ac7eaf791eaf1eeb9ab310563db9f149.ppt

- Количество слайдов: 33

ADJUSTING THE FORAGE HARVESTER FOR CORN SILAGE PARTICLE SIZE Ronald T. Schuler, Professor Extension Agricultural Engineer Biological Systems Engineering Department University of Wisconsin-Madison Team Forage

ADJUSTING THE FORAGE HARVESTER FOR CORN SILAGE PARTICLE SIZE Ronald T. Schuler, Professor Extension Agricultural Engineer Biological Systems Engineering Department University of Wisconsin-Madison Team Forage

Corn Silage Particle Size-Factors § Machine Adjustment h. Feed roll and cutterhead h. Crop processor § Crop maturity § Storage § Animal

Corn Silage Particle Size-Factors § Machine Adjustment h. Feed roll and cutterhead h. Crop processor § Crop maturity § Storage § Animal

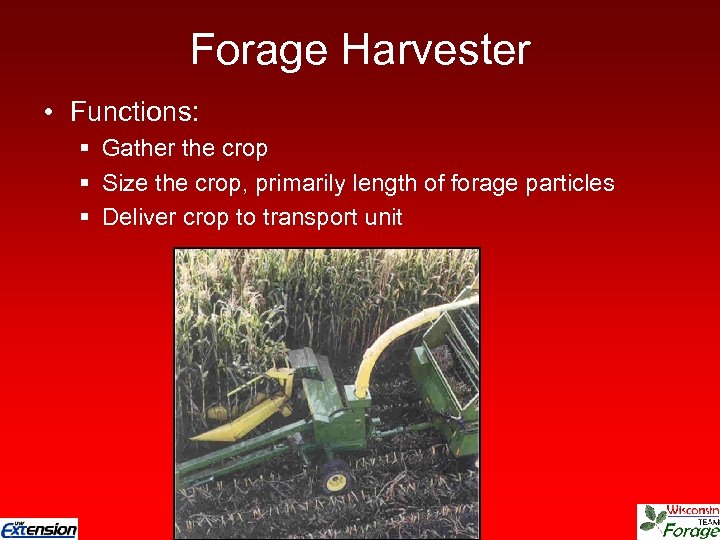

Forage Harvester • Functions: § Gather the crop § Size the crop, primarily length of forage particles § Deliver crop to transport unit

Forage Harvester • Functions: § Gather the crop § Size the crop, primarily length of forage particles § Deliver crop to transport unit

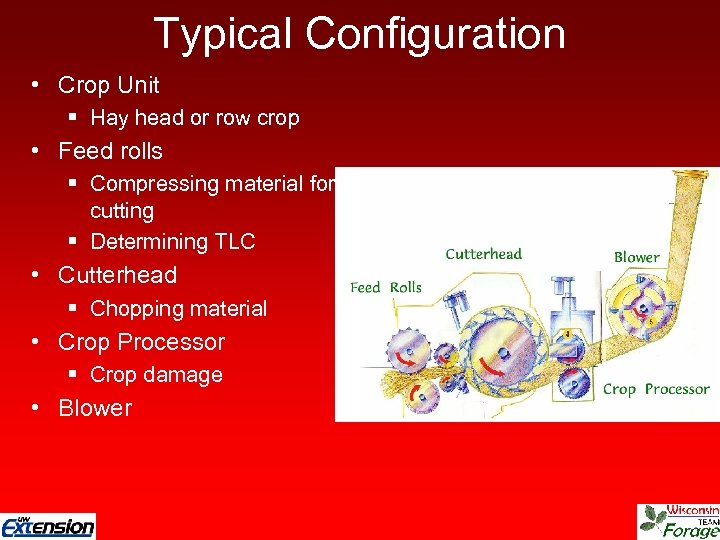

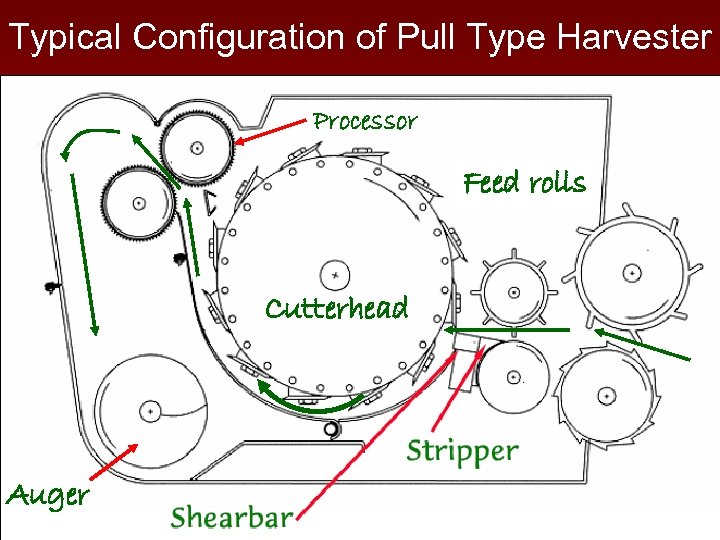

Typical Configuration • Crop Unit § Hay head or row crop • Feed rolls § Compressing material for cutting § Determining TLC • Cutterhead § Chopping material • Crop Processor § Crop damage • Blower

Typical Configuration • Crop Unit § Hay head or row crop • Feed rolls § Compressing material for cutting § Determining TLC • Cutterhead § Chopping material • Crop Processor § Crop damage • Blower

Typical Configuration of Pull Type Harvester Processor Feed rolls Cutterhead Auger

Typical Configuration of Pull Type Harvester Processor Feed rolls Cutterhead Auger

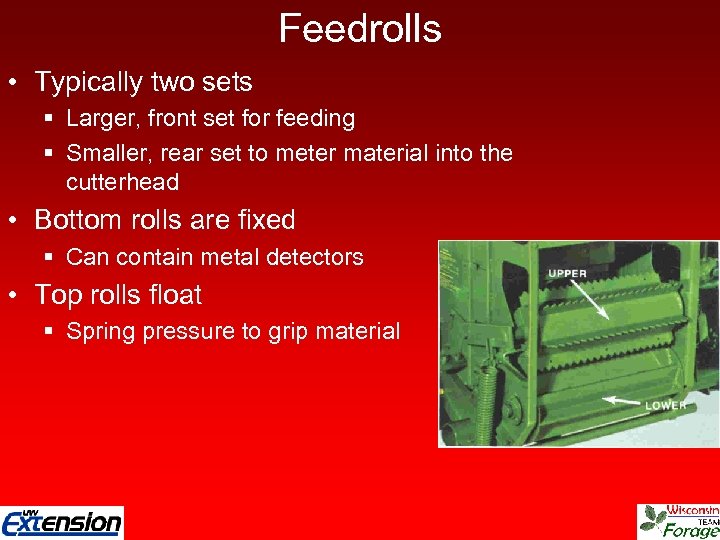

Feedrolls • Typically two sets § Larger, front set for feeding § Smaller, rear set to meter material into the cutterhead • Bottom rolls are fixed § Can contain metal detectors • Top rolls float § Spring pressure to grip material

Feedrolls • Typically two sets § Larger, front set for feeding § Smaller, rear set to meter material into the cutterhead • Bottom rolls are fixed § Can contain metal detectors • Top rolls float § Spring pressure to grip material

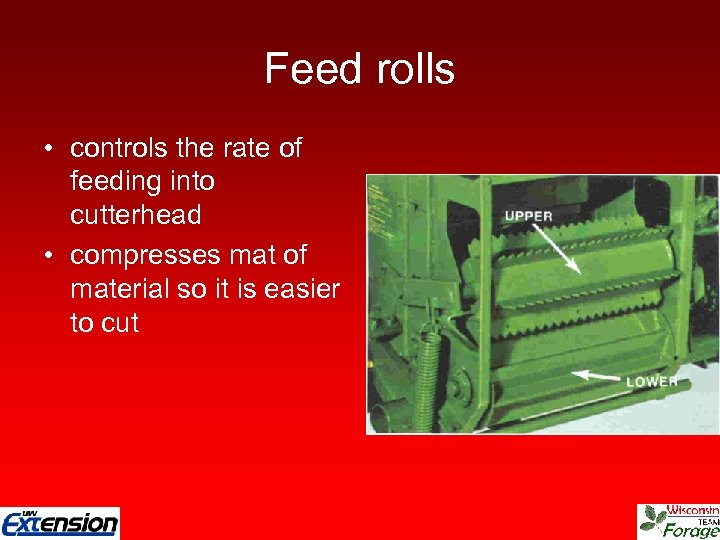

Feed rolls • controls the rate of feeding into cutterhead • compresses mat of material so it is easier to cut

Feed rolls • controls the rate of feeding into cutterhead • compresses mat of material so it is easier to cut

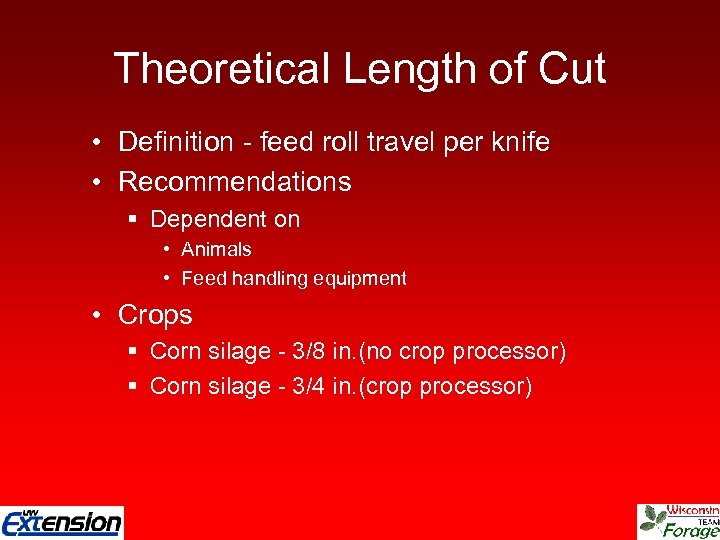

Theoretical Length of Cut • Definition - feed roll travel per knife • Recommendations § Dependent on • Animals • Feed handling equipment • Crops § Corn silage - 3/8 in. (no crop processor) § Corn silage - 3/4 in. (crop processor)

Theoretical Length of Cut • Definition - feed roll travel per knife • Recommendations § Dependent on • Animals • Feed handling equipment • Crops § Corn silage - 3/8 in. (no crop processor) § Corn silage - 3/4 in. (crop processor)

Theoretical Length of Cut • Adjusting theoretical length of cut § Feed roll speed § Number of knives § Cutterhead speed • Not practical

Theoretical Length of Cut • Adjusting theoretical length of cut § Feed roll speed § Number of knives § Cutterhead speed • Not practical

Actual Length of Cut • Longer than the TLC • Windrowed crops longer than row crops § Alfalfa feeds in a tangled mat of material § Corn stalks feed mostly straight

Actual Length of Cut • Longer than the TLC • Windrowed crops longer than row crops § Alfalfa feeds in a tangled mat of material § Corn stalks feed mostly straight

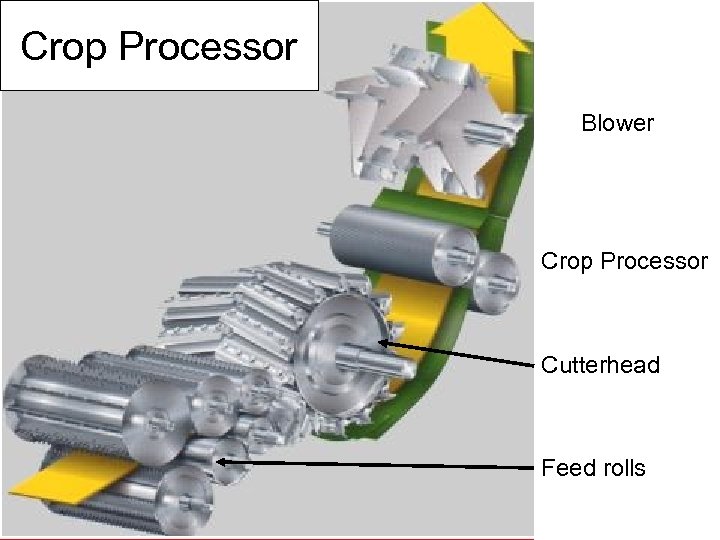

Crop Processor Blower Crop Processor Cutterhead Feed rolls

Crop Processor Blower Crop Processor Cutterhead Feed rolls

Crop Processing • Used only for whole plant corn silage • Kernels are difficult to digest § Contain starch and energy • Damaging the kernel shell allows the rumen bacteria to digest the starch • Breakup cob pieces (avoid hockey pucks)

Crop Processing • Used only for whole plant corn silage • Kernels are difficult to digest § Contain starch and energy • Damaging the kernel shell allows the rumen bacteria to digest the starch • Breakup cob pieces (avoid hockey pucks)

Crop Processing • In the past, very short lengths of cut were used to damage more kernels § Recutter screens also used • Increased power requirements drastically • Shortened fiber length too much

Crop Processing • In the past, very short lengths of cut were used to damage more kernels § Recutter screens also used • Increased power requirements drastically • Shortened fiber length too much

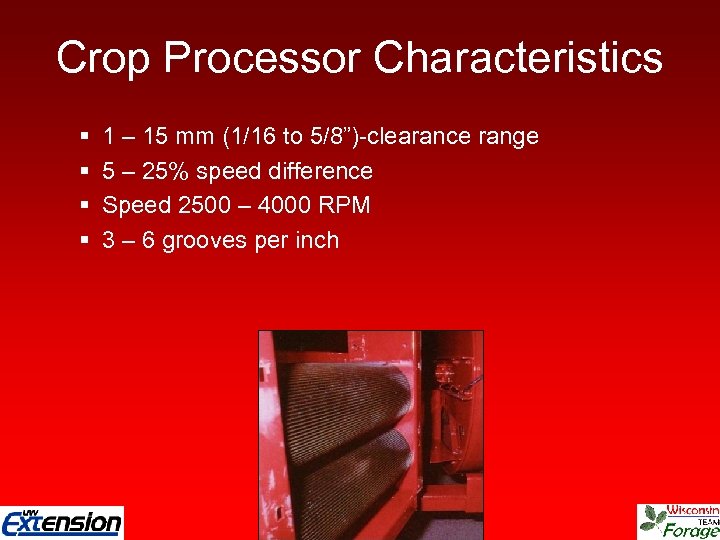

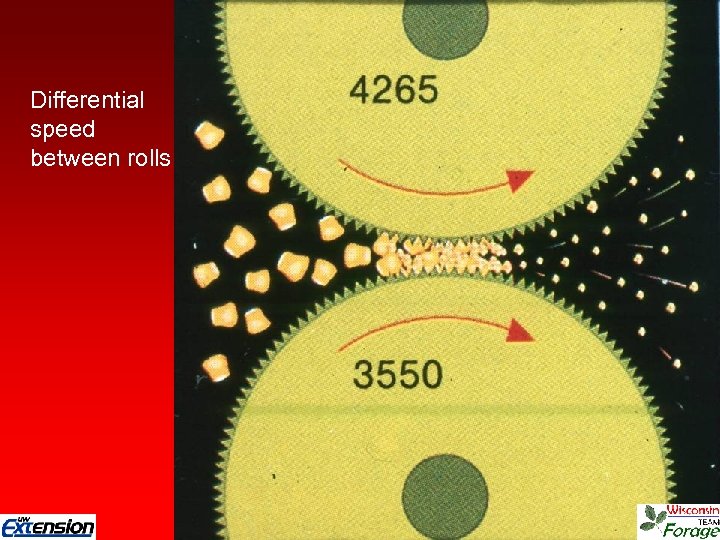

Crop Processor Characteristics § § 1 – 15 mm (1/16 to 5/8”)-clearance range 5 – 25% speed difference Speed 2500 – 4000 RPM 3 – 6 grooves per inch

Crop Processor Characteristics § § 1 – 15 mm (1/16 to 5/8”)-clearance range 5 – 25% speed difference Speed 2500 – 4000 RPM 3 – 6 grooves per inch

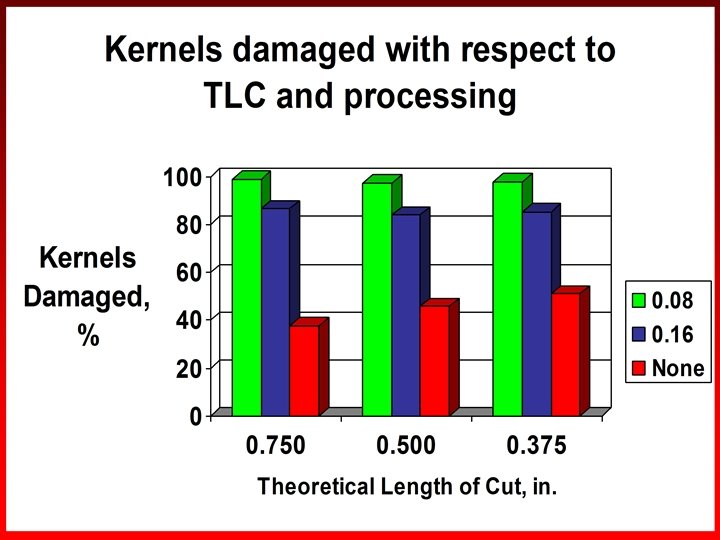

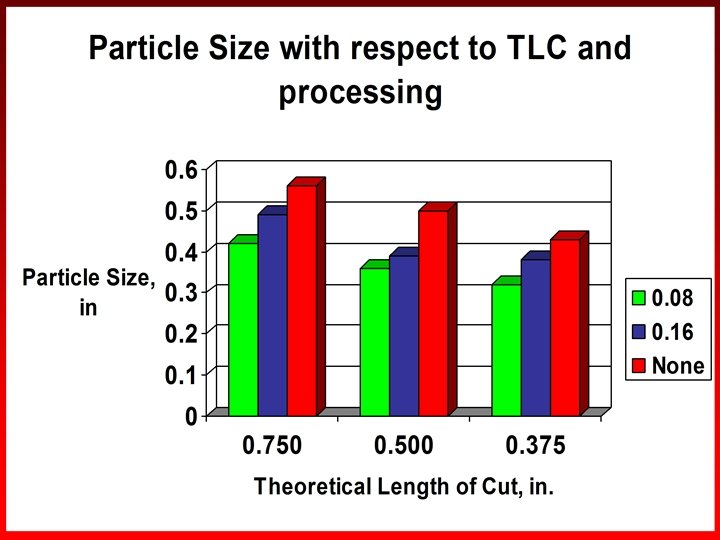

Crop Processing A properly adjusted kernel processor § Damages more than 90% of the kernels § Pulverize cob pieces • Minimizes waste in the feed bunk § Allows for longer length of cut • Longer fiber • Less power consumption

Crop Processing A properly adjusted kernel processor § Damages more than 90% of the kernels § Pulverize cob pieces • Minimizes waste in the feed bunk § Allows for longer length of cut • Longer fiber • Less power consumption

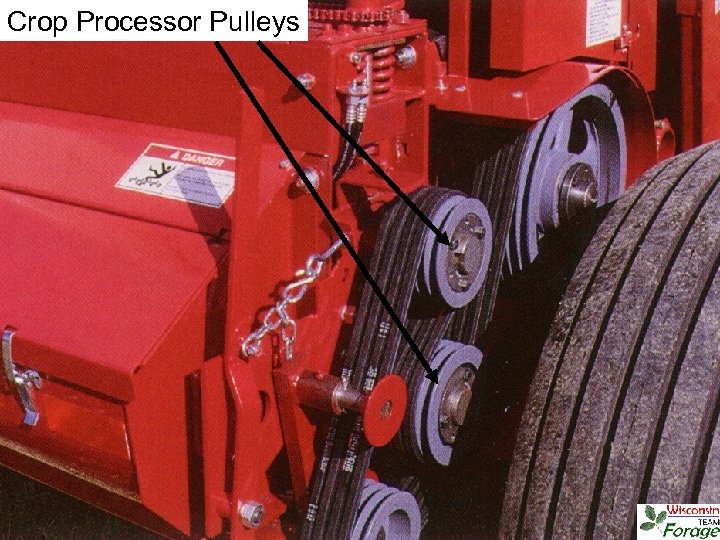

Crop Processor Pulleys

Crop Processor Pulleys

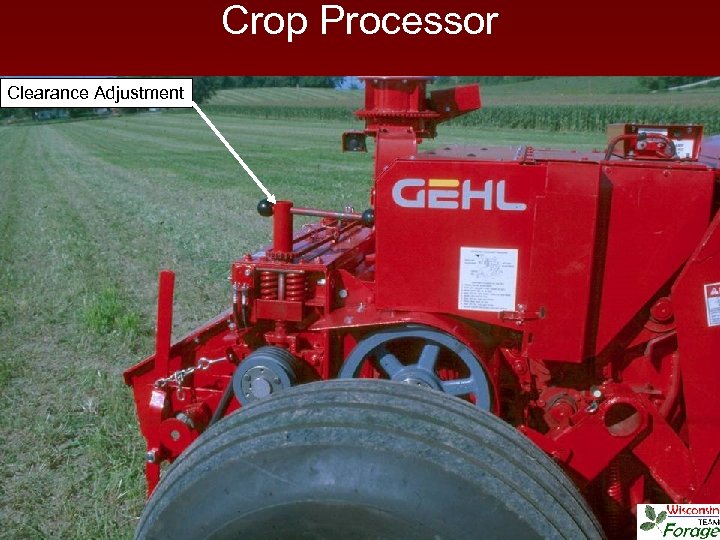

Crop Processor Clearance Adjustment

Crop Processor Clearance Adjustment

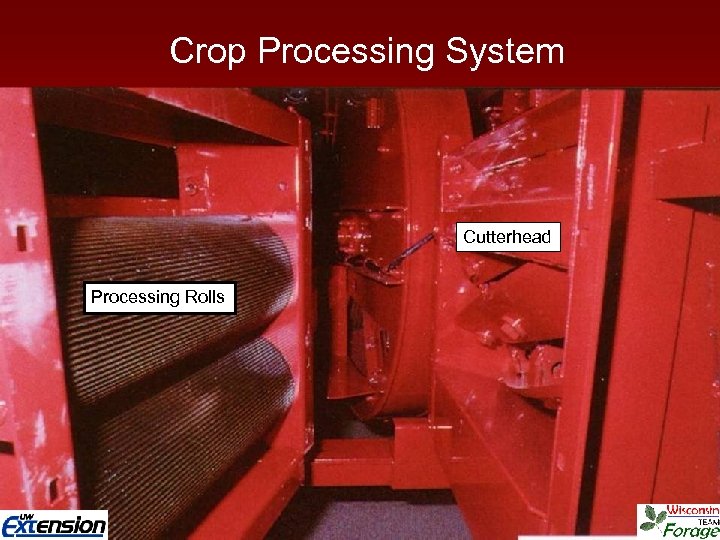

Crop Processing System Cutterhead Processing Rolls

Crop Processing System Cutterhead Processing Rolls

Differential speed between rolls

Differential speed between rolls

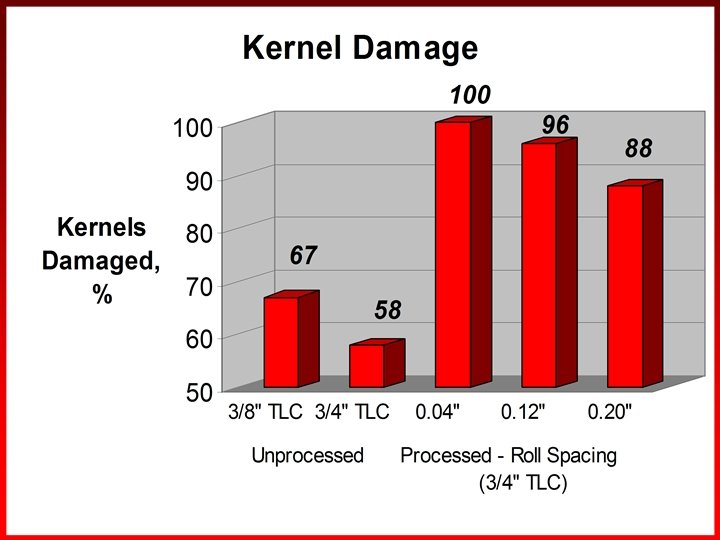

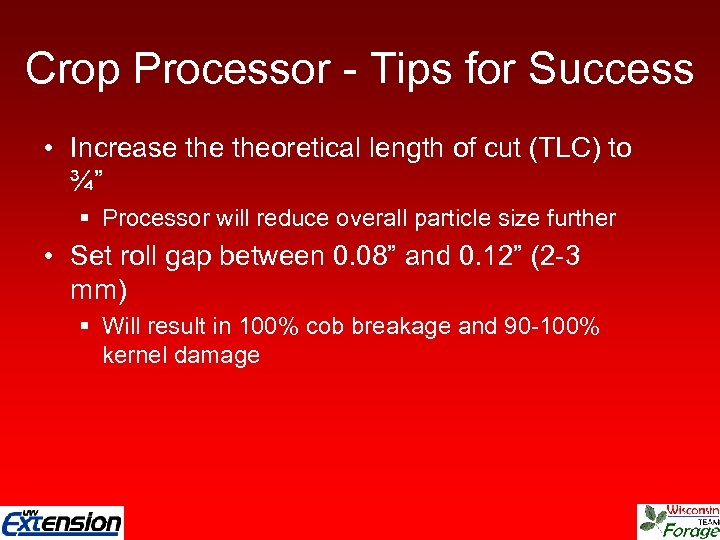

Crop Processor - Tips for Success • Increase theoretical length of cut (TLC) to ¾” § Processor will reduce overall particle size further • Set roll gap between 0. 08” and 0. 12” (2 -3 mm) § Will result in 100% cob breakage and 90 -100% kernel damage

Crop Processor - Tips for Success • Increase theoretical length of cut (TLC) to ¾” § Processor will reduce overall particle size further • Set roll gap between 0. 08” and 0. 12” (2 -3 mm) § Will result in 100% cob breakage and 90 -100% kernel damage

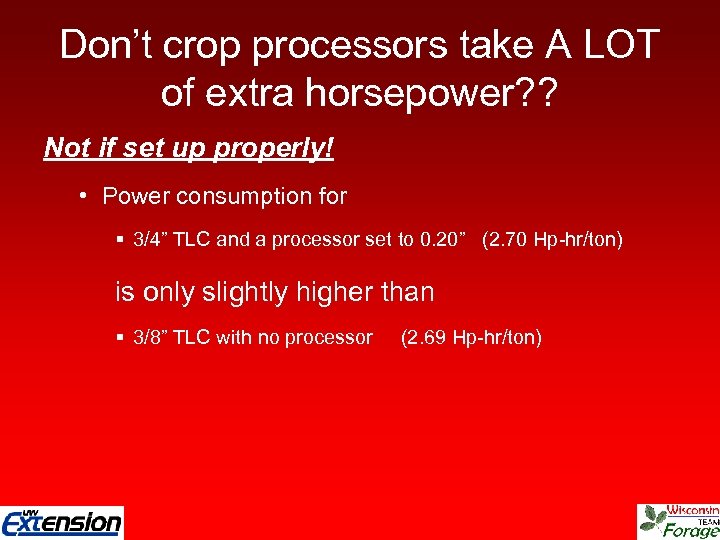

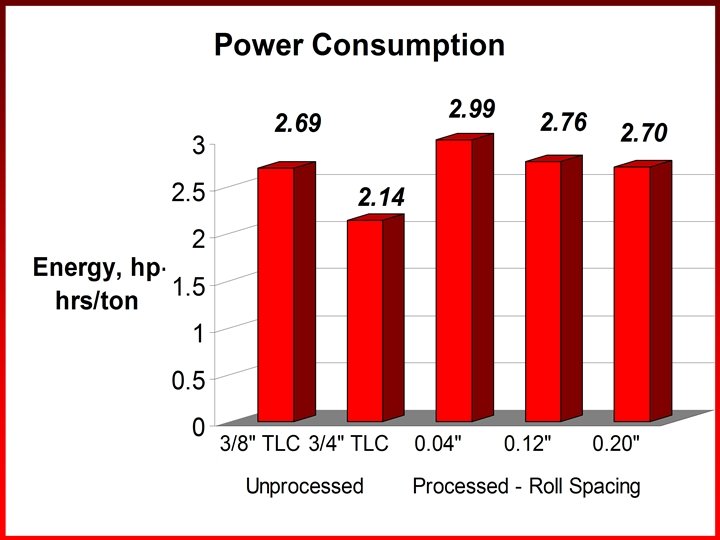

Don’t crop processors take A LOT of extra horsepower? ? Not if set up properly! • Power consumption for § 3/4” TLC and a processor set to 0. 20” (2. 70 Hp-hr/ton) is only slightly higher than § 3/8” TLC with no processor (2. 69 Hp-hr/ton)

Don’t crop processors take A LOT of extra horsepower? ? Not if set up properly! • Power consumption for § 3/4” TLC and a processor set to 0. 20” (2. 70 Hp-hr/ton) is only slightly higher than § 3/8” TLC with no processor (2. 69 Hp-hr/ton)

Roll Wear § PTFH - Rolls Wear At Center § SPFH - Rolls Wear At Edges § Helical Knives - Uneven Wear § As Teeth Wear: • Capacity Is Reduced • Plugging More Likely • Processing More Difficult

Roll Wear § PTFH - Rolls Wear At Center § SPFH - Rolls Wear At Edges § Helical Knives - Uneven Wear § As Teeth Wear: • Capacity Is Reduced • Plugging More Likely • Processing More Difficult

Dealing with Worn Rolls § Replacement ~ $1, 500 per Roll § Re-Grooving ~ 1/3 to 1/2 Cost of New § Re-Grooving Considerations: h Won’t Last As Long As Original h Can Only Be Done Once h Tolerances Not As Good

Dealing with Worn Rolls § Replacement ~ $1, 500 per Roll § Re-Grooving ~ 1/3 to 1/2 Cost of New § Re-Grooving Considerations: h Won’t Last As Long As Original h Can Only Be Done Once h Tolerances Not As Good

WHAT TO LOOK FOR IN A CROP PROCESSOR § Roll Diameter § Tooth Pitch § Ease of Checking and Adjusting Roll Clearance § Ease of Unplugging § Ease of Switching Between Corn silage and Haylage

WHAT TO LOOK FOR IN A CROP PROCESSOR § Roll Diameter § Tooth Pitch § Ease of Checking and Adjusting Roll Clearance § Ease of Unplugging § Ease of Switching Between Corn silage and Haylage

Machine Power Consumption § Gathering and feeding • 20% of total § Cutterhead and processor • 40 – 50% of total § Blowing into wagon / truck • 30 – 40% of total

Machine Power Consumption § Gathering and feeding • 20% of total § Cutterhead and processor • 40 – 50% of total § Blowing into wagon / truck • 30 – 40% of total

Reducing Power Loss § § Maintain sharp knives Keep close knife to shearbar clearance Properly adjust processor Keep blower band clearance small

Reducing Power Loss § § Maintain sharp knives Keep close knife to shearbar clearance Properly adjust processor Keep blower band clearance small

Concluding Remarks § No Processor-TLC=0. 375 in. § Processor-TLC = 0. 75 in and roll clearance= 0. 8 to 0. 12 in.

Concluding Remarks § No Processor-TLC=0. 375 in. § Processor-TLC = 0. 75 in and roll clearance= 0. 8 to 0. 12 in.

Questions

Questions

QUESTIONS

QUESTIONS