d8be8bc426d33b40b5863e01b6fed918.ppt

- Количество слайдов: 30

Agenda n Review Menu Engineering n Chapter 7 n Sample problems OH 7 -1

Agenda n Review Menu Engineering n Chapter 7 n Sample problems OH 7 -1

7 OH 7 -2 Controlling Food Cost in Production n Controlling Foodservice Costs

7 OH 7 -2 Controlling Food Cost in Production n Controlling Foodservice Costs

Chapter Learning Objectives n Develop a food production chart. n Describe how a waste report helps control food costs. n Use a conversion factor to calculate a new yield for an existing recipe. n Determine a recipe’s yield and the number of portions it will produce. OH 7 -3

Chapter Learning Objectives n Develop a food production chart. n Describe how a waste report helps control food costs. n Use a conversion factor to calculate a new yield for an existing recipe. n Determine a recipe’s yield and the number of portions it will produce. OH 7 -3

Monitoring Standards n Tasting foods regularly is one way to ensure standards are met. The use of standardized recipes is another. OH 7 -4

Monitoring Standards n Tasting foods regularly is one way to ensure standards are met. The use of standardized recipes is another. OH 7 -4

Food That Does Not Meet the Restaurant’s Standards n Should not be served n Should be salvaged (all or part), if possible n Should be discarded if not salvageable n Increase costs n Reduce profits OH 7 -5

Food That Does Not Meet the Restaurant’s Standards n Should not be served n Should be salvaged (all or part), if possible n Should be discarded if not salvageable n Increase costs n Reduce profits OH 7 -5

Questions to Ask When Food Fails to Meet Standards n Is the recipe clearly written? n Did the cook understand the recipe? OH 7 -6

Questions to Ask When Food Fails to Meet Standards n Is the recipe clearly written? n Did the cook understand the recipe? OH 7 -6

Questions to Ask When Food Fails to Meet Standards continued n Are ingredients used in the recipe clearly labeled? n Are the appropriate ingredients in the proper containers? (Do ingredients in containers match the containers’ labels? ) OH 7 -7 OH 7 -6

Questions to Ask When Food Fails to Meet Standards continued n Are ingredients used in the recipe clearly labeled? n Are the appropriate ingredients in the proper containers? (Do ingredients in containers match the containers’ labels? ) OH 7 -7 OH 7 -6

Determining Quantity to Produce n Accurate food production schedules are important because n Overproduction causes excessive leftovers and waste. n Underproduction causes production shortages and unhappy customers. n Both situations reduce profits! OH 7 -8

Determining Quantity to Produce n Accurate food production schedules are important because n Overproduction causes excessive leftovers and waste. n Underproduction causes production shortages and unhappy customers. n Both situations reduce profits! OH 7 -8

Determining Quantity to Produce continued To maximize guest satisfaction, managers help their production staff know how much to prepare on the proper day and at the proper time. OH 7 -9

Determining Quantity to Produce continued To maximize guest satisfaction, managers help their production staff know how much to prepare on the proper day and at the proper time. OH 7 -9

To Ensure Proper Production n Professional managers always use food production charts! OH 7 -10

To Ensure Proper Production n Professional managers always use food production charts! OH 7 -10

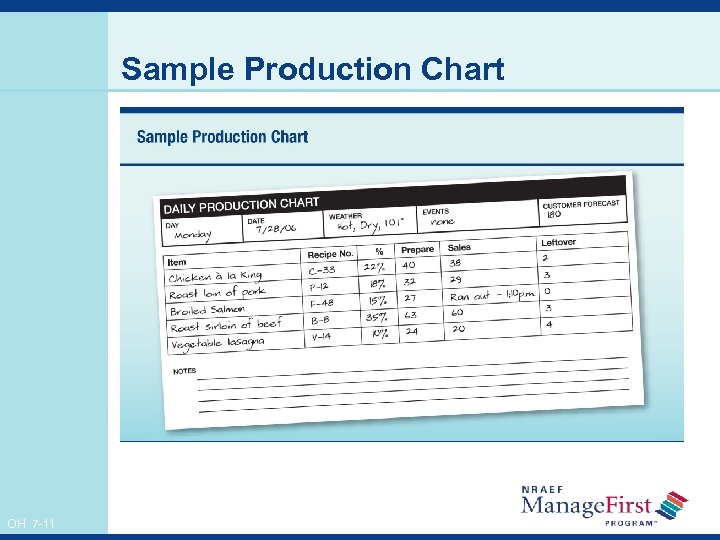

Sample Production Chart OH 7 -11

Sample Production Chart OH 7 -11

Food Production Charts n Created by studying past sales (sales histories) n Generally, the best predictor of what guests will buy in the future is what they purchased in the past. n Created based upon management’s estimate of future sales OH 7 -12

Food Production Charts n Created by studying past sales (sales histories) n Generally, the best predictor of what guests will buy in the future is what they purchased in the past. n Created based upon management’s estimate of future sales OH 7 -12

When Using Production Charts n Prepare an estimate of the number of guests to be served. n Indicate the actual number of items to be produced. n Post the production chart where it can be seen easily. OH 7 -13

When Using Production Charts n Prepare an estimate of the number of guests to be served. n Indicate the actual number of items to be produced. n Post the production chart where it can be seen easily. OH 7 -13

When Using Production Charts continued n Ensure the required standardized recipes are readily available. n Periodically check the actual recipe yield against that listed on the standardized recipe. OH 7 -14

When Using Production Charts continued n Ensure the required standardized recipes are readily available. n Periodically check the actual recipe yield against that listed on the standardized recipe. OH 7 -14

Waste Reports n Critical to food cost control n Easily completed n Should be maintained for each shift n May indicate n Where training is needed n Production concerns that require attention OH 7 -15

Waste Reports n Critical to food cost control n Easily completed n Should be maintained for each shift n May indicate n Where training is needed n Production concerns that require attention OH 7 -15

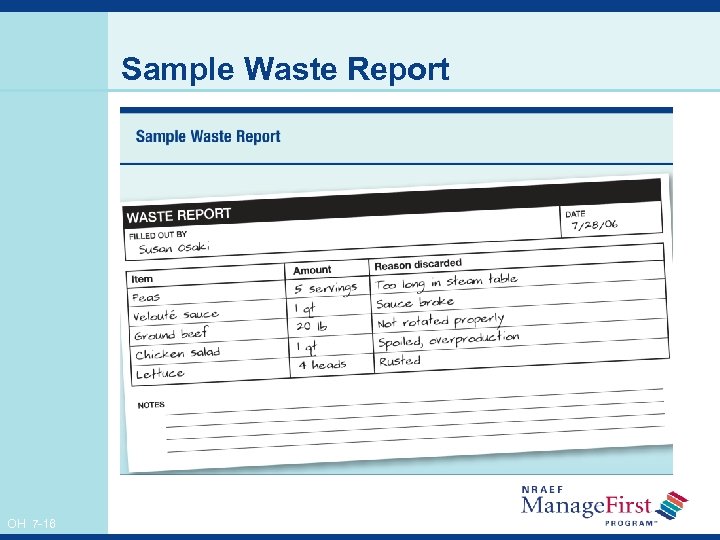

Sample Waste Report OH 7 -16

Sample Waste Report OH 7 -16

Analysis of Waste Reports n Determine why each item had to be discarded. n Develop a strategy to prevent similar future losses. n Share findings with those who need to know. OH 7 -17

Analysis of Waste Reports n Determine why each item had to be discarded. n Develop a strategy to prevent similar future losses. n Share findings with those who need to know. OH 7 -17

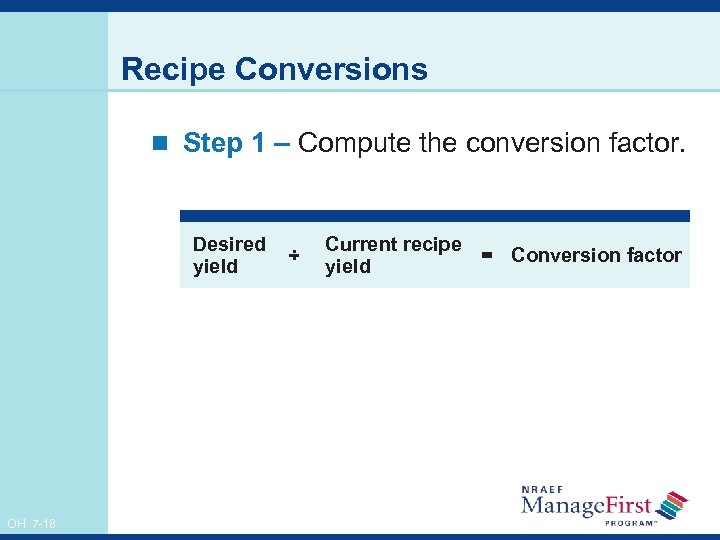

Recipe Conversions n Step 1 – Compute the conversion factor. Desired yield OH 7 -18 ÷ Current recipe = Conversion factor yield

Recipe Conversions n Step 1 – Compute the conversion factor. Desired yield OH 7 -18 ÷ Current recipe = Conversion factor yield

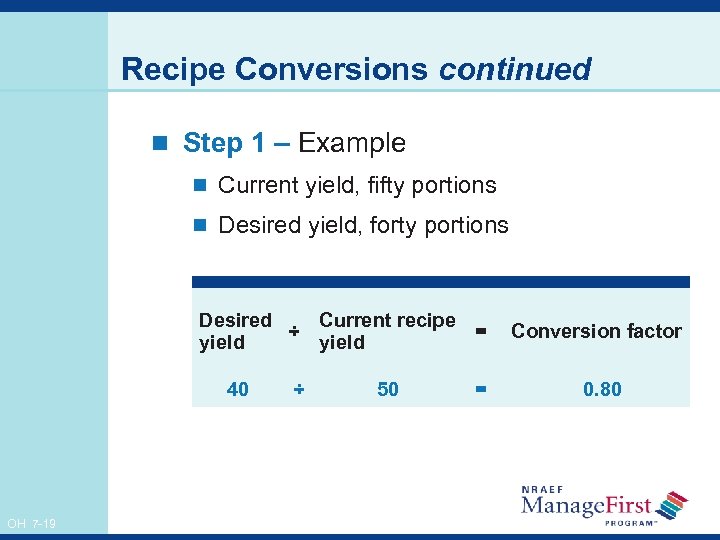

Recipe Conversions continued n Step 1 – Example n Current yield, fifty portions n Desired yield, forty portions Desired Current recipe ÷ = yield 40 OH 7 -19 ÷ 50 = Conversion factor 0. 80

Recipe Conversions continued n Step 1 – Example n Current yield, fifty portions n Desired yield, forty portions Desired Current recipe ÷ = yield 40 OH 7 -19 ÷ 50 = Conversion factor 0. 80

Recipe Conversions continued n Step 2 – Convert ingredients into units that can be easily multiplied or divided. n Convert weights to ounces. n Convert cups, pints, and quarts to fluid ounces. OH 7 -20

Recipe Conversions continued n Step 2 – Convert ingredients into units that can be easily multiplied or divided. n Convert weights to ounces. n Convert cups, pints, and quarts to fluid ounces. OH 7 -20

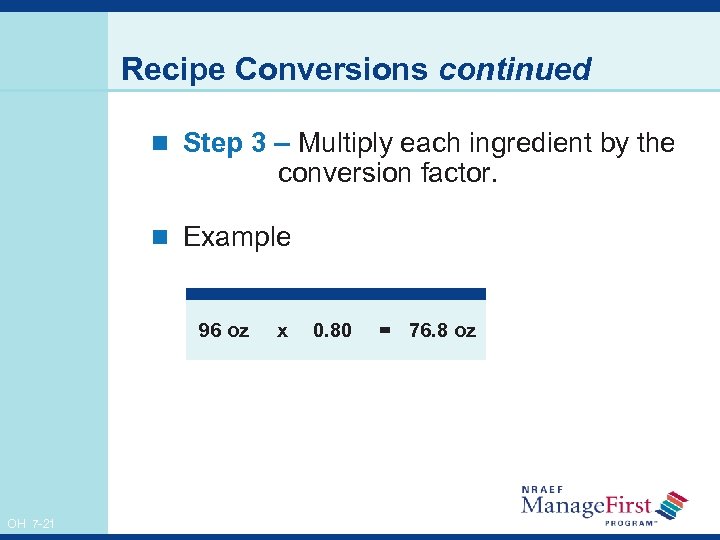

Recipe Conversions continued n Step 3 – Multiply each ingredient by the conversion factor. n Example 96 oz OH 7 -21 x 0. 80 = 76. 8 oz

Recipe Conversions continued n Step 3 – Multiply each ingredient by the conversion factor. n Example 96 oz OH 7 -21 x 0. 80 = 76. 8 oz

Recipe Conversions continued n Step 4 – Convert ingredient amounts back to normally used units. n Example 76. 8 oz OH 7 -22 ÷ 8 oz = 9. 6 c; or 2 qt, 1½ c

Recipe Conversions continued n Step 4 – Convert ingredient amounts back to normally used units. n Example 76. 8 oz OH 7 -22 ÷ 8 oz = 9. 6 c; or 2 qt, 1½ c

Recipe Yields n Recipe yields must be known. n Accurate costing of menu items is not possible without known and consistent yields from standardized recipes. n Effective production planning is also impossible without known recipe yields. OH 7 -23

Recipe Yields n Recipe yields must be known. n Accurate costing of menu items is not possible without known and consistent yields from standardized recipes. n Effective production planning is also impossible without known recipe yields. OH 7 -23

Recipe Yields continued n To calculate a recipe yield, compute the total volume of the recipe by n Weight—for those recipes where portion size is determined by weight. n Volume—for those recipes where portion size is determined by volume. OH 7 -24

Recipe Yields continued n To calculate a recipe yield, compute the total volume of the recipe by n Weight—for those recipes where portion size is determined by weight. n Volume—for those recipes where portion size is determined by volume. OH 7 -24

Calculating Recipe Yield n Weigh or measure only the major ingredients. n Account for cooking loss, especially for n Meats n Vegetables n Fruit OH 7 -25

Calculating Recipe Yield n Weigh or measure only the major ingredients. n Account for cooking loss, especially for n Meats n Vegetables n Fruit OH 7 -25

Butcher’s Yield Tests n Determine actual costs associated with buying larger cuts of meat and fabricating n Some will just calculate the cost based on the final end products and use that for pricing others factor value for each utilization n Utilization of byproducts (100% or less? ) n Weigh each component n Determine market value for components OH 7 -26 used

Butcher’s Yield Tests n Determine actual costs associated with buying larger cuts of meat and fabricating n Some will just calculate the cost based on the final end products and use that for pricing others factor value for each utilization n Utilization of byproducts (100% or less? ) n Weigh each component n Determine market value for components OH 7 -26 used

Butcher’s Yield Tests n Total trim weight and value n Subtract trim weight from AP weight to determine yield of item n Subtract trim weight from AP weight to determine net price n Divide net price by yield of item to get Cost Per Pound EP n Consider labor & cooking loss OH 7 -27

Butcher’s Yield Tests n Total trim weight and value n Subtract trim weight from AP weight to determine yield of item n Subtract trim weight from AP weight to determine net price n Divide net price by yield of item to get Cost Per Pound EP n Consider labor & cooking loss OH 7 -27

How Would You Answer the Following Questions? 1. 2. 3. It (is/is not) possible for a cook using a standardized recipe to create a substandard menu item. Waste reports indicate when employees overportion and waste food. (True/False) How many steps does the recipe conversion process have? A. B. C. D. 4. OH 7 -28 Three Four Five Six A recipe (yield/portion conversion) test is a calculation of the number of portions produced by a standardized recipe.

How Would You Answer the Following Questions? 1. 2. 3. It (is/is not) possible for a cook using a standardized recipe to create a substandard menu item. Waste reports indicate when employees overportion and waste food. (True/False) How many steps does the recipe conversion process have? A. B. C. D. 4. OH 7 -28 Three Four Five Six A recipe (yield/portion conversion) test is a calculation of the number of portions produced by a standardized recipe.

Key Term Review n Conversion factor n Food production chart n Recipe conversion n Recipe yield n Taste test n Waste report OH 7 -29

Key Term Review n Conversion factor n Food production chart n Recipe conversion n Recipe yield n Taste test n Waste report OH 7 -29

Chapter Learning Objectives— What Did You Learn? n Develop a food production chart. n Describe how a waste report helps control food costs. n Use a conversion factor to calculate a new yield for an existing recipe. n Determine a recipe’s yield and the number of portions it will produce. OH 7 -30

Chapter Learning Objectives— What Did You Learn? n Develop a food production chart. n Describe how a waste report helps control food costs. n Use a conversion factor to calculate a new yield for an existing recipe. n Determine a recipe’s yield and the number of portions it will produce. OH 7 -30