7423562adb51765ab73e95568257da62.ppt

- Количество слайдов: 27

Air-Pro. TM Compressed Air Piping Systems by Asahi/America

Air-Pro Material MATERIAL Eltex TUB 124 High Density Polyethylene Blue Color Code (1/2 -4”) Black Color (6 -12”) Blue coded may be available upon request

System Data TEMP LIMITS: n Up to 140 F PRESSURE RANGE: n n 230 psi at 70 F 20 - 110 mm(1/2 - 4”) Socket Fusion 150 psi at 70 f 160 - 315 mm (6 - 12”) Butt & all Electro-Fusion JOINING METHOD: n n n Socket Fusion (1/2 - 4”) Electro-Fusion (1/2 - 12”) Butt Fusion (6 - 12”) w Puts an end to leaky threads w Sets in minutes, no waiting for cure times

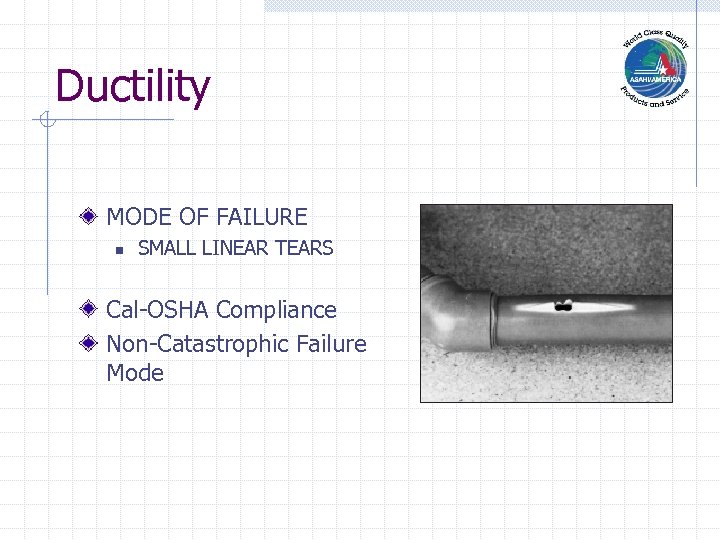

Ductility California-OSHA n Pressure Testing: w Quick Burst Pressure Test w 1000 Hour Pressure Test n Impact Testing w Sharp, Object Strike -Pressurized w Blunt, Object Strike -Pressurized w Object Strike -0 F -Pressurized

Ductility MODE OF FAILURE n SMALL LINEAR TEARS Cal-OSHA Compliance Non-Catastrophic Failure Mode

Chemical Resistance to Mineral and Synthetic Compressor Oil Resistance to wide range of Chemical and Vapors No solvent joining cements to worry about!

Pressure Drop FRICTION FACTOR n NEW: w AIR-PRO w IRON n AGED: w AIR-PRO w IRON n C = 150 C = 100 TO 110 C = 150 C = Decreased Decrease is due to Internal Corrosion, Pitting and scaling

Pressure Drop Comparison Metal Air - Pro L= 200 m p= 12 bar V= 40 l/s result: pipe dimension: ID= 53, 0 mm OD= 60, 3 mm L= 200 m p= 12 bar V= 40 l/s result: pipe dimension: ID= 53, 0 (54) mm OD= 72, 6 (75) mm pressure drop: Dp= 0. 335 psi pressure drop: Dp= 0. 210 psi ðDifference of pressure drop ~26%

Stress Curve The calculated service life of pipe is based on the results of the creep rupture tests under internal compression carried out by the material manufacturers as per DIN 8075, and on longterm tests of the ageing stability in temperature controlled oxygen fresh water. MRS 10: minimum required strength for an operating time of 50 years and a temperature of 20°C = 10 N/mm 2 Design life of 50 years

Pressure vs. Temperature Values based on 20 mm-110 mm Socket Fusion Material

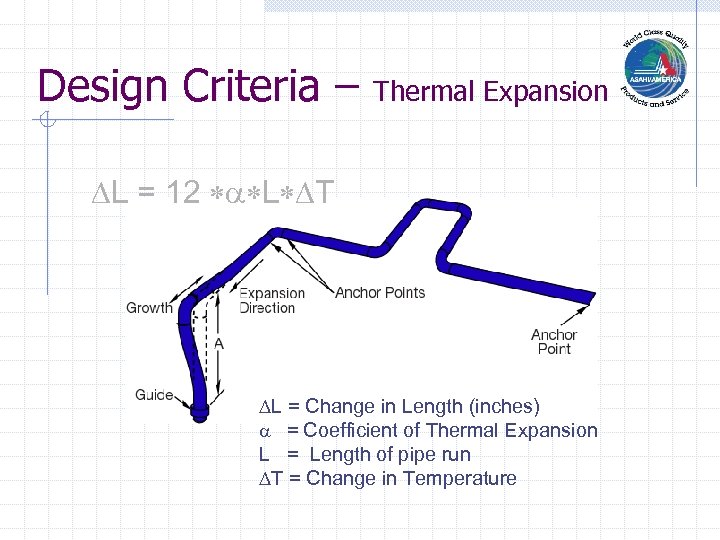

Design Criteria – Thermal Expansion L = 12 L T L = Change in Length (inches) = Coefficient of Thermal Expansion L = Length of pipe run T = Change in Temperature

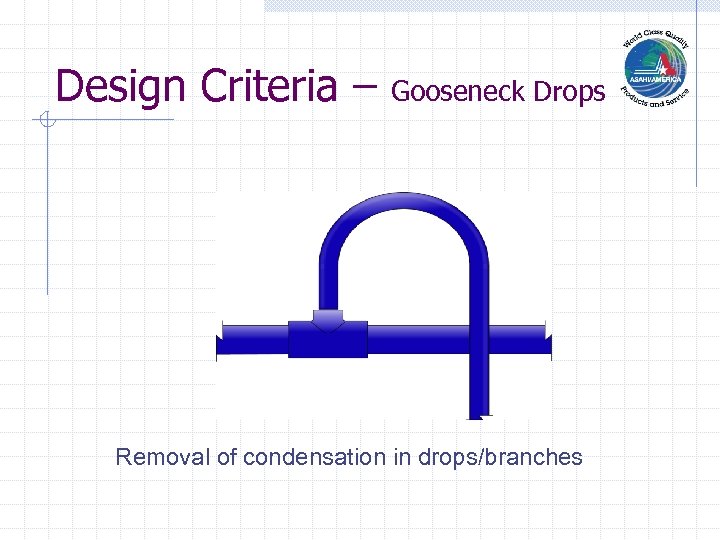

Design Criteria – Gooseneck Drops Removal of condensation in drops/branches

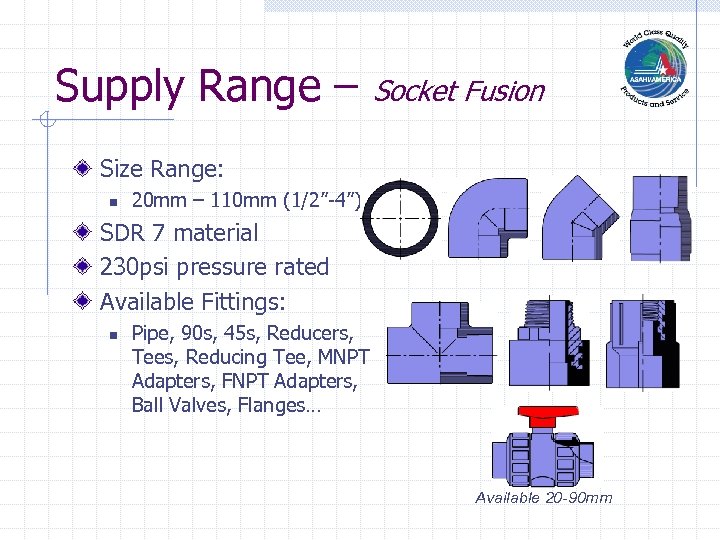

Supply Range – Socket Fusion Size Range: n 20 mm – 110 mm (1/2”-4”) SDR 7 material 230 psi pressure rated Available Fittings: n Pipe, 90 s, 45 s, Reducers, Tees, Reducing Tee, MNPT Adapters, FNPT Adapters, Ball Valves, Flanges… Available 20 -90 mm

Supply Range – Size Range: n 160 mm – 315 mm (6”-12”) SDR 11 material 150 psi pressure rated Available Fittings: n Pipe, 90 s, 45 s, Reducers, Tees, Reducing Tee, & Flanges… Butt Fusion

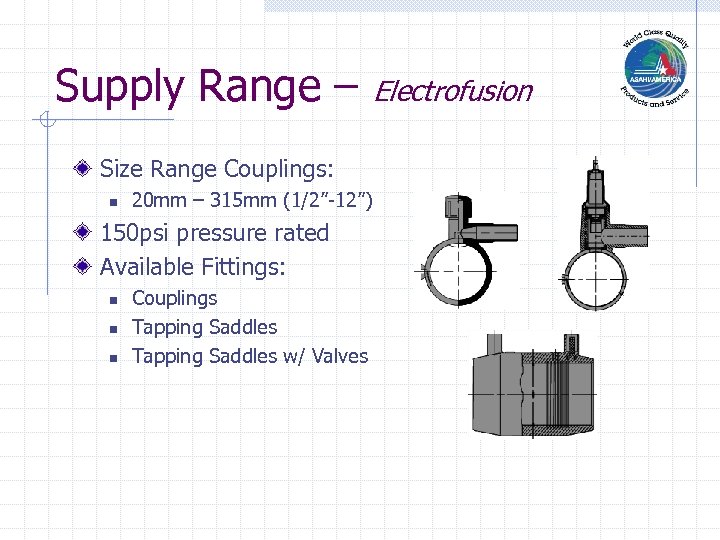

Supply Range – Electrofusion Size Range Couplings: n 20 mm – 315 mm (1/2”-12”) 150 psi pressure rated Available Fittings: n n n Couplings Tapping Saddles w/ Valves

Type 078 Tapping Saddle Low Branch Height PE-Sealing Cap Stainless Steel Tapping Screw EPDM O-Ring Cap Seal

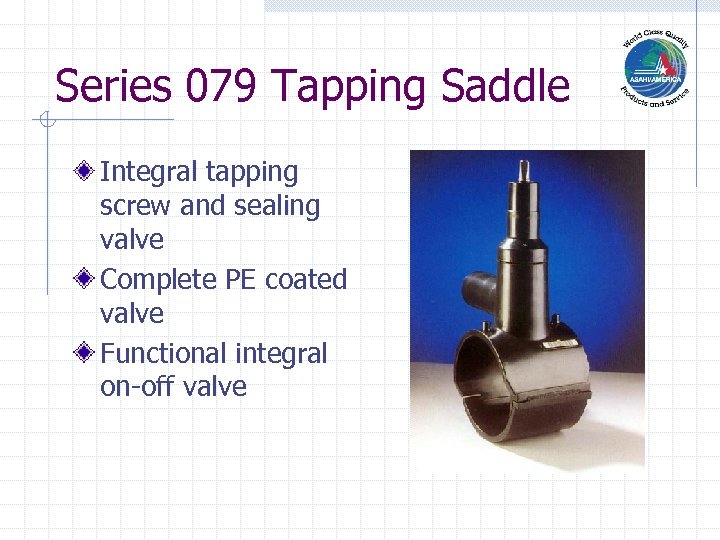

Series 079 Tapping Saddle Integral tapping screw and sealing valve Complete PE coated valve Functional integral on-off valve

Series 079 Tapping Saddle Sealing Ring Valve Sealing Surface Embedded Brass Insert Tapping Screw Completely Coated PE Valve End Stop Valve Seat

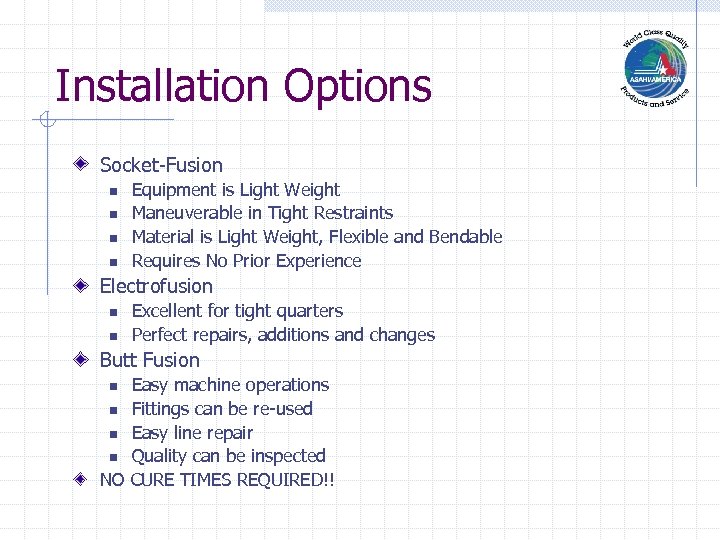

Installation Options Socket-Fusion n n Equipment is Light Weight Maneuverable in Tight Restraints Material is Light Weight, Flexible and Bendable Requires No Prior Experience Electrofusion n n Excellent for tight quarters Perfect repairs, additions and changes Butt Fusion Easy machine operations n Fittings can be re-used n Easy line repair n Quality can be inspected NO CURE TIMES REQUIRED!! n

Socket Fusion

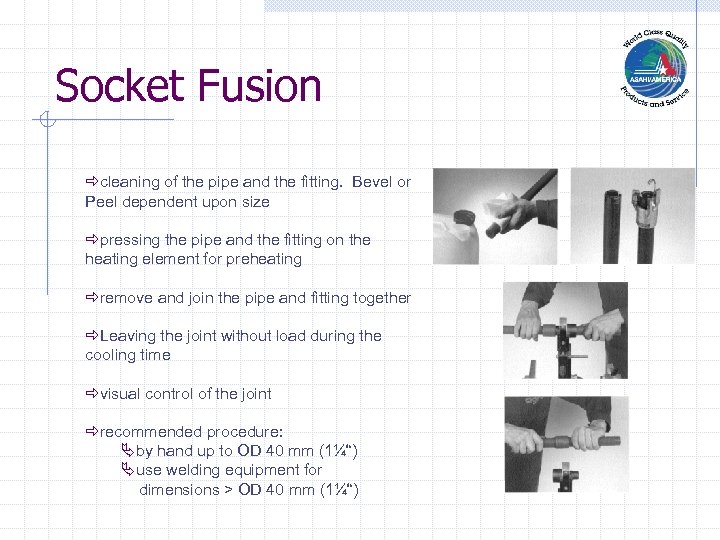

Socket Fusion ðcleaning of the pipe and the fitting. Bevel or Peel dependent upon size ðpressing the pipe and the fitting on the heating element for preheating ðremove and join the pipe and fitting together ðLeaving the joint without load during the cooling time ðvisual control of the joint ðrecommended procedure: Äby hand up to OD 40 mm (1¼“) Äuse welding equipment for dimensions > OD 40 mm (1¼“)

Electrofusion Mark Depth Peal Surface Secure and Connect Leads Scan Bar Code Clean Weld Area Insert and Align Start Weld

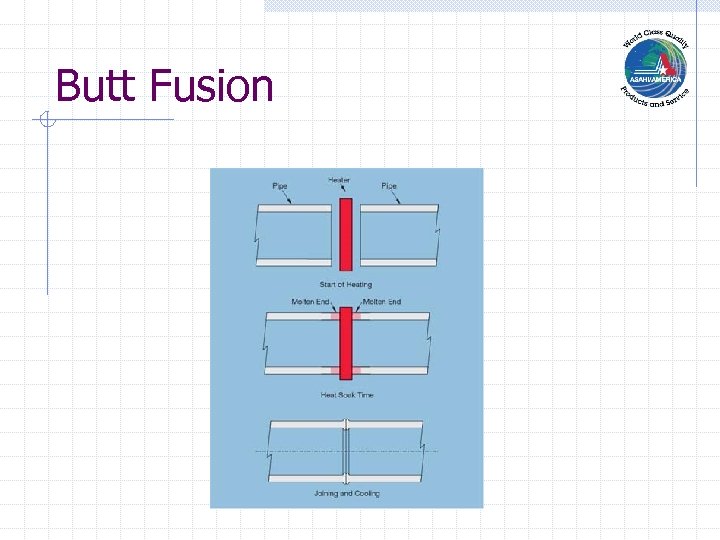

Butt Fusion

Welding Machines

Welding Accessories – Electro-Fusion Tapping Saddle Clamping Tool Tapping Saddle Set Scraper Tool n Required for Electrofusion

Welding Accessories – Socket Fusion Pipe Scraper n Recommended for 90 mm 110 mm Socket Fusion Pipe Beveller n Recommended for 2063 mm Socket Fusion

Thank You Questions?

7423562adb51765ab73e95568257da62.ppt