1864ec67934b45e7603b7a7b97e51bb3.ppt

- Количество слайдов: 42

AIAA Design/Build/Fly Competition - 2011 University of California, Irvine – UCI Team Caddyshack

Introduction The UCI AIAA student chapter participates in the annual AIAA Design Build Fly (DBF) competition. This competition gives the engineering students a chance to apply classroom knowledge, gain hands on skills, and experience an industry level project-development from conceptual design to building and testing an optimized final product. Over the past 6 years this project has grown substantially in size and skill with the help of previous DBF students, currently working in the aerospace industry, who meeting with the current team weekly.

Outline Introduction Team Organization 2011 Competition Conceptual Design Preliminary Design Detailed Design Manufacturing Testing Expected Final Performance

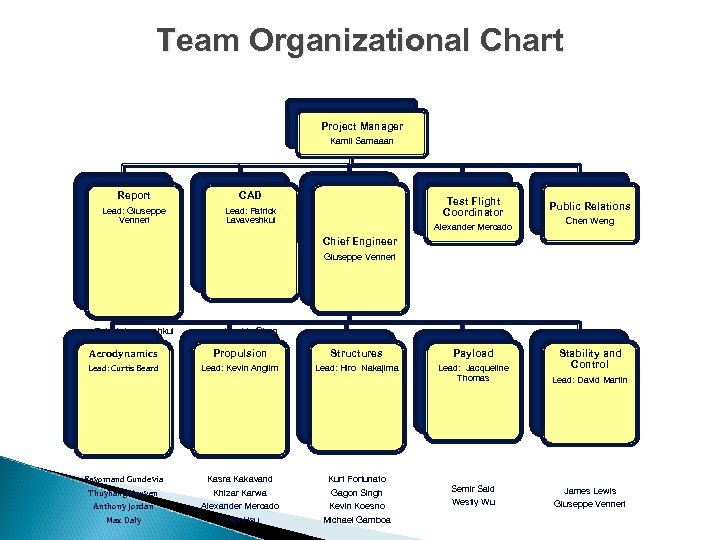

Team Organizational Chart Project Manager Kamil Samaaan Report CAD Lead: Giuseppe Venneri Lead: Patrick Lavaveshkul Test Flight Coordinator Alexander Mercado Public Relations Chen Weng Chief Engineer Giuseppe Venneri Patrick Lavaveshkul Semir Said Aerodynamics Westly Wu Lead: Curtis Beard Byron Frenkiel Rayomand Gundevia Thuyhang Nguyen Anthony Jordan Max Daly Kerchia Chen Sothea Sok Propulsion Angela Grayr Lead: Kevin Wang Erica Anglim Structures Payload Lead: Hiro Nakajima Lead: Jacqueline Thomas Lead: David Martin Kasra Kakavand Khizar Karwa Alexander Mercado Yi-lin Hsu Kurt Fortunato Gagon Singh Kevin Koesno Michael Gamboa Semir Said Westly Wu James Lewis Giuseppe Venneri Stability and Control

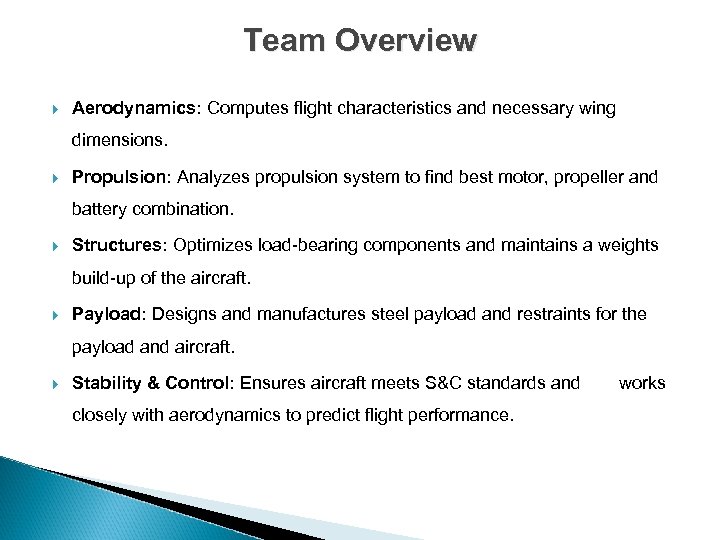

Team Overview Aerodynamics: Computes flight characteristics and necessary wing dimensions. Propulsion: Analyzes propulsion system to find best motor, propeller and battery combination. Structures: Optimizes load-bearing components and maintains a weights build-up of the aircraft. Payload: Designs and manufactures steel payload and restraints for the payload and aircraft. Stability & Control: Ensures aircraft meets S&C standards and closely with aerodynamics to predict flight performance. works

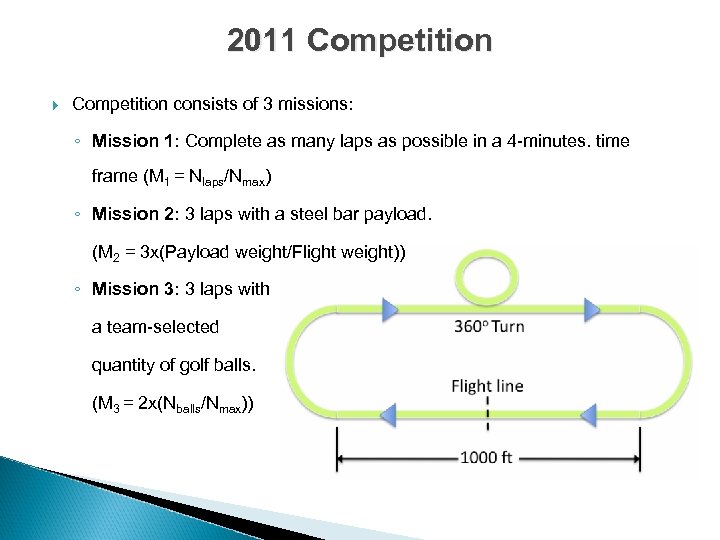

2011 Competition consists of 3 missions: ◦ Mission 1: Complete as many laps as possible in a 4 -minutes. time frame (M 1 = Nlaps/Nmax) ◦ Mission 2: 3 laps with a steel bar payload. (M 2 = 3 x(Payload weight/Flight weight)) ◦ Mission 3: 3 laps with a team-selected quantity of golf balls. (M 3 = 2 x(Nballs/Nmax))

2011 Competition (Cont. ) Constraints for 2011: ◦ Battery weight: ¾ lb ◦ 20 amp slow-blow fuse ◦ Aircraft must fit in a commercially-available carry-on suitcase. ◦ L + W + H = 45 inches (no dimension can exceed 22 in. ) ◦ Suitcase must include entire flight system, including aircraft, battery and all required parts and tools. ◦ Golf balls are regulation sized and the steel bar payload dimensions are constrained: 3 in. width x 4 in. length minimum. ◦ Aircraft must be hand-launched.

Conceptual Design Sensitivity Analysis Configuration Figures of Merit ◦ Aircraft Configuration Subsystems Selection ◦ Motor Position ◦ Landing Methods ◦ Yaw Control ◦ Wing Attachment Methods ◦ Payload Configuration Final Configuration

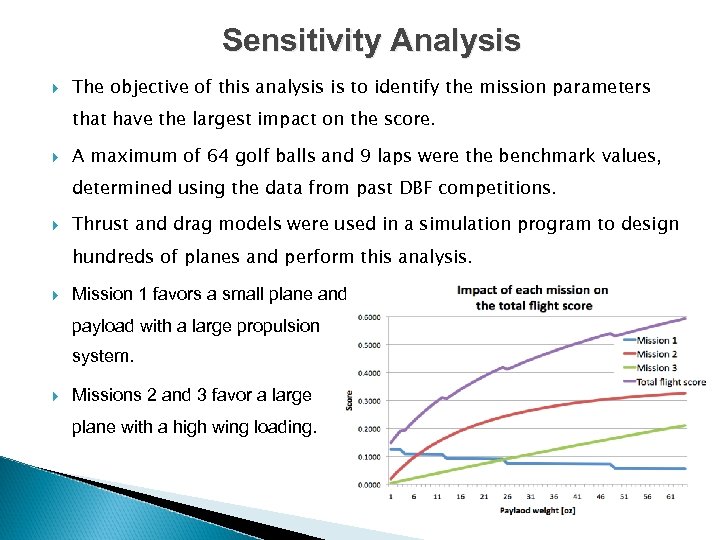

Sensitivity Analysis The objective of this analysis is to identify the mission parameters that have the largest impact on the score. A maximum of 64 golf balls and 9 laps were the benchmark values, determined using the data from past DBF competitions. Thrust and drag models were used in a simulation program to design hundreds of planes and perform this analysis. Mission 1 favors a small plane and payload with a large propulsion system. Missions 2 and 3 favor a large plane with a high wing loading.

Configuration Figures of Merit In order to select an aircraft configuration, a scoring system based on figures of merit was produced. Each was weighted based on results of the scoring analysis: ◦ System weight (35%) ◦ L/D (20%) ◦ Cargo space (15%) ◦ Maneuverability (10%) ◦ Manufacturing (10%) ◦ Hand launch (10%)

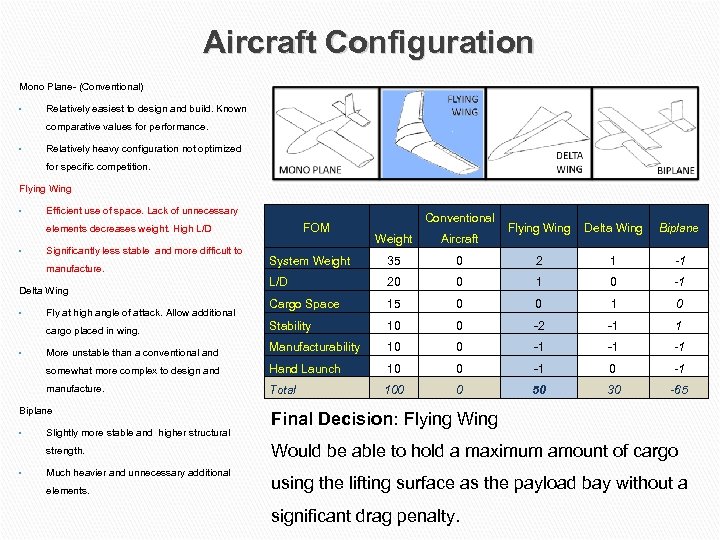

Aircraft Configuration Mono Plane- (Conventional) • Relatively easiest to design and build. Known comparative values for performance. • Relatively heavy configuration not optimized for specific competition. Flying Wing • Efficient use of space. Lack of unnecessary FOM Conventional Flying Wing Delta Wing Biplane 0 2 1 -1 20 0 1 0 -1 Cargo Space 15 0 0 1 0 cargo placed in wing. Stability 10 0 -2 -1 1 More unstable than a conventional and Manufacturability 10 0 -1 -1 -1 somewhat more complex to design and Hand Launch 10 0 -1 0 -1 manufacture. Total 100 0 50 30 -65 elements decreases weight. High L/D • Significantly less stable and more difficult to manufacture. Delta Wing • • Fly at high angle of attack. Allow additional Biplane • Slightly more stable and higher structural strength. • Much heavier and unnecessary additional elements. Weight Aircraft System Weight 35 L/D Final Decision: Flying Would be able to hold a maximum amount of cargo using the lifting surface as the payload bay without a significant drag penalty.

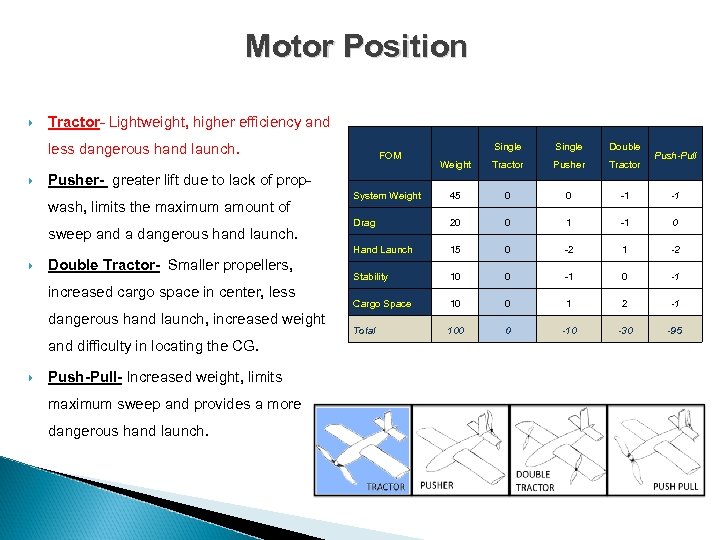

Motor Position Tractor- Lightweight, higher efficiency and Single Double Weight Tractor Pusher Tractor System Weight 45 0 0 -1 -1 Drag 20 0 1 -1 0 Hand Launch 15 0 -2 1 -2 Stability 10 0 -1 Cargo Space 10 0 1 2 -1 Total 100 0 -10 -30 -95 less dangerous hand launch. sweep and a dangerous hand launch. Double Tractor- Smaller propellers, increased cargo space in center, less dangerous hand launch, increased weight and difficulty in locating the CG. Push-Pull Pusher- greater lift due to lack of propwash, limits the maximum amount of FOM Push-Pull- Increased weight, limits maximum sweep and provides a more dangerous hand launch.

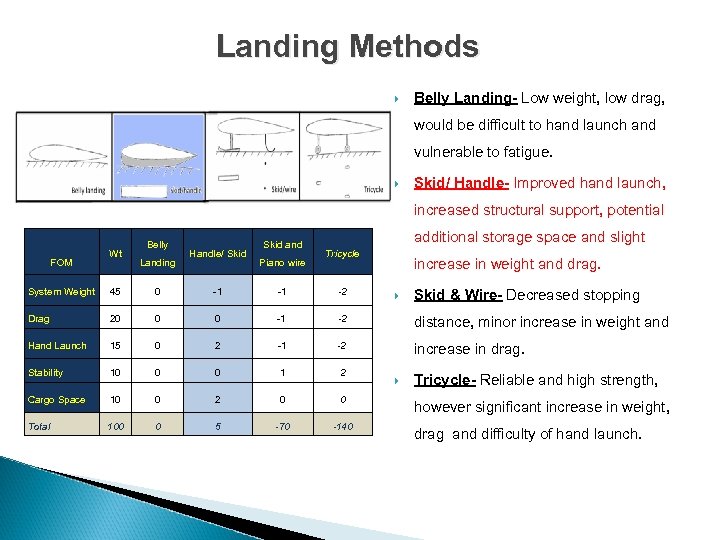

Landing Methods Belly Landing- Low weight, low drag, would be difficult to hand launch and vulnerable to fatigue. Skid/ Handle- Improved hand launch, increased structural support, potential FOM Wt Belly Landing Handle/ Skid and Piano wire additional storage space and slight Tricycle increase in weight and drag. Skid & Wire- Decreased stopping System Weight 45 0 -1 -1 -2 Drag 20 0 0 -1 -2 distance, minor increase in weight and Hand Launch 15 0 2 -1 -2 increase in drag. Stability 10 0 0 1 2 Cargo Space 10 0 2 0 0 Total 100 0 5 -70 -140 Tricycle- Reliable and high strength, however significant increase in weight, drag and difficulty of hand launch.

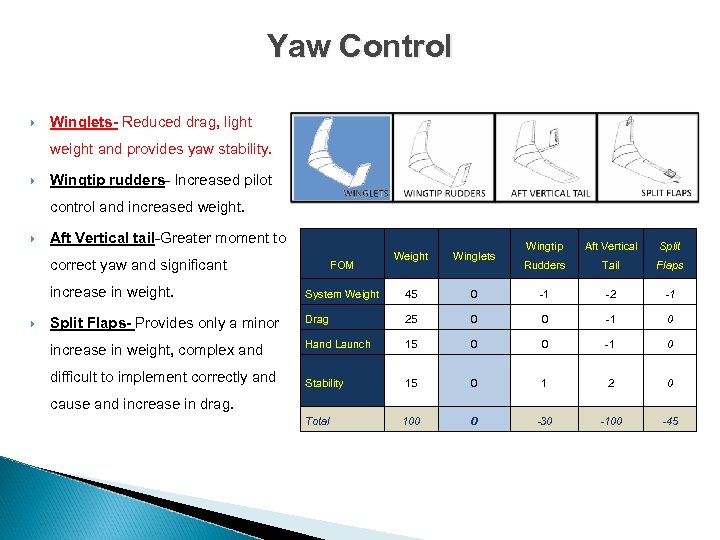

Yaw Control Winglets- Reduced drag, light weight and provides yaw stability. Wingtip rudders- Increased pilot control and increased weight. Aft Vertical tail-Greater moment to correct yaw and significant FOM Weight Winglets Wingtip Aft Vertical Split Rudders Tail Flaps increase in weight. System Weight 45 0 -1 -2 -1 Split Flaps- Provides only a minor Drag 25 0 0 -1 0 increase in weight, complex and Hand Launch 15 0 0 -1 0 Stability 15 0 1 2 0 Total 100 0 -30 -100 -45 difficult to implement correctly and cause and increase in drag.

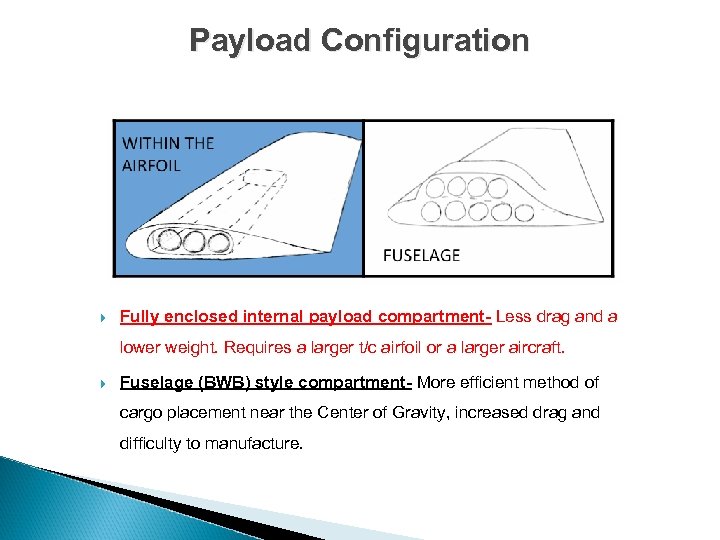

Payload Configuration Fully enclosed internal payload compartment- Less drag and a lower weight. Requires a larger t/c airfoil or a larger aircraft. Fuselage (BWB) style compartment- More efficient method of cargo placement near the Center of Gravity, increased drag and difficulty to manufacture.

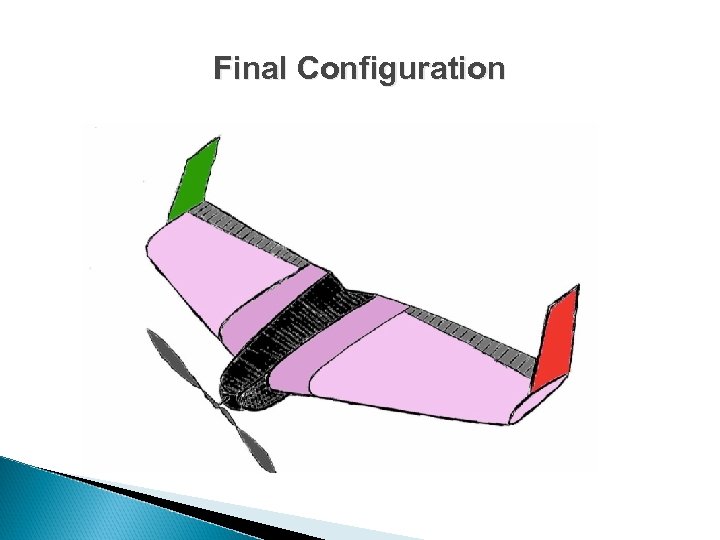

Final Configuration

Preliminary Design and Optimization Programs Design Methodology ◦ Mean Aerodynamic Chord Mission Model ◦ Winglets Aerodynamics ◦ Airfoil Selection ◦ Wing Sizing Propulsion Sizing Drag Lift Stability and Control

Programs Used During Design and Optimization Solid. Works: used to model aircraft prototypes and to help determine airfoil selection XFOIL: Used to analyze possible airfoil choices for aerodynamic characteristics Microsoft Excel: Used extensively for data analysis, storage and graphing AVL: Used for flight-dynamic analysis and to ensure overall stability of the aircraft MATLAB: Used to create an optimization program

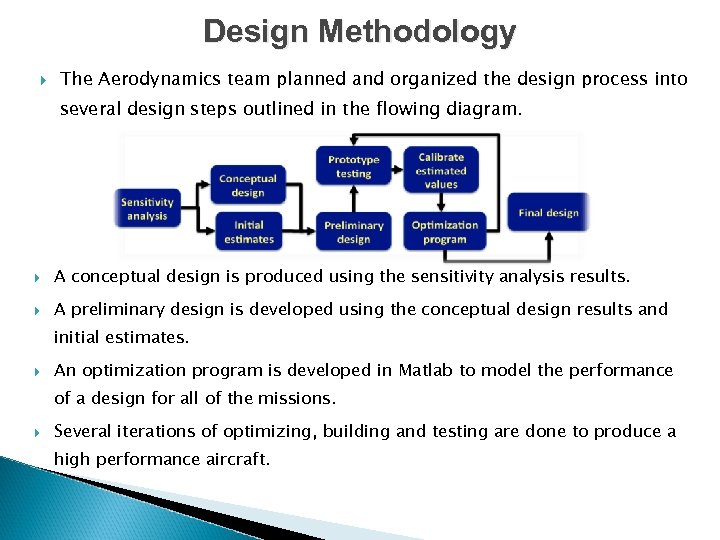

Design Methodology The Aerodynamics team planned and organized the design process into several design steps outlined in the flowing diagram. A conceptual design is produced using the sensitivity analysis results. A preliminary design is developed using the conceptual design results and initial estimates. An optimization program is developed in Matlab to model the performance of a design for all of the missions. Several iterations of optimizing, building and testing are done to produce a high performance aircraft.

Mission Profile Optimization Program The mission profile was modeled using for loops and while loops in MATLAB. The aerodynamic and propulsion forces were computed for every loopiteration to determine the change in position and velocity of the aircraft during that period of time. The program assumed some initial conditions for takeoff such as hand launch velocity and wind conditions. The mission model program computes: ◦ the energy used ◦ the number of laps completed in 4 minutes ◦ The maximum payload capacity a design could carry. The total flight score is computed for several designs which resulted in an optimized design.

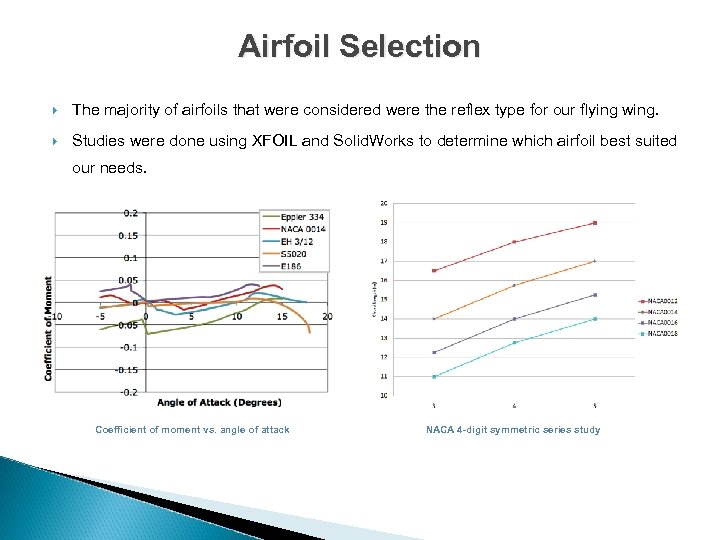

Airfoil Selection The majority of airfoils that were considered were the reflex type for our flying wing. Studies were done using XFOIL and Solid. Works to determine which airfoil best suited our needs. Coefficient of moment vs. angle of attack NACA 4 -digit symmetric series study

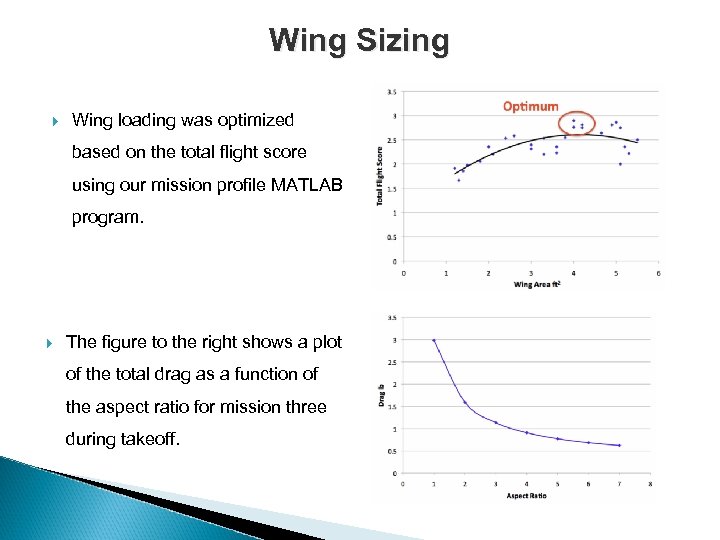

Wing Sizing Wing loading was optimized based on the total flight score using our mission profile MATLAB program. The figure to the right shows a plot of the total drag as a function of the aspect ratio for mission three during takeoff.

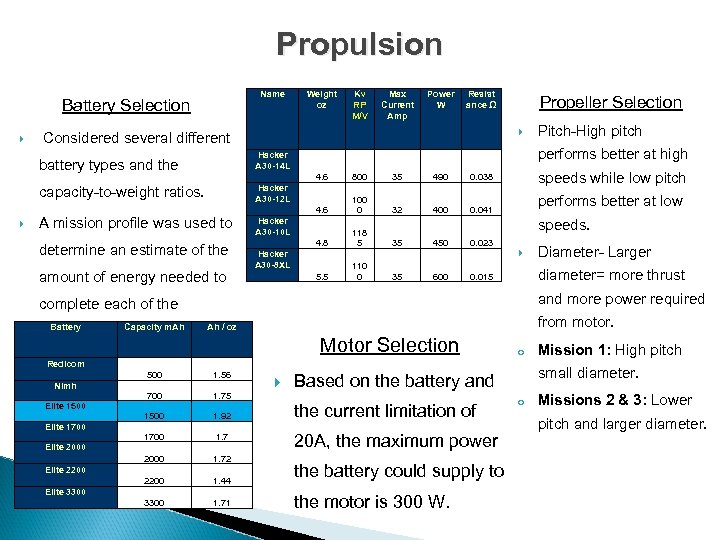

Propulsion Name Battery Selection Kv RP M/V Max Current Amp Power W Resist ance Ω Propeller Selection Considered several different battery types and the Hacker A 30 -12 L 4. 6 A mission profile was used to determine an estimate of the amount of energy needed to 800 35 490 4. 6 100 0 32 400 0. 041 4. 8 118 5 35 450 0. 023 5. 5 110 0 35 600 speeds while low pitch 0. 038 0. 015 Hacker A 30 -10 L Hacker A 30 -8 XL performs better at low speeds. Capacity m. Ah and more power required from motor. Ah / oz Motor Selection o Redicom 500 Elite 1700 1. 75 1500 1. 92 1700 1. 72 2200 Elite 1500 1. 56 2000 Nimh Diameter- Larger diameter= more thrust complete each of the Battery missions. Pitch-High pitch performs better at high Hacker A 30 -14 L capacity-to-weight ratios. Weight oz 1. 44 3300 1. 71 Elite 2000 Elite 2200 Elite 3300 small diameter. Based on the battery and the current limitation of 20 A, the maximum power the battery could supply to the motor is 300 W. Mission 1: High pitch o Missions 2 & 3: Lower pitch and larger diameter.

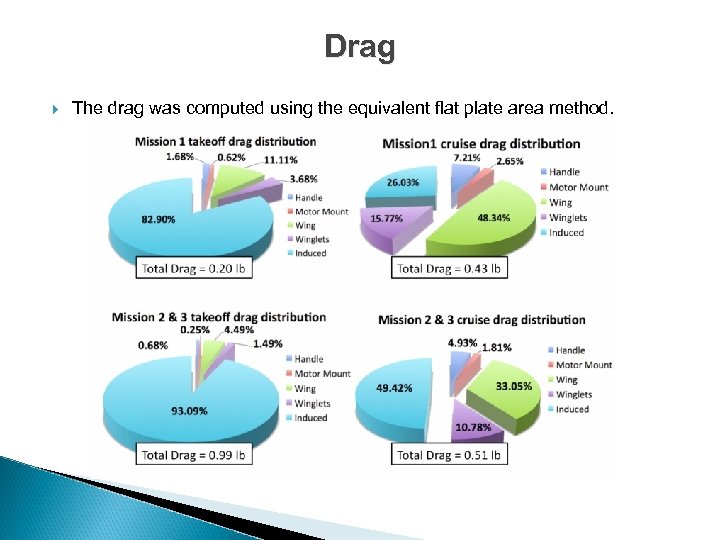

Drag The drag was computed using the equivalent flat plate area method.

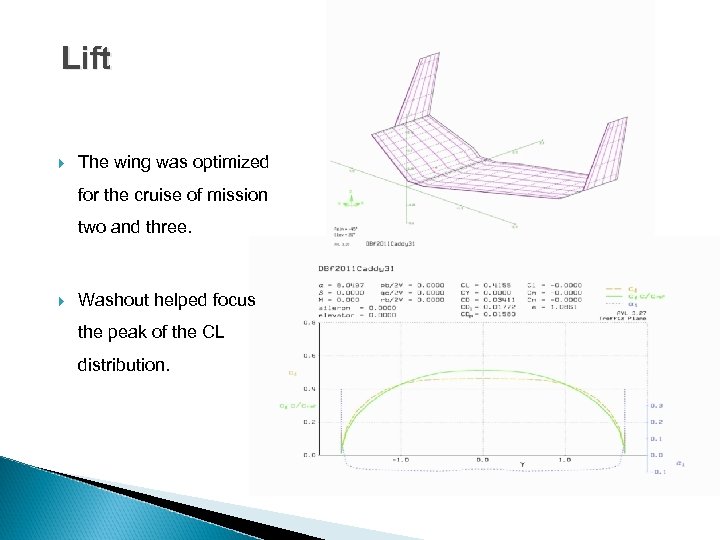

Lift The wing was optimized for the cruise of mission two and three. Washout helped focus the peak of the CL distribution.

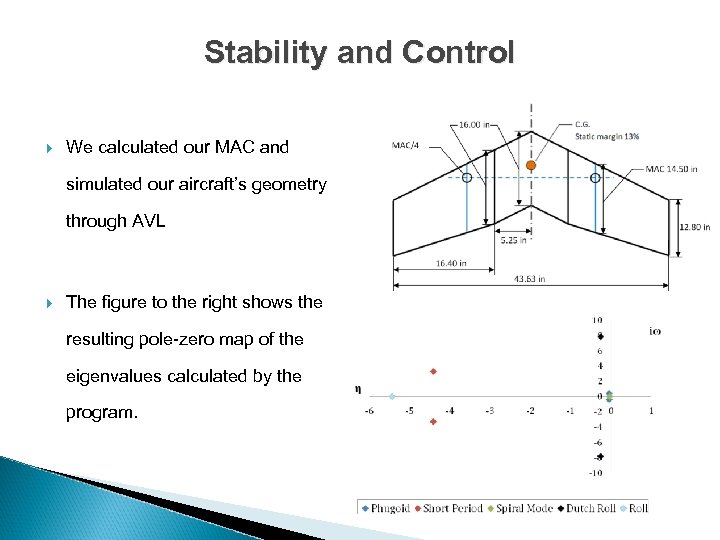

Stability and Control We calculated our MAC and simulated our aircraft’s geometry through AVL The figure to the right shows the resulting pole-zero map of the eigenvalues calculated by the program.

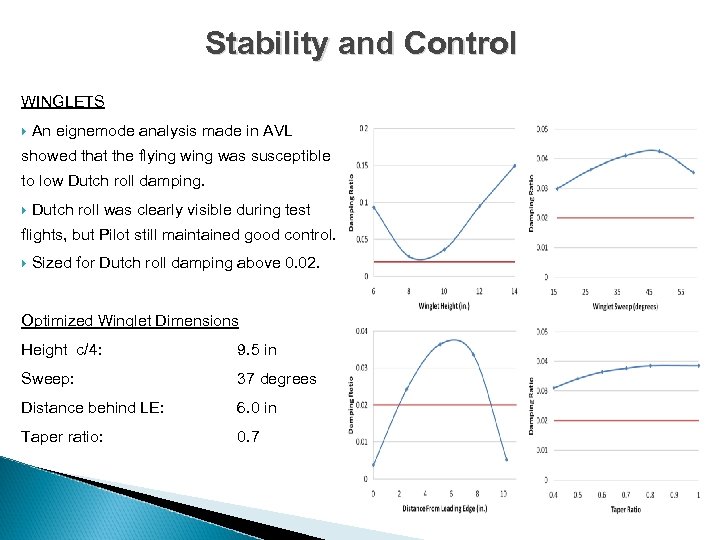

Stability and Control WINGLETS An eignemode analysis made in AVL showed that the flying was susceptible to low Dutch roll damping. Dutch roll was clearly visible during test flights, but Pilot still maintained good control. Sized for Dutch roll damping above 0. 02. Optimized Winglet Dimensions Height c/4: 9. 5 in Sweep: 37 degrees Distance behind LE: 6. 0 in Taper ratio: 0. 7

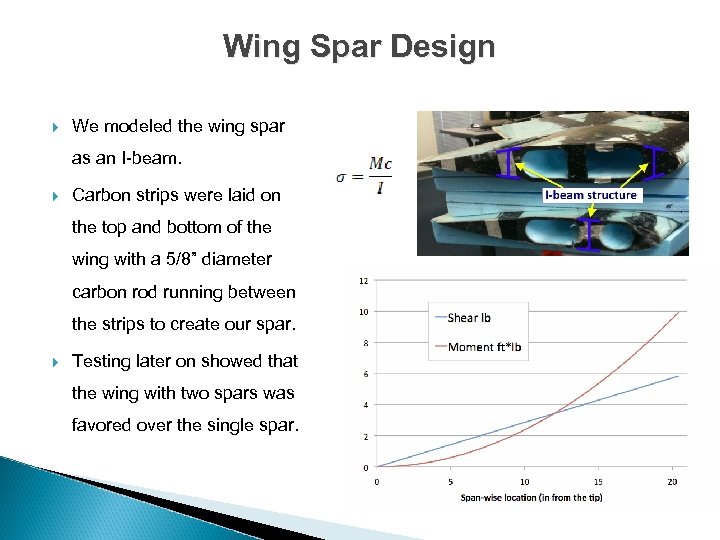

Wing Spar Design We modeled the wing spar as an I-beam. Carbon strips were laid on the top and bottom of the wing with a 5/8” diameter carbon rod running between the strips to create our spar. Testing later on showed that the wing with two spars was favored over the single spar.

Planform Design

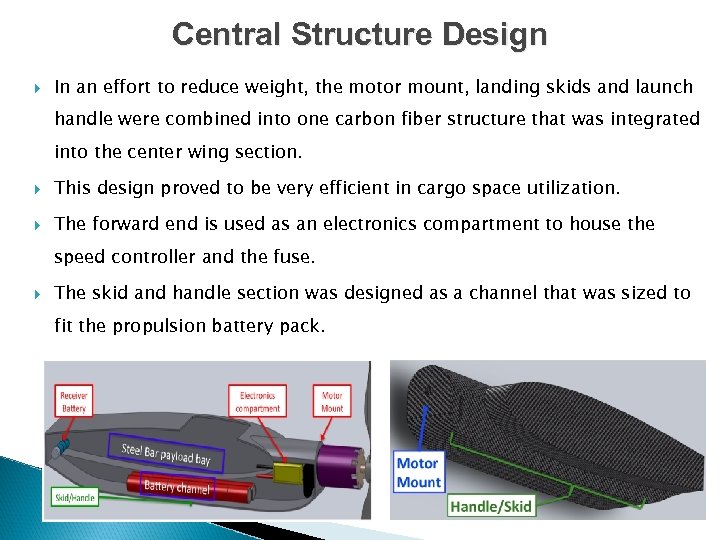

Central Structure Design In an effort to reduce weight, the motor mount, landing skids and launch handle were combined into one carbon fiber structure that was integrated into the center wing section. This design proved to be very efficient in cargo space utilization. The forward end is used as an electronics compartment to house the speed controller and the fuse. The skid and handle section was designed as a channel that was sized to fit the propulsion battery pack.

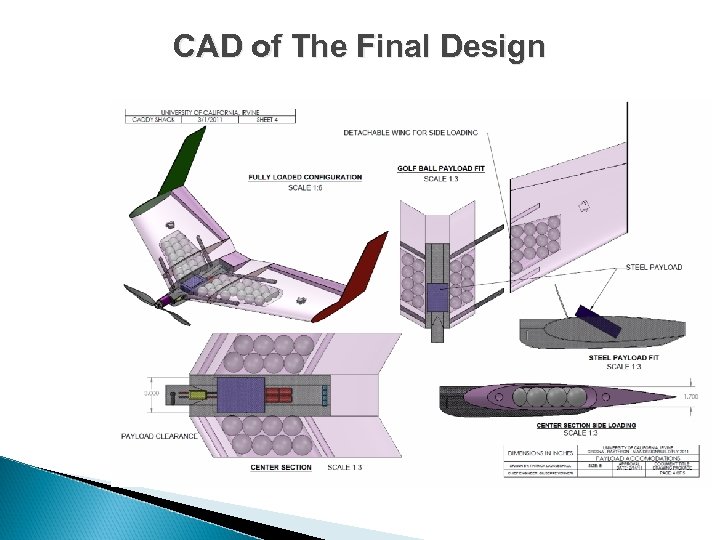

CAD of The Final Design

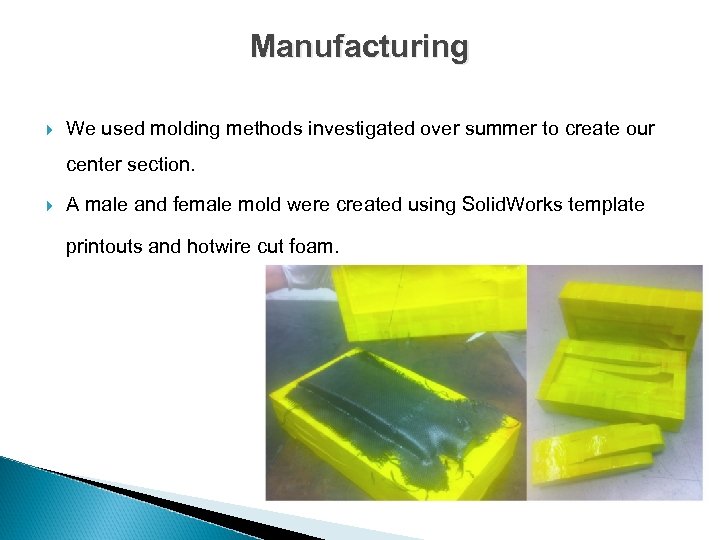

Manufacturing We used molding methods investigated over summer to create our center section. A male and female mold were created using Solid. Works template printouts and hotwire cut foam.

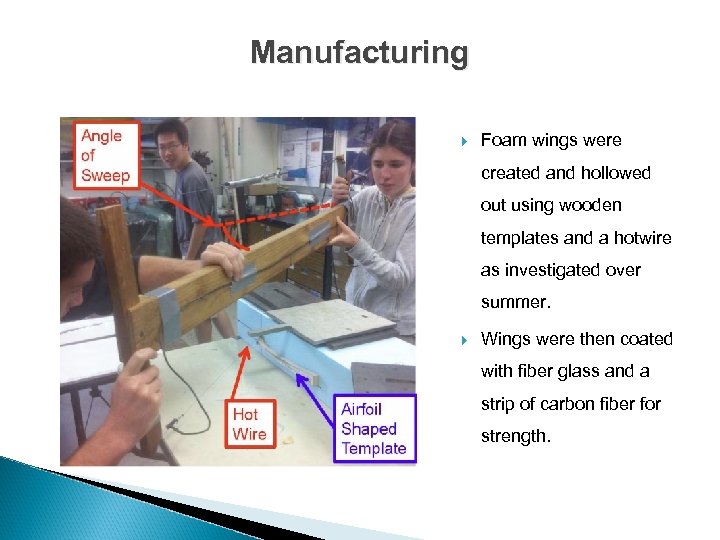

Manufacturing Foam wings were created and hollowed out using wooden templates and a hotwire as investigated over summer. Wings were then coated with fiber glass and a strip of carbon fiber for strength.

Testing Wingtip Testing Propulsion Testing Handle Design Tests Flight Tests

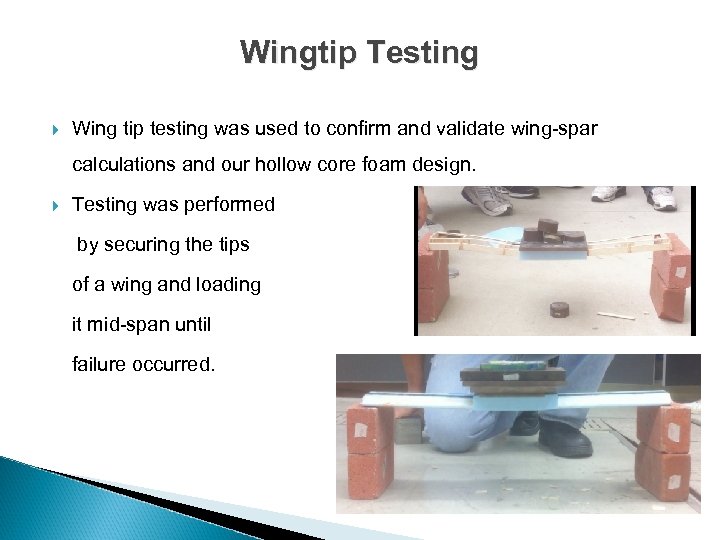

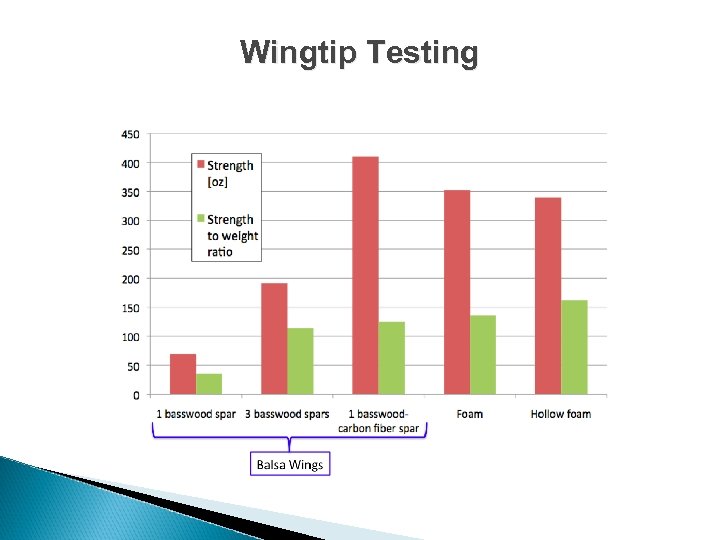

Wingtip Testing Wing tip testing was used to confirm and validate wing-spar calculations and our hollow core foam design. Testing was performed by securing the tips of a wing and loading it mid-span until failure occurred.

Wingtip Testing

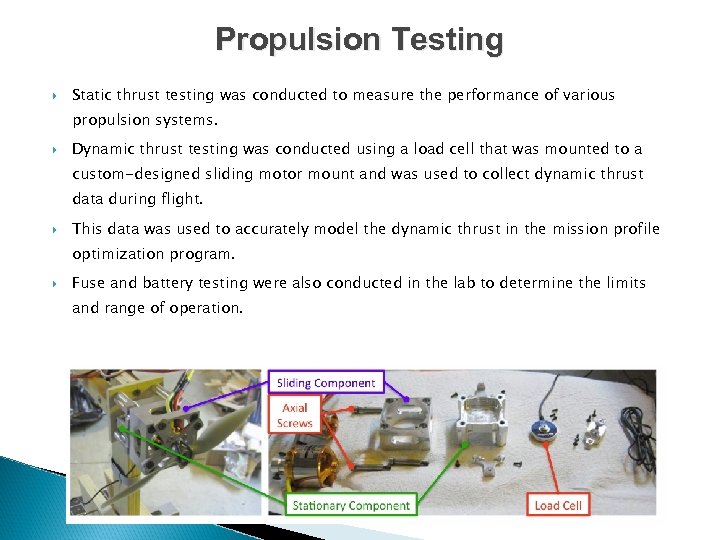

Propulsion Testing Static thrust testing was conducted to measure the performance of various propulsion systems. Dynamic thrust testing was conducted using a load cell that was mounted to a custom-designed sliding motor mount and was used to collect dynamic thrust data during flight. This data was used to accurately model the dynamic thrust in the mission profile optimization program. Fuse and battery testing were also conducted in the lab to determine the limits and range of operation.

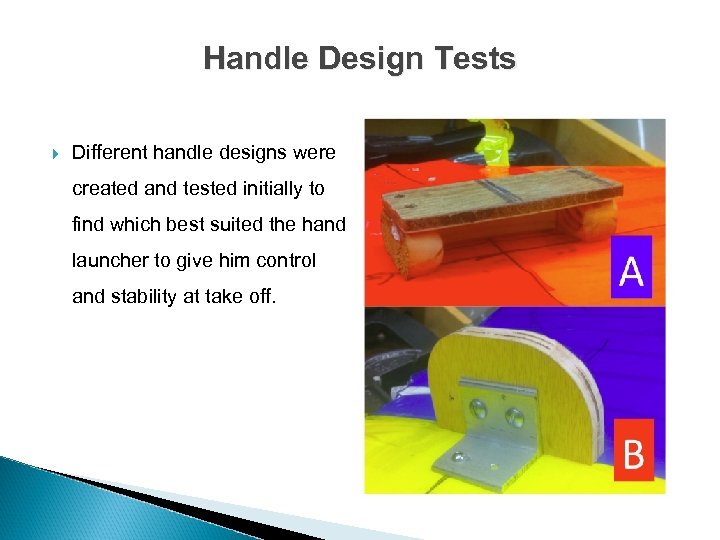

Handle Design Tests Different handle designs were created and tested initially to find which best suited the hand launcher to give him control and stability at take off.

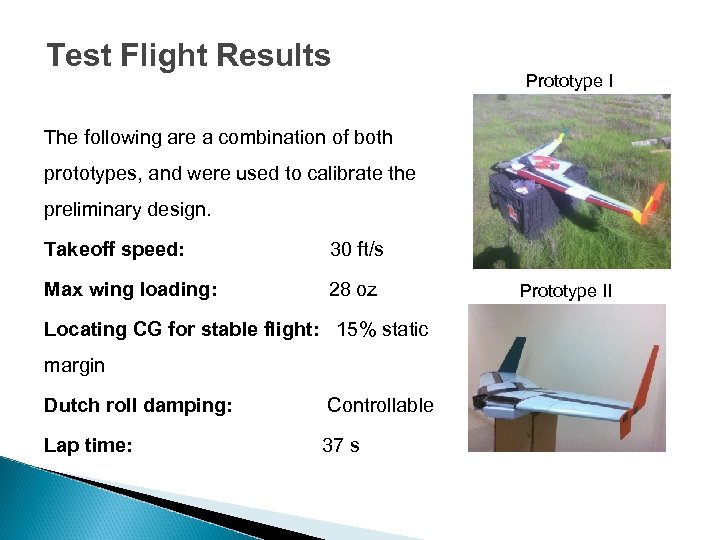

Test Flight Results Prototype I The following are a combination of both prototypes, and were used to calibrate the preliminary design. Takeoff speed: 30 ft/s Max wing loading: 28 oz Locating CG for stable flight: 15% static margin Dutch roll damping: Controllable Lap time: 37 s Prototype II

Test Flight Results Prototype I ◦ Provided insight into launch and landing techniques. ◦ Provided data for the calibration of the wing loading. Prototype II ◦ Improved stability. ◦ Increased payload space.

Competition Results Maximum of 4 flight attempts allowed Mission One: ◦ 1 st flight attempt: 6 laps in 4 minutes Late in the day Mission Two: ◦ 2 nd flight attempt: fuse blew within seconds after hand launch Noon, +90°F, No wind ◦ 3 rd flight attempt: ran out of battery with one more turn left in the course Late in the day Very spectacular flight ◦ 4 th flight attempt: Propulsion strategy gone amiss Noon, Even with a reduced payload, our plan to increase thrust on the downwind blew the fuse.

Lessons Learned The conditions surrounding the fuse in Tucson are very different than those in Irvine. The fuse will blow at a lower current in Tucson. Flying later in the day helped with the above handicap, when it was cooler. In fact, heavy planes like those from Israel and MIT skipped their noon rotation and waited till the late afternoon to fly their airplanes (9 lbs!!). Conduct propulsion tests and test flights with competition weather conditions in mind.

1864ec67934b45e7603b7a7b97e51bb3.ppt