1a3060cca14274de22bd65c2252468ba.ppt

- Количество слайдов: 19

AFP Fast Timing Beam Test October 19 -29 UTA, U Alberta, Stony Brook U SLAC, OSU, UNM

Test Beam Oct 19 - 29 – People Coordination: Davide Caforio (Bologna) – Local AFP Timing contact: Justin Griffiths (UTA; CERN) UTA – – Andrew Brandt: Oct 22 – 29 Ian Howley (Ph. D): Justin Griffiths (PD; CERN): Oct 22 - … James Bourbeau (UG): Stony Brook – Michael Rijssenbeek: – R. Dean Schamberger: Oct 18 – 28 Oct 18 – 27 U Alberta – Jim Pinfold: – Shengli Liu: Oct 22 – 28 Saclay: Hervey +Eric Lecce: ? Silicon help with EUDET and data analysis: – korchak@fzu. cz; (Oleksandr Korchak), Petr Sticho

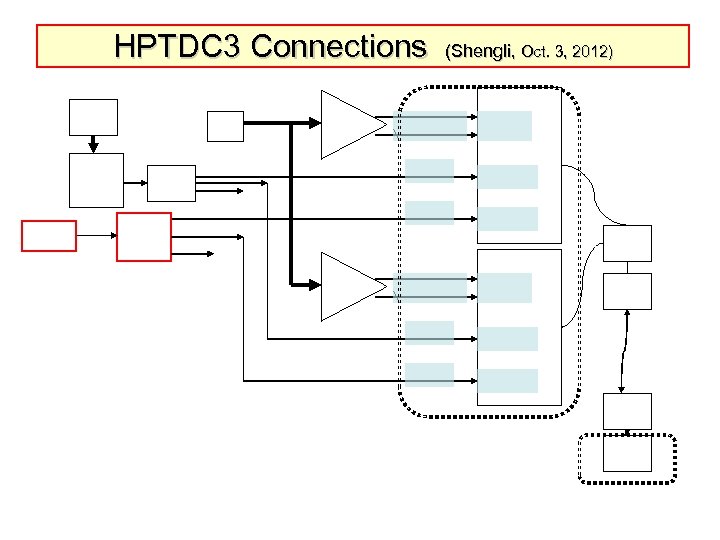

HPTDC 3 Connections (Shengli, Oct. 3, 2012)

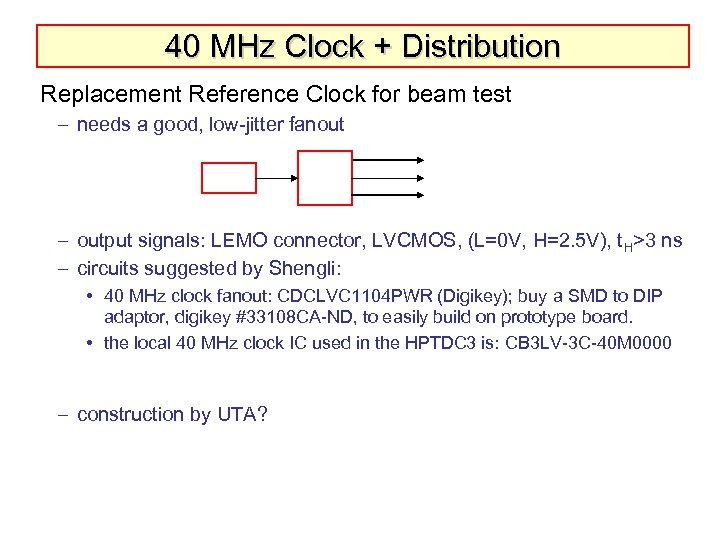

40 MHz Clock + Distribution Replacement Reference Clock for beam test – needs a good, low-jitter fanout – output signals: LEMO connector, LVCMOS, (L=0 V, H=2. 5 V), t. H>3 ns – circuits suggested by Shengli: • 40 MHz clock fanout: CDCLVC 1104 PWR (Digikey); buy a SMD to DIP adaptor, digikey #33108 CA-ND, to easily build on prototype board. • the local 40 MHz clock IC used in the HPTDC 3 is: CB 3 LV-3 C-40 M 0000 – construction by UTA?

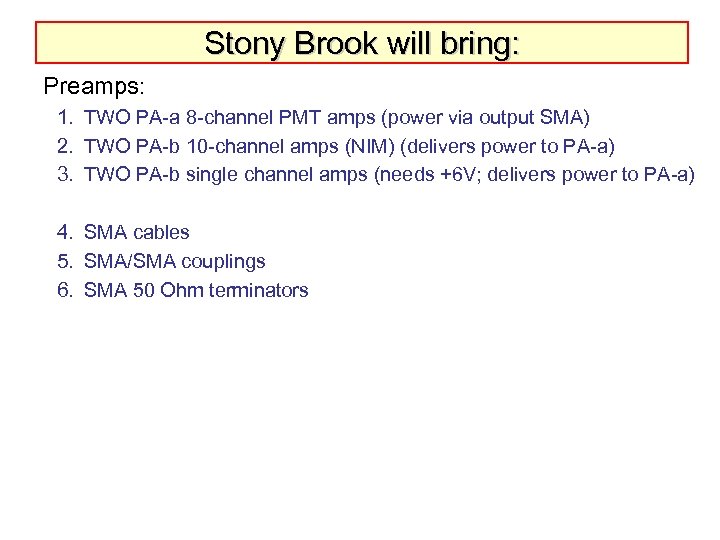

Stony Brook will bring: Preamps: 1. TWO PA-a 8 -channel PMT amps (power via output SMA) 2. TWO PA-b 10 -channel amps (NIM) (delivers power to PA-a) 3. TWO PA-b single channel amps (needs +6 V; delivers power to PA-a) 4. SMA cables 5. SMA/SMA couplings 6. SMA 50 Ohm terminators

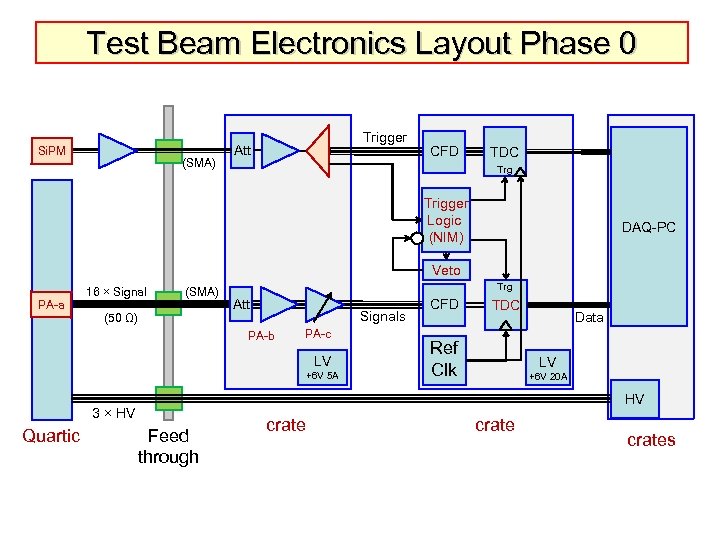

Test Beam Electronics Layout Phase 0 Si. PM (SMA) Trigger Att CFD TDC Trg Trigger Logic (NIM) DAQ-PC Veto PA-a 16 × Signal (SMA) (50 Ω) Trg Att Signals PA-b PA-c LV +6 V 5 A TDC Ref Clk Data LV +6 V 20 A HV 3 × HV Quartic CFD Feed through crates

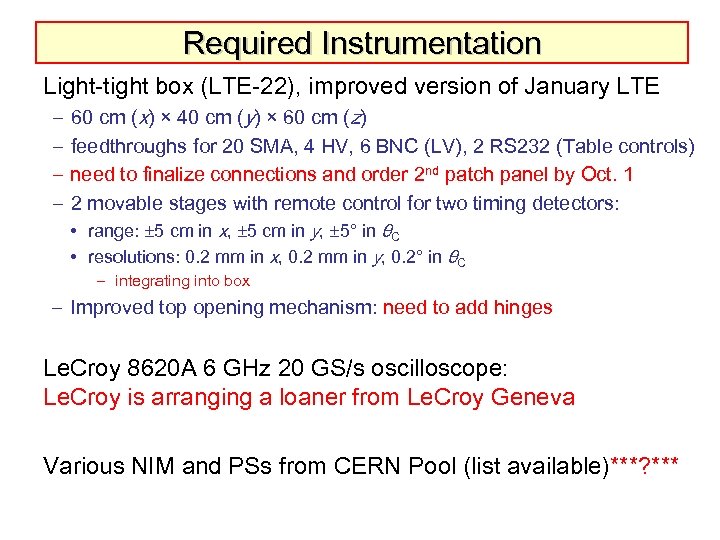

Required Instrumentation Light-tight box (LTE-22), improved version of January LTE – – 60 cm (x) × 40 cm (y) × 60 cm (z) feedthroughs for 20 SMA, 4 HV, 6 BNC (LV), 2 RS 232 (Table controls) need to finalize connections and order 2 nd patch panel by Oct. 1 2 movable stages with remote control for two timing detectors: • range: ± 5 cm in x, ± 5 cm in y, ± 5° in θC • resolutions: 0. 2 mm in x, 0. 2 mm in y, 0. 2° in θC – integrating into box – Improved top opening mechanism: need to add hinges Le. Croy 8620 A 6 GHz 20 GS/s oscilloscope: Le. Croy is arranging a loaner from Le. Croy Geneva Various NIM and PSs from CERN Pool (list available)***? ***

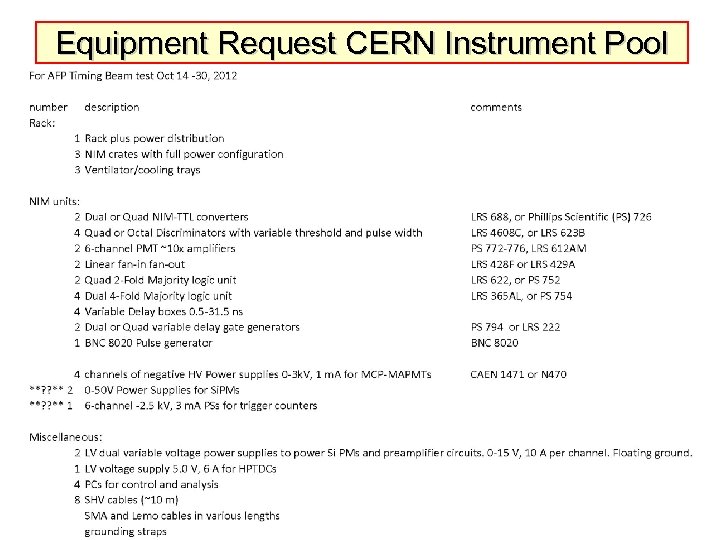

Equipment Request CERN Instrument Pool

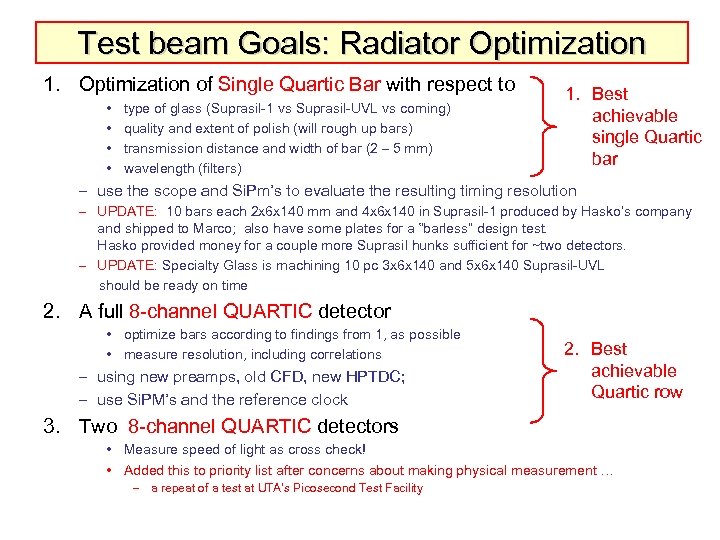

Test beam Goals: Radiator Optimization 1. Optimization of Single Quartic Bar with respect to • • type of glass (Suprasil-1 vs Suprasil-UVL vs corning) quality and extent of polish (will rough up bars) transmission distance and width of bar (2 – 5 mm) wavelength (filters) 1. Best achievable single Quartic bar – use the scope and Si. Pm’s to evaluate the resulting timing resolution – UPDATE: 10 bars each 2 x 6 x 140 mm and 4 x 6 x 140 in Suprasil-1 produced by Hasko’s company and shipped to Marco; also have some plates for a “barless” design test. Hasko provided money for a couple more Suprasil hunks sufficient for ~two detectors. – UPDATE: Specialty Glass is machining 10 pc 3 x 6 x 140 and 5 x 6 x 140 Suprasil-UVL should be ready on time 2. A full 8 -channel QUARTIC detector • optimize bars according to findings from 1, as possible • measure resolution, including correlations – using new preamps, old CFD, new HPTDC; – use Si. PM’s and the reference clock 2. Best achievable Quartic row 3. Two 8 -channel QUARTIC detectors • Measure speed of light as cross check! • Added this to priority list after concerns about making physical measurement … – a repeat of a test at UTA’s Picosecond Test Facility

Test beam Goals: Radiator Optimization 4. Secondary goals (as time and resources permit) – Test a parallel fiber bundle as a Phase I detector option – Test an LBAR option provided by Michael Albrow • Received detector; need extra Si. PM and LV power supply

Optimizing Detector: Radiator

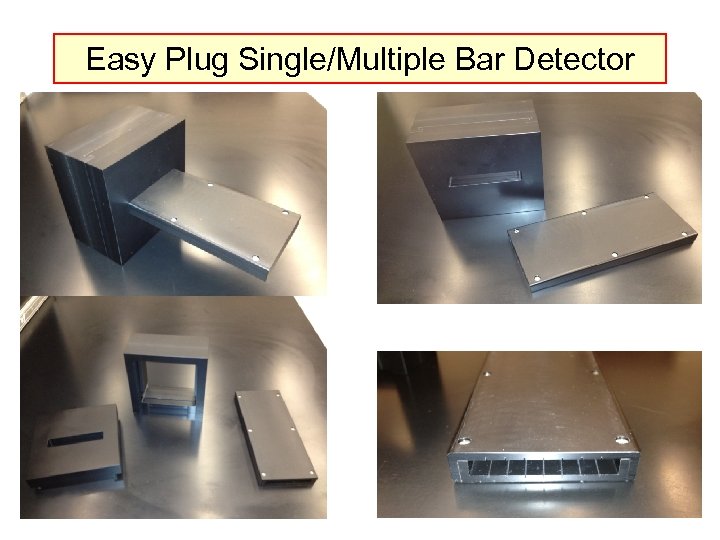

Easy Plug Single/Multiple Bar Detector

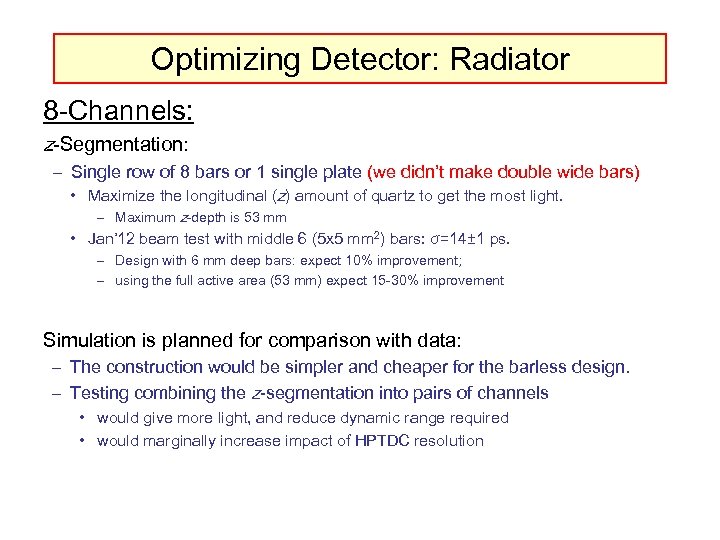

Optimizing Detector: Radiator 8 -Channels: z-Segmentation: – Single row of 8 bars or 1 single plate (we didn’t make double wide bars) • Maximize the longitudinal (z) amount of quartz to get the most light. – Maximum z-depth is 53 mm • Jan’ 12 beam test with middle 6 (5 x 5 mm 2) bars: σ=14± 1 ps. – Design with 6 mm deep bars: expect 10% improvement; – using the full active area (53 mm) expect 15 -30% improvement Simulation is planned for comparison with data: – The construction would be simpler and cheaper for the barless design. – Testing combining the z-segmentation into pairs of channels • would give more light, and reduce dynamic range required • would marginally increase impact of HPTDC resolution

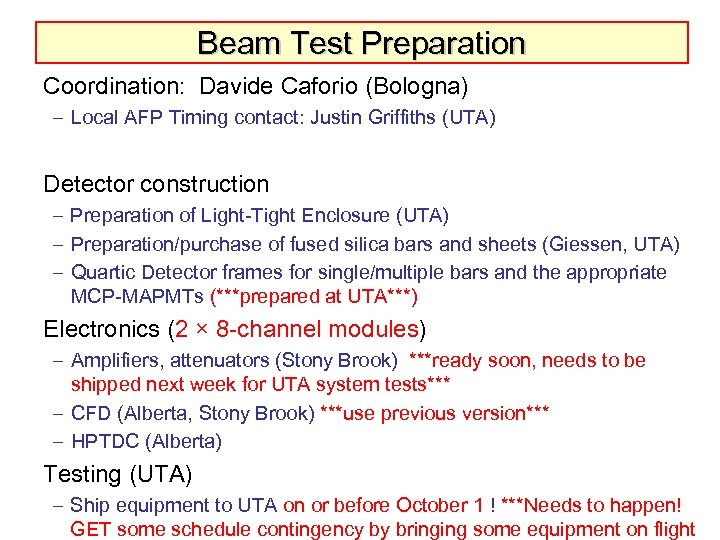

Beam Test Preparation Coordination: Davide Caforio (Bologna) – Local AFP Timing contact: Justin Griffiths (UTA) Detector construction – Preparation of Light-Tight Enclosure (UTA) – Preparation/purchase of fused silica bars and sheets (Giessen, UTA) – Quartic Detector frames for single/multiple bars and the appropriate MCP-MAPMTs (***prepared at UTA***) Electronics (2 × 8 -channel modules) – Amplifiers, attenuators (Stony Brook) ***ready soon, needs to be shipped next week for UTA system tests*** – CFD (Alberta, Stony Brook) ***use previous version*** – HPTDC (Alberta) Testing (UTA) – Ship equipment to UTA on or before October 1 ! ***Needs to happen! GET some schedule contingency by bringing some equipment on flight

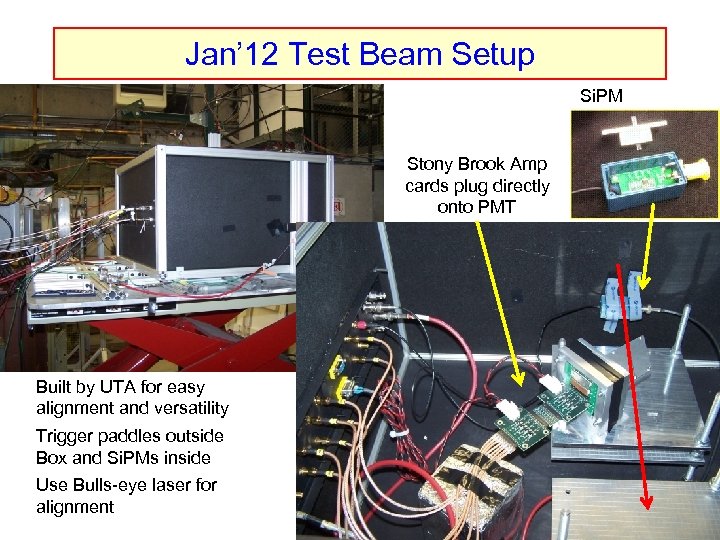

Jan’ 12 Test Beam Setup Si. PM Stony Brook Amp cards plug directly onto PMT Built by UTA for easy alignment and versatility Trigger paddles outside Box and Si. PMs inside Use Bulls-eye laser for alignment

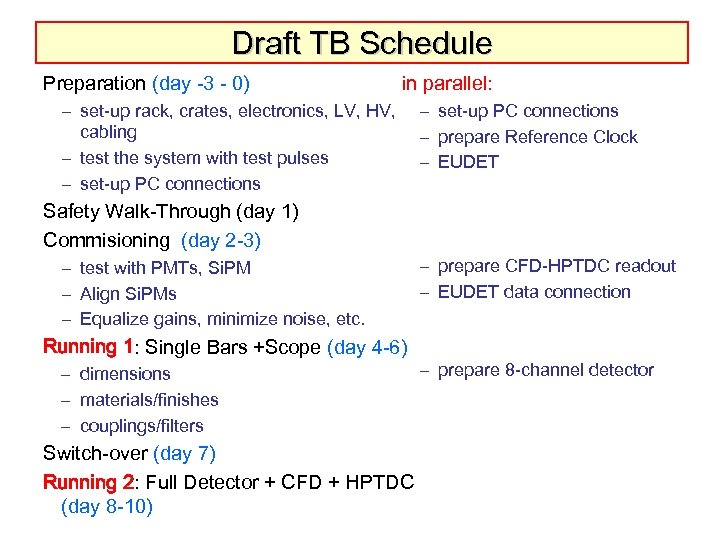

Draft TB Schedule Preparation (day -3 - 0) in parallel: – set-up rack, crates, electronics, LV, HV, cabling – test the system with test pulses – set-up PC connections Safety Walk-Through (day 1) Commisioning (day 2 -3) – test with PMTs, Si. PM – Align Si. PMs – Equalize gains, minimize noise, etc. Running 1: Single Bars +Scope (day 4 -6) – dimensions – materials/finishes – couplings/filters Switch-over (day 7) Running 2: Full Detector + CFD + HPTDC (day 8 -10) – set-up PC connections – prepare Reference Clock – EUDET – prepare CFD-HPTDC readout – EUDET data connection – prepare 8 -channel detector

Summary Need to strictly keep to construction schedule in order to provide in timely fashion (Oct 1 at UTA): • Electronics: Preamps, HPTDCs, cables, PSs • Radiators for testing • Detector box plus movable stages and controls • Not a lot of schedule contingency left • Need final confirmation on Friday, booking of flights, etc. • Hinges for box, extra patch panel, finish, packing, …

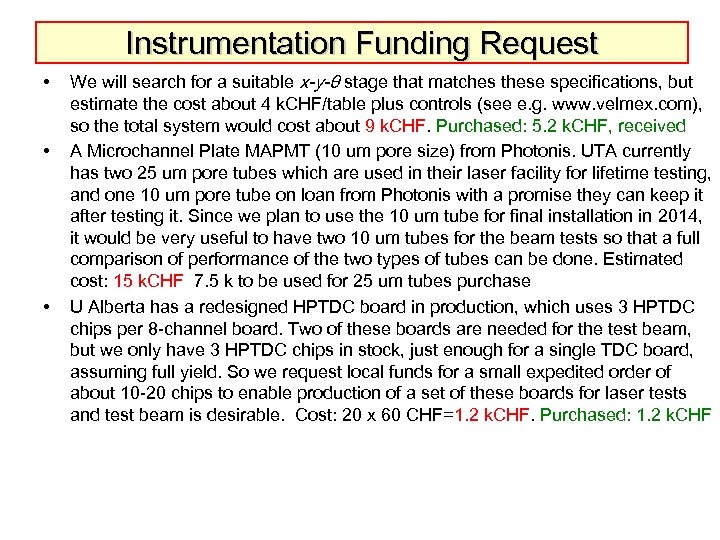

Instrumentation Funding Request • • • We will search for a suitable x-y-θ stage that matches these specifications, but estimate the cost about 4 k. CHF/table plus controls (see e. g. www. velmex. com), so the total system would cost about 9 k. CHF. Purchased: 5. 2 k. CHF, received A Microchannel Plate MAPMT (10 um pore size) from Photonis. UTA currently has two 25 um pore tubes which are used in their laser facility for lifetime testing, and one 10 um pore tube on loan from Photonis with a promise they can keep it after testing it. Since we plan to use the 10 um tube for final installation in 2014, it would be very useful to have two 10 um tubes for the beam tests so that a full comparison of performance of the two types of tubes can be done. Estimated cost: 15 k. CHF 7. 5 k to be used for 25 um tubes purchase U Alberta has a redesigned HPTDC board in production, which uses 3 HPTDC chips per 8 -channel board. Two of these boards are needed for the test beam, but we only have 3 HPTDC chips in stock, just enough for a single TDC board, assuming full yield. So we request local funds for a small expedited order of about 10 -20 chips to enable production of a set of these boards for laser tests and test beam is desirable. Cost: 20 x 60 CHF=1. 2 k. CHF. Purchased: 1. 2 k. CHF

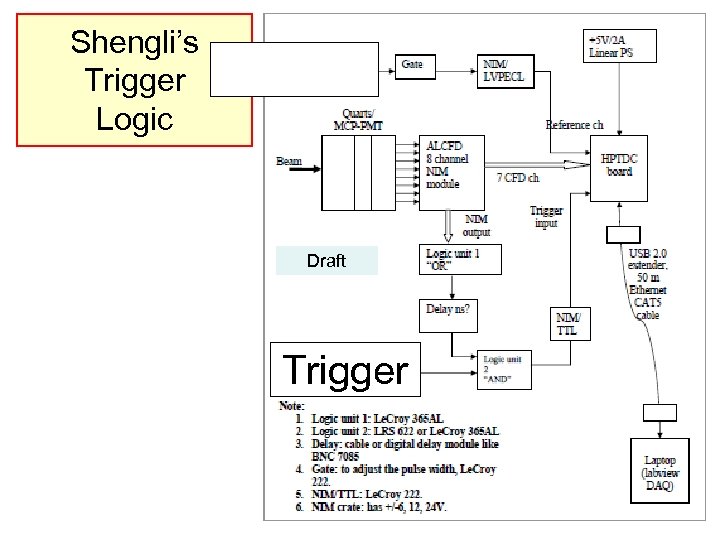

Shengli’s Trigger Logic Draft Trigger

1a3060cca14274de22bd65c2252468ba.ppt