

SECNAV Energy Goals At the Naval Energy Forum, the Honorable Ray Mabus expressed support for President Obama’s goal to reduce consumption of fuel and water and reduce overall greenhouse gas emissions. He announced five DON Energy Goals: New Requirements for Acquisition Processes • Mandatory evaluation factors used when awarding contracts for platforms, weapon systems, and buildings will include: – Lifecycle energy costs – Fully-burdened cost of fuel – Contractor energy footprint Sail the “Great Green Fleet” • DON will demonstrate a Green Strike Group in local operations by 2012 and sail it by 2016 – Nuclear ships – Surface combatants using biofuels with hybrid electric power systems – Aircraft flying on biofuels Reduce Petroleum Use in Non-Tactical Vehicles • By 2015, DON will reduce petroleum use in the commercial fleet by 50 percent – Flex fuel vehicles – Hybrid electric vehicles – Neighborhood electric vehicles Increase Alternative Energy Ashore • By 2020, DON will produce at least 50 percent of shore-based energy requirements from alternative sources – Solar, Wind, Ocean, Geothermal Increase Alternative Energy Use Navy-wide • By 2020, 50 percent of total DON energy consumption will come from alternative sources 42

What’s Next After HRJ? • Fully synthetic fuels (cycloparaffins, aromatics for density, seal swell) • Need to access non-fat/oil feedstocks • Fermentation (w/ microorganisms) to alcohols, conversion to hydrocarbons (or direct) – Initially using sugar, ultimate goal is cellulosic dehydration, oligomerization, fermentation hydroprocessing jet fuels, sugars alcohols components “direct fermentation” • Pyrolysis of ligno-cellulosics biomass stabilization, hydroprocessing “pyrolysis oil” jet fuels, components 43

What’s Next After HRJ? • Fully synthetic fuels (cycloparaffins, aromatics for density, seal swell) • Need to access non-fat/oil feedstocks • Fermentation (w/ microorganisms) to alcohols, conversion to hydrocarbons (or direct) – Initially using sugar, ultimate goal is cellulosic dehydration, oligomerization, fermentation hydroprocessing jet fuels, sugars alcohols components “direct fermentation” • Pyrolysis of ligno-cellulosics biomass stabilization, hydroprocessing “pyrolysis oil” jet fuels, components 43

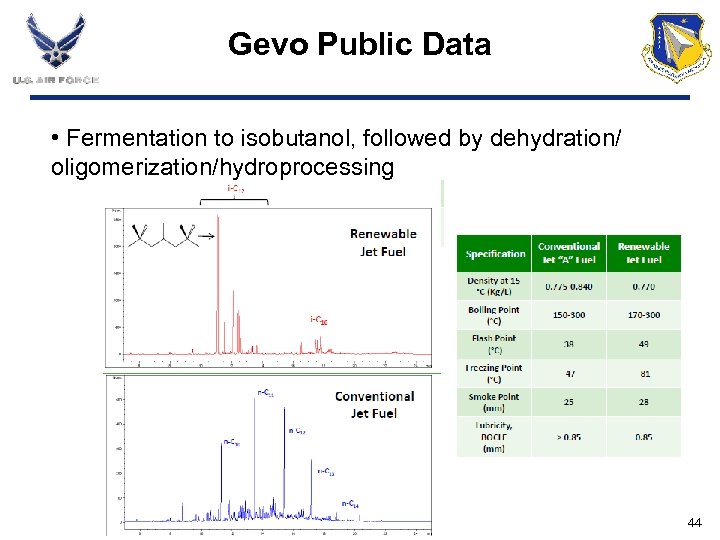

Gevo Public Data • Fermentation to isobutanol, followed by dehydration/ oligomerization/hydroprocessing 44

Gevo Public Data • Fermentation to isobutanol, followed by dehydration/ oligomerization/hydroprocessing 44