8b7a4f9772302fdc5f1c428ae0de4dfb.ppt

- Количество слайдов: 80

Agenda • • • Company profile Global Glass Manufacturer Float Glass Manufacturing Process Locally Produced Products How to Choose Glass Heat Flows in Malaysia Why Low E? Technical Information Product Range - Pilkington Optifloat™ - Pilkington Specialty Glass - Pilkington Coated Glass • Performance Data

Company Profile • 1971 – MSG Established • 2004 – Wholly owned by Nippon Sheet Glass (NSG) • June 2006 – Acquisition of Pilkington by NSG

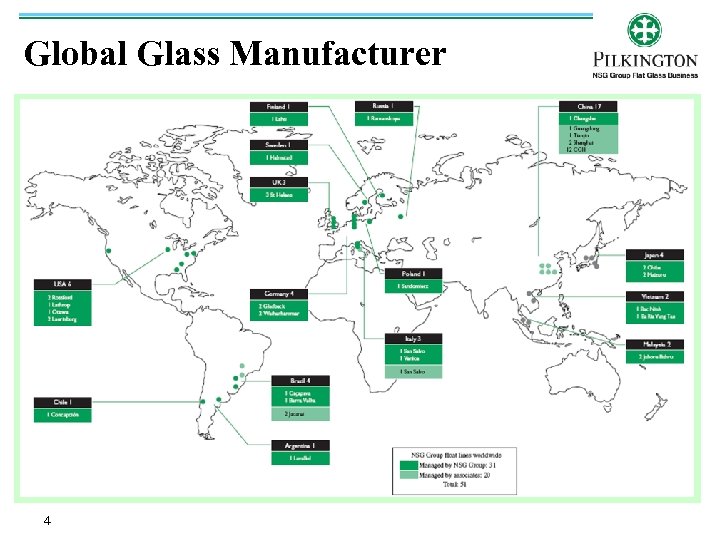

Global Glass Manufacturer 4

FLOAT GLASS MANUFACTURING PROCESS 5

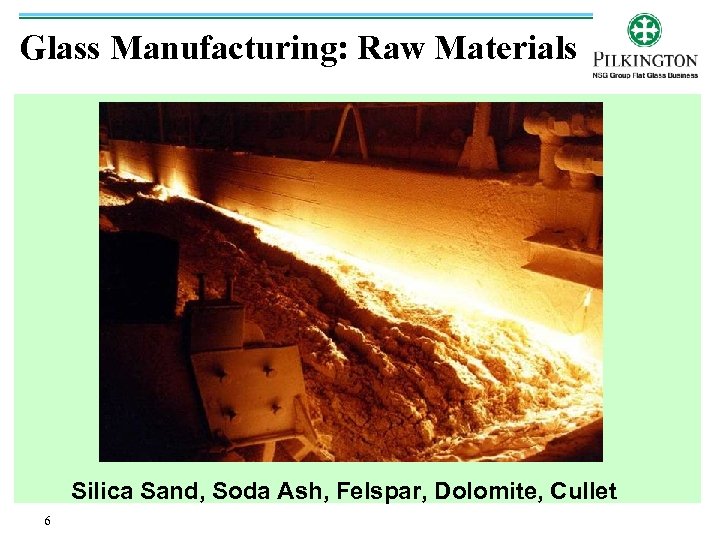

Glass Manufacturing: Raw Materials Silica Sand, Soda Ash, Felspar, Dolomite, Cullet 6

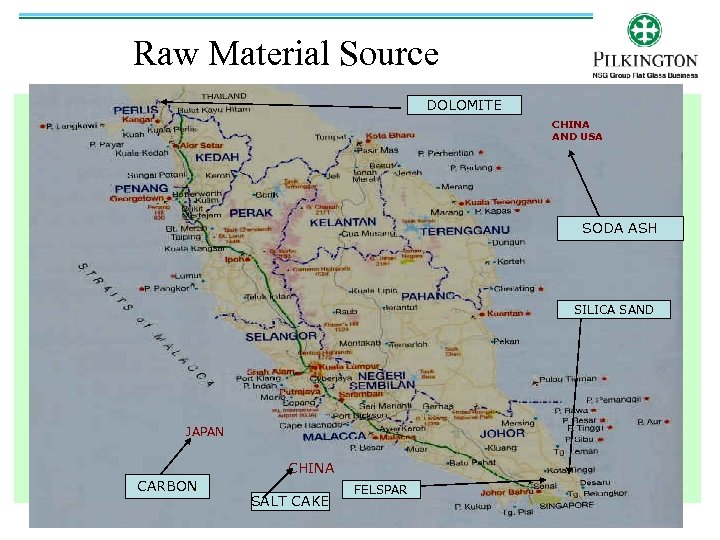

Raw Material Source DOLOMITE CHINA AND USA SODA ASH SILICA SAND JAPAN CHINA CARBON SALT CAKE FELSPAR

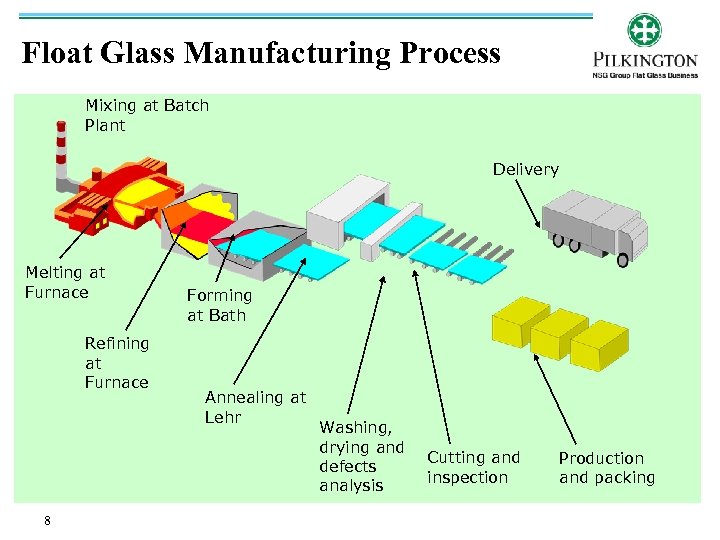

Float Glass Manufacturing Process Mixing at Batch Plant Delivery Melting at Furnace Refining at Furnace 8 Forming at Bath Annealing at Lehr Washing, drying and defects analysis Cutting and inspection Production and packing

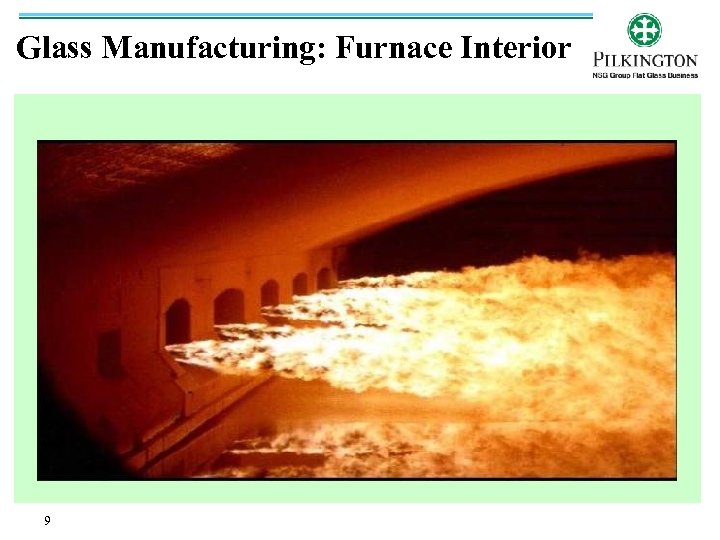

Glass Manufacturing: Furnace Interior 9

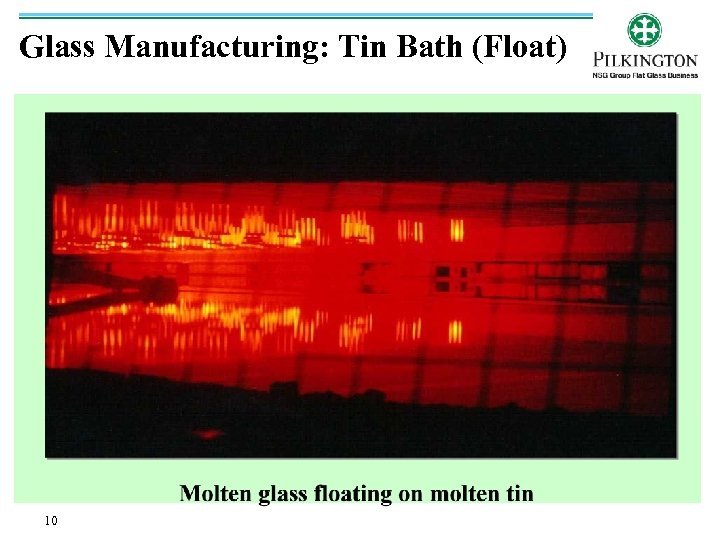

Glass Manufacturing: Tin Bath (Float) 10

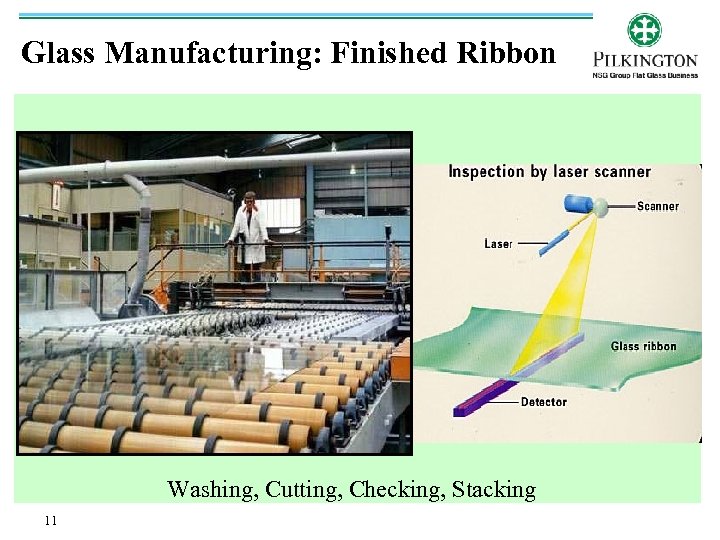

Glass Manufacturing: Finished Ribbon Washing, Cutting, Checking, Stacking 11

Pilkington Optifloat™ Clear Glass • Available from 4 mm ~ 19 mm thick 12

Pilkington Optifloat™ Clear Glass Features & Benefits • • Maximizes daylight transmittance Wide range of thicknesses High clarity Flat surface

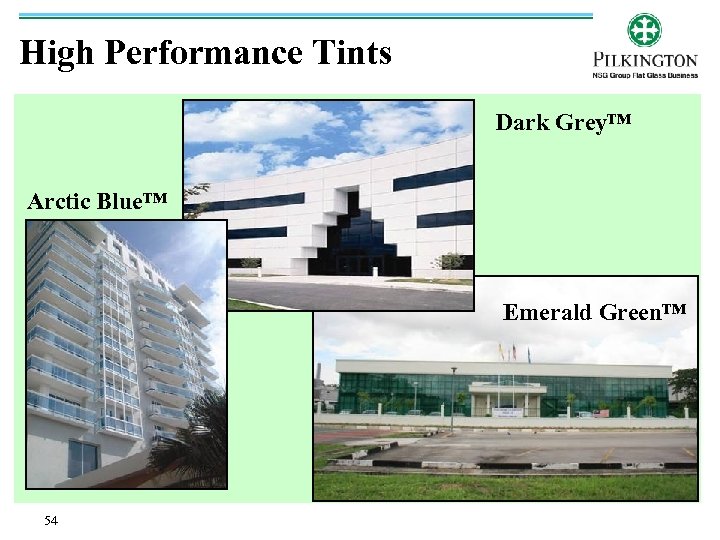

Pilkington Optifloat™ Tinted • Green • Emerald Green • Blue • Bronze • Dark Grey • Arctic Blue 14

Pilkington Arctic Blue™ & Emerald Green™ High Performance Tint • Provides both lower shading coefficient and good daylight transmittance compared to regular tints • Low exterior reflectance • Low UV transmittance • Excellent performance when combined with Low-E for reduced heat gain • All these are produced & available in Malaysia 15

Pilkington Optifloat™ Tinted Features & Benefits • Good solar control • Reduces cooling loads • Low external & internal reflectance

Reflite™ Reflective Glass New coating facility in Malaysia Features & Benefits • Medium solar control (low SHGC) • Low Shading coefficient (SC) • Subtle Reflectivity - privacy • Pyrolytic coating (hard coat) • Easy to handle • Good glare control • Air conditioning costs reduced 17

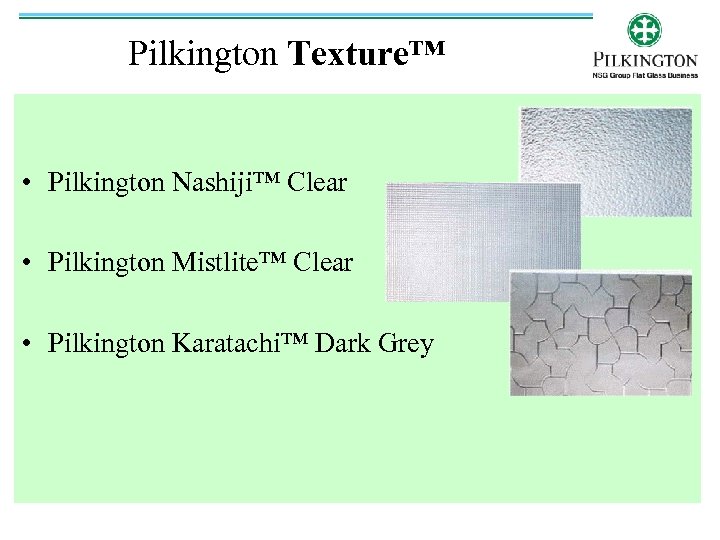

Pilkington Texture™ • Pilkington Nashiji™ Clear • Pilkington Mistlite™ Clear • Pilkington Karatachi™ Dark Grey

Pilkington Texture™ Features & Benefits • • Decorative Privacy Diffused daylight High light transmittance

Benefits of Using Local Glass • • • Complies with local & International Standards Stock availability Quick replacements Prompt technical support Survival of local industries Reduced carbon footprints

VARIABLES The many window innovations available today require a designer to make selections in at least 16 different variables

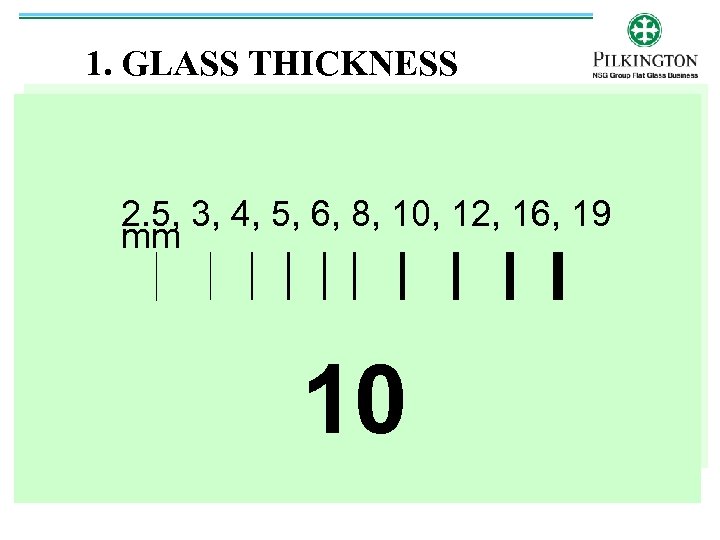

1. GLASS THICKNESS 2. 5, 3, 4, 5, 6, 8, 10, 12, 16, 19 mm 10

2. TINTS: Low-Iron Clear, Green, Blue -Green, Blue, Bronze, Light Grey, Dark Grey 9 90

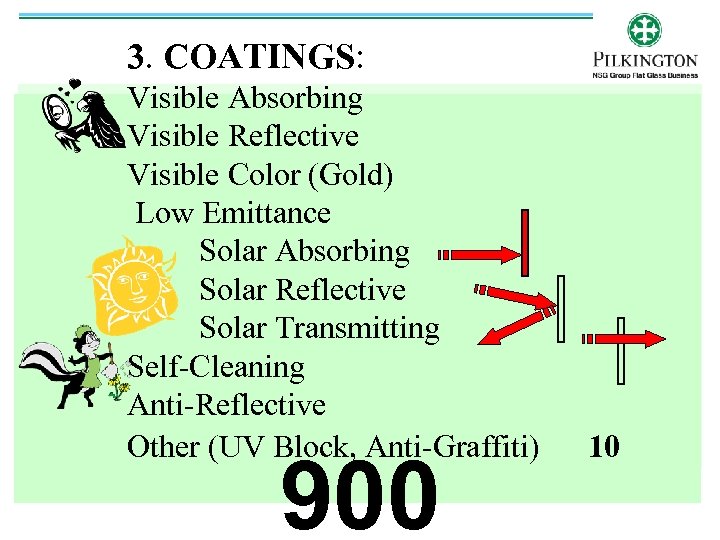

3. COATINGS: Visible Absorbing Visible Reflective Visible Color (Gold) Low Emittance Solar Absorbing Solar Reflective Solar Transmitting Self-Cleaning Anti-Reflective Other (UV Block, Anti-Graffiti) 900 10

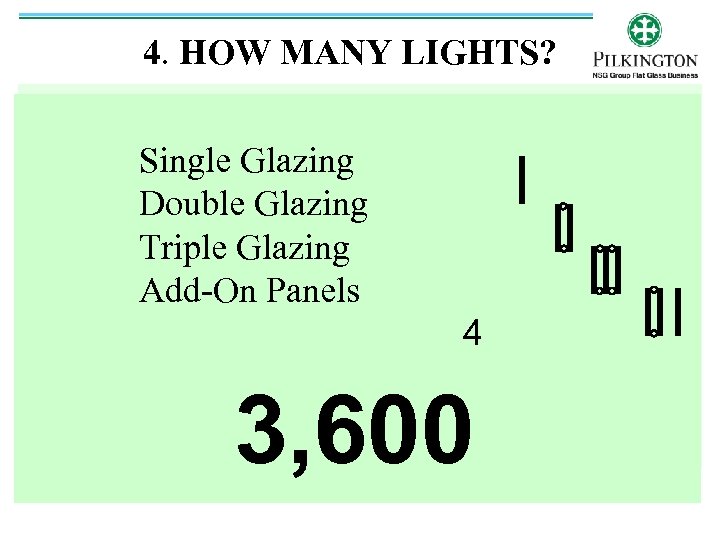

4. HOW MANY LIGHTS? Single Glazing Double Glazing Triple Glazing Add-On Panels 4 3, 600

5. IG SPACER Aluminum, Partly Insulating, ‘Warm Edge’ 3 10, 800

6. Gas Fill Air, Argon, Krypton 3 32, 400

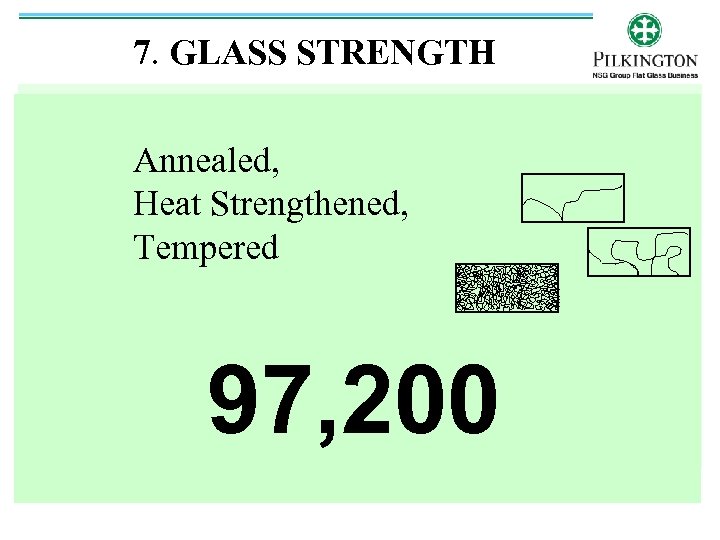

7. GLASS STRENGTH Annealed, Heat Strengthened, Tempered 97, 200

8. IMPACT RESISTANCE Laminated 0. 015” pvb Laminated 0. 030” pvb Laminated 0. 060” pvb Laminated 0. 090” pvb Colour interlayer Impact Resistant Interlayer Acoustic Insulating Interlayer CIP (Cast in Place Epoxy Laminate) 8 777, 600

9. LAMINATION ORIENTATION Coated plies: Coating to air side OR Coating against interlayer (pvb etc. ) n. b. Low-E coatings touching the interlayer lose their low-e property because glass is opaque to Far IR! 2 1, 555, 200

10. FIRE RESISTANCE: Wired Glass, Intumescent Laminates 20, 30, 60, 90, 120 minutes Fire Rating 5 7, 776, 000

11. ELECTROCHROMIC: Switch between High & Low SHGC. Switch between Transparent & Translucent. 2 15, 552, 000

12. ELECTROMAGNETIC SHIELDING: Prevent electronic data escaping. Prevent interference entering. Different db shielding levels 3 46, 656, 000

13. ORIENTATION OF OUTER LIGHT 2 93, 312, 000

14. ORIENTATION OF INNER LIGHT 2 186, 624, 000

15. ORIENTATION OF IGU Everyone should use hand-held coating detector meters 2 373, 248, 000

That makes about millions different combinations! ONE is the best. All others are likely less than best. HOW DO YOU CHOOSE?

CONCLUSIONS Glazing choices are many and varied IG gas fills and some coatings (4 at least) are invisible You cannot see by eye: U-Factor or SHGC There are tools, codes, standards and certification programs available Which bring us to low e, energy savings, and green issues….

Glass for Malaysia • • • How do you choose? Performance issues Look of the building Energy Savings Green initiatives Many, many factors

TECHNICAL INFORMATION 40

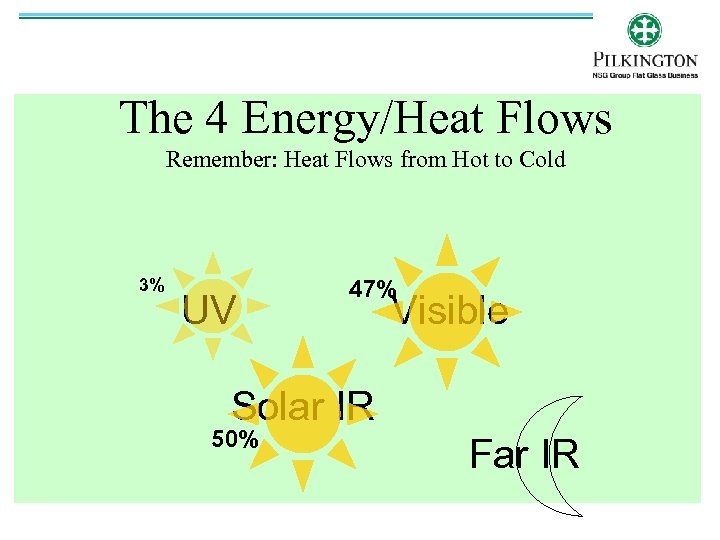

The 4 Energy/Heat Flows Remember: Heat Flows from Hot to Cold 3% UV 47% Visible Solar IR 50% Far IR

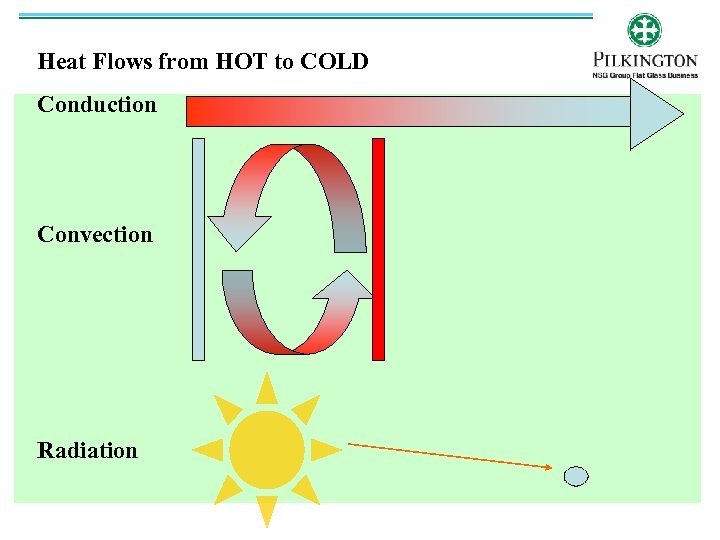

Heat Flows from HOT to COLD Conduction Convection Radiation

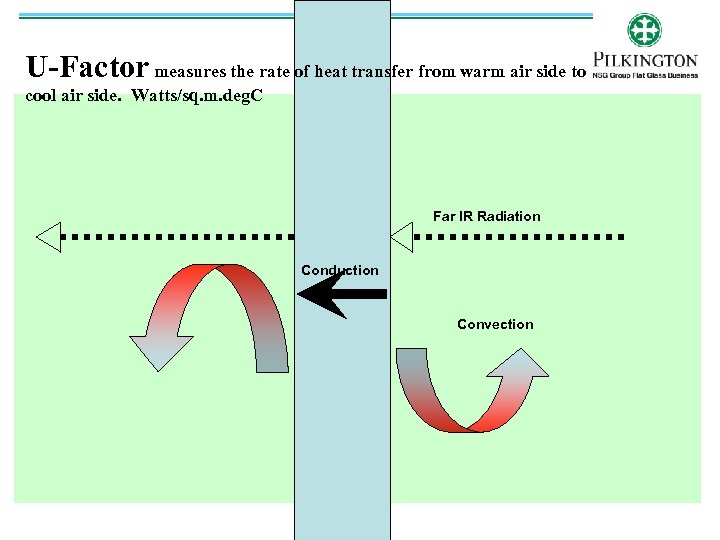

U-Factor measures the rate of heat transfer from warm air side to cool air side. Watts/sq. m. deg. C Far IR Radiation Conduction Convection

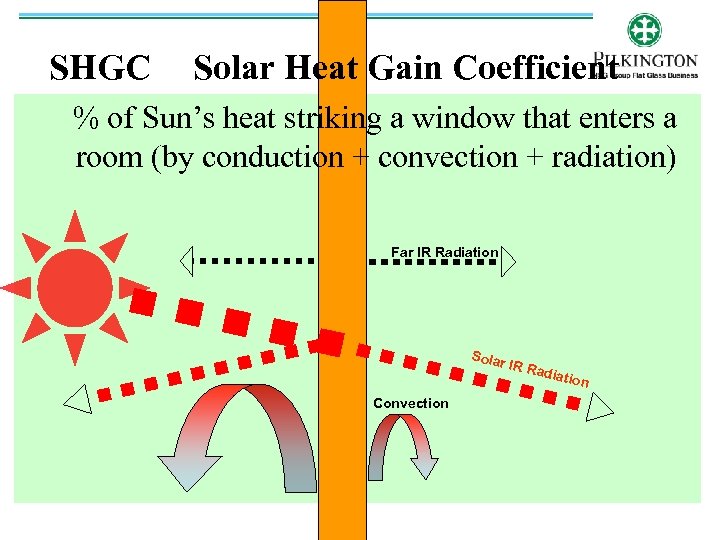

SHGC Solar Heat Gain Coefficient % of Sun’s heat striking a window that enters a room (by conduction + convection + radiation) Far IR Radiation Solar Convection IR Ra diatio n

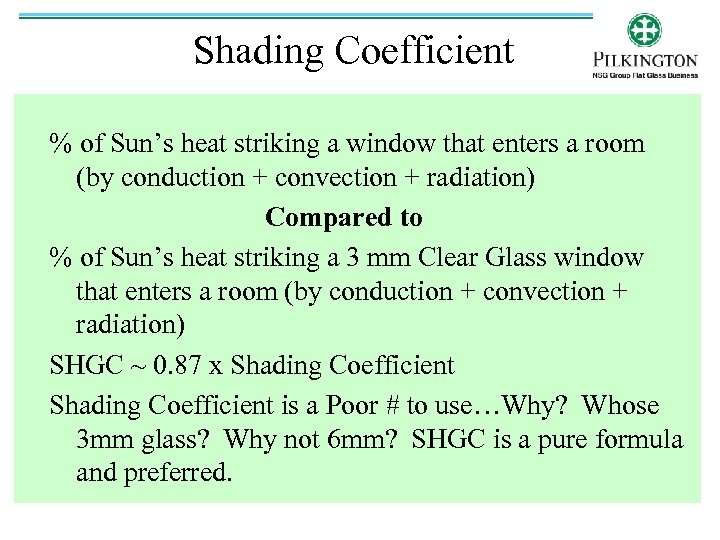

Shading Coefficient % of Sun’s heat striking a window that enters a room (by conduction + convection + radiation) Compared to % of Sun’s heat striking a 3 mm Clear Glass window that enters a room (by conduction + convection + radiation) SHGC ~ 0. 87 x Shading Coefficient is a Poor # to use…Why? Whose 3 mm glass? Why not 6 mm? SHGC is a pure formula and preferred.

Heat enters when the sun shines through the glass: SHGC (Solar Heat Gain Coefficient) or SF or S/C About half as much enters over a 24 hour day by conduction (U-Factor, or K factor) for 15 °C difference (40 °C outside, 25 °C inside) Adding Low Emissivity always helps because it lowers SHGC and it lowers U-Factor

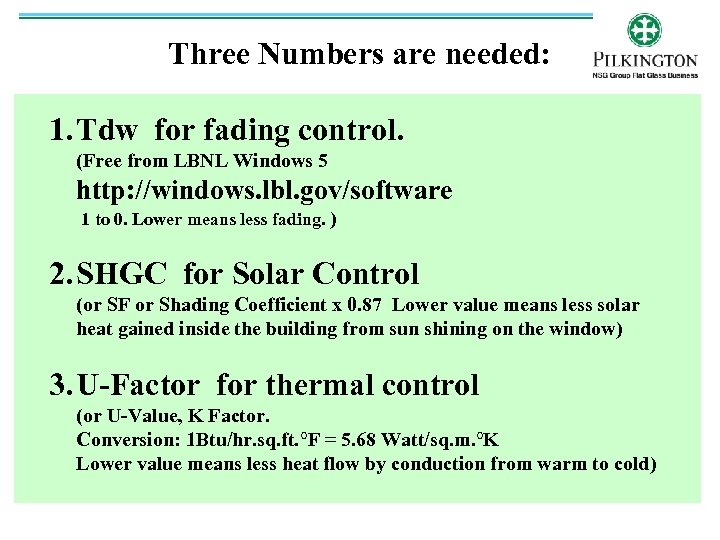

Three Numbers are needed: 1. Tdw for fading control. (Free from LBNL Windows 5 http: //windows. lbl. gov/software 1 to 0. Lower means less fading. ) 2. SHGC for Solar Control (or SF or Shading Coefficient x 0. 87 Lower value means less solar heat gained inside the building from sun shining on the window) 3. U-Factor for thermal control (or U-Value, K Factor. Conversion: 1 Btu/hr. sq. ft. °F = 5. 68 Watt/sq. m. °K Lower value means less heat flow by conduction from warm to cold)

WHAT TO DO: 1. Select Glass for appearance, daylight transmission, color, reflectivity, etc. 2. Add a Low Emissivity property, and add a light of glass, for better Solar control if a solar absorbing layer is present. 3. For better Thermal control add Low-E, and add a light of glass (double glazing)

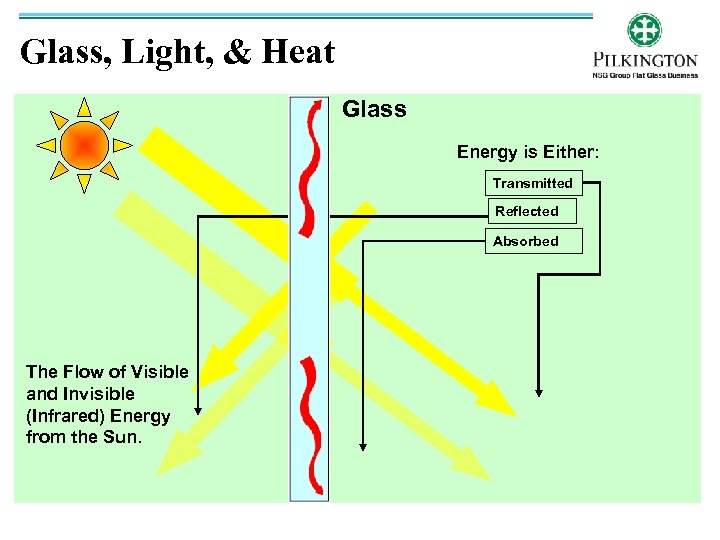

Glass, Light, & Heat Glass Energy is Either: Transmitted Reflected Absorbed The Flow of Visible and Invisible (Infrared) Energy from the Sun.

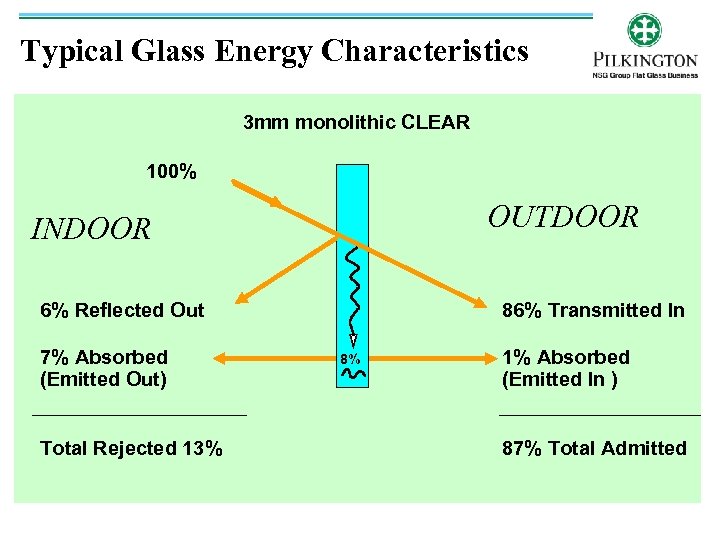

Typical Glass Energy Characteristics 3 mm monolithic CLEAR 100% OUTDOOR INDOOR 6% Reflected Out 7% Absorbed (Emitted Out) Total Rejected 13% 86% Transmitted In 8% 1% Absorbed (Emitted In ) 87% Total Admitted

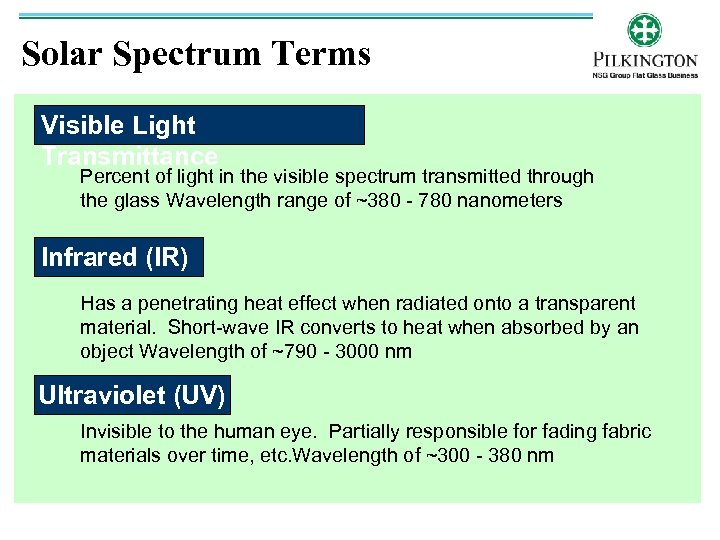

Solar Spectrum Terms Visible Light Transmittance Percent of light in the visible spectrum transmitted through the glass Wavelength range of ~380 - 780 nanometers Infrared (IR) Has a penetrating heat effect when radiated onto a transparent material. Short-wave IR converts to heat when absorbed by an object Wavelength of ~790 - 3000 nm Ultraviolet (UV) Invisible to the human eye. Partially responsible for fading fabric materials over time, etc. Wavelength of ~300 - 380 nm

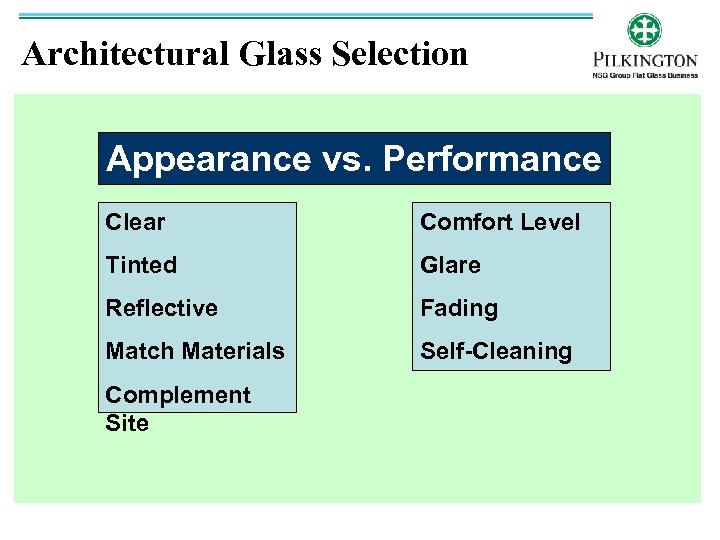

Architectural Glass Selection Appearance vs. Performance Clear Comfort Level Tinted Glare Reflective Fading Match Materials Self-Cleaning Complement Site

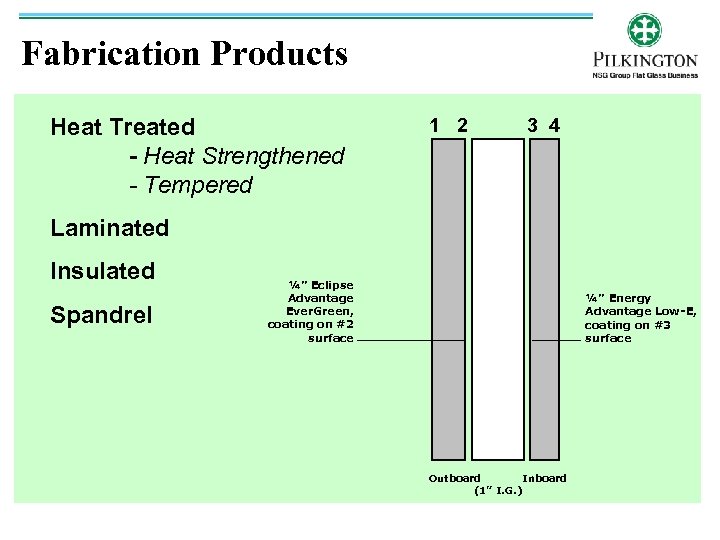

Fabrication Products Heat Treated - Heat Strengthened - Tempered 1 2 3 4 Laminated Insulated Spandrel ¼” Eclipse Advantage Ever. Green, coating on #2 surface ¼” Energy Advantage Low-E, coating on #3 surface Outboard Inboard (1” I. G. )

High Performance Tints Dark Grey™ Arctic Blue™ Emerald Green™ 54

Coating Processes “Hard Coat” Pyrolitic Coating VS. “Soft Coat” Sputter Coating

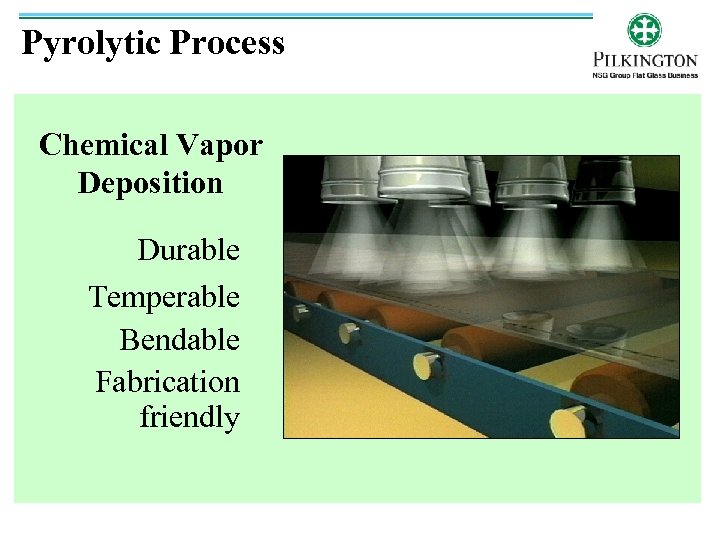

Pyrolytic Process Chemical Vapor Deposition Durable Temperable Bendable Fabrication friendly

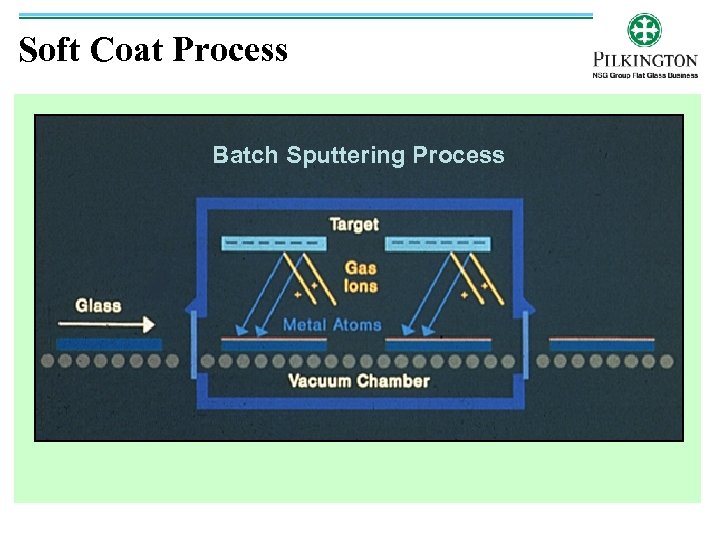

Soft Coat Process Batch Sputtering Process

Coating Processes • • • Sputtered (“Soft Coat”) Produced off-line Enhanced performance Limited shelf life Wide range of products Project driven • • Pyrolytic (“Hard Coat”) Produced on-line Enhanced performance Post-temperable Unlimited shelf life Select product range Inventoried

PILKINGTON COATED GLASS (Energy Efficient ) 59

Low-E Glass Pilkington Energy Advantage™, Solar-E™ & Eclipse Advantage™ 60

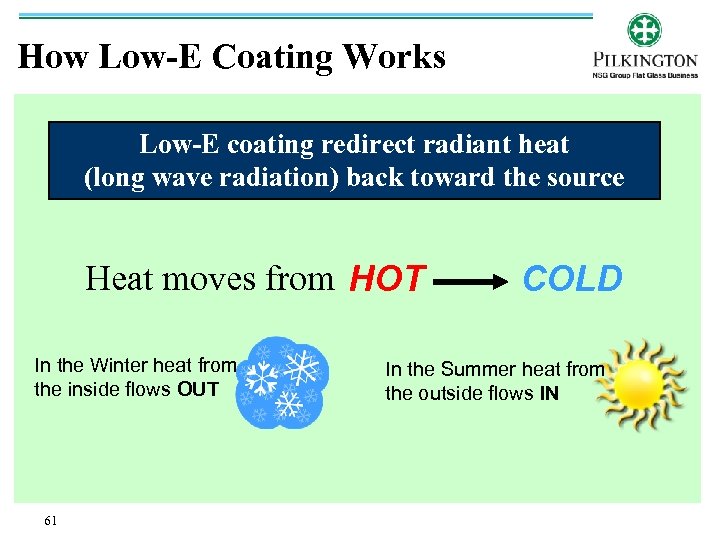

How Low-E Coating Works Low-E coating redirect radiant heat (long wave radiation) back toward the source Heat moves from HOT In the Winter heat from the inside flows OUT 61 COLD In the Summer heat from the outside flows IN

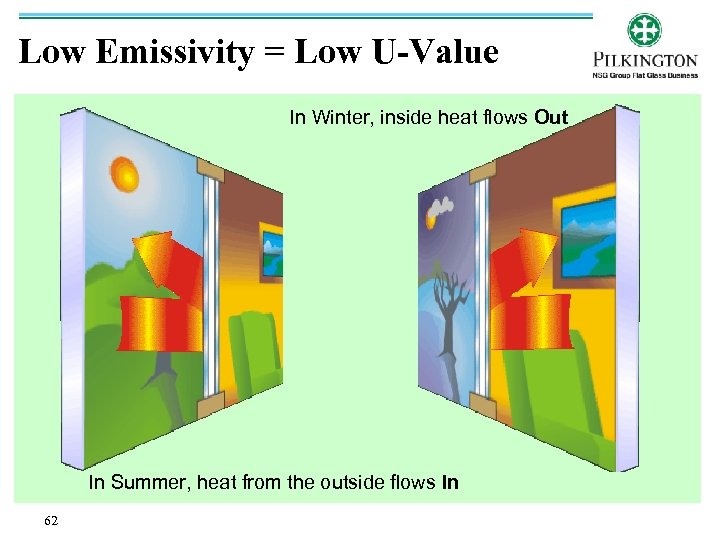

Low Emissivity = Low U-Value In Winter, inside heat flows Out In Summer, heat from the outside flows In 62

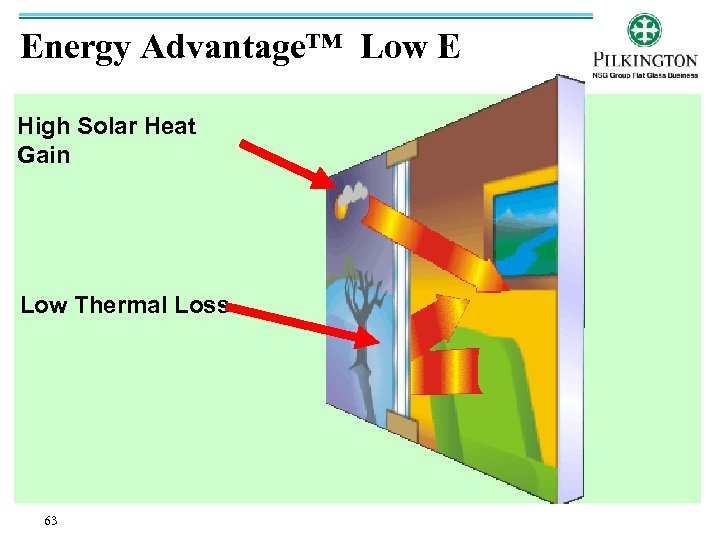

Energy Advantage™ Low E High Solar Heat Gain Low Thermal Loss 63

Solar-E™ Low-E Solar and Thermal control in a single pyrolytic surface 64

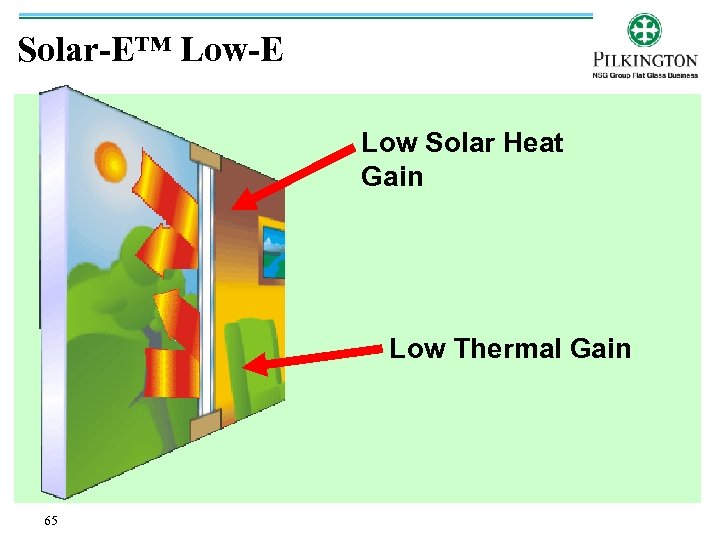

Solar-E™ Low-E Low Solar Heat Gain Low Thermal Gain 65

Eclipse Advantage™ Architectural Community asked for: ü Higher Visible Light Transmittance (more natural light) ü ü ü Color options Excellent Solar and Thermal control characteristics Reduced Glare Providing an element of privacy for occupants Readily available (inventoried locally, short lead times)

Eclipse Advantage™ Next generation coating technology by Pilkington: ü Combines multiple attributes into single coating: ü ü ü High visible light transmittance Excellent solar control (low SHGC) Good thermal control (low U-value) Subtle Reflectivity Pyrolytic coating (hard coat)

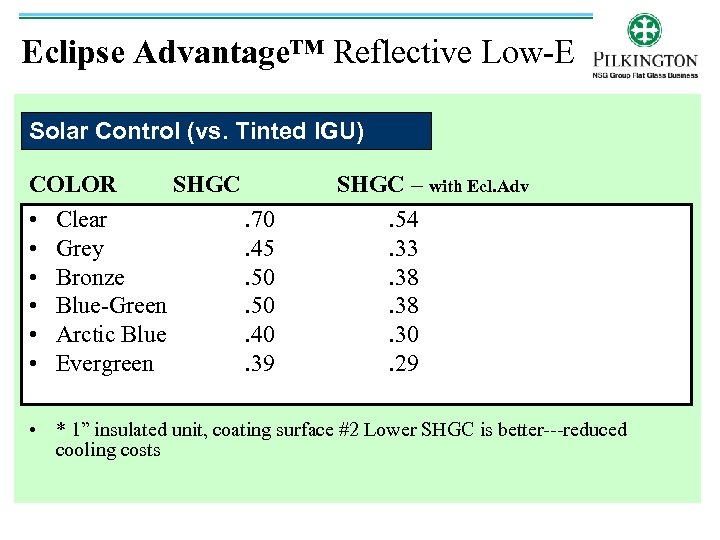

Eclipse Advantage™ Reflective Low-E Solar Control (vs. Tinted IGU) COLOR SHGC • Clear. 70 • Grey. 45 • Bronze. 50 • Blue-Green. 50 • Arctic Blue. 40 • Evergreen. 39 SHGC – with Ecl. Adv. 54. 33. 38. 30. 29 • * 1” insulated unit, coating surface #2 Lower SHGC is better---reduced cooling costs

Eclipse Advantage™ Low-E Thermal Control COLOR • Clear • Grey • Bronze • Blue-Green • Arctic Blue • Evergreen U-Value. 58. 58. 58 U-Value (Eclipse Advantage). 35. 35. 35 • * 1” insulated unit, coating surface #2, winter u-value Lower U-value is better ---less heating/cooling costs, (comparison to tint or reflective with no low-E) U-value = 1/R-value

Reflite™ Reflective Glass New coating facility in Malaysia Features & Benefits • Medium solar control (low SHGC) • Low Shading coefficient (SC) • Subtle Reflectivity - privacy • Pyrolytic coating (hard coat) • Easy to handle • Good glare control • Air conditioning costs reduced 70

Project Photos

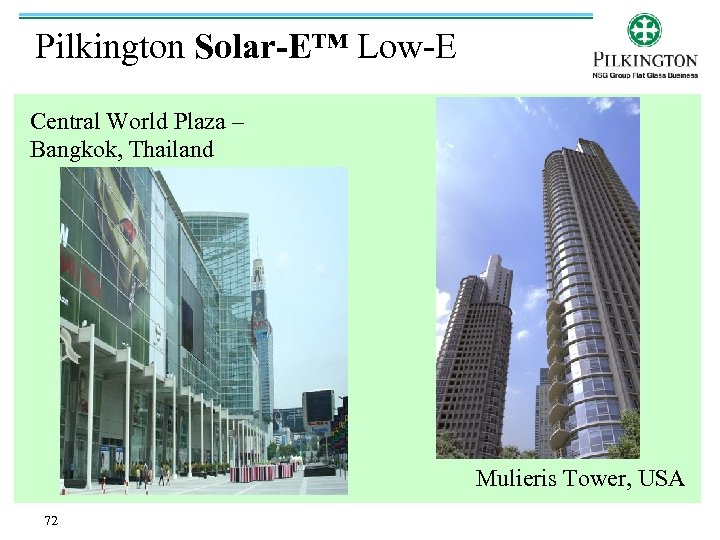

Pilkington Solar-E™ Low-E Central World Plaza – Bangkok, Thailand Mulieris Tower, USA 72

Pilkington Arctic Blue™ Call Centre, Poland

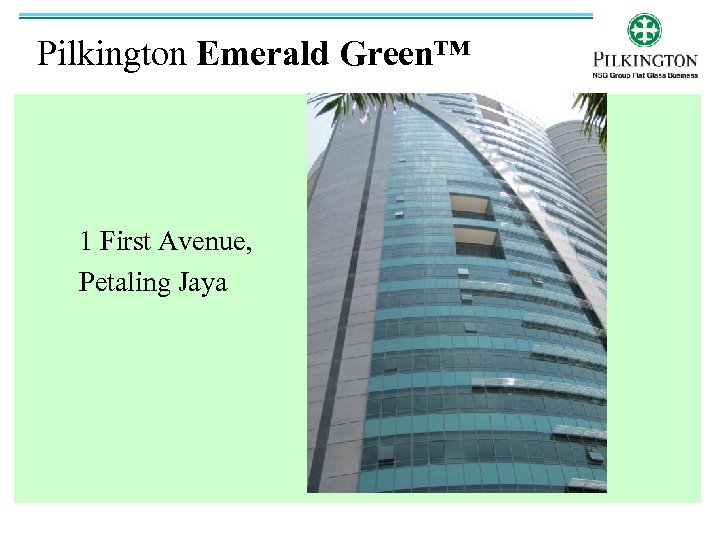

Pilkington Emerald Green™ 1 First Avenue, Petaling Jaya

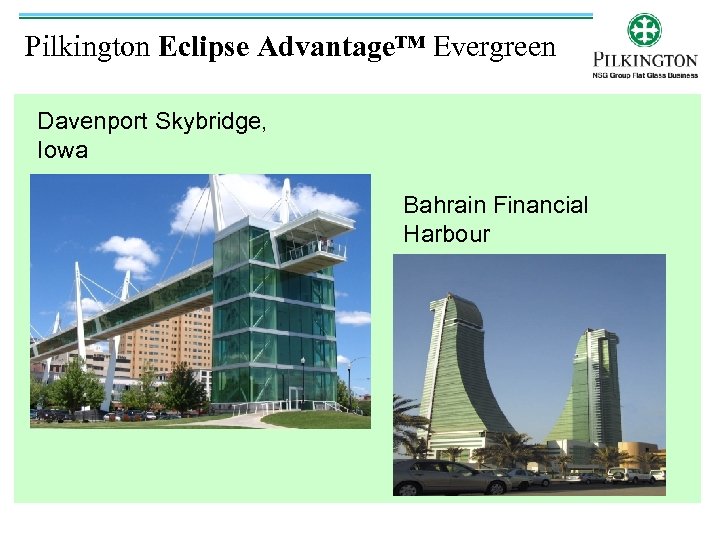

Pilkington Eclipse Advantage™ Evergreen Davenport Skybridge, Iowa Bahrain Financial Harbour

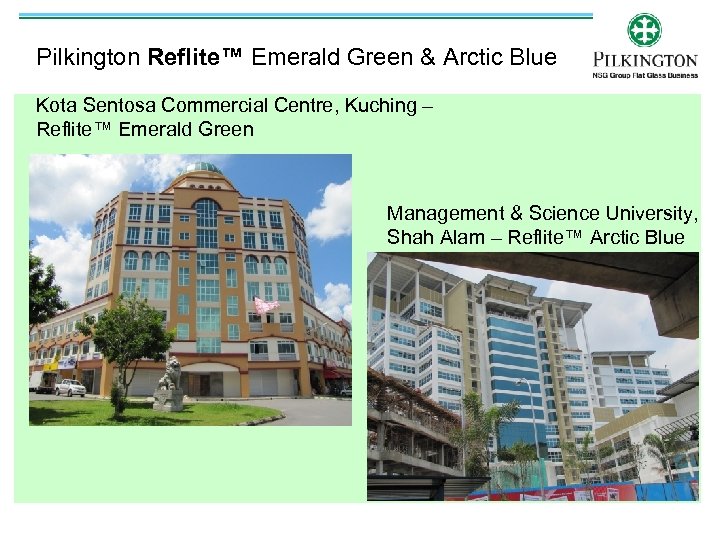

Pilkington Reflite™ Emerald Green & Arctic Blue Kota Sentosa Commercial Centre, Kuching – Reflite™ Emerald Green Management & Science University, Shah Alam – Reflite™ Arctic Blue

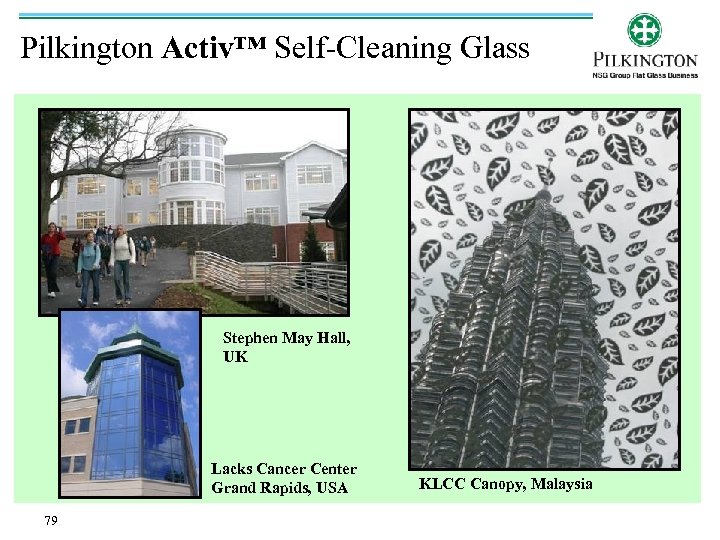

Pilkington Activ™ Self-Cleaning Glass 77

Pilkington Activ™ Self-Cleaning Glass “What makes a glass self-cleaning? ” Pyrolytic Coating – Hard Coat Photocatalytic Properties – Dirt Destroying Hydrophyllic Properties – Water Sheeting 78

Pilkington Activ™ Self-Cleaning Glass Stephen May Hall, UK Lacks Cancer Center Grand Rapids, USA 79 KLCC Canopy, Malaysia

8b7a4f9772302fdc5f1c428ae0de4dfb.ppt