bea7e44fa74ad9b408b3d8f327e768f5.ppt

- Количество слайдов: 85

Adhesive Selection & Characterization What You Don't Know Can Kill You Blain Olbert University of Arizona Steward Observatory Mirror Lab UASO Engineering Seminar, Aug 04 1

Adhesive Selection & Characterization What You Don't Know Can Kill You Blain Olbert University of Arizona Steward Observatory Mirror Lab UASO Engineering Seminar, Aug 04 1

Objective ® Present a general overview of adhesive bonding issues to raise the designer’s “awareness level. ” ® Strength & longevity of polymer adhesive bonds is the focus topic. ® Discuss recent findings that show conventional design philosophy fails. ® Describe test facilities at UASO-ML for adhesive bond characterization. UASO Engineering Seminar, Aug 04 2

Objective ® Present a general overview of adhesive bonding issues to raise the designer’s “awareness level. ” ® Strength & longevity of polymer adhesive bonds is the focus topic. ® Discuss recent findings that show conventional design philosophy fails. ® Describe test facilities at UASO-ML for adhesive bond characterization. UASO Engineering Seminar, Aug 04 2

Scope ® The presentation is aimed at practicing designers with some understanding of damage micromechanics, polymer chemistry & polymer physics. UASO Engineering Seminar, Aug 04 3

Scope ® The presentation is aimed at practicing designers with some understanding of damage micromechanics, polymer chemistry & polymer physics. UASO Engineering Seminar, Aug 04 3

Scope limitations ® This is not a detailed recipe for selection & characterization of adhesive. ® No such recipe exists! UASO Engineering Seminar, Aug 04 4

Scope limitations ® This is not a detailed recipe for selection & characterization of adhesive. ® No such recipe exists! UASO Engineering Seminar, Aug 04 4

Adhesive fundamentals ® The basic function of adhesive is to join parts. Adhesives offer alternatives to conventional joining methods such as soldering, welding & bolting. ® Some materials need adhesively bonded joins for optimum or adequate performance. ® Prime example: joining of notch sensitive “brittle” materials that are intolerant of bolt holes (e. g. , engineering composites, ceramics, glass). ® UASO Engineering Seminar, Aug 04 5

Adhesive fundamentals ® The basic function of adhesive is to join parts. Adhesives offer alternatives to conventional joining methods such as soldering, welding & bolting. ® Some materials need adhesively bonded joins for optimum or adequate performance. ® Prime example: joining of notch sensitive “brittle” materials that are intolerant of bolt holes (e. g. , engineering composites, ceramics, glass). ® UASO Engineering Seminar, Aug 04 5

Adhesive fundamentals ® Adhesives offer a convenient or costeffective way to join parts. ® But don’t assume adhesives are a cure-all solution for every critical joining problem. ® When long-term reliability is paramount, bolting may be the best option after the full magnitude of the problem is understood. This may hold true even though bolted connections may be difficult & expensive to implement and may significantly reduce the ultimate load bearing capacity of a structure. UASO Engineering Seminar, Aug 04 6

Adhesive fundamentals ® Adhesives offer a convenient or costeffective way to join parts. ® But don’t assume adhesives are a cure-all solution for every critical joining problem. ® When long-term reliability is paramount, bolting may be the best option after the full magnitude of the problem is understood. This may hold true even though bolted connections may be difficult & expensive to implement and may significantly reduce the ultimate load bearing capacity of a structure. UASO Engineering Seminar, Aug 04 6

Adhesive fundamentals ® Some common adhesive material classes: ® ® Polymers Metals (solders) Inorganic glass powders (“frits”, solder glasses) Polymer adhesives are the most commonly used bonding agents. ® ® Epoxies (contain the epoxide functional group) Acrylics (contain the aryl functional group) Urethanes (contain the urethane functional group) Silicones (contain the siloxane functional group) UASO Engineering Seminar, Aug 04 7

Adhesive fundamentals ® Some common adhesive material classes: ® ® Polymers Metals (solders) Inorganic glass powders (“frits”, solder glasses) Polymer adhesives are the most commonly used bonding agents. ® ® Epoxies (contain the epoxide functional group) Acrylics (contain the aryl functional group) Urethanes (contain the urethane functional group) Silicones (contain the siloxane functional group) UASO Engineering Seminar, Aug 04 7

Adhesive fundamentals ® Adhesive properties can show broad variation between & within material classes. ® ® ® The primary information source for material property data is the technical data sheet from the manufacturer. Scientific & engineering literature may contain a wealth of additional information on certain adhesives used in high-risk applications (aerospace, defense). Do a literature search. Cost of adhesive varies widely. ® Some of the better-characterized engineering adhesives are relatively inexpensive. UASO Engineering Seminar, Aug 04 8

Adhesive fundamentals ® Adhesive properties can show broad variation between & within material classes. ® ® ® The primary information source for material property data is the technical data sheet from the manufacturer. Scientific & engineering literature may contain a wealth of additional information on certain adhesives used in high-risk applications (aerospace, defense). Do a literature search. Cost of adhesive varies widely. ® Some of the better-characterized engineering adhesives are relatively inexpensive. UASO Engineering Seminar, Aug 04 8

Adhesive fundamentals ® Polymer rapidly. adhesive technology advances Survey current offerings before you pick adhesive for a new application or review an old application. ® Do not assume “rules” forever hold true, such as “epoxies are brittle. ” New nano processing technologies, such as polymer chain engineering at the molecular level, are re-writing the rules. ® Even polymer experts do not fully understand the mechanical properties of adhesives. Designer beware! ® UASO Engineering Seminar, Aug 04 9

Adhesive fundamentals ® Polymer rapidly. adhesive technology advances Survey current offerings before you pick adhesive for a new application or review an old application. ® Do not assume “rules” forever hold true, such as “epoxies are brittle. ” New nano processing technologies, such as polymer chain engineering at the molecular level, are re-writing the rules. ® Even polymer experts do not fully understand the mechanical properties of adhesives. Designer beware! ® UASO Engineering Seminar, Aug 04 9

Chemistry fundamentals ® Polymer structure ® The fundamental molecular building blocks of a polymer are monomers. Polymer means “many mers. ” ® Monomers generally consist of several atoms that are chemically bonded to one another. ® One or more atoms of the monomer are chemically reactive and will bond to other monomer atoms under certain conditions. UASO Engineering Seminar, Aug 04 10

Chemistry fundamentals ® Polymer structure ® The fundamental molecular building blocks of a polymer are monomers. Polymer means “many mers. ” ® Monomers generally consist of several atoms that are chemically bonded to one another. ® One or more atoms of the monomer are chemically reactive and will bond to other monomer atoms under certain conditions. UASO Engineering Seminar, Aug 04 10

Chemistry fundamentals ® Polymer structure ® The characteristic 3 D molecular chain structure of a polymer is built-up as the monomers link together in a controlled chemical reaction. ® The degree of polymerization of monomers (i. e. , molecule chain length between crosslinks & number of crosslinks between chains) impacts the mechanical properties. UASO Engineering Seminar, Aug 04 11

Chemistry fundamentals ® Polymer structure ® The characteristic 3 D molecular chain structure of a polymer is built-up as the monomers link together in a controlled chemical reaction. ® The degree of polymerization of monomers (i. e. , molecule chain length between crosslinks & number of crosslinks between chains) impacts the mechanical properties. UASO Engineering Seminar, Aug 04 11

Chemistry fundamentals ® Polymer structure ® The polymerization chemistry of commercial adhesives is usually complex. ® A initiator (cross-linking agent and/or a catalyst) is purposely introduced to trigger the polymerization reaction of the “base” material & “cure” the adhesive. There are two popular cure systems: l “two-part” system: the initiator is mixed into the base just before use. l “one-part” system: the initiator is water vapor that’s introduced to base by exposure to ambient air. UASO Engineering Seminar, Aug 04 12

Chemistry fundamentals ® Polymer structure ® The polymerization chemistry of commercial adhesives is usually complex. ® A initiator (cross-linking agent and/or a catalyst) is purposely introduced to trigger the polymerization reaction of the “base” material & “cure” the adhesive. There are two popular cure systems: l “two-part” system: the initiator is mixed into the base just before use. l “one-part” system: the initiator is water vapor that’s introduced to base by exposure to ambient air. UASO Engineering Seminar, Aug 04 12

Chemistry fundamentals ® Polymer structure ® Adhesive base material is usually short chain molecules that were prepared by controlled monomer reactions. ® Since chain properties (overall length, entanglement tendency, etc. ) control viscosity of the base material, the same adhesive may come in a range of viscosities. UASO Engineering Seminar, Aug 04 13

Chemistry fundamentals ® Polymer structure ® Adhesive base material is usually short chain molecules that were prepared by controlled monomer reactions. ® Since chain properties (overall length, entanglement tendency, etc. ) control viscosity of the base material, the same adhesive may come in a range of viscosities. UASO Engineering Seminar, Aug 04 13

Chemistry fundamentals ® Curing characteristics ® ® ® One-part systems cure by diffusion of initiator thru the bond. Years may be needed for a thick bond to fully cure! Two-part systems cure uniformly throughout the bulk and so are preferred for thick section bonds. Both one-part & two-parts systems nearly always emit reaction products ® ® Reaction products may be corrosive (e. g. , acetic acid) or flammable (e. g. , methanol). Read the data sheet! If the reaction products are not removed by diffusion, the curing reaction will slow down & possibly reverse itself (depolymerization or “reversion”). UASO Engineering Seminar, Aug 04 14

Chemistry fundamentals ® Curing characteristics ® ® ® One-part systems cure by diffusion of initiator thru the bond. Years may be needed for a thick bond to fully cure! Two-part systems cure uniformly throughout the bulk and so are preferred for thick section bonds. Both one-part & two-parts systems nearly always emit reaction products ® ® Reaction products may be corrosive (e. g. , acetic acid) or flammable (e. g. , methanol). Read the data sheet! If the reaction products are not removed by diffusion, the curing reaction will slow down & possibly reverse itself (depolymerization or “reversion”). UASO Engineering Seminar, Aug 04 14

Chemistry fundamentals ® Bulk properties ® Bulk physical properties (e. g. , mechanical properties, thermal properties, etc. ) depend on monomer properties & chain structure. ® Bulk properties, by definition, are not influenced by the chemistry & physics of interfaces. UASO Engineering Seminar, Aug 04 15

Chemistry fundamentals ® Bulk properties ® Bulk physical properties (e. g. , mechanical properties, thermal properties, etc. ) depend on monomer properties & chain structure. ® Bulk properties, by definition, are not influenced by the chemistry & physics of interfaces. UASO Engineering Seminar, Aug 04 15

Chemistry fundamentals ® Interface properties Adhesion is an interface property that influences the fundamental bond strength between substrate & adhesive. ® Adhesion is controlled by surface chemistry. During cure, full adhesion properties typically develop hours or days after bulk properties. ® Surface chemistry is notoriously susceptible to trace quantities of molecular compounds. Pay attention to purity of cleaning chemicals & solvents; chemical compatibility of storage, mixing & applicator materials. ® UASO Engineering Seminar, Aug 04 16

Chemistry fundamentals ® Interface properties Adhesion is an interface property that influences the fundamental bond strength between substrate & adhesive. ® Adhesion is controlled by surface chemistry. During cure, full adhesion properties typically develop hours or days after bulk properties. ® Surface chemistry is notoriously susceptible to trace quantities of molecular compounds. Pay attention to purity of cleaning chemicals & solvents; chemical compatibility of storage, mixing & applicator materials. ® UASO Engineering Seminar, Aug 04 16

Chemistry fundamentals ® Interface properties Adhesion, like any property that depends on surface or interface chemistry & physics, can posses bewildering complexity. ® Commercial adhesives often contain small quantities of molecular compounds to promote adhesion. ® Some adhesive formulations, when used with certain substrates, require adhesion promoters (primers) - the property data sheet should tell you this. ® UASO Engineering Seminar, Aug 04 17

Chemistry fundamentals ® Interface properties Adhesion, like any property that depends on surface or interface chemistry & physics, can posses bewildering complexity. ® Commercial adhesives often contain small quantities of molecular compounds to promote adhesion. ® Some adhesive formulations, when used with certain substrates, require adhesion promoters (primers) - the property data sheet should tell you this. ® UASO Engineering Seminar, Aug 04 17

Chemistry fundamentals ® Interface properties ® Precisely why adhesion promoters work is rarely understood - formulation of promoters is a quasiempirical, black art. Their use must be tested in your specific application. ® ® Temperature & humidity generally play important roles in primer activation, and must be monitored & controlled if possible. Surface cleanliness is critical to adhesion. A consistent surface preparation technique, executed by process procedures, is essential. UASO Engineering Seminar, Aug 04 18

Chemistry fundamentals ® Interface properties ® Precisely why adhesion promoters work is rarely understood - formulation of promoters is a quasiempirical, black art. Their use must be tested in your specific application. ® ® Temperature & humidity generally play important roles in primer activation, and must be monitored & controlled if possible. Surface cleanliness is critical to adhesion. A consistent surface preparation technique, executed by process procedures, is essential. UASO Engineering Seminar, Aug 04 18

Mechanics fundamentals ® Strength is defined here as stress at rupture. ® Rupture is due to propagation of damage through the bond. When damage accumulates to a critical level, the bond ruptures. ® Because strength depends on the rupture condition, its fate is tied to the details of damage evolution. UASO Engineering Seminar, Aug 04 19

Mechanics fundamentals ® Strength is defined here as stress at rupture. ® Rupture is due to propagation of damage through the bond. When damage accumulates to a critical level, the bond ruptures. ® Because strength depends on the rupture condition, its fate is tied to the details of damage evolution. UASO Engineering Seminar, Aug 04 19

Mechanics fundamentals ® Strength ® The rupture condition for a given material cannot be predicted from the laws of mechanics alone. Experimental data are needed (e. g. , toughness – a material property, flaw size – usually a specimen property that can vary significantly). UASO Engineering Seminar, Aug 04 20

Mechanics fundamentals ® Strength ® The rupture condition for a given material cannot be predicted from the laws of mechanics alone. Experimental data are needed (e. g. , toughness – a material property, flaw size – usually a specimen property that can vary significantly). UASO Engineering Seminar, Aug 04 20

Mechanics fundamentals ® Damage ® “Damage” as used here is an umbrella term that includes many different specific mechanisms such as: ® ® ® Initiation & growth of quasi-homogeneously distributed damage such as microcracks or microcavities. Initiation & growth of a discrete crack. Damage initiation begins at the atomic level and so is fundamentally governed by quantum physics, not classical physics. UASO Engineering Seminar, Aug 04 21

Mechanics fundamentals ® Damage ® “Damage” as used here is an umbrella term that includes many different specific mechanisms such as: ® ® ® Initiation & growth of quasi-homogeneously distributed damage such as microcracks or microcavities. Initiation & growth of a discrete crack. Damage initiation begins at the atomic level and so is fundamentally governed by quantum physics, not classical physics. UASO Engineering Seminar, Aug 04 21

Mechanics fundamentals ® Damage ® When the spatial extent of damage is sufficiently large & homogeneous, classical field equations & the laws of continuum mechanics can be used to characterize damage. ® Classical fracture mechanics is a special damage case where evolution of a discrete, well-defined crack is described by the laws of continuum mechanics & constitutive laws for sub-critical crack growth (e. g. , chemically-assisted crack growth). UASO Engineering Seminar, Aug 04 22

Mechanics fundamentals ® Damage ® When the spatial extent of damage is sufficiently large & homogeneous, classical field equations & the laws of continuum mechanics can be used to characterize damage. ® Classical fracture mechanics is a special damage case where evolution of a discrete, well-defined crack is described by the laws of continuum mechanics & constitutive laws for sub-critical crack growth (e. g. , chemically-assisted crack growth). UASO Engineering Seminar, Aug 04 22

Mechanics fundamentals ® Damage ® Critical damage usually appears first at corner or edge fillets due to localized stress concentrations plus direct exposure to corrosive species in the environment. UASO Engineering Seminar, Aug 04 23

Mechanics fundamentals ® Damage ® Critical damage usually appears first at corner or edge fillets due to localized stress concentrations plus direct exposure to corrosive species in the environment. UASO Engineering Seminar, Aug 04 23

Mechanics fundamentals ® Damage ® Fractography (analysis of fracture surfaces) often gives valuable insight into the damage evolution process. Preserve your test specimens. ® Accurate & full interpretation of fracture surfaces is an expert, specialized skill usually practiced by consultants. A few textbooks discuss fractography. UASO Engineering Seminar, Aug 04 24

Mechanics fundamentals ® Damage ® Fractography (analysis of fracture surfaces) often gives valuable insight into the damage evolution process. Preserve your test specimens. ® Accurate & full interpretation of fracture surfaces is an expert, specialized skill usually practiced by consultants. A few textbooks discuss fractography. UASO Engineering Seminar, Aug 04 24

Mechanics fundamentals ® Damage ® The precise way that critical damage accumulates in a given material varies from specimen to specimen even with specimens of the same geometry under the same loading condition. ® Hence strength, which depends on the critical damage level, is not a true material constant. l The apparent exception of note is the (ultimate) strength of ductile engineering alloys with or without notches. But the constant strength approximation breaks down in extreme cases where a notch is present in a very large specimen. UASO Engineering Seminar, Aug 04 25

Mechanics fundamentals ® Damage ® The precise way that critical damage accumulates in a given material varies from specimen to specimen even with specimens of the same geometry under the same loading condition. ® Hence strength, which depends on the critical damage level, is not a true material constant. l The apparent exception of note is the (ultimate) strength of ductile engineering alloys with or without notches. But the constant strength approximation breaks down in extreme cases where a notch is present in a very large specimen. UASO Engineering Seminar, Aug 04 25

Mechanics fundamentals ® Basic damage modes ® Cohesive failure results from critical damage in the bulk region of the bond. ® Adhesive failure results from critical damage along the interface between substrate & adhesive. ® We implicitly assume the substrate does not fail (cohesive or adhesive). ® If the substrate fails, then the strongest possible bond has been achieved. UASO Engineering Seminar, Aug 04 26

Mechanics fundamentals ® Basic damage modes ® Cohesive failure results from critical damage in the bulk region of the bond. ® Adhesive failure results from critical damage along the interface between substrate & adhesive. ® We implicitly assume the substrate does not fail (cohesive or adhesive). ® If the substrate fails, then the strongest possible bond has been achieved. UASO Engineering Seminar, Aug 04 26

Mechanics fundamentals ® Cohesive failure ® Always associated with the strongest possible bond. ® Goal is to achieve cohesive failure every time by proper adhesive-primer selection & development of good bond preparation technique. UASO Engineering Seminar, Aug 04 27

Mechanics fundamentals ® Cohesive failure ® Always associated with the strongest possible bond. ® Goal is to achieve cohesive failure every time by proper adhesive-primer selection & development of good bond preparation technique. UASO Engineering Seminar, Aug 04 27

Mechanics fundamentals ® Adhesive failure ® Usually occurs from poor bonding of adhesive to substrate. Strength depends on interface properties & interface mechanics - not bulk properties per se. ® Strength is very sensitive to surface preparation method due to the importance of interface chemistry. UASO Engineering Seminar, Aug 04 28

Mechanics fundamentals ® Adhesive failure ® Usually occurs from poor bonding of adhesive to substrate. Strength depends on interface properties & interface mechanics - not bulk properties per se. ® Strength is very sensitive to surface preparation method due to the importance of interface chemistry. UASO Engineering Seminar, Aug 04 28

Mechanics fundamentals ® Adhesive ® ® failure Strength may be increased by changing surface preparation method and by using a proper adhesion promoter or “primer. ” ® Most primers are fussy & substrate specific – they must be used with care & consistency. Damage predictions based on bulk material behavior are usually erroneous. ® Interface properties may have no relation to measured bulk properties! ® Do not confuse bulk strength with adhesive bond strength. Sometimes both values are quoted on data sheets. UASO Engineering Seminar, Aug 04 29

Mechanics fundamentals ® Adhesive ® ® failure Strength may be increased by changing surface preparation method and by using a proper adhesion promoter or “primer. ” ® Most primers are fussy & substrate specific – they must be used with care & consistency. Damage predictions based on bulk material behavior are usually erroneous. ® Interface properties may have no relation to measured bulk properties! ® Do not confuse bulk strength with adhesive bond strength. Sometimes both values are quoted on data sheets. UASO Engineering Seminar, Aug 04 29

Design guidelines ® The “golden rule” for design with adhesive: ® Never conceptualize a design that requires a critical adhesive bond without addressing the bond problem early on. UASO Engineering Seminar, Aug 04 30

Design guidelines ® The “golden rule” for design with adhesive: ® Never conceptualize a design that requires a critical adhesive bond without addressing the bond problem early on. UASO Engineering Seminar, Aug 04 30

Design guidelines ® General recommendations: ® Always use pedigreed engineering adhesive. ® Do not use adhesive if very-high, quantifiable bond reliability is required for a long time (>10 years) unless hard data or past experience prove that the specific adhesive meets the requirements under all conditions. UASO Engineering Seminar, Aug 04 31

Design guidelines ® General recommendations: ® Always use pedigreed engineering adhesive. ® Do not use adhesive if very-high, quantifiable bond reliability is required for a long time (>10 years) unless hard data or past experience prove that the specific adhesive meets the requirements under all conditions. UASO Engineering Seminar, Aug 04 31

Design guidelines ® Problem background work ® In addition to detailed stress analysis, obtain a complete description of the problem such as: ® Operating environment details l Temperature, humidity, chemical species present. l Extreme environmental conditions & the time spent at those conditions. ® Substrate particulars l Standard metallic alloys: specify alloy designation (AISI, SAE), heat treatment condition & other form/physical conditions. l Glasses & ceramics: specify chemistry, physical properties, anneal condition. l Polymers: specify chemistry & physical properties. UASO Engineering Seminar, Aug 04 32

Design guidelines ® Problem background work ® In addition to detailed stress analysis, obtain a complete description of the problem such as: ® Operating environment details l Temperature, humidity, chemical species present. l Extreme environmental conditions & the time spent at those conditions. ® Substrate particulars l Standard metallic alloys: specify alloy designation (AISI, SAE), heat treatment condition & other form/physical conditions. l Glasses & ceramics: specify chemistry, physical properties, anneal condition. l Polymers: specify chemistry & physical properties. UASO Engineering Seminar, Aug 04 32

Design guidelines ® Problem background work ® Pay close attention to the operational temperature range. ® ® Polymers become brittle & show remarkably different properties when taken below their glass transition temperature (Tg). Find Tg for your adhesive! Polymers creep at widely different rates. If bond dimensional stability is important, be aware of creep. l Creep rate usually increases exponentially with temperature and sometimes applied stress. Creep rate also increases with humidity level for most adhesives. UASO Engineering Seminar, Aug 04 33

Design guidelines ® Problem background work ® Pay close attention to the operational temperature range. ® ® Polymers become brittle & show remarkably different properties when taken below their glass transition temperature (Tg). Find Tg for your adhesive! Polymers creep at widely different rates. If bond dimensional stability is important, be aware of creep. l Creep rate usually increases exponentially with temperature and sometimes applied stress. Creep rate also increases with humidity level for most adhesives. UASO Engineering Seminar, Aug 04 33

Design guidelines ® Problem ® Bond ® longevity What is the reliability requirement? l ® background work <1% failure probability over life? What is the average lifetime requirement? l 1 yr? 50 yr? UASO Engineering Seminar, Aug 04 34

Design guidelines ® Problem ® Bond ® longevity What is the reliability requirement? l ® background work <1% failure probability over life? What is the average lifetime requirement? l 1 yr? 50 yr? UASO Engineering Seminar, Aug 04 34

Design guidelines ® Collate data ® Compare all of the forgoing requirements to published adhesive property data. ® ® ® Does the adhesive meet all requirements under all operating conditions? What vital adhesive property information is missing? If the known property database does not address all requirements, you have a potentially serious problem. l It’s time to get help & put on the lab coat, or find a different adhesive that’s better characterized. UASO Engineering Seminar, Aug 04 35

Design guidelines ® Collate data ® Compare all of the forgoing requirements to published adhesive property data. ® ® ® Does the adhesive meet all requirements under all operating conditions? What vital adhesive property information is missing? If the known property database does not address all requirements, you have a potentially serious problem. l It’s time to get help & put on the lab coat, or find a different adhesive that’s better characterized. UASO Engineering Seminar, Aug 04 35

Processing guidelines ® Before you make a bond: ® Collect all existing processing procedures. ® ® Scour the technical data sheet for processing information (i. e. , the details about how the bonds were prepared). Request processing information from the technical representative. Search the literature. If there is no processing procedure, you must prepare one to raise the odds of making consistent bonds & to provide a future reference benchmark. UASO Engineering Seminar, Aug 04 36

Processing guidelines ® Before you make a bond: ® Collect all existing processing procedures. ® ® Scour the technical data sheet for processing information (i. e. , the details about how the bonds were prepared). Request processing information from the technical representative. Search the literature. If there is no processing procedure, you must prepare one to raise the odds of making consistent bonds & to provide a future reference benchmark. UASO Engineering Seminar, Aug 04 36

Processing guidelines ® Before you make a bond ® Develop a process control punchlist. List would callout items such as: ® ® ® Critical data to log (adhesive batch numbers, batch constituent weights, date, time, temperature, humidity, etc. , and name of worker). Vacuum outgass adhesive to reduce entrapped air bubbles & dissolved gasses that can precipitate as bubbles when the adhesive cures. Bubble defects decrease strength. Witness sample preparation scheme. Always make witness samples and keep leftover batch! UASO Engineering Seminar, Aug 04 37

Processing guidelines ® Before you make a bond ® Develop a process control punchlist. List would callout items such as: ® ® ® Critical data to log (adhesive batch numbers, batch constituent weights, date, time, temperature, humidity, etc. , and name of worker). Vacuum outgass adhesive to reduce entrapped air bubbles & dissolved gasses that can precipitate as bubbles when the adhesive cures. Bubble defects decrease strength. Witness sample preparation scheme. Always make witness samples and keep leftover batch! UASO Engineering Seminar, Aug 04 37

Design pitfalls ® Do not assume that the strength factor-of-safety (FOS) design strategy applies to adhesive. ® ® FOS was developed & proven for ductile engineering alloys in static, non-corrosive, non-creep conditions. A static (time-independent) FOS cannot be applied unless the adhesive is below its damage threshold. l Examples of materials with no damage threshold: superalloys used at high temperature; silicate glass (controversial subject) UASO Engineering Seminar, Aug 04 38

Design pitfalls ® Do not assume that the strength factor-of-safety (FOS) design strategy applies to adhesive. ® ® FOS was developed & proven for ductile engineering alloys in static, non-corrosive, non-creep conditions. A static (time-independent) FOS cannot be applied unless the adhesive is below its damage threshold. l Examples of materials with no damage threshold: superalloys used at high temperature; silicate glass (controversial subject) UASO Engineering Seminar, Aug 04 38

Design pitfalls ® Stress analysis ® Analyze the exact bond geometry in detail, especially stresses near corners & fillets. Critical damage will nearly always initiate in the region of highest stress. ® Analysis must include all driving forces such as: ® Residual stresses caused by bulk expansion/contraction of adhesive during curing. ® Differential thermal stresses. UASO Engineering Seminar, Aug 04 39

Design pitfalls ® Stress analysis ® Analyze the exact bond geometry in detail, especially stresses near corners & fillets. Critical damage will nearly always initiate in the region of highest stress. ® Analysis must include all driving forces such as: ® Residual stresses caused by bulk expansion/contraction of adhesive during curing. ® Differential thermal stresses. UASO Engineering Seminar, Aug 04 39

Design pitfalls ® Fracture mechanics & strength ® ® ® Nearly all polymers (including elastomers) behave as brittle materials, and so linear elastic fracture mechanics can be used to estimate strength. ® This implies that a constant toughness serves to characterize energy dissipation in the fracture process zone. Note this implicitly assumes that the fracture process zone is small compared to specimen dimensions. In bonds, the substrate constrains the free-development of damage compared to bulk. Interface mechanics become important. Fracture mechanics estimates of bond strength based on cracks in bulk material are still useful for benchmark comparisons. UASO Engineering Seminar, Aug 04 40

Design pitfalls ® Fracture mechanics & strength ® ® ® Nearly all polymers (including elastomers) behave as brittle materials, and so linear elastic fracture mechanics can be used to estimate strength. ® This implies that a constant toughness serves to characterize energy dissipation in the fracture process zone. Note this implicitly assumes that the fracture process zone is small compared to specimen dimensions. In bonds, the substrate constrains the free-development of damage compared to bulk. Interface mechanics become important. Fracture mechanics estimates of bond strength based on cracks in bulk material are still useful for benchmark comparisons. UASO Engineering Seminar, Aug 04 40

Design pitfalls ® The implicit assumption that materials exist which meet every imagined requirement is poor design practice. ® Keep the design envelope within easy reach of existing materials. Use your mechanical ingenuity to overcome material limitations. UASO Engineering Seminar, Aug 04 41

Design pitfalls ® The implicit assumption that materials exist which meet every imagined requirement is poor design practice. ® Keep the design envelope within easy reach of existing materials. Use your mechanical ingenuity to overcome material limitations. UASO Engineering Seminar, Aug 04 41

Facts of life ® Lifetime is the fundamental design metric. Nothing physical lasts forever. No bond lasts forever. Lifetime depends on strain level & environment (temperature, humidity, chemical species present, etc. . ) ® Probabilistic lifetime is the most useful design parameter but is rarely ever addressed explicitly. ® UASO Engineering Seminar, Aug 04 42

Facts of life ® Lifetime is the fundamental design metric. Nothing physical lasts forever. No bond lasts forever. Lifetime depends on strain level & environment (temperature, humidity, chemical species present, etc. . ) ® Probabilistic lifetime is the most useful design parameter but is rarely ever addressed explicitly. ® UASO Engineering Seminar, Aug 04 42

Facts of life ® Most time-delayed bond failures observed in the field are adhesive failures. ® This can happen even though short-time lab tests always showed cohesive failure! ® Such is the insidious nature of interface damage processes. UASO Engineering Seminar, Aug 04 43

Facts of life ® Most time-delayed bond failures observed in the field are adhesive failures. ® This can happen even though short-time lab tests always showed cohesive failure! ® Such is the insidious nature of interface damage processes. UASO Engineering Seminar, Aug 04 43

Facts of life Damage may propagate in time through the bulk adhesive, along the adhesive-substrate interface, or a combination of bulk & interface (mixed failure). ® Sometimes the substrate suffers critical damage over time by corrosion or weathering that undermines the adhesive bond. ® ® Propagating damage may therefore change mode from cohesive to adhesive over time. UASO Engineering Seminar, Aug 04 44

Facts of life Damage may propagate in time through the bulk adhesive, along the adhesive-substrate interface, or a combination of bulk & interface (mixed failure). ® Sometimes the substrate suffers critical damage over time by corrosion or weathering that undermines the adhesive bond. ® ® Propagating damage may therefore change mode from cohesive to adhesive over time. UASO Engineering Seminar, Aug 04 44

Facts of life ® There are no specific rules, formulas or procedures to predict adhesive bond lifetime. ® ® Barring quality lifetime data from the lab, field data are the best source of information. Determination of accurate bond lifetime predictor equations requires extensive experimental testing & fitting to theoretical or empirical models. ® Such data is rarely available to the design engineer. UASO Engineering Seminar, Aug 04 45

Facts of life ® There are no specific rules, formulas or procedures to predict adhesive bond lifetime. ® ® Barring quality lifetime data from the lab, field data are the best source of information. Determination of accurate bond lifetime predictor equations requires extensive experimental testing & fitting to theoretical or empirical models. ® Such data is rarely available to the design engineer. UASO Engineering Seminar, Aug 04 45

Accelerated testing is the favorite red herring of lifetime prediction novices. ® There are serious questions associated with accelerated testing: ® ® ® Precisely what damage mechanism/s are being accelerated? Are you accelerating the mechanism that’s active at nominal conditions and only that mechanism? What is the appropriate acceleration variable? ® Elevated temperature? Elevated stress? Elevated humidity? Elevated everything? UASO Engineering Seminar, Aug 04 46

Accelerated testing is the favorite red herring of lifetime prediction novices. ® There are serious questions associated with accelerated testing: ® ® ® Precisely what damage mechanism/s are being accelerated? Are you accelerating the mechanism that’s active at nominal conditions and only that mechanism? What is the appropriate acceleration variable? ® Elevated temperature? Elevated stress? Elevated humidity? Elevated everything? UASO Engineering Seminar, Aug 04 46

Accelerated testing ® The challenge of accelerated testing: ® How do you scale lifetime under accelerated conditions back to nominal conditions? ® What is the exact functional form of the lifetime scaling equation? l l Does life decrease exponentially with increasing stress level? Does life obey time-temperature superposition? UASO Engineering Seminar, Aug 04 47

Accelerated testing ® The challenge of accelerated testing: ® How do you scale lifetime under accelerated conditions back to nominal conditions? ® What is the exact functional form of the lifetime scaling equation? l l Does life decrease exponentially with increasing stress level? Does life obey time-temperature superposition? UASO Engineering Seminar, Aug 04 47

Accelerated testing Unless the damage mechanism/s are understood in detail, and physical models exist that predict damage evolution with the accelerated variable, it’s impossible to accurately fit data to a life predictor model. ® With no fundamental understanding, the only option is quasi-empirical or purely empirical modeling. ® ® But there is no clear way to validate an empirical model unless you compare lifetime measured under nominal conditions to the predicted lifetime from accelerated testing. It‘s usually not feasible to verify lifetime of many years – if it were, you probably wouldn’t be doing accelerated testing. UASO Engineering Seminar, Aug 04 48

Accelerated testing Unless the damage mechanism/s are understood in detail, and physical models exist that predict damage evolution with the accelerated variable, it’s impossible to accurately fit data to a life predictor model. ® With no fundamental understanding, the only option is quasi-empirical or purely empirical modeling. ® ® But there is no clear way to validate an empirical model unless you compare lifetime measured under nominal conditions to the predicted lifetime from accelerated testing. It‘s usually not feasible to verify lifetime of many years – if it were, you probably wouldn’t be doing accelerated testing. UASO Engineering Seminar, Aug 04 48

What can a designer do? ® The knowledge & lab skills needed to characterize an adhesive bond lifetime is not part of formal skill training of most designers. Be absolutely certain that you must use an uncharacterized adhesive before you start an expensive, time consuming test & evaluation program. ® Seek help if you must press on & don’t know how to proceed. ® UASO Engineering Seminar, Aug 04 49

What can a designer do? ® The knowledge & lab skills needed to characterize an adhesive bond lifetime is not part of formal skill training of most designers. Be absolutely certain that you must use an uncharacterized adhesive before you start an expensive, time consuming test & evaluation program. ® Seek help if you must press on & don’t know how to proceed. ® UASO Engineering Seminar, Aug 04 49

The lifetime problem signature ® Two simple tests will show if longevity is a potential issue: A dependence of strength on testing speed indicates that a time-dependent damage mechanism is active. ® Failure after some time under static load is a surefire indication of a time-dependent damage mechanism. ® UASO Engineering Seminar, Aug 04 50

The lifetime problem signature ® Two simple tests will show if longevity is a potential issue: A dependence of strength on testing speed indicates that a time-dependent damage mechanism is active. ® Failure after some time under static load is a surefire indication of a time-dependent damage mechanism. ® UASO Engineering Seminar, Aug 04 50

The next step ® If the forgoing simple tests show there’s a potential longevity issue, further investigation is warranted. UASO Engineering Seminar, Aug 04 51

The next step ® If the forgoing simple tests show there’s a potential longevity issue, further investigation is warranted. UASO Engineering Seminar, Aug 04 51

The fatal mistake ® In spite of pitfalls, may engineers push ahead with a simple FOS or statistical strength design. ® We offer two recent case studies to prove that hidden details can kill you. ® We hope these examples may save a soul. Good luck! UASO Engineering Seminar, Aug 04 52

The fatal mistake ® In spite of pitfalls, may engineers push ahead with a simple FOS or statistical strength design. ® We offer two recent case studies to prove that hidden details can kill you. ® We hope these examples may save a soul. Good luck! UASO Engineering Seminar, Aug 04 52

Example #1: puck bond strength ® Background history ® Dow-Corning Q 3 -6093 RTV silicone has been used by UASO since 1997 as a compliant adhesive to bond high-expansion steel pucks to the backplate of low expansion mirrors. ® The mirror support system bolts into the pucks (see photos, page 54). If the bonds fail, the mirror may be destroyed & serious injury may occur. UASO Engineering Seminar, Aug 04 53

Example #1: puck bond strength ® Background history ® Dow-Corning Q 3 -6093 RTV silicone has been used by UASO since 1997 as a compliant adhesive to bond high-expansion steel pucks to the backplate of low expansion mirrors. ® The mirror support system bolts into the pucks (see photos, page 54). If the bonds fail, the mirror may be destroyed & serious injury may occur. UASO Engineering Seminar, Aug 04 53

Example #1: puck bond strength ® Background history ® Initial work by P. Gray showed an average witness puck bond shear strength of 0. 8 MPa with a standard deviation of ~10% of the mean. ® An average strength of 0. 8 MPa exceeds the highest nominal shear stress by ~10 X. UASO Engineering Seminar, Aug 04 54

Example #1: puck bond strength ® Background history ® Initial work by P. Gray showed an average witness puck bond shear strength of 0. 8 MPa with a standard deviation of ~10% of the mean. ® An average strength of 0. 8 MPa exceeds the highest nominal shear stress by ~10 X. UASO Engineering Seminar, Aug 04 54

Example #1: puck bond strength ® Background history ® At a LOTIS SRR review in 2001, B. Cuerden reported empirical data that indicated LOTIS collimator puck bonds would fail in ~15 years due to an ageweakening process. ® A study was ordered by Lockheed-Martin MPE to evaluate this critical safety threat in more detail. The foregoing slides are selected results from that study. UASO Engineering Seminar, Aug 04 55

Example #1: puck bond strength ® Background history ® At a LOTIS SRR review in 2001, B. Cuerden reported empirical data that indicated LOTIS collimator puck bonds would fail in ~15 years due to an ageweakening process. ® A study was ordered by Lockheed-Martin MPE to evaluate this critical safety threat in more detail. The foregoing slides are selected results from that study. UASO Engineering Seminar, Aug 04 55

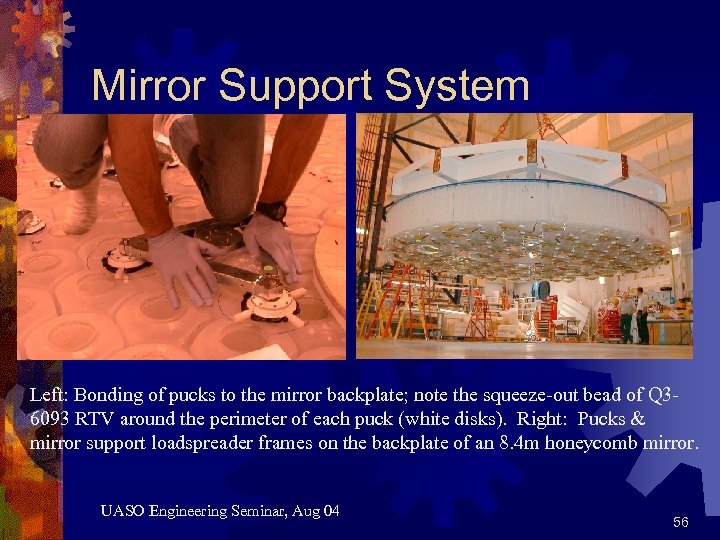

Mirror Support System Left: Bonding of pucks to the mirror backplate; note the squeeze-out bead of Q 36093 RTV around the perimeter of each puck (white disks). Right: Pucks & mirror support loadspreader frames on the backplate of an 8. 4 m honeycomb mirror. UASO Engineering Seminar, Aug 04 56

Mirror Support System Left: Bonding of pucks to the mirror backplate; note the squeeze-out bead of Q 36093 RTV around the perimeter of each puck (white disks). Right: Pucks & mirror support loadspreader frames on the backplate of an 8. 4 m honeycomb mirror. UASO Engineering Seminar, Aug 04 56

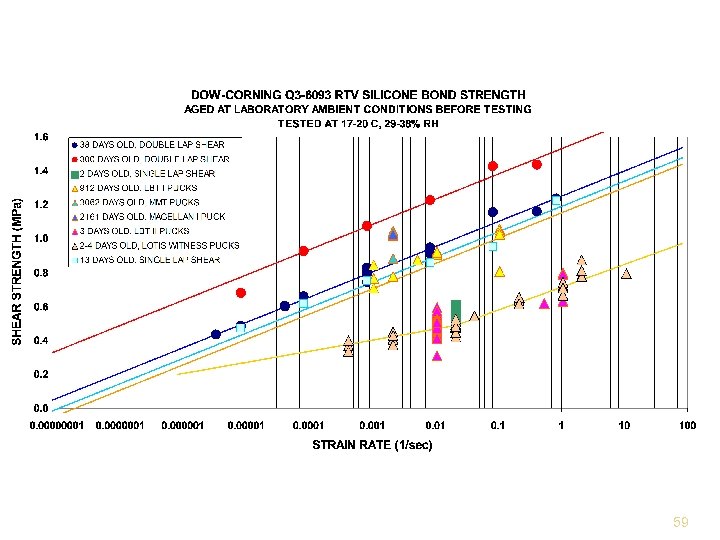

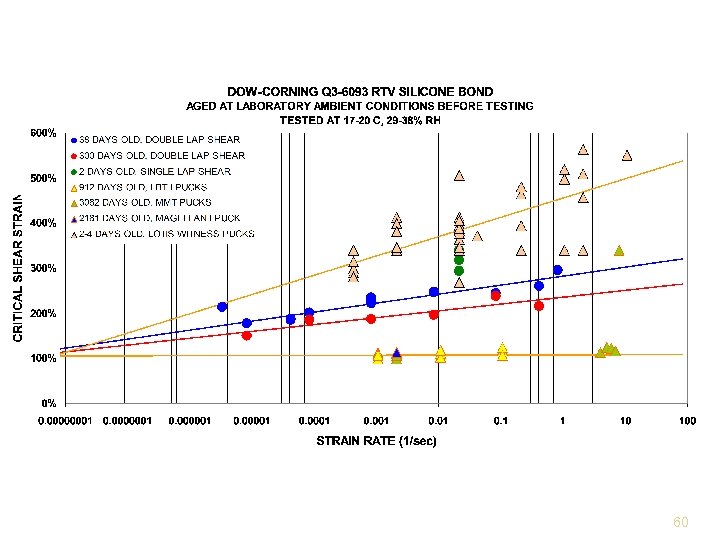

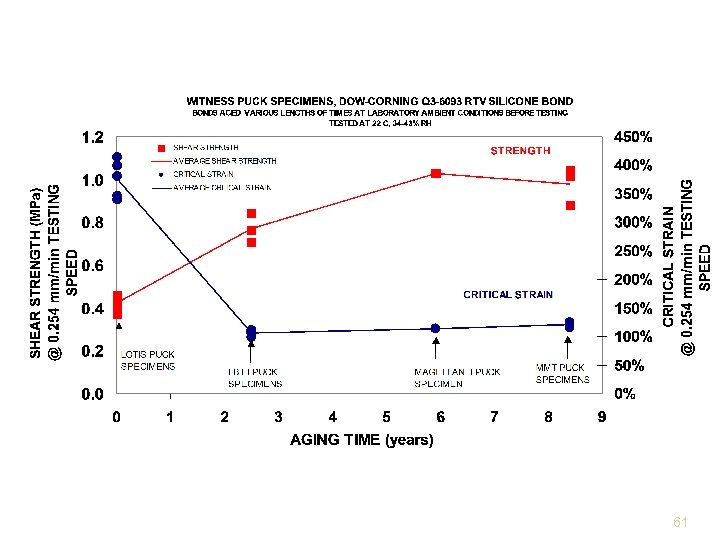

RTV bond tests at constant speed Shear strength depends on testing speed & bond geometry. ® Shear strength depends on bond age initially, but becomes independent of age sometime between 2. 5 -6 yr. ® Shear strain at rupture (“critical strain”) depends on testing speed & age initially, but becomes independent of speed & age sometime between 1 -2. 5 yr, reaching a constant value of ~100%. ® UASO Engineering Seminar, Aug 04 57

RTV bond tests at constant speed Shear strength depends on testing speed & bond geometry. ® Shear strength depends on bond age initially, but becomes independent of age sometime between 2. 5 -6 yr. ® Shear strain at rupture (“critical strain”) depends on testing speed & age initially, but becomes independent of speed & age sometime between 1 -2. 5 yr, reaching a constant value of ~100%. ® UASO Engineering Seminar, Aug 04 57

RTV bond tests at constant speed ® Inspection of fracture surfaces showed 100% cohesive failure occurred in all cases. UASO Engineering Seminar, Aug 04 58

RTV bond tests at constant speed ® Inspection of fracture surfaces showed 100% cohesive failure occurred in all cases. UASO Engineering Seminar, Aug 04 58

59

59

60

60

61

61

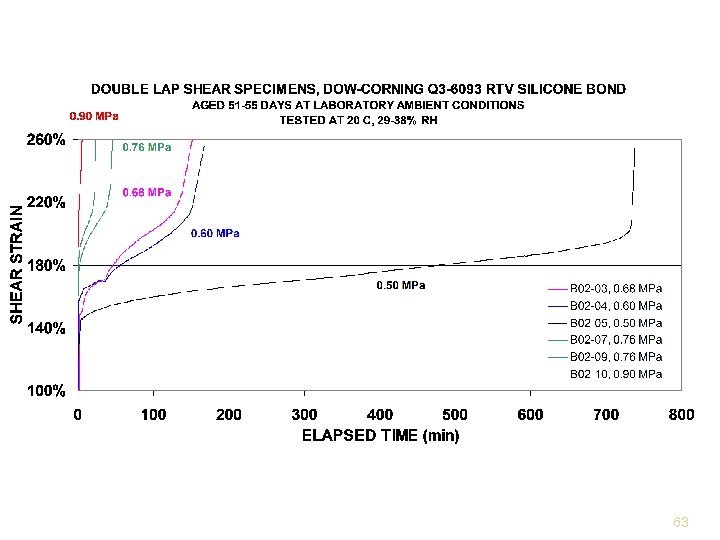

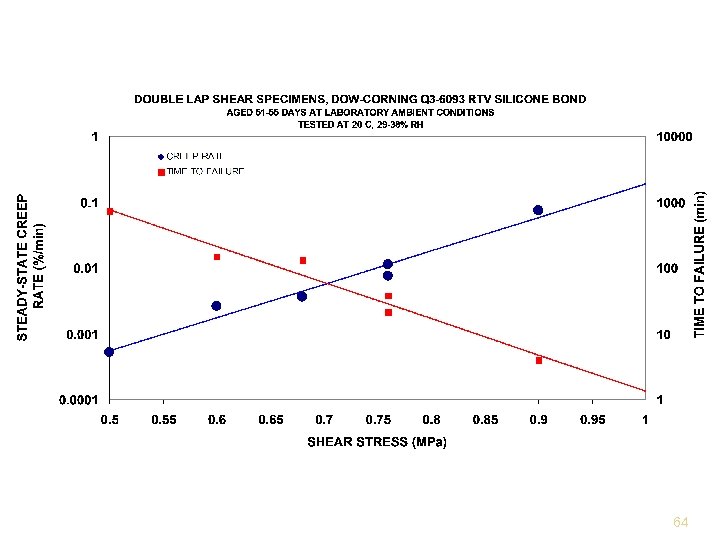

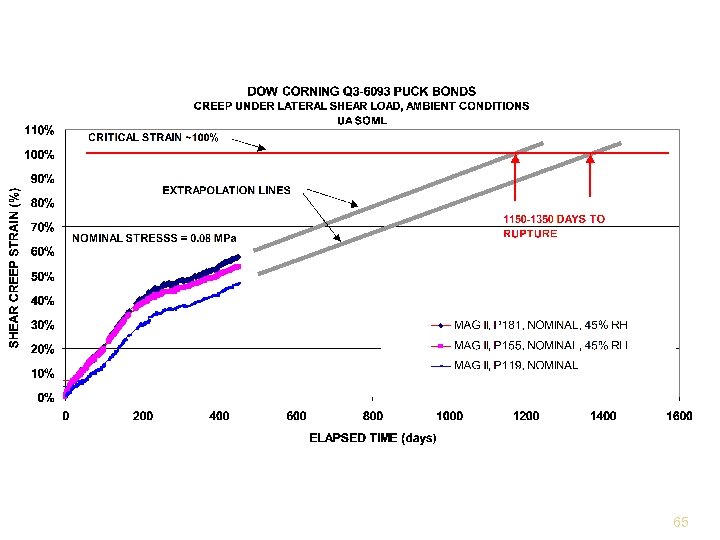

RTV tests under static load Young lap shear bonds (8 wk old) show power law creep-rupture behavior in the shear stress range 0. 5 -0. 9 MPa. ® Aged witness puck bonds (5+ years old) show linear creep in the shear stress range 0 -0. 08 MPa. ® ® Assuming that pucks rupture when they reach a critical shear strain of ~100%, the lifetime extrapolated from the measured creep curve is ~3. 4 years at 0. 08 MPa (0. 08 MPa the nominal shear stress level for a fixed horizon-pointing mirror). UASO Engineering Seminar, Aug 04 62

RTV tests under static load Young lap shear bonds (8 wk old) show power law creep-rupture behavior in the shear stress range 0. 5 -0. 9 MPa. ® Aged witness puck bonds (5+ years old) show linear creep in the shear stress range 0 -0. 08 MPa. ® ® Assuming that pucks rupture when they reach a critical shear strain of ~100%, the lifetime extrapolated from the measured creep curve is ~3. 4 years at 0. 08 MPa (0. 08 MPa the nominal shear stress level for a fixed horizon-pointing mirror). UASO Engineering Seminar, Aug 04 62

63

63

64

64

65

65

Simple conclusions ® Gray’s original bond strength tests at uncontrolled high speed failed to capture the significant timedependent nature of bond strength. ® ® Although strength tests were carried out to prove good adhesion properties of the RTV, they were of insufficient scope to identify longevity problems. Now UASO is faced with a serious problem: ® ® What should be done to three 6. 5 m & two 8. 4 m telescope mirrors that have Q 3 -6093 puck bonds? Will they fail in the 50 year design lifetime? We don’t yet know! Note that a bond life problem could have been identified early in the design phase by just a few more simple strength tests. UASO Engineering Seminar, Aug 04 66

Simple conclusions ® Gray’s original bond strength tests at uncontrolled high speed failed to capture the significant timedependent nature of bond strength. ® ® Although strength tests were carried out to prove good adhesion properties of the RTV, they were of insufficient scope to identify longevity problems. Now UASO is faced with a serious problem: ® ® What should be done to three 6. 5 m & two 8. 4 m telescope mirrors that have Q 3 -6093 puck bonds? Will they fail in the 50 year design lifetime? We don’t yet know! Note that a bond life problem could have been identified early in the design phase by just a few more simple strength tests. UASO Engineering Seminar, Aug 04 66

Simple conclusions ® Although subsequently shown to be insufficient, Gray’s work went far beyond what a typical designer would do. UASO Engineering Seminar, Aug 04 67

Simple conclusions ® Although subsequently shown to be insufficient, Gray’s work went far beyond what a typical designer would do. UASO Engineering Seminar, Aug 04 67

Simple conclusions A typical designer would probably use conventional statistical strength (e. g. , 99% CI on strength) or FOS design based on data in the manufacturer’s product data sheet or in-house data collected at one testing speed. ® For Q 3 -6093, the strength decreases with time, eating away the design margin as time passes. ® ® Note the product data sheet doesn't mention a strength-speed or strength-time dependence. Designer beware! UASO Engineering Seminar, Aug 04 68

Simple conclusions A typical designer would probably use conventional statistical strength (e. g. , 99% CI on strength) or FOS design based on data in the manufacturer’s product data sheet or in-house data collected at one testing speed. ® For Q 3 -6093, the strength decreases with time, eating away the design margin as time passes. ® ® Note the product data sheet doesn't mention a strength-speed or strength-time dependence. Designer beware! UASO Engineering Seminar, Aug 04 68

Simple conclusions The bond also creeps under load & the creep rate depends on humidity. There is no mention of creep in the product data sheet. ® At fixed testing speed, strength depends on specimen geometry. The exact bond geometry must be tested to reveal this fact. ® ® Note this “fact” is universally recognized by experienced designers even though no explicit mention of it is made in the product data sheet. Designer beware! UASO Engineering Seminar, Aug 04 69

Simple conclusions The bond also creeps under load & the creep rate depends on humidity. There is no mention of creep in the product data sheet. ® At fixed testing speed, strength depends on specimen geometry. The exact bond geometry must be tested to reveal this fact. ® ® Note this “fact” is universally recognized by experienced designers even though no explicit mention of it is made in the product data sheet. Designer beware! UASO Engineering Seminar, Aug 04 69

Simple conclusions ® Strength vs. testing speed cannot be directly related to time-to-failure under static load by the laws of continumm mechanics alone. UASO Engineering Seminar, Aug 04 70

Simple conclusions ® Strength vs. testing speed cannot be directly related to time-to-failure under static load by the laws of continumm mechanics alone. UASO Engineering Seminar, Aug 04 70

Data unification ® Can strength vs. testing speed and lifetime under static load be related & folded into a universal lifetime prediction model? ® ® Yes - if the damage mechanism is quantitatively understood. The challenge is developing & verifying the damage model. ® Attempts to unify the RTV test data by assuming the backbone molecule is cut by a hydrolytic scission mechanism has failed. ® The next approach is to assume that damage is proportional to a strain that’s viscoelastic in nature. If this proves to be true, bond life should obey time-temperature superposition & accurate life extrapolations are possible. UASO Engineering Seminar, Aug 04 71

Data unification ® Can strength vs. testing speed and lifetime under static load be related & folded into a universal lifetime prediction model? ® ® Yes - if the damage mechanism is quantitatively understood. The challenge is developing & verifying the damage model. ® Attempts to unify the RTV test data by assuming the backbone molecule is cut by a hydrolytic scission mechanism has failed. ® The next approach is to assume that damage is proportional to a strain that’s viscoelastic in nature. If this proves to be true, bond life should obey time-temperature superposition & accurate life extrapolations are possible. UASO Engineering Seminar, Aug 04 71

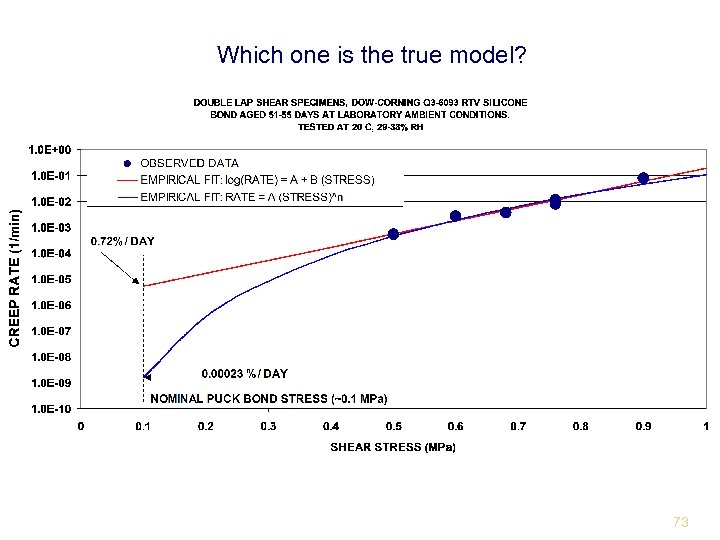

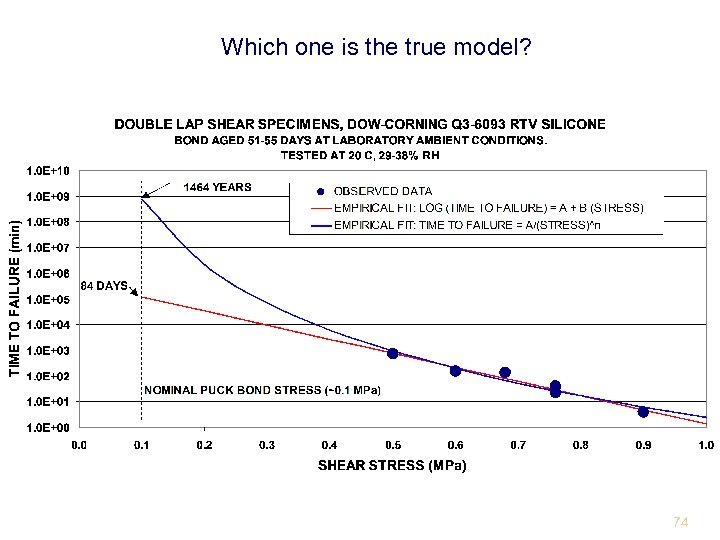

Empirical modeling ® Time-to-failure & creep rate under static loads can, in principle, be extrapolated from high stress levels (where measurements are fast & easy) to low stress levels (where measurements take years & so there’s little or no data). ® ® ® But accurate extrapolation requires a predictor equation that obeys the true damage physics. Oftentimes, theory or purely empirical curve fitting offer competing models. What is the correct model? Extrapolations far from the last observation can give remarkably bad predictions if the model is inaccurate. And without an observation at low stress levels, it is impossible to empirically discriminate between competing models! UASO Engineering Seminar, Aug 04 72

Empirical modeling ® Time-to-failure & creep rate under static loads can, in principle, be extrapolated from high stress levels (where measurements are fast & easy) to low stress levels (where measurements take years & so there’s little or no data). ® ® ® But accurate extrapolation requires a predictor equation that obeys the true damage physics. Oftentimes, theory or purely empirical curve fitting offer competing models. What is the correct model? Extrapolations far from the last observation can give remarkably bad predictions if the model is inaccurate. And without an observation at low stress levels, it is impossible to empirically discriminate between competing models! UASO Engineering Seminar, Aug 04 72

Which one is the true model? 73

Which one is the true model? 73

Which one is the true model? 74

Which one is the true model? 74

Example #2: 3 M Scotchweld 2216 epoxy bonds ® Scotchweld 2216 is a moderately compliant two-part epoxy often used to bond hardware to glass. ® A substrate primer is recommended for optimum bond strength. ® The longevity of 2216 bonds is not discussed in the manufacturer’s data sheet or in the literature. UASO Engineering Seminar, Aug 04 75

Example #2: 3 M Scotchweld 2216 epoxy bonds ® Scotchweld 2216 is a moderately compliant two-part epoxy often used to bond hardware to glass. ® A substrate primer is recommended for optimum bond strength. ® The longevity of 2216 bonds is not discussed in the manufacturer’s data sheet or in the literature. UASO Engineering Seminar, Aug 04 75

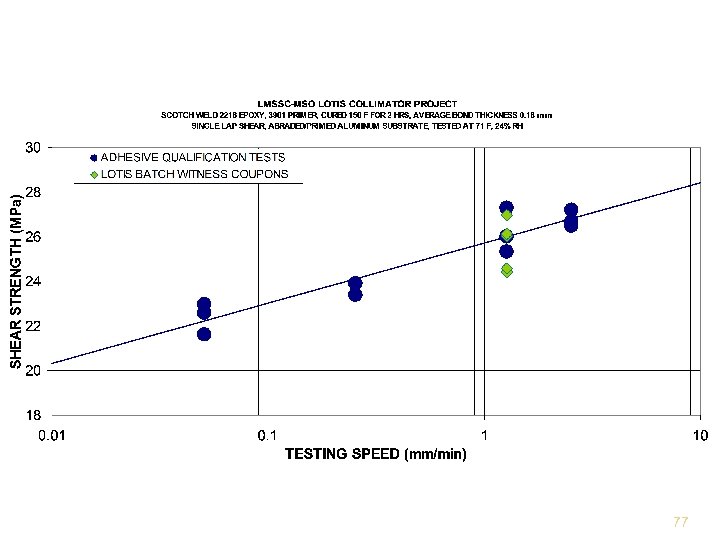

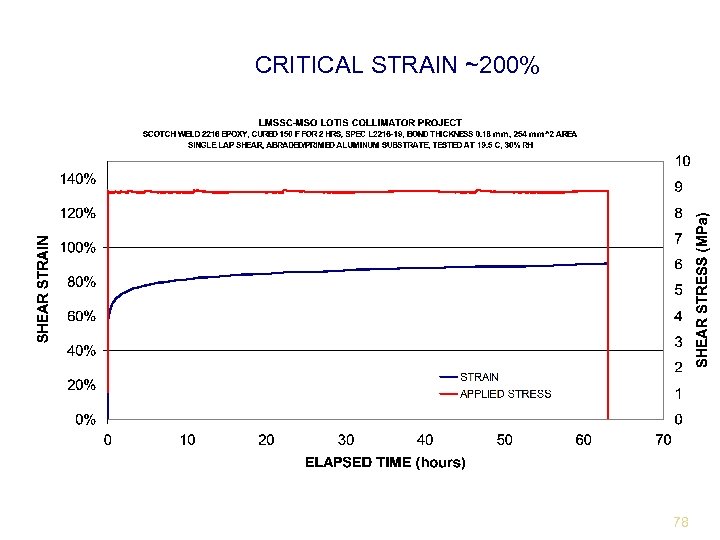

Scotchweld 2216 ® Tests showed that: ® Bond shear strength depends on testing speed. ® The bond creeps under load. ® Bonds under moderately high shear stress (18 MPa) failed < 2 hours. ® Critical shear strain ~200%. ® Predominantly adhesive failure was observed (<10% cohesive). UASO Engineering Seminar, Aug 04 76

Scotchweld 2216 ® Tests showed that: ® Bond shear strength depends on testing speed. ® The bond creeps under load. ® Bonds under moderately high shear stress (18 MPa) failed < 2 hours. ® Critical shear strain ~200%. ® Predominantly adhesive failure was observed (<10% cohesive). UASO Engineering Seminar, Aug 04 76

77

77

CRITICAL STRAIN ~200% 78

CRITICAL STRAIN ~200% 78

Scotchweld 2216 ® Preliminary results show that longevity concerns are warranted even though field data indicate no bond life problems. ® Much more work is needed to develop a lifetime predictor model! UASO Engineering Seminar, Aug 04 79

Scotchweld 2216 ® Preliminary results show that longevity concerns are warranted even though field data indicate no bond life problems. ® Much more work is needed to develop a lifetime predictor model! UASO Engineering Seminar, Aug 04 79

UASO-ML testing capabilities ® Specialized ® ® test equipment: Universal electromechanical (screw driven) testing machines: ® Instron 4501, 1100 lbf load capacity. Instron Series IX & Merlin software control package. ® Instron 1125, 20000 lbf load capacity. Instron Series IX & Merlin software control package. Olympus BH-2 polarizing microscope with optical petrographic analysis accessories. Cahn C-31 microbalance, 0. 1 micro-gram sensitivity. General data acquisition PC running Dasylab software. UASO Engineering Seminar, Aug 04 80

UASO-ML testing capabilities ® Specialized ® ® test equipment: Universal electromechanical (screw driven) testing machines: ® Instron 4501, 1100 lbf load capacity. Instron Series IX & Merlin software control package. ® Instron 1125, 20000 lbf load capacity. Instron Series IX & Merlin software control package. Olympus BH-2 polarizing microscope with optical petrographic analysis accessories. Cahn C-31 microbalance, 0. 1 micro-gram sensitivity. General data acquisition PC running Dasylab software. UASO Engineering Seminar, Aug 04 80

UASO-ML testing capabilities ® Services ® UASO does not provide general-use testing services. ® Equipment is purchased & maintained by specific projects. This is expensive equipment whose cost to maintain, operate & replace is not managed by a UASO overhead account. ® Use of equipment by outside projects is done on a courtesy basis free-of-charge provided it does not interfere with principal program needs & does not consume more than a few man hours of labor. UASO Engineering Seminar, Aug 04 81

UASO-ML testing capabilities ® Services ® UASO does not provide general-use testing services. ® Equipment is purchased & maintained by specific projects. This is expensive equipment whose cost to maintain, operate & replace is not managed by a UASO overhead account. ® Use of equipment by outside projects is done on a courtesy basis free-of-charge provided it does not interfere with principal program needs & does not consume more than a few man hours of labor. UASO Engineering Seminar, Aug 04 81

UASO-ML testing capabilities ® Services ® Outside requestors must provide their own labor or a charge number for extended use of ML labor. ® Users must demonstrate competence or must be trained prior to equipment operation. Users must provide specialized tooling & their own test plan. ® Cost to repair damage caused by user negligence will be billed to project. UASO Engineering Seminar, Aug 04 82

UASO-ML testing capabilities ® Services ® Outside requestors must provide their own labor or a charge number for extended use of ML labor. ® Users must demonstrate competence or must be trained prior to equipment operation. Users must provide specialized tooling & their own test plan. ® Cost to repair damage caused by user negligence will be billed to project. UASO Engineering Seminar, Aug 04 82

Puck bond references Peter Gray, “ 6. 5 m MMT Mirror Support Load Spreader Gluing: Summary of Problems, Investigations and Solutions, ” MMT Observatory Technical Report #29, July 1997. ® Amar Brar, Brian Cuerden, Kurt Kenagy, Blain Olbert and Steve Warner, “LMSSC-MSO LOTIS Collimator Project Mirror Puck Bond Test Plan, ” LOTIS Project Technical Memo, 14 Nov. 02. File: Puck Bonding Plan R 03. doc ® Blain H. Olbert, “LMSSC-MSO LOTIS Collimator Project: Physics & Rationale of Mirror Puck Test Plan, ” LOTIS Project Technical Memo, 12 Dec. 2002, File: Puck Bonding Plan Theory R 03. doc ® Blain H. Olbert, “LMSSC-MSO LOTIS COLLIMATOR PROJECT, MIRROR PUCK TEST PLAN SUMMARY, ” Power. Point Summary, 1 Feb. 2003, File: LOTIS_PUCKTEST_SUM_01. Ppt ® UASO Engineering Seminar, Aug 04 83

Puck bond references Peter Gray, “ 6. 5 m MMT Mirror Support Load Spreader Gluing: Summary of Problems, Investigations and Solutions, ” MMT Observatory Technical Report #29, July 1997. ® Amar Brar, Brian Cuerden, Kurt Kenagy, Blain Olbert and Steve Warner, “LMSSC-MSO LOTIS Collimator Project Mirror Puck Bond Test Plan, ” LOTIS Project Technical Memo, 14 Nov. 02. File: Puck Bonding Plan R 03. doc ® Blain H. Olbert, “LMSSC-MSO LOTIS Collimator Project: Physics & Rationale of Mirror Puck Test Plan, ” LOTIS Project Technical Memo, 12 Dec. 2002, File: Puck Bonding Plan Theory R 03. doc ® Blain H. Olbert, “LMSSC-MSO LOTIS COLLIMATOR PROJECT, MIRROR PUCK TEST PLAN SUMMARY, ” Power. Point Summary, 1 Feb. 2003, File: LOTIS_PUCKTEST_SUM_01. Ppt ® UASO Engineering Seminar, Aug 04 83

Puck bond references Blain Olbert, “LMSSC-MSO LOTIS COLLIMATOR PROJECT, MIRROR PUCK & RTV TESTING: PLAN SUMMARY, STATUS & RESULTS TO-DATE, ” Power. Point Summary, 02/27/03, File: LOTIS_PUCKTEST_UPDATE_02. ppt ® Blain Olbert, “LMSSC-MSO LOTIS COLLIMATOR PROJECT, MIRROR PUCK BOND & RTV TESTING, STATUS REPORT & RESULTS SINCE 03/04/03 GROUP TELECON, ” Power. Point Summary, 04/25/03, File: LOTIS_PUCKTEST_UPDATE_03. ppt ® Blain Olbert, “LMSSC-MSO LOTIS COLLIMATOR PROJECT, MIRROR PUCK BOND & RTV TESTING, STATUS REPORT & RESULTS SINCE 05/01/03 GROUP TELECON, ” Power. Point Summary, 04/25/03, File: LOTIS_PUCKTEST_UPDATE_04. ppt ® Brian Cuerden and Steven Bauman, “Safety Clip System Design Concept, ” 07/01/03, File: LOTIS 070103 -SOLM. ppt ® UASO Engineering Seminar, Aug 04 84

Puck bond references Blain Olbert, “LMSSC-MSO LOTIS COLLIMATOR PROJECT, MIRROR PUCK & RTV TESTING: PLAN SUMMARY, STATUS & RESULTS TO-DATE, ” Power. Point Summary, 02/27/03, File: LOTIS_PUCKTEST_UPDATE_02. ppt ® Blain Olbert, “LMSSC-MSO LOTIS COLLIMATOR PROJECT, MIRROR PUCK BOND & RTV TESTING, STATUS REPORT & RESULTS SINCE 03/04/03 GROUP TELECON, ” Power. Point Summary, 04/25/03, File: LOTIS_PUCKTEST_UPDATE_03. ppt ® Blain Olbert, “LMSSC-MSO LOTIS COLLIMATOR PROJECT, MIRROR PUCK BOND & RTV TESTING, STATUS REPORT & RESULTS SINCE 05/01/03 GROUP TELECON, ” Power. Point Summary, 04/25/03, File: LOTIS_PUCKTEST_UPDATE_04. ppt ® Brian Cuerden and Steven Bauman, “Safety Clip System Design Concept, ” 07/01/03, File: LOTIS 070103 -SOLM. ppt ® UASO Engineering Seminar, Aug 04 84

Puck bond references ® Blain H. Olbert, “Proposal to Explore the Long-Term Potential for Catastrophic Failure of the AFRL 3. 5 m SOR Primary Mirror Support, ” Prepared for AFRL Starfire Optical Range, Kirtland AFB, Albuquerque, NM. UASO Engineering Seminar, Aug 04 85

Puck bond references ® Blain H. Olbert, “Proposal to Explore the Long-Term Potential for Catastrophic Failure of the AFRL 3. 5 m SOR Primary Mirror Support, ” Prepared for AFRL Starfire Optical Range, Kirtland AFB, Albuquerque, NM. UASO Engineering Seminar, Aug 04 85