7de411b4de9fa01f3d8940e56213c9b8.ppt

- Количество слайдов: 30

Agile Product Lifecycle Management (PLM) 16 March 2018 HOST: John Kelley – VP, PLM Product Strategy

Agile Product Lifecycle Management (PLM) 16 March 2018 HOST: John Kelley – VP, PLM Product Strategy

Safe Harbor Statement The following is intended to outline our general product direction. It is intended for information purposes only, and may not be incorporated into any contract. It is not a commitment to deliver any material, code, or functionality, and should not be relied upon in making purchasing decision. The development, release, and timing of any features or functionality described for Oracle’s products remains at the sole discretion of Oracle. © 2007 Oracle Corporation – Proprietary and Confidential 2

Safe Harbor Statement The following is intended to outline our general product direction. It is intended for information purposes only, and may not be incorporated into any contract. It is not a commitment to deliver any material, code, or functionality, and should not be relied upon in making purchasing decision. The development, release, and timing of any features or functionality described for Oracle’s products remains at the sole discretion of Oracle. © 2007 Oracle Corporation – Proprietary and Confidential 2

Agenda • The Profitable Innovation Challenge • How Complexity impact your Innovation Pipeline • Today's System & Business Problems • Agile PLM • Definition, Value and Customers • Agile PLM Solution Overview • Q&A © 2007 Oracle Corporation – Proprietary and Confidential 3

Agenda • The Profitable Innovation Challenge • How Complexity impact your Innovation Pipeline • Today's System & Business Problems • Agile PLM • Definition, Value and Customers • Agile PLM Solution Overview • Q&A © 2007 Oracle Corporation – Proprietary and Confidential 3

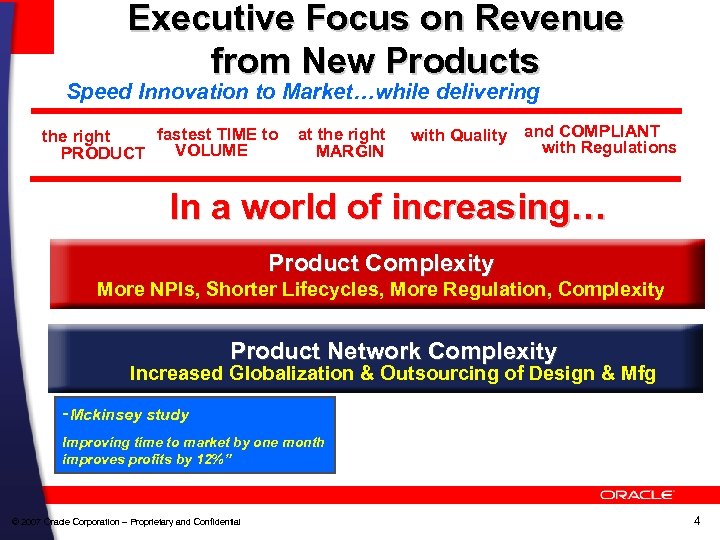

Executive Focus on Revenue from New Products Speed Innovation to Market…while delivering fastest TIME to the right VOLUME PRODUCT at the right MARGIN with Quality and COMPLIANT with Regulations In a world of increasing… Product Complexity More NPIs, Shorter Lifecycles, More Regulation, Complexity Product Network Complexity Increased Globalization & Outsourcing of Design & Mfg -Mckinsey study Improving time to market by one month improves profits by 12%” © 2007 Oracle Corporation – Proprietary and Confidential 4

Executive Focus on Revenue from New Products Speed Innovation to Market…while delivering fastest TIME to the right VOLUME PRODUCT at the right MARGIN with Quality and COMPLIANT with Regulations In a world of increasing… Product Complexity More NPIs, Shorter Lifecycles, More Regulation, Complexity Product Network Complexity Increased Globalization & Outsourcing of Design & Mfg -Mckinsey study Improving time to market by one month improves profits by 12%” © 2007 Oracle Corporation – Proprietary and Confidential 4

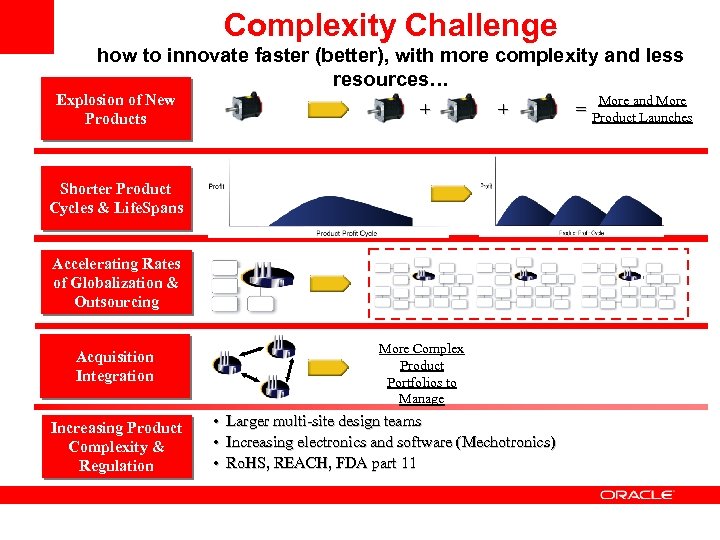

Complexity Challenge how to innovate faster (better), with more complexity and less resources… Explosion of New Products + + Shorter Product Cycles & Life. Spans Accelerating Rates of Globalization & Outsourcing Acquisition Integration Increasing Product Complexity & Regulation More Complex Product Portfolios to Manage • Larger multi-site design teams • Increasing electronics and software (Mechotronics) • Ro. HS, REACH, FDA part 11 More and More = Product Launches

Complexity Challenge how to innovate faster (better), with more complexity and less resources… Explosion of New Products + + Shorter Product Cycles & Life. Spans Accelerating Rates of Globalization & Outsourcing Acquisition Integration Increasing Product Complexity & Regulation More Complex Product Portfolios to Manage • Larger multi-site design teams • Increasing electronics and software (Mechotronics) • Ro. HS, REACH, FDA part 11 More and More = Product Launches

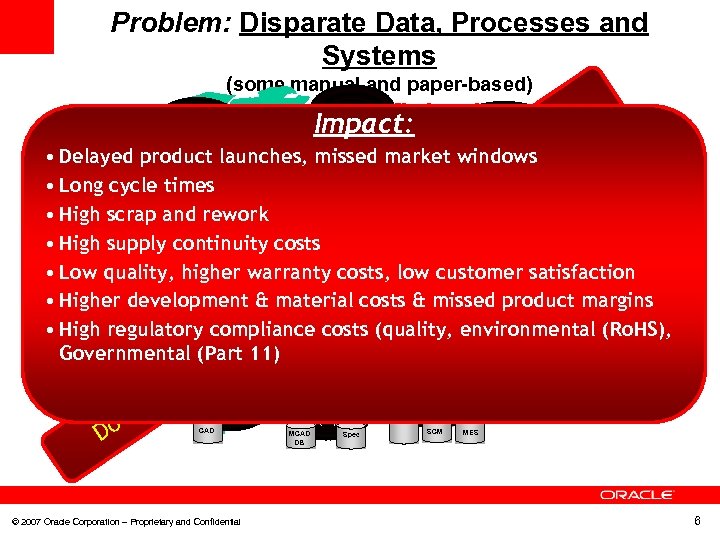

Problem: Disparate Data, Processes and Systems (some manual and paper-based) ARTWORK DESIGN …Cause Profit Leaks … is? Impact: h SUPPLIERS OUTSOURCED PARTNERS T • Delayed product launches, missed market windows ike k. L CUSTOMERS • Long cycle times Design oo REGULATORY L Samples Briefs BODIES Packages • High scrap and rework Designs m Submission ste • High supply continuity costs Value Chain Files Artwork Sy Formulas Files • Enterprise quality, higher warrantyacosts, low customer satisfaction Low nd s Ideas • Higher development tions material costs & Audits & sse missed product. LEGAL & CA margins Specifica MARKETING e CAD Models oc • High regulatory compliance costs (quality, environmental (Ro. HS), Pr Governmental (Part 11) ign CAD Adobe Quark SCM ERP Notes Project Excel R&D (EUROPE) Excel ou Y Recipe Mgmt Do r es D EDMS Access PROCUREMENT R&D (ASIA) CAD © 2007 Oracle Corporation – Proprietary and Confidential PRODUCTION R&D (US) MCAD DB Spec SCM ERP MES 6

Problem: Disparate Data, Processes and Systems (some manual and paper-based) ARTWORK DESIGN …Cause Profit Leaks … is? Impact: h SUPPLIERS OUTSOURCED PARTNERS T • Delayed product launches, missed market windows ike k. L CUSTOMERS • Long cycle times Design oo REGULATORY L Samples Briefs BODIES Packages • High scrap and rework Designs m Submission ste • High supply continuity costs Value Chain Files Artwork Sy Formulas Files • Enterprise quality, higher warrantyacosts, low customer satisfaction Low nd s Ideas • Higher development tions material costs & Audits & sse missed product. LEGAL & CA margins Specifica MARKETING e CAD Models oc • High regulatory compliance costs (quality, environmental (Ro. HS), Pr Governmental (Part 11) ign CAD Adobe Quark SCM ERP Notes Project Excel R&D (EUROPE) Excel ou Y Recipe Mgmt Do r es D EDMS Access PROCUREMENT R&D (ASIA) CAD © 2007 Oracle Corporation – Proprietary and Confidential PRODUCTION R&D (US) MCAD DB Spec SCM ERP MES 6

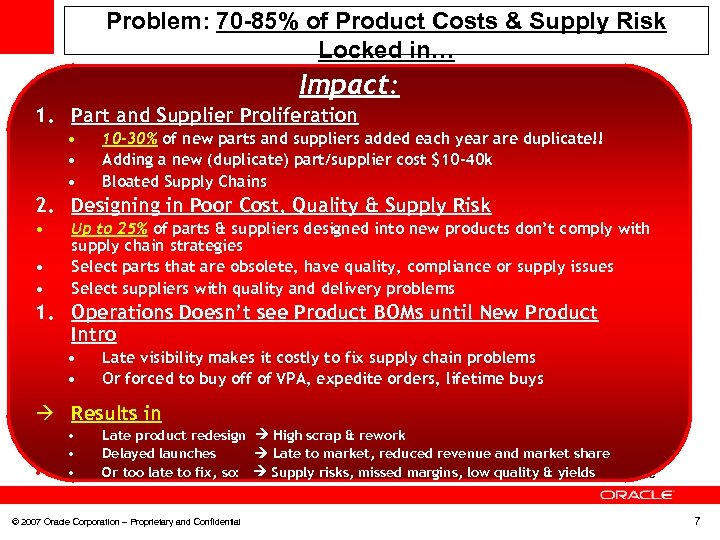

Problem: 70 -85% of Product Costs & Supply Risk Locked in… by the Sourcing Decisions Made During the Design Cycle 95% 100 Life Cycle Cost Determinations Impact: 85% 1. Part and Supplier Proliferation 70% Fate was determined back here ! • • • 80 10 -30% of new parts and suppliers added each year are duplicate!! Adding 60 a new (duplicate) part/supplier cost $10 -40 k Market, Margin, Risk Design Time to Freeze Bloated Supply Chains and Quality start in Design! 40 2. Designing in Poor Cost, Quality & Supply Risk 20 • • • 20 Up to 25% of parts & suppliers designed into new products don’t comply with Conceptual Design Detailed Design Production Operations supply chain strategiesphase) (creative, early (engineering And Support phase) Select parts that. Source: DARPA Rapid Design Exploration andquality, compliance or supply issues are obsolete, have Optimization Project Select suppliers with quality and delivery problems Problem: The Gap between Design and Operations 1. Operations Doesn’t see Product BOMs until New Product 1. Intro Engineers make a majority of Sourcing Designs • Don’t Late visibility makes it costly to fix supply chain problems limitations or factor in sourcing strategies, supplier performance, manufacturing • supply chain constraints in those decisions • Or forced to buy off of VPA, expedite orders, lifetime buys They try to but…. Don’t have visibility into the business information stored in their manufacturing systems Results in • • Late product redesign High scrap & rework • • Engineers spend 20 -30% of their market, reduced revenue and market share Delayed launches Late to time “attempting” to find this information • • Easier. Or too late to new so: Supply risks, then find and reuse an existing preferred one to introduce fix, parts and suppliers missed margins, low quality & yields © 2007 Oracle Corporation – Proprietary and Confidential 7

Problem: 70 -85% of Product Costs & Supply Risk Locked in… by the Sourcing Decisions Made During the Design Cycle 95% 100 Life Cycle Cost Determinations Impact: 85% 1. Part and Supplier Proliferation 70% Fate was determined back here ! • • • 80 10 -30% of new parts and suppliers added each year are duplicate!! Adding 60 a new (duplicate) part/supplier cost $10 -40 k Market, Margin, Risk Design Time to Freeze Bloated Supply Chains and Quality start in Design! 40 2. Designing in Poor Cost, Quality & Supply Risk 20 • • • 20 Up to 25% of parts & suppliers designed into new products don’t comply with Conceptual Design Detailed Design Production Operations supply chain strategiesphase) (creative, early (engineering And Support phase) Select parts that. Source: DARPA Rapid Design Exploration andquality, compliance or supply issues are obsolete, have Optimization Project Select suppliers with quality and delivery problems Problem: The Gap between Design and Operations 1. Operations Doesn’t see Product BOMs until New Product 1. Intro Engineers make a majority of Sourcing Designs • Don’t Late visibility makes it costly to fix supply chain problems limitations or factor in sourcing strategies, supplier performance, manufacturing • supply chain constraints in those decisions • Or forced to buy off of VPA, expedite orders, lifetime buys They try to but…. Don’t have visibility into the business information stored in their manufacturing systems Results in • • Late product redesign High scrap & rework • • Engineers spend 20 -30% of their market, reduced revenue and market share Delayed launches Late to time “attempting” to find this information • • Easier. Or too late to new so: Supply risks, then find and reuse an existing preferred one to introduce fix, parts and suppliers missed margins, low quality & yields © 2007 Oracle Corporation – Proprietary and Confidential 7

Agenda • The Profitable Innovation Challenge • How Complexity impact your Innovation Pipeline • Today's System & Business Problems • Agile PLM • Definition, Value and Customers • Agile PLM Solution Overview • Q&A © 2007 Oracle Corporation – Proprietary and Confidential 8

Agenda • The Profitable Innovation Challenge • How Complexity impact your Innovation Pipeline • Today's System & Business Problems • Agile PLM • Definition, Value and Customers • Agile PLM Solution Overview • Q&A © 2007 Oracle Corporation – Proprietary and Confidential 8

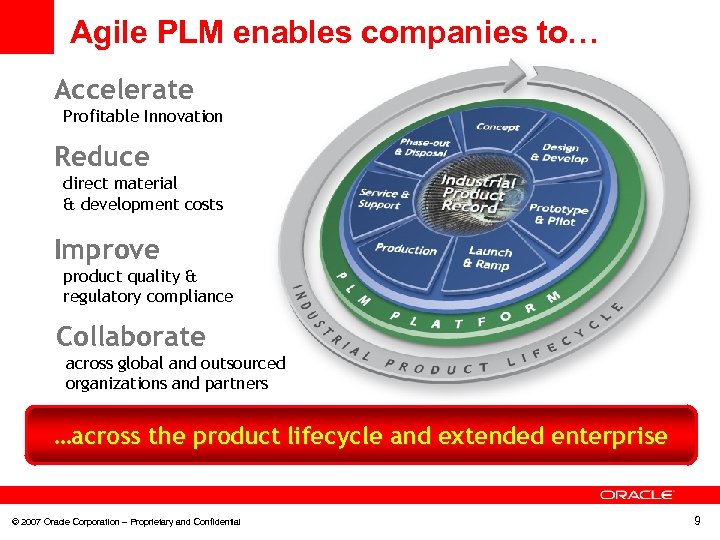

Agile PLM enables companies to… Accelerate Profitable Innovation Reduce direct material & development costs Improve product quality & regulatory compliance Collaborate across global and outsourced organizations and partners …across the product lifecycle and extended enterprise © 2007 Oracle Corporation – Proprietary and Confidential 9

Agile PLM enables companies to… Accelerate Profitable Innovation Reduce direct material & development costs Improve product quality & regulatory compliance Collaborate across global and outsourced organizations and partners …across the product lifecycle and extended enterprise © 2007 Oracle Corporation – Proprietary and Confidential 9

What is Agile PLM? PLM enables companies to accelerate profitable product innovation… …through the management of the information, processes and decisions about their products… …throughout the product lifecycle and securely & collaboratively across the global product network © 2007 Oracle Corporation – Proprietary and Confidential 10

What is Agile PLM? PLM enables companies to accelerate profitable product innovation… …through the management of the information, processes and decisions about their products… …throughout the product lifecycle and securely & collaboratively across the global product network © 2007 Oracle Corporation – Proprietary and Confidential 10

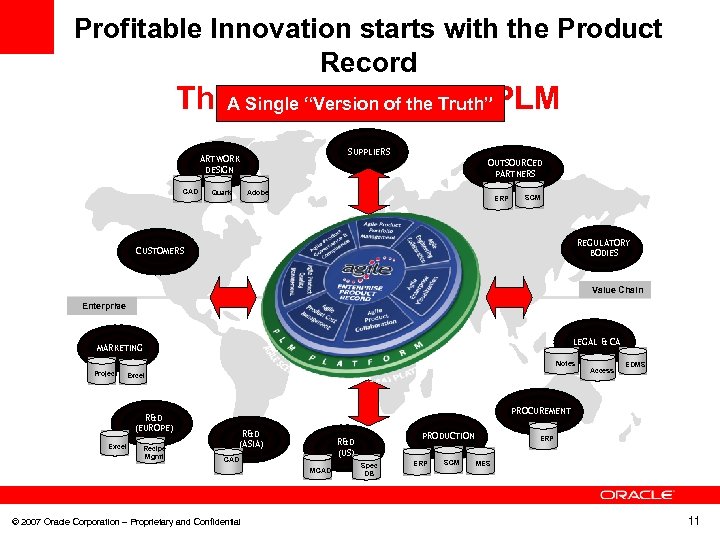

Profitable Innovation starts with the Product Record The. A Solution = Agile PLM Single “Version of the Truth” SUPPLIERS ARTWORK DESIGN CAD Quark OUTSOURCED PARTNERS Adobe ERP SCM REGULATORY BODIES CUSTOMERS Value Chain Enterprise LEGAL & CA MARKETING Notes Project Excel R&D (EUROPE) Excel Recipe Mgmt Access EDMS PROCUREMENT R&D (ASIA) CAD MCAD © 2007 Oracle Corporation – Proprietary and Confidential PRODUCTION R&D (US) Spec DB ERP SCM ERP MES 11

Profitable Innovation starts with the Product Record The. A Solution = Agile PLM Single “Version of the Truth” SUPPLIERS ARTWORK DESIGN CAD Quark OUTSOURCED PARTNERS Adobe ERP SCM REGULATORY BODIES CUSTOMERS Value Chain Enterprise LEGAL & CA MARKETING Notes Project Excel R&D (EUROPE) Excel Recipe Mgmt Access EDMS PROCUREMENT R&D (ASIA) CAD MCAD © 2007 Oracle Corporation – Proprietary and Confidential PRODUCTION R&D (US) Spec DB ERP SCM ERP MES 11

The Enterprise (integrated) Product Record Customer Information Compliance Information - Regulatory - Standards - Audits - Corrective Actions Field instructions Service BOMs g is hin Manufacturing Information ryt - Bills of Materials Eve - Mfg. Instructions - Revisions - a Service Information - Portfolio Information Requirements Configurations Quality Issues , S d cte e rch a e n on C ble a Programs Schedules Resources Deliverables d. C n cks li y wa A Design Information - Schematics & Drawings CAD Models Software/Firmware Design Reviews Purchasing Information Supplier Information - Approved Vendors - Preference/Status - Availability - Pricing - Part/BOM Costs - Price History The integrated product record securely manages & shares all the key product information and connects & automates © 2007 Oracleall the business processes required by the Product Network 12 Corporation – Proprietary and Confidential

The Enterprise (integrated) Product Record Customer Information Compliance Information - Regulatory - Standards - Audits - Corrective Actions Field instructions Service BOMs g is hin Manufacturing Information ryt - Bills of Materials Eve - Mfg. Instructions - Revisions - a Service Information - Portfolio Information Requirements Configurations Quality Issues , S d cte e rch a e n on C ble a Programs Schedules Resources Deliverables d. C n cks li y wa A Design Information - Schematics & Drawings CAD Models Software/Firmware Design Reviews Purchasing Information Supplier Information - Approved Vendors - Preference/Status - Availability - Pricing - Part/BOM Costs - Price History The integrated product record securely manages & shares all the key product information and connects & automates © 2007 Oracleall the business processes required by the Product Network 12 Corporation – Proprietary and Confidential

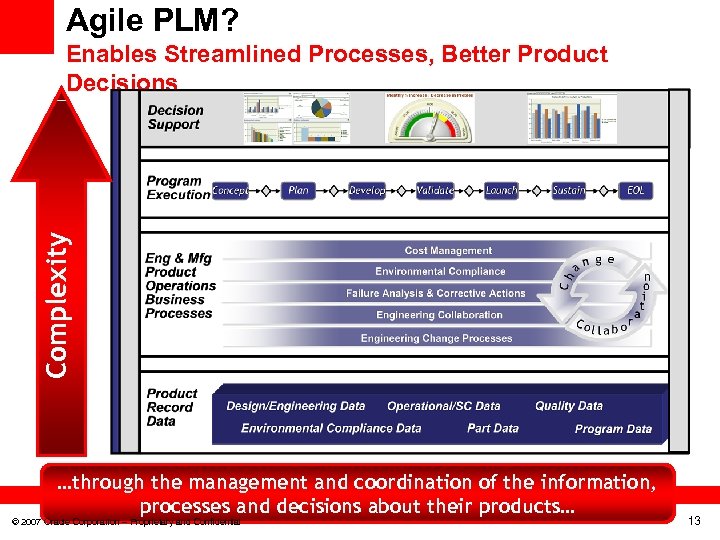

Agile PLM? Complexity Enables Streamlined Processes, Better Product Decisions …through the management and coordination of the information, processes and decisions about their products… © 2007 Oracle Corporation – Proprietary and Confidential 13

Agile PLM? Complexity Enables Streamlined Processes, Better Product Decisions …through the management and coordination of the information, processes and decisions about their products… © 2007 Oracle Corporation – Proprietary and Confidential 13

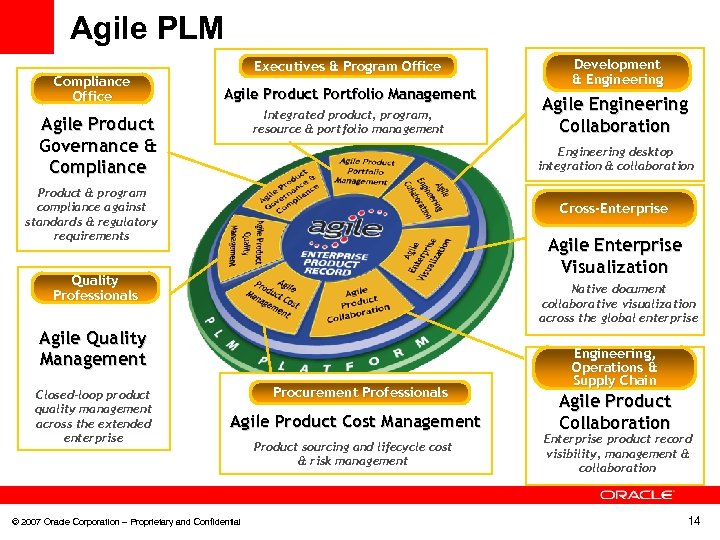

Agile PLM Compliance Office Executives & Program Office Agile Product Portfolio Management Integrated product, program, resource & portfolio management Agile Product Governance & Compliance Agile Engineering Collaboration Engineering desktop integration & collaboration Product & program compliance against standards & regulatory requirements Cross-Enterprise Agile Enterprise Visualization Quality Professionals Native document collaborative visualization across the global enterprise Agile Quality Management Closed-loop product quality management across the extended enterprise Development & Engineering Procurement Professionals Agile Product Cost Management © 2007 Oracle Corporation – Proprietary and Confidential Product sourcing and lifecycle cost & risk management Engineering, Operations & Supply Chain Agile Product Collaboration Enterprise product record visibility, management & collaboration 14

Agile PLM Compliance Office Executives & Program Office Agile Product Portfolio Management Integrated product, program, resource & portfolio management Agile Product Governance & Compliance Agile Engineering Collaboration Engineering desktop integration & collaboration Product & program compliance against standards & regulatory requirements Cross-Enterprise Agile Enterprise Visualization Quality Professionals Native document collaborative visualization across the global enterprise Agile Quality Management Closed-loop product quality management across the extended enterprise Development & Engineering Procurement Professionals Agile Product Cost Management © 2007 Oracle Corporation – Proprietary and Confidential Product sourcing and lifecycle cost & risk management Engineering, Operations & Supply Chain Agile Product Collaboration Enterprise product record visibility, management & collaboration 14

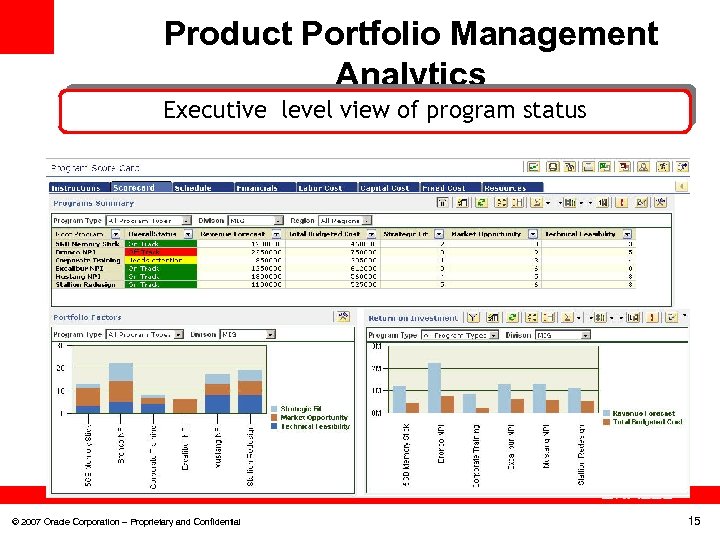

Product Portfolio Management Analytics Track volume Portfoliolevel and rate ofof program Fit, & Executive the. Scorecard, Strategicstatus ROI view new process requests. © 2007 Oracle Corporation – Proprietary and Confidential 15

Product Portfolio Management Analytics Track volume Portfoliolevel and rate ofof program Fit, & Executive the. Scorecard, Strategicstatus ROI view new process requests. © 2007 Oracle Corporation – Proprietary and Confidential 15

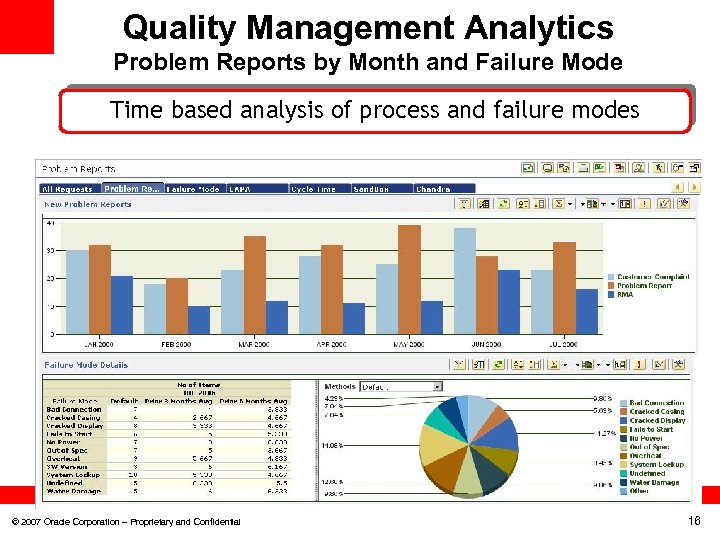

Quality Management Analytics Problem Reports by Month and Failure Mode Track the volume and rate of new process requests. Time based analysis of process and failure modes © 2007 Oracle Corporation – Proprietary and Confidential 16

Quality Management Analytics Problem Reports by Month and Failure Mode Track the volume and rate of new process requests. Time based analysis of process and failure modes © 2007 Oracle Corporation – Proprietary and Confidential 16

BOM Mgmt (Line BOM) © 2007 Oracle Corporation – Proprietary and Confidential 17

BOM Mgmt (Line BOM) © 2007 Oracle Corporation – Proprietary and Confidential 17

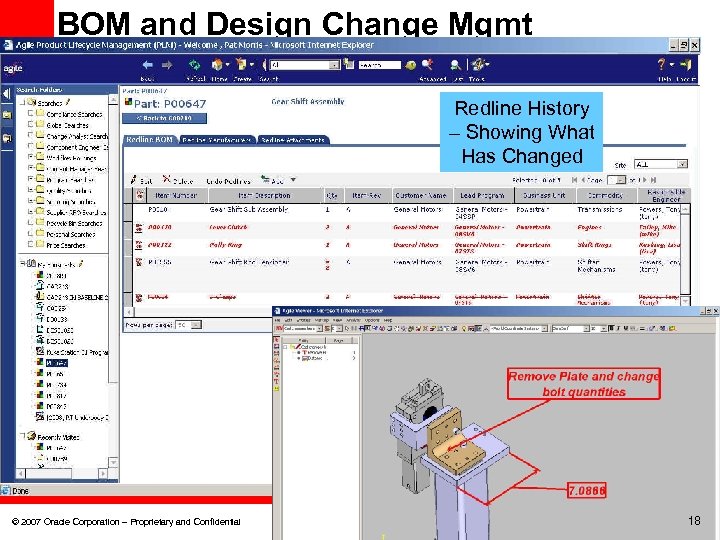

BOM and Design Change Mgmt Redline History – Showing What Has Changed © 2007 Oracle Corporation – Proprietary and Confidential 18

BOM and Design Change Mgmt Redline History – Showing What Has Changed © 2007 Oracle Corporation – Proprietary and Confidential 18

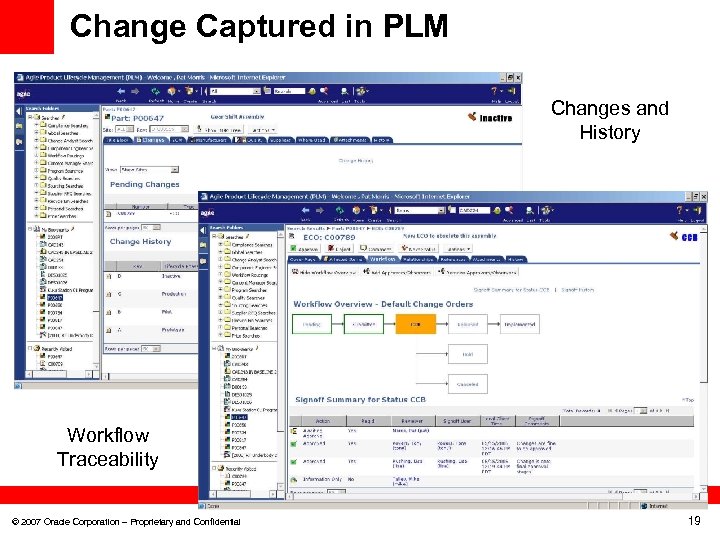

Change Captured in PLM Changes and History Workflow Traceability © 2007 Oracle Corporation – Proprietary and Confidential 19

Change Captured in PLM Changes and History Workflow Traceability © 2007 Oracle Corporation – Proprietary and Confidential 19

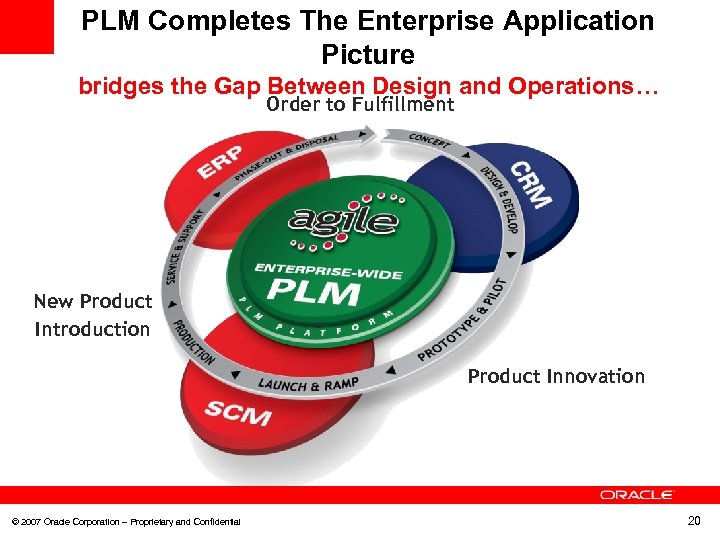

PLM Completes The Enterprise Application Picture bridges the Gap Between Design and Operations… Order to Fulfillment New Product Introduction Product Innovation © 2007 Oracle Corporation – Proprietary and Confidential 20

PLM Completes The Enterprise Application Picture bridges the Gap Between Design and Operations… Order to Fulfillment New Product Introduction Product Innovation © 2007 Oracle Corporation – Proprietary and Confidential 20

PLM Enables you to Answer Key Business Problems 1. Across an Increasingly Globalized and Outsourced Design & Supply Chain Which New Product Ideas Should be Funded? 4 are the Funded Projects on Time and on Margin 2. How do I Reduce Cycle Time? 4 and Reduce Scrap, Rework and E&O 3. Are my Products “Designed for Supply” at Launch? 4 at Target Cost, Quality, Supply Risk 4. How do I Ensure Regulatory Compliance? 4 reduce the cost & time for ROHS, WEEE, FDA, Part 11, ISO audits 5. How do I Enable Globalization and Outsourcing Model 4 Securely Collaborate on data and business processes and Synchronize resources, schedules and deliverables across global sites and partners © 2007 Oracle Corporation – Proprietary and Confidential 21

PLM Enables you to Answer Key Business Problems 1. Across an Increasingly Globalized and Outsourced Design & Supply Chain Which New Product Ideas Should be Funded? 4 are the Funded Projects on Time and on Margin 2. How do I Reduce Cycle Time? 4 and Reduce Scrap, Rework and E&O 3. Are my Products “Designed for Supply” at Launch? 4 at Target Cost, Quality, Supply Risk 4. How do I Ensure Regulatory Compliance? 4 reduce the cost & time for ROHS, WEEE, FDA, Part 11, ISO audits 5. How do I Enable Globalization and Outsourcing Model 4 Securely Collaborate on data and business processes and Synchronize resources, schedules and deliverables across global sites and partners © 2007 Oracle Corporation – Proprietary and Confidential 21

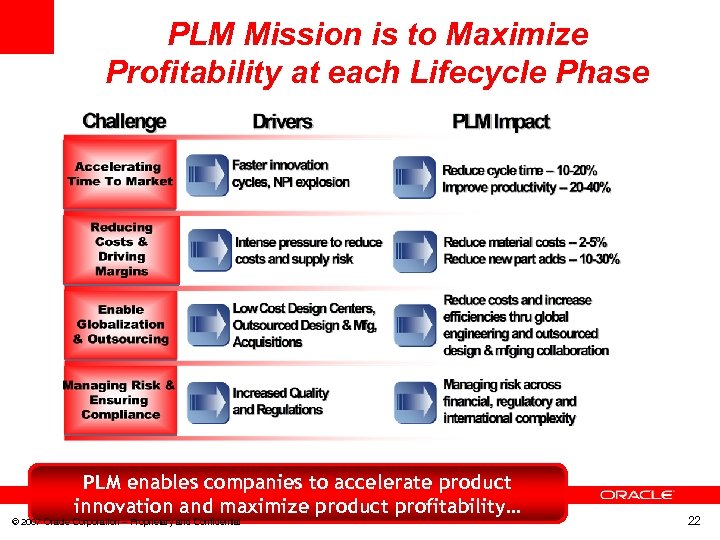

PLM Mission is to Maximize Profitability at each Lifecycle Phase PLM enables companies to accelerate product innovation and maximize product profitability… © 2007 Oracle Corporation – Proprietary and Confidential 22

PLM Mission is to Maximize Profitability at each Lifecycle Phase PLM enables companies to accelerate product innovation and maximize product profitability… © 2007 Oracle Corporation – Proprietary and Confidential 22

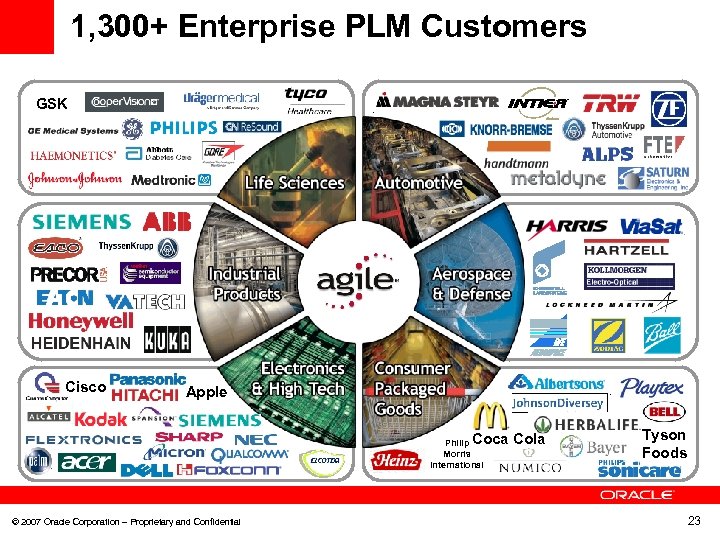

1, 300+ Enterprise PLM Customers GSK Cisco Apple Coca Cola Philip Morris International © 2007 Oracle Corporation – Proprietary and Confidential Tyson Foods 23

1, 300+ Enterprise PLM Customers GSK Cisco Apple Coca Cola Philip Morris International © 2007 Oracle Corporation – Proprietary and Confidential Tyson Foods 23

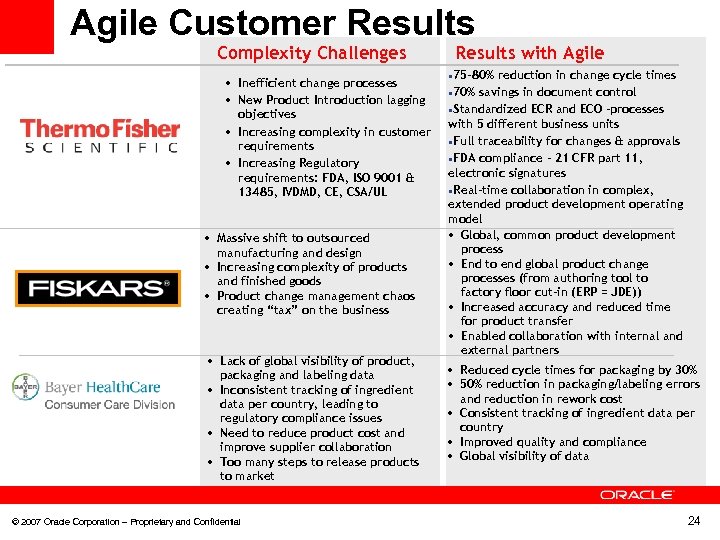

Agile Customer Results Complexity Challenges • Inefficient change processes • New Product Introduction lagging objectives • Increasing complexity in customer requirements • Increasing Regulatory requirements: FDA, ISO 9001 & 13485, IVDMD, CE, CSA/UL • Massive shift to outsourced manufacturing and design • Increasing complexity of products and finished goods • Product change management chaos creating “tax” on the business • Lack of global visibility of product, packaging and labeling data • Inconsistent tracking of ingredient data per country, leading to regulatory compliance issues • Need to reduce product cost and improve supplier collaboration • Too many steps to release products to market © 2007 Oracle Corporation – Proprietary and Confidential Results with Agile • 75 -80% reduction in change cycle times • 70% savings in document control • Standardized ECR and ECO -processes with 5 different business units • Full traceability for changes & approvals • FDA compliance - 21 CFR part 11, electronic signatures • Real-time collaboration in complex, extended product development operating model • Global, common product development process • End to end global product change processes (from authoring tool to factory floor cut-in (ERP = JDE)) • Increased accuracy and reduced time for product transfer • Enabled collaboration with internal and external partners • Reduced cycle times for packaging by 30% • 50% reduction in packaging/labeling errors and reduction in rework cost • Consistent tracking of ingredient data per country • Improved quality and compliance • Global visibility of data 24

Agile Customer Results Complexity Challenges • Inefficient change processes • New Product Introduction lagging objectives • Increasing complexity in customer requirements • Increasing Regulatory requirements: FDA, ISO 9001 & 13485, IVDMD, CE, CSA/UL • Massive shift to outsourced manufacturing and design • Increasing complexity of products and finished goods • Product change management chaos creating “tax” on the business • Lack of global visibility of product, packaging and labeling data • Inconsistent tracking of ingredient data per country, leading to regulatory compliance issues • Need to reduce product cost and improve supplier collaboration • Too many steps to release products to market © 2007 Oracle Corporation – Proprietary and Confidential Results with Agile • 75 -80% reduction in change cycle times • 70% savings in document control • Standardized ECR and ECO -processes with 5 different business units • Full traceability for changes & approvals • FDA compliance - 21 CFR part 11, electronic signatures • Real-time collaboration in complex, extended product development operating model • Global, common product development process • End to end global product change processes (from authoring tool to factory floor cut-in (ERP = JDE)) • Increased accuracy and reduced time for product transfer • Enabled collaboration with internal and external partners • Reduced cycle times for packaging by 30% • 50% reduction in packaging/labeling errors and reduction in rework cost • Consistent tracking of ingredient data per country • Improved quality and compliance • Global visibility of data 24

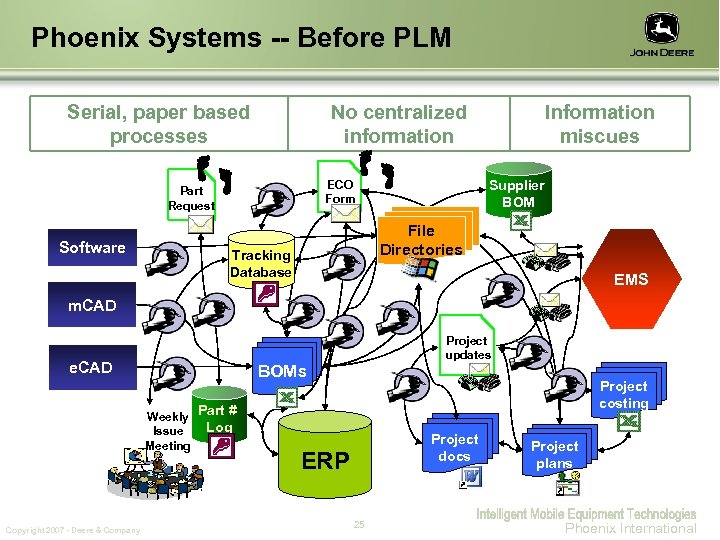

Phoenix Systems -- Before PLM Serial, paper based processes No centralized information Software Supplier BOM ECO Form Part Request Information miscues File Directories Tracking Database EMS m. CAD e. CAD BOMs Weekly Part # Log Issue Meeting Copyright 2007 - Deere & Company Project updates Project costing Project docs ERP 25 Project plans Phoenix International

Phoenix Systems -- Before PLM Serial, paper based processes No centralized information Software Supplier BOM ECO Form Part Request Information miscues File Directories Tracking Database EMS m. CAD e. CAD BOMs Weekly Part # Log Issue Meeting Copyright 2007 - Deere & Company Project updates Project costing Project docs ERP 25 Project plans Phoenix International

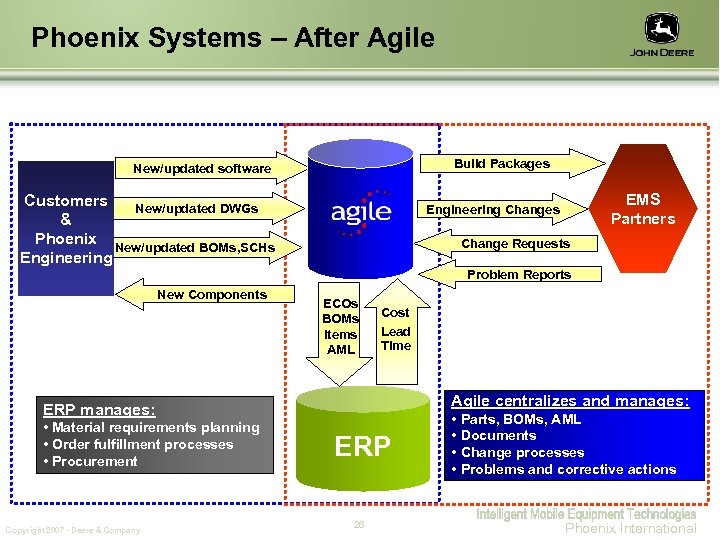

Phoenix Systems – After Agile Build Packages New/updated software Customers New/updated DWGs & Phoenix New/updated BOMs, SCHs Engineering EMS Partners Engineering Changes Change Requests Problem Reports New Components ECOs BOMs Items AML Cost Lead Time Agile centralizes and manages: ERP manages: • Material requirements planning • Order fulfillment processes • Procurement Copyright 2007 - Deere & Company ERP 26 • Parts, BOMs, AML • Documents • Change processes • Problems and corrective actions Phoenix International

Phoenix Systems – After Agile Build Packages New/updated software Customers New/updated DWGs & Phoenix New/updated BOMs, SCHs Engineering EMS Partners Engineering Changes Change Requests Problem Reports New Components ECOs BOMs Items AML Cost Lead Time Agile centralizes and manages: ERP manages: • Material requirements planning • Order fulfillment processes • Procurement Copyright 2007 - Deere & Company ERP 26 • Parts, BOMs, AML • Documents • Change processes • Problems and corrective actions Phoenix International

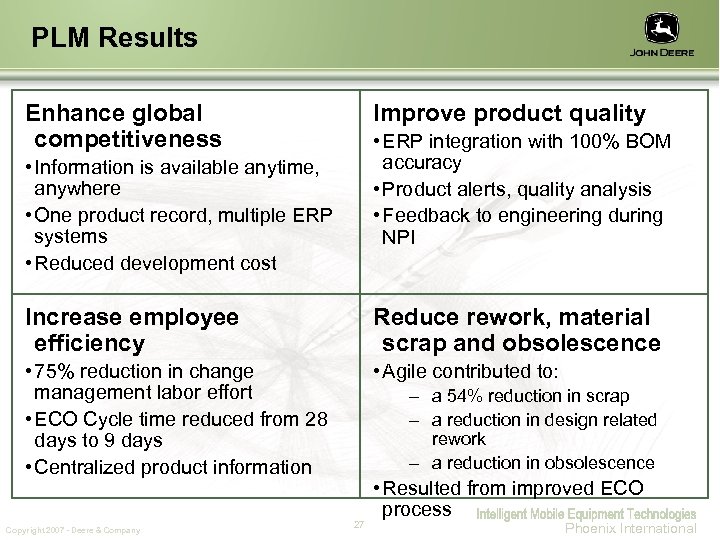

PLM Results Enhance global competitiveness Improve product quality • ERP integration with 100% BOM accuracy • Product alerts, quality analysis • Feedback to engineering during NPI • Information is available anytime, anywhere • One product record, multiple ERP systems • Reduced development cost Increase employee efficiency Reduce rework, material scrap and obsolescence • 75% reduction in change management labor effort • ECO Cycle time reduced from 28 days to 9 days • Centralized product information • Agile contributed to: Copyright 2007 - Deere & Company – a 54% reduction in scrap – a reduction in design related rework – a reduction in obsolescence 27 • Resulted from improved ECO process Phoenix International

PLM Results Enhance global competitiveness Improve product quality • ERP integration with 100% BOM accuracy • Product alerts, quality analysis • Feedback to engineering during NPI • Information is available anytime, anywhere • One product record, multiple ERP systems • Reduced development cost Increase employee efficiency Reduce rework, material scrap and obsolescence • 75% reduction in change management labor effort • ECO Cycle time reduced from 28 days to 9 days • Centralized product information • Agile contributed to: Copyright 2007 - Deere & Company – a 54% reduction in scrap – a reduction in design related rework – a reduction in obsolescence 27 • Resulted from improved ECO process Phoenix International

Agenda • The Profitable Innovation Challenge • How Complexity impact your Innovation Pipeline • Today's System & Business Problems • Agile PLM • Definition, Value and Customers • Agile PLM Solution Overview • Q&A © 2007 Oracle Corporation – Proprietary and Confidential 28

Agenda • The Profitable Innovation Challenge • How Complexity impact your Innovation Pipeline • Today's System & Business Problems • Agile PLM • Definition, Value and Customers • Agile PLM Solution Overview • Q&A © 2007 Oracle Corporation – Proprietary and Confidential 28

Agenda • The Profitable Innovation Challenge • How Complexity impact your Innovation Pipeline • Today's System & Business Problems • Agile PLM • Definition, Value and Customers • Agile PLM Solution Overview • Q&A © 2007 Oracle Corporation – Proprietary and Confidential 29

Agenda • The Profitable Innovation Challenge • How Complexity impact your Innovation Pipeline • Today's System & Business Problems • Agile PLM • Definition, Value and Customers • Agile PLM Solution Overview • Q&A © 2007 Oracle Corporation – Proprietary and Confidential 29