fbfba7e0b42e43cc6a9946282ed966ba.ppt

- Количество слайдов: 20

AIDC Overview Oct 26, 2006 Hershey, PA Rob Leibrandt Robert. leibrandt@osd. mil

ISO/IEC JTC 1 SC 31 – Automatic Identification & Data Capture Techniques SC 31 Convener – Charles Biss • Working Group on Data Carriers (SC 31/WG 1) – Convener: Sprague Ackley (United States), E-Mail: sackley@compuserve. com • Working Group on Data Structure (SC 31/WG 2) – Convener: Toshihiro Yoshioka (Japan), E-Mail: toshihiro. yoshioka@ai-soken. com • Working Group on Conformance (SC 31/WG 3) – Convener: Charles Biss (United States), E-Mail: chuck. biss@handheld. com • Working Group on RFID for Item Management (SC 31/WG 4) – Convener: Henri Barthel (Belgium), E-Mail: henri. barthel@gs 1. org • Working Group on Real Time Locating Systems (RTLS) (SC 31/WG 5) – Convener: Marsha Harmon (United States), E-mail: marsha. harmon@qed. org

Some SC 31 Work Areas • Linear Bar Codes and 2 -D Symbols – Information Technology, Automatic Identification and Data Capture Techniques Bar Code Print Quality Test Specification – Information Technology, Automatic Identification and Data Capture Techniques – Bar Code Verifier Conformance Specification – Information Technology - Automatic Identification and Data Capture Techniques Bar Code Scanner and Decoder Performance Testing • Unique IDentification – Information Technology — Unique Identification — ISO/IEC 15459 • • Part 1: Unique Identification of Transport Units Part 2: Registration procedures Part 3: Common rules for unique identification Part 4: Unique item identification Part 5: Unique Identification of Returnable Transport Items (RTIs) Part 6: Unique identification for product groupings Radio Frequency Identification – Information Technology - Automatic Identification and Data Capture Techniques RFID Device Performance Test Methods – Radio Frequency Identification (RFID) for Item Management • Real-Time Locating Systems – ISO/IEC 24730 - Real Time Locating Systems (RTLS)

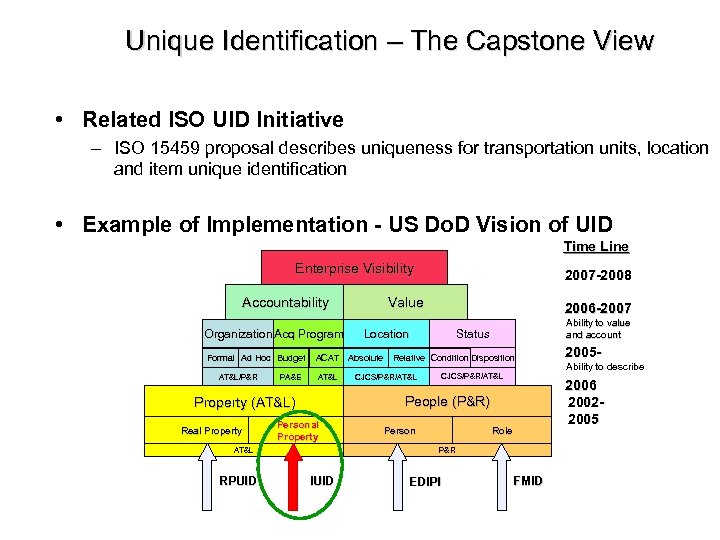

Unique Identification – The Capstone View • Related ISO UID Initiative – ISO 15459 proposal describes uniqueness for transportation units, location and item unique identification • Example of Implementation - US Do. D Vision of UID Time Line Enterprise Visibility Accountability Organization Acq Program Formal Ad Hoc Budget AT&L/P&R PA&E AT&L 2006 -2007 Location Ability to value and account Status CJCS/P&R/AT&L Personal Property Person Role P&R IUID EDIPI 2005 Ability to describe 2006 20022005 People (P&R) AT&L RPUID Value ACAT Absolute Relative Condition Disposition Property (AT&L) Real Property 2007 -2008 FMID

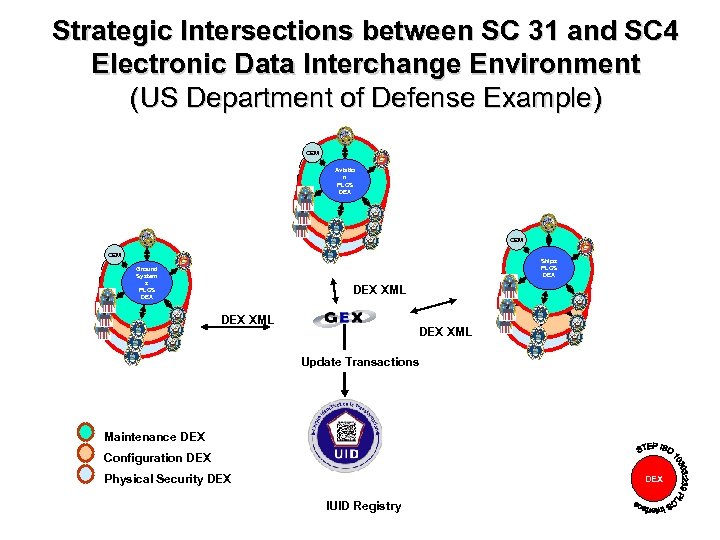

Strategic Intersections between SC 31 and SC 4 Electronic Data Interchange Environment (US Department of Defense Example) OEM OEM Aviatio Groun n d PLCS Groun Syste DEX d ms Syste PLCS ms DEX PLCS DEX OEM OEM OEM Ground System Groun ds Groun PLCS Syste DEX d ms Syste PLCS ms DEX PLCS DEX OEM DEX XML Ships PLCS Groun DEX d Groun Syste d ms Syste PLCS ms DEX PLCS DEX Update Transactions Maintenance DEX Configuration DEX Physical Security DEX IUID Registry

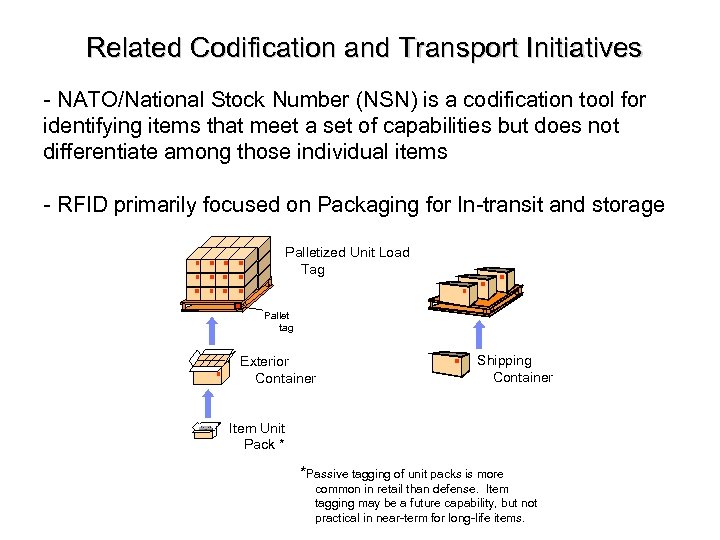

Related Codification and Transport Initiatives - NATO/National Stock Number (NSN) is a codification tool for identifying items that meet a set of capabilities but does not differentiate among those individual items - RFID primarily focused on Packaging for In-transit and storage Palletized Unit Load Tag YES Pallet tag Exterior Container YES Shipping Container YES Item Unit Pack * NO *Passive tagging of unit packs is more common in retail than defense. Item tagging may be a future capability, but not practical in near-term for long-life items.

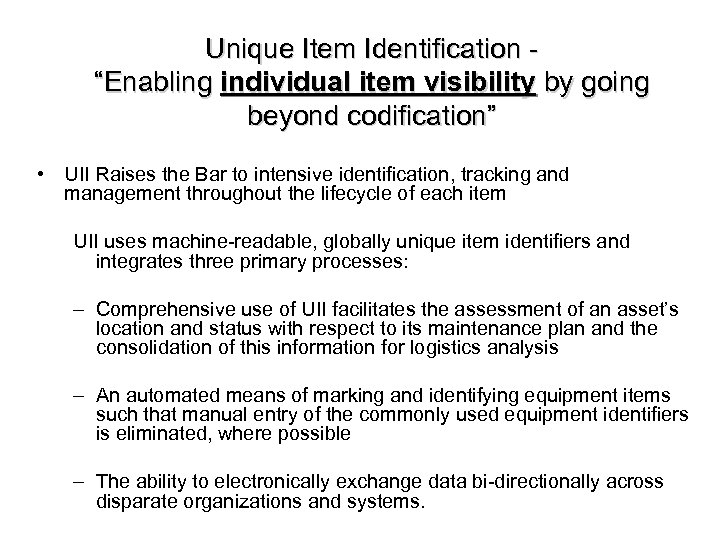

Unique Item Identification “Enabling individual item visibility by going beyond codification” • UII Raises the Bar to intensive identification, tracking and management throughout the lifecycle of each item UII uses machine-readable, globally unique item identifiers and integrates three primary processes: – Comprehensive use of UII facilitates the assessment of an asset’s location and status with respect to its maintenance plan and the consolidation of this information for logistics analysis – An automated means of marking and identifying equipment items such that manual entry of the commonly used equipment identifiers is eliminated, where possible – The ability to electronically exchange data bi-directionally across disparate organizations and systems.

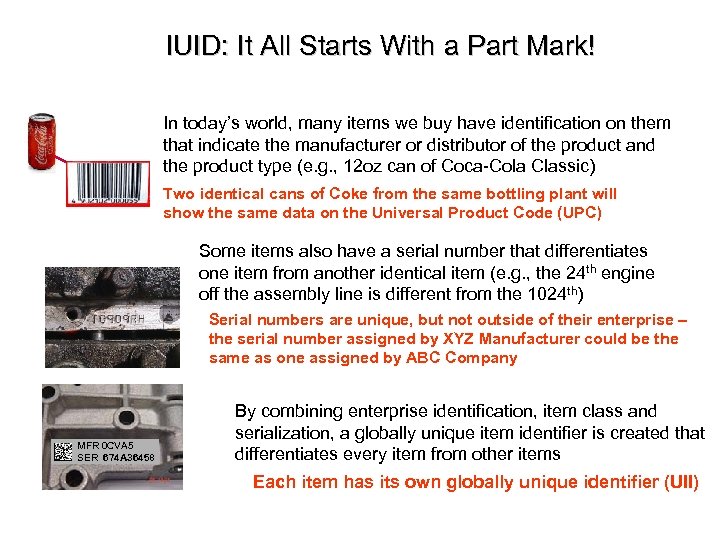

IUID: It All Starts With a Part Mark! In today’s world, many items we buy have identification on them that indicate the manufacturer or distributor of the product and the product type (e. g. , 12 oz can of Coca-Cola Classic) Two identical cans of Coke from the same bottling plant will show the same data on the Universal Product Code (UPC) Some items also have a serial number that differentiates one item from another identical item (e. g. , the 24 th engine off the assembly line is different from the 1024 th) Serial numbers are unique, but not outside of their enterprise – the serial number assigned by XYZ Manufacturer could be the same as one assigned by ABC Company MFR 0 CVA 5 SER 674 A 36458 By combining enterprise identification, item class and serialization, a globally unique item identifier is created that differentiates every item from other items Each item has its own globally unique identifier (UII)

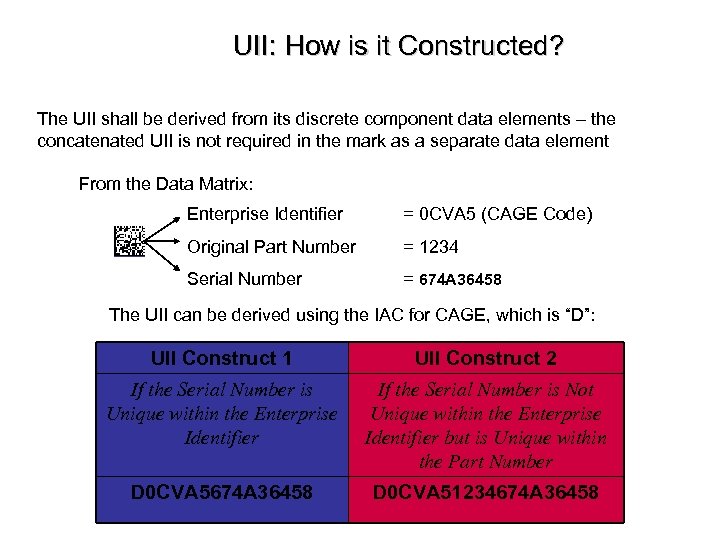

UII: How is it Constructed? The UII shall be derived from its discrete component data elements – the concatenated UII is not required in the mark as a separate data element From the Data Matrix: Enterprise Identifier = 0 CVA 5 (CAGE Code) Original Part Number = 1234 Serial Number = 674 A 36458 The UII can be derived using the IAC for CAGE, which is “D”: UII Construct 1 UII Construct 2 If the Serial Number is Unique within the Enterprise Identifier If the Serial Number is Not Unique within the Enterprise Identifier but is Unique within the Part Number D 0 CVA 5674 A 36458 D 0 CVA 51234674 A 36458

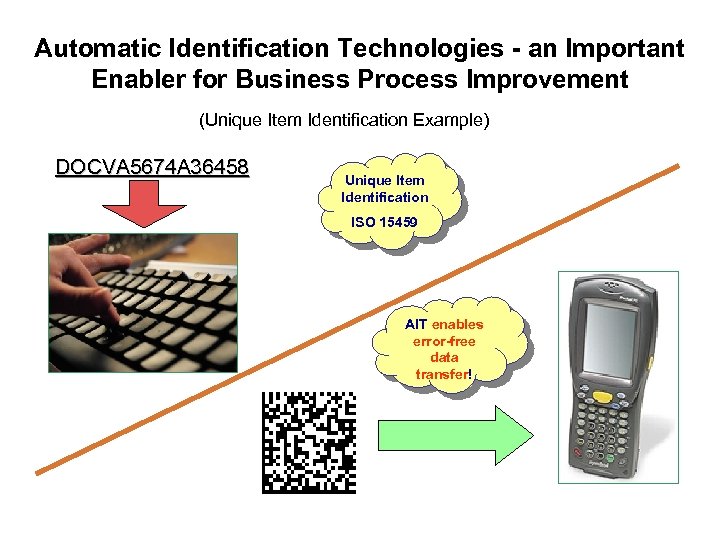

Automatic Identification Technologies - an Important Enabler for Business Process Improvement (Unique Item Identification Example) DOCVA 5674 A 36458 Unique Item Identification ISO 15459 AIT enables error-free data transfer!

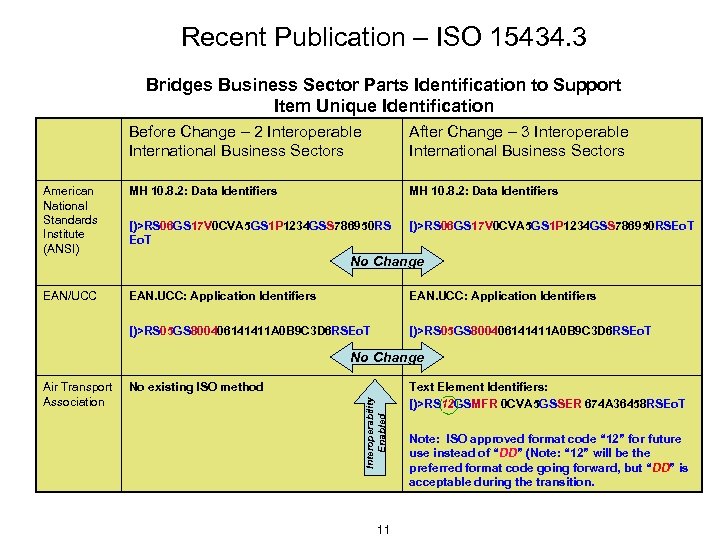

Recent Publication – ISO 15434. 3 Bridges Business Sector Parts Identification to Support Item Unique Identification Before Change – 2 Interoperable International Business Sectors After Change – 3 Interoperable International Business Sectors American National Standards Institute (ANSI) MH 10. 8. 2: Data Identifiers [)>RS 06 GS 17 V 0 CVA 5 GS 1 P 1234 GSS 786950 RS Eo. T [)>RS 06 GS 17 V 0 CVA 5 GS 1 P 1234 GSS 786950 RSEo. T EAN/UCC EAN. UCC: Application Identifiers [)>RS 05 GS 800406141411 A 0 B 9 C 3 D 6 RSEo. T No Change No existing ISO method Interoperability Enabled Air Transport Association 11 Text Element Identifiers: [)>RS 12 GSMFR 0 CVA 5 GSSER 674 A 36458 RSEo. T Note: ISO approved format code “ 12” for future use instead of “DD” (Note: “ 12” will be the preferred format code going forward, but “DD” is acceptable during the transition.

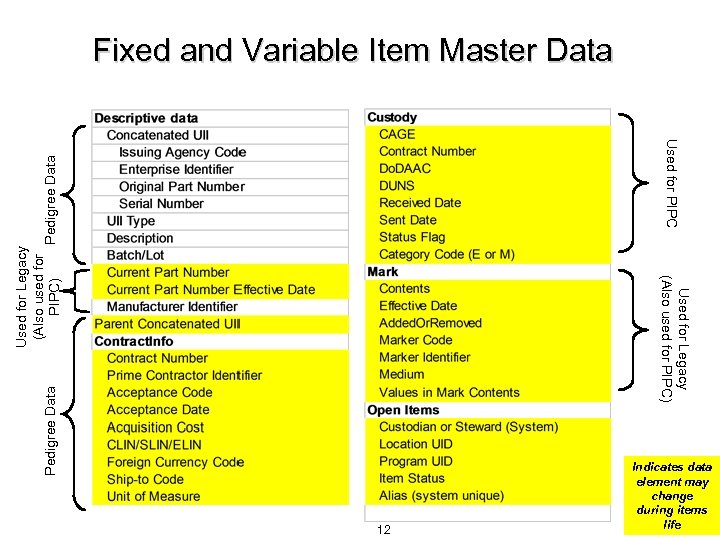

Fixed and Variable Item Master Data Pedigree Data Used for Legacy (Also used for PIPC) Used for Legacy (Also used for Pedigree Data PIPC) Used for PIPC 12 Indicates data element may change during items life

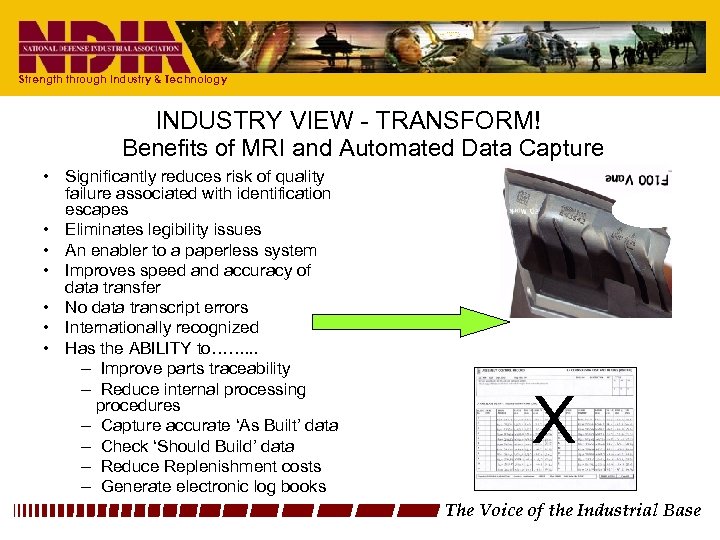

Strength through Industry & Technology INDUSTRY VIEW - TRANSFORM! Benefits of MRI and Automated Data Capture • Significantly reduces risk of quality failure associated with identification escapes • Eliminates legibility issues • An enabler to a paperless system • Improves speed and accuracy of data transfer • No data transcript errors • Internationally recognized • Has the ABILITY to……. . . – Improve parts traceability – Reduce internal processing procedures – Capture accurate ‘As Built’ data – Check ‘Should Build’ data – Reduce Replenishment costs – Generate electronic log books X The Voice of the Industrial Base

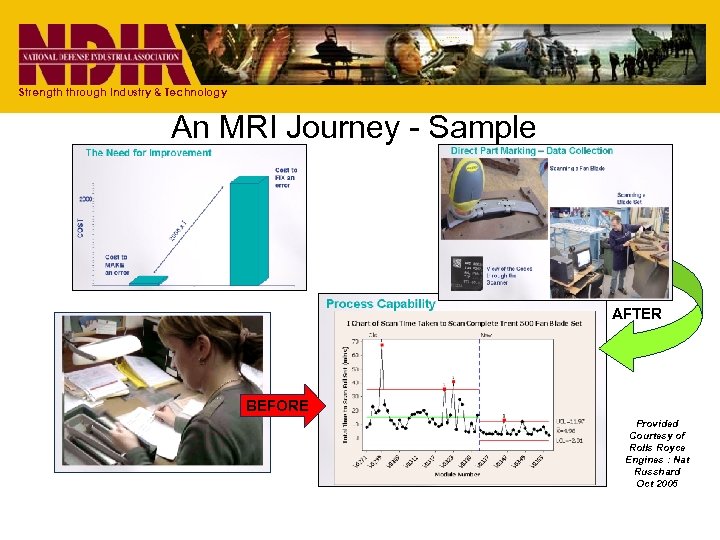

Strength through Industry & Technology An MRI Journey - Sample AFTER BEFORE Provided Courtesy of Rolls Royce Engines : Nat Russhard Oct 2005 Result: Achieved savings across aerospace engine manufacturing of as much as 4% of direct labor

Unique Item Identification is Not Just a US Do. D Mandate – Very Similar Efforts are Underway by: Ford Motor Company Total Traceability Vision Unique Item Marking Sample of Commercial Companies With Proven Compliance Capability

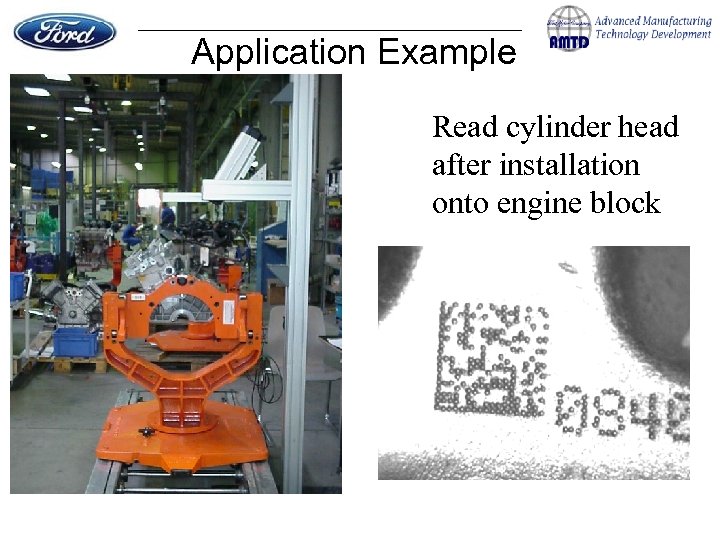

Application Example Read cylinder head after installation onto engine block

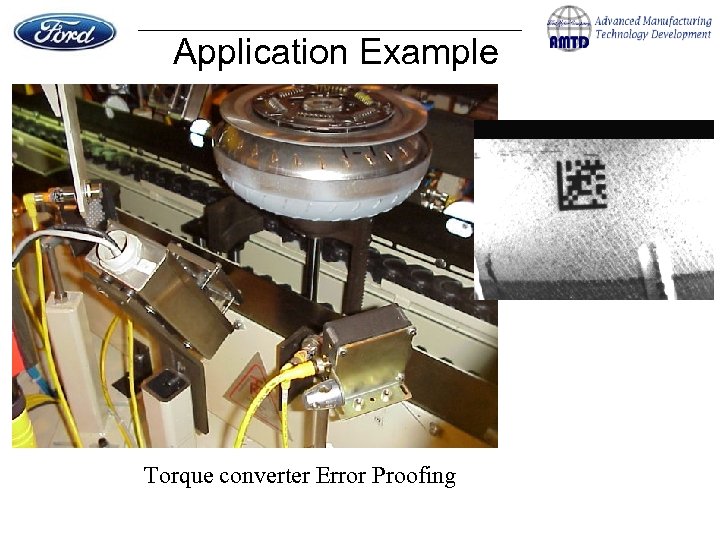

Application Example Torque converter impeller – part spinning Torque converter Error Proofing

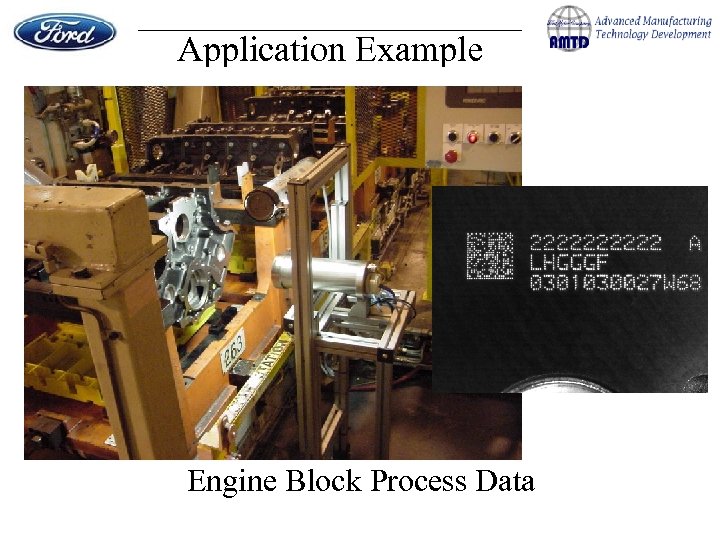

Application Example Engine Block Process Data

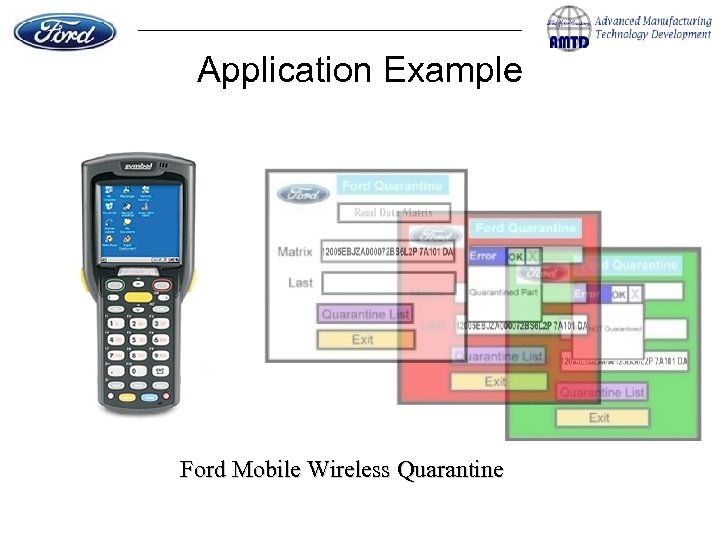

Application Example Ford Mobile Wireless Quarantine

Contact Information • Rob Leibrandt Robert. leibrandt@osd. mil (703) 695 -1099 • ISO/IEC JTC 1 SC 31 Website www. autoid. org

fbfba7e0b42e43cc6a9946282ed966ba.ppt