4f851a4ecbf132aa75c4d17ee0704734.ppt

- Количество слайдов: 45

Air Pollution Control « Air Pollution Control Ordinance » ( Chapter 311 ) 1

Air Pollution Control « Air Pollution Control Ordinance » ( Chapter 311 ) 1

« Air Pollution Control Regulations » Relevant to the Construction Industry ü (Construction Dust) Regulation ü (Specified Processes) Regulation ü (Smoke) Regulation ü (Fuel Restriction) Regulation ü (Open Burning) Regulation 2

« Air Pollution Control Regulations » Relevant to the Construction Industry ü (Construction Dust) Regulation ü (Specified Processes) Regulation ü (Smoke) Regulation ü (Fuel Restriction) Regulation ü (Open Burning) Regulation 2

« Air Pollution Control Regulations » Relevant to the Construction Industry (Specified Processes) Regulation Bitumen plant Concrete batching plant 3

« Air Pollution Control Regulations » Relevant to the Construction Industry (Specified Processes) Regulation Bitumen plant Concrete batching plant 3

« Air Pollution Control Regulations » Relevant to the Construction Industry (Smoke) Regulation (Fuel Restriction) Regulation r 4

« Air Pollution Control Regulations » Relevant to the Construction Industry (Smoke) Regulation (Fuel Restriction) Regulation r 4

Air Pollution Control (Open Burning) Regulation • Purpose Prohibit / Control Open Burning Activities • Effective date 26 Feb 1996 5

Air Pollution Control (Open Burning) Regulation • Purpose Prohibit / Control Open Burning Activities • Effective date 26 Feb 1996 5

Prohibited Open Burning r Disposal of construction Waste Disposal of Tyres Site clearance Salvage of metal 6

Prohibited Open Burning r Disposal of construction Waste Disposal of Tyres Site clearance Salvage of metal 6

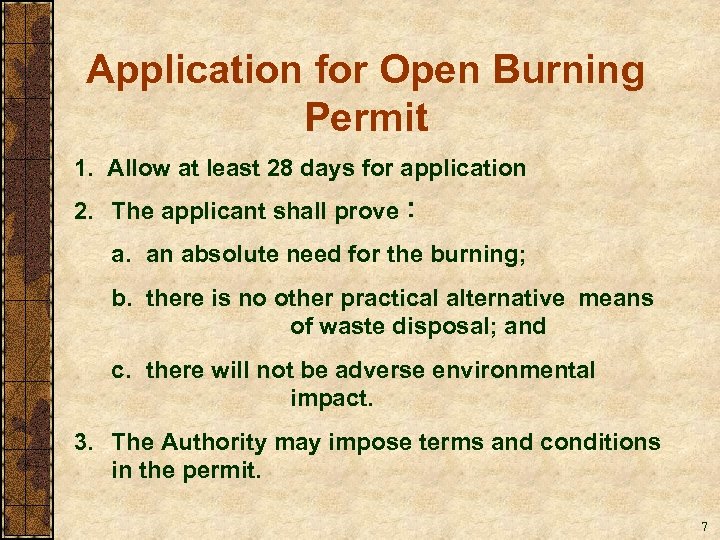

Application for Open Burning Permit 1. Allow at least 28 days for application 2. The applicant shall prove︰ a. an absolute need for the burning; b. there is no other practical alternative means of waste disposal; and c. there will not be adverse environmental impact. 3. The Authority may impose terms and conditions in the permit. 7

Application for Open Burning Permit 1. Allow at least 28 days for application 2. The applicant shall prove︰ a. an absolute need for the burning; b. there is no other practical alternative means of waste disposal; and c. there will not be adverse environmental impact. 3. The Authority may impose terms and conditions in the permit. 7

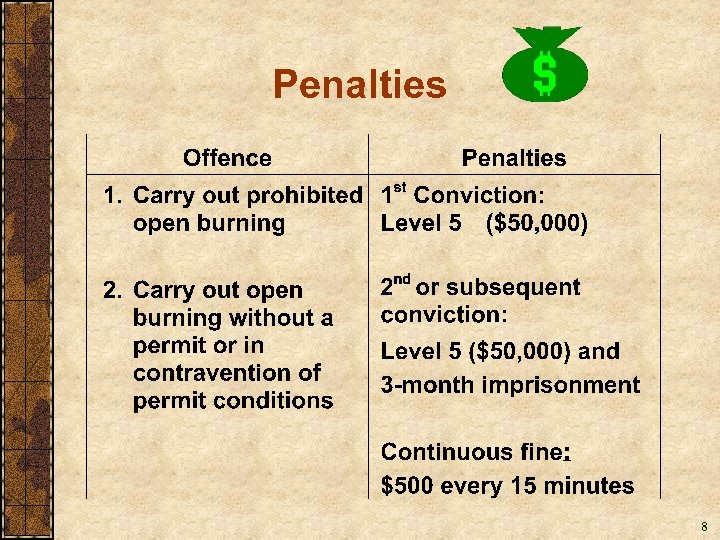

Penalties 8

Penalties 8

« Air Pollution Control (Construction Dust) Regulation » Purpose • Employ effective dust abatement measures to • Reduce dust emission, • Reduce air nuisance, and • Improve general air quality. • Set out appropriate dust control measures and make them as standard practice in the construction industry. 9

« Air Pollution Control (Construction Dust) Regulation » Purpose • Employ effective dust abatement measures to • Reduce dust emission, • Reduce air nuisance, and • Improve general air quality. • Set out appropriate dust control measures and make them as standard practice in the construction industry. 9

Classification of Construction Works • Three main types of construction works: – Notifiable work: building demolition, construction of superstructure, site formation, reclamation, etc. – Regulatory work (Notification not required) : road opening /resurfacing, external renovation, slope stabilization. – Excluded work (Notification not required) : internal renovation, specified process, etc. 10

Classification of Construction Works • Three main types of construction works: – Notifiable work: building demolition, construction of superstructure, site formation, reclamation, etc. – Regulatory work (Notification not required) : road opening /resurfacing, external renovation, slope stabilization. – Excluded work (Notification not required) : internal renovation, specified process, etc. 10

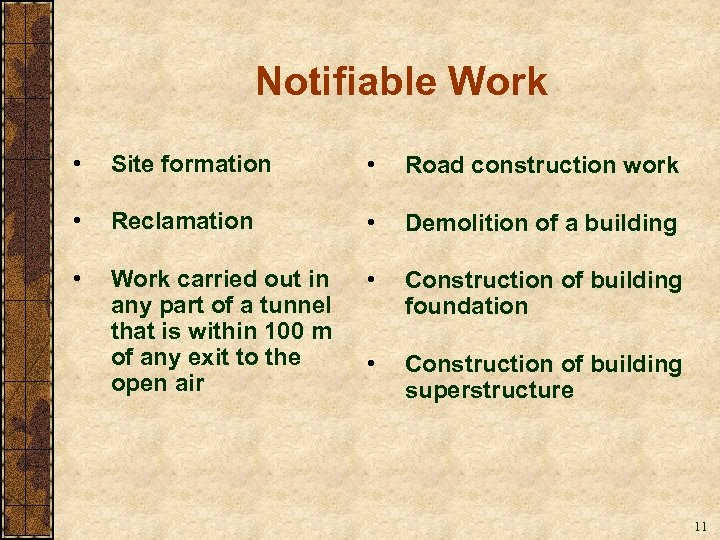

Notifiable Work • Site formation • Road construction work • Reclamation • Demolition of a building • Work carried out in any part of a tunnel that is within 100 m of any exit to the open air • Construction of building foundation • Construction of building superstructure 11

Notifiable Work • Site formation • Road construction work • Reclamation • Demolition of a building • Work carried out in any part of a tunnel that is within 100 m of any exit to the open air • Construction of building foundation • Construction of building superstructure 11

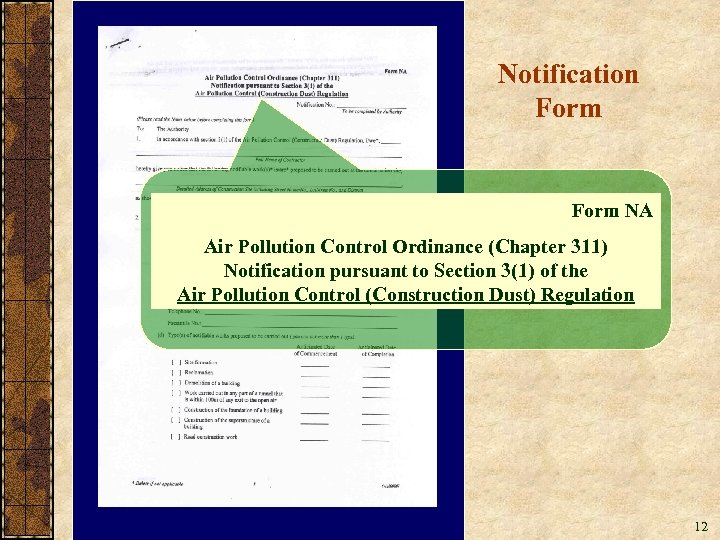

Notification Form NA Air Pollution Control Ordinance (Chapter 311) Notification pursuant to Section 3(1) of the Air Pollution Control (Construction Dust) Regulation 12

Notification Form NA Air Pollution Control Ordinance (Chapter 311) Notification pursuant to Section 3(1) of the Air Pollution Control (Construction Dust) Regulation 12

Dust Control Requirement 13

Dust Control Requirement 13

Part III of Schedule General Control Requirements 14

Part III of Schedule General Control Requirements 14

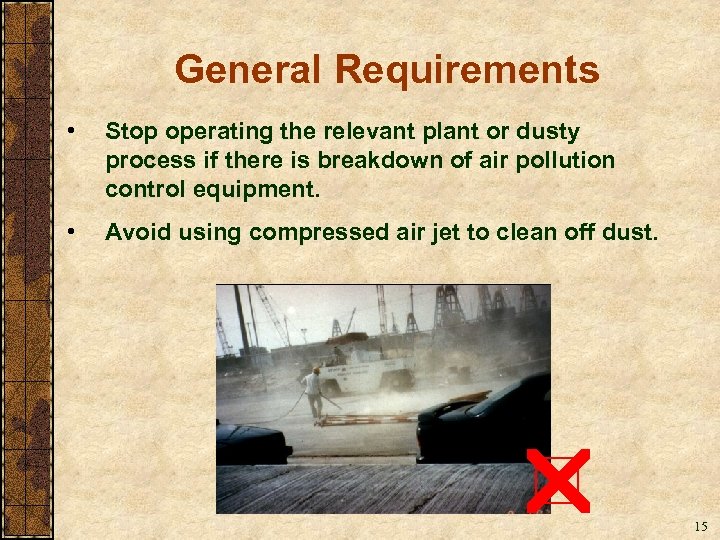

General Requirements • Stop operating the relevant plant or dusty process if there is breakdown of air pollution control equipment. • Avoid using compressed air jet to clean off dust. r 15

General Requirements • Stop operating the relevant plant or dusty process if there is breakdown of air pollution control equipment. • Avoid using compressed air jet to clean off dust. r 15

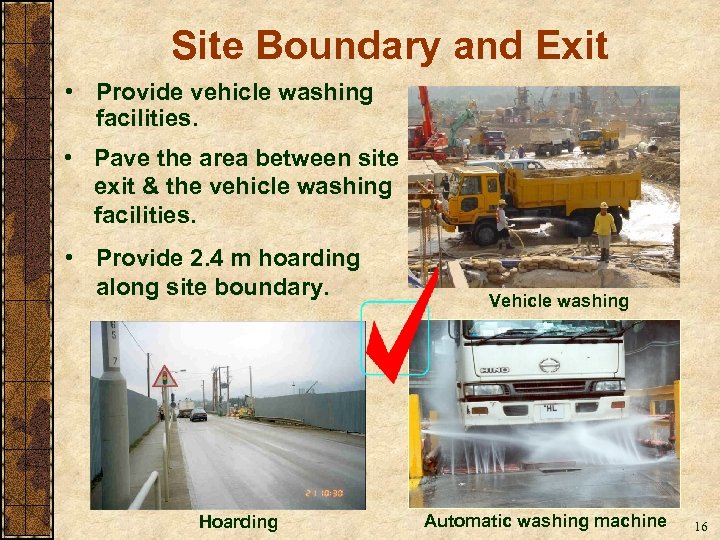

Site Boundary and Exit • Provide vehicle washing facilities. • Pave the area between site exit & the vehicle washing facilities. • Provide 2. 4 m hoarding along site boundary. Hoarding Vehicle washing Automatic washing machine 16

Site Boundary and Exit • Provide vehicle washing facilities. • Pave the area between site exit & the vehicle washing facilities. • Provide 2. 4 m hoarding along site boundary. Hoarding Vehicle washing Automatic washing machine 16

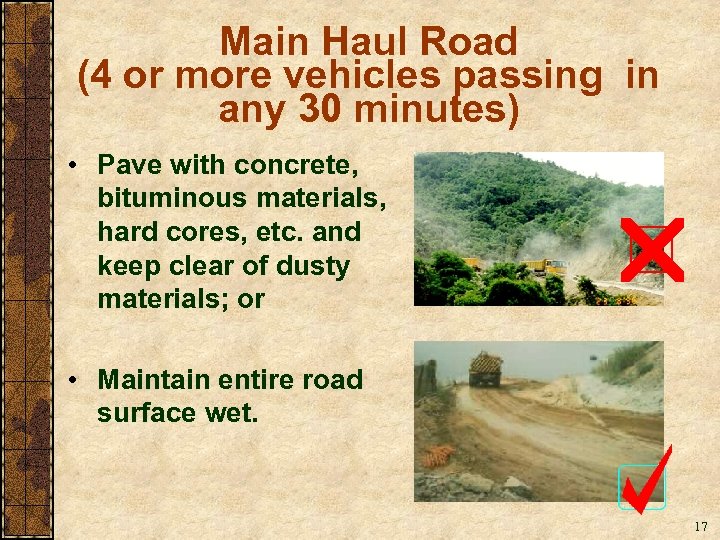

Main Haul Road (4 or more vehicles passing in any 30 minutes) • Pave with concrete, bituminous materials, hard cores, etc. and keep clear of dusty materials; or r • Maintain entire road surface wet. 17

Main Haul Road (4 or more vehicles passing in any 30 minutes) • Pave with concrete, bituminous materials, hard cores, etc. and keep clear of dusty materials; or r • Maintain entire road surface wet. 17

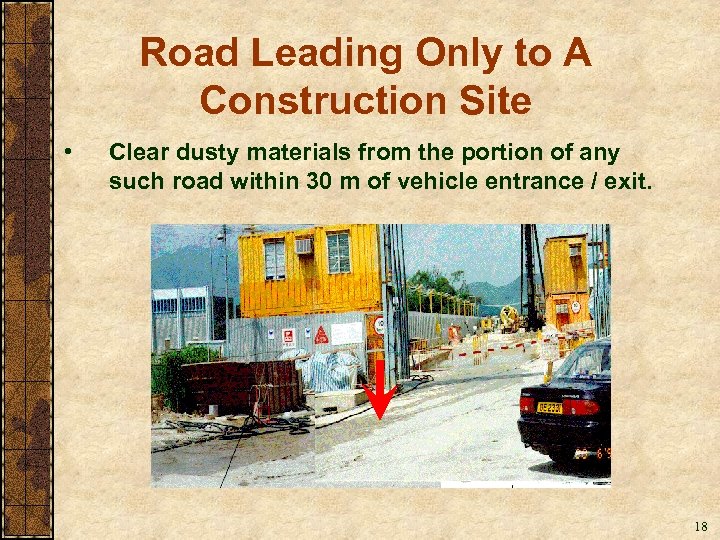

Road Leading Only to A Construction Site • Clear dusty materials from the portion of any such road within 30 m of vehicle entrance / exit. 18

Road Leading Only to A Construction Site • Clear dusty materials from the portion of any such road within 30 m of vehicle entrance / exit. 18

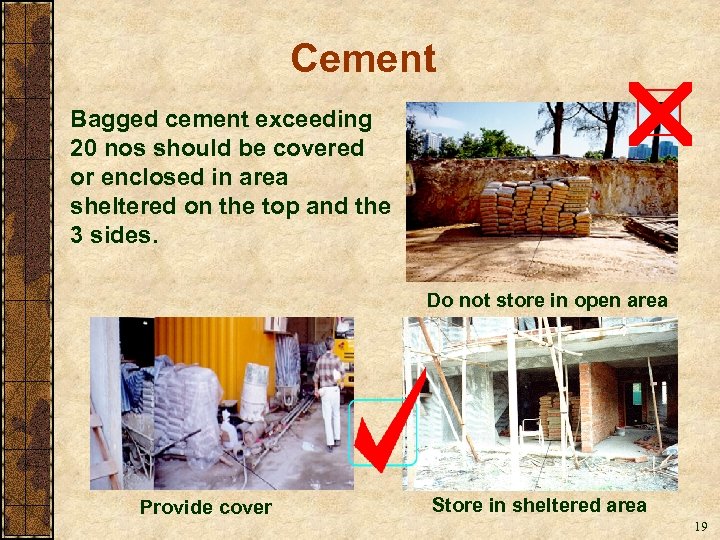

Cement Bagged cement exceeding 20 nos should be covered or enclosed in area sheltered on the top and the 3 sides. r Do not store in open area Provide cover Store in sheltered area 19

Cement Bagged cement exceeding 20 nos should be covered or enclosed in area sheltered on the top and the 3 sides. r Do not store in open area Provide cover Store in sheltered area 19

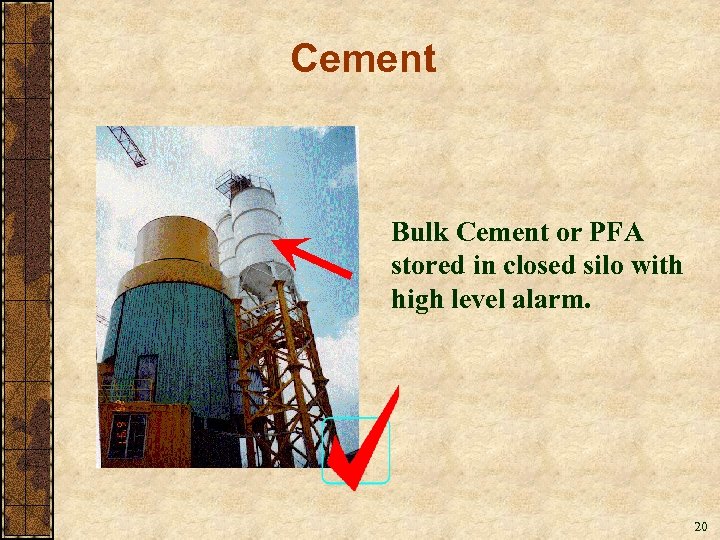

Cement Bulk Cement or PFA stored in closed silo with high level alarm. 20

Cement Bulk Cement or PFA stored in closed silo with high level alarm. 20

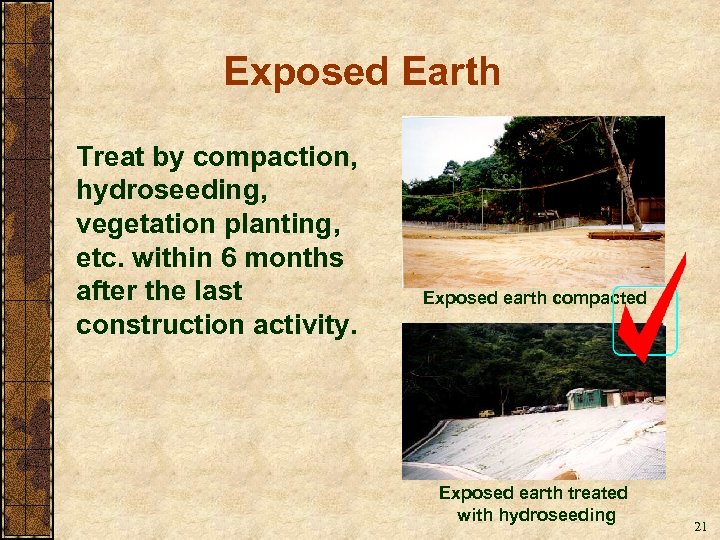

Exposed Earth Treat by compaction, hydroseeding, vegetation planting, etc. within 6 months after the last construction activity. Exposed earth compacted Exposed earth treated with hydroseeding 21

Exposed Earth Treat by compaction, hydroseeding, vegetation planting, etc. within 6 months after the last construction activity. Exposed earth compacted Exposed earth treated with hydroseeding 21

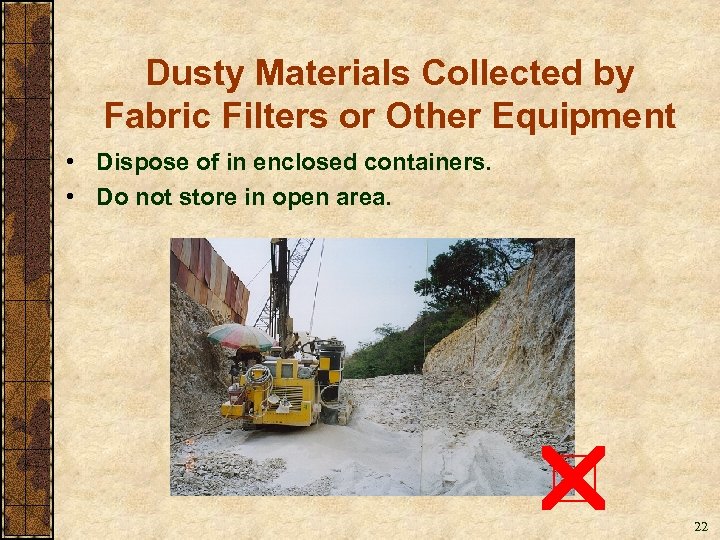

Dusty Materials Collected by Fabric Filters or Other Equipment • Dispose of in enclosed containers. • Do not store in open area. 22 r

Dusty Materials Collected by Fabric Filters or Other Equipment • Dispose of in enclosed containers. • Do not store in open area. 22 r

Part IV of Schedule Control Requirements for Individual Activities 23

Part IV of Schedule Control Requirements for Individual Activities 23

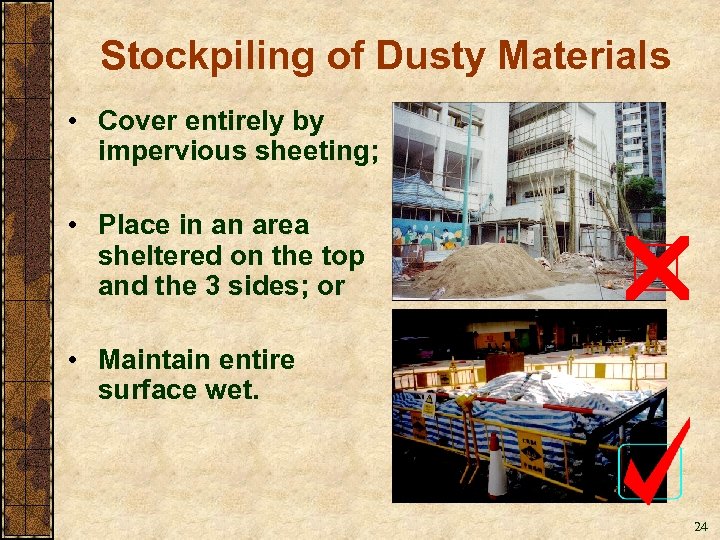

Stockpiling of Dusty Materials • Cover entirely by impervious sheeting; • Place in an area sheltered on the top and the 3 sides; or r • Maintain entire surface wet. 24

Stockpiling of Dusty Materials • Cover entirely by impervious sheeting; • Place in an area sheltered on the top and the 3 sides; or r • Maintain entire surface wet. 24

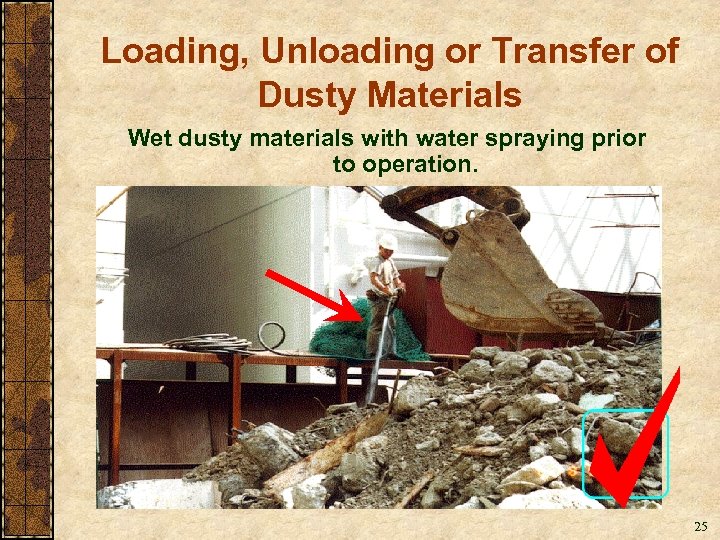

Loading, Unloading or Transfer of Dusty Materials Wet dusty materials with water spraying prior to operation. 25

Loading, Unloading or Transfer of Dusty Materials Wet dusty materials with water spraying prior to operation. 25

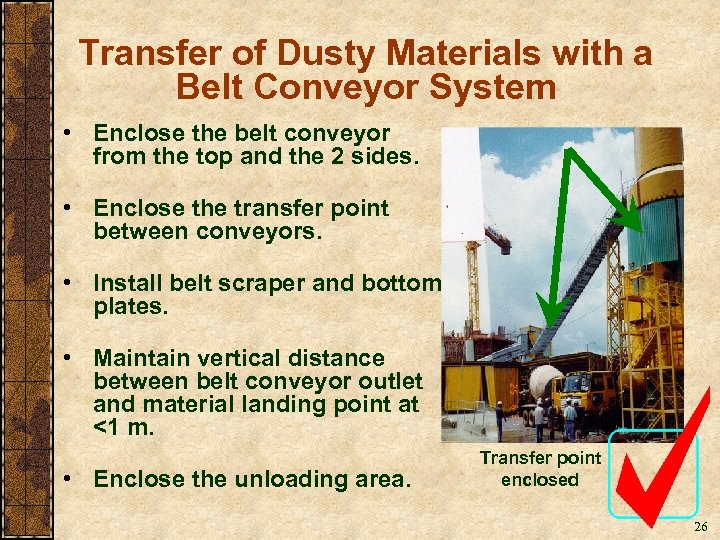

Transfer of Dusty Materials with a Belt Conveyor System • Enclose the belt conveyor from the top and the 2 sides. • Enclose the transfer point between conveyors. • Install belt scraper and bottom plates. • Maintain vertical distance between belt conveyor outlet and material landing point at <1 m. • Enclose the unloading area. Transfer point enclosed 26

Transfer of Dusty Materials with a Belt Conveyor System • Enclose the belt conveyor from the top and the 2 sides. • Enclose the transfer point between conveyors. • Install belt scraper and bottom plates. • Maintain vertical distance between belt conveyor outlet and material landing point at <1 m. • Enclose the unloading area. Transfer point enclosed 26

Use of Vehicles • Wash every vehicle before leaving the site to remove dusty materials from body and wheels. • Cover any load of dusty materials. r Wash vehicle before leaving site Load on truck inadequately Load on truck covered 27

Use of Vehicles • Wash every vehicle before leaving the site to remove dusty materials from body and wheels. • Cover any load of dusty materials. r Wash vehicle before leaving site Load on truck inadequately Load on truck covered 27

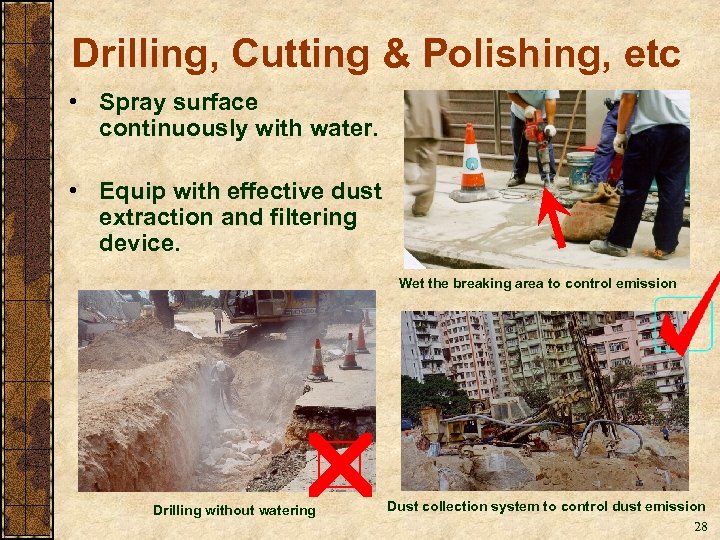

Drilling, Cutting & Polishing, etc • Spray surface continuously with water. • Equip with effective dust extraction and filtering device. Wet the breaking area to control emission r Drilling without watering Dust collection system to control dust emission 28

Drilling, Cutting & Polishing, etc • Spray surface continuously with water. • Equip with effective dust extraction and filtering device. Wet the breaking area to control emission r Drilling without watering Dust collection system to control dust emission 28

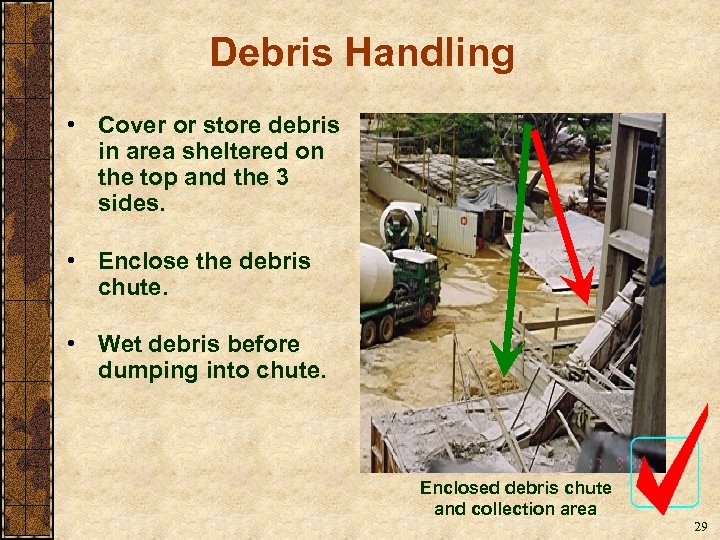

Debris Handling • Cover or store debris in area sheltered on the top and the 3 sides. • Enclose the debris chute. • Wet debris before dumping into chute. Enclosed debris chute and collection area 29

Debris Handling • Cover or store debris in area sheltered on the top and the 3 sides. • Enclose the debris chute. • Wet debris before dumping into chute. Enclosed debris chute and collection area 29

Excavation or Earth Moving • Spray the working area with water or chemicals before, during and immediately after the operation to maintain entire surface wet. r 30

Excavation or Earth Moving • Spray the working area with water or chemicals before, during and immediately after the operation to maintain entire surface wet. r 30

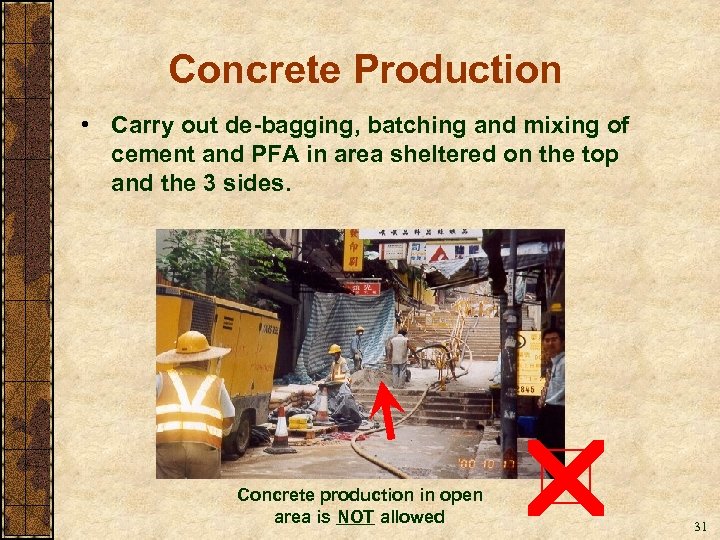

Concrete Production • Carry out de-bagging, batching and mixing of cement and PFA in area sheltered on the top and the 3 sides. Concrete production in open area is NOT allowed r 31

Concrete Production • Carry out de-bagging, batching and mixing of cement and PFA in area sheltered on the top and the 3 sides. Concrete production in open area is NOT allowed r 31

Site Clearance • Wet the working area before, during and immediately after the operation. • Cover all demolished items or place in area sheltered on the top and the 3 sides within a day of demolition. r Dusty material should be covered or removed 32

Site Clearance • Wet the working area before, during and immediately after the operation. • Cover all demolished items or place in area sheltered on the top and the 3 sides within a day of demolition. r Dusty material should be covered or removed 32

Blasting • Wet area within 30 m before blasting. • No blasting during the strong wind signal or tropical cyclone warning No. 3 or above is hoisted unless permitted by Commissioner of Mines. 33

Blasting • Wet area within 30 m before blasting. • No blasting during the strong wind signal or tropical cyclone warning No. 3 or above is hoisted unless permitted by Commissioner of Mines. 33

Part I of Schedule Control Requirements for Notifiable Works 34

Part I of Schedule Control Requirements for Notifiable Works 34

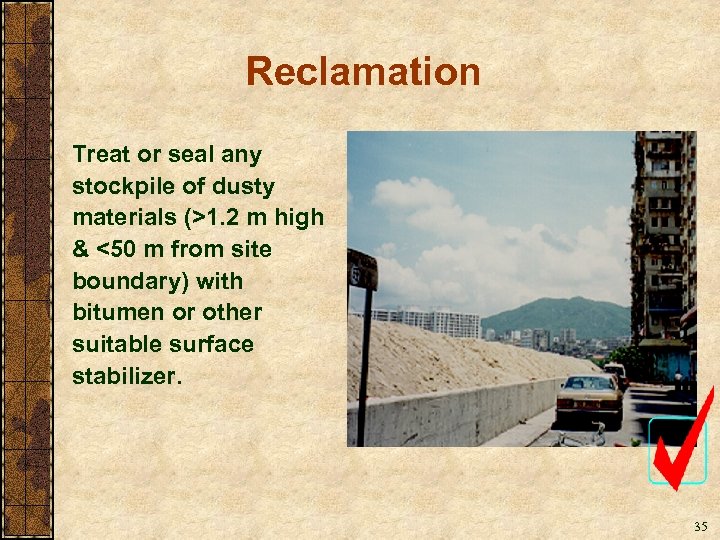

Reclamation Treat or seal any stockpile of dusty materials (>1. 2 m high & <50 m from site boundary) with bitumen or other suitable surface stabilizer. 35

Reclamation Treat or seal any stockpile of dusty materials (>1. 2 m high & <50 m from site boundary) with bitumen or other suitable surface stabilizer. 35

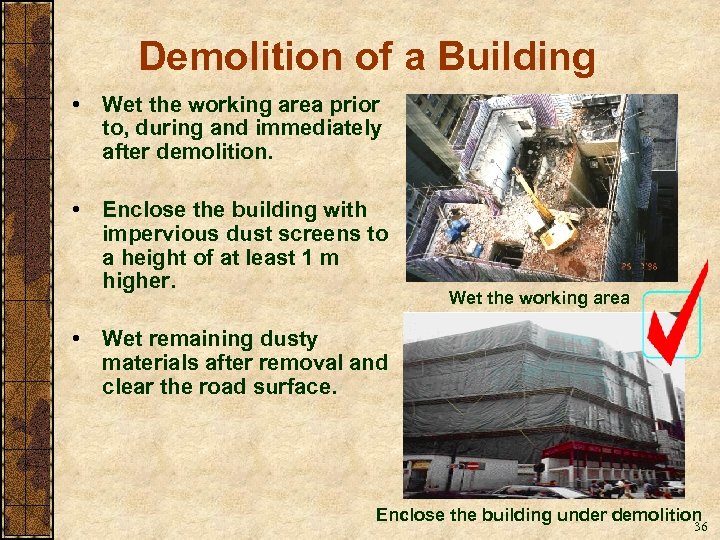

Demolition of a Building • Wet the working area prior to, during and immediately after demolition. • Enclose the building with impervious dust screens to a height of at least 1 m higher. • Wet the working area Wet remaining dusty materials after removal and clear the road surface. Enclose the building under demolition 36

Demolition of a Building • Wet the working area prior to, during and immediately after demolition. • Enclose the building with impervious dust screens to a height of at least 1 m higher. • Wet the working area Wet remaining dusty materials after removal and clear the road surface. Enclose the building under demolition 36

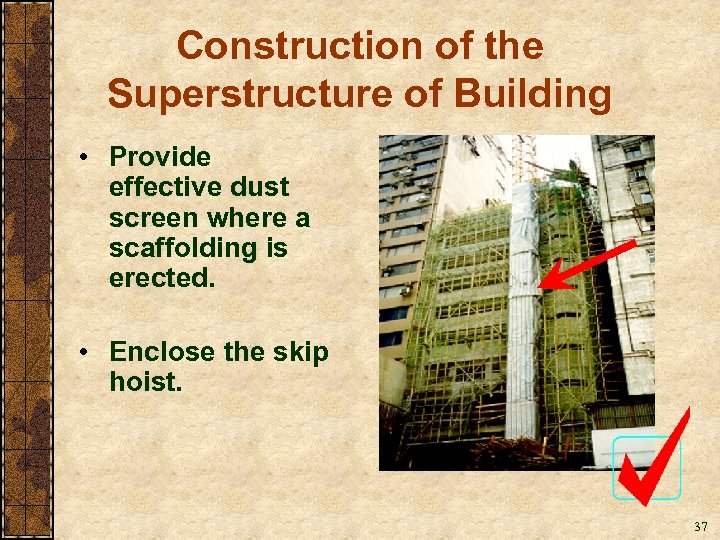

Construction of the Superstructure of Building • Provide effective dust screen where a scaffolding is erected. • Enclose the skip hoist. 37

Construction of the Superstructure of Building • Provide effective dust screen where a scaffolding is erected. • Enclose the skip hoist. 37

Part II of Schedule Control Requirements for Regulatory Works 38

Part II of Schedule Control Requirements for Regulatory Works 38

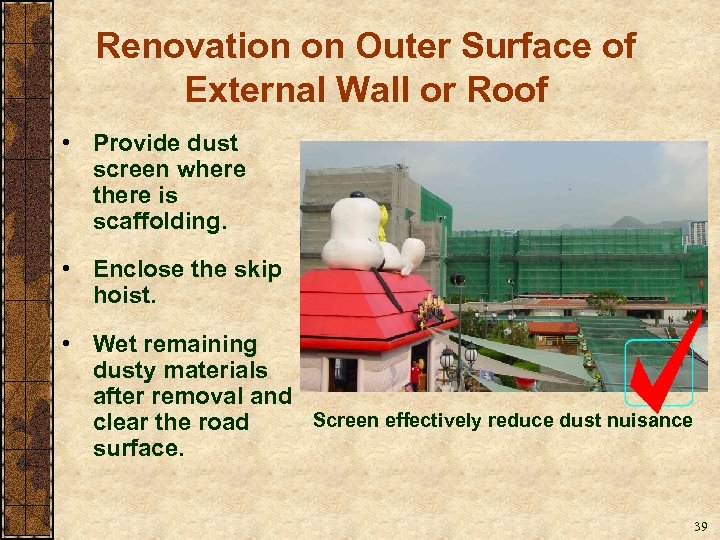

Renovation on Outer Surface of External Wall or Roof • Provide dust screen where there is scaffolding. • Enclose the skip hoist. • Wet remaining dusty materials after removal and Screen effectively reduce dust nuisance clear the road surface. 39

Renovation on Outer Surface of External Wall or Roof • Provide dust screen where there is scaffolding. • Enclose the skip hoist. • Wet remaining dusty materials after removal and Screen effectively reduce dust nuisance clear the road surface. 39

Road Opening Resurfacing Work • Cover dusty material. • Spray, remove / backfill / reinstate dusty materials within 24 hours. • Dusty materials shall not be extended beyond pedestrian barriers, fencing or traffic cones. r Remaining dusty materials should be wetted and cleared • Any remaining dusty materials after removal shall be wetted and cleared from road surface. 40

Road Opening Resurfacing Work • Cover dusty material. • Spray, remove / backfill / reinstate dusty materials within 24 hours. • Dusty materials shall not be extended beyond pedestrian barriers, fencing or traffic cones. r Remaining dusty materials should be wetted and cleared • Any remaining dusty materials after removal shall be wetted and cleared from road surface. 40

Exemption • Road construction work • exempt from hoarding requirement. • Road opening or resurfacing work • exempt from vehicle washing facilities and hoarding requirements. • Slope stabilization • exempt from vehicle washing facilities requirement, and • exempt from hoarding requirement if the site boundary adjoins road for vehicular traffic. 41

Exemption • Road construction work • exempt from hoarding requirement. • Road opening or resurfacing work • exempt from vehicle washing facilities and hoarding requirements. • Slope stabilization • exempt from vehicle washing facilities requirement, and • exempt from hoarding requirement if the site boundary adjoins road for vehicular traffic. 41

Exemption for Emergency Work • Where there is a threat to human life or building safety. • Immediate repair of utility services, road collapse or road blockage due to accidents. 42

Exemption for Emergency Work • Where there is a threat to human life or building safety. • Immediate repair of utility services, road collapse or road blockage due to accidents. 42

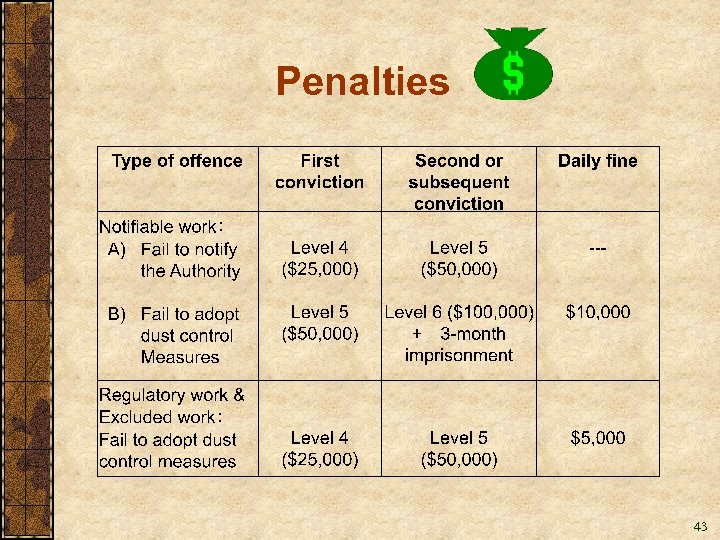

Penalties 43

Penalties 43

Tips to Reduce Dust Emission 1. Include the plan and budget of implementation of dust control measures in the tender. 2. Arrange delivery of dust suppression materials and equipment to site at an early stage. 3. Ensure good communication between frontline workers and management staff. 4. Promote staff awareness on dust control measures. 5. Supervise frontline workers. 44

Tips to Reduce Dust Emission 1. Include the plan and budget of implementation of dust control measures in the tender. 2. Arrange delivery of dust suppression materials and equipment to site at an early stage. 3. Ensure good communication between frontline workers and management staff. 4. Promote staff awareness on dust control measures. 5. Supervise frontline workers. 44

Environmental Protection Department 45

Environmental Protection Department 45