268c288e6427f40f9c6ce60db116c40c.ppt

- Количество слайдов: 20

ALLARDS INTERNATIONAL Highly Reliable Services for Heat Transfer Technologies www. allards-int. com

l Engineering design, project management and sales office ALLARDS INTERNATIONAL in Falun, Sweden and Dundee, Scotland l Manufacturing partner facilities in Sweden and Scotland l International Profile Companyclients from UK, Scandinavia, Europe and USA. l First Point Assessment supplier 10044334 l Achilles JQS supplier 25227

ALLARDS INTERNATIONAL Capabilities l Heat Transfer Solutions – – – l Equipment Supply – – l Heat Exchangers and Process Vessels Complete Skid Packages Sales and Engineering Capability – – l Thermal Design Feasibility Studies Troubleshooting, de-bottlenecking service Electronic bidding, budget pricing Strength calculations using in-house and commercial software Drawings and layouts in 2 D & 3 D Document control & Progress reporting Development of Technology – Welded Plate Heat Exchanger

ALLARDS INTERNATIONAL Engineering Standards l Design and manufacture to all relevant standards including: – – – PED 97/23/EC EN-13445 PD 5500 ASME VIII and IX TEMA Norsok – – – AD Merkblätter Stoomwezen TÜV DNV CODAP Scandinavian codes

ALLARDS INTERNATIONAL Equipment Manufacture & Supply l Wide metallurgical experience including carbon steel, stainless steel, duplex, titanium and nickel alloys l Heat Exchangers – – – l Shell and tube Profiled tube Double pipe Welded plate Plate and frame l Process Vessels – – – Separator vessels VOC vessels Scrubber units Cyclones Tanks Heat Transfer Systems combining heat exchangers, process vessels with necessary ancillary equipment.

ALLARDS INTERNATIONAL Client Base

ALLARDS INTERNATIONAL Recent Client List l Aker. Kvaerner l Naturgass Vest l AMEC l Nexfor Ltd l Borealis AB l Norsk Hydro l BP Exploration l PGS Atlantic Power l Halliburton l Phillips Petroleum l Hitec Marine l Shell l Kanfa AS/Sevan Marine AS l Statoil l Kvaerner Process Systems l Talisman Energy l Mustang Engineering l Wood Group Engineering

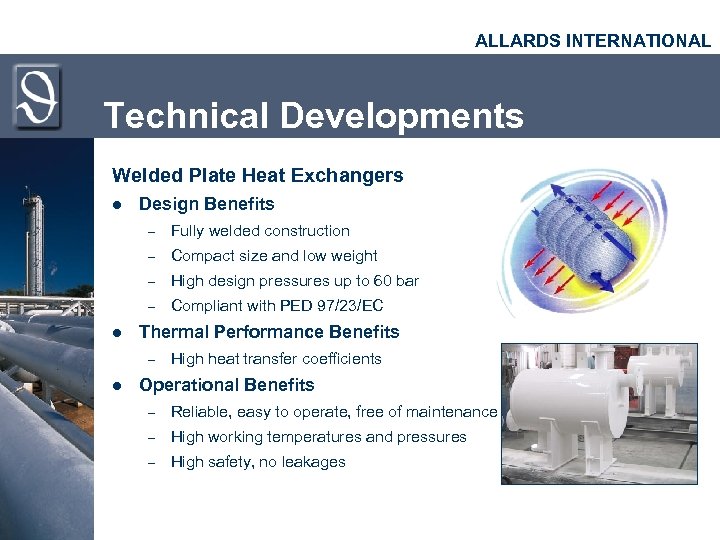

ALLARDS INTERNATIONAL Technical Developments Welded Plate Heat Exchangers l Design Benefits – – Compact size and low weight – High design pressures up to 60 bar – l Fully welded construction Compliant with PED 97/23/EC Thermal Performance Benefits – l High heat transfer coefficients Operational Benefits – Reliable, easy to operate, free of maintenance – High working temperatures and pressures – High safety, no leakages

ALLARDS INTERNATIONAL Manufacturing Facilities l Manufacturing Partners Quality Assurance & Certification include: – – – ISO 9001 ISO 14001 Directive on health & safety Swedish Nuclear Power Industry Approval CE-marking to PED 97/23/EC

ALLARDS INTERNATIONAL Projects l l l BP Clair Phase 1 Contractor: Wood Group / Mustang Engineering Design, engineering, manufacture and supply 12 off shell and tube heat exchangers (Duplex steel tubes) Contract >€ 1, 000

ALLARDS INTERNATIONAL Projects l l l Red Band - Knock Taggart FPSO Nigeria Contractor: Kanfa / Fred Olsen Production Supply: 3 off Shell and tube heat exchangers and separator and coalescer process vessels

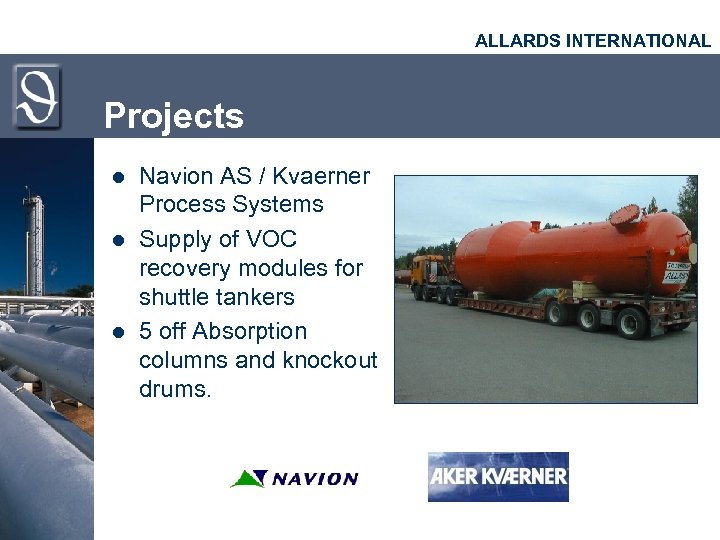

ALLARDS INTERNATIONAL Projects l l l Navion AS / Kvaerner Process Systems Supply of VOC recovery modules for shuttle tankers 5 off Absorption columns and knockout drums.

ALLARDS INTERNATIONAL Projects l l l Norsk Hydro Heimdal Contractor: Halliburton Supply: 2 off Floating head shell and tube heat exchangers

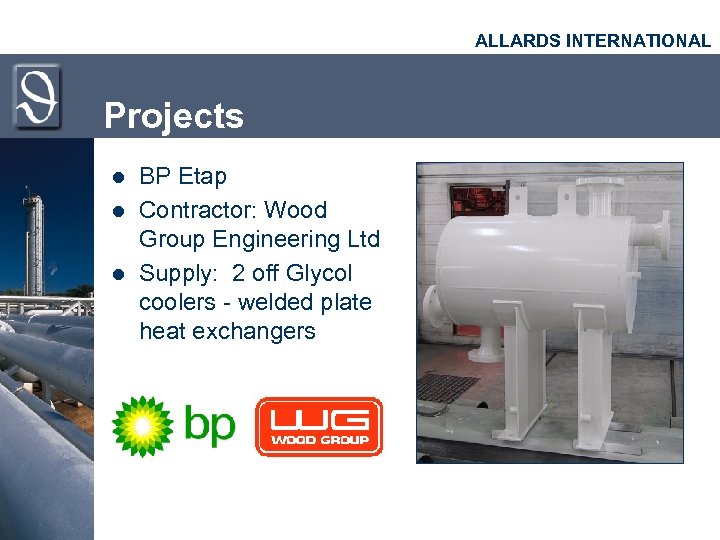

ALLARDS INTERNATIONAL Projects l l l BP Etap Contractor: Wood Group Engineering Ltd Supply: 2 off Glycol coolers - welded plate heat exchangers

ALLARDS INTERNATIONAL Projects l l l Statoil Statfjord C Contractor: Aker Kvaerner Supply: Nitrogen Scrubber units

ALLARDS INTERNATIONAL Projects l l l Phillips Petroleum / Ekofisk Alliance Contractor: Kvaerner Supply: Process vessel

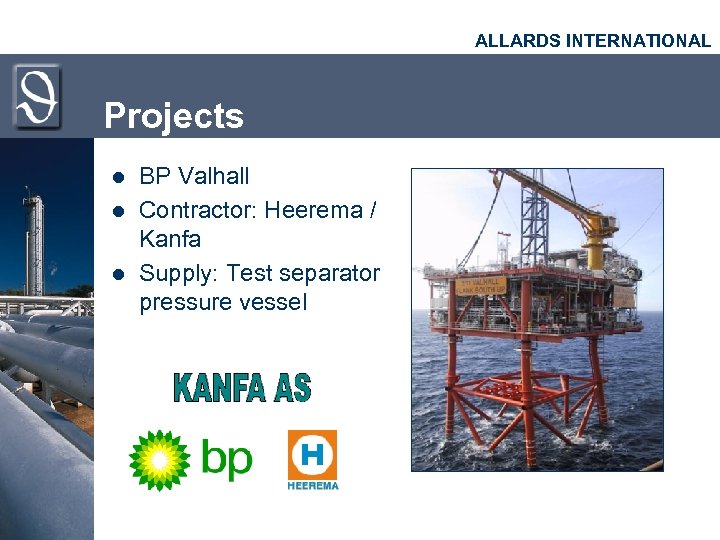

ALLARDS INTERNATIONAL Projects l l l BP Valhall Contractor: Heerema / Kanfa Supply: Test separator pressure vessel

ALLARDS INTERNATIONAL Company Summary l Experienced multi-disciplined engineering team l Heat Transfer Engineering Solutions – High Quality Heat Exchangers – Process Vessels l Developing new technology applications l Based in Sweden & Scotland working in an international market l Flexible & responsive to market needs

ALLARDS INTERNATIONAL Allards International AB Sundbornsvägen 60 SE-791 47 Falun Sweden Tel: +46 (0)23 788 880 Fax: +46 (0)23 788 889 Allards International Ltd XM Services Building Baldovie Road Dundee, DD 4 8 UQ Scotland Tel: +44 (0)1382 770720 Fax: +44 (0)1382 770599 Email: email@allards-int. com Web: www. allards-int. com

SPECIALIZED IN PRESSURE RETAINING EQUIPMENT ü ü ü Inspection & Expediting Design Review Design and Engineering of Heat Exch. & Pressure Vessels Project Management Supplier Evaluation & Audits Quality Assurance www. spocon. se FALUN SWEDEN

268c288e6427f40f9c6ce60db116c40c.ppt