0964b4588813f86ad6cf0fe3f782eeee.ppt

- Количество слайдов: 18

Aero-Space Propulsion Simulation and Modeling Dr. John K. Lytle Chief, Computing and Interdisciplinary Systems Office April 4 - 5, 2000 GLENN RESEARCH CENTER at Lewis Field

Aero-Space Propulsion Simulation and Modeling Dr. John K. Lytle Chief, Computing and Interdisciplinary Systems Office April 4 - 5, 2000 GLENN RESEARCH CENTER at Lewis Field

NASA Goals Directly Supported by Simulation and Modeling Provide next generation design tools and experimental aircraft to increase design confidence, and cut the development cycle time for aircraft in half.

NASA Goals Directly Supported by Simulation and Modeling Provide next generation design tools and experimental aircraft to increase design confidence, and cut the development cycle time for aircraft in half.

Outline • High Fidelity, Physics-based Simulations • Combustion • Turbomachinery • Aeroelasticity • Probabilistic Methods • Full System • Virtual Design Environment, Life Cycle Simulation Intelligent Synthesis Environment Program (La. RC) Intelligent Systems Program (ARC) Aero-Space Propulsion and Power R&T Base (GRC) High Performance Computing and Communications Program (ARC) Advanced Space Transportation Program (MSFC) Information Technology R&T Base Program (ARC)

Outline • High Fidelity, Physics-based Simulations • Combustion • Turbomachinery • Aeroelasticity • Probabilistic Methods • Full System • Virtual Design Environment, Life Cycle Simulation Intelligent Synthesis Environment Program (La. RC) Intelligent Systems Program (ARC) Aero-Space Propulsion and Power R&T Base (GRC) High Performance Computing and Communications Program (ARC) Advanced Space Transportation Program (MSFC) Information Technology R&T Base Program (ARC)

The National Combustion Code is an integrated system of computer codes that takes advantage of solid modeling and automated meshing of complex geometries. The National Combustion Code uses unstructured meshes and parallel computing. Physical models include: a turbulence module containing the nonlinear k-epsilon models; conventional reduced chemical kinetics or the Intrinsic Low Dimensional Manifold (ILDM) approach; a spray module; and a joint probability density function for species and enthalpy. Fuel Nozzle Flow Midplane Temperature Contour Cold and Hot Isotherm Interactions Midplane Total Pressure Contour

The National Combustion Code is an integrated system of computer codes that takes advantage of solid modeling and automated meshing of complex geometries. The National Combustion Code uses unstructured meshes and parallel computing. Physical models include: a turbulence module containing the nonlinear k-epsilon models; conventional reduced chemical kinetics or the Intrinsic Low Dimensional Manifold (ILDM) approach; a spray module; and a joint probability density function for species and enthalpy. Fuel Nozzle Flow Midplane Temperature Contour Cold and Hot Isotherm Interactions Midplane Total Pressure Contour

APNASA 21 Blade Row Compressor Simulation Turnaround Time Reduced by a Factor of 400: 1 Estimated Turnaround Time Factors Influencing Turnaround Time BASELINE ANALYSIS 1992 Hours PARALLEL PROCESSING ~ ÷ 40 ~÷ 6 ALGORITHMIC CHANGES ~ 2. 4 X INCREASED RESOLUTION COMPUTER HARDWARE IMPROVEMENTS ~÷ 4

APNASA 21 Blade Row Compressor Simulation Turnaround Time Reduced by a Factor of 400: 1 Estimated Turnaround Time Factors Influencing Turnaround Time BASELINE ANALYSIS 1992 Hours PARALLEL PROCESSING ~ ÷ 40 ~÷ 6 ALGORITHMIC CHANGES ~ 2. 4 X INCREASED RESOLUTION COMPUTER HARDWARE IMPROVEMENTS ~÷ 4

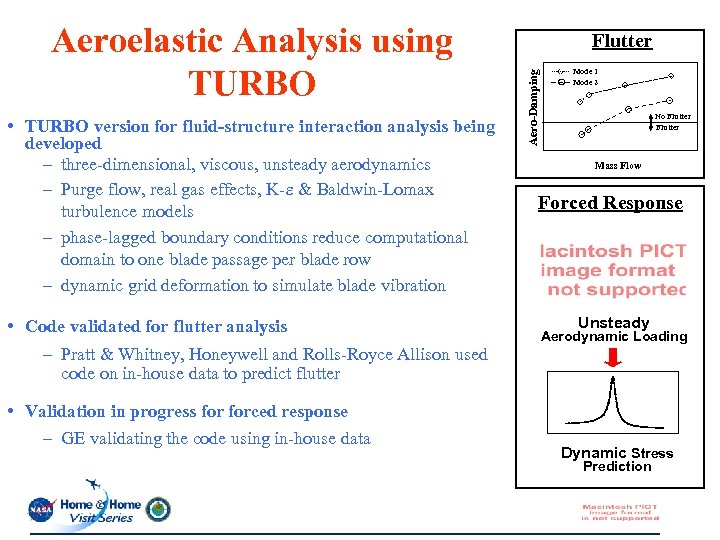

• TURBO version for fluid-structure interaction analysis being developed – three-dimensional, viscous, unsteady aerodynamics – Purge flow, real gas effects, K-e & Baldwin-Lomax turbulence models – phase-lagged boundary conditions reduce computational domain to one blade passage per blade row – dynamic grid deformation to simulate blade vibration • Code validated for flutter analysis – Pratt & Whitney, Honeywell and Rolls-Royce Allison used code on in-house data to predict flutter • Validation in progress forced response – GE validating the code using in-house data Flutter Aero-Damping Aeroelastic Analysis using TURBO Mode 1 Mode 2 No Flutter Mass Flow Forced Response Unsteady Aerodynamic Loading Dynamic Stress Prediction

• TURBO version for fluid-structure interaction analysis being developed – three-dimensional, viscous, unsteady aerodynamics – Purge flow, real gas effects, K-e & Baldwin-Lomax turbulence models – phase-lagged boundary conditions reduce computational domain to one blade passage per blade row – dynamic grid deformation to simulate blade vibration • Code validated for flutter analysis – Pratt & Whitney, Honeywell and Rolls-Royce Allison used code on in-house data to predict flutter • Validation in progress forced response – GE validating the code using in-house data Flutter Aero-Damping Aeroelastic Analysis using TURBO Mode 1 Mode 2 No Flutter Mass Flow Forced Response Unsteady Aerodynamic Loading Dynamic Stress Prediction

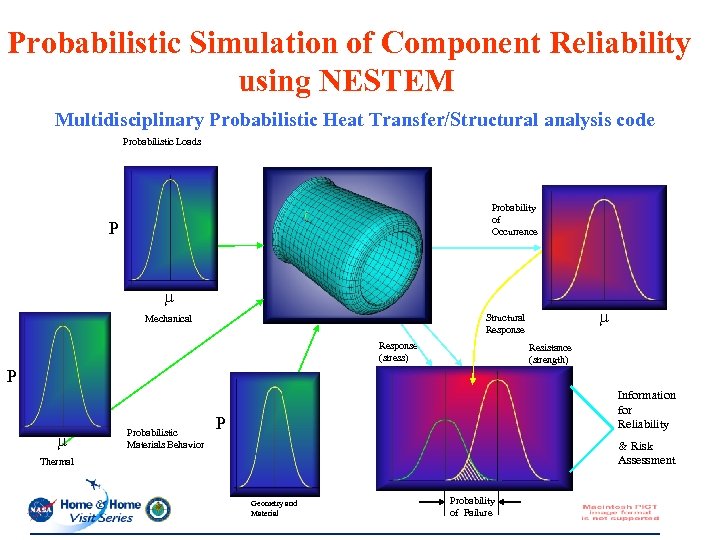

Probabilistic Simulation of Component Reliability using NESTEM Multidisciplinary Probabilistic Heat Transfer/Structural analysis code Probabilistic Loads Probability of Occurrence P m m Structural Response Mechanical Response (stress) Resistance (strength) P m Probabilistic Materials Behavior Information for Reliability P & Risk Assessment Thermal Geometry and Material Probability of Failure

Probabilistic Simulation of Component Reliability using NESTEM Multidisciplinary Probabilistic Heat Transfer/Structural analysis code Probabilistic Loads Probability of Occurrence P m m Structural Response Mechanical Response (stress) Resistance (strength) P m Probabilistic Materials Behavior Information for Reliability P & Risk Assessment Thermal Geometry and Material Probability of Failure

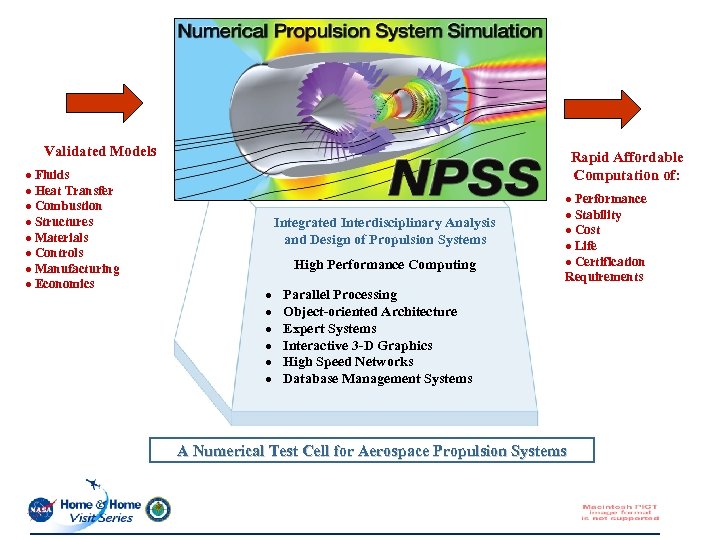

Validated Models · Fluids · Heat Transfer · Combustion · Structures · Materials · Controls · Manufacturing · Economics Rapid Affordable Computation of: Integrated Interdisciplinary Analysis and Design of Propulsion Systems High Performance Computing · · · · Performance · Stability · Cost · Life · Certification Requirements Parallel Processing Object-oriented Architecture Expert Systems Interactive 3 -D Graphics High Speed Networks Database Management Systems A Numerical Test Cell for Aerospace Propulsion Systems

Validated Models · Fluids · Heat Transfer · Combustion · Structures · Materials · Controls · Manufacturing · Economics Rapid Affordable Computation of: Integrated Interdisciplinary Analysis and Design of Propulsion Systems High Performance Computing · · · · Performance · Stability · Cost · Life · Certification Requirements Parallel Processing Object-oriented Architecture Expert Systems Interactive 3 -D Graphics High Speed Networks Database Management Systems A Numerical Test Cell for Aerospace Propulsion Systems

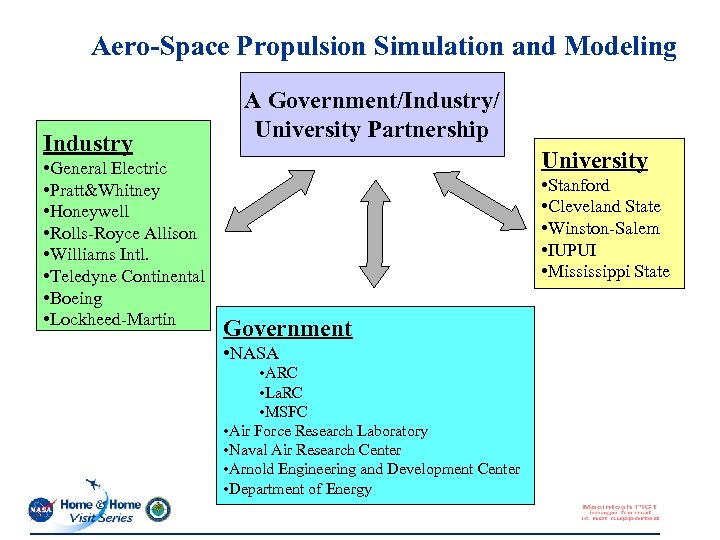

Aero-Space Propulsion Simulation and Modeling Industry • General Electric • Pratt&Whitney • Honeywell • Rolls-Royce Allison • Williams Intl. • Teledyne Continental • Boeing • Lockheed-Martin A Government/Industry/ University Partnership University • Stanford • Cleveland State • Winston-Salem • IUPUI • Mississippi State Government • NASA • ARC • La. RC • MSFC • Air Force Research Laboratory • Naval Air Research Center • Arnold Engineering and Development Center • Department of Energy

Aero-Space Propulsion Simulation and Modeling Industry • General Electric • Pratt&Whitney • Honeywell • Rolls-Royce Allison • Williams Intl. • Teledyne Continental • Boeing • Lockheed-Martin A Government/Industry/ University Partnership University • Stanford • Cleveland State • Winston-Salem • IUPUI • Mississippi State Government • NASA • ARC • La. RC • MSFC • Air Force Research Laboratory • Naval Air Research Center • Arnold Engineering and Development Center • Department of Energy

Simulation Environment • Computationally efficient (cross-platform operation, parallel processing) • Modular design (objectoriented: “Plug-n-Play” system model assembly, easily modified and expanded) • Provide a common modeling tool for U. S. Government, aerospace industry, and academia • Numerical Zooming and Geometry Access Standards through NPSS for physics based modeling • NPSS Common System Model expected to save Aircraft Industry $50 M/year

Simulation Environment • Computationally efficient (cross-platform operation, parallel processing) • Modular design (objectoriented: “Plug-n-Play” system model assembly, easily modified and expanded) • Provide a common modeling tool for U. S. Government, aerospace industry, and academia • Numerical Zooming and Geometry Access Standards through NPSS for physics based modeling • NPSS Common System Model expected to save Aircraft Industry $50 M/year

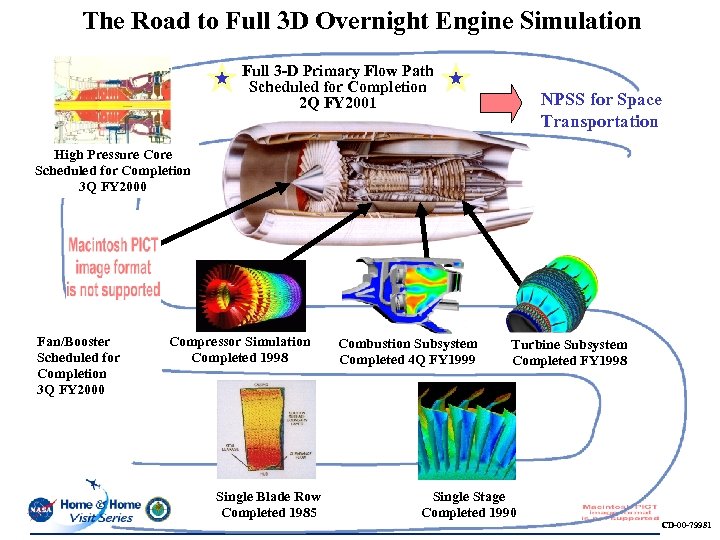

The Road to Full 3 D Overnight Engine Simulation Full 3 -D Primary Flow Path Scheduled for Completion 2 Q FY 2001 NPSS for Space Transportation High Pressure Core Scheduled for Completion 3 Q FY 2000 Fan/Booster Scheduled for Completion 3 Q FY 2000 Compressor Simulation Completed 1998 Single Blade Row Completed 1985 Combustion Subsystem Completed 4 Q FY 1999 Turbine Subsystem Completed FY 1998 Single Stage Completed 1990 CD-00 -79981

The Road to Full 3 D Overnight Engine Simulation Full 3 -D Primary Flow Path Scheduled for Completion 2 Q FY 2001 NPSS for Space Transportation High Pressure Core Scheduled for Completion 3 Q FY 2000 Fan/Booster Scheduled for Completion 3 Q FY 2000 Compressor Simulation Completed 1998 Single Blade Row Completed 1985 Combustion Subsystem Completed 4 Q FY 1999 Turbine Subsystem Completed FY 1998 Single Stage Completed 1990 CD-00 -79981

Engine-Airframe Structural Simulations Provide High Fidelity Analysis and Assessment of Blade-Out Event NASA Glenn, General Electric Aircraft Engines, Pratt & Whitney, and Boeing have teamed to develop new simulation tools for engine-airframe structural systems. Development of these tools will enable high-fidelity analyses of blade-out events, more credible design of engine containment systems and improvements in blade -out margin-of-safety predictions. Industry/Government Standard Simulation Procedures Physics Based Blade Loss Modeling Mathematical Modeling of Turbomachine Rotors

Engine-Airframe Structural Simulations Provide High Fidelity Analysis and Assessment of Blade-Out Event NASA Glenn, General Electric Aircraft Engines, Pratt & Whitney, and Boeing have teamed to develop new simulation tools for engine-airframe structural systems. Development of these tools will enable high-fidelity analyses of blade-out events, more credible design of engine containment systems and improvements in blade -out margin-of-safety predictions. Industry/Government Standard Simulation Procedures Physics Based Blade Loss Modeling Mathematical Modeling of Turbomachine Rotors

ISE Vision and Long-Term Goal Vision To effect a cultural change that integrates into practice widelydistributed science, technology and engineering teams to rapidly create innovative, affordable products Long-Term Goal To develop the capability for personnel at dispersed geographic locations to work together in a virtual environment, using computer simulations to model the complete life-cycle of a product/mission with near real-time response time before commitments are made to produce physical products

ISE Vision and Long-Term Goal Vision To effect a cultural change that integrates into practice widelydistributed science, technology and engineering teams to rapidly create innovative, affordable products Long-Term Goal To develop the capability for personnel at dispersed geographic locations to work together in a virtual environment, using computer simulations to model the complete life-cycle of a product/mission with near real-time response time before commitments are made to produce physical products

A ISE Will Enable Tomorrow What Cannot Be Easily Done Today • Comprehensive life-cycle trade-studies to: – reduce design cycle time and testing – reduce redesign and rework, – reduce maintenance costs – increase performance and safety • Bound uncertainties arising from assumptions, scarcity of knowledge and unknowns • Comprehensive and rapid mission life-cycle simulations will minimize the risks and maximize the benefits • Provide a means for productive teaming of the best and brightest people and capabilities • Create and assess new innovative design options and new technologies from anywhere and at anytime • • • •

A ISE Will Enable Tomorrow What Cannot Be Easily Done Today • Comprehensive life-cycle trade-studies to: – reduce design cycle time and testing – reduce redesign and rework, – reduce maintenance costs – increase performance and safety • Bound uncertainties arising from assumptions, scarcity of knowledge and unknowns • Comprehensive and rapid mission life-cycle simulations will minimize the risks and maximize the benefits • Provide a means for productive teaming of the best and brightest people and capabilities • Create and assess new innovative design options and new technologies from anywhere and at anytime • • • •

Summary Revolutionary advances in simulation and modeling will lead to increased design confidence that translates into significant reductions in aerospace propulsion: • Development, manufacturing and certification time and cost • Maintenance and operations costs Greater opportunities to introduce advanced technologies that “buy their way” into new products Government/Industry/University partnerships are required to accomplish these goals and to ensure technology transfer Useful products must be delivered throughout the Program on a frequent basis to sustain interest

Summary Revolutionary advances in simulation and modeling will lead to increased design confidence that translates into significant reductions in aerospace propulsion: • Development, manufacturing and certification time and cost • Maintenance and operations costs Greater opportunities to introduce advanced technologies that “buy their way” into new products Government/Industry/University partnerships are required to accomplish these goals and to ensure technology transfer Useful products must be delivered throughout the Program on a frequent basis to sustain interest

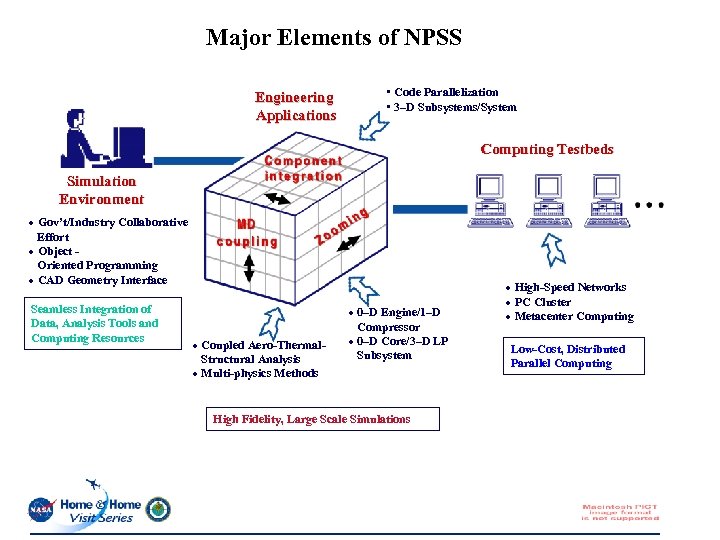

Major Elements of NPSS Engineering Applications • Code Parallelization • 3–D Subsystems/System Computing Testbeds Simulation Environment · Gov’t/Industry Collaborative Effort · Object Oriented Programming · CAD Geometry Interface Seamless Integration of Data, Analysis Tools and Computing Resources · Coupled Aero-Thermal. Structural Analysis · Multi-physics Methods · 0–D Engine/1–D Compressor · 0–D Core/3–D LP Subsystem High Fidelity, Large Scale Simulations · High-Speed Networks · PC Cluster · Metacenter Computing Low-Cost, Distributed Parallel Computing

Major Elements of NPSS Engineering Applications • Code Parallelization • 3–D Subsystems/System Computing Testbeds Simulation Environment · Gov’t/Industry Collaborative Effort · Object Oriented Programming · CAD Geometry Interface Seamless Integration of Data, Analysis Tools and Computing Resources · Coupled Aero-Thermal. Structural Analysis · Multi-physics Methods · 0–D Engine/1–D Compressor · 0–D Core/3–D LP Subsystem High Fidelity, Large Scale Simulations · High-Speed Networks · PC Cluster · Metacenter Computing Low-Cost, Distributed Parallel Computing

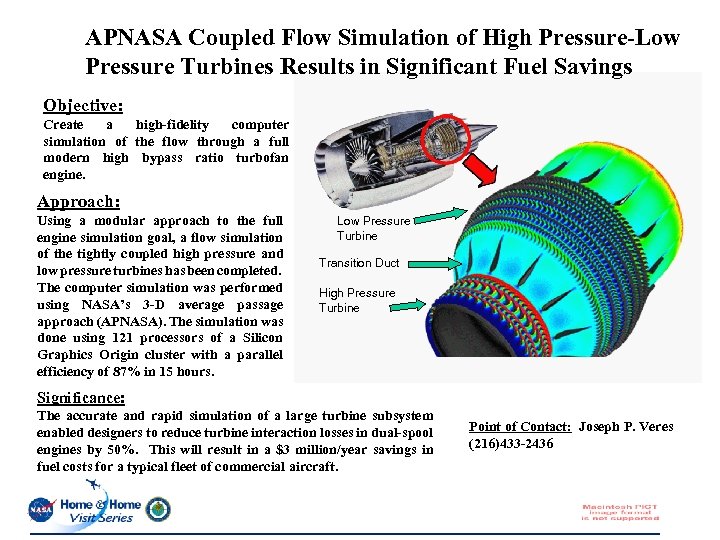

APNASA Coupled Flow Simulation of High Pressure-Low Pressure Turbines Results in Significant Fuel Savings Objective: Create a high-fidelity computer simulation of the flow through a full modern high bypass ratio turbofan engine. Approach: Using a modular approach to the full engine simulation goal, a flow simulation of the tightly coupled high pressure and low pressure turbines has been completed. The computer simulation was performed using NASA’s 3 -D average passage approach (APNASA). The simulation was done using 121 processors of a Silicon Graphics Origin cluster with a parallel efficiency of 87% in 15 hours. Low Pressure Turbine Transition Duct High Pressure Turbine Significance: The accurate and rapid simulation of a large turbine subsystem enabled designers to reduce turbine interaction losses in dual-spool engines by 50%. This will result in a $3 million/year savings in fuel costs for a typical fleet of commercial aircraft. Point of Contact: Joseph P. Veres (216)433 -2436

APNASA Coupled Flow Simulation of High Pressure-Low Pressure Turbines Results in Significant Fuel Savings Objective: Create a high-fidelity computer simulation of the flow through a full modern high bypass ratio turbofan engine. Approach: Using a modular approach to the full engine simulation goal, a flow simulation of the tightly coupled high pressure and low pressure turbines has been completed. The computer simulation was performed using NASA’s 3 -D average passage approach (APNASA). The simulation was done using 121 processors of a Silicon Graphics Origin cluster with a parallel efficiency of 87% in 15 hours. Low Pressure Turbine Transition Duct High Pressure Turbine Significance: The accurate and rapid simulation of a large turbine subsystem enabled designers to reduce turbine interaction losses in dual-spool engines by 50%. This will result in a $3 million/year savings in fuel costs for a typical fleet of commercial aircraft. Point of Contact: Joseph P. Veres (216)433 -2436