81da2e575fde692fb92f2646f62f02d9.ppt

- Количество слайдов: 41

AGRU - Kunststofftechnik Gmb. H AGRU - Technology in Plastics IR Fusion Equipment 紅外線熔接設備 SP-Series 1

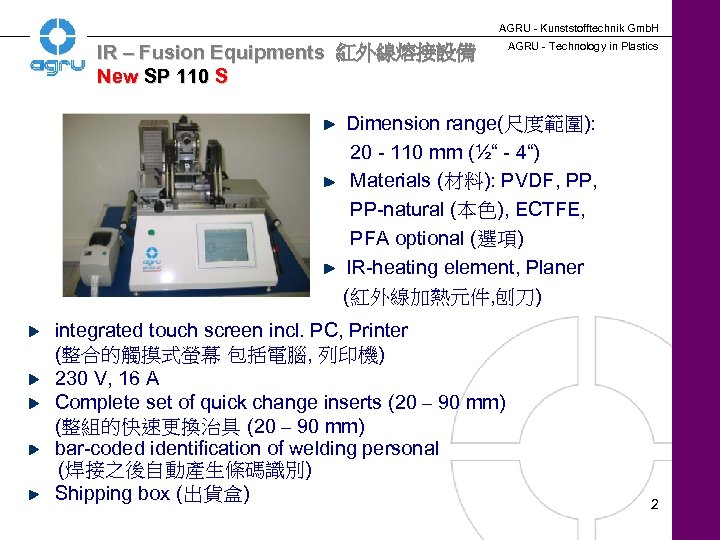

AGRU - Kunststofftechnik Gmb. H IR – Fusion Equipments 紅外線熔接設備 New SP 110 S AGRU - Technology in Plastics Dimension range(尺度範圍): 20 - 110 mm (½“ - 4“) Materials (材料): PVDF, PP-natural (本色), ECTFE, PFA optional (選項) IR-heating element, Planer (紅外線加熱元件, 刨刀) integrated touch screen incl. PC, Printer (整合的觸摸式螢幕 包括電腦, 列印機) 230 V, 16 A Complete set of quick change inserts (20 – 90 mm) (整組的快速更換治具 (20 – 90 mm) bar-coded identification of welding personal (焊接之後自動產生條碼識別) Shipping box (出貨盒) 2

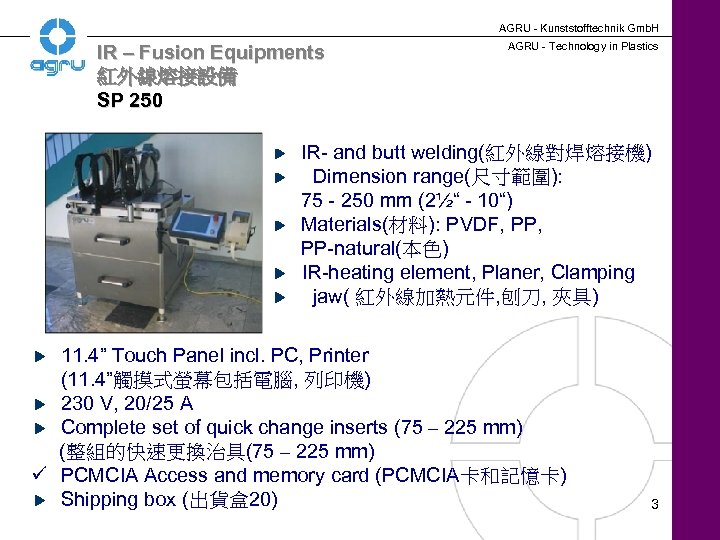

AGRU - Kunststofftechnik Gmb. H IR – Fusion Equipments 紅外線熔接設備 SP 250 AGRU - Technology in Plastics IR- and butt welding(紅外線對焊熔接機) Dimension range(尺寸範圍): 75 - 250 mm (2½“ - 10“) Materials(材料): PVDF, PP-natural(本色) IR-heating element, Planer, Clamping jaw( 紅外線加熱元件, 刨刀, 夾具) 11. 4” Touch Panel incl. PC, Printer (11. 4”觸摸式螢幕包括電腦, 列印機) 230 V, 20/25 A Complete set of quick change inserts (75 – 225 mm) (整組的快速更換治具(75 – 225 mm) ü PCMCIA Access and memory card (PCMCIA卡和記憶卡) Shipping box (出貨盒 20) 3

AGRU - Kunststofftechnik Gmb. H IR – Fusion Equipments 紅外線熔接設備 New SP 110 S AGRU - Technology in Plastics compact construction (結構輕巧) low weight (重量輕) automatic move-in and move-out of the heating element (加熱元件自動定位) • integrated process data software for easy administration of all recorded welding data (整合的處理資料軟體,輕鬆管理全部的焊接數據記錄) site and workshop equipment (設備適合 地和 廠 程施 ) 4

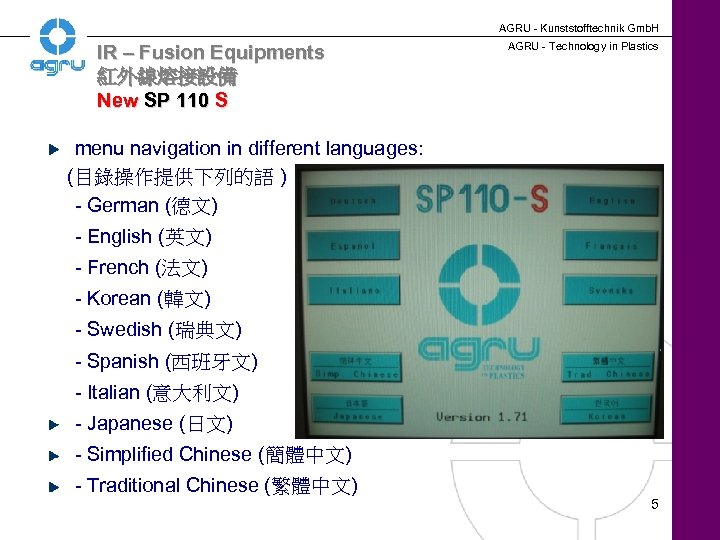

AGRU - Kunststofftechnik Gmb. H IR – Fusion Equipments 紅外線熔接設備 New SP 110 S AGRU - Technology in Plastics menu navigation in different languages: (目錄操作提供下列的語 ) - German (德文) - English (英文) - French (法文) - Korean (韓文) - Swedish (瑞典文) - Spanish (西班牙文) - Italian (意大利文) - Japanese (日文) - Simplified Chinese (簡體中文) - Traditional Chinese (繁體中文) 5

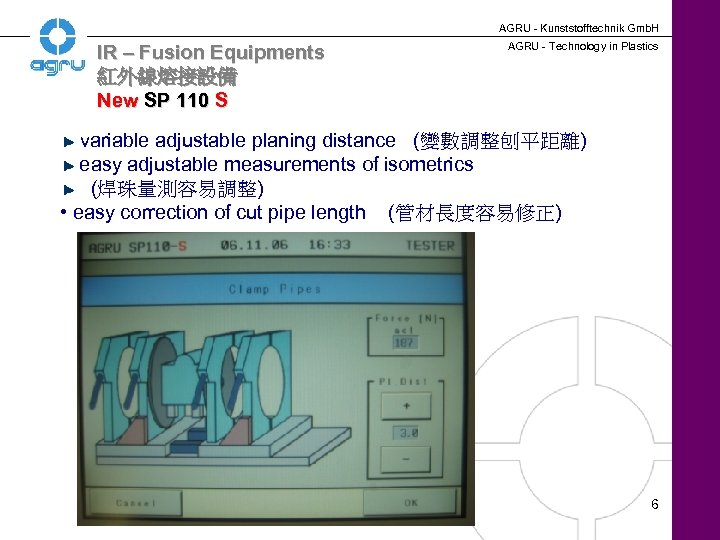

AGRU - Kunststofftechnik Gmb. H IR – Fusion Equipments 紅外線熔接設備 New SP 110 S AGRU - Technology in Plastics variable adjustable planing distance (變數調整刨平距離) easy adjustable measurements of isometrics (焊珠量測容易調整) • easy correction of cut pipe length (管材長度容易修正) 6

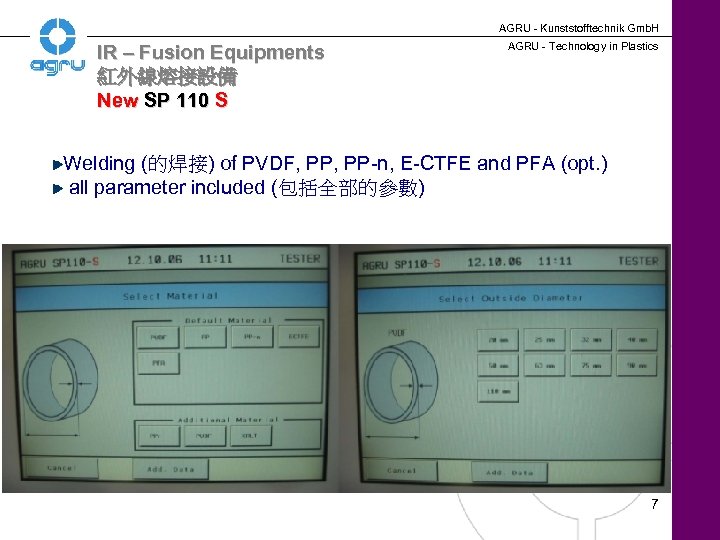

AGRU - Kunststofftechnik Gmb. H IR – Fusion Equipments 紅外線熔接設備 New SP 110 S AGRU - Technology in Plastics Welding (的焊接) of PVDF, PP-n, E-CTFE and PFA (opt. ) all parameter included (包括全部的參數) 7

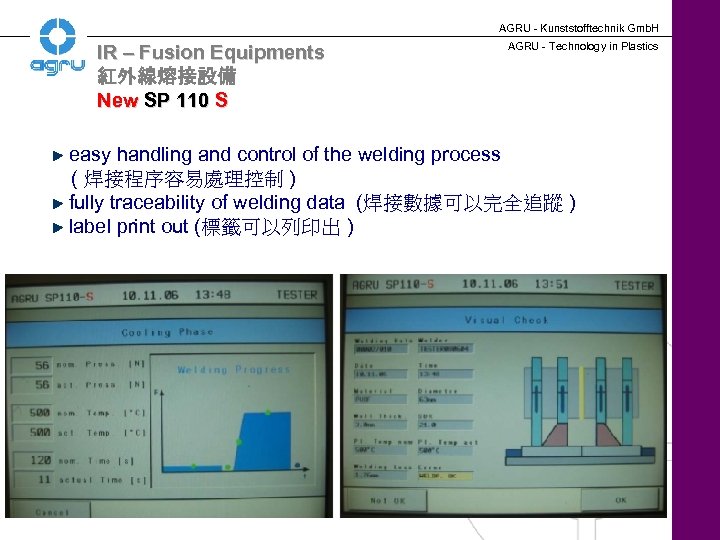

AGRU - Kunststofftechnik Gmb. H IR – Fusion Equipments 紅外線熔接設備 New SP 110 S AGRU - Technology in Plastics easy handling and control of the welding process ( 焊接程序容易處理控制 ) fully traceability of welding data (焊接數據可以完全追蹤 ) label print out (標籤可以列印出 ) 8

AGRU - Kunststofftechnik Gmb. H IR – Fusion Equipments (紅外線熔接設備) Features of SP machines (SP機種特色) AGRU - Technology in Plastics Fully automated welding process (完全自動化的焊接程序) ü Minimized influence of the operators (不良的人為操作減至最低) ü 100 % reliability of the welding quality (100 % 可靠的焊接品質) ü Perfect weld bead shape (完美的焊珠形狀 ) (high mechanical weld strength, reduced bead and small tolerance of the bead size around the whole weld bead circumference. (高機械焊接強度, 減少整個焊接周圍的焊珠尺寸公差) • Welding process is in accordance the DVS-guidelines (焊接程序符合 DVS-標準) Shortest weld times (pre-heating cooling) 最短的焊接時間 (預熱 冷卻) • Single phase power source, control of power supply 9 (單相電源, 電源供應器控制)

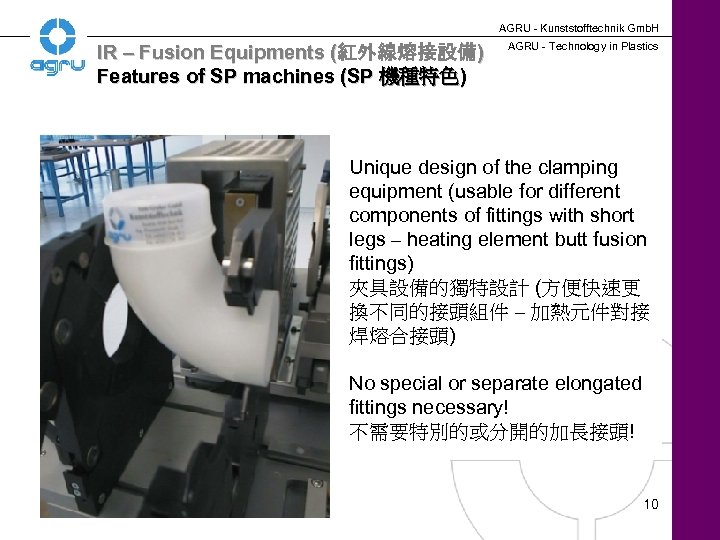

AGRU - Kunststofftechnik Gmb. H IR – Fusion Equipments (紅外線熔接設備) Features of SP machines (SP 機種特色) AGRU - Technology in Plastics Unique design of the clamping equipment (usable for different components of fittings with short legs – heating element butt fusion fittings) 夾具設備的獨特設計 (方便快速更 換不同的接頭組件 – 加熱元件對接 焊熔合接頭) No special or separate elongated fittings necessary! 不需要特別的或分開的加長接頭! 10

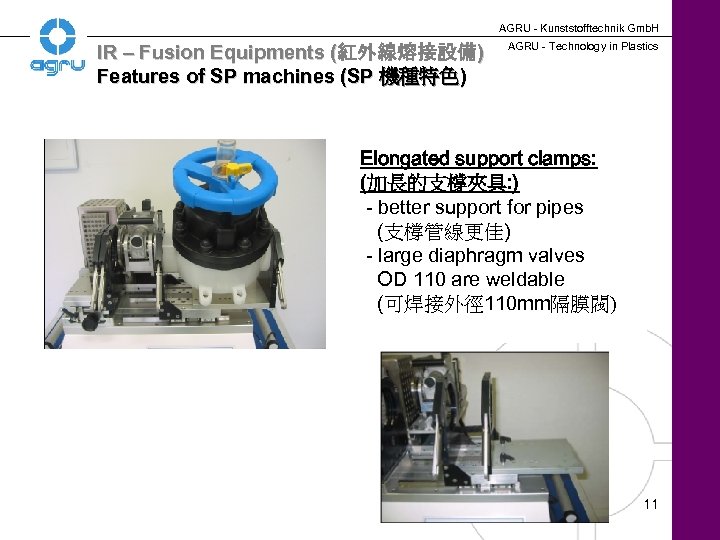

AGRU - Kunststofftechnik Gmb. H IR – Fusion Equipments (紅外線熔接設備) Features of SP machines (SP 機種特色) AGRU - Technology in Plastics Elongated support clamps: (加長的支橕夾具: ) - better support for pipes (支橕管線更佳) - large diaphragm valves OD 110 are weldable (可焊接外徑 110 mm隔膜閥) 11

AGRU - Kunststofftechnik Gmb. H IR – Fusion Equipments (紅外線熔接設備) Features of SP machines (SP 機種特定) AGRU - Technology in Plastics New kind of closing mechanism: (新式的閉合機構) Ensures uniform and repeatable clamping pressure (確保夾具壓力的一致性和重覆性) • Clamps are movable (可移動式夾具) Vertical and horizontal offset (垂直和水平偏置) Magnetic fixation of the clamping inserts: (夾持治具的磁鐵定位: )) Reduced exchange time (減少換刀時間) Reduced particle contamination (減少粒塵污染) • Universal clamping equipment (萬用夾具設備) 12

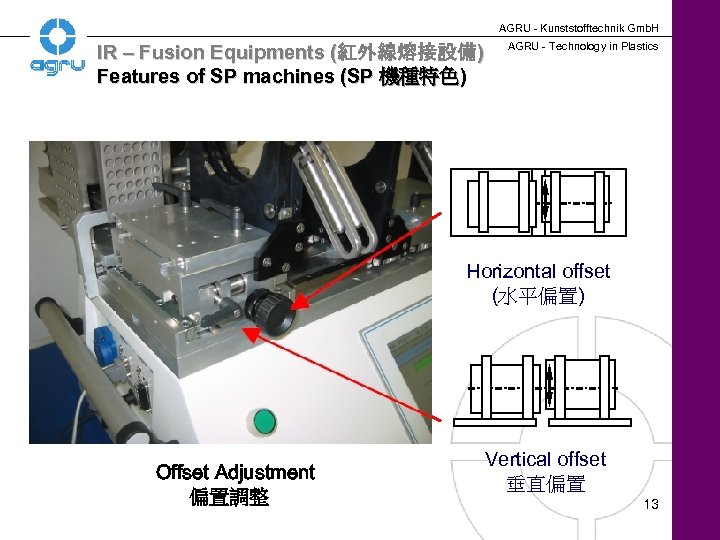

AGRU - Kunststofftechnik Gmb. H IR – Fusion Equipments (紅外線熔接設備) Features of SP machines (SP 機種特色) AGRU - Technology in Plastics Horizontal offset (水平偏置) Offset Adjustment 偏置調整 Vertical offset 垂直偏置 13

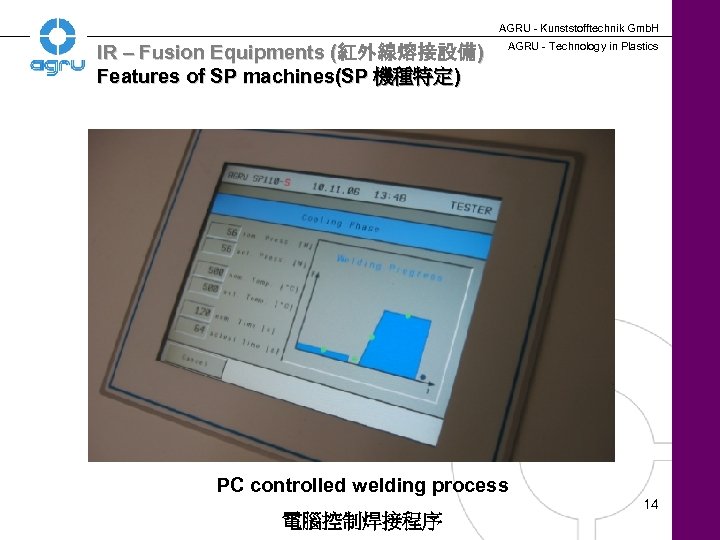

AGRU - Kunststofftechnik Gmb. H IR – Fusion Equipments (紅外線熔接設備) Features of SP machines(SP 機種特定) AGRU - Technology in Plastics PC controlled welding process 電腦控制焊接程序 14

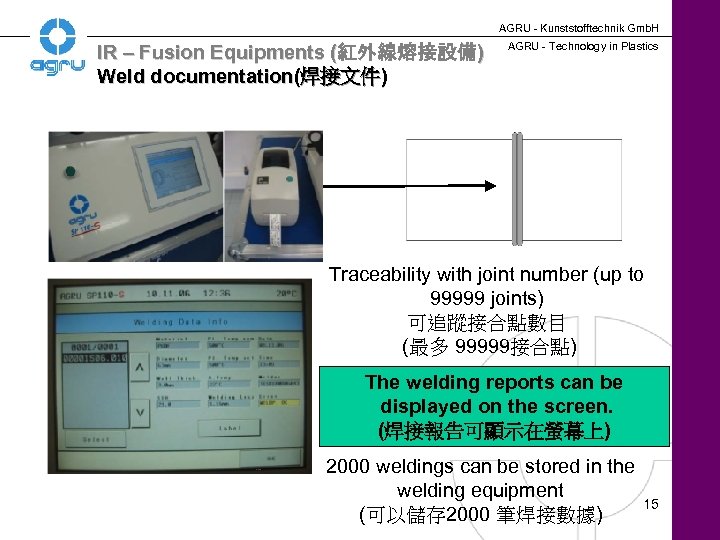

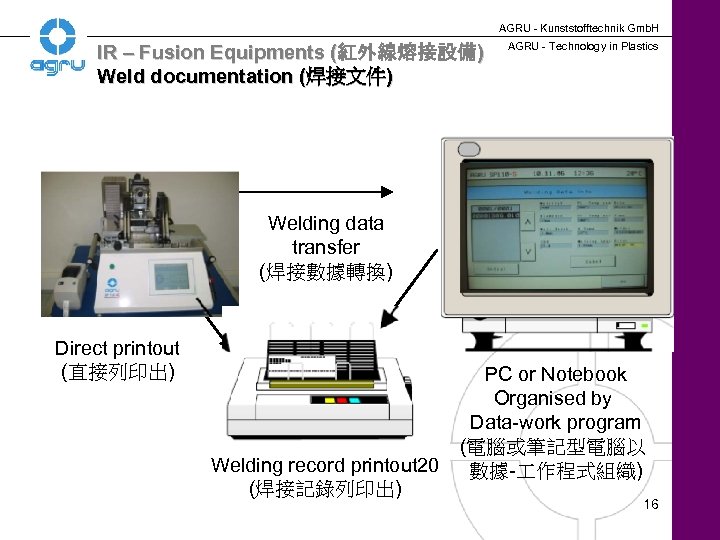

AGRU - Kunststofftechnik Gmb. H IR – Fusion Equipments (紅外線熔接設備) Weld documentation(焊接文件) AGRU - Technology in Plastics Traceability with joint number (up to 99999 joints) 可追蹤接合點數目 (最多 99999接合點) The welding reports can be displayed on the screen. (焊接報告可顯示在螢幕上) 2000 weldings can be stored in the welding equipment (可以儲存 2000 筆焊接數據) 15

AGRU - Kunststofftechnik Gmb. H IR – Fusion Equipments (紅外線熔接設備) Weld documentation (焊接文件) AGRU - Technology in Plastics Welding data transfer (焊接數據轉換) Direct printout (直接列印出) Welding record printout 20 (焊接記錄列印出) PC or Notebook Organised by Data-work program (電腦或筆記型電腦以 數據- 作程式組織) 16

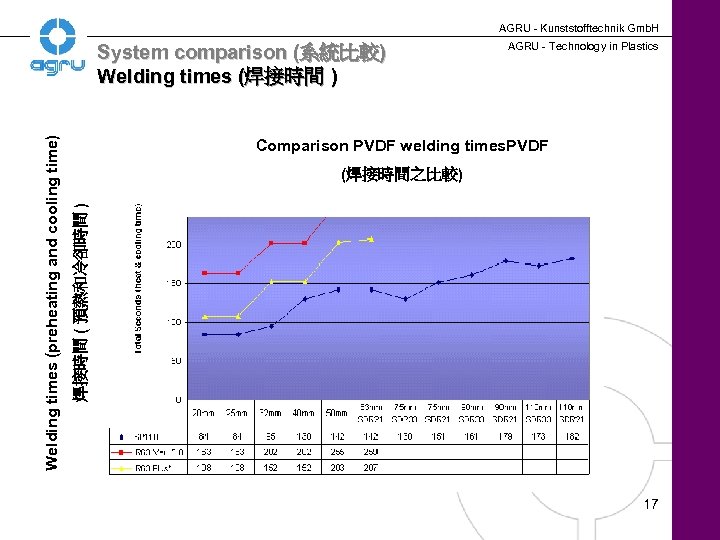

AGRU - Kunststofftechnik Gmb. H AGRU - Technology in Plastics Vergleich der PP Schweißzeiten Comparison PVDF welding times. PVDF Schweißzeit (Anwärm- und Kühlzeit) (焊接時間之比較) 焊接時間 ( 預熱和冷卻時間 ) Welding times (preheating and cooling time) System comparison (系統比較) Welding times (焊接時間 ) 17

AGRU - Kunststofftechnik Gmb. H AGRU - Technology in Plastics IR Welding Equipment 紅外線焊接設備 Training Program and Certification 訓練計劃和認證 18

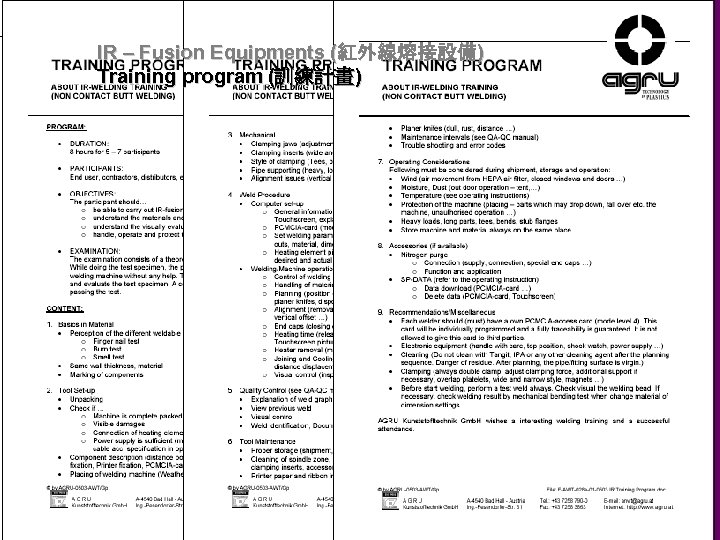

AGRU - Kunststofftechnik Gmb. H IR – Fusion Equipments (紅外線熔接設備) Training program (訓練計畫) AGRU - Technology in Plastics AGRU provides combined welding training, welding certification and maintenance courses… § In-house at the AGRU Training Centre in Bad Hall/Austria § At customer’s place § On site at the customer’s project place § Evaluate welding joints and issues welding training certificates FREE OF CHARGE! Additional on request: AGRU provides SUPERVISING on site with special educated and certified welding personnel 19

AGRU - Kunststofftechnik Gmb. H IR – Fusion Equipments (紅外線熔接設備) Operator certification (操作人員認證) Theoretical Test (學科測驗): § Basic in Material(材料基礎) § Tool set-up ( 具設定) § Mechanical (機械) § Weld Procedure (焊接程序) § Quality Control (品質管理) § Tool Maintenance ( 具維護) § Operation Considerations (操作考量) § Accessories (if available) (附屬元件 (如果有)) § Name, Signature and Date of Welder and Trainer (焊接者和訓練者姓名, 簽名和日期) Practical Test (實務測驗): § Operation of Welding Machine, Trouble Shooting and Weld coupon (焊接機的操作, 故障排除, 焊接測試樣板) AGRU - Technology in Plastics 20

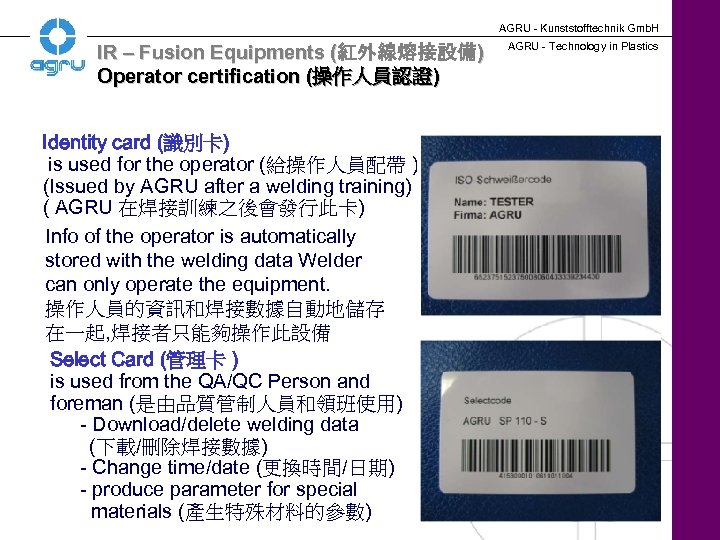

AGRU - Kunststofftechnik Gmb. H IR – Fusion Equipments (紅外線熔接設備) Operator certification (操作人員認證) Identity card (識別卡) is used for the operator (給操作人員配帶 ) (Issued by AGRU after a welding training) ( AGRU 在焊接訓練之後會發行此卡) Info of the operator is automatically stored with the welding data Welder can only operate the equipment. 操作人員的資訊和焊接數據自動地儲存 在一起, 焊接者只能夠操作此設備 Select Card (管理卡 ) is used from the QA/QC Person and foreman (是由品質管制人員和領班使用) - Download/delete welding data (下載/刪除焊接數據) - Change time/date (更換時間/日期) - produce parameter for special materials (產生特殊材料的參數) AGRU - Technology in Plastics 21

AGRU - Kunststofftechnik Gmb. H IR – Fusion Equipments (紅外線熔接設備) QA/QC Manuals (品管手冊) AGRU - Technology in Plastics Content (內容): 1. 2. 2. 3. 3. 4. 4. 5. 6. • Set-up of the SP welding machine. SP (機種的設定) Guidelines for Maintenance/Service (維修/服務的指導) Guidelines for Welding Personnel (焊接人員的指導) Guidelines for Evaluation of Welding Joints (焊接點的評估之指導) Guideline for Documentation (文件製作的指導) QA/QC Guidelines during Installation (安裝時期的品管指導) 22

AGRU - Kunststofftechnik Gmb. H AGRU - Technology in Plastics Welding quality on IR- fusion for PVDF and PP PVDF 和 PP在紅外線的焊接品質

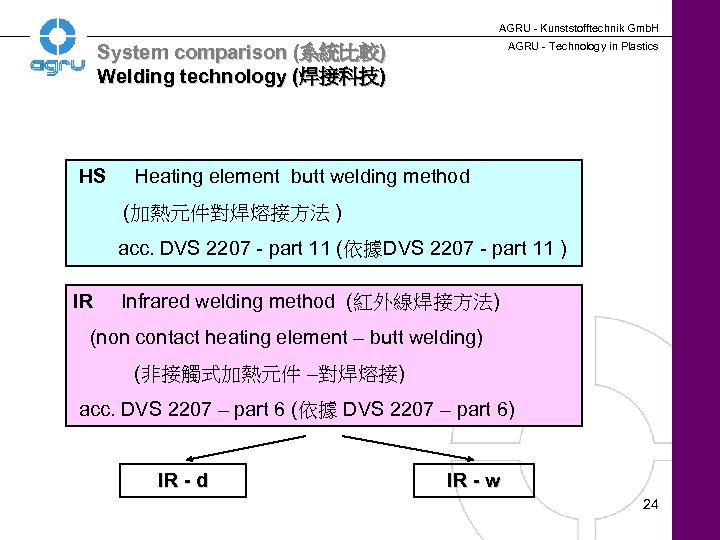

AGRU - Kunststofftechnik Gmb. H AGRU - Technology in Plastics System comparison (系統比較) Welding technology (焊接科技) HS Heating element butt welding method (加熱元件對焊熔接方法 ) acc. DVS 2207 - part 11 (依據DVS 2207 - part 11 ) IR Infrared welding method (紅外線焊接方法) (non contact heating element – butt welding) (非接觸式加熱元件 –對焊熔接) acc. DVS 2207 – part 6 (依據 DVS 2207 – part 6) IR - d IR - w 24

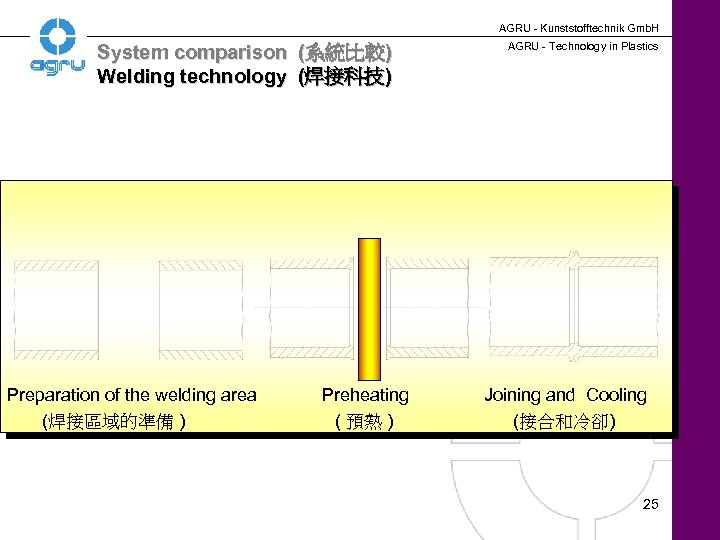

AGRU - Kunststofftechnik Gmb. H System comparison (系統比較) Welding technology (焊接科技) Preparation of the welding area (焊接區域的準備 ) Preheating ( 預熱 ) AGRU - Technology in Plastics Joining and Cooling (接合和冷卻) 25

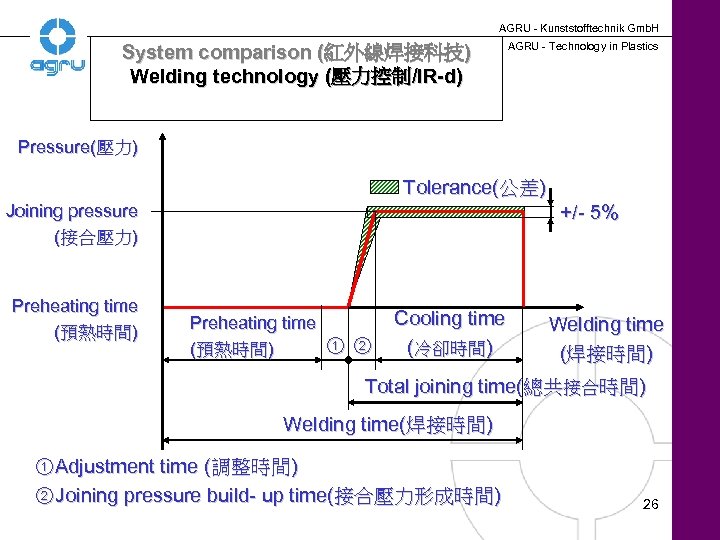

AGRU - Kunststofftechnik Gmb. H System comparison (紅外線焊接科技) Welding technology (壓力控制/IR-d) AGRU - Technology in Plastics Pressure(壓力) Tolerance(公差) Joining pressure (接合壓力) Preheating time (預熱時間) Preheating time ①② (預熱時間) Cooling time (冷卻時間) +/- 5% Welding time (焊接時間) Total joining time(總共接合時間) Welding time(焊接時間) ①Adjustment time (調整時間) ②Joining pressure build- up time(接合壓力形成時間) 26

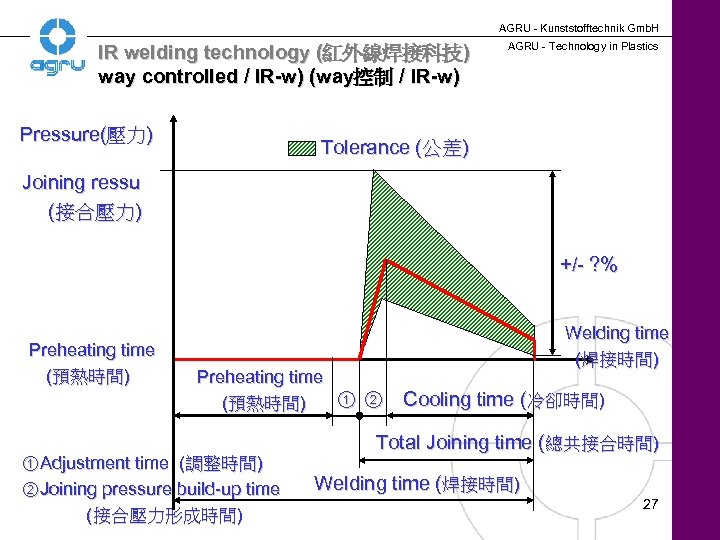

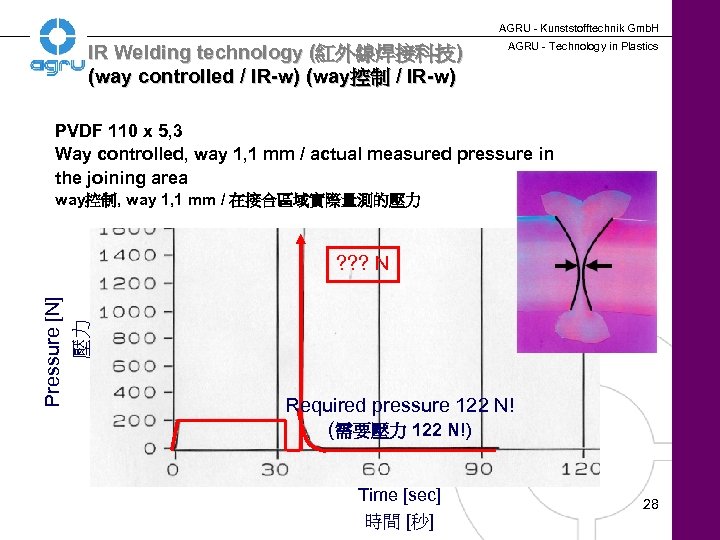

AGRU - Kunststofftechnik Gmb. H IR welding technology (紅外線焊接科技) way controlled / IR-w) (way控制 / IR-w) Pressure(壓力) AGRU - Technology in Plastics Tolerance (公差) Joining ressu (接合壓力) +/- ? % Preheating time (預熱時間) Preheating time ①② (預熱時間) ①Adjustment time (調整時間) ②Joining pressure build-up time (接合壓力形成時間) Welding time (焊接時間) Cooling time (冷卻時間) Total Joining time (總共接合時間) Welding time (焊接時間) 27

AGRU - Kunststofftechnik Gmb. H IR Welding technology (紅外線焊接科技) (way controlled / IR-w) (way控制 / IR-w) AGRU - Technology in Plastics PVDF 110 x 5, 3 Way controlled, way 1, 1 mm / actual measured pressure in the joining area way控制, way 1, 1 mm / 在接合區域實際量測的壓力 Pressure [N] 壓力 ? ? ? N Required pressure 122 N! (需要壓力 122 N!) Time [sec] 時間 [秒] 28

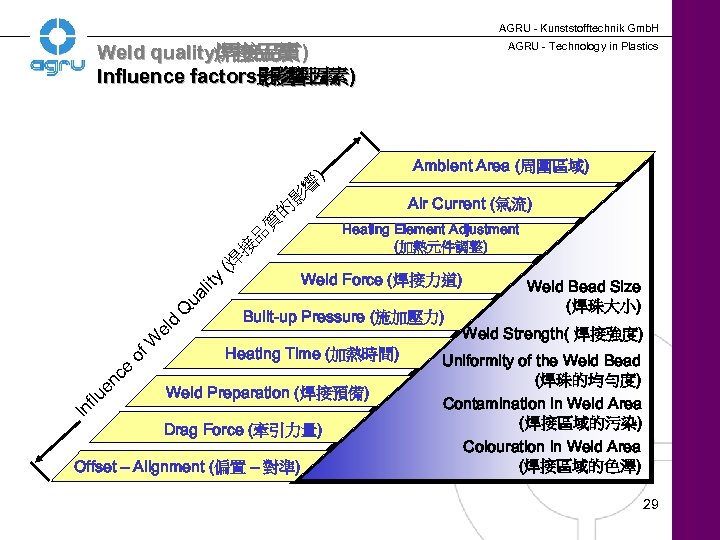

AGRU - Kunststofftechnik Gmb. H AGRU - Technology in Plastics Weld quality焊接品質 ) quality(焊接品質 Influence factors影響因素 ) (影響因素 影 響 ) Ambient Area (周圍區域) 質 的 Air Current (氣流) (焊 接 品 Heating Element Adjustment (加熱元件調整) Built-up Pressure (施加壓力) Heating Time (加熱時間) In flu en c e of W el d Q ua l ity Weld Force (焊接力道) Weld Preparation (焊接預備) Drag Force (牽引力量) Offset – Alignment (偏置 – 對準) Weld Bead Size (焊珠大小) Weld Strength( 焊接強度) Uniformity of the Weld Bead (焊珠的均勻度) Contamination in Weld Area (焊接區域的污染) Colouration in Weld Area (焊接區域的色澤) 29

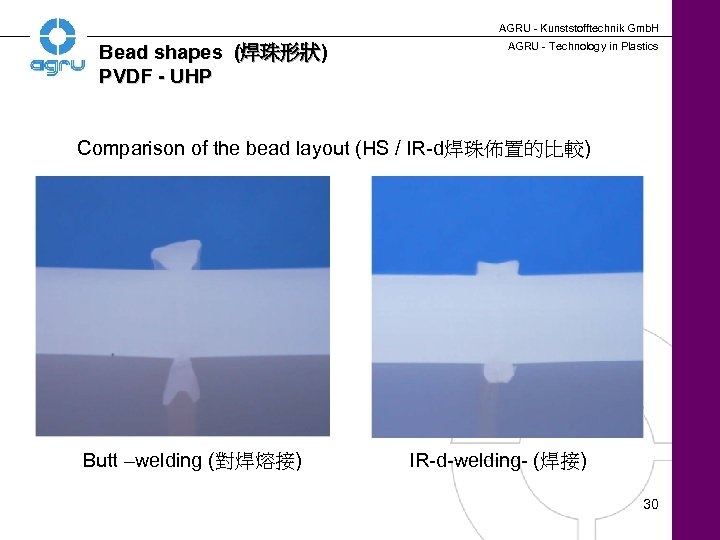

AGRU - Kunststofftechnik Gmb. H Bead shapes (焊珠形狀) PVDF - UHP AGRU - Technology in Plastics Comparison of the bead layout (HS / IR-d焊珠佈置的比較) Butt –welding (對焊熔接) IR-d-welding- (焊接) 30

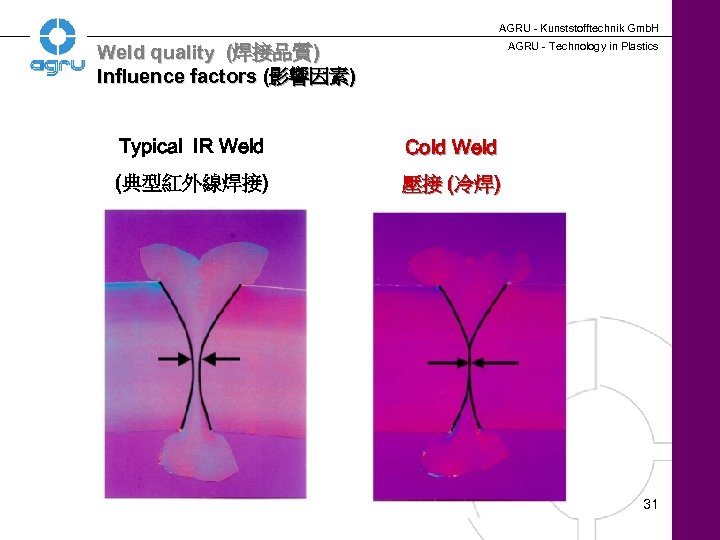

AGRU - Kunststofftechnik Gmb. H AGRU - Technology in Plastics Weld quality (焊接品質) Influence factors (影響因素) Typical IR Weld Cold Weld (典型紅外線焊接) 壓接 (冷焊) 31

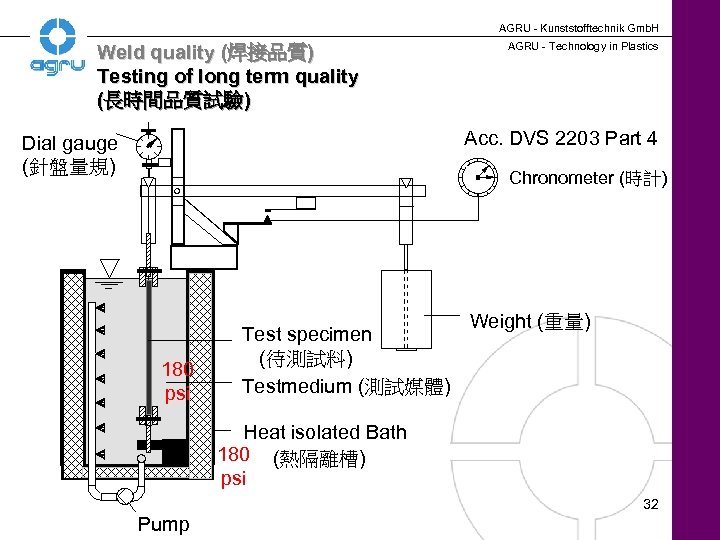

AGRU - Kunststofftechnik Gmb. H Weld quality (焊接品質) Testing of long term quality (長時間品質試驗) AGRU - Technology in Plastics Acc. DVS 2203 Part 4 Dial gauge (針盤量規) Chronometer (時計) 180 psi Test specimen (待測試料) Testmedium (測試媒體) Weight (重量) Heat isolated Bath 180 (熱隔離槽) psi Pump 32

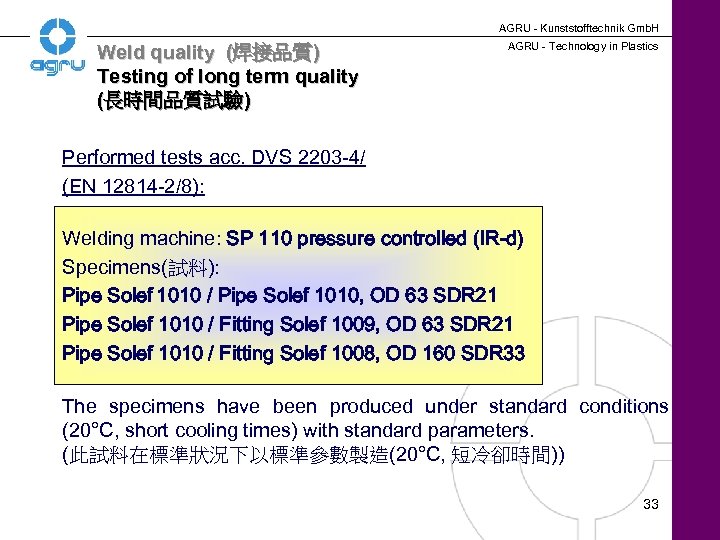

AGRU - Kunststofftechnik Gmb. H Weld quality (焊接品質) Testing of long term quality (長時間品質試驗) AGRU - Technology in Plastics Performed tests acc. DVS 2203 -4/ (EN 12814 -2/8): Welding machine: SP 110 pressure controlled (IR-d) Specimens(試料): Pipe Solef 1010 / Pipe Solef 1010, OD 63 SDR 21 Pipe Solef 1010 / Fitting Solef 1009, OD 63 SDR 21 Pipe Solef 1010 / Fitting Solef 1008, OD 160 SDR 33 The specimens have been produced under standard conditions (20°C, short cooling times) with standard parameters. (此試料在標準狀況下以標準參數製造(20°C, 短冷卻時間)) 33

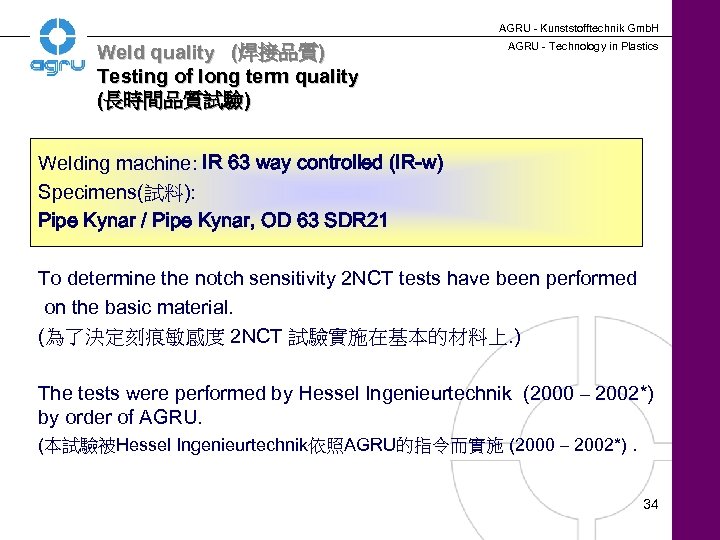

AGRU - Kunststofftechnik Gmb. H Weld quality (焊接品質) Testing of long term quality (長時間品質試驗) AGRU - Technology in Plastics Welding machine: IR 63 way controlled (IR-w) Specimens(試料): Pipe Kynar / Pipe Kynar, OD 63 SDR 21 To determine the notch sensitivity 2 NCT tests have been performed on the basic material. (為了決定刻痕敏感度 2 NCT 試驗實施在基本的材料上. ) The tests were performed by Hessel Ingenieurtechnik (2000 – 2002*) by order of AGRU. (本試驗被Hessel Ingenieurtechnik依照AGRU的指令而實施 (2000 – 2002*). 34

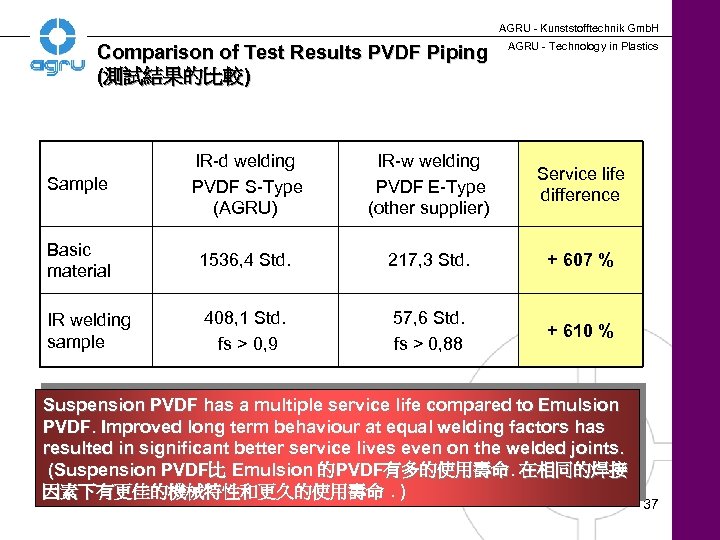

AGRU - Kunststofftechnik Gmb. H Comparison of Test Results PVDF Piping (測試結果的比較) AGRU - Technology in Plastics Sample IR-d welding PVDF S-Type (AGRU) IR-w welding PVDF E-Type (other supplier) Service life difference Basic material 1536, 4 Std. 217, 3 Std. + 607 % IR welding sample 408, 1 Std. fs > 0, 9 57, 6 Std. fs > 0, 88 + 610 % Suspension PVDF has a multiple service life compared to Emulsion PVDF. Improved long term behaviour at equal welding factors has resulted in significant better service lives even on the welded joints. (Suspension PVDF比 Emulsion 的PVDF有多的使用壽命. 在相同的焊接 因素下有更佳的機械特性和更久的使用壽命. ) 37

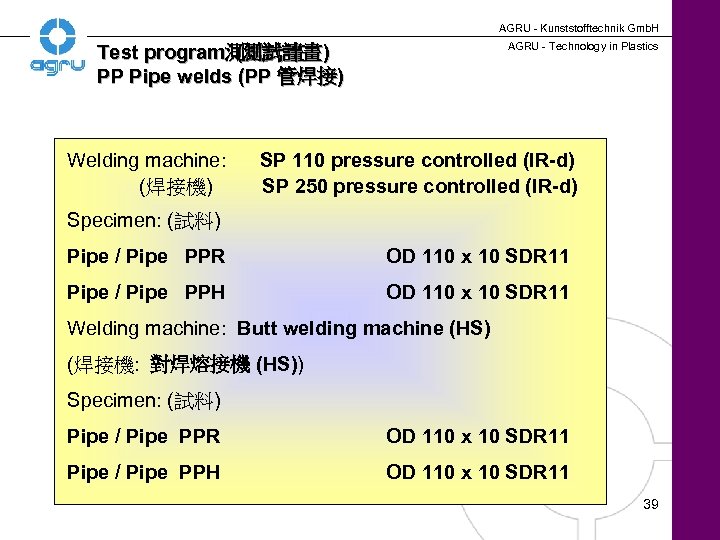

AGRU - Kunststofftechnik Gmb. H AGRU - Technology in Plastics Test program測試計畫 ) (測試計畫 PP Pipe welds (PP 管焊接) Welding machine: (焊接機) SP 110 pressure controlled (IR-d) SP 250 pressure controlled (IR-d) Specimen: (試料) Pipe / Pipe PPR OD 110 x 10 SDR 11 Pipe / Pipe PPH OD 110 x 10 SDR 11 Welding machine: Butt welding machine (HS) (焊接機: 對焊熔接機 (HS)) Specimen: (試料) Pipe / Pipe PPR OD 110 x 10 SDR 11 Pipe / Pipe PPH OD 110 x 10 SDR 11 39

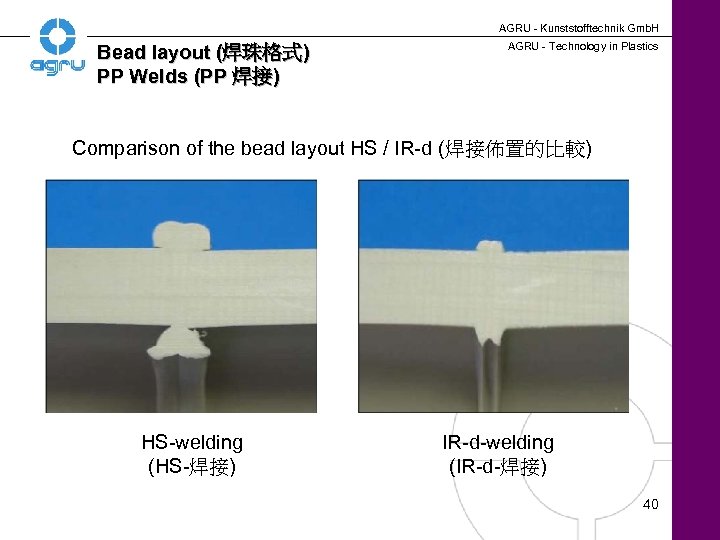

AGRU - Kunststofftechnik Gmb. H Bead layout (焊珠格式) PP Welds (PP 焊接) AGRU - Technology in Plastics Comparison of the bead layout HS / IR-d (焊接佈置的比較) HS-welding (HS-焊接) IR-d-welding (IR-d-焊接) 40

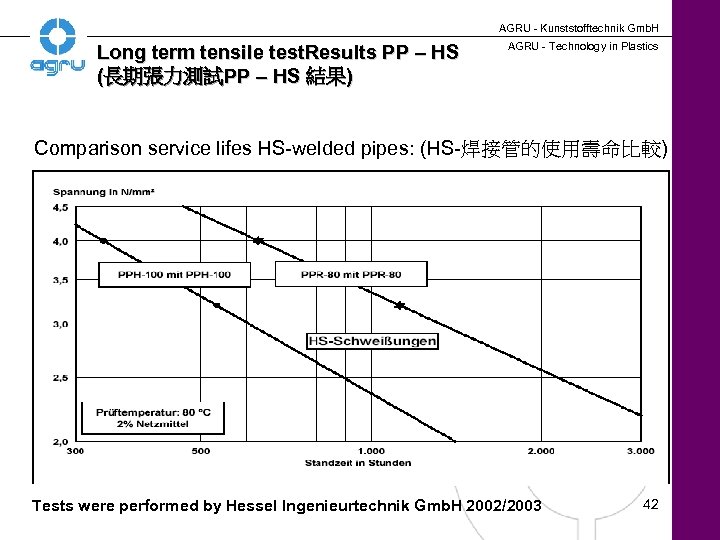

AGRU - Kunststofftechnik Gmb. H Long term tensile test. Results PP – HS (長期張力測試PP – HS 結果) AGRU - Technology in Plastics Comparison service lifes HS-welded pipes: (HS-焊接管的使用壽命比較) Tests were performed by Hessel Ingenieurtechnik Gmb. H 2002/2003 42

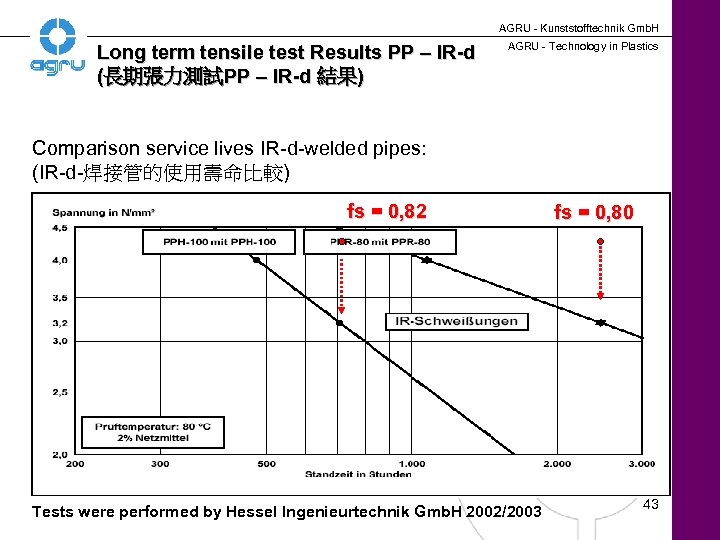

AGRU - Kunststofftechnik Gmb. H Long term tensile test Results PP – IR-d (長期張力測試PP – IR-d 結果) AGRU - Technology in Plastics Comparison service lives IR-d-welded pipes: (IR-d-焊接管的使用壽命比較) fs = 0, 82 Tests were performed by Hessel Ingenieurtechnik Gmb. H 2002/2003 fs = 0, 80 43

AGRU - Kunststofftechnik Gmb. H Conclusion 結論 AGRU - Technology in Plastics • Consideration of service life is important (考慮到使用壽命是重要的 ) • Effective long term behaviour of the fitting type is important: at equal welding factors significant higher service lives and higher security of the welded joints could be reached. (接頭型式的耐久機械性能是很重要的: 在相同的焊接因素下可以達到 更長的使用壽命和焊接安全性能. ) • Suspension PVDF ensures significant higher service lives (Suspension PVDF 確保更長久的使用壽命) • PP-R has compared to PP-H clear advantages. (PP-R 比PP-H 有明顯的優點) 45

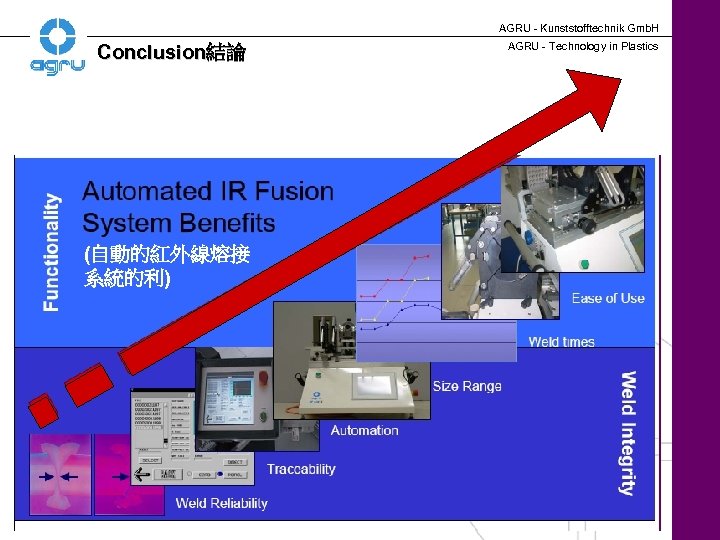

AGRU - Kunststofftechnik Gmb. H AGRU - Technology in Plastics Functionality Conclusion結論 Automated IR Fusion. System Benefits (自動的紅外線熔接系統的利益) (自動的紅外線熔接 系統的利) Ease of Use Weld times Automation Traceability Weld Integrity Size Range 46 Weld Reliability (自動的紅外線熔接)

81da2e575fde692fb92f2646f62f02d9.ppt