2acb963718bd0e01b06d5aa48f6ffbf4.ppt

- Количество слайдов: 38

AEROSPACE QUALITY MANAGEMENT SYSTEM 9100 Dale K. Gordon Past Chairman Americas Aerospace Quality Group SAE Aerospace Committee G-14 20 February 2001 September 25 th 2002 D. K. Gordon

AEROSPACE QUALITY MANAGEMENT SYSTEM 9100 Dale K. Gordon Past Chairman Americas Aerospace Quality Group SAE Aerospace Committee G-14 20 February 2001 September 25 th 2002 D. K. Gordon

Aerospace Quality Standards Numbering System l International Standards - 91 xx – Are planned for harmonization across all 3 aerospace sectors and are recognized globally l Americas Standards - 90 xx – Are published for use by AAQG, may become an 91 XX standard at a later date l “AS” Standards - Americas – Published by Society of Automotive Engineers l “EN” Standards - Europe – published in Europe by AECMA l “JIS Q”or “SJAC” is the Japan / Asian Equivalent Dale K. Gordon 2

Aerospace Quality Standards Numbering System l International Standards - 91 xx – Are planned for harmonization across all 3 aerospace sectors and are recognized globally l Americas Standards - 90 xx – Are published for use by AAQG, may become an 91 XX standard at a later date l “AS” Standards - Americas – Published by Society of Automotive Engineers l “EN” Standards - Europe – published in Europe by AECMA l “JIS Q”or “SJAC” is the Japan / Asian Equivalent Dale K. Gordon 2

Aerospace Quality System Standards l INTERNATIONAL STANDARDS – 9100 - Quality System for Aerospace Manufacturers – 9101 - Checksheet for 9100 – 9110 - Quality System for Aerospace Repair Stations – 9111 - Checksheet for 9110 – 9120 - Quality System for “Pass-Through” Distributors – 9121 - Checksheet for 9120 Dale K. Gordon 3

Aerospace Quality System Standards l INTERNATIONAL STANDARDS – 9100 - Quality System for Aerospace Manufacturers – 9101 - Checksheet for 9100 – 9110 - Quality System for Aerospace Repair Stations – 9111 - Checksheet for 9110 – 9120 - Quality System for “Pass-Through” Distributors – 9121 - Checksheet for 9120 Dale K. Gordon 3

Aerospace Quality Standards (cont. ) Other Projects International Standards l l l First Article Inspection (9102) Management of Key Characteristics (9103) Record Retention (9130) Nonconformance Documentation (9131) 2 D Bar Coding (9132) Part Qualification Process 9133) l l l l AS 9003 - “Less than” 9100 Production Process Planning Verification (software) Software Quality (Embedded / Product Acceptance) Sampling Plans Sub-tier Supplier Control Direct Shipments (ARP 9004) Electronic Signatures Digital Data Storage Dale K. Gordon 4

Aerospace Quality Standards (cont. ) Other Projects International Standards l l l First Article Inspection (9102) Management of Key Characteristics (9103) Record Retention (9130) Nonconformance Documentation (9131) 2 D Bar Coding (9132) Part Qualification Process 9133) l l l l AS 9003 - “Less than” 9100 Production Process Planning Verification (software) Software Quality (Embedded / Product Acceptance) Sampling Plans Sub-tier Supplier Control Direct Shipments (ARP 9004) Electronic Signatures Digital Data Storage Dale K. Gordon 4

HISTORY OF 9100 20 February 2001 D. K. Gordon

HISTORY OF 9100 20 February 2001 D. K. Gordon

Background - Early to mid 1990 s l Do. D canceled quality system specifications l FAA lacks a definitive description of a quality system l Primes began to flow ISO 9000 series plus unique requirements to suppliers l Suppliers asked industry to standardize – Needed to operate a single quality system – Already adopting ISO 9000 series Dale K. Gordon 6

Background - Early to mid 1990 s l Do. D canceled quality system specifications l FAA lacks a definitive description of a quality system l Primes began to flow ISO 9000 series plus unique requirements to suppliers l Suppliers asked industry to standardize – Needed to operate a single quality system – Already adopting ISO 9000 series Dale K. Gordon 6

U. S. Industry Response - 1995 Supplier Management and Quality Assurance professionals from: Allied. Signal Pratt & Whitney Boeing Rockwell Collins GE Engines Rolls-Royce Allison Lockheed Martin Sundstrand Mc. Donnell Douglas Northrop Grumman Sponsors • Aviation/Space & Defense Division of American Society for Quality • SAE Aerospace Council Dale K. Gordon 7

U. S. Industry Response - 1995 Supplier Management and Quality Assurance professionals from: Allied. Signal Pratt & Whitney Boeing Rockwell Collins GE Engines Rolls-Royce Allison Lockheed Martin Sundstrand Mc. Donnell Douglas Northrop Grumman Sponsors • Aviation/Space & Defense Division of American Society for Quality • SAE Aerospace Council Dale K. Gordon 7

AAQG Members Agree “Where aerospace quality is concerned. . . there is no competitive advantage” Dale K. Gordon 8

AAQG Members Agree “Where aerospace quality is concerned. . . there is no competitive advantage” Dale K. Gordon 8

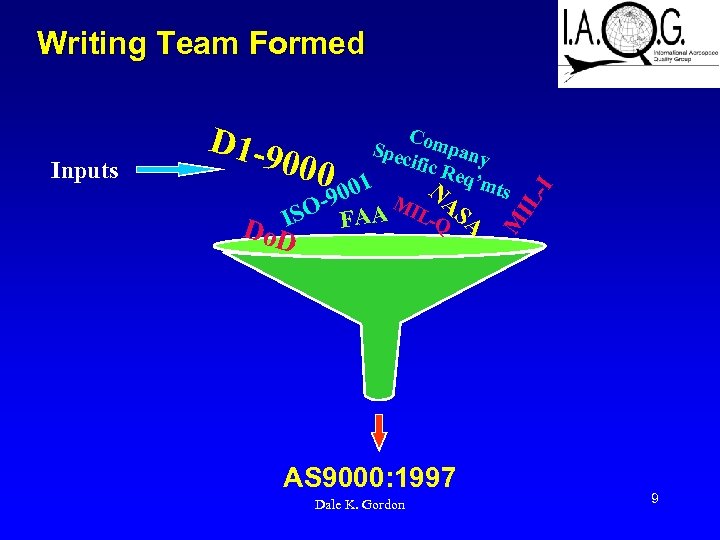

C Spec ompany ific R e NA q’mts 01 -90 O FAA MIL-Q SA IS IL 000 Do. D M Inputs D 1 -9 -I Writing Team Formed AS 9000: 1997 Dale K. Gordon 9

C Spec ompany ific R e NA q’mts 01 -90 O FAA MIL-Q SA IS IL 000 Do. D M Inputs D 1 -9 -I Writing Team Formed AS 9000: 1997 Dale K. Gordon 9

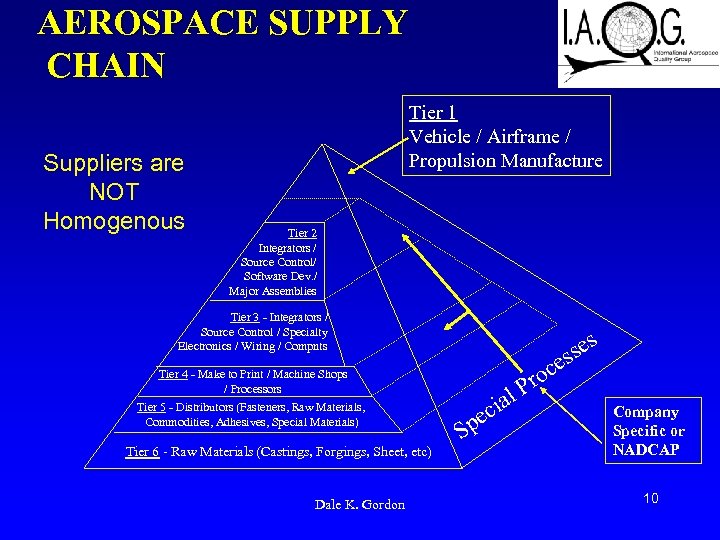

AEROSPACE SUPPLY CHAIN Suppliers are NOT Homogenous Tier 1 Vehicle / Airframe / Propulsion Manufacture Tier 2 Integrators / Source Control/ Software Dev. / Major Assemblies Tier 3 - Integrators / Source Control / Specialty Electronics / Wiring / Compnts ses es Tier 4 - Make to Print / Machine Shops / Processors Tier 5 - Distributors (Fasteners, Raw Materials, Commodities, Adhesives, Special Materials) Tier 6 - Raw Materials (Castings, Forgings, Sheet, etc) Dale K. Gordon S pe ial c roc P Company Specific or NADCAP 10

AEROSPACE SUPPLY CHAIN Suppliers are NOT Homogenous Tier 1 Vehicle / Airframe / Propulsion Manufacture Tier 2 Integrators / Source Control/ Software Dev. / Major Assemblies Tier 3 - Integrators / Source Control / Specialty Electronics / Wiring / Compnts ses es Tier 4 - Make to Print / Machine Shops / Processors Tier 5 - Distributors (Fasteners, Raw Materials, Commodities, Adhesives, Special Materials) Tier 6 - Raw Materials (Castings, Forgings, Sheet, etc) Dale K. Gordon S pe ial c roc P Company Specific or NADCAP 10

Global Quality Standard Activity Dale K. Gordon 11

Global Quality Standard Activity Dale K. Gordon 11

ISO TC 20 - WG 11 ISO Technical Committee 20 - Aircraft & Space Vehicles – Established Working Group 11 (April 1997) • Chartered to develop and publish an international quality system standard based upon ISO 9001 for the aerospace industry • United States (Gene Barker) Convener • Members: Brazil China France Germany Japan Mexico United Kingdom United States Dale K. Gordon 12

ISO TC 20 - WG 11 ISO Technical Committee 20 - Aircraft & Space Vehicles – Established Working Group 11 (April 1997) • Chartered to develop and publish an international quality system standard based upon ISO 9001 for the aerospace industry • United States (Gene Barker) Convener • Members: Brazil China France Germany Japan Mexico United Kingdom United States Dale K. Gordon 12

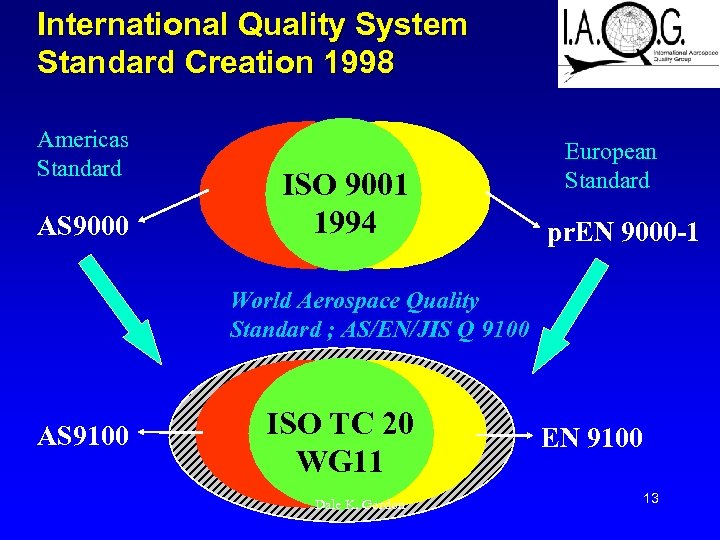

International Quality System Standard Creation 1998 Americas Standard AS 9000 ISO 9001 1994 European Standard pr. EN 9000 -1 World Aerospace Quality Standard ; AS/EN/JIS Q 9100 AS 9100 ISO TC 20 WG 11 Dale K. Gordon EN 9100 13

International Quality System Standard Creation 1998 Americas Standard AS 9000 ISO 9001 1994 European Standard pr. EN 9000 -1 World Aerospace Quality Standard ; AS/EN/JIS Q 9100 AS 9100 ISO TC 20 WG 11 Dale K. Gordon EN 9100 13

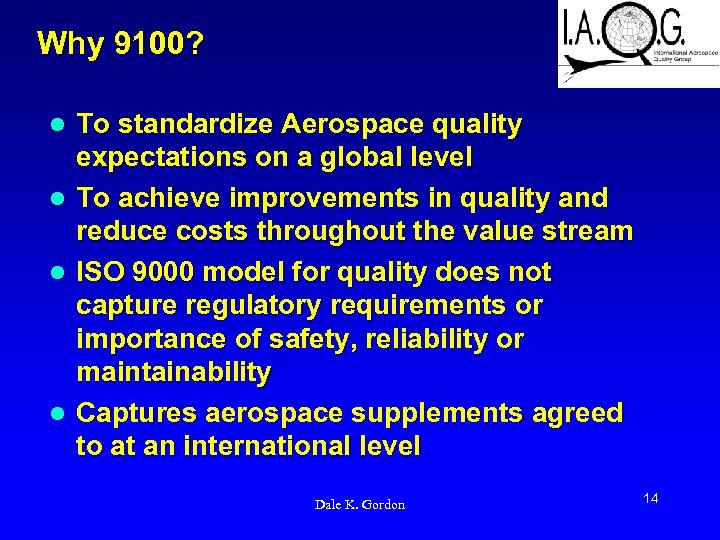

Why 9100? To standardize Aerospace quality expectations on a global level l To achieve improvements in quality and reduce costs throughout the value stream l ISO 9000 model for quality does not capture regulatory requirements or importance of safety, reliability or maintainability l Captures aerospace supplements agreed to at an international level l Dale K. Gordon 14

Why 9100? To standardize Aerospace quality expectations on a global level l To achieve improvements in quality and reduce costs throughout the value stream l ISO 9000 model for quality does not capture regulatory requirements or importance of safety, reliability or maintainability l Captures aerospace supplements agreed to at an international level l Dale K. Gordon 14

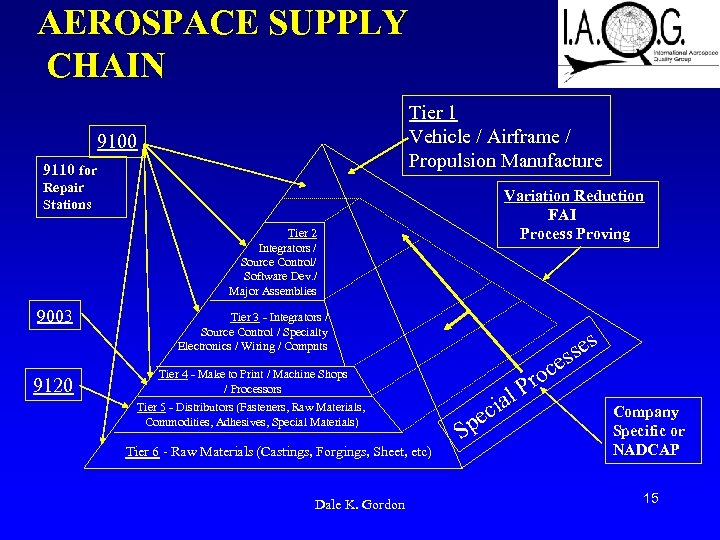

AEROSPACE SUPPLY CHAIN Tier 1 Vehicle / Airframe / Propulsion Manufacture 9100 9110 for Repair Stations Variation Reduction FAI Process Proving Tier 2 Integrators / Source Control/ Software Dev. / Major Assemblies 9003 9120 Tier 3 - Integrators / Source Control / Specialty Electronics / Wiring / Compnts ses es Tier 4 - Make to Print / Machine Shops / Processors Tier 5 - Distributors (Fasteners, Raw Materials, Commodities, Adhesives, Special Materials) Tier 6 - Raw Materials (Castings, Forgings, Sheet, etc) Dale K. Gordon S pe ial c roc P Company Specific or NADCAP 15

AEROSPACE SUPPLY CHAIN Tier 1 Vehicle / Airframe / Propulsion Manufacture 9100 9110 for Repair Stations Variation Reduction FAI Process Proving Tier 2 Integrators / Source Control/ Software Dev. / Major Assemblies 9003 9120 Tier 3 - Integrators / Source Control / Specialty Electronics / Wiring / Compnts ses es Tier 4 - Make to Print / Machine Shops / Processors Tier 5 - Distributors (Fasteners, Raw Materials, Commodities, Adhesives, Special Materials) Tier 6 - Raw Materials (Castings, Forgings, Sheet, etc) Dale K. Gordon S pe ial c roc P Company Specific or NADCAP 15

Year 2000 ISO 9000 Revisions A moving target. . . Dale K. Gordon 16

Year 2000 ISO 9000 Revisions A moving target. . . Dale K. Gordon 16

9100 Standard Alignment with ISO 9001: 2000 l IAQG has the responsibility l Aligned aerospace requirements with the new ISO 9001: 2000 Incorporated lessons learned - clarified requirements l Coordination and resolution was by geographic sectors l Americas (AAQG) Europe (EAQG) Asia (SJAC) l Goal to publish revision to 9100 - est. June 2001 l AS 9100 A published by SAE in August 2001 l JIS Q 9100: 2001 published by JSA in November 2001 Dale K. Gordon 17

9100 Standard Alignment with ISO 9001: 2000 l IAQG has the responsibility l Aligned aerospace requirements with the new ISO 9001: 2000 Incorporated lessons learned - clarified requirements l Coordination and resolution was by geographic sectors l Americas (AAQG) Europe (EAQG) Asia (SJAC) l Goal to publish revision to 9100 - est. June 2001 l AS 9100 A published by SAE in August 2001 l JIS Q 9100: 2001 published by JSA in November 2001 Dale K. Gordon 17

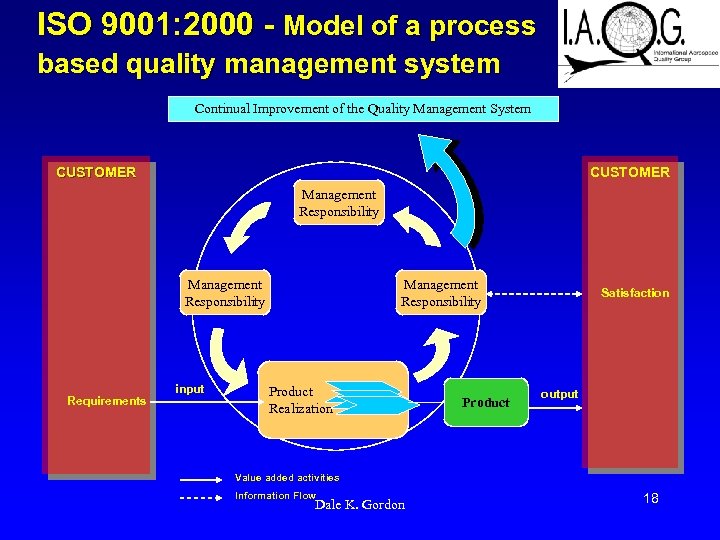

ISO 9001: 2000 - Model of a process based quality management system Continual Improvement of the Quality Management System CUSTOMER Management Responsibility Requirements input Management Responsibility Product Realization Product Satisfaction output Value added activities Information Flow Dale K. Gordon 18

ISO 9001: 2000 - Model of a process based quality management system Continual Improvement of the Quality Management System CUSTOMER Management Responsibility Requirements input Management Responsibility Product Realization Product Satisfaction output Value added activities Information Flow Dale K. Gordon 18

ISO 9001: 2000 QUALITY STANDARD REVISION IMPACT l Aerospace unique requirements are not changed in new version of 9100 – ISO 9000 revision now has requirements desired by industry, eliminating some requirements from 9100: 1999 version – Some requirements from ISO 9001: 1994 are desired by industry and were added back to 9100: 2001 version – 9100: 2000 contains 80 aerospace unique requirements and 18 amplifications Dale K. Gordon 19

ISO 9001: 2000 QUALITY STANDARD REVISION IMPACT l Aerospace unique requirements are not changed in new version of 9100 – ISO 9000 revision now has requirements desired by industry, eliminating some requirements from 9100: 1999 version – Some requirements from ISO 9001: 1994 are desired by industry and were added back to 9100: 2001 version – 9100: 2000 contains 80 aerospace unique requirements and 18 amplifications Dale K. Gordon 19

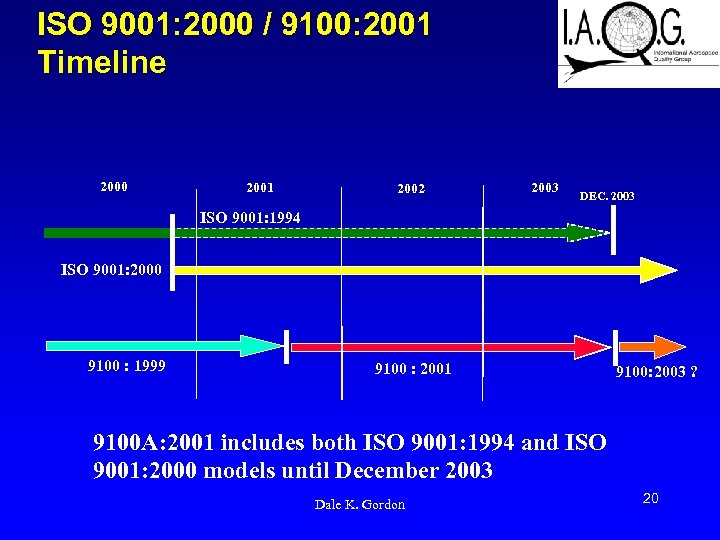

ISO 9001: 2000 / 9100: 2001 Timeline 2000 2001 2002 2003 DEC. 2003 ISO 9001: 1994 ISO 9001: 2000 9100 : 1999 9100 : 2001 9100: 2003 ? 9100 A: 2001 includes both ISO 9001: 1994 and ISO 9001: 2000 models until December 2003 Dale K. Gordon 20

ISO 9001: 2000 / 9100: 2001 Timeline 2000 2001 2002 2003 DEC. 2003 ISO 9001: 1994 ISO 9001: 2000 9100 : 1999 9100 : 2001 9100: 2003 ? 9100 A: 2001 includes both ISO 9001: 1994 and ISO 9001: 2000 models until December 2003 Dale K. Gordon 20

FAA Endorsement of AS 9100: 1999 “The Aircraft Certification Service believes that the effective implementation of AS 9100 will enhance an organization’s overall performance, as long as the statement. . . Other Quality System requirements imposed by the applicable Regulatory Authorities shall be included or referenced in the Quality System documentation is strictly adhered to. Though the FAA does not require the use of the additional elements found in AS 9100, it recognizes their benefits to the aviation in increasing an organizations’ efficiency and reducing product and system variance. ” Dale K. Gordon 21

FAA Endorsement of AS 9100: 1999 “The Aircraft Certification Service believes that the effective implementation of AS 9100 will enhance an organization’s overall performance, as long as the statement. . . Other Quality System requirements imposed by the applicable Regulatory Authorities shall be included or referenced in the Quality System documentation is strictly adhered to. Though the FAA does not require the use of the additional elements found in AS 9100, it recognizes their benefits to the aviation in increasing an organizations’ efficiency and reducing product and system variance. ” Dale K. Gordon 21

Current USA Do. D Position l Proposed Department of Defense (Do. D) Adoption of the AS 9100: 2001 Quality Management Systems - Aerospace Requirements (Nov. 2001) – prepared. . . Do. D adoption notice for the AS 9100: 2001 to provide information for document visibility and facilitate document availability to Do. D personnel. l International Aerospace Quality Standard AS 9100, 2001 edition, Quality Management Systems--Aerospace Requirements, was adopted on March 1, 2002 for use by the Department of Defense (Do. D). The standard specifies additional requirements identified by the aerospace industry specifically for an aerospace quality management system based on ISO 9001: 2000 Quality Management Systems Requirements. 22 Dale K. Gordon

Current USA Do. D Position l Proposed Department of Defense (Do. D) Adoption of the AS 9100: 2001 Quality Management Systems - Aerospace Requirements (Nov. 2001) – prepared. . . Do. D adoption notice for the AS 9100: 2001 to provide information for document visibility and facilitate document availability to Do. D personnel. l International Aerospace Quality Standard AS 9100, 2001 edition, Quality Management Systems--Aerospace Requirements, was adopted on March 1, 2002 for use by the Department of Defense (Do. D). The standard specifies additional requirements identified by the aerospace industry specifically for an aerospace quality management system based on ISO 9001: 2000 Quality Management Systems Requirements. 22 Dale K. Gordon

Current NASA Position on 9100 l NASA issued Adoption notice on April 8 th 2002, signed by Dr. Michael Greenfield, Associate Administrator for Mission and Safety Assurance. l This notice makes AS 9100 A available for use by NASA for procurements for all programs. Dale K. Gordon 23

Current NASA Position on 9100 l NASA issued Adoption notice on April 8 th 2002, signed by Dr. Michael Greenfield, Associate Administrator for Mission and Safety Assurance. l This notice makes AS 9100 A available for use by NASA for procurements for all programs. Dale K. Gordon 23

SPACE CONSIDERATIONS l ISO TC 20 / SC 14 and IAQG have on-going project to supplement 9100 w/ special considerations for Space needs – Includes Risk Management & Safety and Mission Assurance emphasis – Use as supplement to 9100 – Consideration for full inclusion at next revision of 9100 l Other Space considerations with IAQG process / documents to be considered as appropriate Dale K. Gordon 24

SPACE CONSIDERATIONS l ISO TC 20 / SC 14 and IAQG have on-going project to supplement 9100 w/ special considerations for Space needs – Includes Risk Management & Safety and Mission Assurance emphasis – Use as supplement to 9100 – Consideration for full inclusion at next revision of 9100 l Other Space considerations with IAQG process / documents to be considered as appropriate Dale K. Gordon 24

9100 Checklist - 9101 IAQG developed 9101 Common Checklist to be used by industry to cover all ISO 9001 & 9100 elements - allows industry to share audit information l Must be used by Certification Bodies when performing 9100 audits l Scoring feature is currently used by many organizations l Dale K. Gordon 25

9100 Checklist - 9101 IAQG developed 9101 Common Checklist to be used by industry to cover all ISO 9001 & 9100 elements - allows industry to share audit information l Must be used by Certification Bodies when performing 9100 audits l Scoring feature is currently used by many organizations l Dale K. Gordon 25

9110 Repair Station Quality System l EN 9110 developed and implemented in Europe for facilities that perform maintenance and repairs of aircraft and aircraft products – Based on 9100 requirements and FAA / JAA JAR 145 requirements • Corresponding 9111 checklist has also been developed and published • Harmonized AS 9110 is complete will be published soon (2002) Dale K. Gordon 26

9110 Repair Station Quality System l EN 9110 developed and implemented in Europe for facilities that perform maintenance and repairs of aircraft and aircraft products – Based on 9100 requirements and FAA / JAA JAR 145 requirements • Corresponding 9111 checklist has also been developed and published • Harmonized AS 9110 is complete will be published soon (2002) Dale K. Gordon 26

9120 Distributor Quality System l EN 9120 developed and implemented in Europe for “pass through” stockists / distributors that handle parts and supplies that are used in aerospace products – Checklist 9121 is also available – Based on 9100, but only applies necessary system requirements. – AS 9120 International harmonized standard will be published in 2002 Dale K. Gordon 27

9120 Distributor Quality System l EN 9120 developed and implemented in Europe for “pass through” stockists / distributors that handle parts and supplies that are used in aerospace products – Checklist 9121 is also available – Based on 9100, but only applies necessary system requirements. – AS 9120 International harmonized standard will be published in 2002 Dale K. Gordon 27

Industry Leaders are Listening l l Agreed to improve the overall approach to quality Major Aerospace Companies have agreed upon Quality Management System approval approaches l A key objective is to reduce the number of audits l There are significant benefits to the Aerospace Industry l l Working to develop our International processes to incorporate the new approach International approach is based on a single agreed standard, harmonization of system application and shared information Dale K. Gordon 28

Industry Leaders are Listening l l Agreed to improve the overall approach to quality Major Aerospace Companies have agreed upon Quality Management System approval approaches l A key objective is to reduce the number of audits l There are significant benefits to the Aerospace Industry l l Working to develop our International processes to incorporate the new approach International approach is based on a single agreed standard, harmonization of system application and shared information Dale K. Gordon 28

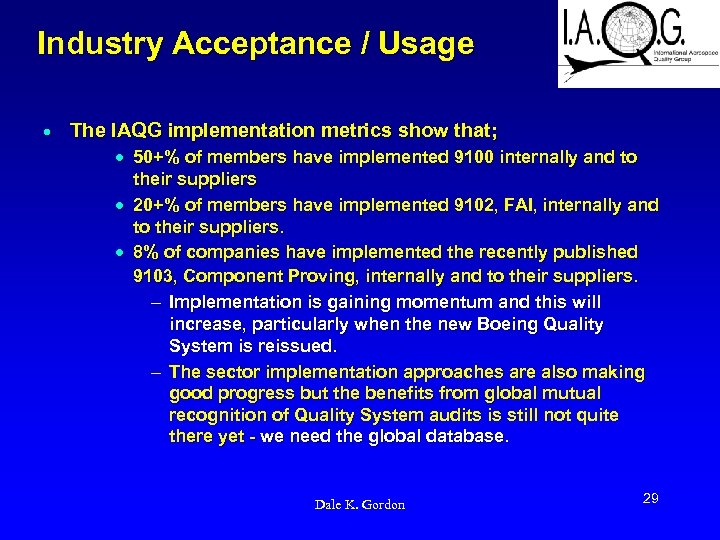

Industry Acceptance / Usage · The IAQG implementation metrics show that; · 50+% of members have implemented 9100 internally and to their suppliers · 20+% of members have implemented 9102, FAI, internally and to their suppliers. · 8% of companies have implemented the recently published 9103, Component Proving, internally and to their suppliers. – Implementation is gaining momentum and this will increase, particularly when the new Boeing Quality System is reissued. – The sector implementation approaches are also making good progress but the benefits from global mutual recognition of Quality System audits is still not quite there yet - we need the global database. Dale K. Gordon 29

Industry Acceptance / Usage · The IAQG implementation metrics show that; · 50+% of members have implemented 9100 internally and to their suppliers · 20+% of members have implemented 9102, FAI, internally and to their suppliers. · 8% of companies have implemented the recently published 9103, Component Proving, internally and to their suppliers. – Implementation is gaining momentum and this will increase, particularly when the new Boeing Quality System is reissued. – The sector implementation approaches are also making good progress but the benefits from global mutual recognition of Quality System audits is still not quite there yet - we need the global database. Dale K. Gordon 29

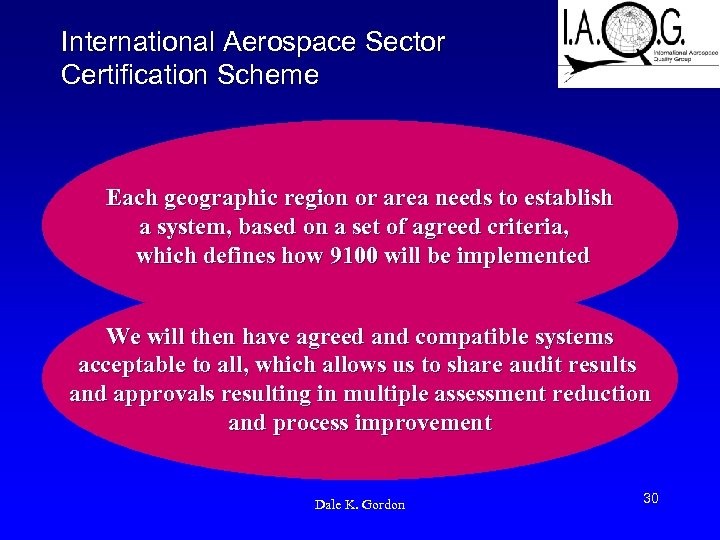

International Aerospace Sector Certification Scheme Each geographic region or area needs to establish a system, based on a set of agreed criteria, which defines how 9100 will be implemented We will then have agreed and compatible systems acceptable to all, which allows us to share audit results and approvals resulting in multiple assessment reduction and process improvement Dale K. Gordon 30

International Aerospace Sector Certification Scheme Each geographic region or area needs to establish a system, based on a set of agreed criteria, which defines how 9100 will be implemented We will then have agreed and compatible systems acceptable to all, which allows us to share audit results and approvals resulting in multiple assessment reduction and process improvement Dale K. Gordon 30

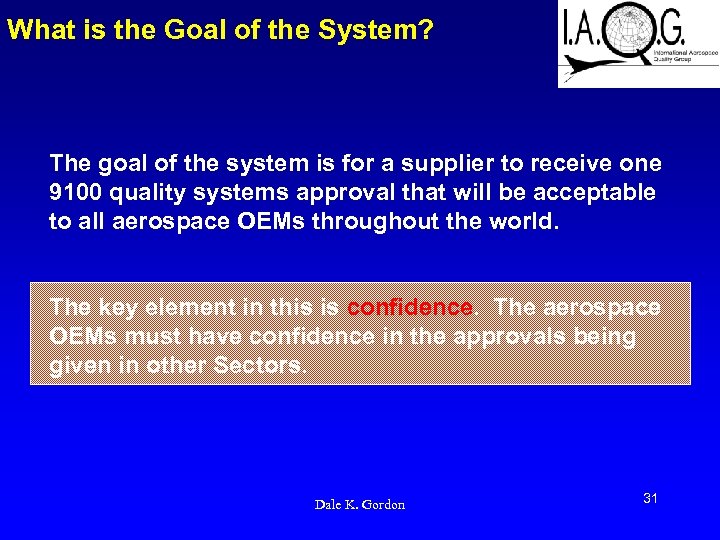

What is the Goal of the System? The goal of the system is for a supplier to receive one 9100 quality systems approval that will be acceptable to all aerospace OEMs throughout the world. The key element in this is confidence. The aerospace OEMs must have confidence in the approvals being given in other Sectors. Dale K. Gordon 31

What is the Goal of the System? The goal of the system is for a supplier to receive one 9100 quality systems approval that will be acceptable to all aerospace OEMs throughout the world. The key element in this is confidence. The aerospace OEMs must have confidence in the approvals being given in other Sectors. Dale K. Gordon 31

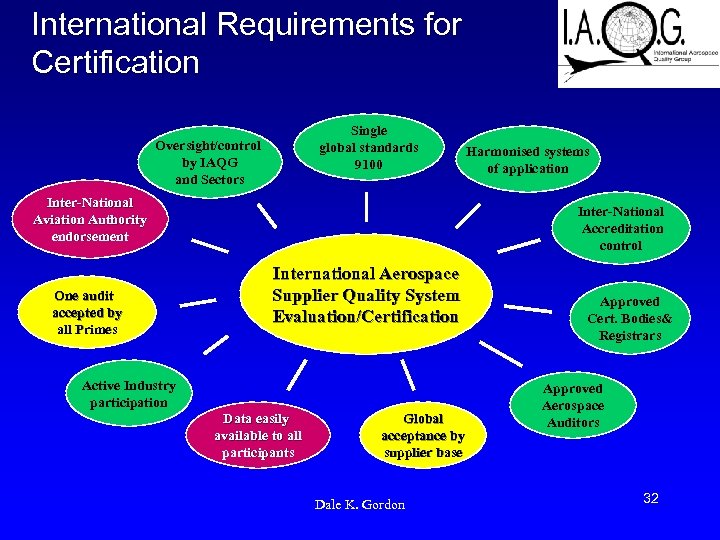

International Requirements for Certification Single global standards 9100 Oversight/control by IAQG and Sectors Inter-National Aviation Authority endorsement One audit accepted by all Primes Harmonised systems of application Inter-National Accreditation control International Aerospace Supplier Quality System Evaluation/Certification Active Industry participation Data easily available to all participants Global acceptance by supplier base Dale K. Gordon Approved Cert. Bodies& Registrars Approved Aerospace Auditors 32

International Requirements for Certification Single global standards 9100 Oversight/control by IAQG and Sectors Inter-National Aviation Authority endorsement One audit accepted by all Primes Harmonised systems of application Inter-National Accreditation control International Aerospace Supplier Quality System Evaluation/Certification Active Industry participation Data easily available to all participants Global acceptance by supplier base Dale K. Gordon Approved Cert. Bodies& Registrars Approved Aerospace Auditors 32

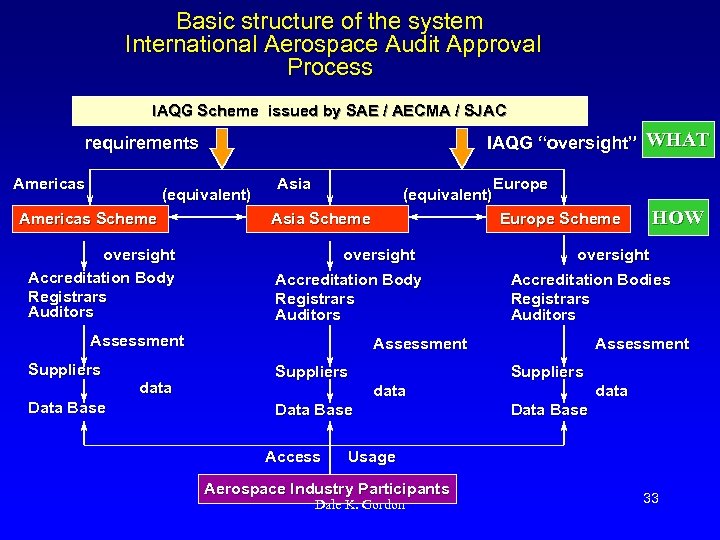

Basic structure of the system International Aerospace Audit Approval Process IAQG Scheme issued by SAE / AECMA / SJAC IAQG “oversight” WHAT requirements Americas (equivalent) Americas Scheme oversight Accreditation Body Registrars Auditors Asia Scheme oversight Accreditation Body Registrars Auditors Assessment Suppliers Data Base data Europe (equivalent) Europe Scheme oversight Accreditation Bodies Registrars Auditors Assessment Suppliers data Data Base Access HOW Assessment Suppliers data Data Base Usage Aerospace Industry Participants Dale K. Gordon 33

Basic structure of the system International Aerospace Audit Approval Process IAQG Scheme issued by SAE / AECMA / SJAC IAQG “oversight” WHAT requirements Americas (equivalent) Americas Scheme oversight Accreditation Body Registrars Auditors Asia Scheme oversight Accreditation Body Registrars Auditors Assessment Suppliers Data Base data Europe (equivalent) Europe Scheme oversight Accreditation Bodies Registrars Auditors Assessment Suppliers data Data Base Access HOW Assessment Suppliers data Data Base Usage Aerospace Industry Participants Dale K. Gordon 33

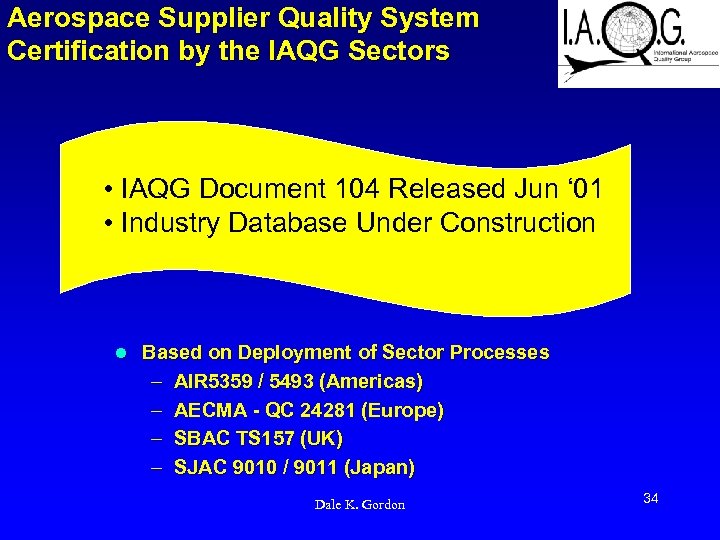

Aerospace Supplier Quality System Certification by the IAQG Sectors • IAQG Document 104 Released Jun ‘ 01 • Industry Database Under Construction l Based on Deployment of Sector Processes – AIR 5359 / 5493 (Americas) – AECMA - QC 24281 (Europe) – SBAC TS 157 (UK) – SJAC 9010 / 9011 (Japan) Dale K. Gordon 34

Aerospace Supplier Quality System Certification by the IAQG Sectors • IAQG Document 104 Released Jun ‘ 01 • Industry Database Under Construction l Based on Deployment of Sector Processes – AIR 5359 / 5493 (Americas) – AECMA - QC 24281 (Europe) – SBAC TS 157 (UK) – SJAC 9010 / 9011 (Japan) Dale K. Gordon 34

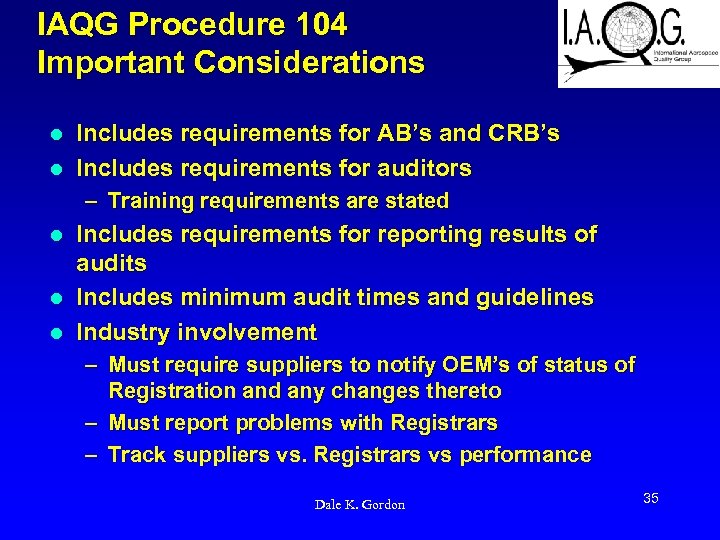

IAQG Procedure 104 Important Considerations Includes requirements for AB’s and CRB’s l Includes requirements for auditors l – Training requirements are stated Includes requirements for reporting results of audits l Includes minimum audit times and guidelines l Industry involvement l – Must require suppliers to notify OEM’s of status of Registration and any changes thereto – Must report problems with Registrars – Track suppliers vs. Registrars vs performance Dale K. Gordon 35

IAQG Procedure 104 Important Considerations Includes requirements for AB’s and CRB’s l Includes requirements for auditors l – Training requirements are stated Includes requirements for reporting results of audits l Includes minimum audit times and guidelines l Industry involvement l – Must require suppliers to notify OEM’s of status of Registration and any changes thereto – Must report problems with Registrars – Track suppliers vs. Registrars vs performance Dale K. Gordon 35

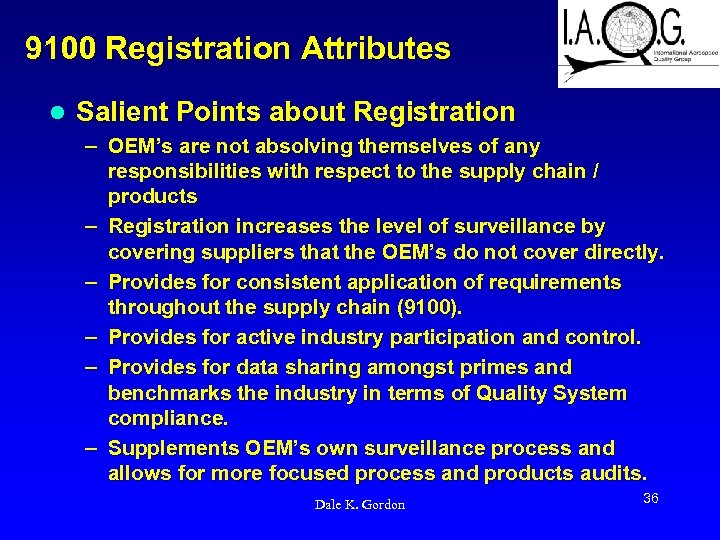

9100 Registration Attributes l Salient Points about Registration – OEM’s are not absolving themselves of any responsibilities with respect to the supply chain / products – Registration increases the level of surveillance by covering suppliers that the OEM’s do not cover directly. – Provides for consistent application of requirements throughout the supply chain (9100). – Provides for active industry participation and control. – Provides for data sharing amongst primes and benchmarks the industry in terms of Quality System compliance. – Supplements OEM’s own surveillance process and allows for more focused process and products audits. Dale K. Gordon 36

9100 Registration Attributes l Salient Points about Registration – OEM’s are not absolving themselves of any responsibilities with respect to the supply chain / products – Registration increases the level of surveillance by covering suppliers that the OEM’s do not cover directly. – Provides for consistent application of requirements throughout the supply chain (9100). – Provides for active industry participation and control. – Provides for data sharing amongst primes and benchmarks the industry in terms of Quality System compliance. – Supplements OEM’s own surveillance process and allows for more focused process and products audits. Dale K. Gordon 36

Summary l Industry Co-operation on Quality System Requirements l A single global 9100 Aerospace standard l An agreed International process for procedure creation l Sector processes for 2 nd or 3 rd party approvals l Individual sector plans launched / global plans in work l Implementation planned progressively during 2002 l Establish a mechanism for data exchange l International auditor training and qualifications l Communication to Authorities and Stakeholders l Industry will Monitor results and maintain momentum Dale K. Gordon 37

Summary l Industry Co-operation on Quality System Requirements l A single global 9100 Aerospace standard l An agreed International process for procedure creation l Sector processes for 2 nd or 3 rd party approvals l Individual sector plans launched / global plans in work l Implementation planned progressively during 2002 l Establish a mechanism for data exchange l International auditor training and qualifications l Communication to Authorities and Stakeholders l Industry will Monitor results and maintain momentum Dale K. Gordon 37

QUESTIONS Dale K. Gordon 38

QUESTIONS Dale K. Gordon 38