fd145d6879c86b9b8d61fbab1c9822d5.ppt

- Количество слайдов: 79

ALMANSOORI PRODUCTION SERVICES

ALMANSOORI PRODUCTION SERVICES

ALMANSOORI PRODUCTION SERVICES INDEX Company History Organization HSE & Quality Geographical Spread & Contacts Client List Awards Services Provided Equipment Engineering Support

ALMANSOORI PRODUCTION SERVICES INDEX Company History Organization HSE & Quality Geographical Spread & Contacts Client List Awards Services Provided Equipment Engineering Support

ALMANSOORI PRODUCTION SERVICES COMPANY HISTORY 1985 - MSE became a joint venture with Baker Production Services. The blend of Baker’s specialized resources with the expertise developed by Al. Mansoori, coupled with its extensive knowledge of the local environment and conditions, made Baker Al. Mansoori Production Services one of the leaders in the field. 1991 - The company was renamed as Al. Mansoori Production Services (MPS) with MSE acquiring the interest of its partner, making it 100% owned. Today, MPS is enjoying the status of a respected forerunner in the production testing services.

ALMANSOORI PRODUCTION SERVICES COMPANY HISTORY 1985 - MSE became a joint venture with Baker Production Services. The blend of Baker’s specialized resources with the expertise developed by Al. Mansoori, coupled with its extensive knowledge of the local environment and conditions, made Baker Al. Mansoori Production Services one of the leaders in the field. 1991 - The company was renamed as Al. Mansoori Production Services (MPS) with MSE acquiring the interest of its partner, making it 100% owned. Today, MPS is enjoying the status of a respected forerunner in the production testing services.

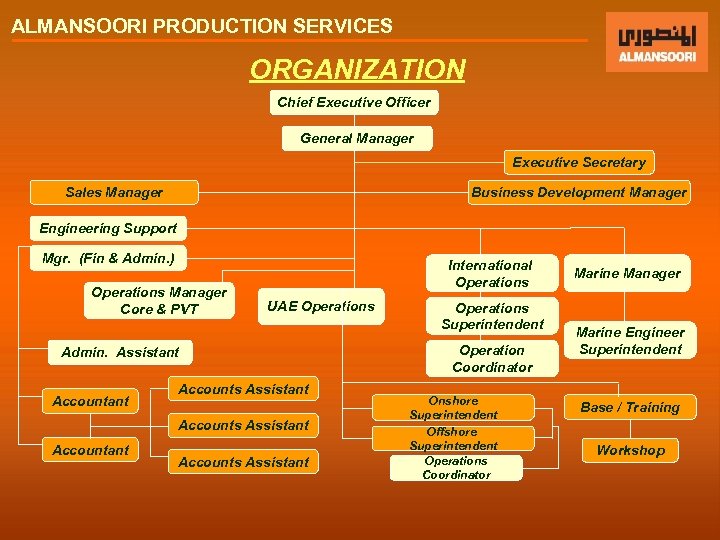

ALMANSOORI PRODUCTION SERVICES ORGANIZATION Chief Executive Officer General Manager Executive Secretary Sales Manager Business Development Manager Engineering Support Mgr. (Fin & Admin. ) Operations Manager Core & PVT International Operations UAE Operations Admin. Assistant Accounts Assistant Accountant Accounts Assistant Operations Superintendent Operation Coordinator Onshore Superintendent Offshore Superintendent Operations Coordinator Marine Manager Marine Engineer Superintendent Base / Training Workshop

ALMANSOORI PRODUCTION SERVICES ORGANIZATION Chief Executive Officer General Manager Executive Secretary Sales Manager Business Development Manager Engineering Support Mgr. (Fin & Admin. ) Operations Manager Core & PVT International Operations UAE Operations Admin. Assistant Accounts Assistant Accountant Accounts Assistant Operations Superintendent Operation Coordinator Onshore Superintendent Offshore Superintendent Operations Coordinator Marine Manager Marine Engineer Superintendent Base / Training Workshop

ALMANSOORI PRODUCTION SERVICES HEALTH, SAFETY, ENVIRONMENT & QUALITY THE ALMANSOORI TEAM IS FULLY TRAINED AND EQUIPPED TO MEET THE RISING NEED FOR QUALITY SERVICE IN THE OILFIELD INDUSTRY. REPUTED TO BE ONE OF THE BEST SERVICE ORGANIZATIONS IN THE INDUSTRY WITH WORLD CLASS STANDARDS OF HEALTH , SAFETY, ENVIROMENT & QUALITY, ALMANSOORI CONTINUES TO PURSUE ITS COMMITMENT TO SERVICE EXCELLENCE. CONSISTENT WITH OUR VISION , MISSION, and VALUES, WE CONDUCT OUR OILFIELD ACTIVITIES & OTHER RELATED OPERATIONS IN SUCH A WAY AS TO MAINTAIN THE SAFETY OF OUR EMPLOYEES AND CONTRACTORS ALIKE WITH THE END GOAL OF SETTING THE HIGHEST STANDARD OF HEALTH, SAFETY, ENVIRONMENT AND QUALITY. OCCUPATIONAL HEALTH, ENVIRONMENTAL PROTECTION & QUALITY IS A WAY OF LIFE CONSCIOUSLY PRACTICED BY ALMANSOORI AND ALL ITS AFFILIATES.

ALMANSOORI PRODUCTION SERVICES HEALTH, SAFETY, ENVIRONMENT & QUALITY THE ALMANSOORI TEAM IS FULLY TRAINED AND EQUIPPED TO MEET THE RISING NEED FOR QUALITY SERVICE IN THE OILFIELD INDUSTRY. REPUTED TO BE ONE OF THE BEST SERVICE ORGANIZATIONS IN THE INDUSTRY WITH WORLD CLASS STANDARDS OF HEALTH , SAFETY, ENVIROMENT & QUALITY, ALMANSOORI CONTINUES TO PURSUE ITS COMMITMENT TO SERVICE EXCELLENCE. CONSISTENT WITH OUR VISION , MISSION, and VALUES, WE CONDUCT OUR OILFIELD ACTIVITIES & OTHER RELATED OPERATIONS IN SUCH A WAY AS TO MAINTAIN THE SAFETY OF OUR EMPLOYEES AND CONTRACTORS ALIKE WITH THE END GOAL OF SETTING THE HIGHEST STANDARD OF HEALTH, SAFETY, ENVIRONMENT AND QUALITY. OCCUPATIONAL HEALTH, ENVIRONMENTAL PROTECTION & QUALITY IS A WAY OF LIFE CONSCIOUSLY PRACTICED BY ALMANSOORI AND ALL ITS AFFILIATES.

ALMANSOORI PRODUCTION SERVICES Integrated Management System 18001: Occupational Health & Safety

ALMANSOORI PRODUCTION SERVICES Integrated Management System 18001: Occupational Health & Safety

ALMANSOORI PRODUCTION SERVICES Integrated Management System 9001: Quality

ALMANSOORI PRODUCTION SERVICES Integrated Management System 9001: Quality

ALMANSOORI PRODUCTION SERVICES Integrated Management System 14001: Environment

ALMANSOORI PRODUCTION SERVICES Integrated Management System 14001: Environment

ALMANSOORI PRODUCTION SERVICES GEOGRAPHICAL SPREAD & CONTACTS UAE Main Offices U. A. E Yemen Canada Egypt Bangladesh India Libya Iraq Oman Tanzania Kuwait Qatar Saudi Arabia Malaysia Russia

ALMANSOORI PRODUCTION SERVICES GEOGRAPHICAL SPREAD & CONTACTS UAE Main Offices U. A. E Yemen Canada Egypt Bangladesh India Libya Iraq Oman Tanzania Kuwait Qatar Saudi Arabia Malaysia Russia

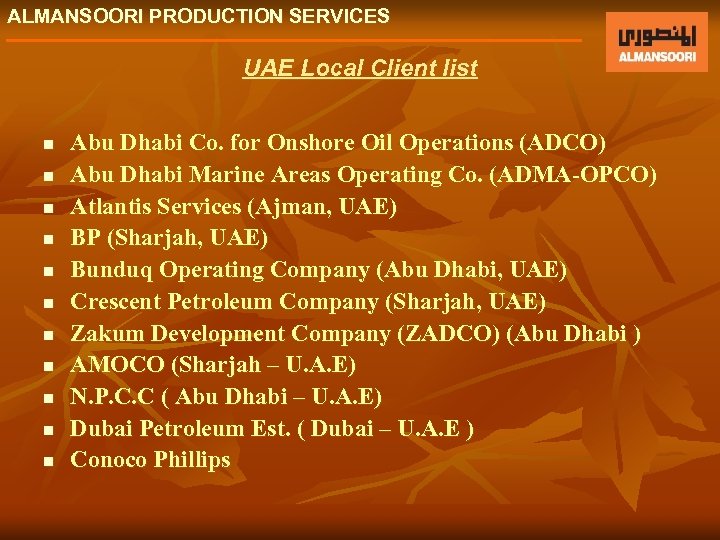

ALMANSOORI PRODUCTION SERVICES UAE Local Client list n n n Abu Dhabi Co. for Onshore Oil Operations (ADCO) Abu Dhabi Marine Areas Operating Co. (ADMA-OPCO) Atlantis Services (Ajman, UAE) BP (Sharjah, UAE) Bunduq Operating Company (Abu Dhabi, UAE) Crescent Petroleum Company (Sharjah, UAE) Zakum Development Company (ZADCO) (Abu Dhabi ) AMOCO (Sharjah – U. A. E) N. P. C. C ( Abu Dhabi – U. A. E) Dubai Petroleum Est. ( Dubai – U. A. E ) Conoco Phillips

ALMANSOORI PRODUCTION SERVICES UAE Local Client list n n n Abu Dhabi Co. for Onshore Oil Operations (ADCO) Abu Dhabi Marine Areas Operating Co. (ADMA-OPCO) Atlantis Services (Ajman, UAE) BP (Sharjah, UAE) Bunduq Operating Company (Abu Dhabi, UAE) Crescent Petroleum Company (Sharjah, UAE) Zakum Development Company (ZADCO) (Abu Dhabi ) AMOCO (Sharjah – U. A. E) N. P. C. C ( Abu Dhabi – U. A. E) Dubai Petroleum Est. ( Dubai – U. A. E ) Conoco Phillips

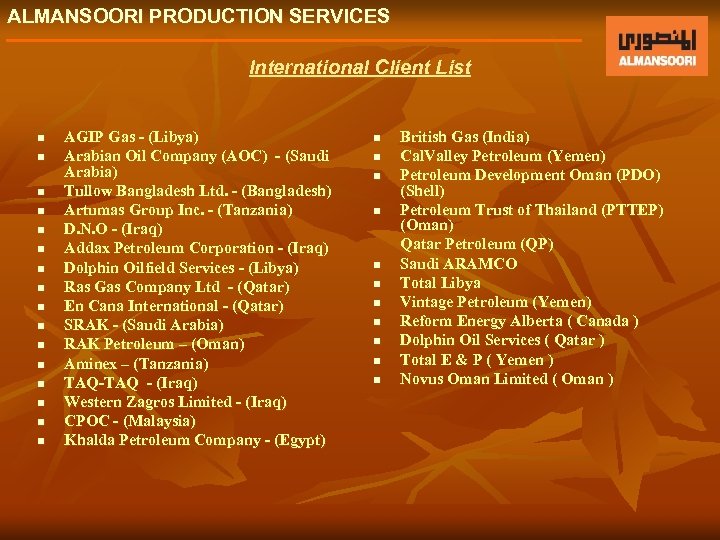

ALMANSOORI PRODUCTION SERVICES International Client List n n n n AGIP Gas - (Libya) Arabian Oil Company (AOC) - (Saudi Arabia) Tullow Bangladesh Ltd. - (Bangladesh) Artumas Group Inc. - (Tanzania) D. N. O - (Iraq) Addax Petroleum Corporation - (Iraq) Dolphin Oilfield Services - (Libya) Ras Gas Company Ltd - (Qatar) En Cana International - (Qatar) SRAK - (Saudi Arabia) RAK Petroleum – (Oman) Aminex – (Tanzania) TAQ-TAQ - (Iraq) Western Zagros Limited - (Iraq) CPOC - (Malaysia) Khalda Petroleum Company - (Egypt) n n n British Gas (India) Cal. Valley Petroleum (Yemen) Petroleum Development Oman (PDO) (Shell) Petroleum Trust of Thailand (PTTEP) (Oman) Qatar Petroleum (QP) Saudi ARAMCO Total Libya Vintage Petroleum (Yemen) Reform Energy Alberta ( Canada ) Dolphin Oil Services ( Qatar ) Total E & P ( Yemen ) Novus Oman Limited ( Oman )

ALMANSOORI PRODUCTION SERVICES International Client List n n n n AGIP Gas - (Libya) Arabian Oil Company (AOC) - (Saudi Arabia) Tullow Bangladesh Ltd. - (Bangladesh) Artumas Group Inc. - (Tanzania) D. N. O - (Iraq) Addax Petroleum Corporation - (Iraq) Dolphin Oilfield Services - (Libya) Ras Gas Company Ltd - (Qatar) En Cana International - (Qatar) SRAK - (Saudi Arabia) RAK Petroleum – (Oman) Aminex – (Tanzania) TAQ-TAQ - (Iraq) Western Zagros Limited - (Iraq) CPOC - (Malaysia) Khalda Petroleum Company - (Egypt) n n n British Gas (India) Cal. Valley Petroleum (Yemen) Petroleum Development Oman (PDO) (Shell) Petroleum Trust of Thailand (PTTEP) (Oman) Qatar Petroleum (QP) Saudi ARAMCO Total Libya Vintage Petroleum (Yemen) Reform Energy Alberta ( Canada ) Dolphin Oil Services ( Qatar ) Total E & P ( Yemen ) Novus Oman Limited ( Oman )

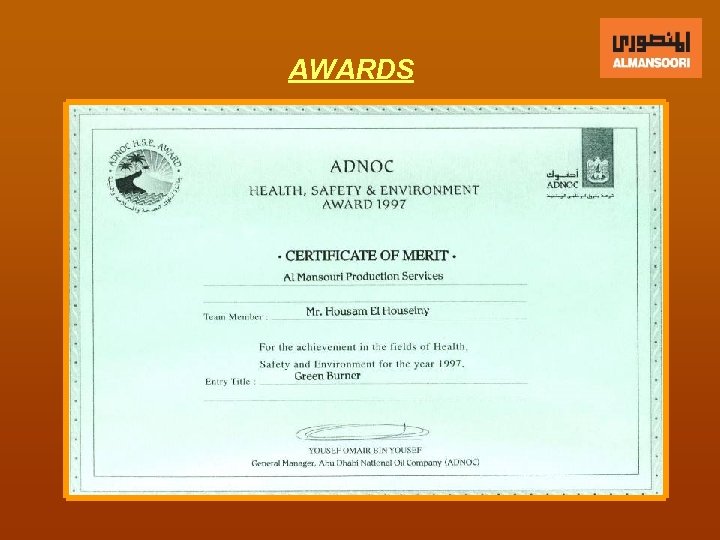

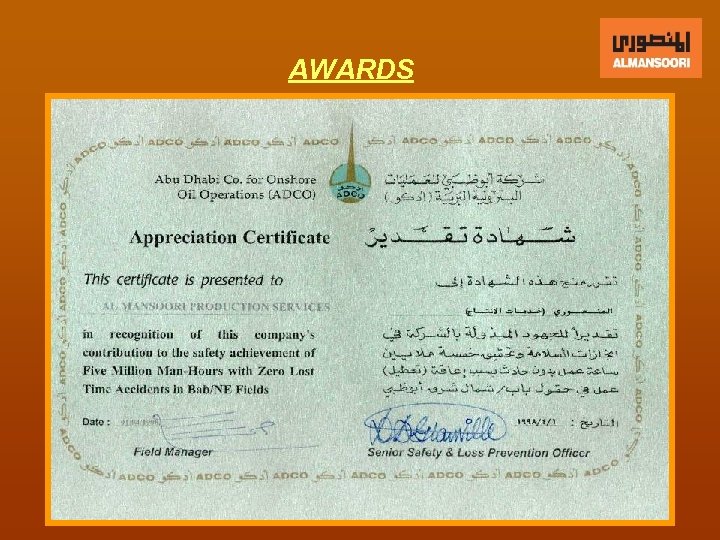

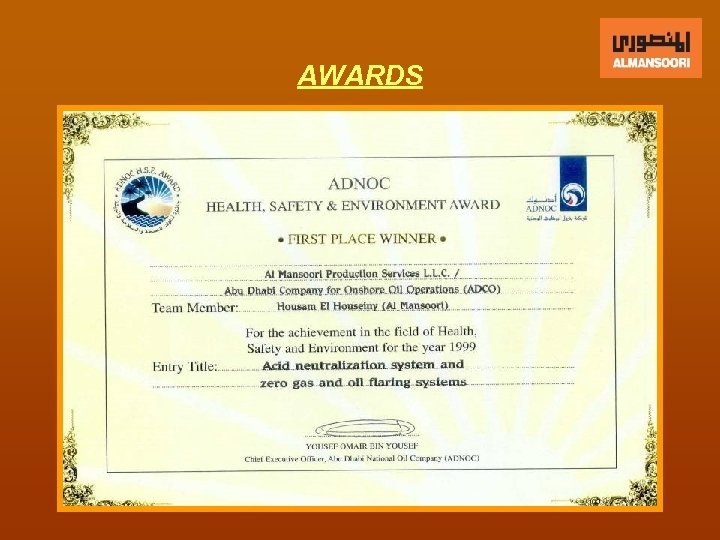

AWARDS

AWARDS

AWARDS

AWARDS

AWARDS

AWARDS

AWARDS

AWARDS

AWARDS

AWARDS

AWARDS

AWARDS

AWARDS

AWARDS

SERVICES PROVIDED h. OIL & GAS PRODUCTION/EXPLORATION WELL TESTING h. MARINE PRODUCTION TESTING & STIMULATION VESSELS h. ONSHORE & OFFSHORE EARLY PRODUCTION FACILITIES h. PRODUCED WATER TREATMENT h. MULTI-PHASE SYSTEMS h. INTEGRATED WELL SERVICES h. ENVIRONMENTAL SERVICES h. DRILL STEM TESTING h. PROCESS ENGINEERING AND DESIGN h. PVT and CORE ANALYSIS

SERVICES PROVIDED h. OIL & GAS PRODUCTION/EXPLORATION WELL TESTING h. MARINE PRODUCTION TESTING & STIMULATION VESSELS h. ONSHORE & OFFSHORE EARLY PRODUCTION FACILITIES h. PRODUCED WATER TREATMENT h. MULTI-PHASE SYSTEMS h. INTEGRATED WELL SERVICES h. ENVIRONMENTAL SERVICES h. DRILL STEM TESTING h. PROCESS ENGINEERING AND DESIGN h. PVT and CORE ANALYSIS

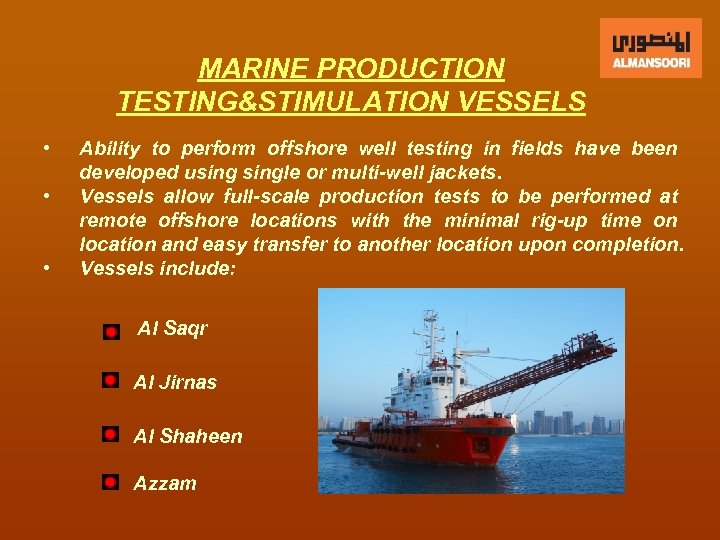

MARINE PRODUCTION TESTING&STIMULATION VESSELS • • • Ability to perform offshore well testing in fields have been developed usingle or multi-well jackets. Vessels allow full-scale production tests to be performed at remote offshore locations with the minimal rig-up time on location and easy transfer to another location upon completion. Vessels include: Al Saqr Al Jirnas Al Shaheen Azzam

MARINE PRODUCTION TESTING&STIMULATION VESSELS • • • Ability to perform offshore well testing in fields have been developed usingle or multi-well jackets. Vessels allow full-scale production tests to be performed at remote offshore locations with the minimal rig-up time on location and easy transfer to another location upon completion. Vessels include: Al Saqr Al Jirnas Al Shaheen Azzam

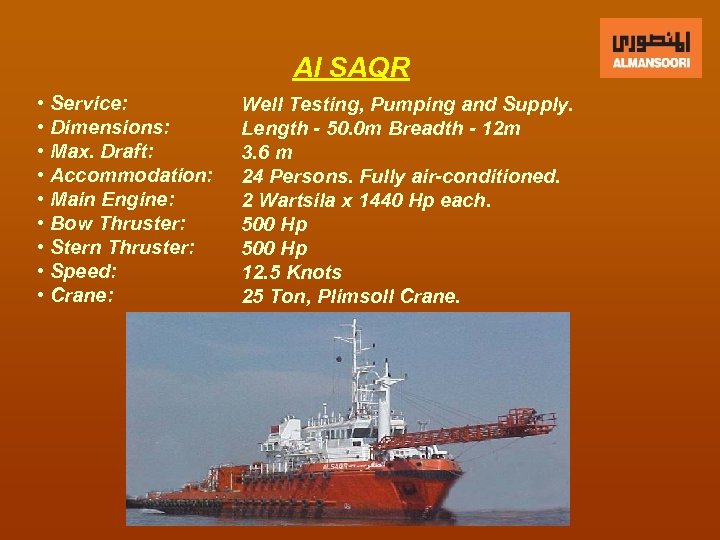

Al SAQR • Service: • Dimensions: • Max. Draft: • Accommodation: • Main Engine: • Bow Thruster: • Stern Thruster: • Speed: • Crane: Well Testing, Pumping and Supply. Length - 50. 0 m Breadth - 12 m 3. 6 m 24 Persons. Fully air-conditioned. 2 Wartsila x 1440 Hp each. 500 Hp 12. 5 Knots 25 Ton, Plimsoll Crane.

Al SAQR • Service: • Dimensions: • Max. Draft: • Accommodation: • Main Engine: • Bow Thruster: • Stern Thruster: • Speed: • Crane: Well Testing, Pumping and Supply. Length - 50. 0 m Breadth - 12 m 3. 6 m 24 Persons. Fully air-conditioned. 2 Wartsila x 1440 Hp each. 500 Hp 12. 5 Knots 25 Ton, Plimsoll Crane.

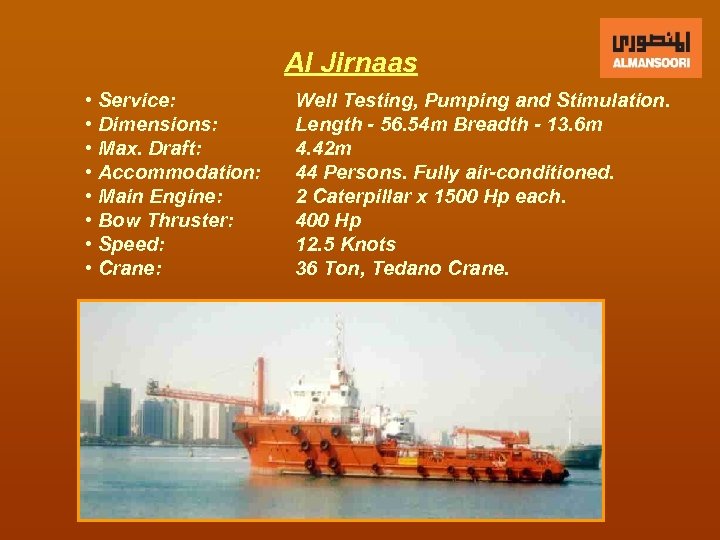

Al Jirnaas • Service: • Dimensions: • Max. Draft: • Accommodation: • Main Engine: • Bow Thruster: • Speed: • Crane: Well Testing, Pumping and Stimulation. Length - 56. 54 m Breadth - 13. 6 m 4. 42 m 44 Persons. Fully air-conditioned. 2 Caterpillar x 1500 Hp each. 400 Hp 12. 5 Knots 36 Ton, Tedano Crane.

Al Jirnaas • Service: • Dimensions: • Max. Draft: • Accommodation: • Main Engine: • Bow Thruster: • Speed: • Crane: Well Testing, Pumping and Stimulation. Length - 56. 54 m Breadth - 13. 6 m 4. 42 m 44 Persons. Fully air-conditioned. 2 Caterpillar x 1500 Hp each. 400 Hp 12. 5 Knots 36 Ton, Tedano Crane.

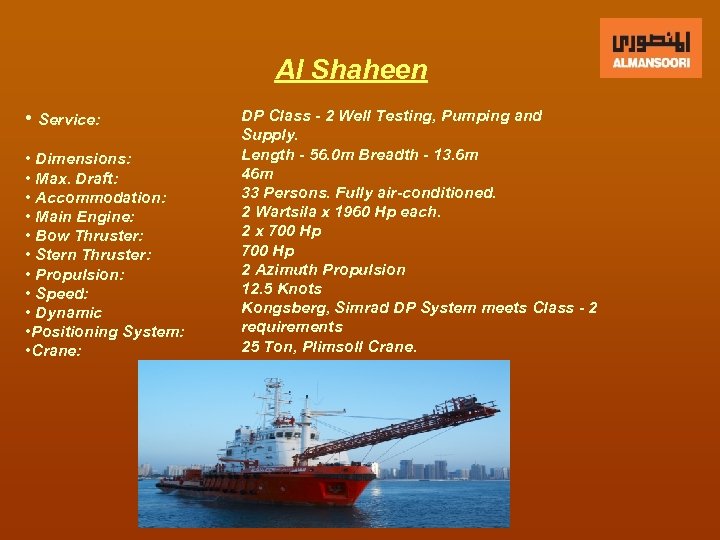

Al Shaheen • Service: • Dimensions: • Max. Draft: • Accommodation: • Main Engine: • Bow Thruster: • Stern Thruster: • Propulsion: • Speed: • Dynamic • Positioning System: • Crane: DP Class - 2 Well Testing, Pumping and Supply. Length - 56. 0 m Breadth - 13. 6 m 46 m 33 Persons. Fully air-conditioned. 2 Wartsila x 1960 Hp each. 2 x 700 Hp 2 Azimuth Propulsion 12. 5 Knots Kongsberg, Simrad DP System meets Class - 2 requirements 25 Ton, Plimsoll Crane.

Al Shaheen • Service: • Dimensions: • Max. Draft: • Accommodation: • Main Engine: • Bow Thruster: • Stern Thruster: • Propulsion: • Speed: • Dynamic • Positioning System: • Crane: DP Class - 2 Well Testing, Pumping and Supply. Length - 56. 0 m Breadth - 13. 6 m 46 m 33 Persons. Fully air-conditioned. 2 Wartsila x 1960 Hp each. 2 x 700 Hp 2 Azimuth Propulsion 12. 5 Knots Kongsberg, Simrad DP System meets Class - 2 requirements 25 Ton, Plimsoll Crane.

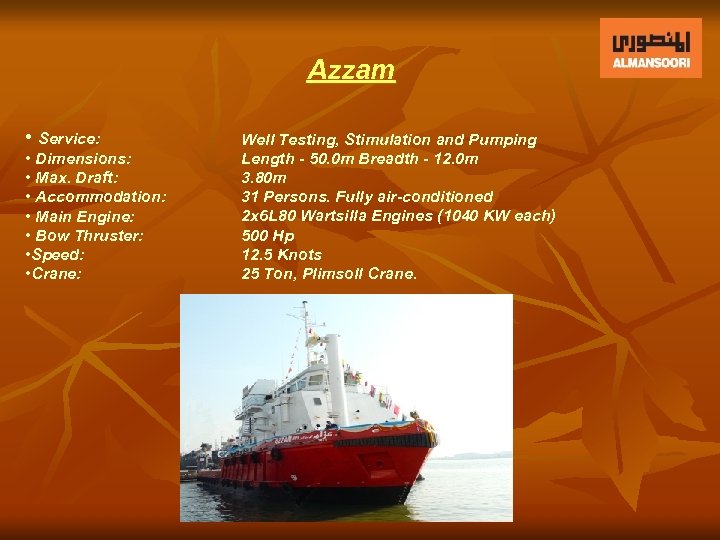

Azzam • Service: • Dimensions: • Max. Draft: • Accommodation: • Main Engine: • Bow Thruster: • Speed: • Crane: Well Testing, Stimulation and Pumping Length - 50. 0 m Breadth - 12. 0 m 3. 80 m 31 Persons. Fully air-conditioned 2 x 6 L 80 Wartsilla Engines (1040 KW each) 500 Hp 12. 5 Knots 25 Ton, Plimsoll Crane.

Azzam • Service: • Dimensions: • Max. Draft: • Accommodation: • Main Engine: • Bow Thruster: • Speed: • Crane: Well Testing, Stimulation and Pumping Length - 50. 0 m Breadth - 12. 0 m 3. 80 m 31 Persons. Fully air-conditioned 2 x 6 L 80 Wartsilla Engines (1040 KW each) 500 Hp 12. 5 Knots 25 Ton, Plimsoll Crane.

EQUIPMENT Test Separator Offshore Burner Boom Onshore Burner Boom Green Burner Head Choke Manifold Oil / Gas Manifold ESD Panel Safety Valve Heater Flexible Hose Lab Cabin SCADA Electronic Data Acquisition Loading Gantry Crude Oil Storage Tank Oil Re-Injection Pump Mobile well Test Packages Surge Tank Pressure Tank Vertical Flare Stack Water Treatment Unit HT 400 TRIPLEX PUMP Multi-Stage Pump Pressure Test System Air compressor and Generator Acid Neutralization Unit Chemical Injection Pump Duplex Cartridge Filter Unit Hydro cyclone and Accumulator Skid Strainer Package Sand Monitoring System Surface Test Tree Transfer Pump Acid Pumping Unit

EQUIPMENT Test Separator Offshore Burner Boom Onshore Burner Boom Green Burner Head Choke Manifold Oil / Gas Manifold ESD Panel Safety Valve Heater Flexible Hose Lab Cabin SCADA Electronic Data Acquisition Loading Gantry Crude Oil Storage Tank Oil Re-Injection Pump Mobile well Test Packages Surge Tank Pressure Tank Vertical Flare Stack Water Treatment Unit HT 400 TRIPLEX PUMP Multi-Stage Pump Pressure Test System Air compressor and Generator Acid Neutralization Unit Chemical Injection Pump Duplex Cartridge Filter Unit Hydro cyclone and Accumulator Skid Strainer Package Sand Monitoring System Surface Test Tree Transfer Pump Acid Pumping Unit

TEST SEPARATOR Three Phase Test Separator 2160 PSI, 1440 PSI, 720 PSI Equipped with Safety Relief Valves and Necessary Instrumentation Certified for Sour Service NACE MR-01 -75

TEST SEPARATOR Three Phase Test Separator 2160 PSI, 1440 PSI, 720 PSI Equipped with Safety Relief Valves and Necessary Instrumentation Certified for Sour Service NACE MR-01 -75

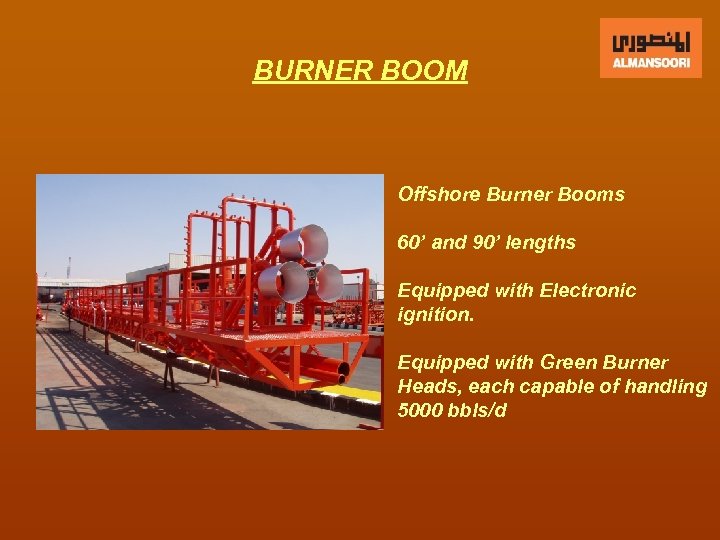

BURNER BOOM Offshore Burner Booms 60’ and 90’ lengths Equipped with Electronic ignition. Equipped with Green Burner Heads, each capable of handling 5000 bbls/d

BURNER BOOM Offshore Burner Booms 60’ and 90’ lengths Equipped with Electronic ignition. Equipped with Green Burner Heads, each capable of handling 5000 bbls/d

ONSHORE BURNER BOOMS Available on 15’ skids Complete with Green Burner Heads for clean and efficient burning Electronic ignition and continuous pilot

ONSHORE BURNER BOOMS Available on 15’ skids Complete with Green Burner Heads for clean and efficient burning Electronic ignition and continuous pilot

CHOKE MANIFOLD 3” X 5 K, and 10 K, and 15 K Choke Manifolds Equipped with Adjustable and Positive Chokes Designed with four gate valves Certified for Sour Service

CHOKE MANIFOLD 3” X 5 K, and 10 K, and 15 K Choke Manifolds Equipped with Adjustable and Positive Chokes Designed with four gate valves Certified for Sour Service

OIL AND GAS MANIFOLD 3” X 5 Way Oil Manifold (1500 PSI WP) 3” x 3 Way Gas Manifold (1500 PSI WP) NACE - MR-01 -75

OIL AND GAS MANIFOLD 3” X 5 Way Oil Manifold (1500 PSI WP) 3” x 3 Way Gas Manifold (1500 PSI WP) NACE - MR-01 -75

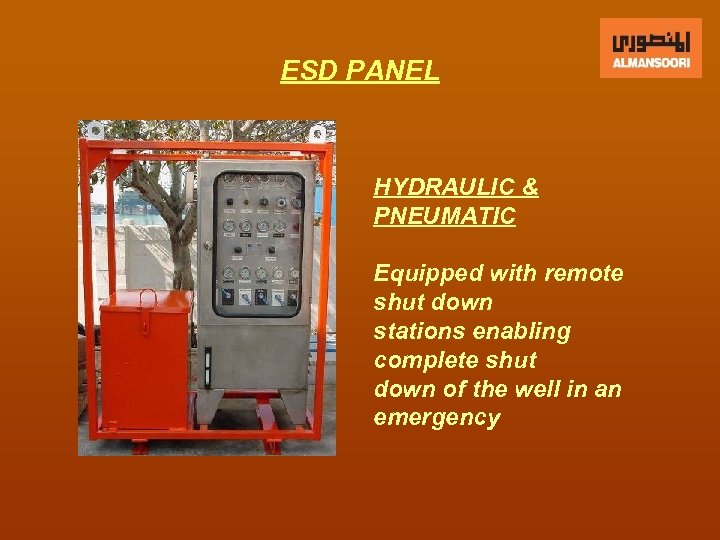

ESD PANEL HYDRAULIC & PNEUMATIC Equipped with remote shut down stations enabling complete shut down of the well in an emergency

ESD PANEL HYDRAULIC & PNEUMATIC Equipped with remote shut down stations enabling complete shut down of the well in an emergency

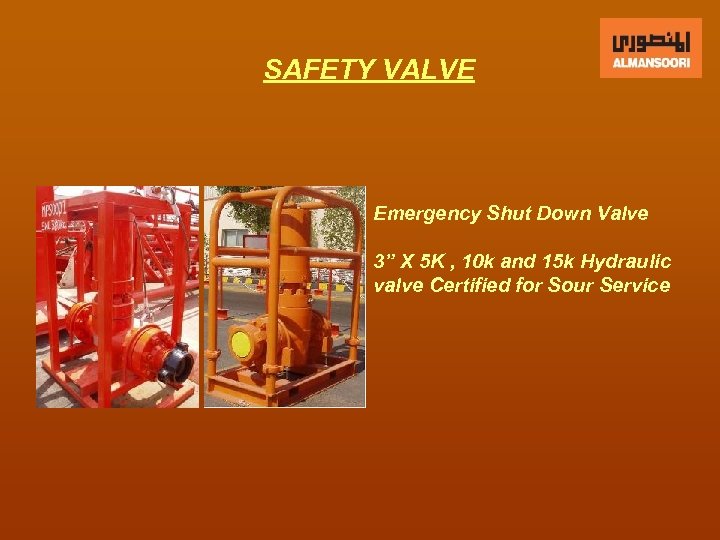

SAFETY VALVE Emergency Shut Down Valve 3” X 5 K , 10 k and 15 k Hydraulic valve Certified for Sour Service

SAFETY VALVE Emergency Shut Down Valve 3” X 5 K , 10 k and 15 k Hydraulic valve Certified for Sour Service

HEATER 2 MM BTU/Hr and 4 MM BTU/Hr. Line Heater Diesel / Gas Fired 3” X 5 K

HEATER 2 MM BTU/Hr and 4 MM BTU/Hr. Line Heater Diesel / Gas Fired 3” X 5 K

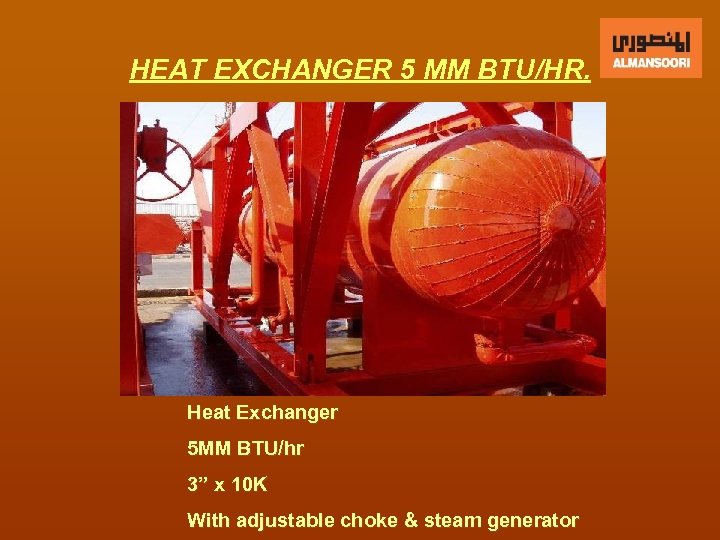

HEAT EXCHANGER 5 MM BTU/HR. Heat Exchanger 5 MM BTU/hr 3” x 10 K With adjustable choke & steam generator

HEAT EXCHANGER 5 MM BTU/HR. Heat Exchanger 5 MM BTU/hr 3” x 10 K With adjustable choke & steam generator

STEAM GENERATOR The CLAYTON Steam Generator is manufactured in conformance with the American Society of Mechanical Engineering (ASME) Power Boiler Code, Section I Manufactured by : CLAYTON INDUSTRIES Model No. E-200 Steam Heat Generator

STEAM GENERATOR The CLAYTON Steam Generator is manufactured in conformance with the American Society of Mechanical Engineering (ASME) Power Boiler Code, Section I Manufactured by : CLAYTON INDUSTRIES Model No. E-200 Steam Heat Generator

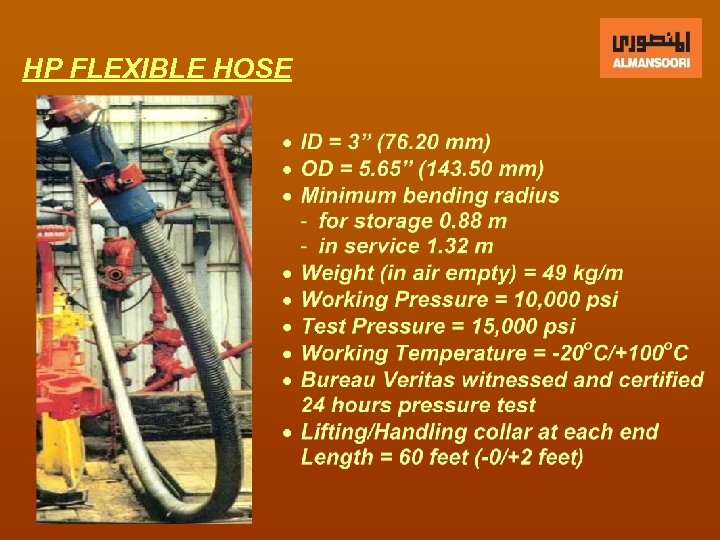

HP FLEXIBLE HOSE

HP FLEXIBLE HOSE

LAB CABIN Skid Mounted Lab Onshore & Offshore Operations Equipped with Necessary Accessories and Instrumentation for Well Testing Services Zone II

LAB CABIN Skid Mounted Lab Onshore & Offshore Operations Equipped with Necessary Accessories and Instrumentation for Well Testing Services Zone II

SCADA SYSTEM Real Time Display Offline Editing and Reporting Facilities Equipped with Pressure, Temperature and Metering Sensors

SCADA SYSTEM Real Time Display Offline Editing and Reporting Facilities Equipped with Pressure, Temperature and Metering Sensors

WIRELESS ELECTRONIC DATA ACQUISITION Features: • Wireless Base Station • Real Time Collection and Reporting Software • Wireless pressure sensors • Wireless Temperature sensors • Wireless Turbine Flow • Packaging, cabling, logging software • Wireless switch closure • Differential Pressure

WIRELESS ELECTRONIC DATA ACQUISITION Features: • Wireless Base Station • Real Time Collection and Reporting Software • Wireless pressure sensors • Wireless Temperature sensors • Wireless Turbine Flow • Packaging, cabling, logging software • Wireless switch closure • Differential Pressure

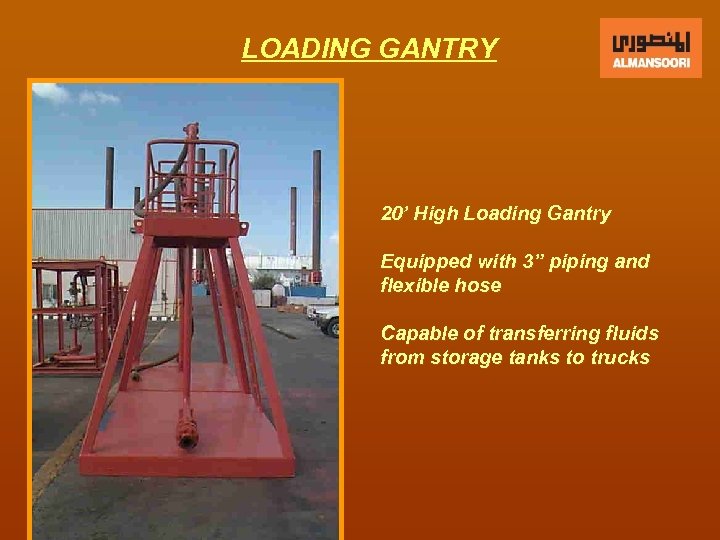

LOADING GANTRY 20’ High Loading Gantry Equipped with 3” piping and flexible hose Capable of transferring fluids from storage tanks to trucks

LOADING GANTRY 20’ High Loading Gantry Equipped with 3” piping and flexible hose Capable of transferring fluids from storage tanks to trucks

CRUDE OIL STORAGE Skid Mounted Tanks 400 BBLS Capacity Equipped with Sight Glasses and Vent Lines

CRUDE OIL STORAGE Skid Mounted Tanks 400 BBLS Capacity Equipped with Sight Glasses and Vent Lines

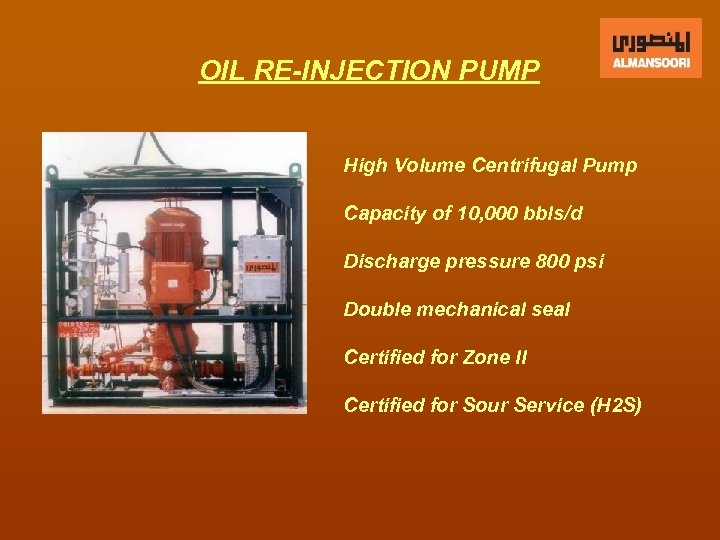

OIL RE-INJECTION PUMP High Volume Centrifugal Pump Capacity of 10, 000 bbls/d Discharge pressure 800 psi Double mechanical seal Certified for Zone II Certified for Sour Service (H 2 S)

OIL RE-INJECTION PUMP High Volume Centrifugal Pump Capacity of 10, 000 bbls/d Discharge pressure 800 psi Double mechanical seal Certified for Zone II Certified for Sour Service (H 2 S)

SURGE TANK 100 bbls capacity 100 psi w. p. Equipped with sight glasses Fluid Accumulation and degassing

SURGE TANK 100 bbls capacity 100 psi w. p. Equipped with sight glasses Fluid Accumulation and degassing

SURGE TANK Skid Mounted 50 bbls Capacity 50 psi W. P. Designed for fluid accumulation and measurement during the testing of low producing wells Useful for Meter Calibration

SURGE TANK Skid Mounted 50 bbls Capacity 50 psi W. P. Designed for fluid accumulation and measurement during the testing of low producing wells Useful for Meter Calibration

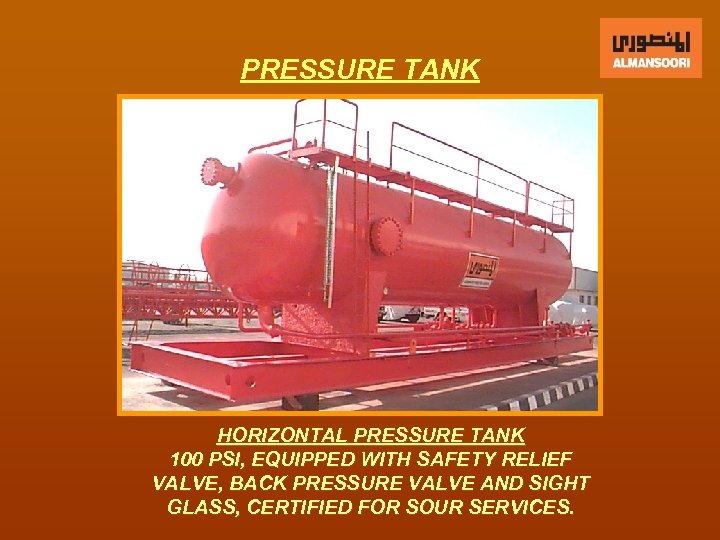

PRESSURE TANK HORIZONTAL PRESSURE TANK 100 PSI, EQUIPPED WITH SAFETY RELIEF VALVE, BACK PRESSURE VALVE AND SIGHT GLASS, CERTIFIED FOR SOUR SERVICES.

PRESSURE TANK HORIZONTAL PRESSURE TANK 100 PSI, EQUIPPED WITH SAFETY RELIEF VALVE, BACK PRESSURE VALVE AND SIGHT GLASS, CERTIFIED FOR SOUR SERVICES.

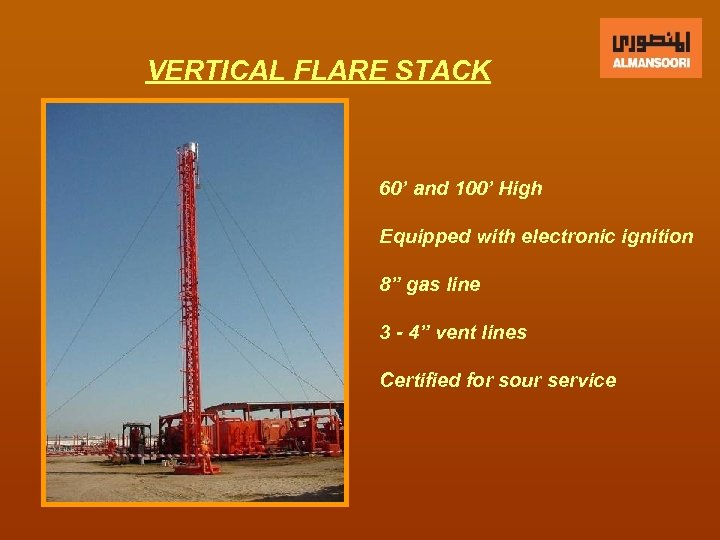

VERTICAL FLARE STACK 60’ and 100’ High Equipped with electronic ignition 8” gas line 3 - 4” vent lines Certified for sour service

VERTICAL FLARE STACK 60’ and 100’ High Equipped with electronic ignition 8” gas line 3 - 4” vent lines Certified for sour service

WATER TREATMENT Skid Mounted System Capacity of 8000 bbls/d This system is located downstream of the water leg of the Test Separator. The water is treated achieving <5 ppm prior to disposal.

WATER TREATMENT Skid Mounted System Capacity of 8000 bbls/d This system is located downstream of the water leg of the Test Separator. The water is treated achieving <5 ppm prior to disposal.

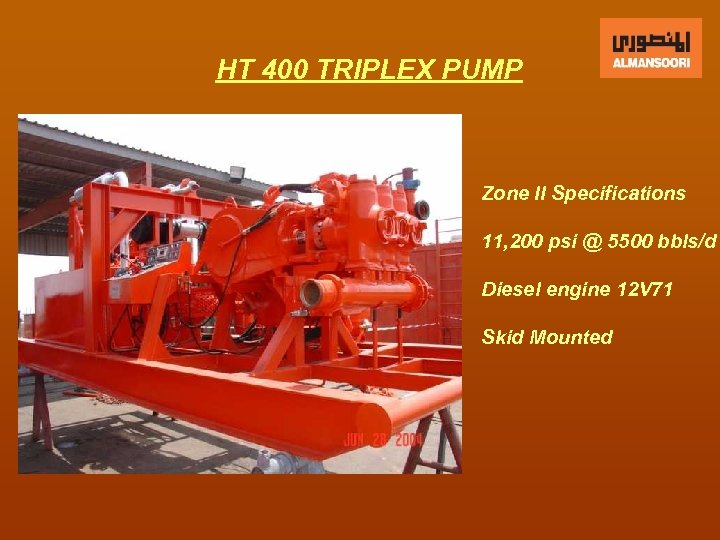

HT 400 TRIPLEX PUMP Zone II Specifications 11, 200 psi @ 5500 bbls/d Diesel engine 12 V 71 Skid Mounted

HT 400 TRIPLEX PUMP Zone II Specifications 11, 200 psi @ 5500 bbls/d Diesel engine 12 V 71 Skid Mounted

MULTI-STAGE PUMP Flow Rate: 10, 000 BBL/D Discharge Pressure 1, 500 psi. Specific Gravity 0. 87 – 0. 94 Max. Area Classification, ZONE I Electrical Power, 415 V, 50 Hz, 3 Phase (Generator)

MULTI-STAGE PUMP Flow Rate: 10, 000 BBL/D Discharge Pressure 1, 500 psi. Specific Gravity 0. 87 – 0. 94 Max. Area Classification, ZONE I Electrical Power, 415 V, 50 Hz, 3 Phase (Generator)

PRESSURE TEST SYSTEM MWP of 20 K psig Rate of 15 Gal/min Power 460 Volt Cycle 60 Hz Current 50 Amps

PRESSURE TEST SYSTEM MWP of 20 K psig Rate of 15 Gal/min Power 460 Volt Cycle 60 Hz Current 50 Amps

Air Compressor and Electrical Power Generator Air Compressor Electrical Power Generator 350, 750 and 900 CFM Zone II Skid Mounted 300 KVA 500 KVA Skid Mounted

Air Compressor and Electrical Power Generator Air Compressor Electrical Power Generator 350, 750 and 900 CFM Zone II Skid Mounted 300 KVA 500 KVA Skid Mounted

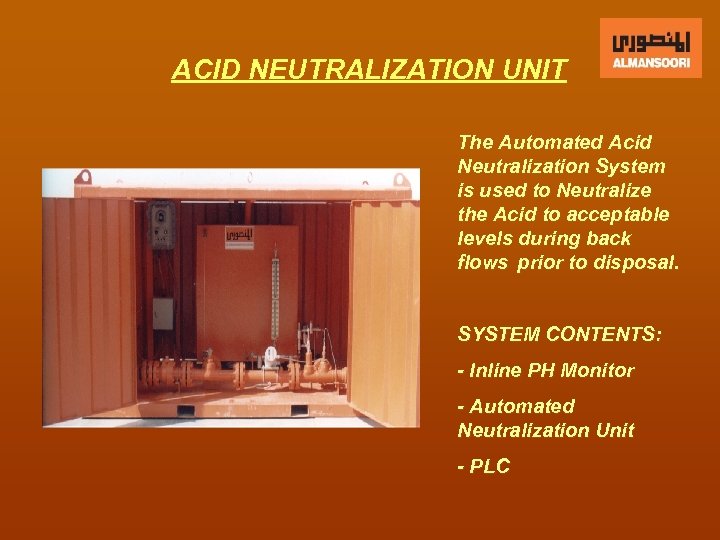

ACID NEUTRALIZATION UNIT The Automated Acid Neutralization System is used to Neutralize the Acid to acceptable levels during back flows prior to disposal. SYSTEM CONTENTS: - Inline PH Monitor - Automated Neutralization Unit - PLC

ACID NEUTRALIZATION UNIT The Automated Acid Neutralization System is used to Neutralize the Acid to acceptable levels during back flows prior to disposal. SYSTEM CONTENTS: - Inline PH Monitor - Automated Neutralization Unit - PLC

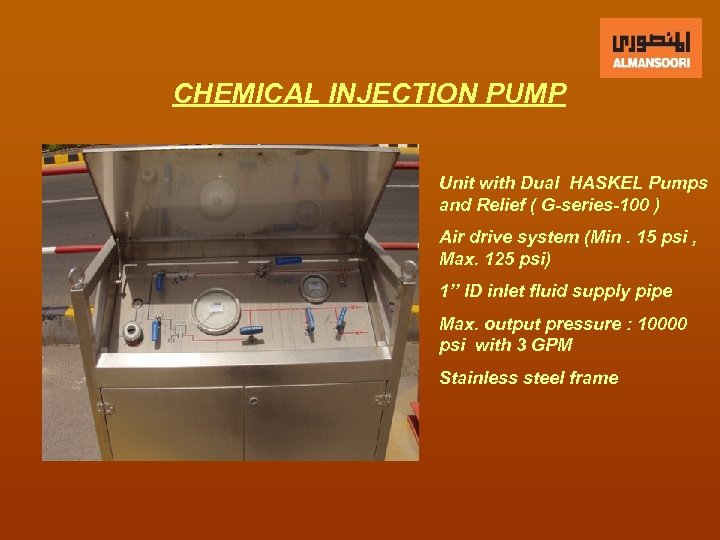

CHEMICAL INJECTION PUMP Unit with Dual HASKEL Pumps and Relief ( G-series-100 ) Air drive system (Min. 15 psi , Max. 125 psi) 1’’ ID inlet fluid supply pipe Max. output pressure : 10000 psi with 3 GPM Stainless steel frame

CHEMICAL INJECTION PUMP Unit with Dual HASKEL Pumps and Relief ( G-series-100 ) Air drive system (Min. 15 psi , Max. 125 psi) 1’’ ID inlet fluid supply pipe Max. output pressure : 10000 psi with 3 GPM Stainless steel frame

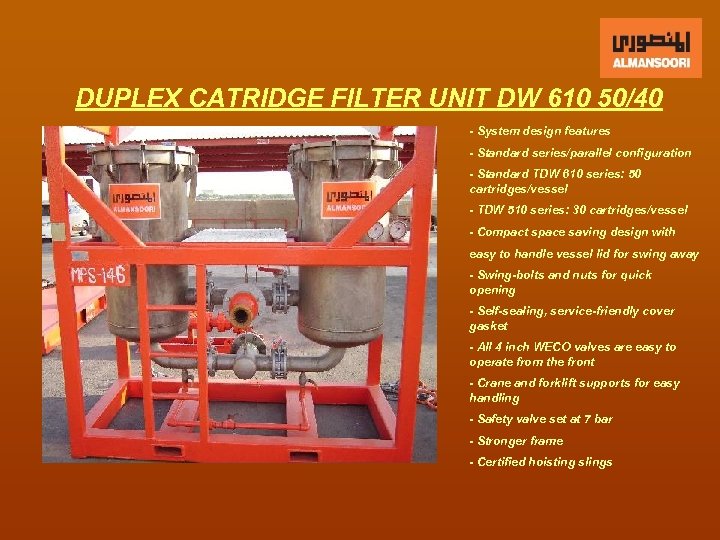

DUPLEX CATRIDGE FILTER UNIT DW 610 50/40 - System design features - Standard series/parallel configuration - Standard TDW 610 series: 50 cartridges/vessel - TDW 510 series: 30 cartridges/vessel - Compact space saving design with easy to handle vessel lid for swing away - Swing-bolts and nuts for quick opening - Self-sealing, service-friendly cover gasket - All 4 inch WECO valves are easy to operate from the front - Crane and forklift supports for easy handling - Safety valve set at 7 bar - Stronger frame - Certified hoisting slings

DUPLEX CATRIDGE FILTER UNIT DW 610 50/40 - System design features - Standard series/parallel configuration - Standard TDW 610 series: 50 cartridges/vessel - TDW 510 series: 30 cartridges/vessel - Compact space saving design with easy to handle vessel lid for swing away - Swing-bolts and nuts for quick opening - Self-sealing, service-friendly cover gasket - All 4 inch WECO valves are easy to operate from the front - Crane and forklift supports for easy handling - Safety valve set at 7 bar - Stronger frame - Certified hoisting slings

HYDROCYCLONE & ACCUMULATOR PACKAGE Design Pressure 15000 psi Design Temperature 50 to 250 F Flow Rate 5000 bbls/d @ 30 MMSCF/D 500 bbls/d @60 MMSCF/D Filter 25 microns

HYDROCYCLONE & ACCUMULATOR PACKAGE Design Pressure 15000 psi Design Temperature 50 to 250 F Flow Rate 5000 bbls/d @ 30 MMSCF/D 500 bbls/d @60 MMSCF/D Filter 25 microns

Skid Strainer Package (15 K) Design Pressure : 15, 000 psi ( @ 350 F) Design Temperature : 50 – 350 F - The Y-Type strainer is used to remove solids from the process stream and is normally connected downstream of the hydrocyclone

Skid Strainer Package (15 K) Design Pressure : 15, 000 psi ( @ 350 F) Design Temperature : 50 – 350 F - The Y-Type strainer is used to remove solids from the process stream and is normally connected downstream of the hydrocyclone

SAND MONITORING SYSTEM High sensitivity. Two serial interfaces based on modbus protocol over RS 485. Modbus on two separate buses. 4 -20 m. A input and output. All data processed internally. All data stored in flash memory. Local status display (LED). Small and compact. No need for a computer in daily use.

SAND MONITORING SYSTEM High sensitivity. Two serial interfaces based on modbus protocol over RS 485. Modbus on two separate buses. 4 -20 m. A input and output. All data processed internally. All data stored in flash memory. Local status display (LED). Small and compact. No need for a computer in daily use.

SURFACE TEST TREE 10 k and 15 k Surface Test Tree Complete with the following; Master Valve Kill Valve Crown Valve Wing Valve: hydraulic operated Swivel assembly Certified for sour service Connections Existing 5”- 4 Stub ACME - 2 G Box on top of Flow Head Stiff Joint top 4 -1/2” EUE Pin (available) Crossover 4 -1/2” CS Hydril Pin top (available) Crossover 3 -1/2” PH-6 Hydril Pin top (available)

SURFACE TEST TREE 10 k and 15 k Surface Test Tree Complete with the following; Master Valve Kill Valve Crown Valve Wing Valve: hydraulic operated Swivel assembly Certified for sour service Connections Existing 5”- 4 Stub ACME - 2 G Box on top of Flow Head Stiff Joint top 4 -1/2” EUE Pin (available) Crossover 4 -1/2” CS Hydril Pin top (available) Crossover 3 -1/2” PH-6 Hydril Pin top (available)

TRANSFER PUMP Power 460 V & 60 Hz NACE MR- 01 -75 Maximum Flow Rate 5, 000 BPD and 10, 000 BPD 50 PSI Discharge Pressure 60 HP Explosion proof motor and starter switch Skid mounted This pump is used to transfer oil/diesel

TRANSFER PUMP Power 460 V & 60 Hz NACE MR- 01 -75 Maximum Flow Rate 5, 000 BPD and 10, 000 BPD 50 PSI Discharge Pressure 60 HP Explosion proof motor and starter switch Skid mounted This pump is used to transfer oil/diesel

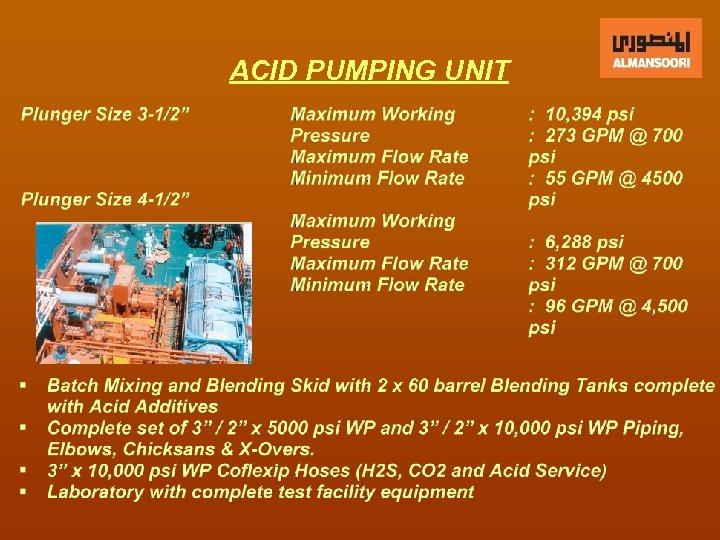

ACID PUMPING UNIT

ACID PUMPING UNIT

Mobile Well Testing Package 40 FT Mobile Well Testing Package : ESD Valve ESD Panel Choke Manifold Indirect Heater (1 MM-BTU) 3 -Phase Separator ( 750 Psi) Surge Tank (50 Psi , 50 bbls) Transfer Pump (5000 BOPD) Re-Injection Pump (5000 BOPD)

Mobile Well Testing Package 40 FT Mobile Well Testing Package : ESD Valve ESD Panel Choke Manifold Indirect Heater (1 MM-BTU) 3 -Phase Separator ( 750 Psi) Surge Tank (50 Psi , 50 bbls) Transfer Pump (5000 BOPD) Re-Injection Pump (5000 BOPD)

Engineering Support 1 - Process Simulation ( HYSYS or Internal Software ). 2 - PFD’s , P&ID’s and Layout. 3 - Process basis of Design (Composition , Criteria and Design Aspects). 4 - Process Calculation (Equipment Sizing, Line Sizing , Relief Valve Sizing, . . . ) 5 - Operating and Shutdown Philosophy. 6 - Dispersion and Heat Radiation Studies. 7 -Cause and Effect Diagrams. 8 - HAZOP , HAZID and Risk Assessments.

Engineering Support 1 - Process Simulation ( HYSYS or Internal Software ). 2 - PFD’s , P&ID’s and Layout. 3 - Process basis of Design (Composition , Criteria and Design Aspects). 4 - Process Calculation (Equipment Sizing, Line Sizing , Relief Valve Sizing, . . . ) 5 - Operating and Shutdown Philosophy. 6 - Dispersion and Heat Radiation Studies. 7 -Cause and Effect Diagrams. 8 - HAZOP , HAZID and Risk Assessments.

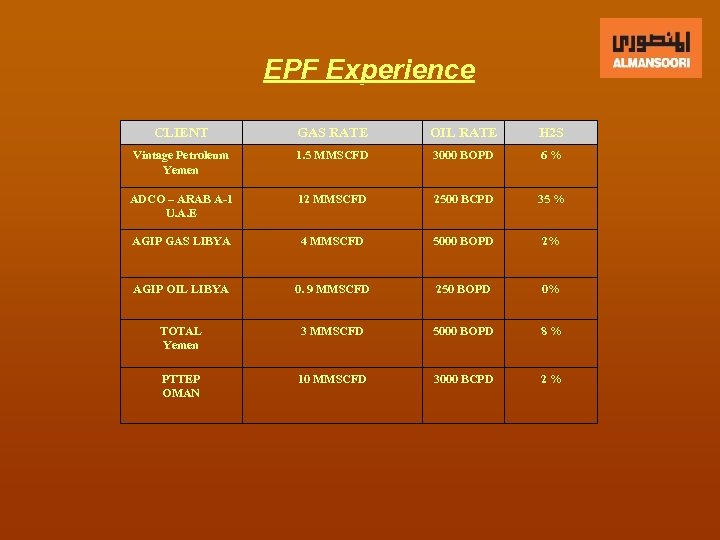

EPF Experience CLIENT GAS RATE OIL RATE H 2 S Vintage Petroleum Yemen 1. 5 MMSCFD 3000 BOPD 6% ADCO – ARAB A-1 U. A. E 12 MMSCFD 2500 BCPD 35 % AGIP GAS LIBYA 4 MMSCFD 5000 BOPD 2% AGIP OIL LIBYA 0. 9 MMSCFD 250 BOPD 0% TOTAL Yemen 3 MMSCFD 5000 BOPD 8% PTTEP OMAN 10 MMSCFD 3000 BCPD 2%

EPF Experience CLIENT GAS RATE OIL RATE H 2 S Vintage Petroleum Yemen 1. 5 MMSCFD 3000 BOPD 6% ADCO – ARAB A-1 U. A. E 12 MMSCFD 2500 BCPD 35 % AGIP GAS LIBYA 4 MMSCFD 5000 BOPD 2% AGIP OIL LIBYA 0. 9 MMSCFD 250 BOPD 0% TOTAL Yemen 3 MMSCFD 5000 BOPD 8% PTTEP OMAN 10 MMSCFD 3000 BCPD 2%

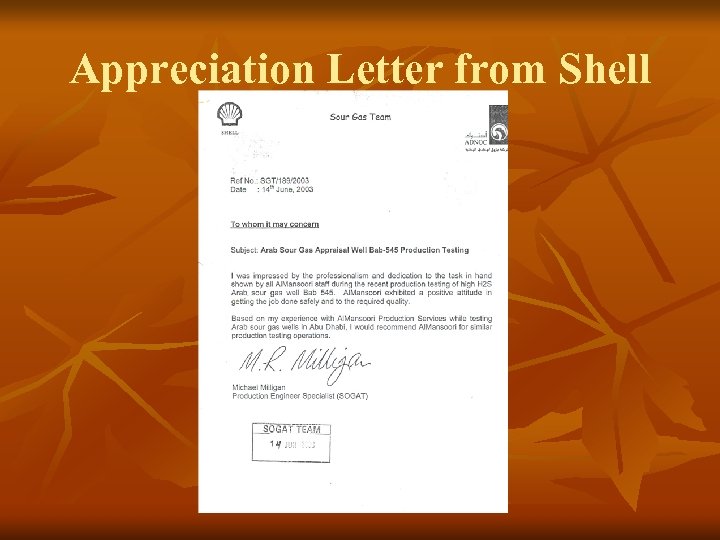

Appreciation Letter from Shell

Appreciation Letter from Shell

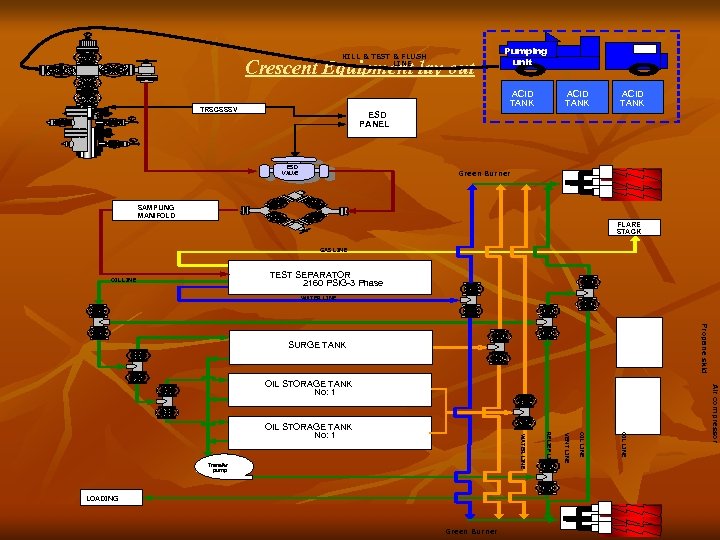

KILL & TEST & FLUSH LINE Crescent Equipment lay out Pumping unit ACID TANK TRSCSSSV ACID TANK ESD PANEL ESD VALVE Green Burner SAMPLING MANIFOLD FLARE STACK GAS LINE TEST SEPARATOR 2160 PSIG-3 Phase OIL LINE WATER LINE Propane skid SURGE TANK OIL LINE Green Burner OIL LINE LOADING VENT LINE Transfer pump RELIEF LINE WATER LINE OIL STORAGE TANK No: 1 Air compressor OIL STORAGE TANK No: 1

KILL & TEST & FLUSH LINE Crescent Equipment lay out Pumping unit ACID TANK TRSCSSSV ACID TANK ESD PANEL ESD VALVE Green Burner SAMPLING MANIFOLD FLARE STACK GAS LINE TEST SEPARATOR 2160 PSIG-3 Phase OIL LINE WATER LINE Propane skid SURGE TANK OIL LINE Green Burner OIL LINE LOADING VENT LINE Transfer pump RELIEF LINE WATER LINE OIL STORAGE TANK No: 1 Air compressor OIL STORAGE TANK No: 1

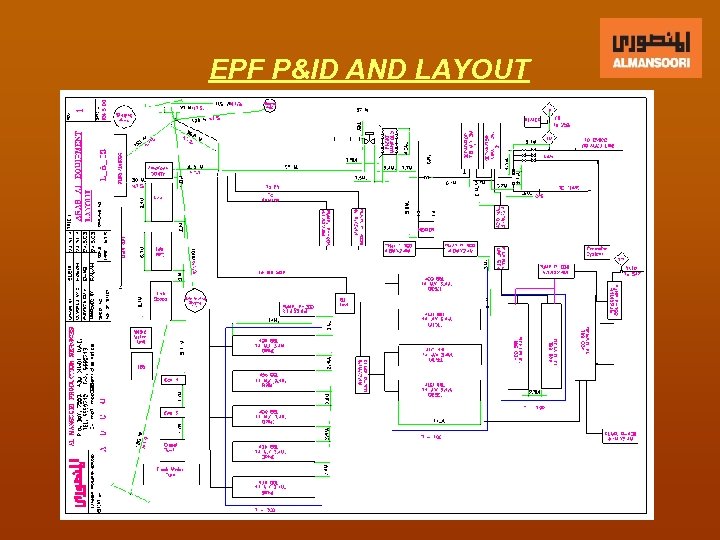

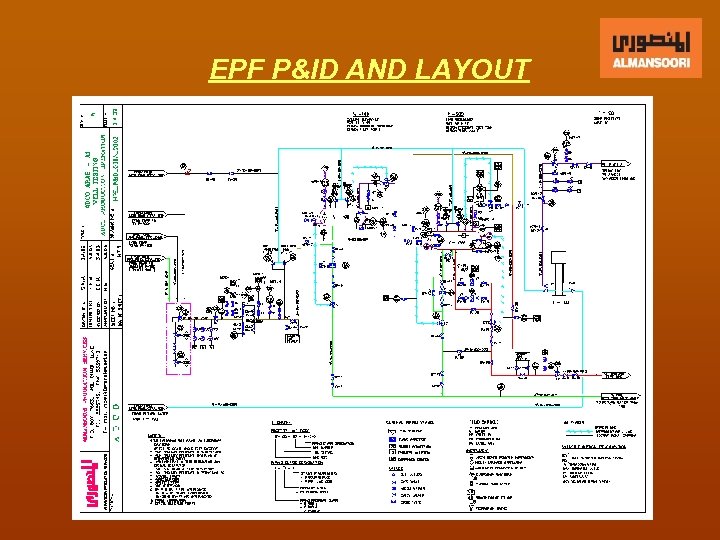

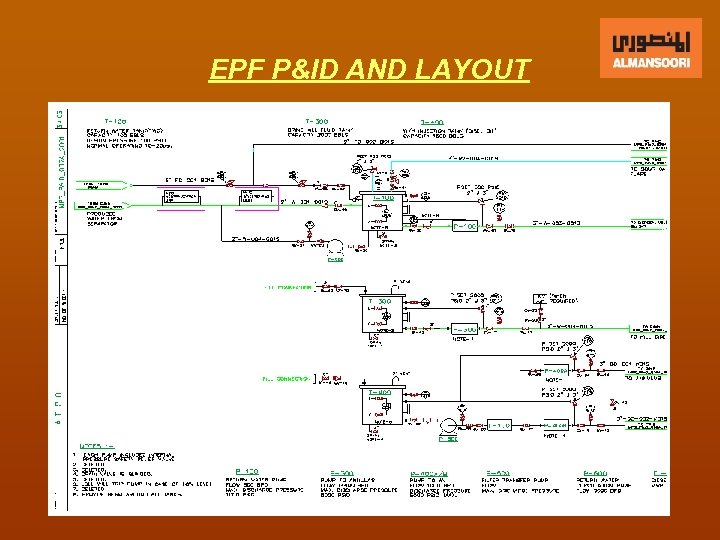

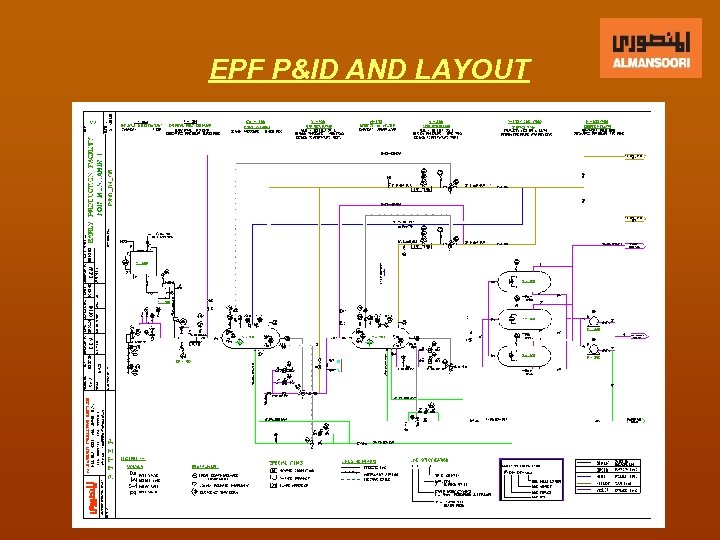

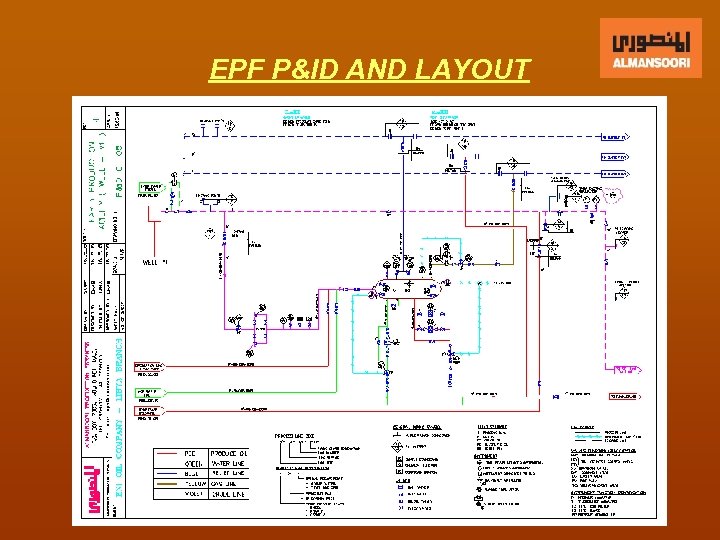

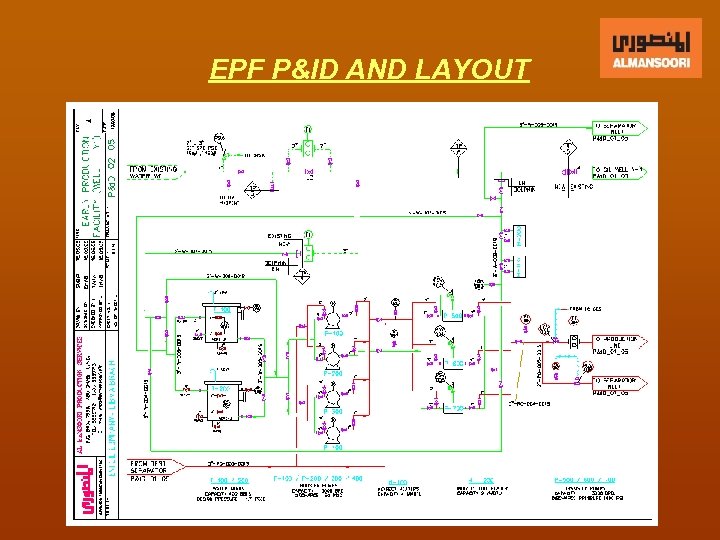

EPF P&ID AND LAYOUT

EPF P&ID AND LAYOUT

EPF P&ID AND LAYOUT

EPF P&ID AND LAYOUT

EPF P&ID AND LAYOUT

EPF P&ID AND LAYOUT

EPF P&ID AND LAYOUT

EPF P&ID AND LAYOUT

EPF P&ID AND LAYOUT

EPF P&ID AND LAYOUT

EPF P&ID AND LAYOUT

EPF P&ID AND LAYOUT

OFFSHORE AND ONSHORE DST SERVICES PROVIDED h. CASED HOLE h. FULLBORE DRILLSTEM TESTING h. SLIM HOLE DRILLSTEM TESTING h. CONVENTIONAL ( MECHANICAL ) DRILLSTEM TESTING h. OPEN HOLE CONVENTIONAL ( MECHANICAL ) DST

OFFSHORE AND ONSHORE DST SERVICES PROVIDED h. CASED HOLE h. FULLBORE DRILLSTEM TESTING h. SLIM HOLE DRILLSTEM TESTING h. CONVENTIONAL ( MECHANICAL ) DRILLSTEM TESTING h. OPEN HOLE CONVENTIONAL ( MECHANICAL ) DST

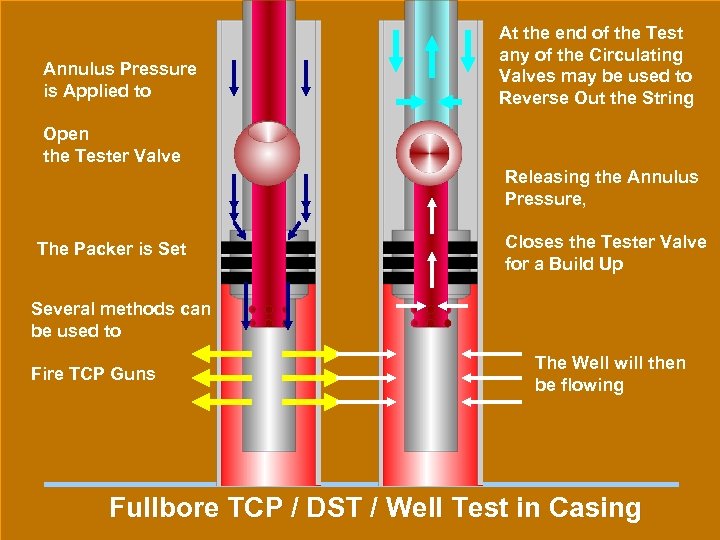

Annulus Pressure is Applied to At the end of the Test any of the Circulating Valves may be used to Reverse Out the String Open the Tester Valve Releasing the Annulus Pressure, The Packer is Set Closes the Tester Valve for a Build Up Several methods can be used to Fire TCP Guns The Well will then be flowing Fullbore TCP / DST / Well Test in Casing

Annulus Pressure is Applied to At the end of the Test any of the Circulating Valves may be used to Reverse Out the String Open the Tester Valve Releasing the Annulus Pressure, The Packer is Set Closes the Tester Valve for a Build Up Several methods can be used to Fire TCP Guns The Well will then be flowing Fullbore TCP / DST / Well Test in Casing

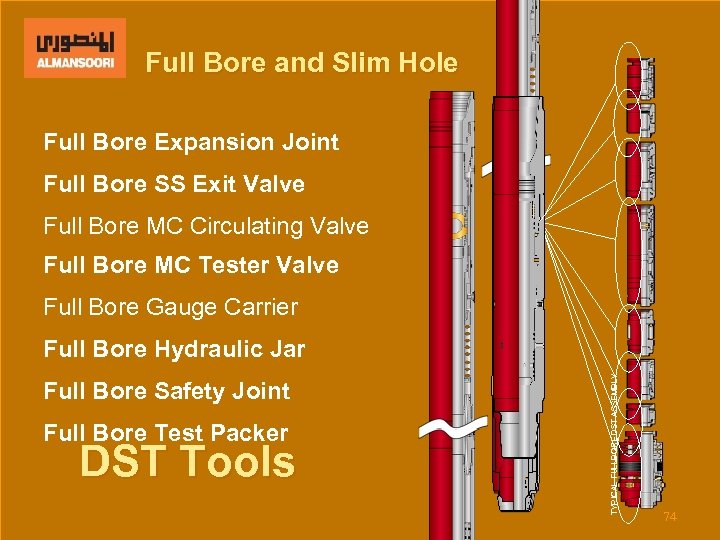

Full Bore and Slim Hole Full Bore Expansion Joint Full Bore SS Exit Valve Full Bore MC Circulating Valve Full Bore MC Tester Valve Full Bore Gauge Carrier Full Bore Safety Joint Full Bore Test Packer DST Tools TYPICAL FULLBORE DST ASSEMBLY Full Bore Hydraulic Jar 74

Full Bore and Slim Hole Full Bore Expansion Joint Full Bore SS Exit Valve Full Bore MC Circulating Valve Full Bore MC Tester Valve Full Bore Gauge Carrier Full Bore Safety Joint Full Bore Test Packer DST Tools TYPICAL FULLBORE DST ASSEMBLY Full Bore Hydraulic Jar 74

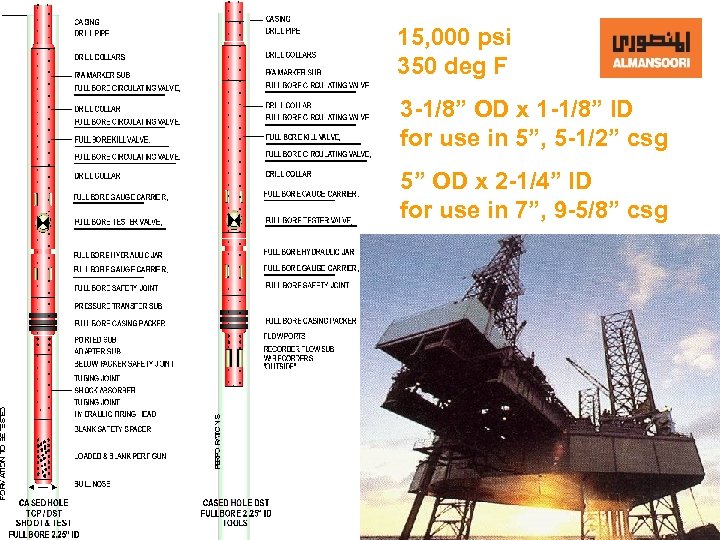

15, 000 psi 350 deg F 3 -1/8” OD x 1 -1/8” ID for use in 5”, 5 -1/2” csg 5” OD x 2 -1/4” ID for use in 7”, 9 -5/8” csg

15, 000 psi 350 deg F 3 -1/8” OD x 1 -1/8” ID for use in 5”, 5 -1/2” csg 5” OD x 2 -1/4” ID for use in 7”, 9 -5/8” csg

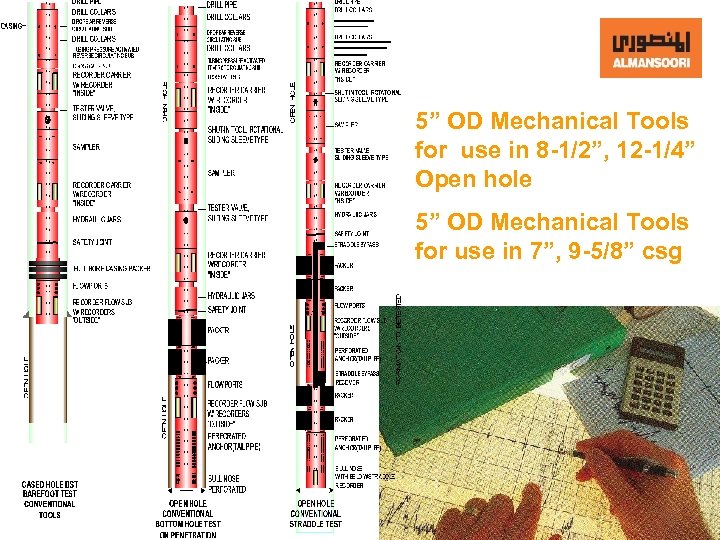

5” OD Mechanical Tools for use in 8 -1/2”, 12 -1/4” Open hole 5” OD Mechanical Tools for use in 7”, 9 -5/8” csg

5” OD Mechanical Tools for use in 8 -1/2”, 12 -1/4” Open hole 5” OD Mechanical Tools for use in 7”, 9 -5/8” csg

DST Tools, Spare Parts Accessories and Equipment

DST Tools, Spare Parts Accessories and Equipment

COREX - Al. Mansoori

COREX - Al. Mansoori

THANK YOU FOR YOUR TIME

THANK YOU FOR YOUR TIME