Air filmcooling through laser drilled nozzles STW project CASA-dag 09. 05. 2006

Air filmcooling through laser drilled nozzles STW project CASA-dag 09. 05. 2006

Outline of the presentation 1. Introduction 2. Current situation 3. Local Uniform Grid Refinement 4. Boundary conditions 5. Conclusions and future plans

Outline of the presentation 1. Introduction 2. Current situation 3. Local Uniform Grid Refinement 4. Boundary conditions 5. Conclusions and future plans

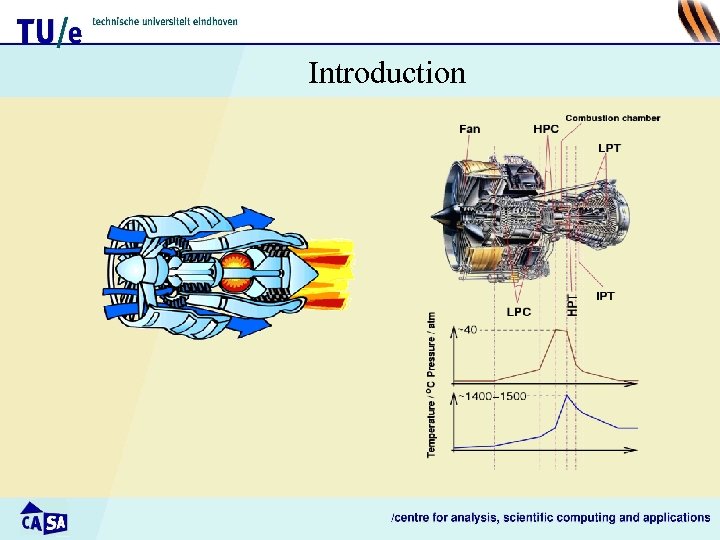

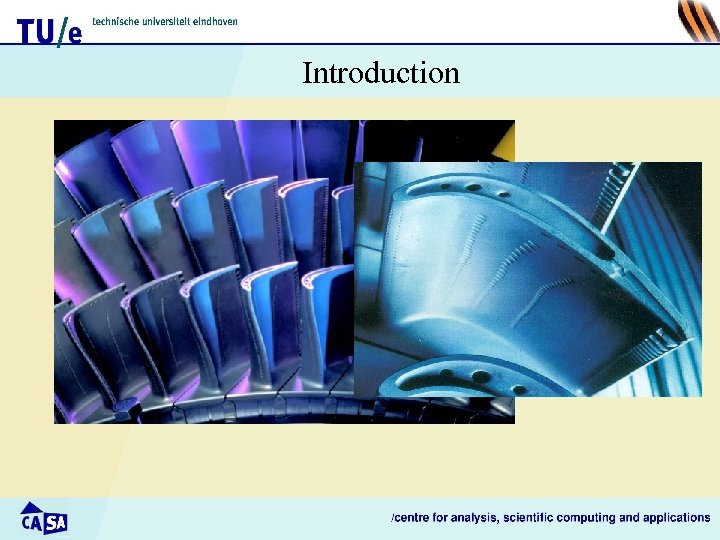

Introduction

Introduction

Introduction

Introduction

Introduction

Introduction

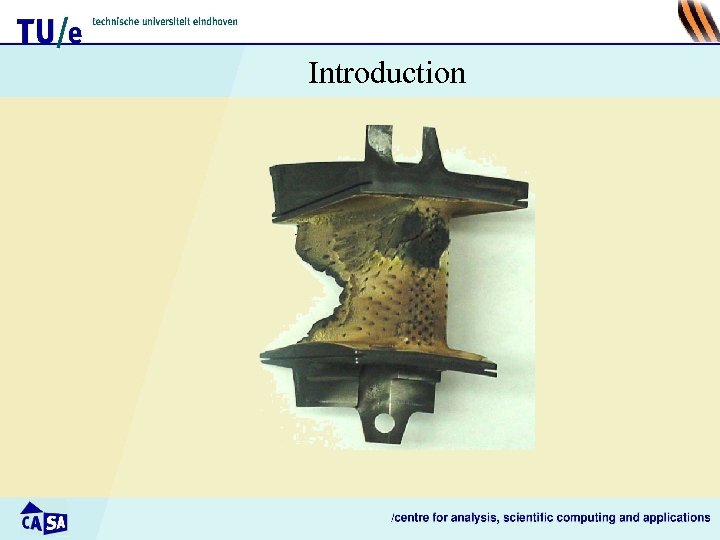

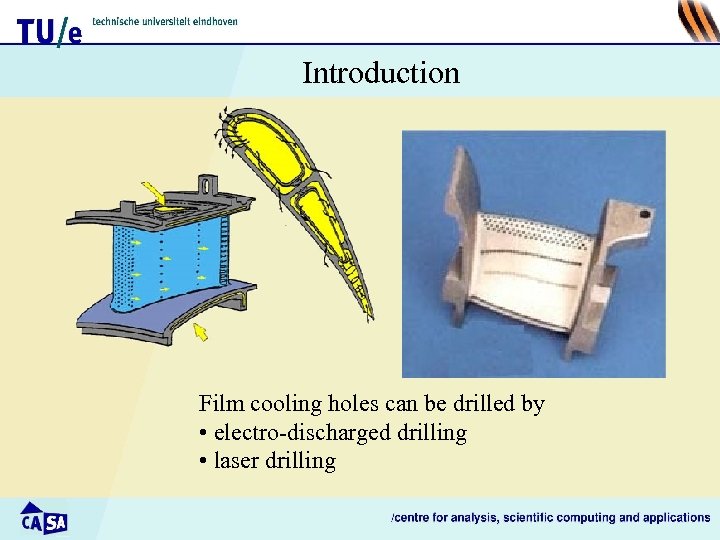

Introduction Film cooling holes can be drilled by • electro-discharged drilling • laser drilling

Introduction Film cooling holes can be drilled by • electro-discharged drilling • laser drilling

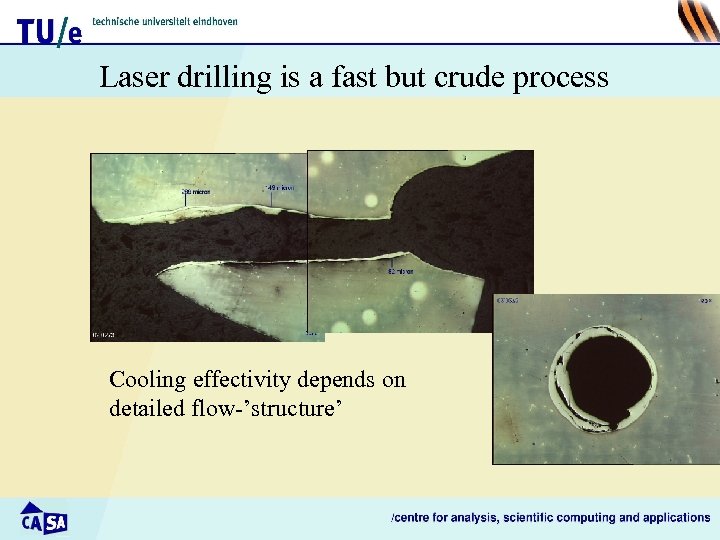

Laser drilling is a fast but crude process Cooling effectivity depends on detailed flow-’structure’

Laser drilling is a fast but crude process Cooling effectivity depends on detailed flow-’structure’

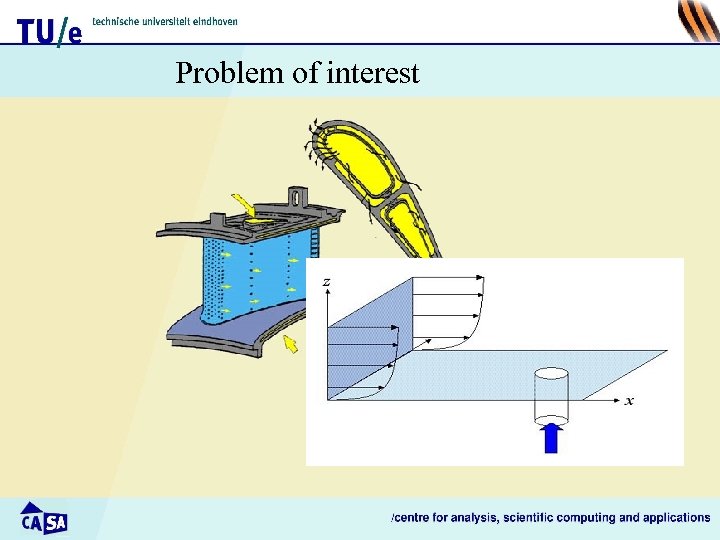

Problem of interest

Problem of interest

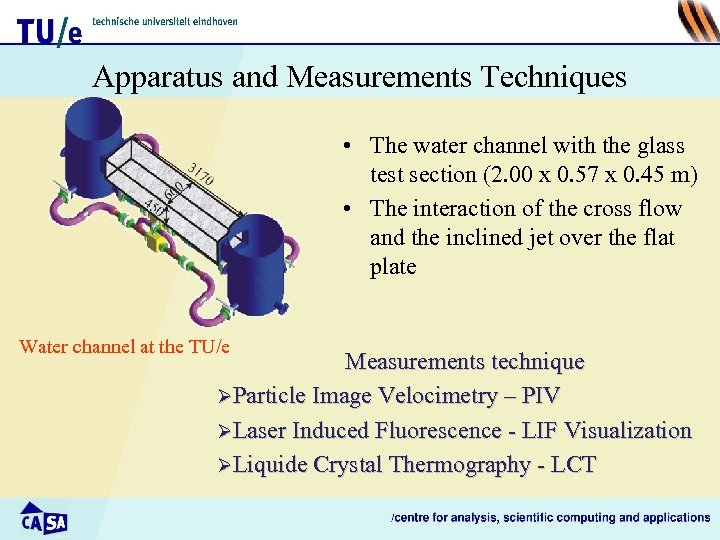

Apparatus and Measurements Techniques • The water channel with the glass test section (2. 00 x 0. 57 x 0. 45 m) • The interaction of the cross flow and the inclined jet over the flat plate Water channel at the TU/e Measurements technique ØParticle Image Velocimetry – PIV ØLaser Induced Fluorescence - LIF Visualization ØLiquide Crystal Thermography - LCT

Apparatus and Measurements Techniques • The water channel with the glass test section (2. 00 x 0. 57 x 0. 45 m) • The interaction of the cross flow and the inclined jet over the flat plate Water channel at the TU/e Measurements technique ØParticle Image Velocimetry – PIV ØLaser Induced Fluorescence - LIF Visualization ØLiquide Crystal Thermography - LCT

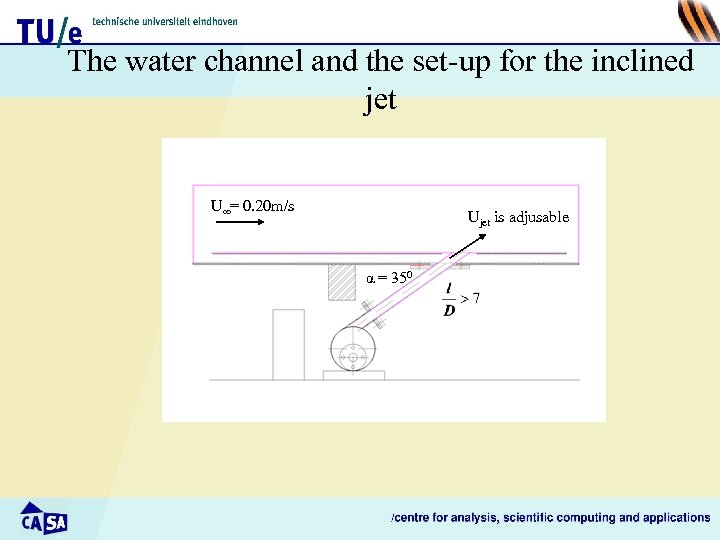

The water channel and the set-up for the inclined jet U = 0. 20 m/s Ujet is adjusable α = 350

The water channel and the set-up for the inclined jet U = 0. 20 m/s Ujet is adjusable α = 350

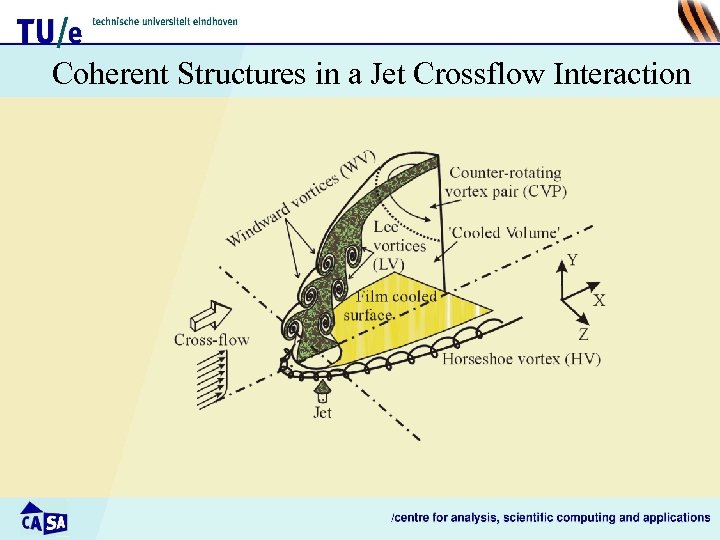

Coherent Structures in a Jet Crossflow Interaction

Coherent Structures in a Jet Crossflow Interaction

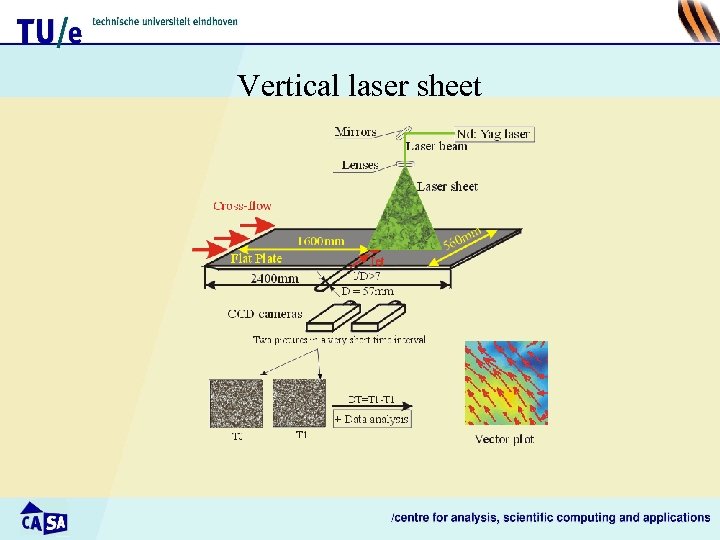

Vertical laser sheet

Vertical laser sheet

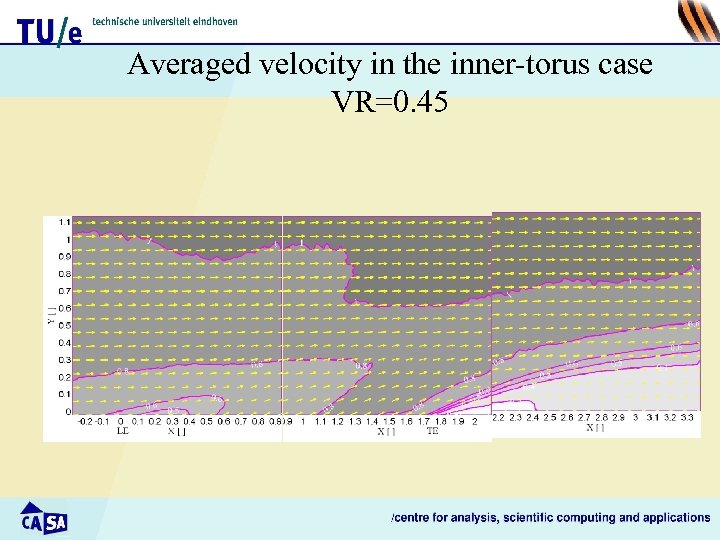

Averaged velocity in the inner-torus case VR=0. 45

Averaged velocity in the inner-torus case VR=0. 45

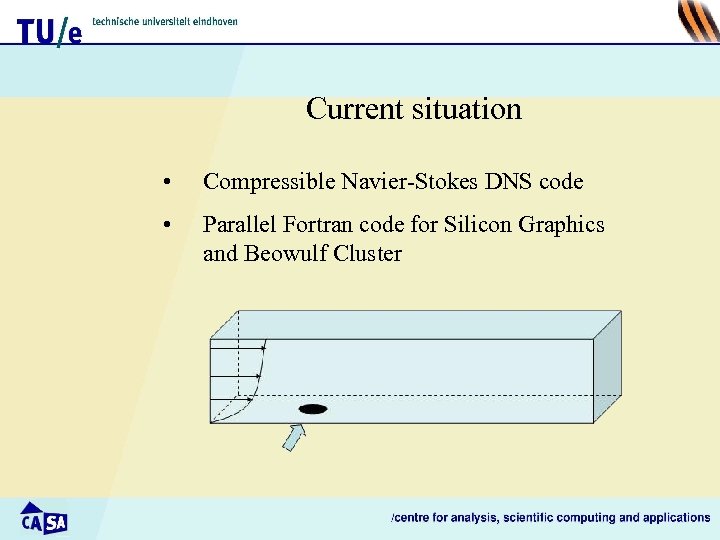

Current situation • Compressible Navier-Stokes DNS code • Parallel Fortran code for Silicon Graphics and Beowulf Cluster

Current situation • Compressible Navier-Stokes DNS code • Parallel Fortran code for Silicon Graphics and Beowulf Cluster

Problem Need more resolution in high activity area Answer (simple) Buy bigger computer Answer (smart) Local grid refinement

Problem Need more resolution in high activity area Answer (simple) Buy bigger computer Answer (smart) Local grid refinement

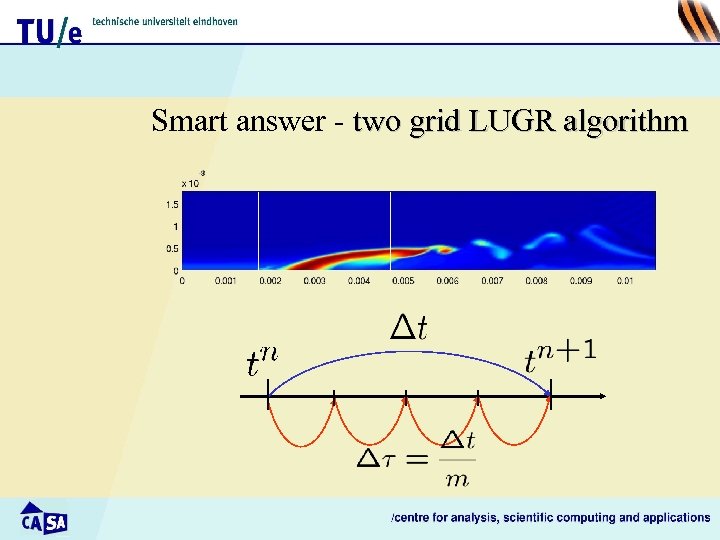

Smart answer - two grid LUGR algorithm

Smart answer - two grid LUGR algorithm

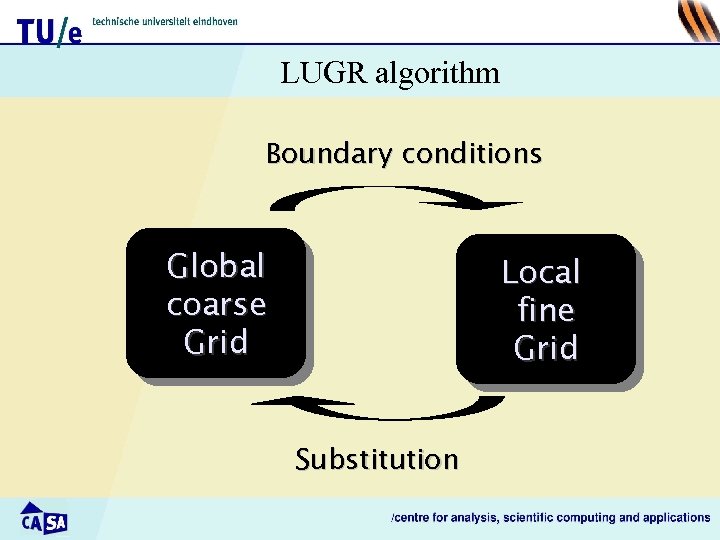

LUGR algorithm Boundary conditions Global coarse Grid Local fine Grid Substitution

LUGR algorithm Boundary conditions Global coarse Grid Local fine Grid Substitution

Boundary conditions for the fine grid Dirichlet BC from the coarse grid • Using “physical” variables (velocity, pressure, etc. ) • Using “acoustical” quantities (directions and amplitudes of the incoming and outgoing waves)

Boundary conditions for the fine grid Dirichlet BC from the coarse grid • Using “physical” variables (velocity, pressure, etc. ) • Using “acoustical” quantities (directions and amplitudes of the incoming and outgoing waves)

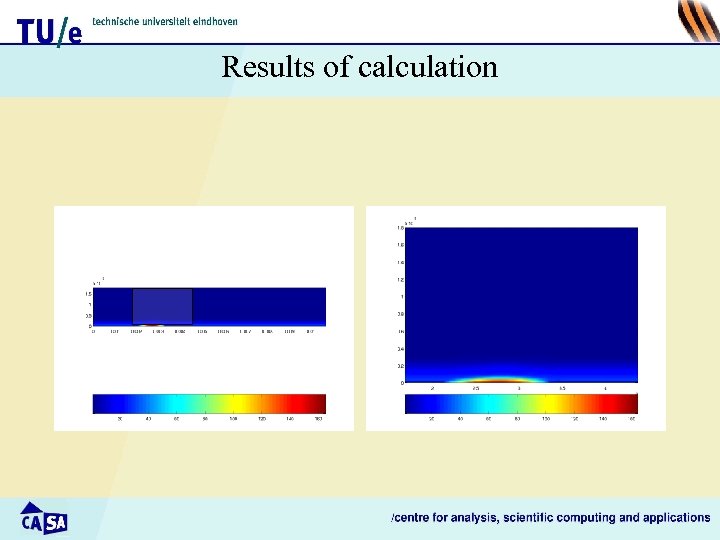

Results of calculation

Results of calculation

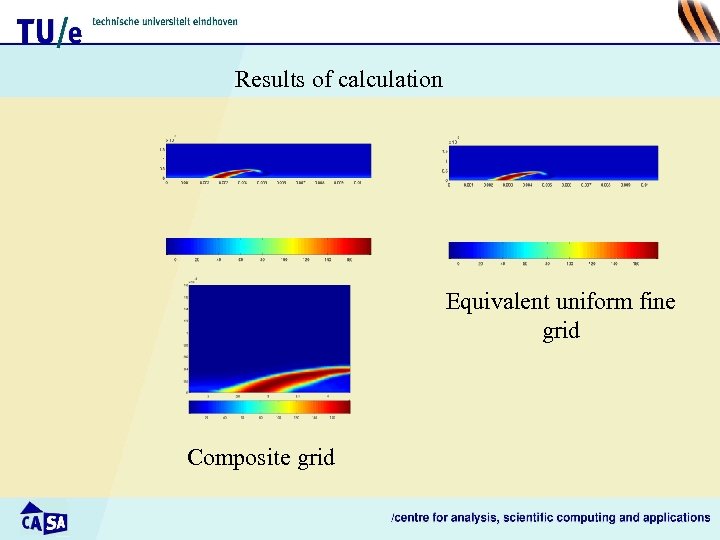

Results of calculation Equivalent uniform fine grid Composite grid

Results of calculation Equivalent uniform fine grid Composite grid

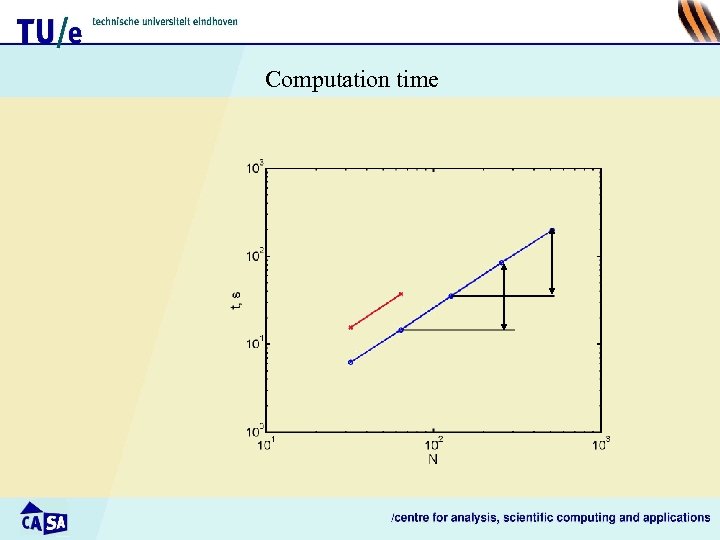

Computation time

Computation time

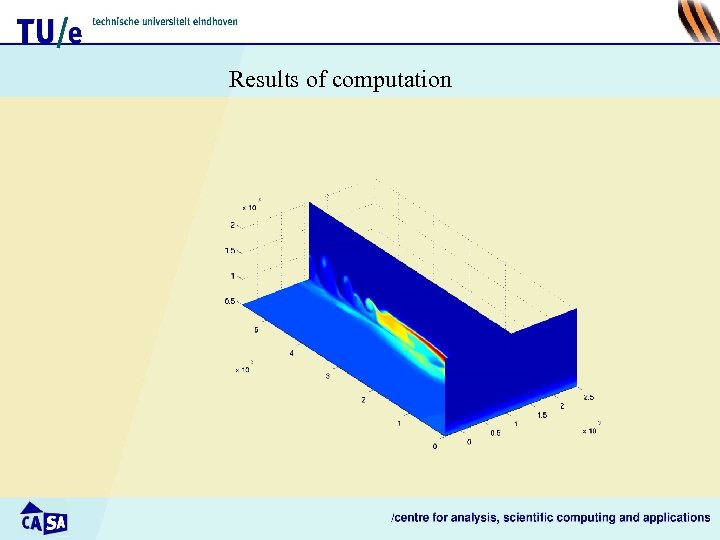

Results of computation

Results of computation

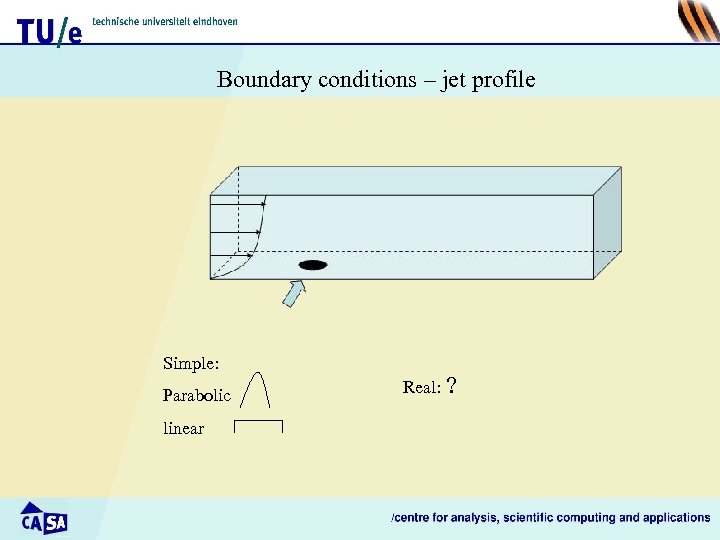

Boundary conditions – jet profile Simple: Parabolic linear Real: ?

Boundary conditions – jet profile Simple: Parabolic linear Real: ?

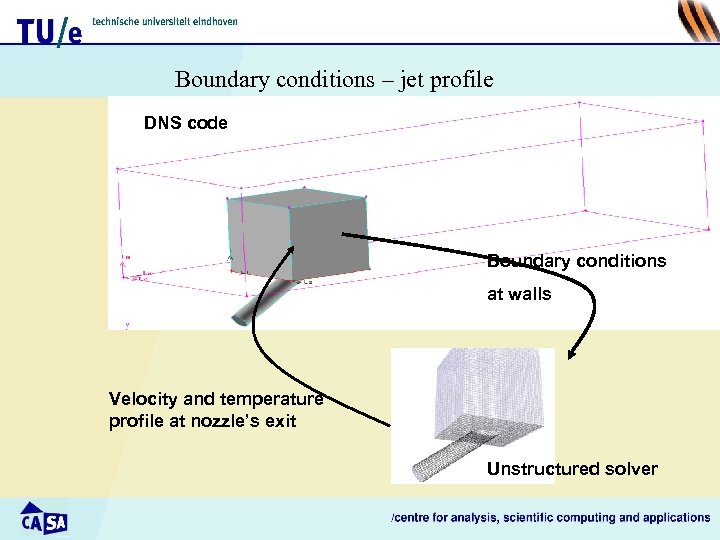

Boundary conditions – jet profile DNS code Boundary conditions at walls Velocity and temperature profile at nozzle’s exit Unstructured solver

Boundary conditions – jet profile DNS code Boundary conditions at walls Velocity and temperature profile at nozzle’s exit Unstructured solver

Imperfections

Imperfections

Imperfections

Imperfections

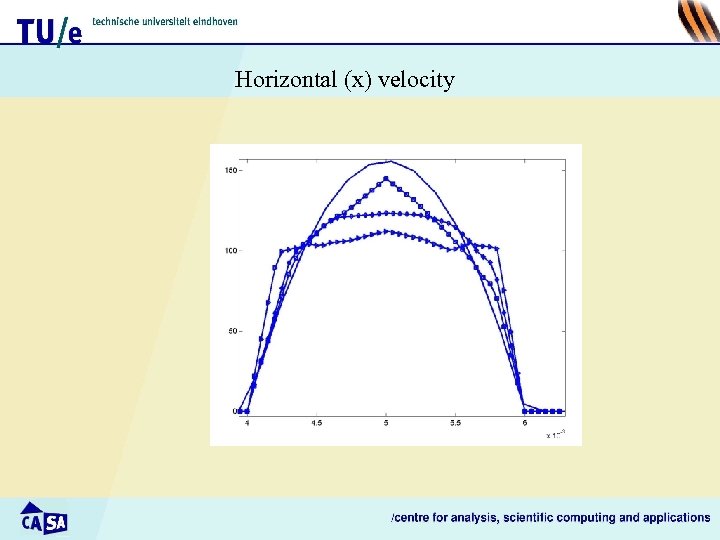

Horizontal (x) velocity

Horizontal (x) velocity

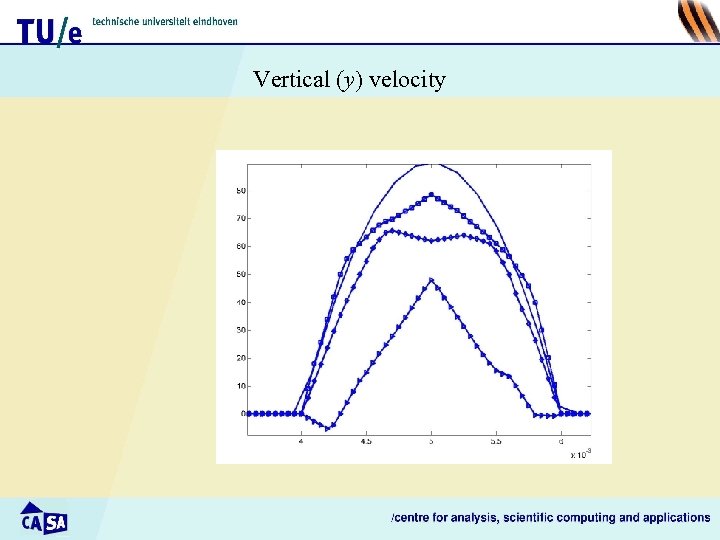

Vertical (y) velocity

Vertical (y) velocity

Some results

Some results

Summary 1. All three velocity components are present 2. Profiles differ from parabolic, specially for inaccuracies close to the exit 3. Qualitative agreement between experimental and numerical results

Summary 1. All three velocity components are present 2. Profiles differ from parabolic, specially for inaccuracies close to the exit 3. Qualitative agreement between experimental and numerical results

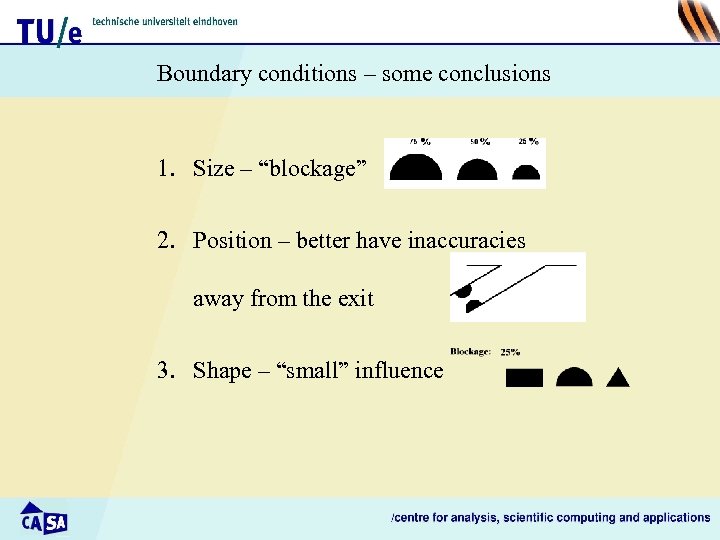

Boundary conditions – some conclusions 1. Size – “blockage” 2. Position – better have inaccuracies away from the exit 3. Shape – “small” influence

Boundary conditions – some conclusions 1. Size – “blockage” 2. Position – better have inaccuracies away from the exit 3. Shape – “small” influence

Conclusions 1. Local grid refinement. 2. First results for inflow profiles. • Different imperfections • Influence of size, shape, position

Conclusions 1. Local grid refinement. 2. First results for inflow profiles. • Different imperfections • Influence of size, shape, position

Future plans (next 1. 5 months) 1. Back substitution of inflow profiles. 2. Comparison of the heat fluxes with experiments.

Future plans (next 1. 5 months) 1. Back substitution of inflow profiles. 2. Comparison of the heat fluxes with experiments.

Questions?

Questions?