966184f02d2718e134691a8db0427684.ppt

- Количество слайдов: 55

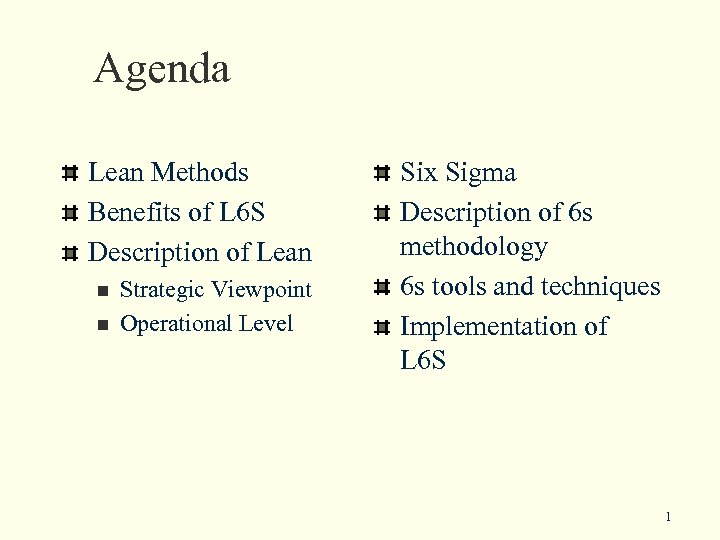

Agenda Lean Methods Benefits of L 6 S Description of Lean n n Strategic Viewpoint Operational Level Six Sigma Description of 6 s methodology 6 s tools and techniques Implementation of L 6 S 1

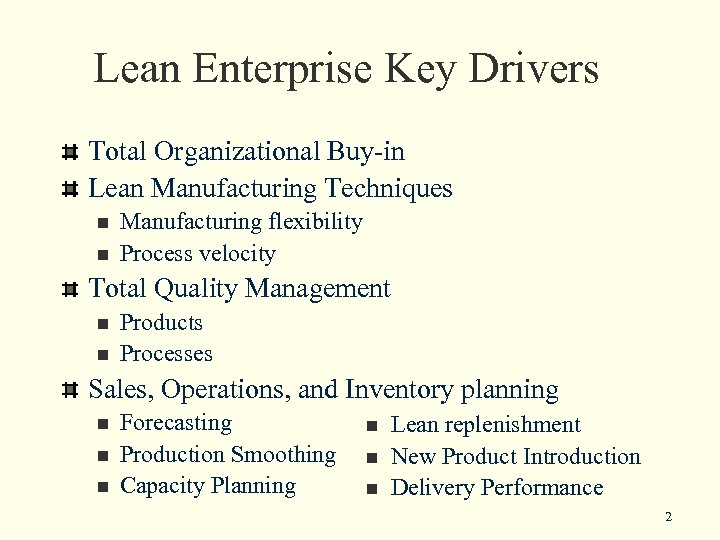

Lean Enterprise Key Drivers Total Organizational Buy-in Lean Manufacturing Techniques n n Manufacturing flexibility Process velocity Total Quality Management n n Products Processes Sales, Operations, and Inventory planning n n n Forecasting Production Smoothing Capacity Planning n n n Lean replenishment New Product Introduction Delivery Performance 2

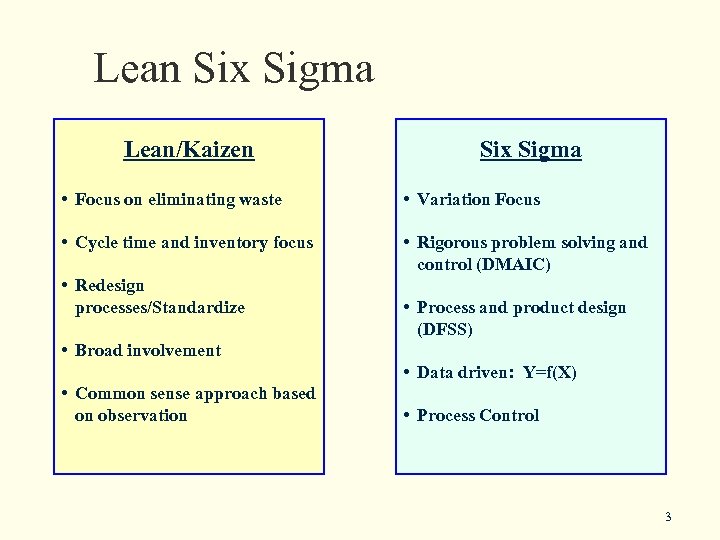

Lean Six Sigma Lean/Kaizen Six Sigma • Focus on eliminating waste • Variation Focus • Cycle time and inventory focus • Rigorous problem solving and control (DMAIC) • Redesign processes/Standardize • Process and product design (DFSS) • Broad involvement • Data driven: Y=f(X) • Common sense approach based on observation • Process Control 3

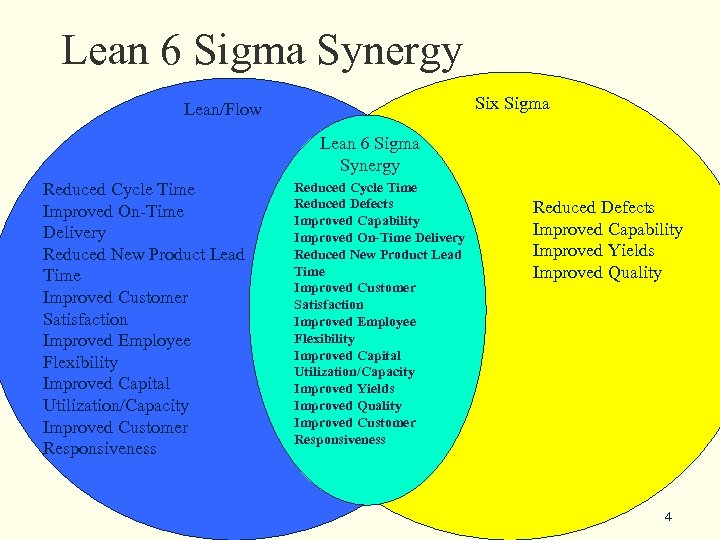

Lean 6 Sigma Synergy Six Sigma Lean/Flow Lean 6 Sigma Synergy Reduced Cycle Time Improved On-Time Delivery Reduced New Product Lead Time Improved Customer Satisfaction Improved Employee Flexibility Improved Capital Utilization/Capacity Improved Customer Responsiveness Reduced Cycle Time Reduced Defects Improved Capability Improved On-Time Delivery Reduced New Product Lead Time Improved Customer Satisfaction Improved Employee Flexibility Improved Capital Utilization/Capacity Improved Yields Improved Quality Improved Customer Responsiveness Reduced Defects Improved Capability Improved Yields Improved Quality 4

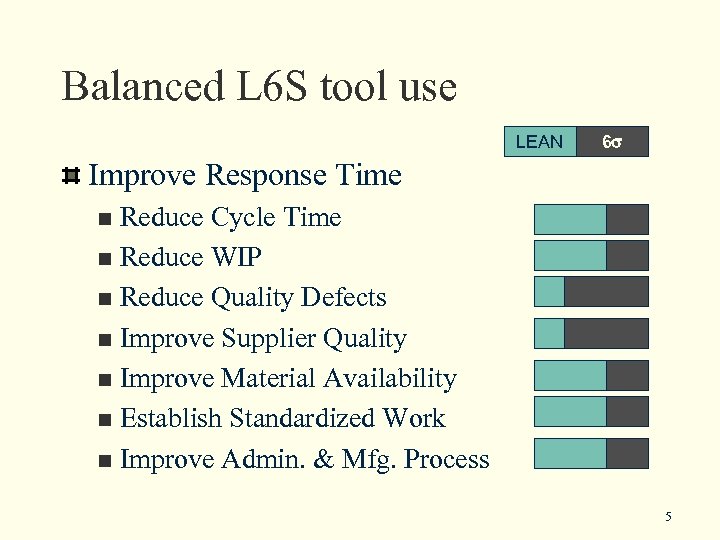

Balanced L 6 S tool use LEAN 6 Improve Response Time Reduce Cycle Time n Reduce WIP n Reduce Quality Defects n Improve Supplier Quality n Improve Material Availability n Establish Standardized Work n Improve Admin. & Mfg. Process n 5

Financial Implications Income Statement Balance Sheet Financial Implications 6

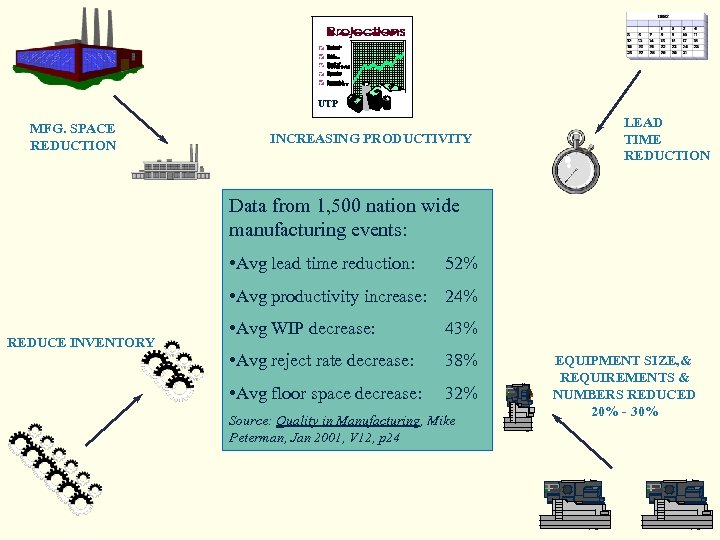

UTP MFG. SPACE REDUCTION INCREASING PRODUCTIVITY LEAD TIME REDUCTION Data from 1, 500 nation wide manufacturing events: • Avg lead time reduction: 52% • Avg productivity increase: 24% REDUCE INVENTORY • Avg WIP decrease: 43% • Avg reject rate decrease: 38% • Avg floor space decrease: 32% Source: Quality in Manufacturing, Mike Peterman, Jan 2001, V 12, p 24 EQUIPMENT SIZE, & REQUIREMENTS & NUMBERS REDUCED 20% - 30% 7

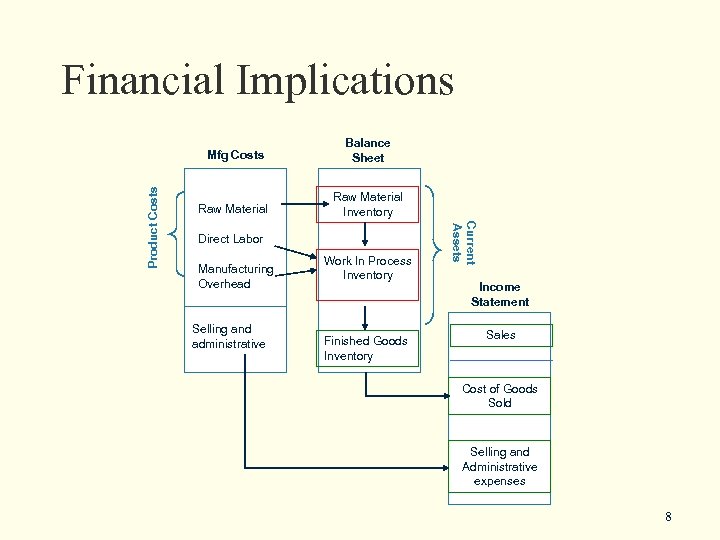

Financial Implications Balance Sheet Raw Material Inventory Direct Labor Manufacturing Overhead Selling and administrative Work In Process Inventory Finished Goods Inventory Current Assets Product Costs Mfg Costs Income Statement Sales Cost of Goods Sold Selling and Administrative expenses 8

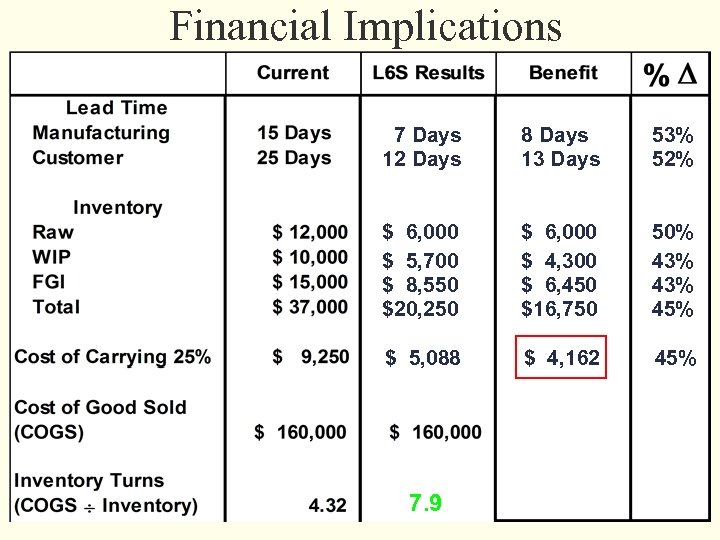

Financial Implications 7 Days 12 Days 8 Days 13 Days 53% 52% $ 6, 000 $ 5, 700 $ 8, 550 $20, 250 $ 6, 000 $ 4, 300 $ 6, 450 $16, 750 50% 43% 45% $ 5, 088 $ 4, 162 45% 7. 9 9

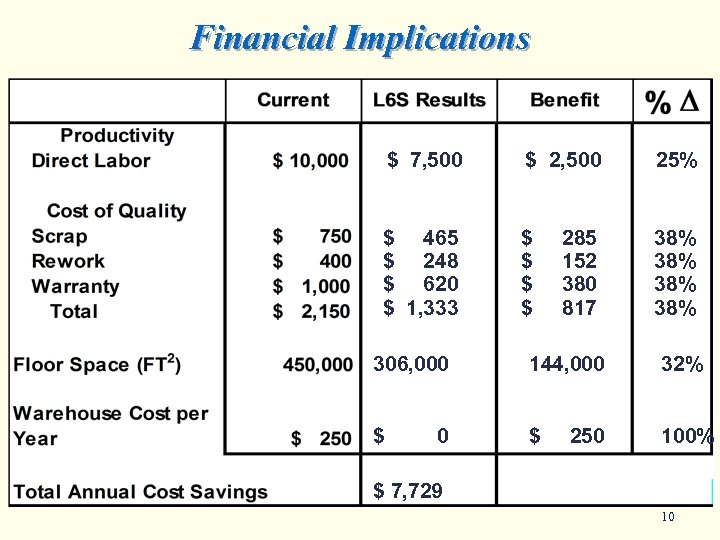

Financial Implications $ 7, 500 $ 2, 500 25% $ 465 $ 248 $ 620 $ 1, 333 $ $ 38% 38% 285 152 380 817 306, 000 144, 000 32% $ $ 100% 0 250 $ 7, 729 10

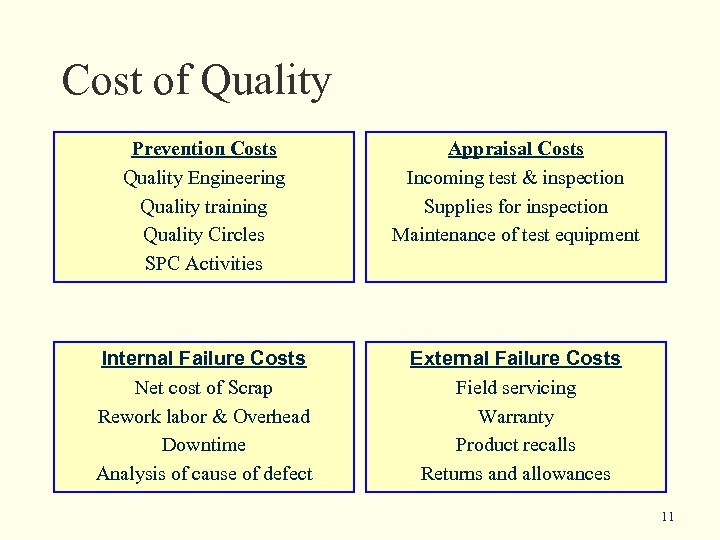

Cost of Quality Prevention Costs Quality Engineering Quality training Quality Circles SPC Activities Appraisal Costs Incoming test & inspection Supplies for inspection Maintenance of test equipment Internal Failure Costs Net cost of Scrap Rework labor & Overhead Downtime Analysis of cause of defect External Failure Costs Field servicing Warranty Product recalls Returns and allowances 11

Lean Methods Strategic Level n Philosophy Operational Level Tools n Traditional vs. Flow concepts n 12

Improvements HBR; “Decoding the DNA of the Toyota Production System”; Sep-Oct. 1999 HBR; “Learning to Lead at Toyota”; May 2004 Companies often implement tools of TPS without the underlying principles. Tools aid in the implementation of a temporary “best practice” until a new problem is discovered. 13

Toyota Production System Rule 1 - How people work is highly specified n Content n Sequence n Timing n Outcome Standard Operating Worksheet n Takt time n 14

Toyota Production System Rule 2 - Every customer-supplier connection must be direct n No question on n Supplier (internal or external) n Number of units required n Timing of delivery Kanban n Service Requests n 15

Toyota Production System Rule 3 - Pathway for every product and service must be simple and direct n Flow along a simple specified path n Does not mean each path is dedicated to only one product n Product Process Matrix Rule 4 - Improvement must be made in accordance with the scientific method at the lowest possible level 16

Improvements People at all levels Assembly line operators n Supervisors n Management n Executives n Structure work and improvements as experiments 17

Improvements Active experimentation for improvement n Standard work n Gaps between what is expected through improvements and what is actually obtained become immediately evident. Operators are responsible for operational improvements n Management helps them understand that responsibility and facilitate improvements. n 18

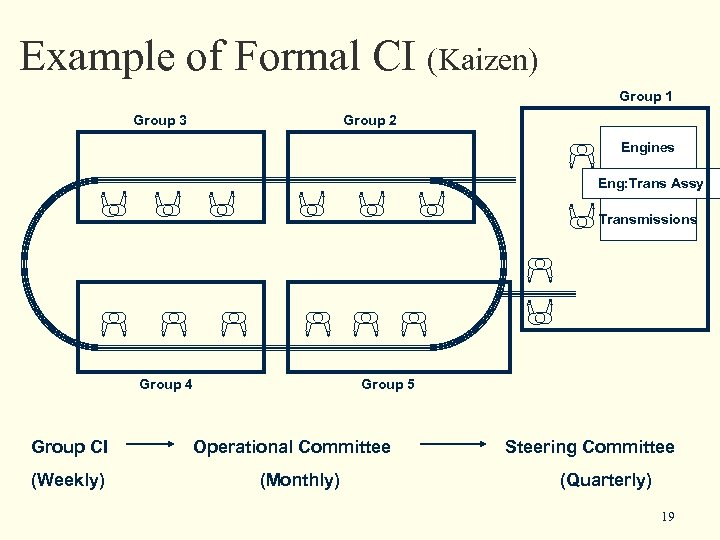

Example of Formal CI (Kaizen) Group 1 Group 3 Group 2 Engines Eng: Trans Assy Transmissions Group 4 Group CI (Weekly) Group 5 Operational Committee (Monthly) Steering Committee (Quarterly) 19

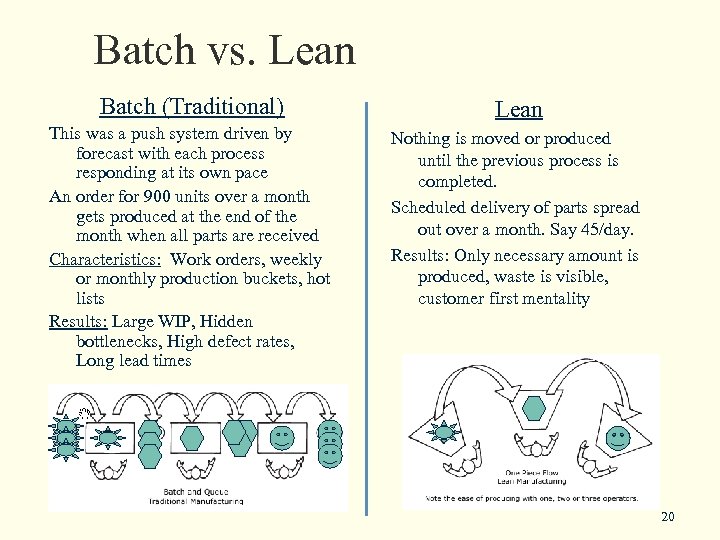

Batch vs. Lean Batch (Traditional) Lean This was a push system driven by forecast with each process responding at its own pace An order for 900 units over a month gets produced at the end of the month when all parts are received Characteristics: Work orders, weekly or monthly production buckets, hot lists Results: Large WIP, Hidden bottlenecks, High defect rates, Long lead times Nothing is moved or produced until the previous process is completed. Scheduled delivery of parts spread out over a month. Say 45/day. Results: Only necessary amount is produced, waste is visible, customer first mentality 20

Hidden Waste FINISHED PRODUCT TO CONSUMER RAW MATERIAL SEA OF INVENTORY POOR SCHEDULING QUALITY PROBLEMS LONG SET-UP TIME LINE IMBALANCE LACK OF HOUSE KEEPING LONG MACHINE ABSENTEEISM COMMUNICATION BREAKDOWN TRANSPORTATION SUPPLIER PROBLEMS DELIVERY 2004© Pharogen, Ltd 21

Exposed Waste FINISHED PRODUCT TO CONSUMER RAW MATERIAL SEA OF INVENTORY POOR SCHEDULING MACHINE BREAKDOWN 2004© Pharogen, Ltd QUALITY PROBLEMS LONG TRANSPORTATION LONG SET-UP TIME SUPPLIER DELIVERY LINE IMBALANCE ABSENTEEISM LACK OF HOUSE KEEPING COMMUNICATION PROBLEMS 22

Process Efficiency Reducing unnecessary wait-time between value added steps Process cycle efficiency= Value Added Time/Total Lead Time 23

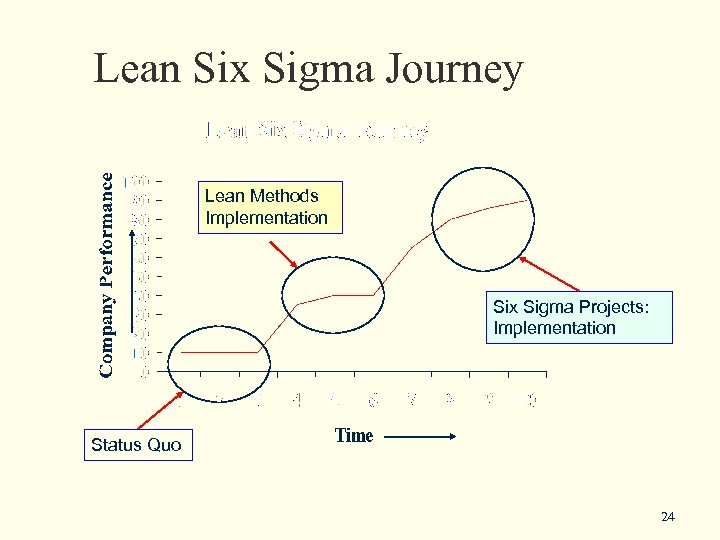

Lean Six Sigma Journey Lean Methods Implementation Six Sigma Projects: Implementation Status Quo 24

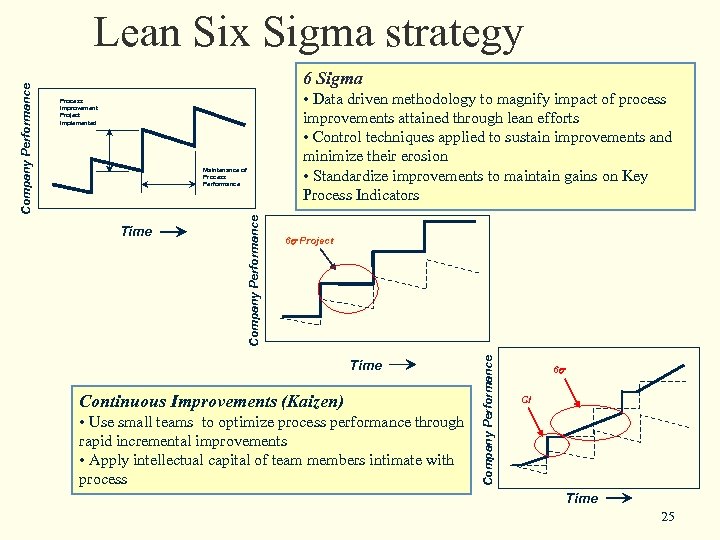

6 Sigma Maintenance of Process Performance Time • Data driven methodology to magnify impact of process improvements attained through lean efforts • Control techniques applied to sustain improvements and minimize their erosion • Standardize improvements to maintain gains on Key Process Indicators 6 s Project Time Continuous Improvements (Kaizen) • Use small teams to optimize process performance through rapid incremental improvements • Apply intellectual capital of team members intimate with process Company Performance Process Improvement Project Implemented Company Performance Lean Six Sigma strategy 6 s CI Time 25

Measurements Customer Order Cycle Time Completed vs. Daily Production Schedule Yield Linearity Workforce Skill Speed to Market: Product Development Process Continuous Improvement: Savings 26

Lean Methods Strategic Level Philosophy n Implementation n Operational Level Tools n Traditional vs. Flow concepts n 27

Minimize Waste Overproduction Excess Inventory Waiting Motion (Worker movement) Transportation Defective parts Unnecessary Processing 28

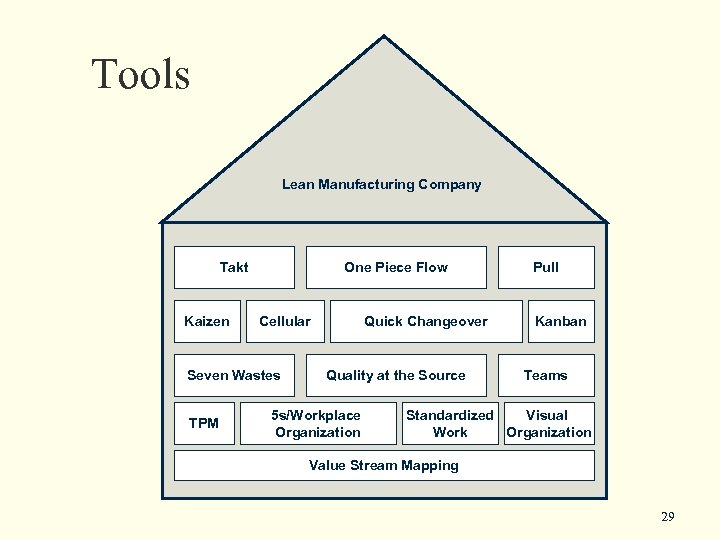

Tools Lean Manufacturing Company Takt Kaizen One Piece Flow Cellular Seven Wastes TPM Quick Changeover Quality at the Source 5 s/Workplace Organization Pull Kanban Teams Standardized Visual Work Organization Value Stream Mapping 29

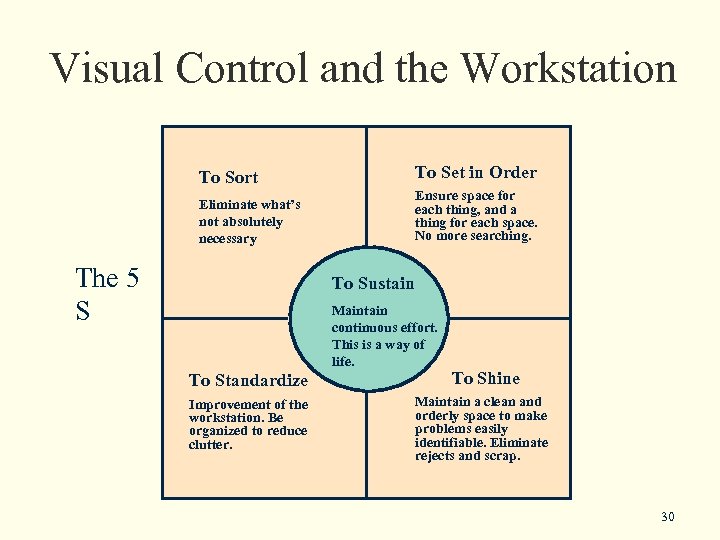

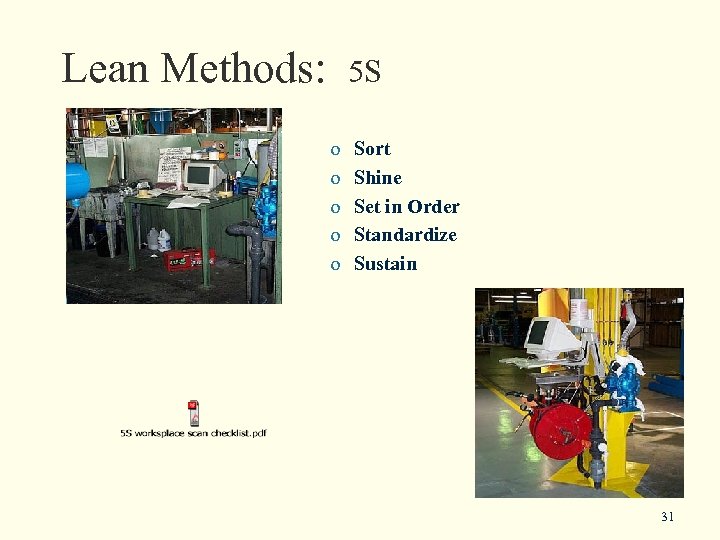

Visual Control and the Workstation To Sort To Set in Order Eliminate what’s not absolutely necessary Ensure space for each thing, and a thing for each space. No more searching. The 5 S To Sustain Maintain continuous effort. This is a way of life. To Standardize Improvement of the workstation. Be organized to reduce clutter. To Shine Maintain a clean and orderly space to make problems easily identifiable. Eliminate rejects and scrap. 30

Lean Methods: 5 S o Sort o Shine o Set in Order o Standardize o Sustain 31

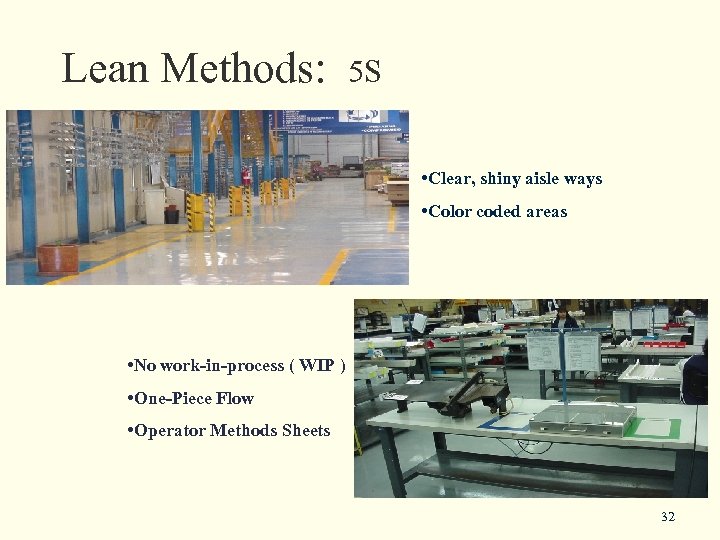

Lean Methods: 5 S • Clear, shiny aisle ways • Color coded areas • No work-in-process ( WIP ) • One-Piece Flow • Operator Methods Sheets 32

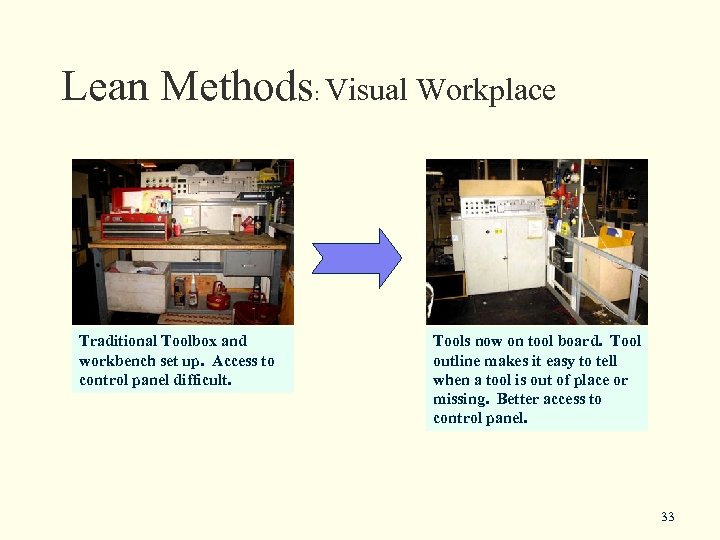

Lean Methods: Visual Workplace Traditional Toolbox and workbench set up. Access to control panel difficult. Tools now on tool board. Tool outline makes it easy to tell when a tool is out of place or missing. Better access to control panel. 33

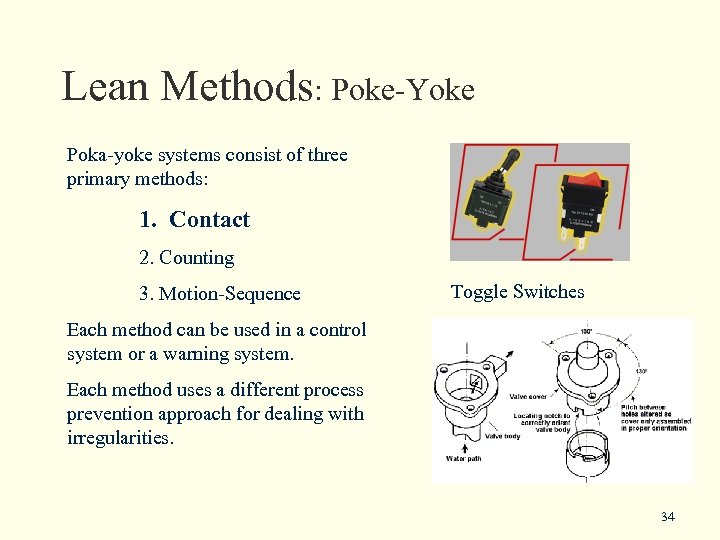

Lean Methods: Poke-Yoke Poka-yoke systems consist of three primary methods: 1. Contact 2. Counting 3. Motion-Sequence Toggle Switches Each method can be used in a control system or a warning system. Each method uses a different process prevention approach for dealing with irregularities. 34

Lean Methods: Poke-Yoke Poka-yoke systems consist of three primary methods: 1. Contact 2. Counting 3. Motion-Sequence Each method can be used in a control system or a warning system. Count the number of parts or components required to complete an operation in advance. If operators finds parts leftover using this method, they will know that something has been omitted from the process. Each method uses a different process prevention approach for dealing with irregularities. 35

Lean Methods: Poke-Yoke Poka-yoke systems consist of three primary methods: 1. Contact 2. Counting 3. Motion-Sequence The third poka-yoke method uses sensors to determine if a motion or a step in a process has occurred. If the step has not occurred or has occurred out of sequence, the sensor signals a timer or other device to stop the machine and signal the operator. Each method can be used in a control system or a warning system. Each method uses a different process prevention approach for dealing with irregularities. 36

Lean Line Design THREE PRINCIPLE RULES WORK TO TAKT TIME ONE PIECE FLOW PULL SCHEDULING 37

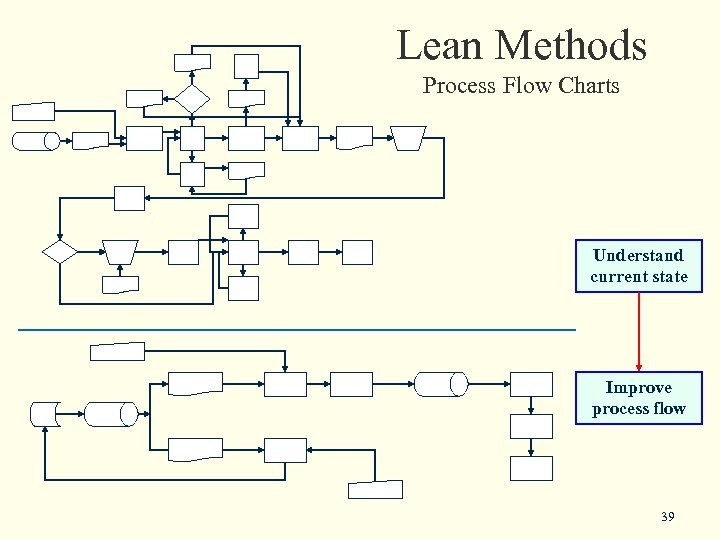

Lean Line Design q q q q q Create Process Flow Charts Develop Standard Operation Worksheets Define Product/Process Matrices Create Multi-Product Process Flow Charts Calculate Takt Review Actual Requirements vs. Design Develop Standard Operations Create the Facility Layout Define Cells 38

Lean Methods Process Flow Charts Understand current state Improve process flow 39

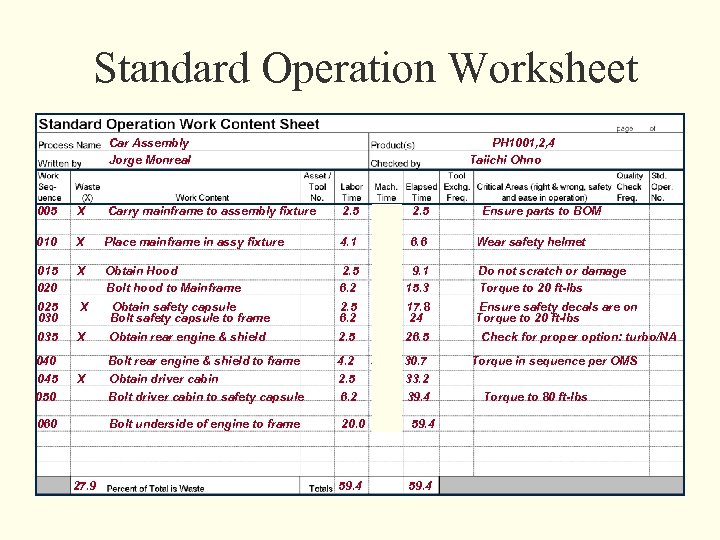

Standard Operation Worksheet Car Assembly Jorge Monreal 005 X 010 X Place mainframe in assy fixture 4. 1 6. 6 015 020 X Obtain Hood Bolt hood to Mainframe 2. 5 6. 2 4. 1 6. 2 9. 1 15. 3 Do not scratch or damage Torque to 20 ft-lbs 025 030 X Obtain safety capsule Bolt safety capsule to frame 2. 5 6. 2 2. 4 17. 8 24 Ensure safety decals are on Torque to 20 ft-lbs 035 X Obtain rear engine & shield 2. 5 2. 4 26. 5 X Bolt rear engine & shield to frame Obtain driver cabin Bolt driver cabin to safety capsule 4. 2 2. 5 6. 2 3. 4 30. 7 33. 2 39. 4 040 045 050 060 Carry mainframe to assembly fixture PH 1001, 2, 4 Taiichi Ohno Bolt underside of engine to frame 27. 9 2. 5 20. 0 59. 4 Ensure parts to BOM Wear safety helmet Check for proper option: turbo/NA Torque in sequence per OMS Torque to 80 ft-lbs

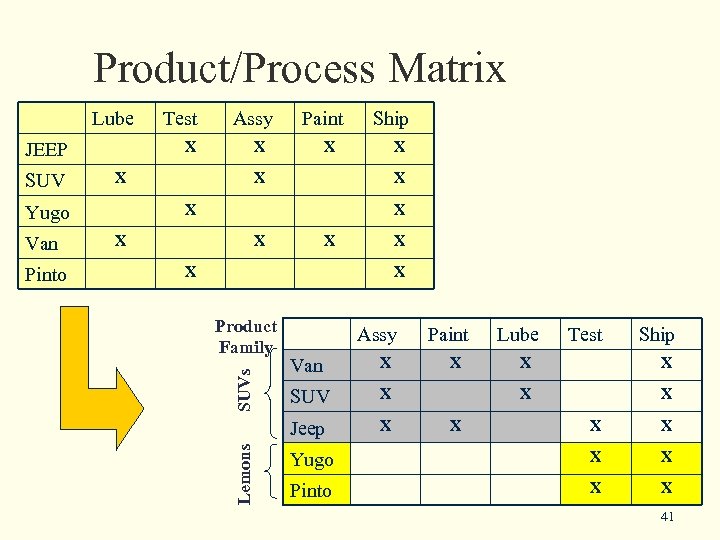

Product/Process Matrix Lube Ship X X X Product Family Assy SUVs Van X SUV X Paint X Jeep Lemons Pinto Paint X X Yugo Van Assy X JEEP SUV Test X Lube Test Ship X X X X Yugo X X Pinto X X 41

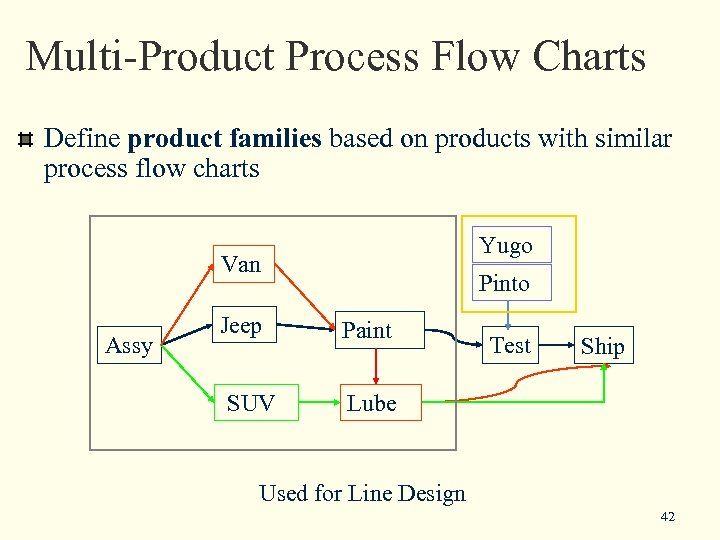

Multi-Product Process Flow Charts Define product families based on products with similar process flow charts Yugo Van Assy Jeep SUV Pinto Paint Test Ship Lube Used for Line Design 42

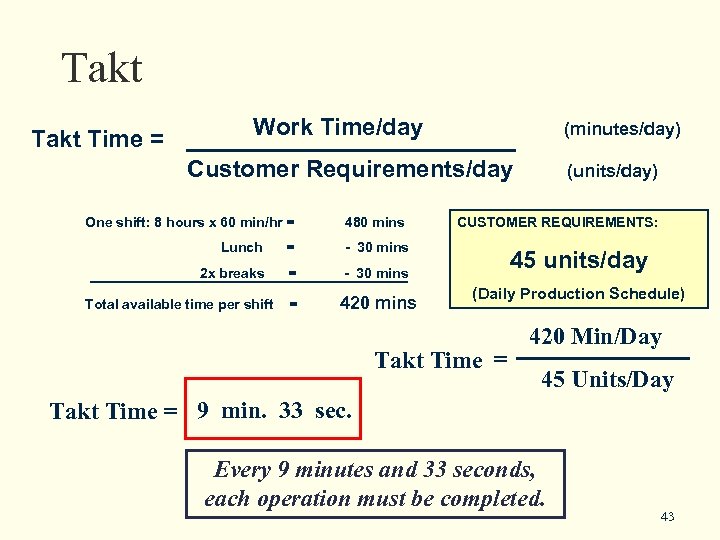

Takt Time = Work Time/day (minutes/day) Customer Requirements/day One shift: 8 hours x 60 min/hr = 480 mins Lunch = = - 30 mins = 420 mins CUSTOMER REQUIREMENTS: - 30 mins 2 x breaks Total available time per shift (units/day) 45 units/day (Daily Production Schedule) Takt Time = 420 Min/Day 45 Units/Day Takt Time = 9 min. 33 sec. Every 9 minutes and 33 seconds, each operation must be completed. 43

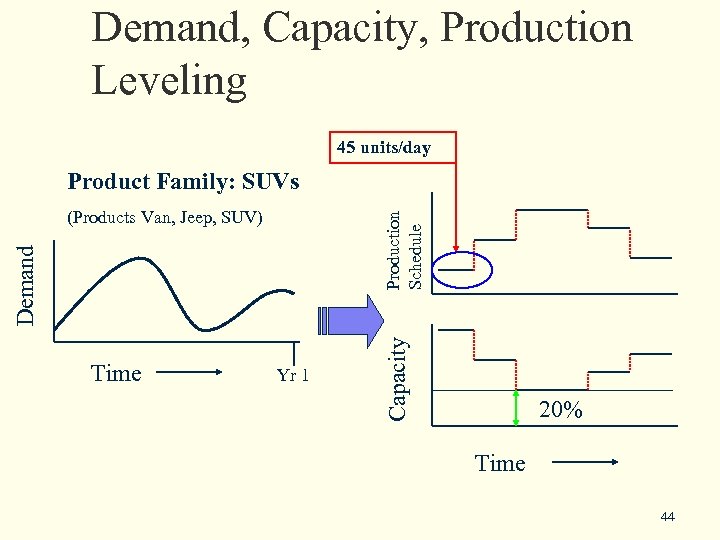

Demand, Capacity, Production Leveling 45 units/day Product Family: SUVs Time Yr 1 Capacity Demand Production Schedule (Products Van, Jeep, SUV) 20% Time 44

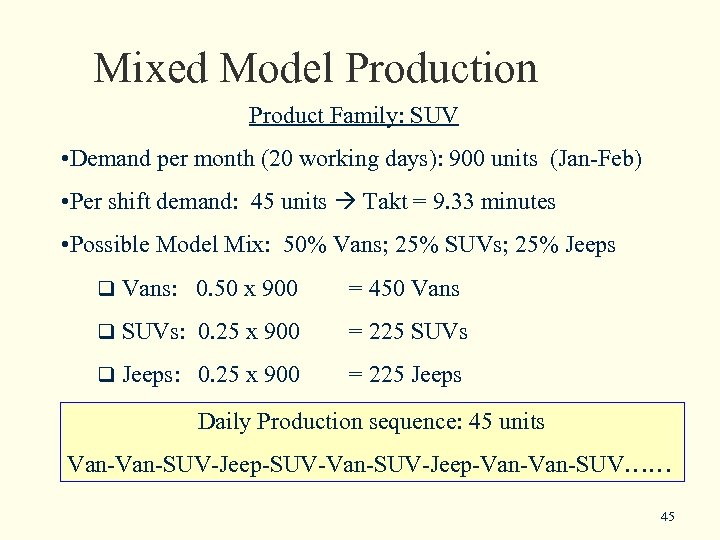

Mixed Model Production Product Family: SUV • Demand per month (20 working days): 900 units (Jan-Feb) • Per shift demand: 45 units Takt = 9. 33 minutes • Possible Model Mix: 50% Vans; 25% SUVs; 25% Jeeps q Vans: 0. 50 x 900 = 450 Vans q SUVs: 0. 25 x 900 = 225 SUVs q Jeeps: 0. 25 x 900 = 225 Jeeps Daily Production sequence: 45 units Van-SUV-Jeep-SUV-Van-SUV-Jeep-Van-SUV…… 45

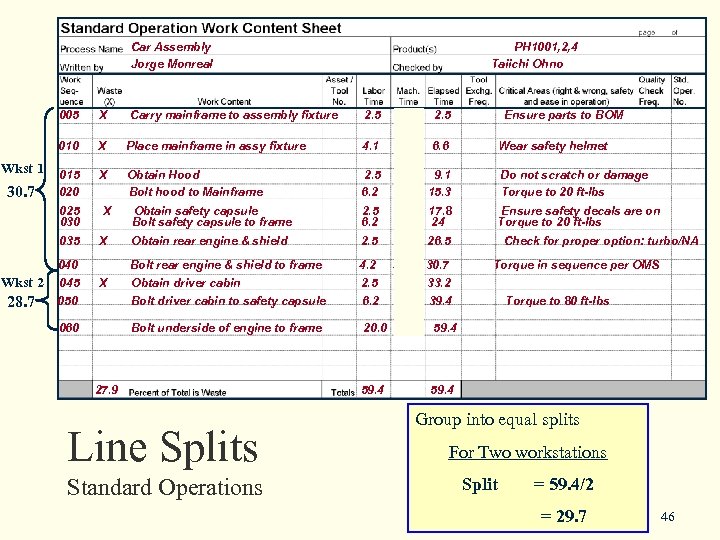

Car Assembly Jorge Monreal 005 28. 7 Place mainframe in assy fixture 4. 1 6. 6 015 020 X Obtain Hood Bolt hood to Mainframe 2. 5 6. 2 4. 1 6. 2 9. 1 15. 3 Do not scratch or damage Torque to 20 ft-lbs X Obtain safety capsule Bolt safety capsule to frame 2. 5 6. 2 2. 4 17. 8 24 Ensure safety decals are on Torque to 20 ft-lbs 035 Wkst 2 X 025 030 30. 7 X 010 Wkst 1 X Obtain rear engine & shield 2. 5 2. 4 26. 5 X Bolt rear engine & shield to frame Obtain driver cabin Bolt driver cabin to safety capsule 4. 2 2. 5 6. 2 3. 4 30. 7 33. 2 39. 4 040 045 050 060 Carry mainframe to assembly fixture PH 1001, 2, 4 Taiichi Ohno Bolt underside of engine to frame 27. 9 Line Splits Standard Operations 2. 5 20. 0 Wear safety helmet Check for proper option: turbo/NA Torque in sequence per OMS Torque to 80 ft-lbs 59. 4 Ensure parts to BOM 59. 4 Group into equal splits For Two workstations Split = 59. 4/2 = 29. 7 46

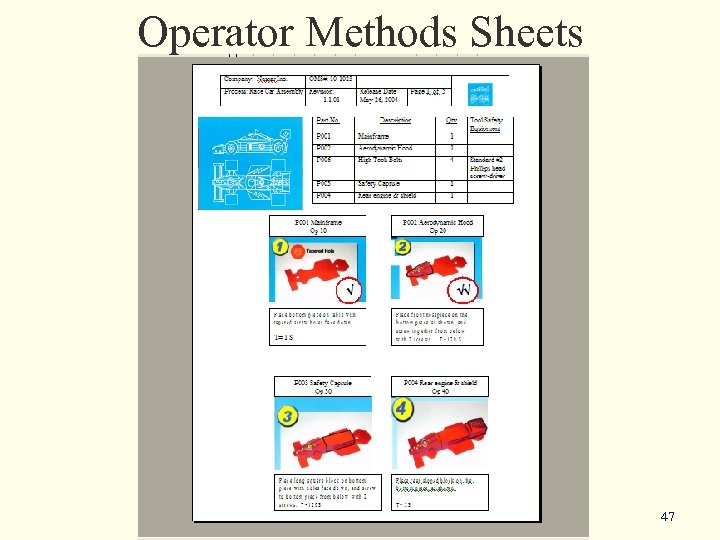

Operator Methods Sheets 47

Operator training Matrix Name Operation 10 -Mnfrm 20 -Hood Assy Operator One X X X 4/14/04 5/20/04 6/20/04 Operator Two X X X 5/20/04 4/14/04 6/20/04 Operator Three Operator Four Operation 30 - Seat Assy Operation 40 -Engine 50 -Cab Assy 48

Operator training Matrix Flexible workforce People move to where work needs to be performed n Help out in case of slow down: above or below n Reduce repetitive stress n Rotate positions every 4 -6 months Allows for some imbalance in the line 49

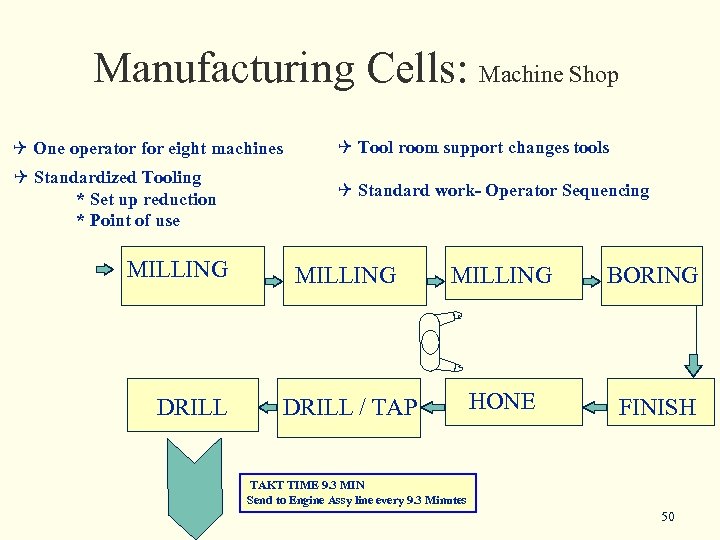

Manufacturing Cells: Machine Shop Q One operator for eight machines Q Tool room support changes tools Q Standardized Tooling * Set up reduction * Point of use Q Standard work- Operator Sequencing MILLING DRILL MILLING BORING DRILL / TAP HONE FINISH TAKT TIME 9. 3 MIN Send to Engine Assy line every 9. 3 Minutes 50

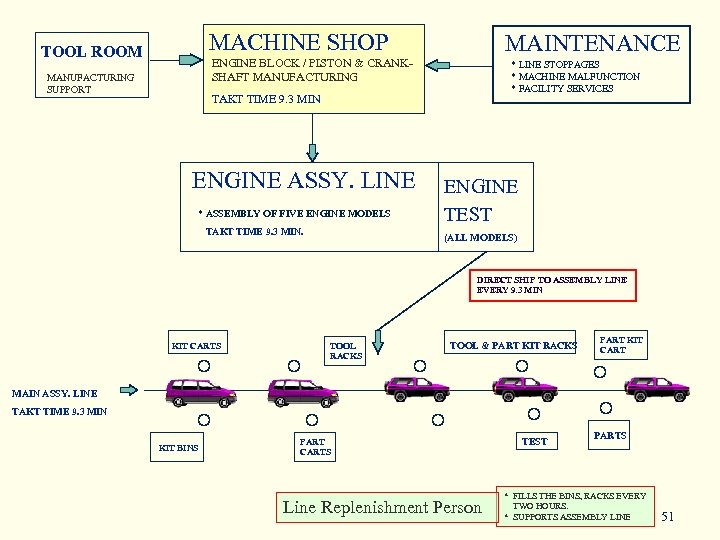

MACHINE SHOP TOOL ROOM MAINTENANCE ENGINE BLOCK / PISTON & CRANKSHAFT MANUFACTURING SUPPORT * LINE STOPPAGES * MACHINE MALFUNCTION * FACILITY SERVICES TAKT TIME 9. 3 MIN ENGINE ASSY. LINE * ASSEMBLY OF FIVE ENGINE MODELS TAKT TIME 9. 3 MIN. ENGINE TEST (ALL MODELS) DIRECT SHIP TO ASSEMBLY LINE EVERY 9. 3 MIN KIT CARTS TOOL RACKS TOOL & PART KIT RACKS PART KIT CART MAIN ASSY. LINE TAKT TIME 9. 3 MIN KIT BINS PART CARTS Line Replenishment Person TEST PARTS * FILLS THE BINS, RACKS EVERY TWO HOURS. * SUPPORTS ASSEMBLY LINE 51

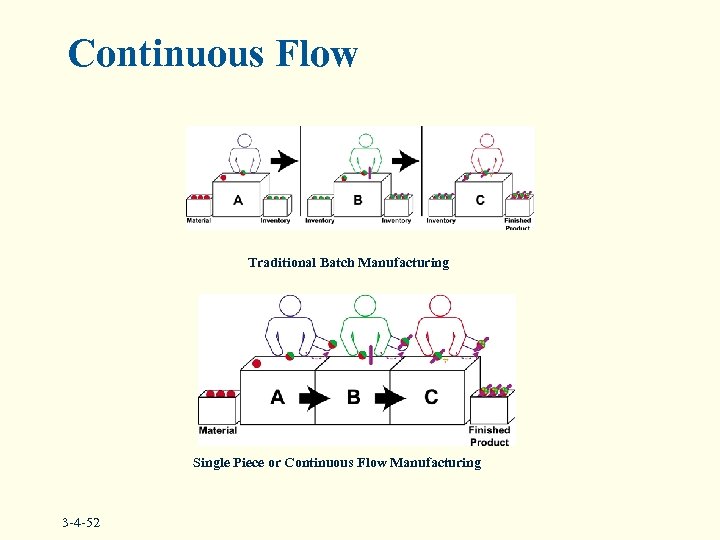

Continuous Flow Traditional Batch Manufacturing Single Piece or Continuous Flow Manufacturing 3 -4 -52

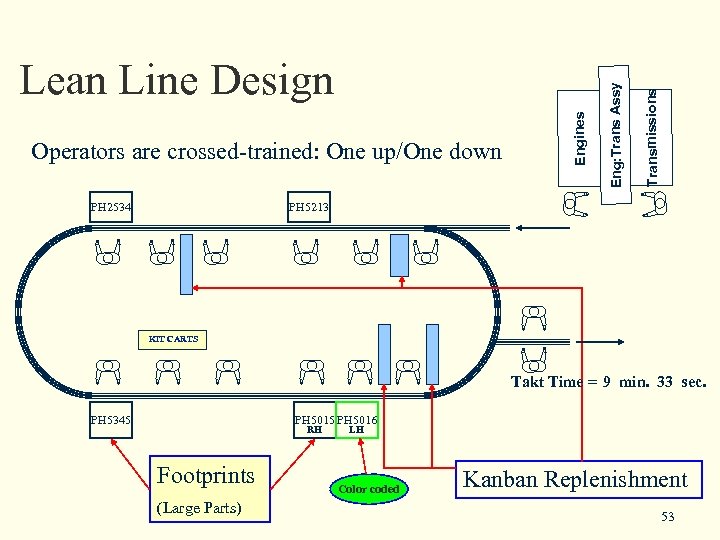

PH 2534 Transmissions Eng: Trans Assy Operators are crossed-trained: One up/One down Engines Lean Line Design PH 5213 KIT CARTS Takt Time = 9 min. 33 sec. PH 5345 PH 5016 RH Footprints (Large Parts) LH Color coded Kanban Replenishment 53

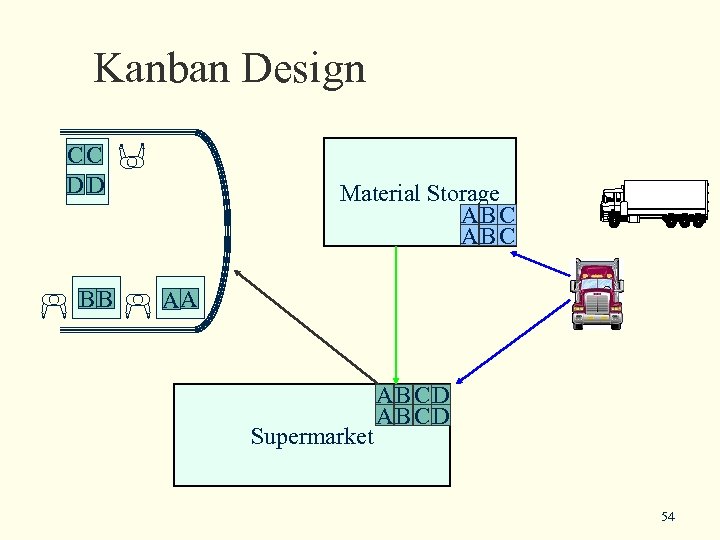

Kanban Design CC DD BB Material Storage AB C AA Supermarket AB CD 54

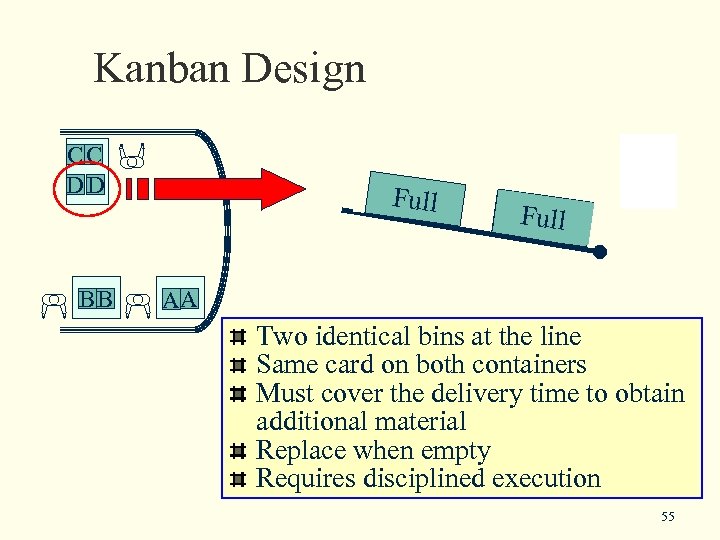

Kanban Design CC DD BB Full EF ull y mpt AA Two identical bins at the line Same card on both containers Must cover the delivery time to obtain additional material Replace when empty Requires disciplined execution 55

966184f02d2718e134691a8db0427684.ppt