be41834561b168ed7f32b829d0e5d93a.ppt

- Количество слайдов: 30

Agnes Water / 1770 Integrated Water Project 1

Agnes Water / 1770 Integrated Water Project 1

United Utilities Australia Carmine Ciccocioppo State Manager - Queensland United Utilities Australia 2

United Utilities Australia Carmine Ciccocioppo State Manager - Queensland United Utilities Australia 2

About United Utilities Australia • United Utilities Australia was established in 1991 and now provides water and wastewater solutions and services to 11 clients and approx 4. 0 million people across five states. • Clients are both public sector (e. g. Water Authorities, local Councils) and private sector (e. g. BHP-Billiton) • National Operations include – – 35 water filtration plants 15 WWTPs, > 2200 km water distribution and trunk mains >1500 km sewer mains • Experience in operating in rural and remote communities 3

About United Utilities Australia • United Utilities Australia was established in 1991 and now provides water and wastewater solutions and services to 11 clients and approx 4. 0 million people across five states. • Clients are both public sector (e. g. Water Authorities, local Councils) and private sector (e. g. BHP-Billiton) • National Operations include – – 35 water filtration plants 15 WWTPs, > 2200 km water distribution and trunk mains >1500 km sewer mains • Experience in operating in rural and remote communities 3

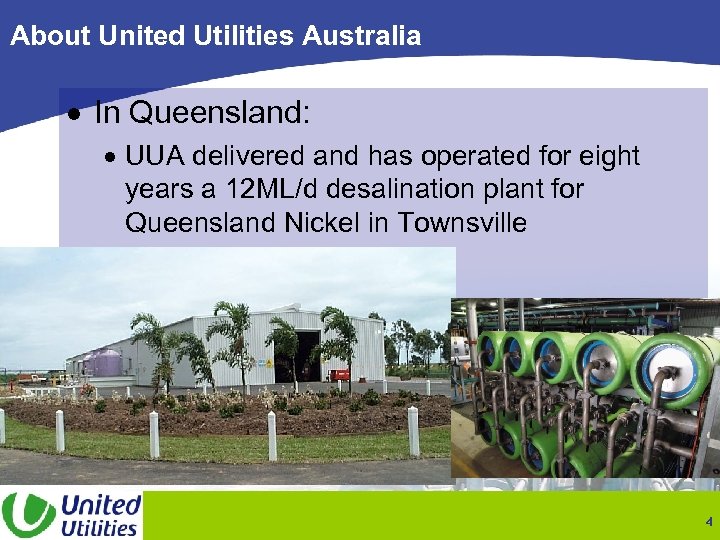

About United Utilities Australia In Queensland: UUA delivered and has operated for eight years a 12 ML/d desalination plant for Queensland Nickel in Townsville 4

About United Utilities Australia In Queensland: UUA delivered and has operated for eight years a 12 ML/d desalination plant for Queensland Nickel in Townsville 4

UUA- Approach to Operations • UUA’s operational philosophy represents industry-best practice • Operational track record with near-perfect compliance • Best-of-Industry: – Safety practices and emergency management systems; and – Environment practices and systems; – Systems third-party accredited to ISO 9001 (QA), ISO 14001 (EMS) and AS 4801 (OH&S) track record demonstrated over 15 years continuous operation across 4 states. • Long Term community relations that are proactive, transparent and honest. 5

UUA- Approach to Operations • UUA’s operational philosophy represents industry-best practice • Operational track record with near-perfect compliance • Best-of-Industry: – Safety practices and emergency management systems; and – Environment practices and systems; – Systems third-party accredited to ISO 9001 (QA), ISO 14001 (EMS) and AS 4801 (OH&S) track record demonstrated over 15 years continuous operation across 4 states. • Long Term community relations that are proactive, transparent and honest. 5

UUA- Approach to Operations • Operators (“Process Controllers”) that are minimum trade qualified and highly experienced • Fully automated control (SCADA) systems that can be operated remotely from a laptop anywhere in the world • Extensive on-line monitoring, alarms and backup systems • Duty/ standby on critical equipment • Well developed asset management systems that maintain plant and equipment in reliable condition at all times 6

UUA- Approach to Operations • Operators (“Process Controllers”) that are minimum trade qualified and highly experienced • Fully automated control (SCADA) systems that can be operated remotely from a laptop anywhere in the world • Extensive on-line monitoring, alarms and backup systems • Duty/ standby on critical equipment • Well developed asset management systems that maintain plant and equipment in reliable condition at all times 6

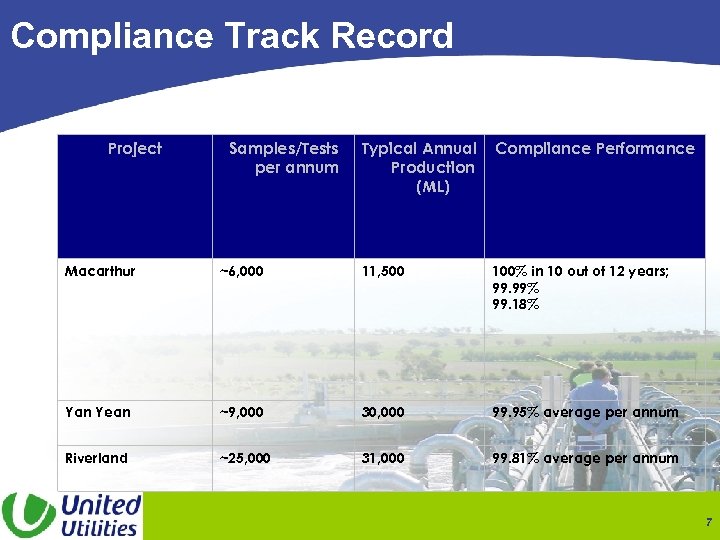

Compliance Track Record Project Samples/Tests per annum Typical Annual Production (ML) Compliance Performance Macarthur ~6, 000 11, 500 100% in 10 out of 12 years; 99. 99% 99. 18% Yan Yean ~9, 000 30, 000 99. 95% average per annum Riverland ~25, 000 31, 000 99. 81% average per annum 7

Compliance Track Record Project Samples/Tests per annum Typical Annual Production (ML) Compliance Performance Macarthur ~6, 000 11, 500 100% in 10 out of 12 years; 99. 99% 99. 18% Yan Yean ~9, 000 30, 000 99. 95% average per annum Riverland ~25, 000 31, 000 99. 81% average per annum 7

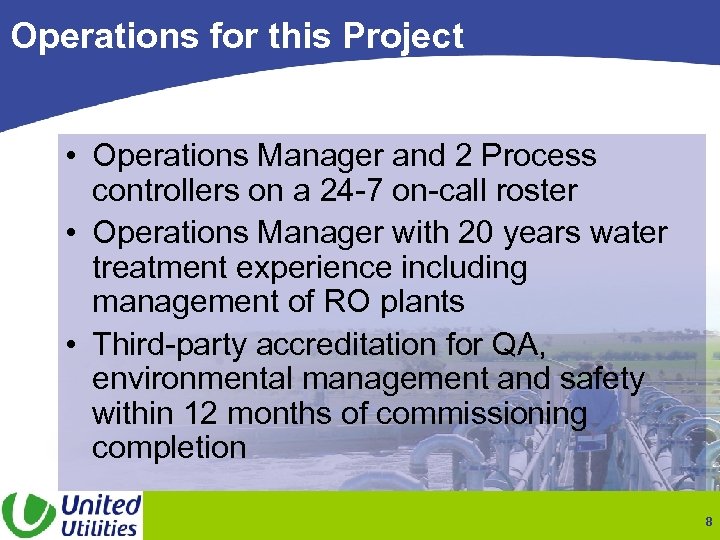

Operations for this Project • Operations Manager and 2 Process controllers on a 24 -7 on-call roster • Operations Manager with 20 years water treatment experience including management of RO plants • Third-party accreditation for QA, environmental management and safety within 12 months of commissioning completion 8

Operations for this Project • Operations Manager and 2 Process controllers on a 24 -7 on-call roster • Operations Manager with 20 years water treatment experience including management of RO plants • Third-party accreditation for QA, environmental management and safety within 12 months of commissioning completion 8

Summary • Company with extensive operations experience in all areas of Australia including rural and remote communities • Track record of near-perfect contractual and statutory compliance • Sophisticated control and monitoring systems • Experienced Team 9

Summary • Company with extensive operations experience in all areas of Australia including rural and remote communities • Track record of near-perfect contractual and statutory compliance • Sophisticated control and monitoring systems • Experienced Team 9

Construction of the Facilities Tim Bradshaw Construction Manager United Utilities Australia 10

Construction of the Facilities Tim Bradshaw Construction Manager United Utilities Australia 10

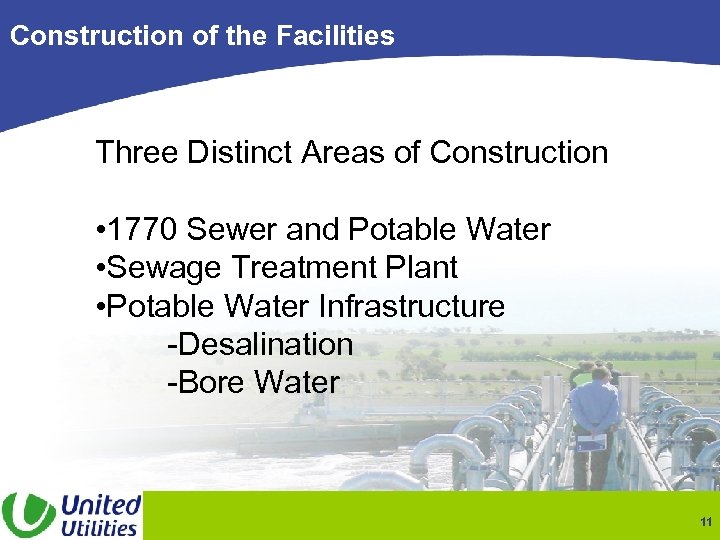

Construction of the Facilities Three Distinct Areas of Construction • 1770 Sewer and Potable Water • Sewage Treatment Plant • Potable Water Infrastructure -Desalination -Bore Water 11

Construction of the Facilities Three Distinct Areas of Construction • 1770 Sewer and Potable Water • Sewage Treatment Plant • Potable Water Infrastructure -Desalination -Bore Water 11

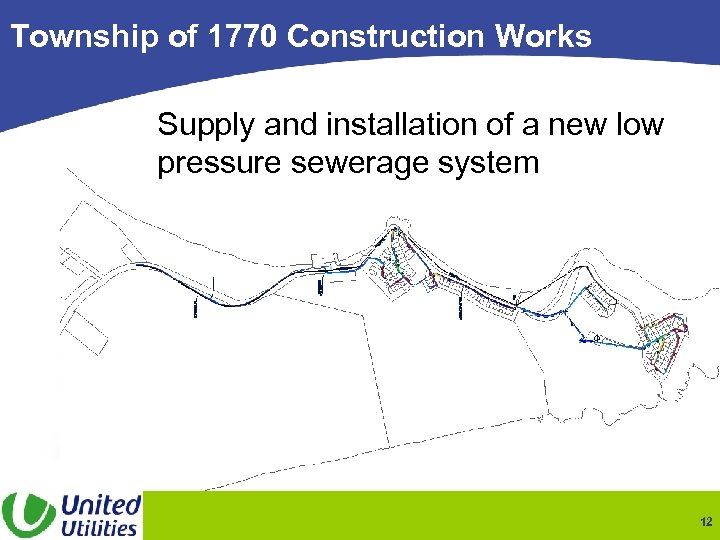

Township of 1770 Construction Works Supply and installation of a new low pressure sewerage system 12

Township of 1770 Construction Works Supply and installation of a new low pressure sewerage system 12

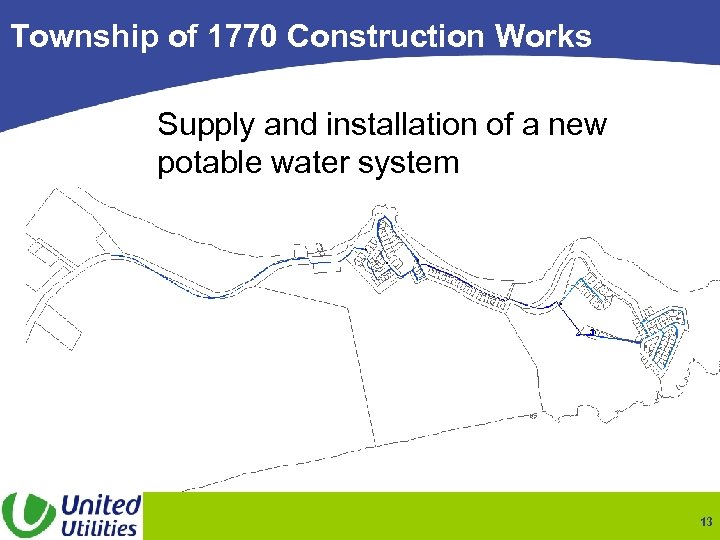

Township of 1770 Construction Works Supply and installation of a new potable water system 13

Township of 1770 Construction Works Supply and installation of a new potable water system 13

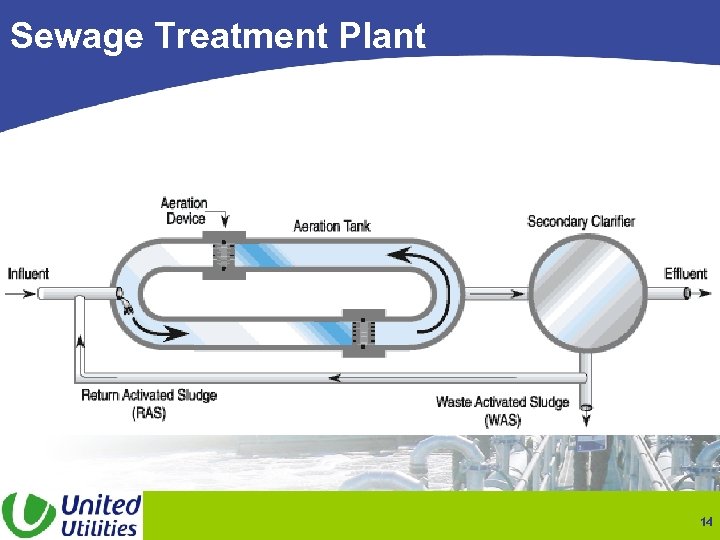

Sewage Treatment Plant 14

Sewage Treatment Plant 14

Sewage Treatment Plant 15

Sewage Treatment Plant 15

Desalination Plant Construction 16

Desalination Plant Construction 16

Desalination Plant Construction Seawater Intake 17

Desalination Plant Construction Seawater Intake 17

Desalination Plant Construction Brine Diffuser 18

Desalination Plant Construction Brine Diffuser 18

Osmoflo Neil Palmer General Manager Technical Services Osmoflo 19

Osmoflo Neil Palmer General Manager Technical Services Osmoflo 19

Desalination o Seawater desalination is very widely practiced around the globe o More than 13, 000 desalination plants are in operation worldwide o Some plants are more than 50 years old o The largest (Ashkelon) can produce 370 ML/d o Australia’s first major seawater desalination plant in Perth (2006) produces 145 ML/d, 17% of the city’s needs 20

Desalination o Seawater desalination is very widely practiced around the globe o More than 13, 000 desalination plants are in operation worldwide o Some plants are more than 50 years old o The largest (Ashkelon) can produce 370 ML/d o Australia’s first major seawater desalination plant in Perth (2006) produces 145 ML/d, 17% of the city’s needs 20

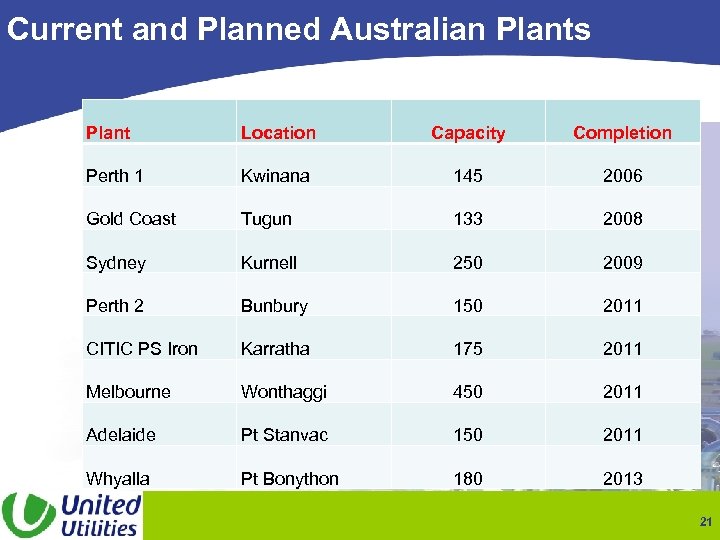

Current and Planned Australian Plants Plant Location Capacity Completion Perth 1 Kwinana 145 2006 Gold Coast Tugun 133 2008 Sydney Kurnell 250 2009 Perth 2 Bunbury 150 2011 CITIC PS Iron Karratha 175 2011 Melbourne Wonthaggi 450 2011 Adelaide Pt Stanvac 150 2011 Whyalla Pt Bonython 180 2013 21

Current and Planned Australian Plants Plant Location Capacity Completion Perth 1 Kwinana 145 2006 Gold Coast Tugun 133 2008 Sydney Kurnell 250 2009 Perth 2 Bunbury 150 2011 CITIC PS Iron Karratha 175 2011 Melbourne Wonthaggi 450 2011 Adelaide Pt Stanvac 150 2011 Whyalla Pt Bonython 180 2013 21

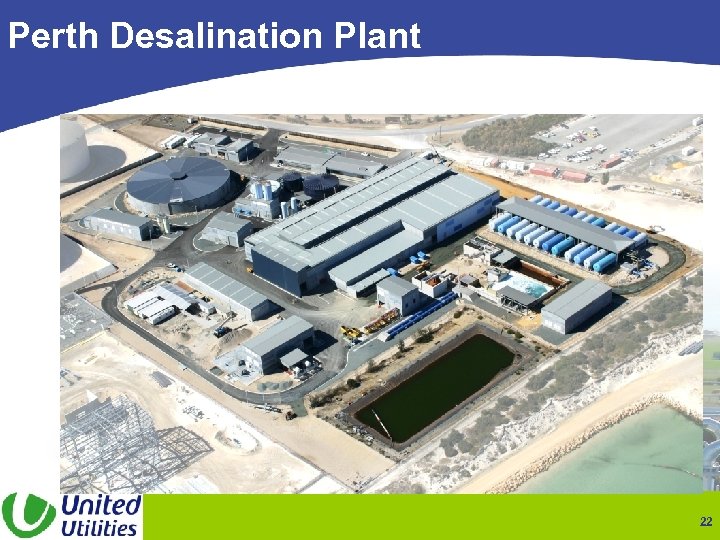

Perth Desalination Plant 22

Perth Desalination Plant 22

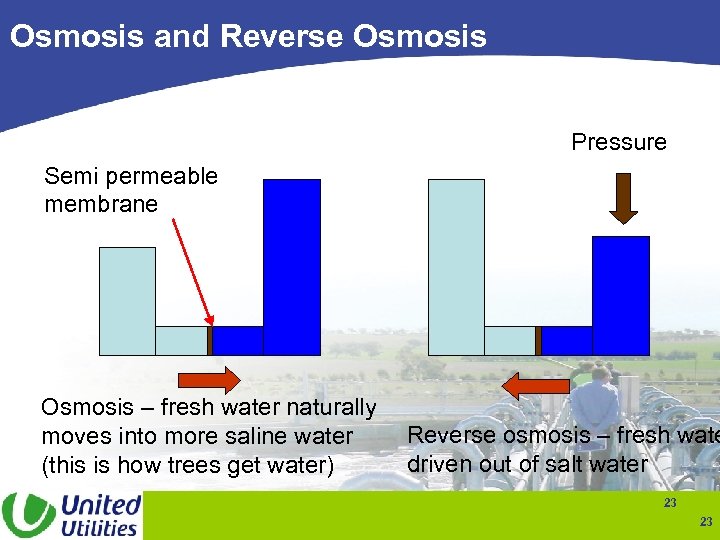

Osmosis and Reverse Osmosis Pressure Semi permeable membrane Osmosis – fresh water naturally moves into more saline water (this is how trees get water) Reverse osmosis – fresh wate driven out of salt water 23 23

Osmosis and Reverse Osmosis Pressure Semi permeable membrane Osmosis – fresh water naturally moves into more saline water (this is how trees get water) Reverse osmosis – fresh wate driven out of salt water 23 23

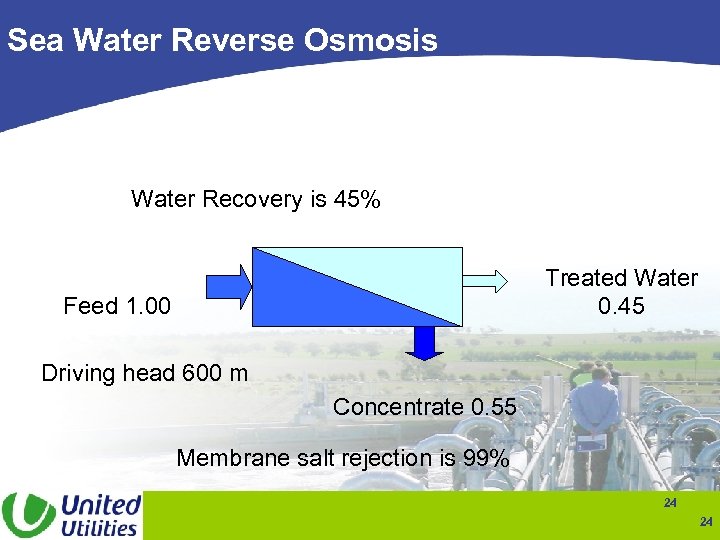

Sea Water Reverse Osmosis Water Recovery is 45% Treated Water 0. 45 Feed 1. 00 Driving head 600 m Concentrate 0. 55 Membrane salt rejection is 99% 24 24

Sea Water Reverse Osmosis Water Recovery is 45% Treated Water 0. 45 Feed 1. 00 Driving head 600 m Concentrate 0. 55 Membrane salt rejection is 99% 24 24

Osmoflo 1. Agnes Water desalination plant is being built for UUA by Australian company Osmoflo 2. Osmoflo has built 150 desalination plants in Australia and overseas 3. Seawater desalination plants are at Scalpay (Scotland), Hong Kong, Marion Bay (SA) Exmouth (WA), Heron, Green, Bedarra and Brampton Islands (Qld) 4. Osmoflo has extensive experience in design, construction and operation of desal plants 25

Osmoflo 1. Agnes Water desalination plant is being built for UUA by Australian company Osmoflo 2. Osmoflo has built 150 desalination plants in Australia and overseas 3. Seawater desalination plants are at Scalpay (Scotland), Hong Kong, Marion Bay (SA) Exmouth (WA), Heron, Green, Bedarra and Brampton Islands (Qld) 4. Osmoflo has extensive experience in design, construction and operation of desal plants 25

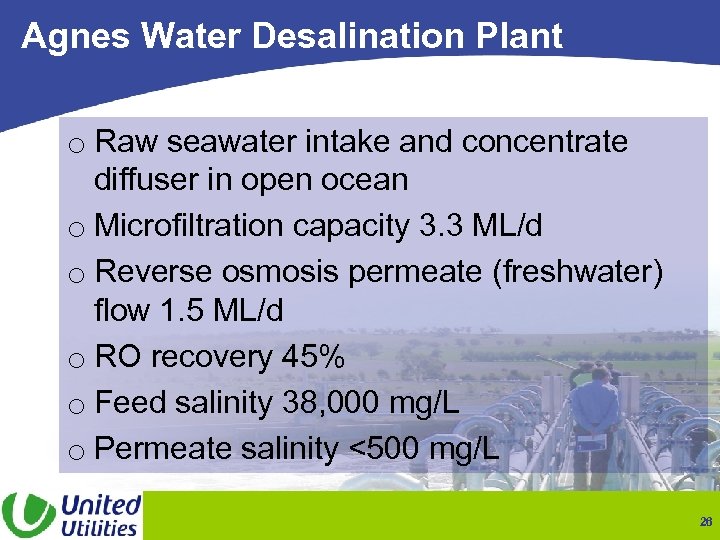

Agnes Water Desalination Plant o Raw seawater intake and concentrate diffuser in open ocean o Microfiltration capacity 3. 3 ML/d o Reverse osmosis permeate (freshwater) flow 1. 5 ML/d o RO recovery 45% o Feed salinity 38, 000 mg/L o Permeate salinity <500 mg/L 26

Agnes Water Desalination Plant o Raw seawater intake and concentrate diffuser in open ocean o Microfiltration capacity 3. 3 ML/d o Reverse osmosis permeate (freshwater) flow 1. 5 ML/d o RO recovery 45% o Feed salinity 38, 000 mg/L o Permeate salinity <500 mg/L 26

Agnes Water Desalination Plant o Permeate to be disinfected and stabilised to prevent corrosion o MF backwash goes to ocean discharge with RO concentrate 27

Agnes Water Desalination Plant o Permeate to be disinfected and stabilised to prevent corrosion o MF backwash goes to ocean discharge with RO concentrate 27

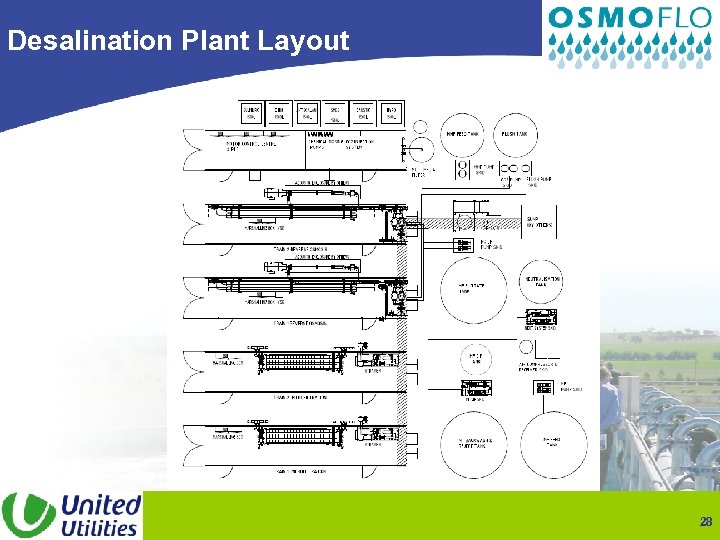

Desalination Plant Layout 28

Desalination Plant Layout 28

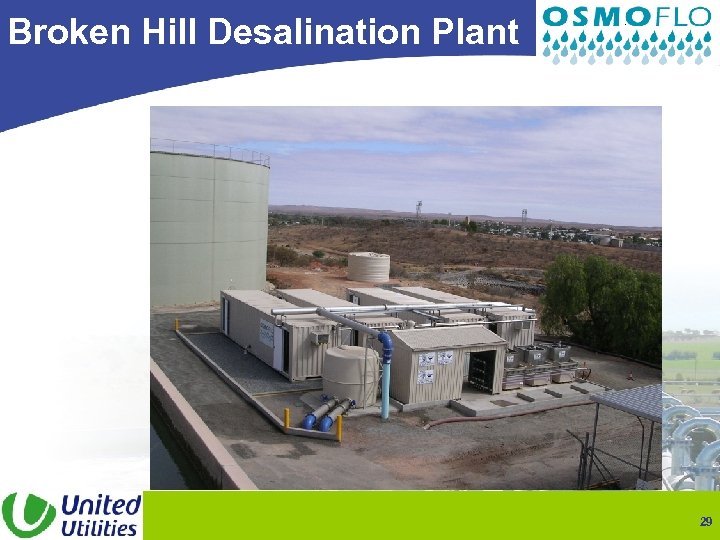

Broken Hill Desalination Plant 29

Broken Hill Desalination Plant 29

Broken Hill Desalination Plant 30

Broken Hill Desalination Plant 30