89e539e75f03ea8ab8e793950c482757.ppt

- Количество слайдов: 53

Agenda: Rockwell Automation Solutions & Technology for the Biofuels Industry • Issues facing the Biofuels Industry • Partnering for Success • Expertise in Europe • Global Supply & Local Capabilities • Delivering Value Solutions & • Technology and Expertise Technology for the Biofuels Industry Presented By: Grant Watkins Copyright © 2007 Rockwell Automation, Inc. All rights reserved.

Agenda: Rockwell Automation Solutions & Technology for the Biofuels Industry • Issues facing the Biofuels Industry • Partnering for Success • Expertise in Europe • Global Supply & Local Capabilities • Delivering Value Solutions & • Technology and Expertise Technology for the Biofuels Industry Presented By: Grant Watkins Copyright © 2007 Rockwell Automation, Inc. All rights reserved.

Agenda • Issues facing the Biofuels Industry • Partnering for Success • Global Supply & Local Capabilities • Delivering Value • Technology and Expertise Copyright © 2007 Rockwell Automation, Inc. All rights reserved.

Agenda • Issues facing the Biofuels Industry • Partnering for Success • Global Supply & Local Capabilities • Delivering Value • Technology and Expertise Copyright © 2007 Rockwell Automation, Inc. All rights reserved.

Issues facing the Biofuels Industry Issues • Planning and implementation – Reduce time required for system design and implementation – Lower risks related to plant commissioning • Process improvement at existing plants – Improve yield – Increase throughput by reducing cycle time • Reduction of operating costs – – Improve maintenance operations Efficient energy usage Optimise labour utilisation through training and improved automation Reduce downtime Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 1/4

Issues facing the Biofuels Industry Issues • Planning and implementation – Reduce time required for system design and implementation – Lower risks related to plant commissioning • Process improvement at existing plants – Improve yield – Increase throughput by reducing cycle time • Reduction of operating costs – – Improve maintenance operations Efficient energy usage Optimise labour utilisation through training and improved automation Reduce downtime Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 1/4

Issues customers face Issues the biofuel industry face: • Pressure to increase operational profits to improve the return on investments and increase shareholder value: – Increased utility and raw material costs – Tight safety and quality standards – Compliances with new environmental regulations – Pressured to look for alternative raw material – Increasing competition Solutions we provide: • Process technology for high yields and low operating costs, which are on time with guaranteed performance and within budget: – Asset optimisation related to process, storage, and utilities utilisation – Saving in consumptions of water, energy and reagents – Reducing wastes applying zero effluent process, dehydration and – incineration Professional and experienced project management Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 2/4

Issues customers face Issues the biofuel industry face: • Pressure to increase operational profits to improve the return on investments and increase shareholder value: – Increased utility and raw material costs – Tight safety and quality standards – Compliances with new environmental regulations – Pressured to look for alternative raw material – Increasing competition Solutions we provide: • Process technology for high yields and low operating costs, which are on time with guaranteed performance and within budget: – Asset optimisation related to process, storage, and utilities utilisation – Saving in consumptions of water, energy and reagents – Reducing wastes applying zero effluent process, dehydration and – incineration Professional and experienced project management Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 2/4

New plant and start up Issues • When building a new Biofuels plant, any delay in reaching production • • • and designed capacity, seriously affects the viability of your customers investment Achieving full production requires a significant investment in electrical equipment and process automation Keeping the plant running profitably requires good equipment maintenance procedures and practices, robust process control, and attention to utility usage and electrical demand Rockwell Automation has demonstrated a successful track-record in delivering automation solutions that simplify both the design and operation of a Biofuels plant, resulting in energy-efficient systems with maximum availability, commissioned in the shortest possible time Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 3/4

New plant and start up Issues • When building a new Biofuels plant, any delay in reaching production • • • and designed capacity, seriously affects the viability of your customers investment Achieving full production requires a significant investment in electrical equipment and process automation Keeping the plant running profitably requires good equipment maintenance procedures and practices, robust process control, and attention to utility usage and electrical demand Rockwell Automation has demonstrated a successful track-record in delivering automation solutions that simplify both the design and operation of a Biofuels plant, resulting in energy-efficient systems with maximum availability, commissioned in the shortest possible time Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 3/4

Response Issues Continuous peak efficiency is essential for any biofuel plant • Reducing engineering and support costs through a single control • • • architecture for process control & modular packaged plant Eliminating integration costs through use of “Intelligent Motor Control Centres” Minimising commissioning through a plant-wide communications architecture Reducing risk and lowering operational costs by providing “turnkey” modular process skids Providing connectivity into your customer’s business systems Maintaining both equipment and personnel safety Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 4/4

Response Issues Continuous peak efficiency is essential for any biofuel plant • Reducing engineering and support costs through a single control • • • architecture for process control & modular packaged plant Eliminating integration costs through use of “Intelligent Motor Control Centres” Minimising commissioning through a plant-wide communications architecture Reducing risk and lowering operational costs by providing “turnkey” modular process skids Providing connectivity into your customer’s business systems Maintaining both equipment and personnel safety Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 4/4

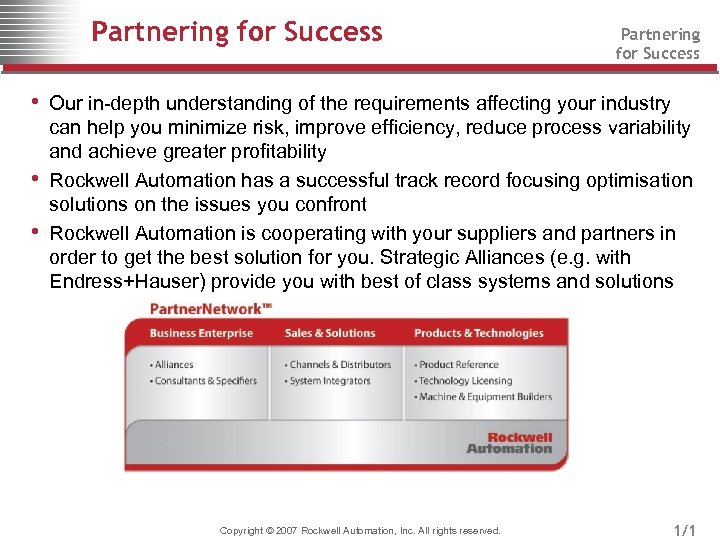

Partnering for Success • Our in-depth understanding of the requirements affecting your industry • • can help you minimize risk, improve efficiency, reduce process variability and achieve greater profitability Rockwell Automation has a successful track record focusing optimisation solutions on the issues you confront Rockwell Automation is cooperating with your suppliers and partners in order to get the best solution for you. Strategic Alliances (e. g. with Endress+Hauser) provide you with best of class systems and solutions Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 1/1

Partnering for Success • Our in-depth understanding of the requirements affecting your industry • • can help you minimize risk, improve efficiency, reduce process variability and achieve greater profitability Rockwell Automation has a successful track record focusing optimisation solutions on the issues you confront Rockwell Automation is cooperating with your suppliers and partners in order to get the best solution for you. Strategic Alliances (e. g. with Endress+Hauser) provide you with best of class systems and solutions Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 1/1

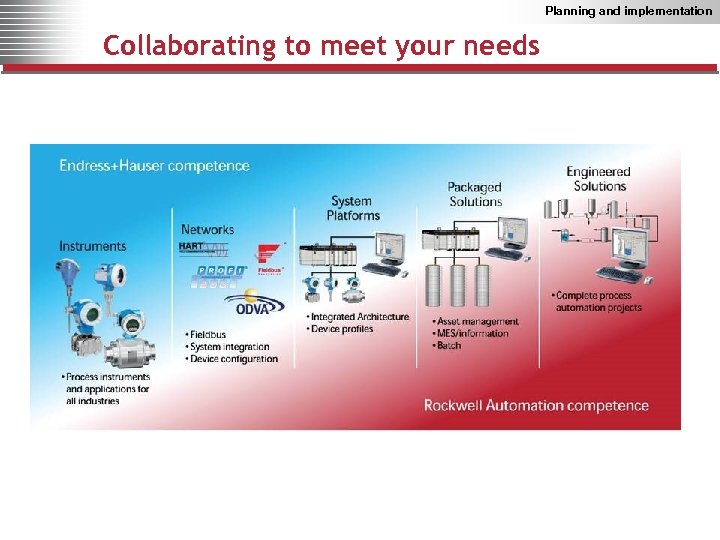

Planning and implementation Collaborating to meet your needs

Planning and implementation Collaborating to meet your needs

Delivered value of compatibility and interoperability Planning and implementation • Single system for the plant – – Reduces time for instrument and loop configuration Reduces development time Reduces training Reduces risk Delivered Value: n Reduced engineering hours n. Reduction of project timeline

Delivered value of compatibility and interoperability Planning and implementation • Single system for the plant – – Reduces time for instrument and loop configuration Reduces development time Reduces training Reduces risk Delivered Value: n Reduced engineering hours n. Reduction of project timeline

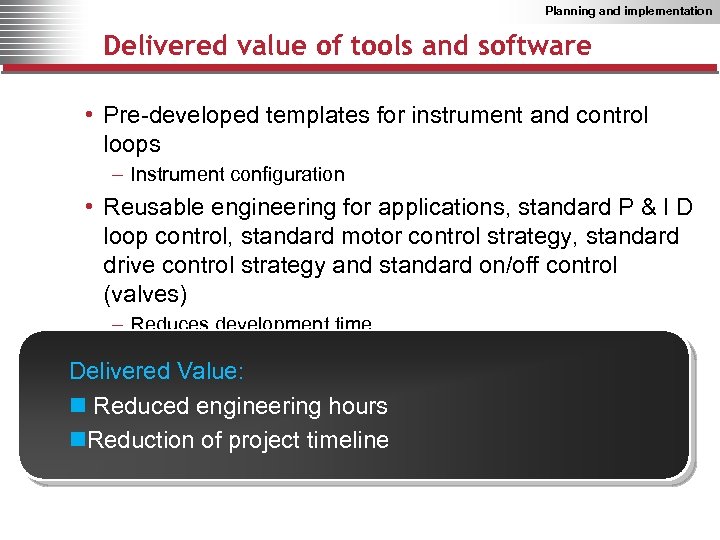

Planning and implementation Delivered value of tools and software • Pre-developed templates for instrument and control loops – Instrument configuration • Reusable engineering for applications, standard P & I D loop control, standard motor control strategy, standard drive control strategy and standard on/off control (valves) – Reduces development time Delivered Value: n Reduced engineering hours n. Reduction of project timeline

Planning and implementation Delivered value of tools and software • Pre-developed templates for instrument and control loops – Instrument configuration • Reusable engineering for applications, standard P & I D loop control, standard motor control strategy, standard drive control strategy and standard on/off control (valves) – Reduces development time Delivered Value: n Reduced engineering hours n. Reduction of project timeline

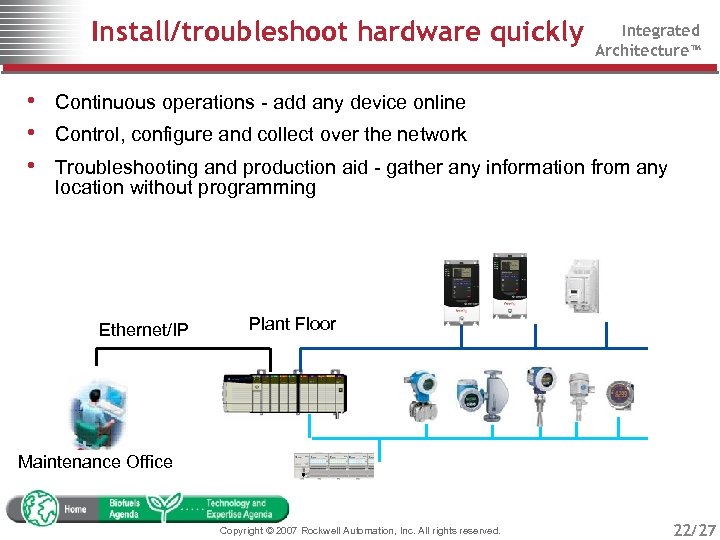

Install/troubleshoot hardware quickly Integrated Architecture™ • Continuous operations - add any device online • Control, configure and collect over the network • Troubleshooting and production aid - gather any information from any location without programming Ethernet/IP Plant Floor Maintenance Office Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 22/27

Install/troubleshoot hardware quickly Integrated Architecture™ • Continuous operations - add any device online • Control, configure and collect over the network • Troubleshooting and production aid - gather any information from any location without programming Ethernet/IP Plant Floor Maintenance Office Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 22/27

Interoperability testing Planning and implementation • Performance measures jointly established by both companies • Verified through completion of common test procedures – Assurance Endress+Hauser field instrument meets Integrated Architecture system interoperability performance • 50 Endress+Hauser devices tested Delivered Value: Ensures a reduced risk solution highlighted by ease of integration and optimum performance

Interoperability testing Planning and implementation • Performance measures jointly established by both companies • Verified through completion of common test procedures – Assurance Endress+Hauser field instrument meets Integrated Architecture system interoperability performance • 50 Endress+Hauser devices tested Delivered Value: Ensures a reduced risk solution highlighted by ease of integration and optimum performance

Example: Sodes Lillebonne Ethanol Production Plant Expertise in Europe BENP Lillebonne Ethanol Plant: – Redundant Fiber Optic Ethernet Network – Redundant Control. Logix with redundant Control. Net card and power supplies – Redundant Servers and Factory Talk View with 10 operating and engineering stations – About total 7000 I/Os – 1800 Hart I/Os and approx. 2000 Analog I/O – 200 Power. Flex 700 Drives and SNC Flex. Starters with Device. Net – Fieldcare Software for Hart device configuration – Cabinets for starters and drives – RSSql and Factory Talk Historian Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 2/3

Example: Sodes Lillebonne Ethanol Production Plant Expertise in Europe BENP Lillebonne Ethanol Plant: – Redundant Fiber Optic Ethernet Network – Redundant Control. Logix with redundant Control. Net card and power supplies – Redundant Servers and Factory Talk View with 10 operating and engineering stations – About total 7000 I/Os – 1800 Hart I/Os and approx. 2000 Analog I/O – 200 Power. Flex 700 Drives and SNC Flex. Starters with Device. Net – Fieldcare Software for Hart device configuration – Cabinets for starters and drives – RSSql and Factory Talk Historian Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 2/3

Biofuel Customers in Europe Expertise in Europe Bioetanol de la Mancha – Bioethanol (Alcázar de San Juan – Ciudad Real, Spain), annual production capacity of 26. 000 tonnes TAGOL - Companhia de Oleaginosas do Tejo, S. A. – Biodiesel (Almada – Lisboa, Portugal) Tereos – Bioethanol (Lillebone - France), annual production capacity of 820. 000 tonnes of corn resulting in 300. 000 m 3 ethanol Greenergy International – Biodiesel (Port of Immingham – England), annual production capacity of 100. 000 tonnes Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 1/3

Biofuel Customers in Europe Expertise in Europe Bioetanol de la Mancha – Bioethanol (Alcázar de San Juan – Ciudad Real, Spain), annual production capacity of 26. 000 tonnes TAGOL - Companhia de Oleaginosas do Tejo, S. A. – Biodiesel (Almada – Lisboa, Portugal) Tereos – Bioethanol (Lillebone - France), annual production capacity of 820. 000 tonnes of corn resulting in 300. 000 m 3 ethanol Greenergy International – Biodiesel (Port of Immingham – England), annual production capacity of 100. 000 tonnes Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 1/3

Expertise in Europe Example: Biodiesel Plant Expertise in Europe Biodiesel Plant (blind story) ―High Availability: Through redundancy and integrated safety and condition monitoring ―Minimised Development, Installation and Start-Up Time: Through integrated multi discipline control and information solution for discrete, process, batch, motion, drives ―Modular and Scalable Process Control Platform: Assures to remain competitive in a changing environment with the freedom to have the flexibility to integrate changing plant wide operations - making this complex task a Biodiesel Production simple one Process Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 3/3

Expertise in Europe Example: Biodiesel Plant Expertise in Europe Biodiesel Plant (blind story) ―High Availability: Through redundancy and integrated safety and condition monitoring ―Minimised Development, Installation and Start-Up Time: Through integrated multi discipline control and information solution for discrete, process, batch, motion, drives ―Modular and Scalable Process Control Platform: Assures to remain competitive in a changing environment with the freedom to have the flexibility to integrate changing plant wide operations - making this complex task a Biodiesel Production simple one Process Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 3/3

Serving Europe, Middle East & Africa Global Supply Europe, Middle East & Africa: 50+ countries 1000+ professionals executing customer projects Critical domain expertise & industry knowledge Leading software, hardware & service solutions Certified project management Worldwide delivery Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 2/3

Serving Europe, Middle East & Africa Global Supply Europe, Middle East & Africa: 50+ countries 1000+ professionals executing customer projects Critical domain expertise & industry knowledge Leading software, hardware & service solutions Certified project management Worldwide delivery Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 2/3

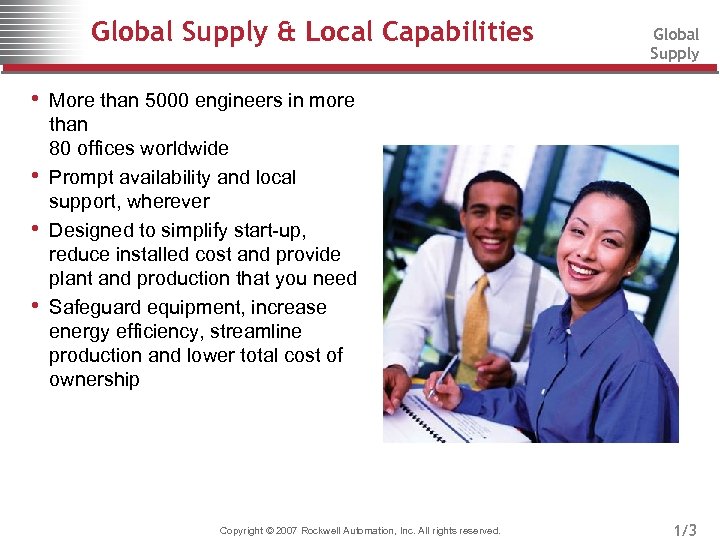

Global Supply & Local Capabilities Global Supply • More than 5000 engineers in more • • • than 80 offices worldwide Prompt availability and local support, wherever Designed to simplify start-up, reduce installed cost and provide plant and production that you need Safeguard equipment, increase energy efficiency, streamline production and lower total cost of ownership Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 1/3

Global Supply & Local Capabilities Global Supply • More than 5000 engineers in more • • • than 80 offices worldwide Prompt availability and local support, wherever Designed to simplify start-up, reduce installed cost and provide plant and production that you need Safeguard equipment, increase energy efficiency, streamline production and lower total cost of ownership Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 1/3

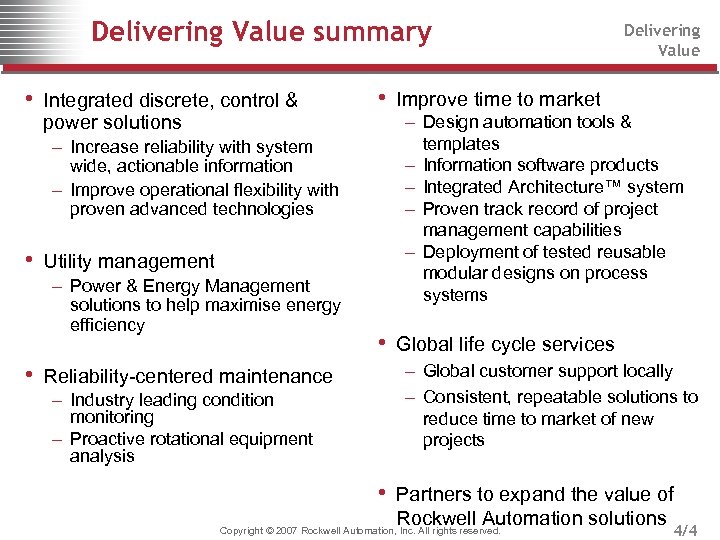

Delivering Value summary • Integrated discrete, control & power solutions – Increase reliability with system wide, actionable information – Improve operational flexibility with proven advanced technologies • Utility management – Power & Energy Management solutions to help maximise energy efficiency • Reliability-centered maintenance – Industry leading condition monitoring – Proactive rotational equipment analysis Delivering Value • Improve time to market – Design automation tools & templates – Information software products – Integrated Architecture™ system – Proven track record of project management capabilities – Deployment of tested reusable modular designs on process systems • Global life cycle services – Global customer support locally – Consistent, repeatable solutions to reduce time to market of new projects • Partners to expand the value of Rockwell Automation solutions Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 4/4

Delivering Value summary • Integrated discrete, control & power solutions – Increase reliability with system wide, actionable information – Improve operational flexibility with proven advanced technologies • Utility management – Power & Energy Management solutions to help maximise energy efficiency • Reliability-centered maintenance – Industry leading condition monitoring – Proactive rotational equipment analysis Delivering Value • Improve time to market – Design automation tools & templates – Information software products – Integrated Architecture™ system – Proven track record of project management capabilities – Deployment of tested reusable modular designs on process systems • Global life cycle services – Global customer support locally – Consistent, repeatable solutions to reduce time to market of new projects • Partners to expand the value of Rockwell Automation solutions Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 4/4

Technology and Expertise • Integrated Architecture • Manufacturing Execution Systems (MES) • Power and Energy Management (PEMS) • Process Technology (Proscon) • Services and Support (MPS + CSM) Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 1/2

Technology and Expertise • Integrated Architecture • Manufacturing Execution Systems (MES) • Power and Energy Management (PEMS) • Process Technology (Proscon) • Services and Support (MPS + CSM) Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 1/2

Area of expertise Technology and Expertise MES Control System Process Modules Production Facility Validation Site Services Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 2/2

Area of expertise Technology and Expertise MES Control System Process Modules Production Facility Validation Site Services Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 2/2

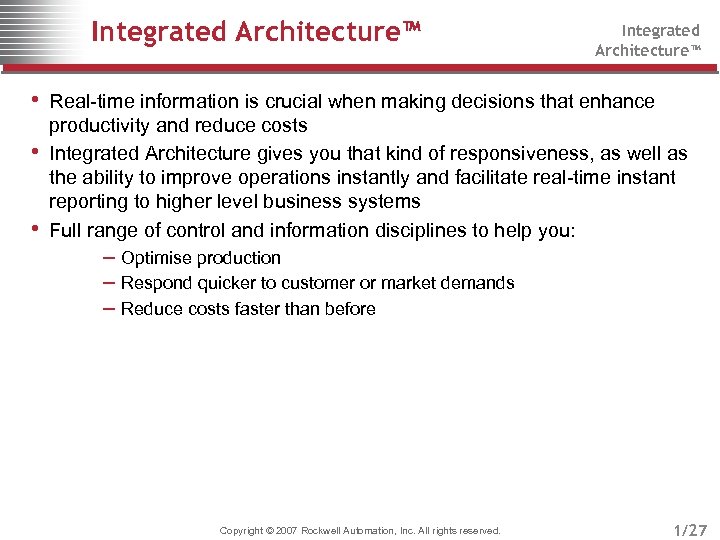

Integrated Architecture™ • Real-time information is crucial when making decisions that enhance • • productivity and reduce costs Integrated Architecture gives you that kind of responsiveness, as well as the ability to improve operations instantly and facilitate real-time instant reporting to higher level business systems Full range of control and information disciplines to help you: – Optimise production – Respond quicker to customer or market demands – Reduce costs faster than before Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 1/27

Integrated Architecture™ • Real-time information is crucial when making decisions that enhance • • productivity and reduce costs Integrated Architecture gives you that kind of responsiveness, as well as the ability to improve operations instantly and facilitate real-time instant reporting to higher level business systems Full range of control and information disciplines to help you: – Optimise production – Respond quicker to customer or market demands – Reduce costs faster than before Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 1/27

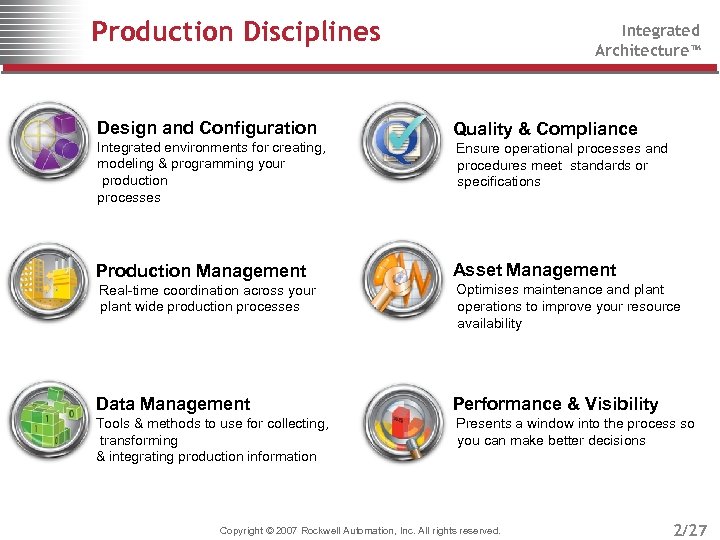

Production Disciplines Design and Configuration Integrated environments for creating, modeling & programming your production processes Integrated Architecture™ Quality & Compliance Ensure operational processes and procedures meet standards or specifications Production Management Asset Management Real-time coordination across your plant wide production processes Optimises maintenance and plant operations to improve your resource availability Data Management Performance & Visibility Tools & methods to use for collecting, transforming & integrating production information Presents a window into the process so you can make better decisions Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 2/27

Production Disciplines Design and Configuration Integrated environments for creating, modeling & programming your production processes Integrated Architecture™ Quality & Compliance Ensure operational processes and procedures meet standards or specifications Production Management Asset Management Real-time coordination across your plant wide production processes Optimises maintenance and plant operations to improve your resource availability Data Management Performance & Visibility Tools & methods to use for collecting, transforming & integrating production information Presents a window into the process so you can make better decisions Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 2/27

Core technologies Integrated Architecture™ The Logix Control Platform, the Factory. Talk Integrated Production Management and Performance Suite are linked through a set of core technologies allowing seamless interaction and information flow: • Logix: multi-disciplined, information enabled and scalable controller family – reducing equipment, training and development costs • Net. Linx: common industrial protocol from plant floor device to IT, improving flexibility and productivity while reducing cost – Control, Configure, and Collect information and data efficiently • View: a common, fully integrated, scalable visualization strategy across your whole manufacturing enterprise – Delivering the information you need for more effective decision-making • Factory. Talk: flexible application development framework, common user interface and industry-standard data models – Premier integration and interoperability Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 4/27

Core technologies Integrated Architecture™ The Logix Control Platform, the Factory. Talk Integrated Production Management and Performance Suite are linked through a set of core technologies allowing seamless interaction and information flow: • Logix: multi-disciplined, information enabled and scalable controller family – reducing equipment, training and development costs • Net. Linx: common industrial protocol from plant floor device to IT, improving flexibility and productivity while reducing cost – Control, Configure, and Collect information and data efficiently • View: a common, fully integrated, scalable visualization strategy across your whole manufacturing enterprise – Delivering the information you need for more effective decision-making • Factory. Talk: flexible application development framework, common user interface and industry-standard data models – Premier integration and interoperability Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 4/27

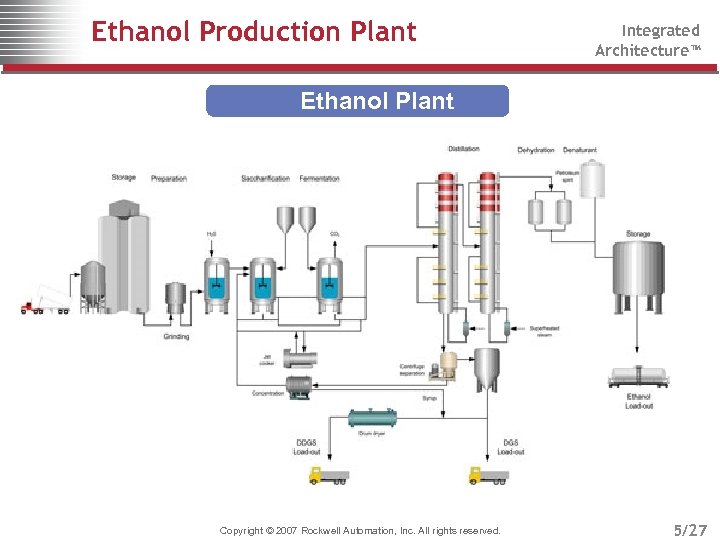

Ethanol Production Plant Integrated Architecture™ Ethanol Plant Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 5/27

Ethanol Production Plant Integrated Architecture™ Ethanol Plant Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 5/27

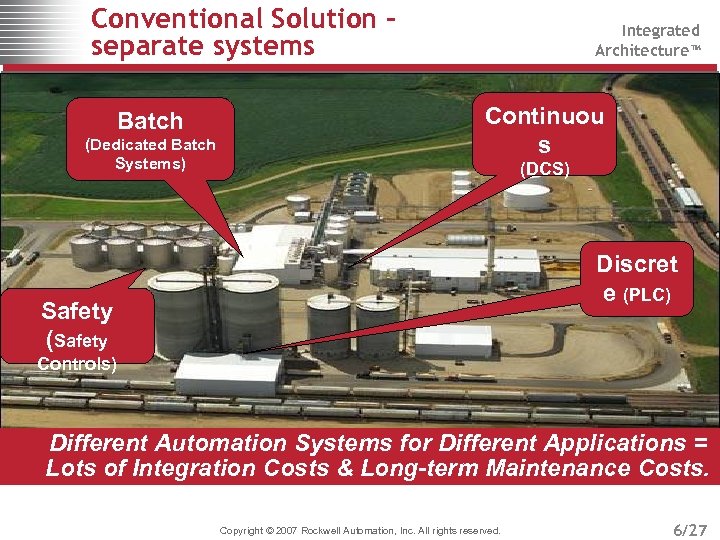

Conventional Solution separate systems Batch (Dedicated Batch Systems) Integrated Architecture™ Continuou s (DCS) Discret e (PLC) Safety (Safety Controls) Different Automation Systems for Different Applications = Lots of Integration Costs & Long-term Maintenance Costs. Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 6/27

Conventional Solution separate systems Batch (Dedicated Batch Systems) Integrated Architecture™ Continuou s (DCS) Discret e (PLC) Safety (Safety Controls) Different Automation Systems for Different Applications = Lots of Integration Costs & Long-term Maintenance Costs. Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 6/27

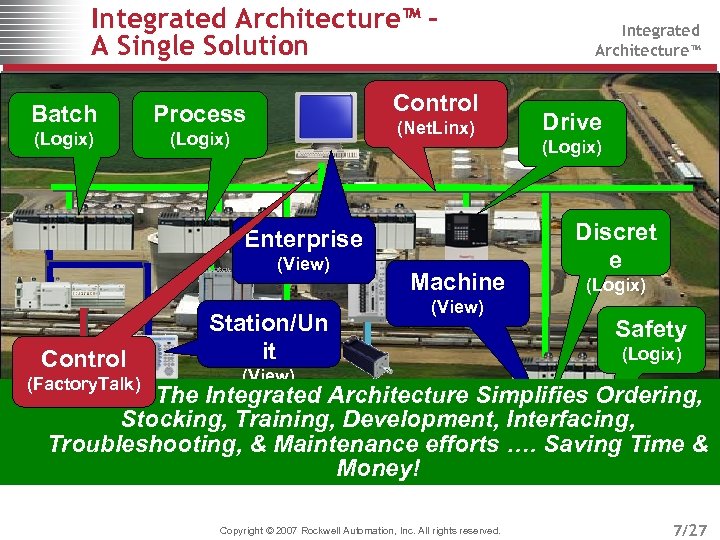

Integrated Architecture™ A Single Solution Batch (Logix) Control Process (Logix) (Net. Linx) Enterprise (View) Control (Factory. Talk) Station/Un it Machine (View) Integrated Architecture™ Drive (Logix) Discret e (Logix) Safety (Logix) (View) Benefit: The Integrated Architecture Simplifies Ordering, Stocking, Training, Development, Interfacing, Troubleshooting, & Maintenance efforts …. Saving Time & Money! Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 7/27

Integrated Architecture™ A Single Solution Batch (Logix) Control Process (Logix) (Net. Linx) Enterprise (View) Control (Factory. Talk) Station/Un it Machine (View) Integrated Architecture™ Drive (Logix) Discret e (Logix) Safety (Logix) (View) Benefit: The Integrated Architecture Simplifies Ordering, Stocking, Training, Development, Interfacing, Troubleshooting, & Maintenance efforts …. Saving Time & Money! Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 7/27

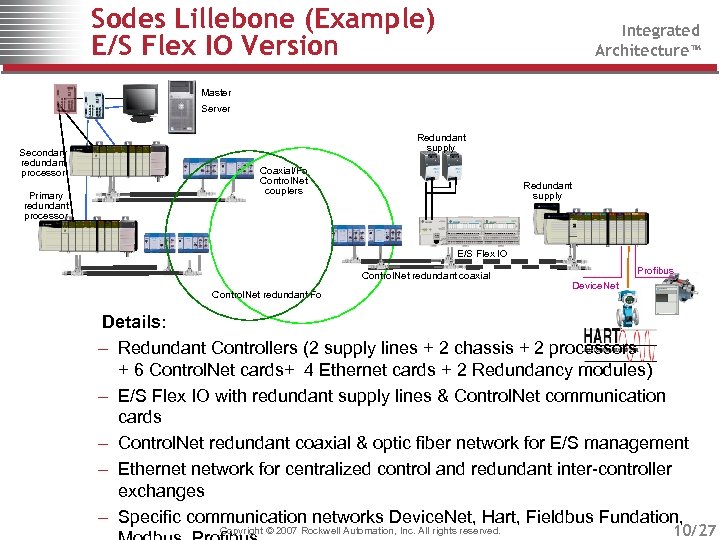

Sodes Lillebone (Example) E/S Flex IO Version Integrated Architecture™ Master Server Secondary redundant processor Primary redundant processor Redundant supply Coaxial/Fo Control. Net couplers Redundant supply E/S Flex IO Control. Net redundant coaxial Control. Net redundant Fo Profibus Device. Net Details: – Redundant Controllers (2 supply lines + 2 chassis + 2 processors + 6 Control. Net cards+ 4 Ethernet cards + 2 Redundancy modules) – E/S Flex IO with redundant supply lines & Control. Net communication cards – Control. Net redundant coaxial & optic fiber network for E/S management – Ethernet network for centralized control and redundant inter-controller exchanges – Specific communication networks Device. Net, Hart, Fieldbus Fundation, Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 10/27

Sodes Lillebone (Example) E/S Flex IO Version Integrated Architecture™ Master Server Secondary redundant processor Primary redundant processor Redundant supply Coaxial/Fo Control. Net couplers Redundant supply E/S Flex IO Control. Net redundant coaxial Control. Net redundant Fo Profibus Device. Net Details: – Redundant Controllers (2 supply lines + 2 chassis + 2 processors + 6 Control. Net cards+ 4 Ethernet cards + 2 Redundancy modules) – E/S Flex IO with redundant supply lines & Control. Net communication cards – Control. Net redundant coaxial & optic fiber network for E/S management – Ethernet network for centralized control and redundant inter-controller exchanges – Specific communication networks Device. Net, Hart, Fieldbus Fundation, Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 10/27

HMI Screens Copyright © 2007 Rockwell Automation, Inc. All rights reserved. Integrated Architecture™ 12/27

HMI Screens Copyright © 2007 Rockwell Automation, Inc. All rights reserved. Integrated Architecture™ 12/27

Ethanol Plants Integrated Architecture™ Operator interface screens – one box, one keyboard, one mouse and one operator Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 13/27

Ethanol Plants Integrated Architecture™ Operator interface screens – one box, one keyboard, one mouse and one operator Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 13/27

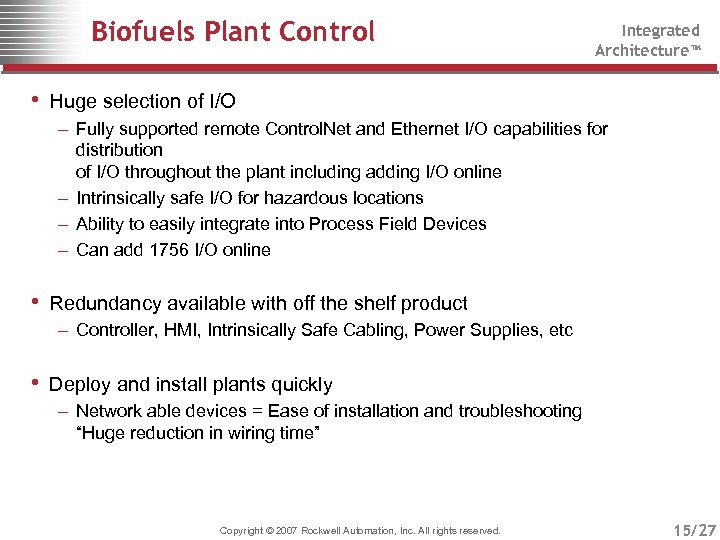

Biofuels Plant Control Integrated Architecture™ • Huge selection of I/O – Fully supported remote Control. Net and Ethernet I/O capabilities for distribution of I/O throughout the plant including adding I/O online – Intrinsically safe I/O for hazardous locations – Ability to easily integrate into Process Field Devices – Can add 1756 I/O online • Redundancy available with off the shelf product – Controller, HMI, Intrinsically Safe Cabling, Power Supplies, etc • Deploy and install plants quickly – Network able devices = Ease of installation and troubleshooting “Huge reduction in wiring time” Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 15/27

Biofuels Plant Control Integrated Architecture™ • Huge selection of I/O – Fully supported remote Control. Net and Ethernet I/O capabilities for distribution of I/O throughout the plant including adding I/O online – Intrinsically safe I/O for hazardous locations – Ability to easily integrate into Process Field Devices – Can add 1756 I/O online • Redundancy available with off the shelf product – Controller, HMI, Intrinsically Safe Cabling, Power Supplies, etc • Deploy and install plants quickly – Network able devices = Ease of installation and troubleshooting “Huge reduction in wiring time” Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 15/27

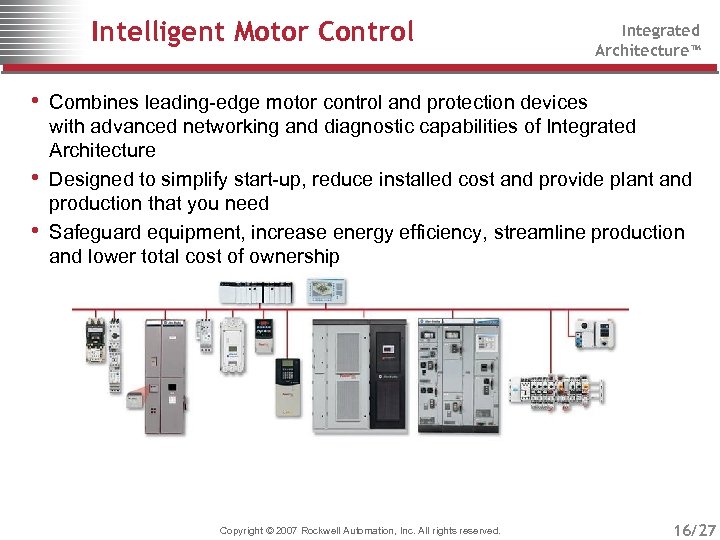

Intelligent Motor Control Integrated Architecture™ • Combines leading-edge motor control and protection devices • • with advanced networking and diagnostic capabilities of Integrated Architecture Designed to simplify start-up, reduce installed cost and provide plant and production that you need Safeguard equipment, increase energy efficiency, streamline production and lower total cost of ownership Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 16/27

Intelligent Motor Control Integrated Architecture™ • Combines leading-edge motor control and protection devices • • with advanced networking and diagnostic capabilities of Integrated Architecture Designed to simplify start-up, reduce installed cost and provide plant and production that you need Safeguard equipment, increase energy efficiency, streamline production and lower total cost of ownership Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 16/27

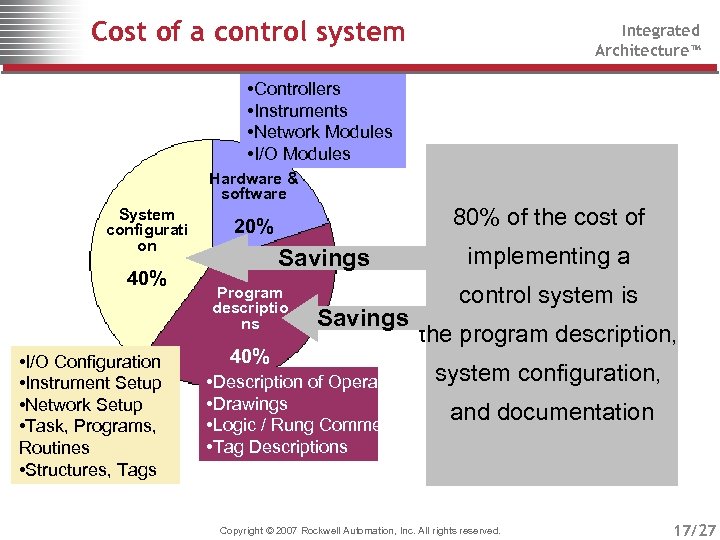

Cost of a control system Integrated Architecture™ • Controllers • Instruments • Network Modules • I/O Modules Hardware & software System configurati on 40% • I/O Configuration • Instrument Setup • Network Setup • Task, Programs, Routines • Structures, Tags 80% of the cost of 20% Savings Program descriptio ns Savings 40% • Description of Operation • Drawings • Logic / Rung Comments • Tag Descriptions implementing a control system is the program description, system configuration, and documentation Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 17/27

Cost of a control system Integrated Architecture™ • Controllers • Instruments • Network Modules • I/O Modules Hardware & software System configurati on 40% • I/O Configuration • Instrument Setup • Network Setup • Task, Programs, Routines • Structures, Tags 80% of the cost of 20% Savings Program descriptio ns Savings 40% • Description of Operation • Drawings • Logic / Rung Comments • Tag Descriptions implementing a control system is the program description, system configuration, and documentation Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 17/27

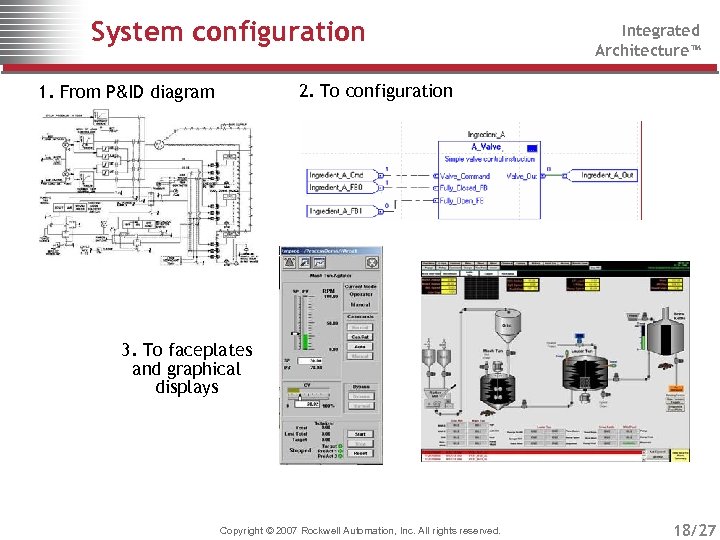

System configuration Integrated Architecture™ 2. To configuration 1. From P&ID diagram 3. To faceplates and graphical displays Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 18/27

System configuration Integrated Architecture™ 2. To configuration 1. From P&ID diagram 3. To faceplates and graphical displays Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 18/27

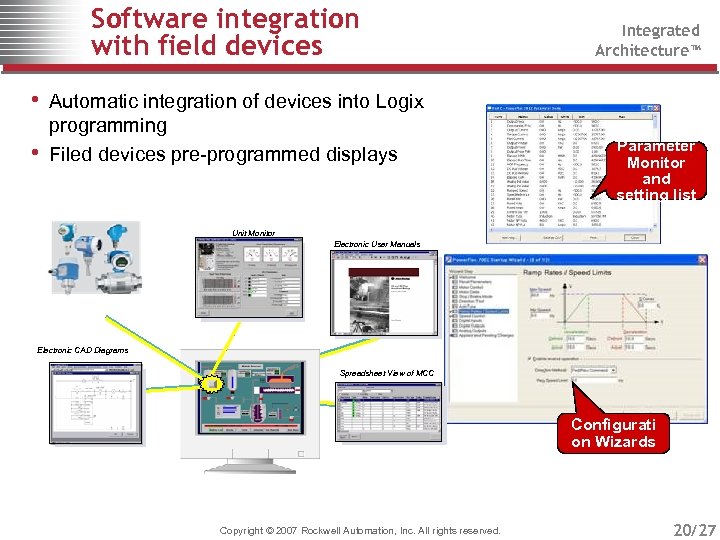

Software integration with field devices Integrated Architecture™ • Automatic integration of devices into Logix • programming Filed devices pre-programmed displays Field Instruments Unit Monitor View Parameter Monitor and setting list Electronic User Manuals Electronic CAD Diagrams Spreadsheet View of MCC Configurati on Wizards Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 20/27

Software integration with field devices Integrated Architecture™ • Automatic integration of devices into Logix • programming Filed devices pre-programmed displays Field Instruments Unit Monitor View Parameter Monitor and setting list Electronic User Manuals Electronic CAD Diagrams Spreadsheet View of MCC Configurati on Wizards Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 20/27

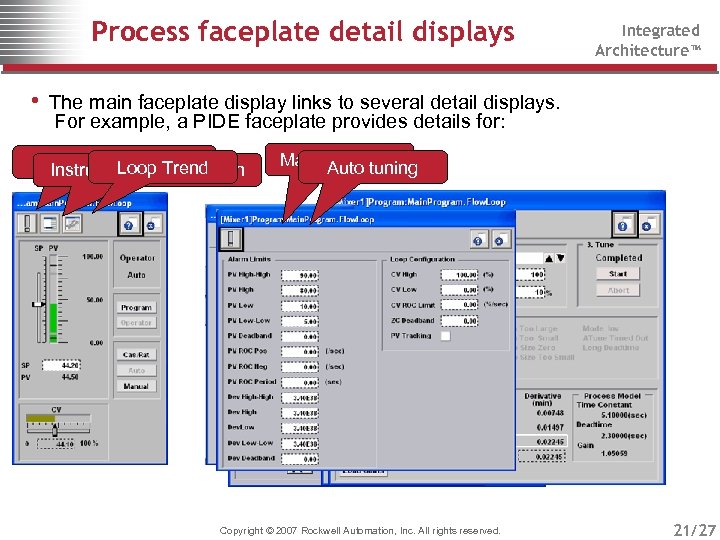

Process faceplate detail displays Integrated Architecture™ • The main faceplate display links to several detail displays. For example, a PIDE faceplate provides details for: Instruction Status Loop Trend Instruction Configuration Manual Tuning Auto tuning Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 21/27

Process faceplate detail displays Integrated Architecture™ • The main faceplate display links to several detail displays. For example, a PIDE faceplate provides details for: Instruction Status Loop Trend Instruction Configuration Manual Tuning Auto tuning Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 21/27

Savings through reusable engineering Integrated Architecture™ • Common Definition – Executing the same project multiple times at lower implementation cost with each iteration • How we put this into practice: – Leveraging a library of field proven, modular elements that are transportable across various projects and businesses resulting in lowest installed cost Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 23/27

Savings through reusable engineering Integrated Architecture™ • Common Definition – Executing the same project multiple times at lower implementation cost with each iteration • How we put this into practice: – Leveraging a library of field proven, modular elements that are transportable across various projects and businesses resulting in lowest installed cost Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 23/27

Data collection (process, alarms, batch) Integrated with data historian Architecture™ • Provides reliable process data collection (no more clipboards!) – Data collection and storage – Analysis of process parameters – Graphical visualisation • Makes “data mining” a snap • Additional set of charting tools to drill into your data – Bar Graph, Grid, Pie Chart, Pareto, etc. • Historian can also analyze data collected by other applications Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 25/27

Data collection (process, alarms, batch) Integrated with data historian Architecture™ • Provides reliable process data collection (no more clipboards!) – Data collection and storage – Analysis of process parameters – Graphical visualisation • Makes “data mining” a snap • Additional set of charting tools to drill into your data – Bar Graph, Grid, Pie Chart, Pareto, etc. • Historian can also analyze data collected by other applications Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 25/27

Increase productivity with advanced process control Integrated Architecture™ • 2 D graph and 3 D graphs with many • • options including zoom, line, grid density, range, axis, texture, etc Simulation mode allows you to watch influence of individual component values Value changes appear also in graphs as “path” Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 26/27

Increase productivity with advanced process control Integrated Architecture™ • 2 D graph and 3 D graphs with many • • options including zoom, line, grid density, range, axis, texture, etc Simulation mode allows you to watch influence of individual component values Value changes appear also in graphs as “path” Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 26/27

Model predictive control of a reactor Integrated Architecture™ Controller capabilities ü 2 x 2 model predictive control ü Rank PV’s in order of importance ü Auto-manual switch for each MV ü Executed in Control. Logix controller ü Uses standard function block library ü Improve yield ü Increase capacity by 10% Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 27/27

Model predictive control of a reactor Integrated Architecture™ Controller capabilities ü 2 x 2 model predictive control ü Rank PV’s in order of importance ü Auto-manual switch for each MV ü Executed in Control. Logix controller ü Uses standard function block library ü Improve yield ü Increase capacity by 10% Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 27/27

Integrated Architecture™ One Architecture for Plant Wide Control & Information Integrated Architecture™ üLower Operationa l Costs üLower Total Cost of Ownership üRegulatory & Standards Complianc e üBetter Informatio n üFaster Decisions Copyright © 2007 Rockwell Automation, Inc. All rights reserved. üIncreased 8/27

Integrated Architecture™ One Architecture for Plant Wide Control & Information Integrated Architecture™ üLower Operationa l Costs üLower Total Cost of Ownership üRegulatory & Standards Complianc e üBetter Informatio n üFaster Decisions Copyright © 2007 Rockwell Automation, Inc. All rights reserved. üIncreased 8/27

Manufacturing Execution Systems • Integrated suite of plant wide information software • Easier integration, faster application development • Seamless information-sharing between factory floor and other • departments Factory. Talk and Logix Control Platform are linked through shared communication services and technologies that allow seamless interaction and technology flow making possible: – Control System Connectivity – Enterprise and Plant System Integration – Human Machine Interface (HMI) – Supervisory Control and Data Acquisition (SCADA) – Manufacturing Execution System (MES) – Asset Management Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 1/2

Manufacturing Execution Systems • Integrated suite of plant wide information software • Easier integration, faster application development • Seamless information-sharing between factory floor and other • departments Factory. Talk and Logix Control Platform are linked through shared communication services and technologies that allow seamless interaction and technology flow making possible: – Control System Connectivity – Enterprise and Plant System Integration – Human Machine Interface (HMI) – Supervisory Control and Data Acquisition (SCADA) – Manufacturing Execution System (MES) – Asset Management Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 1/2

Manufacturing Execution Systems • MES can increase throughput of your plant by: – Eliminating paperwork – Reducing errors – Maintaining high quality standards • MES can eliminate resources that are performing unnecessary tasks and help reduce material waste – Tighter automation integration & extended capabilities for production and – – manufacturing companies Latest version provides on-demand manufacturing information to help improve productivity and reduce time-to-market Extends capabilities in automation information integration Offers increased flexibility in state-of-the-art data management and process execution E. g. software helps simplify the integration of information between resource logistics and order fulfilment Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 2/2

Manufacturing Execution Systems • MES can increase throughput of your plant by: – Eliminating paperwork – Reducing errors – Maintaining high quality standards • MES can eliminate resources that are performing unnecessary tasks and help reduce material waste – Tighter automation integration & extended capabilities for production and – – manufacturing companies Latest version provides on-demand manufacturing information to help improve productivity and reduce time-to-market Extends capabilities in automation information integration Offers increased flexibility in state-of-the-art data management and process execution E. g. software helps simplify the integration of information between resource logistics and order fulfilment Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 2/2

Power and Energy Management • Log usage, demand production data • Create historical trend reports and charts • Establish consumption baseline and user • • defined time of use periods Assign rate plans to meters or groups of meters Create and print daily or monthly cost and billing reports by meter, business group, department, or site Create energy budgets and forecasts. Compare and contrast alternative utility rates; do “what-if” for other rate structures Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 1/1

Power and Energy Management • Log usage, demand production data • Create historical trend reports and charts • Establish consumption baseline and user • • defined time of use periods Assign rate plans to meters or groups of meters Create and print daily or monthly cost and billing reports by meter, business group, department, or site Create energy budgets and forecasts. Compare and contrast alternative utility rates; do “what-if” for other rate structures Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 1/1

Global Applications - PEMS Application Examples ü ü ü ü Power & Energy Management (PEMS) Metal Forming Industrial Combustion Advance Process Control (APC) Coal Handling, Ash Handling, Soot Blower De-Mineralizer Water Treatment Material Handling / Packaging Manufacturing Execution System (MES) Safety Solutions Regulatory Compliance Services Batch Solutions Legacy Conversions Copyright © 2007 Rockwell Automation, Inc. All rights reserved.

Global Applications - PEMS Application Examples ü ü ü ü Power & Energy Management (PEMS) Metal Forming Industrial Combustion Advance Process Control (APC) Coal Handling, Ash Handling, Soot Blower De-Mineralizer Water Treatment Material Handling / Packaging Manufacturing Execution System (MES) Safety Solutions Regulatory Compliance Services Batch Solutions Legacy Conversions Copyright © 2007 Rockwell Automation, Inc. All rights reserved.

Process Domain Expertise Process Distillation & Solvent Recovery Systems Technology • Pros. Con’s highly efficient and energy saving Distillation and Solvent • Recovery systems help you recover more from your manufacturing process at lower energy consumption Assess the viability of distillation and solvent recovery for your application using – Front end studies – Budget development studies – ROI assured through Waste analysis, distillation and recovery simulation, utilising pilot-scale test facility and simulation • Benefits include – Accelerated Construction schedule by parallel path activities – Integrated heat recovery reduces steam consumptions and energy costs – Shrinking the volume of disposable waste and decreasing waste treatment costs – Cut haul-away disposal or incineration charges – Conforming to environmental protection standards – Maintaining quality of solvent and Ethanol concentration Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 1/3

Process Domain Expertise Process Distillation & Solvent Recovery Systems Technology • Pros. Con’s highly efficient and energy saving Distillation and Solvent • Recovery systems help you recover more from your manufacturing process at lower energy consumption Assess the viability of distillation and solvent recovery for your application using – Front end studies – Budget development studies – ROI assured through Waste analysis, distillation and recovery simulation, utilising pilot-scale test facility and simulation • Benefits include – Accelerated Construction schedule by parallel path activities – Integrated heat recovery reduces steam consumptions and energy costs – Shrinking the volume of disposable waste and decreasing waste treatment costs – Cut haul-away disposal or incineration charges – Conforming to environmental protection standards – Maintaining quality of solvent and Ethanol concentration Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 1/3

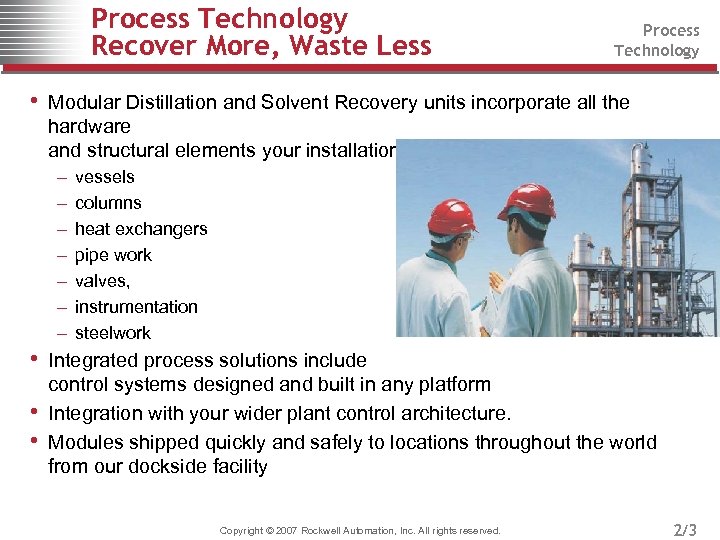

Process Technology Recover More, Waste Less Process Technology • Modular Distillation and Solvent Recovery units incorporate all the hardware and structural elements your installation requires – – – – vessels columns heat exchangers pipe work valves, instrumentation steelwork • Integrated process solutions include • • control systems designed and built in any platform Integration with your wider plant control architecture. Modules shipped quickly and safely to locations throughout the world from our dockside facility Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 2/3

Process Technology Recover More, Waste Less Process Technology • Modular Distillation and Solvent Recovery units incorporate all the hardware and structural elements your installation requires – – – – vessels columns heat exchangers pipe work valves, instrumentation steelwork • Integrated process solutions include • • control systems designed and built in any platform Integration with your wider plant control architecture. Modules shipped quickly and safely to locations throughout the world from our dockside facility Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 2/3

Process Technology Modular Solutions Build Finish Copyright © 2007 Rockwell Automation, Inc. All rights reserved. Process Technology Install 3/3

Process Technology Modular Solutions Build Finish Copyright © 2007 Rockwell Automation, Inc. All rights reserved. Process Technology Install 3/3

MPS - From Concept to Successful Solution ü ü ü ü Feasibility study Counseling and conception of the problem solution Device specifications / calculation Product and functional specifications Control and monitoring concepts Function plans Software implementation Special applications Project management and project realization Commissioning Validation and acceptance Documentation Training Support and maintenance Plant management services Copyright © 2007 Rockwell Automation, Inc. All rights reserved.

MPS - From Concept to Successful Solution ü ü ü ü Feasibility study Counseling and conception of the problem solution Device specifications / calculation Product and functional specifications Control and monitoring concepts Function plans Software implementation Special applications Project management and project realization Commissioning Validation and acceptance Documentation Training Support and maintenance Plant management services Copyright © 2007 Rockwell Automation, Inc. All rights reserved.

A worldwide support at anytime « A worldwide common i. PM methodology integrated with our business systems programs and policies. « Global network of domain expertise, industry knowledge, and world-class offerings create an unparalleled solutions in over 80 countries. « Over 1800 engineers with critical domain expertise understand your business and help you to succeed. « Worldwide local support for engineering and maintenance. Engineering Resource Centers Major Project Implementation Centers

A worldwide support at anytime « A worldwide common i. PM methodology integrated with our business systems programs and policies. « Global network of domain expertise, industry knowledge, and world-class offerings create an unparalleled solutions in over 80 countries. « Over 1800 engineers with critical domain expertise understand your business and help you to succeed. « Worldwide local support for engineering and maintenance. Engineering Resource Centers Major Project Implementation Centers

Services and Support Superior Services & Expertise • Long-term and reliable support with the immediacy you need • Rockwell Automation’s portfolio of services can meet the challenges • • at any stage of the project Machine diagnostics and optimisation, allowing systems to collect and analyse information for efficiency measuring Let us help you optimally manage your assets regardless of the maintenance strategy employed Predictive Preventative Corrective Copyright © 2007 Rockwell Automation, Inc. All rights reserved.

Services and Support Superior Services & Expertise • Long-term and reliable support with the immediacy you need • Rockwell Automation’s portfolio of services can meet the challenges • • at any stage of the project Machine diagnostics and optimisation, allowing systems to collect and analyse information for efficiency measuring Let us help you optimally manage your assets regardless of the maintenance strategy employed Predictive Preventative Corrective Copyright © 2007 Rockwell Automation, Inc. All rights reserved.

Services and Support Condition-Based Maintenance • A strategic approach to maintenance is essential to • minimise downtime Rockwell Automation offers a full line of services and support that significantly reduces unplanned downtime by: – Applying a condition-based maintenance program to your rotating – – machinery and notifying you of problems before they occur Applying a preventative maintenance program to your controls equipment Training your maintenance department to troubleshoot your controls equipment Giving you real-time access to our global network of world-class Customer Support Centres and technical resources Making sure you have the right parts when you need them to get your machine up and running quickly Copyright © 2007 Rockwell Automation, Inc. All rights reserved.

Services and Support Condition-Based Maintenance • A strategic approach to maintenance is essential to • minimise downtime Rockwell Automation offers a full line of services and support that significantly reduces unplanned downtime by: – Applying a condition-based maintenance program to your rotating – – machinery and notifying you of problems before they occur Applying a preventative maintenance program to your controls equipment Training your maintenance department to troubleshoot your controls equipment Giving you real-time access to our global network of world-class Customer Support Centres and technical resources Making sure you have the right parts when you need them to get your machine up and running quickly Copyright © 2007 Rockwell Automation, Inc. All rights reserved.

Transforming maintenance from an expense to a business asset Integrated Architecture™ • Aligning the Resolutions to Your Issues – Using maintenance as a business asset means correlating financial and productivity issues with Strategic Maintenance resolutions – Rather than pick a single mode of maintenance, strategic maintenance combines predictive, preventive and reactive methods in an optimal fashion to reach your goals By implementing a Strategic Approach to Maintenance, companies can reclassify maintenance from an expense to a competitive differentiator and profit driver. Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 19/27

Transforming maintenance from an expense to a business asset Integrated Architecture™ • Aligning the Resolutions to Your Issues – Using maintenance as a business asset means correlating financial and productivity issues with Strategic Maintenance resolutions – Rather than pick a single mode of maintenance, strategic maintenance combines predictive, preventive and reactive methods in an optimal fashion to reach your goals By implementing a Strategic Approach to Maintenance, companies can reclassify maintenance from an expense to a competitive differentiator and profit driver. Copyright © 2007 Rockwell Automation, Inc. All rights reserved. 19/27

Integrated Automation and information solutions using best-in-class solutions for your company

Integrated Automation and information solutions using best-in-class solutions for your company