6ee5f60ce644675cba22a8dd9975283e.ppt

- Количество слайдов: 48

Air Cooled Screw Chiller

Air Cooled Screw Chiller

Air cooled screw chiller Introduction Product line up Features Applications Certifications

Air cooled screw chiller Introduction Product line up Features Applications Certifications

Air Cooled Chiller Introduction

Air Cooled Chiller Introduction

Midea General Introduction Factory Introduction Company Size Factory area : 500, 000 ㎡ Registered capital : 12. 5 MUSD Total investment : 60 MUSD Manufacturing capacity : 250 MUSD

Midea General Introduction Factory Introduction Company Size Factory area : 500, 000 ㎡ Registered capital : 12. 5 MUSD Total investment : 60 MUSD Manufacturing capacity : 250 MUSD

Factory Introduction the ONLY local company who masters core technology of centrifugal chiller including designing, developing and manufacturing 1000 workers, 200 engineers & experienced workers 70 senior engineers, 3 top technical experts 8, 000 KW ,chiller testing stand. Largest in Asia! One of the biggest chiller manufacture base in the world.

Factory Introduction the ONLY local company who masters core technology of centrifugal chiller including designing, developing and manufacturing 1000 workers, 200 engineers & experienced workers 70 senior engineers, 3 top technical experts 8, 000 KW ,chiller testing stand. Largest in Asia! One of the biggest chiller manufacture base in the world.

Factory Introduction History In 1964, General developed and produced independently China’s first centrifugal chiller (R 11) In 1969, General developed China’s first low – temperature centrifugal chiller (-30℃) In 1973, first centrifugal chiller specially for nuclear submarine In 1980, first 3000 TR centrifugal chiller (ammonia) In 1985, General introduced Hitachi technology on Centrifugal chiller design and manufacturing

Factory Introduction History In 1964, General developed and produced independently China’s first centrifugal chiller (R 11) In 1969, General developed China’s first low – temperature centrifugal chiller (-30℃) In 1973, first centrifugal chiller specially for nuclear submarine In 1980, first 3000 TR centrifugal chiller (ammonia) In 1985, General introduced Hitachi technology on Centrifugal chiller design and manufacturing

Factory Introduction History From 1993, General cooperated with York for Producing R 123 a centrifugal chiller In 1994, developed independently compatible centrifugal Chiller for both R 134 and R 11 which won government Environmental protection reward In 1996, obtained ISO 9001 certification In 1998, introduced new centrifugal compressor design technology From North Research & Engineering Corporation (NREC, USA) Upgrade compressor design capability comprehensively In 1999, supply R 134 a centrifugal chillers to Qin. Shan nuclear Power plant. Nice feedback till now In 2001, new generation R 134 a, two compression stage, Low temperature centrifugal chiller (-15℃)

Factory Introduction History From 1993, General cooperated with York for Producing R 123 a centrifugal chiller In 1994, developed independently compatible centrifugal Chiller for both R 134 and R 11 which won government Environmental protection reward In 1996, obtained ISO 9001 certification In 1998, introduced new centrifugal compressor design technology From North Research & Engineering Corporation (NREC, USA) Upgrade compressor design capability comprehensively In 1999, supply R 134 a centrifugal chillers to Qin. Shan nuclear Power plant. Nice feedback till now In 2001, new generation R 134 a, two compression stage, Low temperature centrifugal chiller (-15℃)

Factory Introduction In 2000, imported ANSYS (USA) hydrokinetics analysis software to further improve compressor design capability In 2004, General joined hands with Midea. In 2006, launch the VFD/VSD centrifugal chiller. Complete the product line in water cooled centrifugal chiller, screw chiller, Scroll chiller and all kinds of aircooled chiller. 46 year experience on chiller Solid Developing Steps Leading Technology

Factory Introduction In 2000, imported ANSYS (USA) hydrokinetics analysis software to further improve compressor design capability In 2004, General joined hands with Midea. In 2006, launch the VFD/VSD centrifugal chiller. Complete the product line in water cooled centrifugal chiller, screw chiller, Scroll chiller and all kinds of aircooled chiller. 46 year experience on chiller Solid Developing Steps Leading Technology

Air Cooled Chiller Product lineup

Air Cooled Chiller Product lineup

Product line Up New Reversed M shape heat exchanger 360 k. W 450 k. W 720 k. W 800 k. W 600 k. W 900 k. W

Product line Up New Reversed M shape heat exchanger 360 k. W 450 k. W 720 k. W 800 k. W 600 k. W 900 k. W

Product Line Up V shape heat exchanger 250 k. W 350 k. W p 250+250=500 Kw p 250+350=600 Kw p 350+350=700 Kw Max 2 units can be combined together before ex-factory.

Product Line Up V shape heat exchanger 250 k. W 350 k. W p 250+250=500 Kw p 250+350=600 Kw p 350+350=700 Kw Max 2 units can be combined together before ex-factory.

Product Lineup Nomenclature R 134 a LS B LG C W 250 /M M, A: CE certification 250: nominal cooling capacity (KW) W: Air-cooled condenser C: R 134 a;omit for R 22 LG: screw chiller B: semi-hermetic compressor LS: water chiller

Product Lineup Nomenclature R 134 a LS B LG C W 250 /M M, A: CE certification 250: nominal cooling capacity (KW) W: Air-cooled condenser C: R 134 a;omit for R 22 LG: screw chiller B: semi-hermetic compressor LS: water chiller

Air Cooled Chiller Product Features

Air Cooled Chiller Product Features

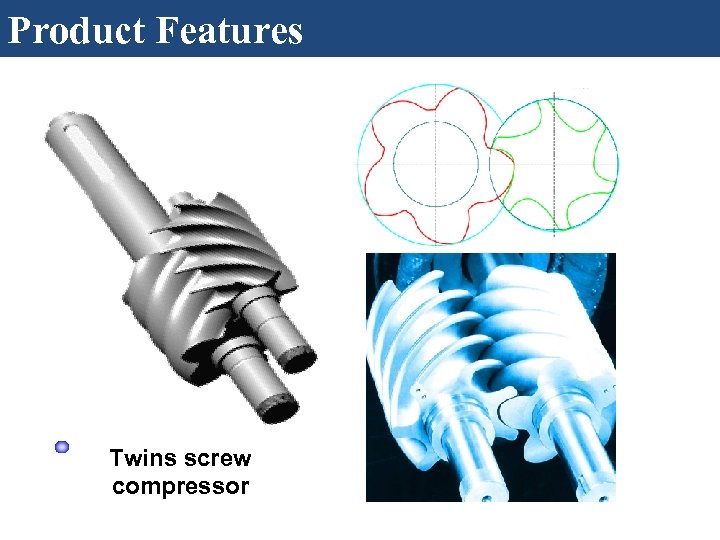

Product Features Compressor Reversed M shape Bitzer High efficiency type V shape ØFusheng screw compressor (R 134 a system) ØHanbell screw compressor(R 22 system)

Product Features Compressor Reversed M shape Bitzer High efficiency type V shape ØFusheng screw compressor (R 134 a system) ØHanbell screw compressor(R 22 system)

Product Features Twins screw compressor

Product Features Twins screw compressor

Product Features Air side heat-exchanger ØReversed M shape ØV shape ØHigh-efficiency copper pipe Ø Hydrophilic blue fin

Product Features Air side heat-exchanger ØReversed M shape ØV shape ØHigh-efficiency copper pipe Ø Hydrophilic blue fin

Product Features Evaporator Water side heat-exchanger Ø Shell and tube type, copper tube Ø DX without any oil return problem Ø 20 mm insulation

Product Features Evaporator Water side heat-exchanger Ø Shell and tube type, copper tube Ø DX without any oil return problem Ø 20 mm insulation

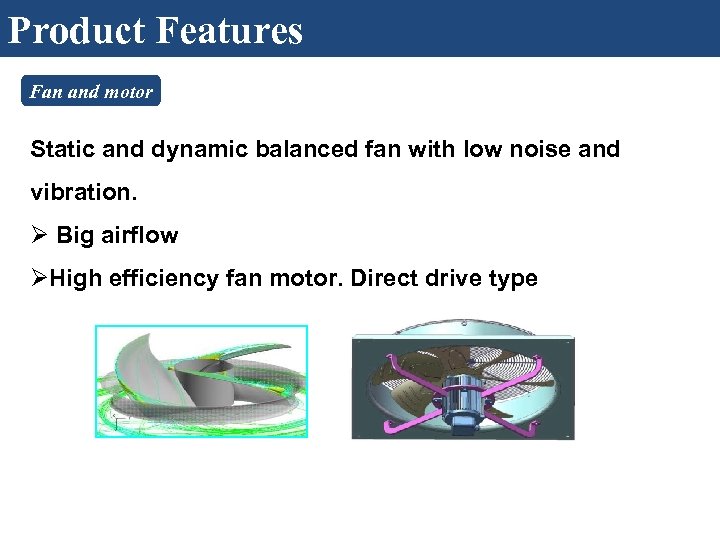

Product Features Fan and motor Static and dynamic balanced fan with low noise and vibration. Ø Big airflow ØHigh efficiency fan motor. Direct drive type

Product Features Fan and motor Static and dynamic balanced fan with low noise and vibration. Ø Big airflow ØHigh efficiency fan motor. Direct drive type

Product Features Refrigerant flow control ØDanfoss brand ØElectronic-expansion valve ØHigh precise control ØReal PID modulation

Product Features Refrigerant flow control ØDanfoss brand ØElectronic-expansion valve ØHigh precise control ØReal PID modulation

Product Features Electrical control system Control box Low voltage side Starter High voltage side

Product Features Electrical control system Control box Low voltage side Starter High voltage side

Product Features PLC & Touchable screen PLC control system : ØPowerful control function ØTouchable screen ØQuick and precise ØRemote control is available(option) ØConnecting with monitor PC is available (option)

Product Features PLC & Touchable screen PLC control system : ØPowerful control function ØTouchable screen ØQuick and precise ØRemote control is available(option) ØConnecting with monitor PC is available (option)

Product Features PLC & Touchable screen Parameter setting Function setting

Product Features PLC & Touchable screen Parameter setting Function setting

Product Features PLC & Touchable screen Working state

Product Features PLC & Touchable screen Working state

Product Protection items Water flow cutout Power Fault protection Anti-freeze protection Contactor Fault protection High-pressure alarm Discharge temperature too high Low-pressure alarm Fin temperature too high Compressor Inside Protection Water Inlet/outlet temperature sensor Oil level protection Ambient temperature sensor open/short circuit Oil pressure differential protection Coil temperature sensor open/short circuit Compressor overload protection Discharge temperature sensor open/short circuit Fan overload protection

Product Protection items Water flow cutout Power Fault protection Anti-freeze protection Contactor Fault protection High-pressure alarm Discharge temperature too high Low-pressure alarm Fin temperature too high Compressor Inside Protection Water Inlet/outlet temperature sensor Oil level protection Ambient temperature sensor open/short circuit Oil pressure differential protection Coil temperature sensor open/short circuit Compressor overload protection Discharge temperature sensor open/short circuit Fan overload protection

Air Cooled Chiller Applications

Air Cooled Chiller Applications

Product Application range § Applicable ambient temp. range: 56 ℃ Series R 22 R 134 a(High ambient temp. type) Ambient temp. 20℃~45℃ 20℃~43℃ 20℃~56℃ § Water outlet temp. adjustable range: Series R 22 units R 134 a units Chilled water outlet temp. 5℃~15℃ 4℃~17℃

Product Application range § Applicable ambient temp. range: 56 ℃ Series R 22 R 134 a(High ambient temp. type) Ambient temp. 20℃~45℃ 20℃~43℃ 20℃~56℃ § Water outlet temp. adjustable range: Series R 22 units R 134 a units Chilled water outlet temp. 5℃~15℃ 4℃~17℃

Product Application range No Content Running range 1 Ambient Temp. R 134 a : 20~43℃ 2 Outlet water Temp. 4℃~17℃ 3 Water flow volume Rating flow volume +20% 4 Max inlet/outlet Temp. difference 7℃ 5 Fouling factor(m 2 C/Kw) 0. 086 6 Power supply 380 V-3 P-50 Hz standard 415 V-3 P-50 Hz; 380 V-3 P-60 Hz as option 7 Voltage tolerance Rating Voltage +10% 8 Phase tolerance +2% 9 Power supply frequency +2% 10 Starter Delta-star 11 Evaporator max. working pressure 1. 0 MPa 12 Compressor Max. start count 4 times/h 13 Environment quality High corrosive environment and high humidity should be avoid 14 Drainage system The height of pounding should not be higher than the base of the unit on the spot. / High temp. type: 20℃~56℃

Product Application range No Content Running range 1 Ambient Temp. R 134 a : 20~43℃ 2 Outlet water Temp. 4℃~17℃ 3 Water flow volume Rating flow volume +20% 4 Max inlet/outlet Temp. difference 7℃ 5 Fouling factor(m 2 C/Kw) 0. 086 6 Power supply 380 V-3 P-50 Hz standard 415 V-3 P-50 Hz; 380 V-3 P-60 Hz as option 7 Voltage tolerance Rating Voltage +10% 8 Phase tolerance +2% 9 Power supply frequency +2% 10 Starter Delta-star 11 Evaporator max. working pressure 1. 0 MPa 12 Compressor Max. start count 4 times/h 13 Environment quality High corrosive environment and high humidity should be avoid 14 Drainage system The height of pounding should not be higher than the base of the unit on the spot. / High temp. type: 20℃~56℃

Application Simple structure and simple application Low initial investment and maintenance cost Air Duct system Air Handling units Air Cooled Screw Chiller Chilled Water Pipe Chilled Water Pump

Application Simple structure and simple application Low initial investment and maintenance cost Air Duct system Air Handling units Air Cooled Screw Chiller Chilled Water Pipe Chilled Water Pump

The Applied Location Comfort cooling & Process application: Restaurant, hotel , hospital, school, office, factory and etc. Place limit Install on the roof or ground Lack Water Popular used in the place lack of water Simple system No need cooling towers , cooling pumps.

The Applied Location Comfort cooling & Process application: Restaurant, hotel , hospital, school, office, factory and etc. Place limit Install on the roof or ground Lack Water Popular used in the place lack of water Simple system No need cooling towers , cooling pumps.

Features Application Air-cooled system, no need cooling water tower at the condensing side, easy to install.

Features Application Air-cooled system, no need cooling water tower at the condensing side, easy to install.

Application Reverse M shape Air-cooled Screw Chiller 360 KW 900 KW Different capacity in single package can be choose freely. u 360 Kw 450 Kw 600 Kw with Single compressor u 720 Kw 800 Kw 900 Kw with Dual compressors u Higher than 900 Kw cooling capacity we recommend to use multi water system

Application Reverse M shape Air-cooled Screw Chiller 360 KW 900 KW Different capacity in single package can be choose freely. u 360 Kw 450 Kw 600 Kw with Single compressor u 720 Kw 800 Kw 900 Kw with Dual compressors u Higher than 900 Kw cooling capacity we recommend to use multi water system

Application V shape Air-cooled Screw Chiller 250 KW 350 KW Modular chiller can be combined together to supply different cooling capacity. u 250 k. W unit, they can combined 8 units together. u 350 k. W unit, they can combined 8 units together. u Capacity range from 250 Kw to 2800 Kw

Application V shape Air-cooled Screw Chiller 250 KW 350 KW Modular chiller can be combined together to supply different cooling capacity. u 250 k. W unit, they can combined 8 units together. u 350 k. W unit, they can combined 8 units together. u Capacity range from 250 Kw to 2800 Kw

Application System sketch

Application System sketch

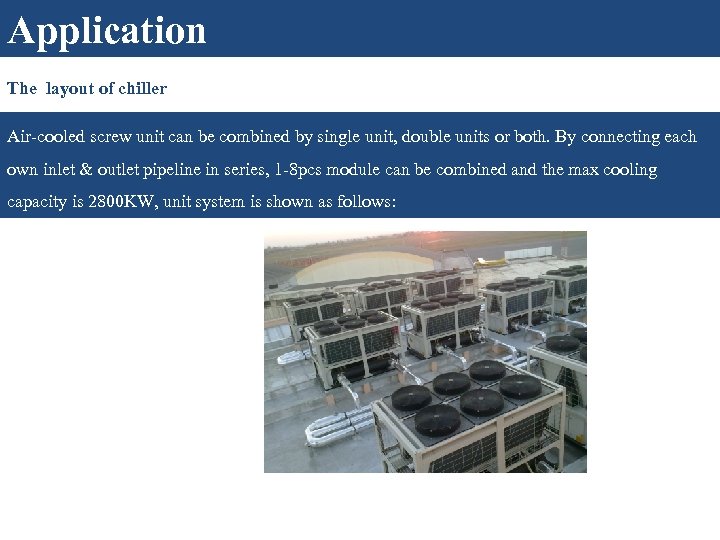

Application The layout of chiller Air-cooled screw unit can be combined by single unit, double units or both. By connecting each own inlet & outlet pipeline in series, 1 -8 pcs module can be combined and the max cooling capacity is 2800 KW, unit system is shown as follows:

Application The layout of chiller Air-cooled screw unit can be combined by single unit, double units or both. By connecting each own inlet & outlet pipeline in series, 1 -8 pcs module can be combined and the max cooling capacity is 2800 KW, unit system is shown as follows:

Application System sketch Water flow switch: It can be used to protect the chiller, when it check the water flow rate is lower than normal level, it will get the chiller stop work. And usually it is installed on the outlet pipe of evaporator.

Application System sketch Water flow switch: It can be used to protect the chiller, when it check the water flow rate is lower than normal level, it will get the chiller stop work. And usually it is installed on the outlet pipe of evaporator.

Air Cooled Chiller Certifications

Air Cooled Chiller Certifications

Certifications CE

Certifications CE

Certifications

Certifications

Air Cooled Chiller Reference projects

Air Cooled Chiller Reference projects

Reference projects Airport LSBLGCW 250*15 Units Maputo International Airport , Mozambique

Reference projects Airport LSBLGCW 250*15 Units Maputo International Airport , Mozambique

Reference projects Airport LSBLGCW 350*4 Units Jakarta International Airport, Indonesia

Reference projects Airport LSBLGCW 350*4 Units Jakarta International Airport, Indonesia

Reference projects Factory Castagna Univel factory, Italy

Reference projects Factory Castagna Univel factory, Italy

Reference projects Factory • Costra Media factory, Dubai UAE • 250 KW 6 units Working temp up to 52 ℃

Reference projects Factory • Costra Media factory, Dubai UAE • 250 KW 6 units Working temp up to 52 ℃

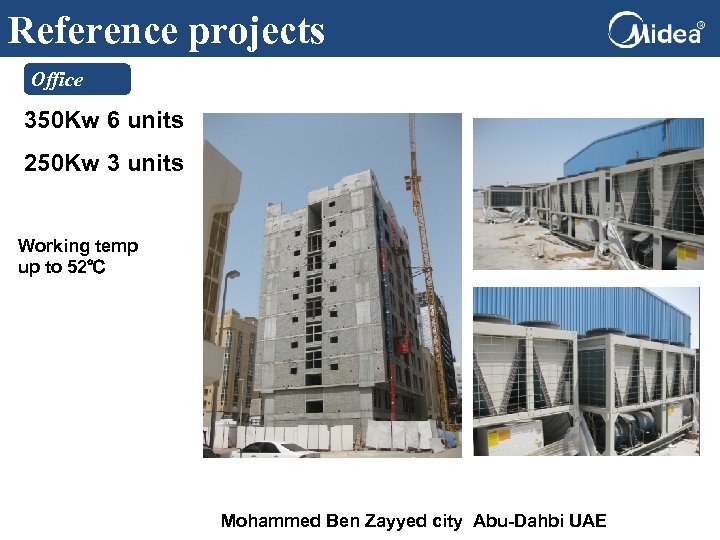

Reference projects Office 350 Kw 6 units 250 Kw 3 units Working temp up to 52℃ Mohammed Ben Zayyed city Abu-Dahbi UAE

Reference projects Office 350 Kw 6 units 250 Kw 3 units Working temp up to 52℃ Mohammed Ben Zayyed city Abu-Dahbi UAE

Reference projects Office Lanco Hill Group , Hyderabad, India; 350 Kw 2 units High ambient type

Reference projects Office Lanco Hill Group , Hyderabad, India; 350 Kw 2 units High ambient type

Reference projects Supermarket • Ufa Supermarket, Russia • 250 KW 2 units

Reference projects Supermarket • Ufa Supermarket, Russia • 250 KW 2 units

Reference projects Station Chinese high speed rail way stations, China 350 Kw 29 units

Reference projects Station Chinese high speed rail way stations, China 350 Kw 29 units

Thank you!

Thank you!