fc9d1014c0df3ea23cf8c0f935397513.ppt

- Количество слайдов: 45

Adaptive Make Radical Advances in System Design & Manufacturing Paul Eremenko eremenko@alum. mit. edu fmr. Deputy Director/Acting Director Tactical Technology Office Briefing prepared for MIT Club of Washington, DC 31 st Annual Seminar Series—Rebuilding U. S. Manufacturing March 12, 2013 The views expressed are those of the author and do not reflect the official policy or position of the Department of Defense or the U. S. Government.

Adaptive Make Radical Advances in System Design & Manufacturing Paul Eremenko eremenko@alum. mit. edu fmr. Deputy Director/Acting Director Tactical Technology Office Briefing prepared for MIT Club of Washington, DC 31 st Annual Seminar Series—Rebuilding U. S. Manufacturing March 12, 2013 The views expressed are those of the author and do not reflect the official policy or position of the Department of Defense or the U. S. Government.

The six frigates (1794) “… the sum of $688, 888… to provide, equip and employ, four ships to carry forty guns each, and two ships to carry thirty-six guns each…. ” --An Act to Provide a Naval Armament, March 27, 1794 2

The six frigates (1794) “… the sum of $688, 888… to provide, equip and employ, four ships to carry forty guns each, and two ships to carry thirty-six guns each…. ” --An Act to Provide a Naval Armament, March 27, 1794 2

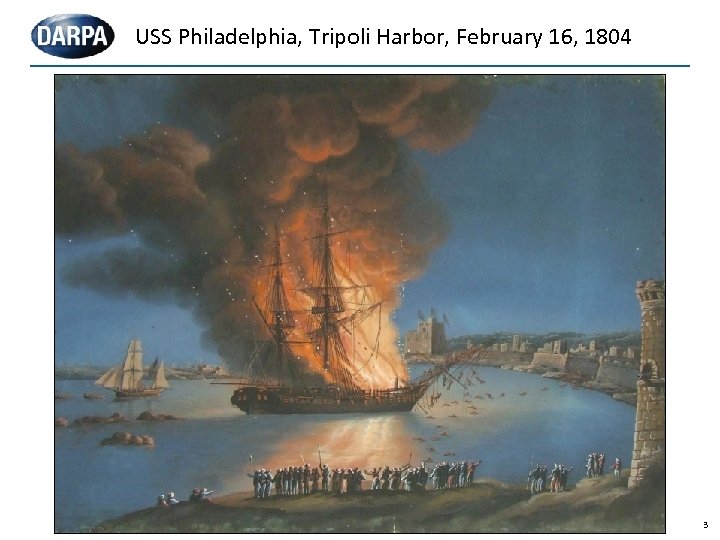

USS Philadelphia, Tripoli Harbor, February 16, 1804 3

USS Philadelphia, Tripoli Harbor, February 16, 1804 3

B-52 Stratofortress (1946) "It is desired that the requirements set forth be considered as a goal and that the proposal be for an interim airplane to approximate all requirements, except that emphasis must be placed on meeting the high speed requirement. . . It is the intent that design proposals should present the best possible over-all airplane. . . " --Directive letter inviting design proposals for the B-52 bomber, February 13, 1946

B-52 Stratofortress (1946) "It is desired that the requirements set forth be considered as a goal and that the proposal be for an interim airplane to approximate all requirements, except that emphasis must be placed on meeting the high speed requirement. . . It is the intent that design proposals should present the best possible over-all airplane. . . " --Directive letter inviting design proposals for the B-52 bomber, February 13, 1946

F-111 Aardvark (1961) 5

F-111 Aardvark (1961) 5

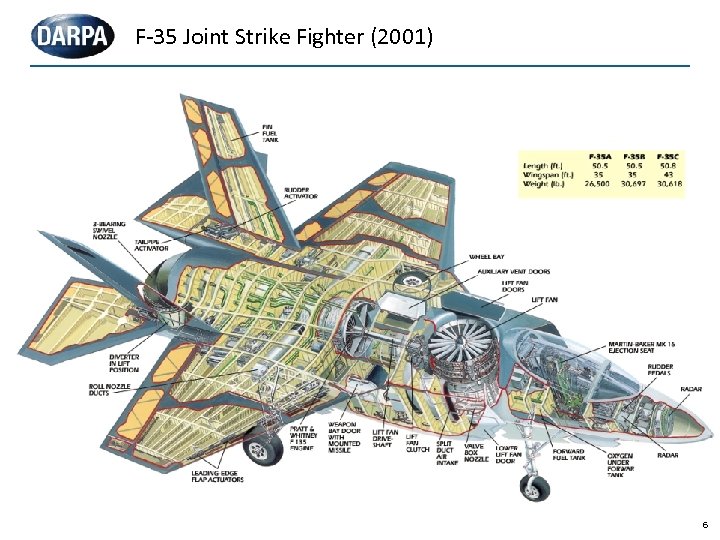

F-35 Joint Strike Fighter (2001) 6

F-35 Joint Strike Fighter (2001) 6

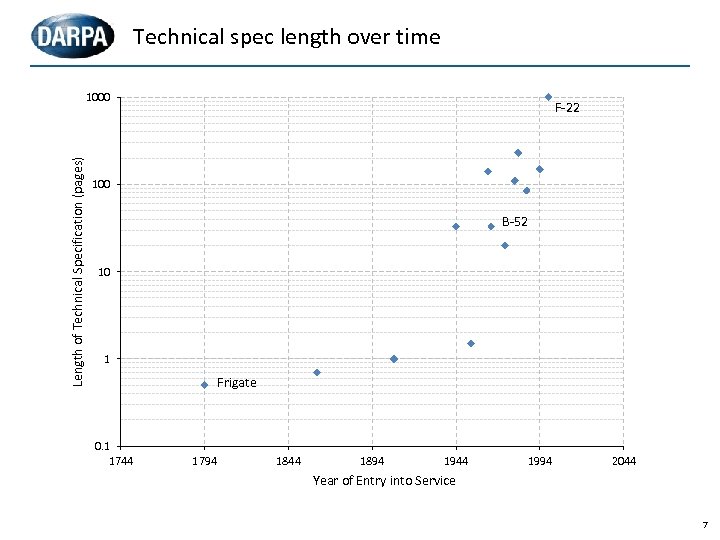

Technical spec length over time Length of Technical Specification (pages) 1000 F-22 100 B-52 10 1 Frigate 0. 1 1744 1794 1844 1894 1944 1994 2044 Year of Entry into Service 7

Technical spec length over time Length of Technical Specification (pages) 1000 F-22 100 B-52 10 1 Frigate 0. 1 1744 1794 1844 1894 1944 1994 2044 Year of Entry into Service 7

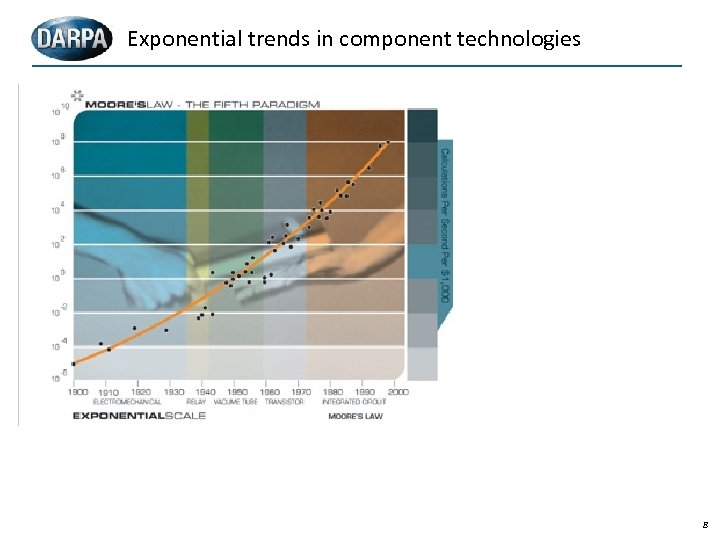

Exponential trends in component technologies 8

Exponential trends in component technologies 8

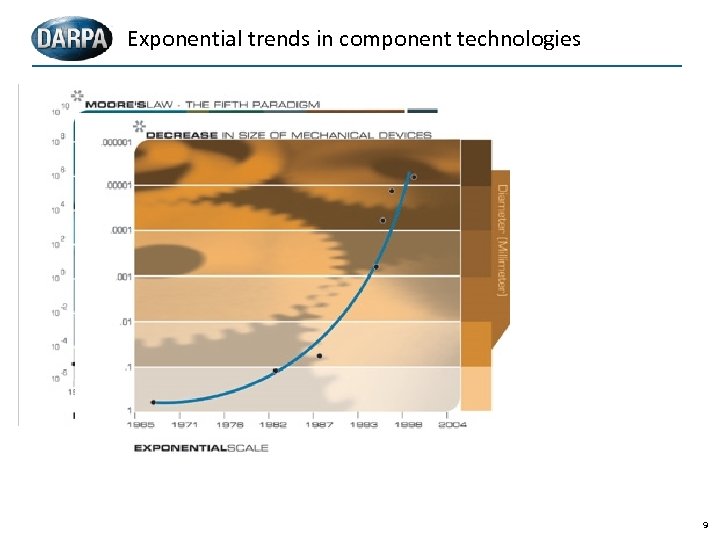

Exponential trends in component technologies 9

Exponential trends in component technologies 9

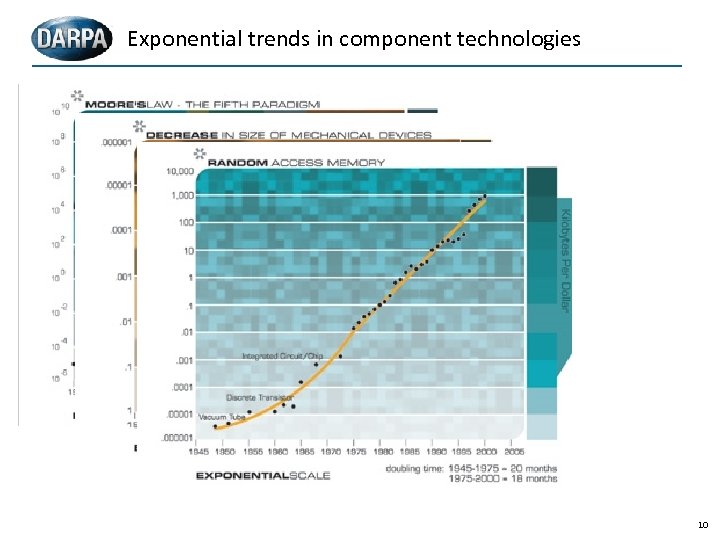

Exponential trends in component technologies 10

Exponential trends in component technologies 10

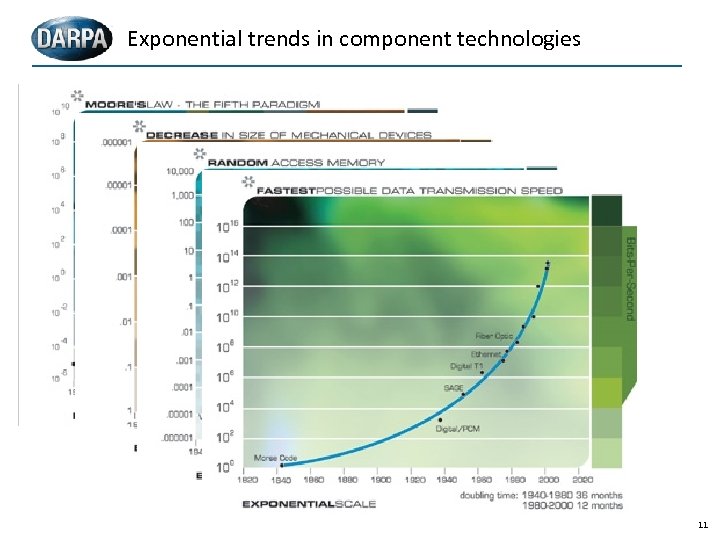

Exponential trends in component technologies 11

Exponential trends in component technologies 11

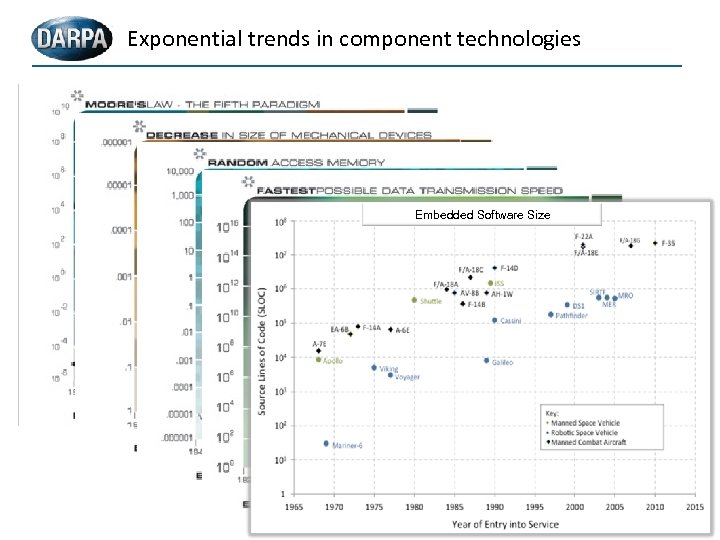

Exponential trends in component technologies Embedded Software Size 12

Exponential trends in component technologies Embedded Software Size 12

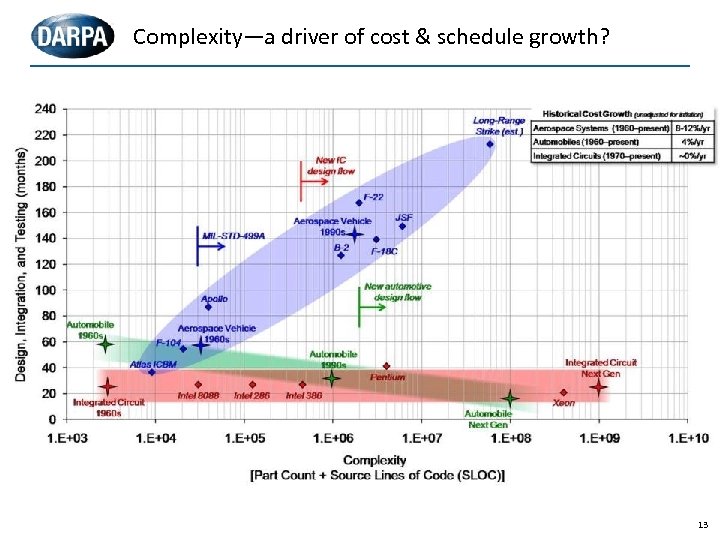

Complexity—a driver of cost & schedule growth? 13

Complexity—a driver of cost & schedule growth? 13

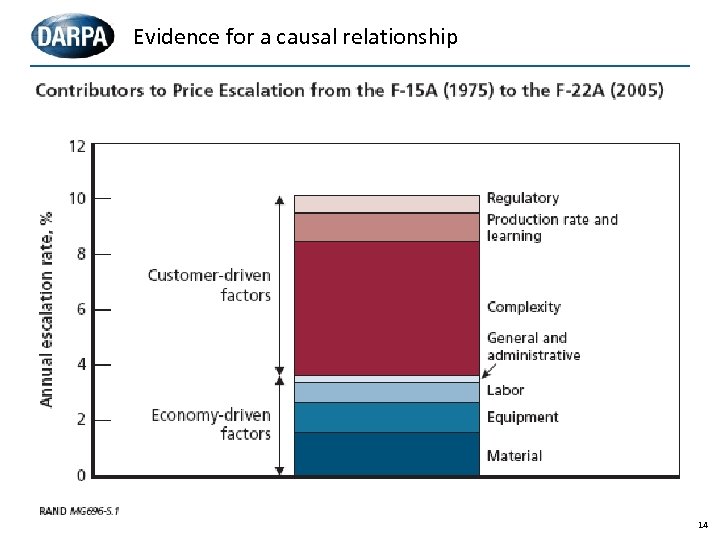

Evidence for a causal relationship 14

Evidence for a causal relationship 14

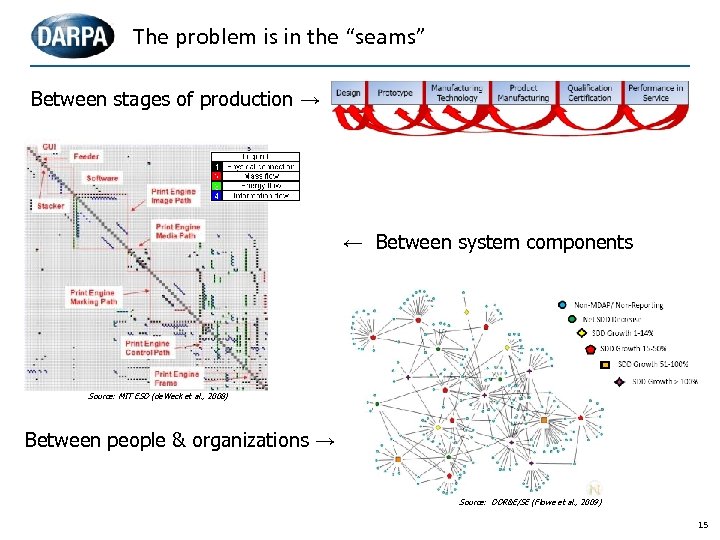

The problem is in the “seams” Between stages of production → ← Between system components Source: MIT ESD (de. Weck et al. , 2008) Between people & organizations → Source: DDR&E/SE (Flowe et al. , 2009) 15

The problem is in the “seams” Between stages of production → ← Between system components Source: MIT ESD (de. Weck et al. , 2008) Between people & organizations → Source: DDR&E/SE (Flowe et al. , 2009) 15

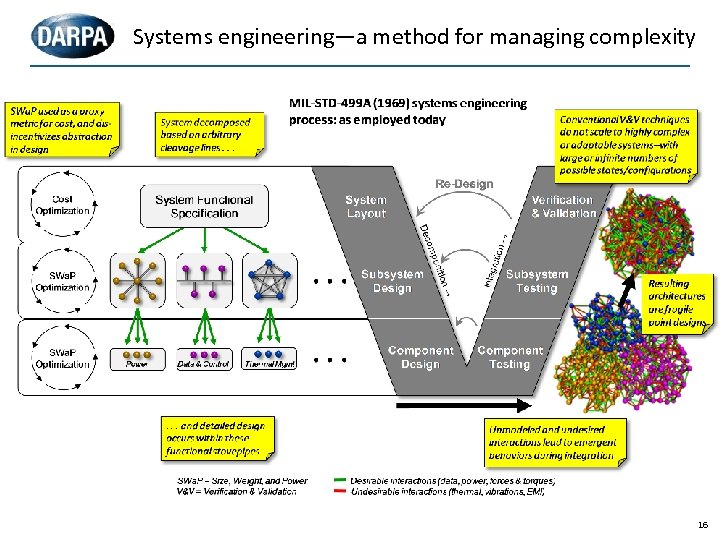

Systems engineering—a method for managing complexity 16

Systems engineering—a method for managing complexity 16

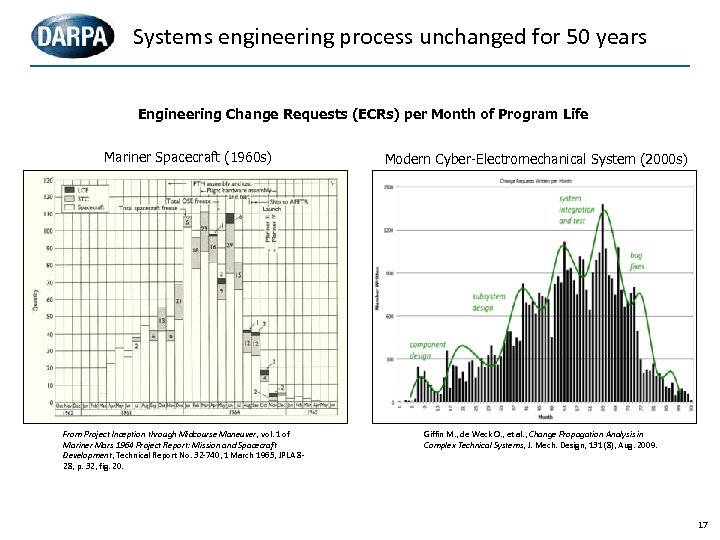

Systems engineering process unchanged for 50 years Engineering Change Requests (ECRs) per Month of Program Life Mariner Spacecraft (1960 s) From Project Inception through Midcourse Maneuver, vol. 1 of Mariner Mars 1964 Project Report: Mission and Spacecraft Development, Technical Report No. 32 -740, 1 March 1965, JPLA 828, p. 32, fig. 20. Modern Cyber-Electromechanical System (2000 s) Giffin M. , de Weck O. , et al. , Change Propagation Analysis in Complex Technical Systems, J. Mech. Design, 131 (8), Aug. 2009. 17

Systems engineering process unchanged for 50 years Engineering Change Requests (ECRs) per Month of Program Life Mariner Spacecraft (1960 s) From Project Inception through Midcourse Maneuver, vol. 1 of Mariner Mars 1964 Project Report: Mission and Spacecraft Development, Technical Report No. 32 -740, 1 March 1965, JPLA 828, p. 32, fig. 20. Modern Cyber-Electromechanical System (2000 s) Giffin M. , de Weck O. , et al. , Change Propagation Analysis in Complex Technical Systems, J. Mech. Design, 131 (8), Aug. 2009. 17

The Consequences 18

The Consequences 18

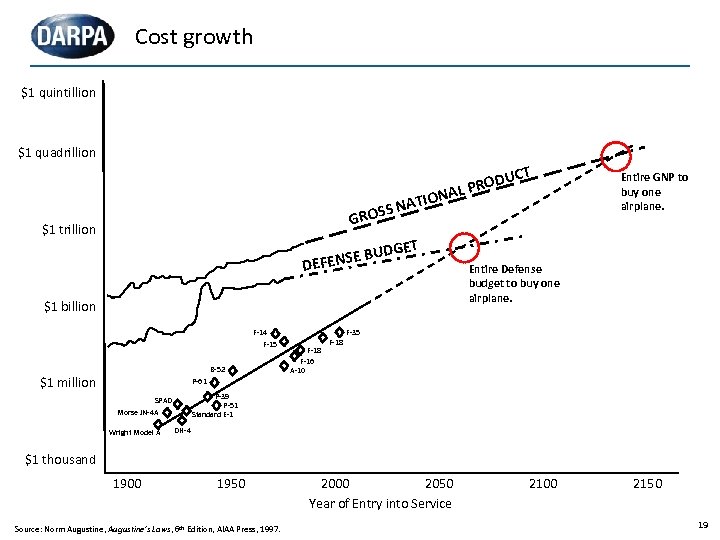

Cost growth $1 quintillion $1 quadrillion CT RODU NAL P TIO NA ROSS G $1 trillion Entire GNP to buy one airplane. ET UDG ENSE B DEF $1 billion F-14 F-15 B-52 $1 million Entire Defense budget to buy one airplane. F-35 F-18 F-16 A-10 F-18 P-61 P-39 P-51 Standard E-1 SPAD Morse JN-4 A Wright Model A DH-4 $1 thousand 1900 1950 Source: Norm Augustine, Augustine’s Laws, 6 th Edition, AIAA Press, 1997. 2000 2050 Year of Entry into Service 2100 2150 19

Cost growth $1 quintillion $1 quadrillion CT RODU NAL P TIO NA ROSS G $1 trillion Entire GNP to buy one airplane. ET UDG ENSE B DEF $1 billion F-14 F-15 B-52 $1 million Entire Defense budget to buy one airplane. F-35 F-18 F-16 A-10 F-18 P-61 P-39 P-51 Standard E-1 SPAD Morse JN-4 A Wright Model A DH-4 $1 thousand 1900 1950 Source: Norm Augustine, Augustine’s Laws, 6 th Edition, AIAA Press, 1997. 2000 2050 Year of Entry into Service 2100 2150 19

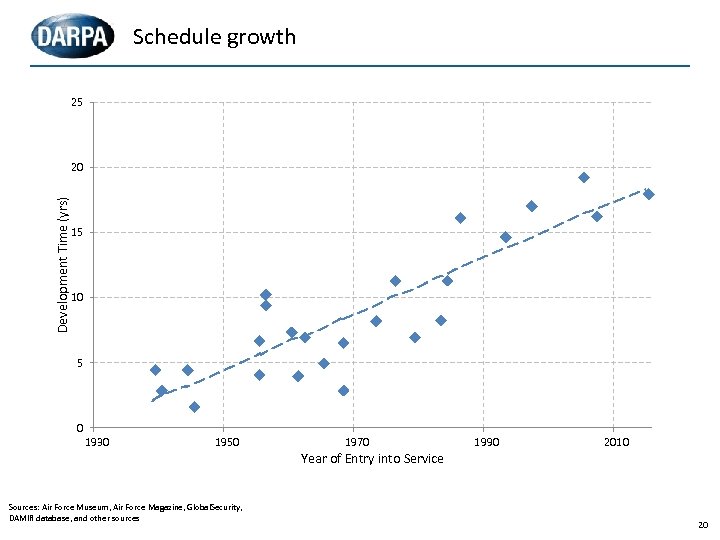

Schedule growth 25 Development Time (yrs) 20 15 10 5 0 1930 1950 Sources: Air Force Museum, Air Force Magazine, Global. Security, DAMIR database, and other sources 1970 Year of Entry into Service 1990 2010 20

Schedule growth 25 Development Time (yrs) 20 15 10 5 0 1930 1950 Sources: Air Force Museum, Air Force Magazine, Global. Security, DAMIR database, and other sources 1970 Year of Entry into Service 1990 2010 20

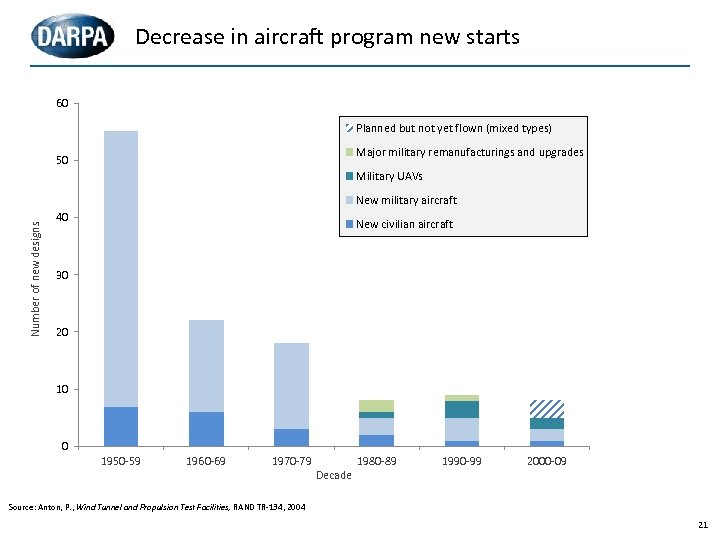

Decrease in aircraft program new starts 60 Planned but not yet flown (mixed types) Major military remanufacturings and upgrades 50 Military UAVs Number of new designs New military aircraft 40 New civilian aircraft 30 20 10 0 1950 -59 1960 -69 1970 -79 Decade 1980 -89 1990 -99 2000 -09 Source: Anton, P. , Wind Tunnel and Propulsion Test Facilities, RAND TR-134, 2004 21

Decrease in aircraft program new starts 60 Planned but not yet flown (mixed types) Major military remanufacturings and upgrades 50 Military UAVs Number of new designs New military aircraft 40 New civilian aircraft 30 20 10 0 1950 -59 1960 -69 1970 -79 Decade 1980 -89 1990 -99 2000 -09 Source: Anton, P. , Wind Tunnel and Propulsion Test Facilities, RAND TR-134, 2004 21

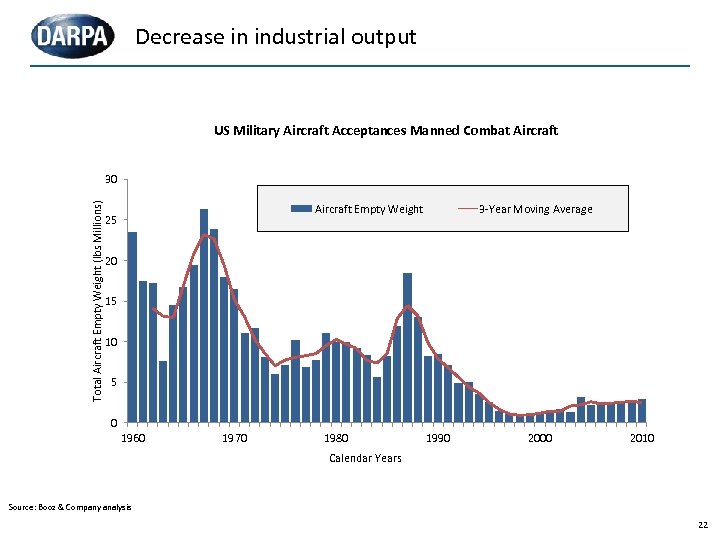

Decrease in industrial output US Military Aircraft Acceptances Manned Combat Aircraft Total Aircraft Empty Weight (lbs Millions) 30 Aircraft Empty Weight 25 3 -Year Moving Average 20 15 10 5 0 1960 1970 1980 1990 2000 2010 Calendar Years Source: Booz & Company analysis 22

Decrease in industrial output US Military Aircraft Acceptances Manned Combat Aircraft Total Aircraft Empty Weight (lbs Millions) 30 Aircraft Empty Weight 25 3 -Year Moving Average 20 15 10 5 0 1960 1970 1980 1990 2000 2010 Calendar Years Source: Booz & Company analysis 22

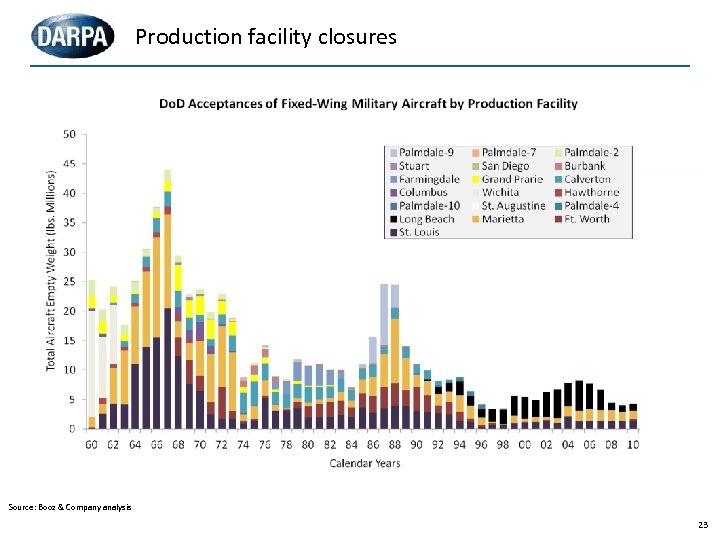

Production facility closures Source: Booz & Company analysis 23

Production facility closures Source: Booz & Company analysis 23

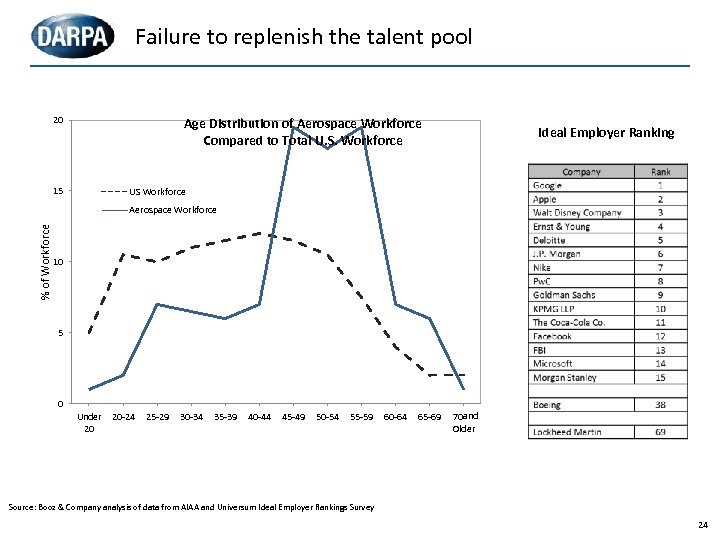

Failure to replenish the talent pool 20 15 Age Distribution of Aerospace Workforce Compared to Total U. S. Workforce Ideal Employer Ranking US Workforce % of Workforce Aerospace Workforce 10 5 0 Under 20 -24 20 25 -29 30 -34 35 -39 40 -44 45 -49 50 -54 55 -59 60 -64 65 -69 70 and an Older Source: Booz & Company analysis of data from AIAA and Universum Ideal Employer Rankings Survey 24

Failure to replenish the talent pool 20 15 Age Distribution of Aerospace Workforce Compared to Total U. S. Workforce Ideal Employer Ranking US Workforce % of Workforce Aerospace Workforce 10 5 0 Under 20 -24 20 25 -29 30 -34 35 -39 40 -44 45 -49 50 -54 55 -59 60 -64 65 -69 70 and an Older Source: Booz & Company analysis of data from AIAA and Universum Ideal Employer Rankings Survey 24

Enter DARPA 25

Enter DARPA 25

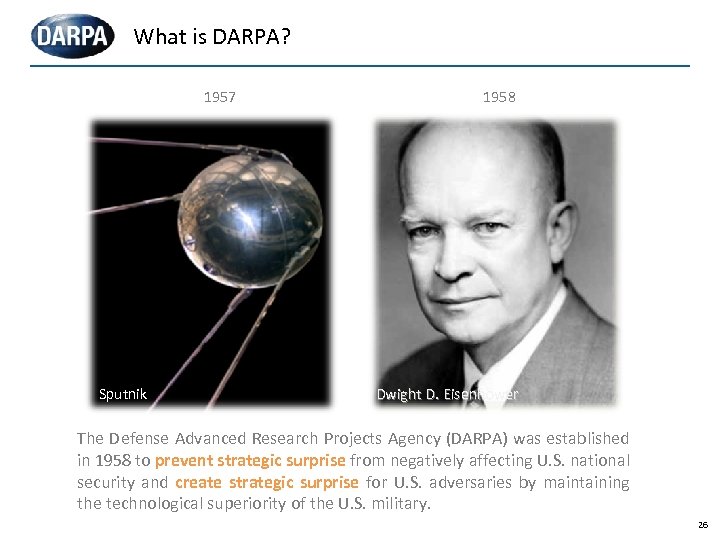

What is DARPA? 1957 Sputnik 1958 Dwight D. Eisenhower The Defense Advanced Research Projects Agency (DARPA) was established in 1958 to prevent strategic surprise from negatively affecting U. S. national security and create strategic surprise for U. S. adversaries by maintaining the technological superiority of the U. S. military. 26

What is DARPA? 1957 Sputnik 1958 Dwight D. Eisenhower The Defense Advanced Research Projects Agency (DARPA) was established in 1958 to prevent strategic surprise from negatively affecting U. S. national security and create strategic surprise for U. S. adversaries by maintaining the technological superiority of the U. S. military. 26

What makes DARPA unique? ► Singular mission to create & prevent strategic surprise ► Not a requirements-driven culture ► Acceptance of risk (technical & process) and failure ► Projects of finite duration culminating in demonstration ► Tenures of finite duration; broad aperture for recruitment ► Agile organization; no labs; no facilities; flexible contracting ► Varied transition paths—sometimes very indirect 27

What makes DARPA unique? ► Singular mission to create & prevent strategic surprise ► Not a requirements-driven culture ► Acceptance of risk (technical & process) and failure ► Projects of finite duration culminating in demonstration ► Tenures of finite duration; broad aperture for recruitment ► Agile organization; no labs; no facilities; flexible contracting ► Varied transition paths—sometimes very indirect 27

TTO’s history of technology demonstrators Space Systems 1997 2006 Mi. TEX 1990 Pegasus Taurus 1985 2003 1995 GLOMR DARPASAT Falcon SLV 2007 Orbital Express Aero-/Hydro-Dynamic Systems 1982 1977 Have Blue 1984 Tacit Blue Sea Shadow 1998 1990 X-31 Global Hawk 2002 X-45/46/47 2005 A-160 2011 HTV-2 Ground/Soldier Systems 2008 1973 M 16 1987 1978 Tank Breaker SSN 2002 Talon 2003 Boomerang 2003 Netfires Big Dog Tactical Technologies 1984 NAVLAB 1990 ALG 1995 AM 3 2004 UGCV 2011 DTC 28

TTO’s history of technology demonstrators Space Systems 1997 2006 Mi. TEX 1990 Pegasus Taurus 1985 2003 1995 GLOMR DARPASAT Falcon SLV 2007 Orbital Express Aero-/Hydro-Dynamic Systems 1982 1977 Have Blue 1984 Tacit Blue Sea Shadow 1998 1990 X-31 Global Hawk 2002 X-45/46/47 2005 A-160 2011 HTV-2 Ground/Soldier Systems 2008 1973 M 16 1987 1978 Tank Breaker SSN 2002 Talon 2003 Boomerang 2003 Netfires Big Dog Tactical Technologies 1984 NAVLAB 1990 ALG 1995 AM 3 2004 UGCV 2011 DTC 28

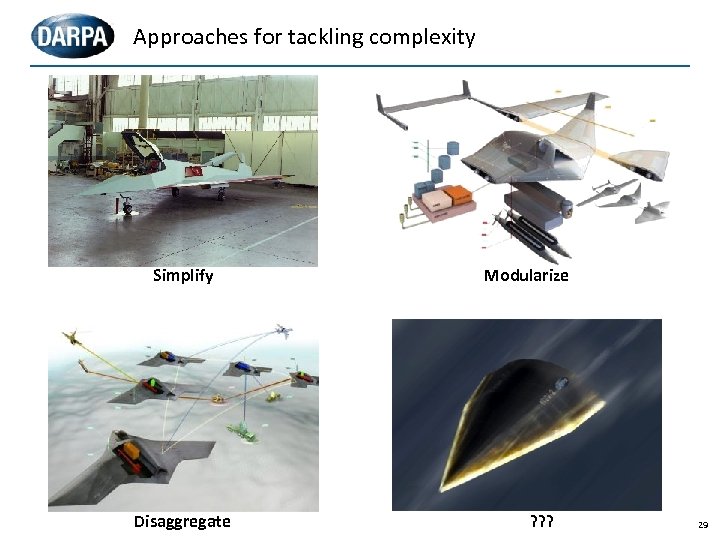

Approaches for tackling complexity Simplify Disaggregate Modularize ? ? ? 29

Approaches for tackling complexity Simplify Disaggregate Modularize ? ? ? 29

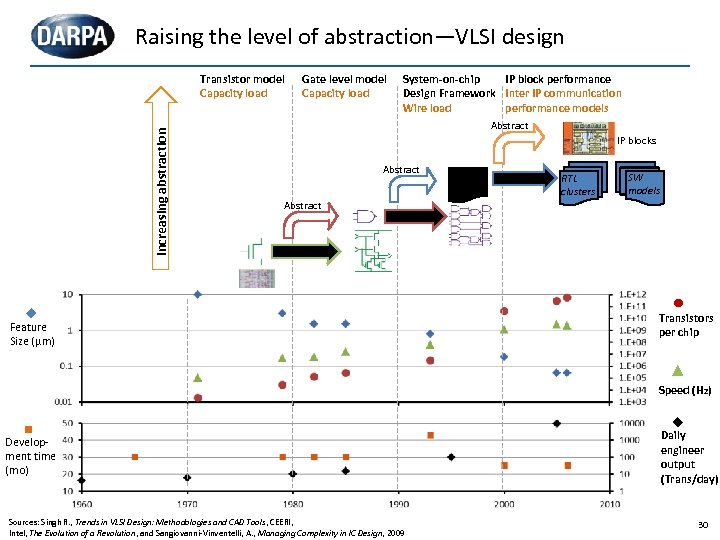

Raising the level of abstraction—VLSI design increasing abstraction Transistor model Capacity load Gate level model Capacity load System-on-chip IP block performance Design Framework Inter IP communication Wire load performance models Abstract IP blocks Abstract RTL Cluster RTL clusters SW models Cluster Feature Size (µm) Transistors per chip Speed (Hz) Development time (mo) Sources: Singh R. , Trends in VLSI Design: Methodologies and CAD Tools, CEERI, Intel, The Evolution of a Revolution, and Sangiovanni-Vinventelli, A. , Managing Complexity in IC Design, 2009 Daily engineer output (Trans/day) 30

Raising the level of abstraction—VLSI design increasing abstraction Transistor model Capacity load Gate level model Capacity load System-on-chip IP block performance Design Framework Inter IP communication Wire load performance models Abstract IP blocks Abstract RTL Cluster RTL clusters SW models Cluster Feature Size (µm) Transistors per chip Speed (Hz) Development time (mo) Sources: Singh R. , Trends in VLSI Design: Methodologies and CAD Tools, CEERI, Intel, The Evolution of a Revolution, and Sangiovanni-Vinventelli, A. , Managing Complexity in IC Design, 2009 Daily engineer output (Trans/day) 30

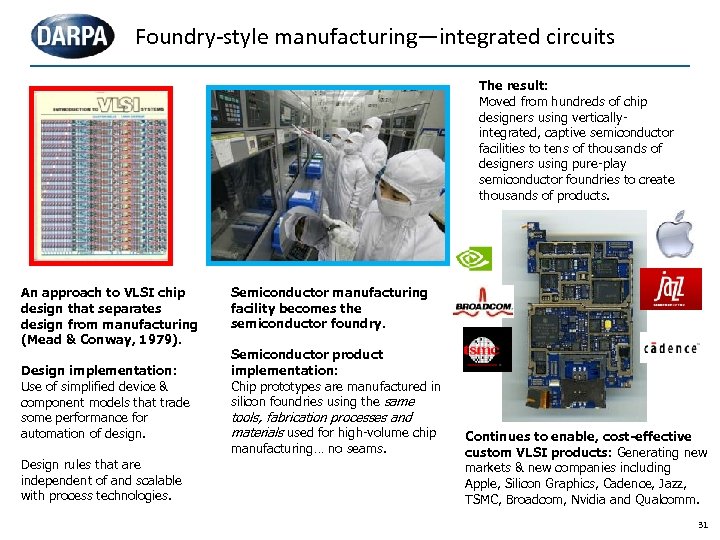

Foundry-style manufacturing—integrated circuits The result: Moved from hundreds of chip designers using verticallyintegrated, captive semiconductor facilities to tens of thousands of designers using pure-play semiconductor foundries to create thousands of products. An approach to VLSI chip design that separates design from manufacturing (Mead & Conway, 1979). Design implementation: Use of simplified device & component models that trade some performance for automation of design. Design rules that are independent of and scalable with process technologies. Semiconductor manufacturing facility becomes the semiconductor foundry. Semiconductor product implementation: Chip prototypes are manufactured in silicon foundries using the same tools, fabrication processes and materials used for high-volume chip manufacturing… no seams. Continues to enable, cost-effective custom VLSI products: Generating new markets & new companies including Apple, Silicon Graphics, Cadence, Jazz, TSMC, Broadcom, Nvidia and Qualcomm. 31

Foundry-style manufacturing—integrated circuits The result: Moved from hundreds of chip designers using verticallyintegrated, captive semiconductor facilities to tens of thousands of designers using pure-play semiconductor foundries to create thousands of products. An approach to VLSI chip design that separates design from manufacturing (Mead & Conway, 1979). Design implementation: Use of simplified device & component models that trade some performance for automation of design. Design rules that are independent of and scalable with process technologies. Semiconductor manufacturing facility becomes the semiconductor foundry. Semiconductor product implementation: Chip prototypes are manufactured in silicon foundries using the same tools, fabrication processes and materials used for high-volume chip manufacturing… no seams. Continues to enable, cost-effective custom VLSI products: Generating new markets & new companies including Apple, Silicon Graphics, Cadence, Jazz, TSMC, Broadcom, Nvidia and Qualcomm. 31

![Effort (total $ * yrs to develop) [$*yr] Raising the level of abstraction—synthetic biology Effort (total $ * yrs to develop) [$*yr] Raising the level of abstraction—synthetic biology](https://present5.com/presentation/fc9d1014c0df3ea23cf8c0f935397513/image-32.jpg) Effort (total $ * yrs to develop) [$*yr] Raising the level of abstraction—synthetic biology minimal bacterium 1011 yeast SOA Design 107 106 $0. 004 2 days Mb’s weeks <1 day <10 s genes routine: <10 103 -104 genes 7 yrs <1 yr LF: after 6 mos 105 Living Foundries 104 metabolic engineering genome rewrite complex genetic circuits 103 $0. 45 -$0. 75 2 wks-2 mos 20 kb Total Time 108 <1 week Complexity 109 1 -3 months Test/Debug DARPA annual budget Goal DNA Synth. 1010 100 1, 000 100, 000 Complexity (# genes inserted/modified) 32

Effort (total $ * yrs to develop) [$*yr] Raising the level of abstraction—synthetic biology minimal bacterium 1011 yeast SOA Design 107 106 $0. 004 2 days Mb’s weeks <1 day <10 s genes routine: <10 103 -104 genes 7 yrs <1 yr LF: after 6 mos 105 Living Foundries 104 metabolic engineering genome rewrite complex genetic circuits 103 $0. 45 -$0. 75 2 wks-2 mos 20 kb Total Time 108 <1 week Complexity 109 1 -3 months Test/Debug DARPA annual budget Goal DNA Synth. 1010 100 1, 000 100, 000 Complexity (# genes inserted/modified) 32

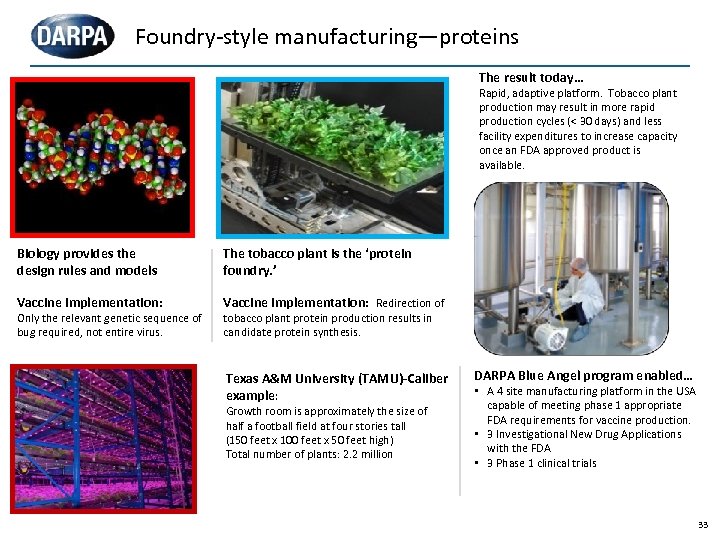

Foundry-style manufacturing—proteins The result today… Rapid, adaptive platform. Tobacco plant production may result in more rapid production cycles (< 30 days) and less facility expenditures to increase capacity once an FDA approved product is available. Biology provides the design rules and models The tobacco plant is the ‘protein foundry. ’ Vaccine implementation: Redirection of Only the relevant genetic sequence of bug required, not entire virus. tobacco plant protein production results in candidate protein synthesis. Texas A&M University (TAMU)-Caliber example: Growth room is approximately the size of half a football field at four stories tall (150 feet x 100 feet x 50 feet high) Total number of plants: 2. 2 million DARPA Blue Angel program enabled… • A 4 site manufacturing platform in the USA capable of meeting phase 1 appropriate FDA requirements for vaccine production. • 3 Investigational New Drug Applications with the FDA • 3 Phase 1 clinical trials 33

Foundry-style manufacturing—proteins The result today… Rapid, adaptive platform. Tobacco plant production may result in more rapid production cycles (< 30 days) and less facility expenditures to increase capacity once an FDA approved product is available. Biology provides the design rules and models The tobacco plant is the ‘protein foundry. ’ Vaccine implementation: Redirection of Only the relevant genetic sequence of bug required, not entire virus. tobacco plant protein production results in candidate protein synthesis. Texas A&M University (TAMU)-Caliber example: Growth room is approximately the size of half a football field at four stories tall (150 feet x 100 feet x 50 feet high) Total number of plants: 2. 2 million DARPA Blue Angel program enabled… • A 4 site manufacturing platform in the USA capable of meeting phase 1 appropriate FDA requirements for vaccine production. • 3 Investigational New Drug Applications with the FDA • 3 Phase 1 clinical trials 33

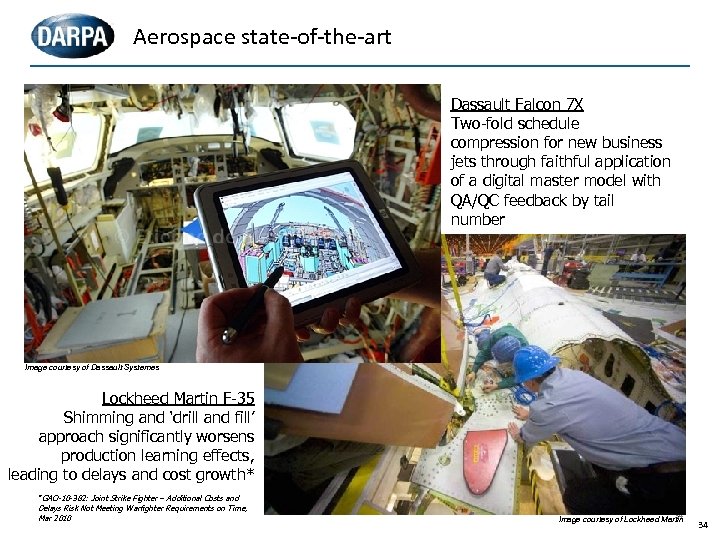

Aerospace state-of-the-art Dassault Falcon 7 X Two-fold schedule compression for new business jets through faithful application of a digital master model with QA/QC feedback by tail number Image courtesy of Dassault Systemes Lockheed Martin F-35 Shimming and ‘drill and fill’ approach significantly worsens production learning effects, leading to delays and cost growth* * GAO-10 -382: Joint Strike Fighter – Additional Costs and Delays Risk Not Meeting Warfighter Requirements on Time, Mar 2010 34 Image courtesy of Lockheed Martin 34

Aerospace state-of-the-art Dassault Falcon 7 X Two-fold schedule compression for new business jets through faithful application of a digital master model with QA/QC feedback by tail number Image courtesy of Dassault Systemes Lockheed Martin F-35 Shimming and ‘drill and fill’ approach significantly worsens production learning effects, leading to delays and cost growth* * GAO-10 -382: Joint Strike Fighter – Additional Costs and Delays Risk Not Meeting Warfighter Requirements on Time, Mar 2010 34 Image courtesy of Lockheed Martin 34

Adaptive Vehicle Make 35

Adaptive Vehicle Make 35

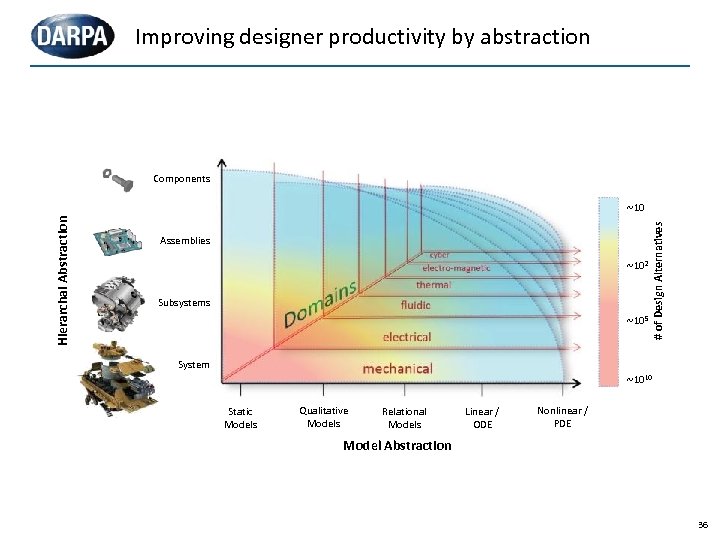

Improving designer productivity by abstraction Components Assemblies ~102 Subsystems ~105 # of Design Alternatives Hierarchal Abstraction ~10 System ~1010 Static Models Qualitative Models Relational Models Linear / ODE Nonlinear / PDE Model Abstraction 36

Improving designer productivity by abstraction Components Assemblies ~102 Subsystems ~105 # of Design Alternatives Hierarchal Abstraction ~10 System ~1010 Static Models Qualitative Models Relational Models Linear / ODE Nonlinear / PDE Model Abstraction 36

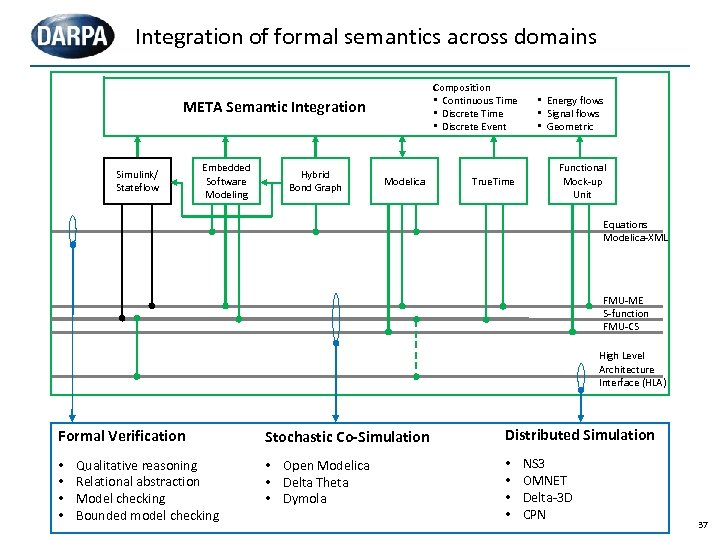

Integration of formal semantics across domains Composition • Continuous Time • Discrete Event META Semantic Integration Simulink/ Stateflow Embedded Software Modeling Hybrid Bond Graph Modelica True. Time • Energy flows • Signal flows • Geometric Functional Mock-up Unit Equations Modelica-XML FMU-ME S-function FMU-CS High Level Architecture Interface (HLA) Formal Verification • • Qualitative reasoning Relational abstraction Model checking Bounded model checking Stochastic Co-Simulation Distributed Simulation • Open Modelica • Delta Theta • Dymola • • NS 3 OMNET Delta-3 D CPN 37

Integration of formal semantics across domains Composition • Continuous Time • Discrete Event META Semantic Integration Simulink/ Stateflow Embedded Software Modeling Hybrid Bond Graph Modelica True. Time • Energy flows • Signal flows • Geometric Functional Mock-up Unit Equations Modelica-XML FMU-ME S-function FMU-CS High Level Architecture Interface (HLA) Formal Verification • • Qualitative reasoning Relational abstraction Model checking Bounded model checking Stochastic Co-Simulation Distributed Simulation • Open Modelica • Delta Theta • Dymola • • NS 3 OMNET Delta-3 D CPN 37

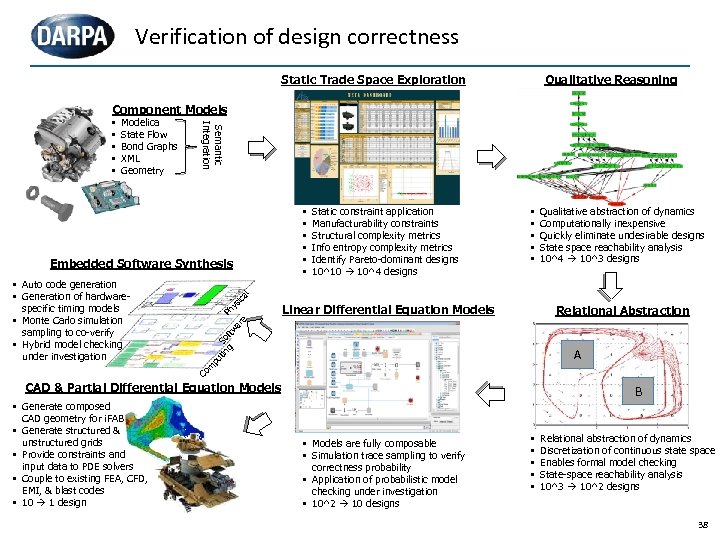

Verification of design correctness Qualitative Reasoning Static Trade Space Exploration Component Models Modelica State Flow Bond Graphs XML Geometry Semantic Integration • • • Qualitative abstraction of dynamics Computationally inexpensive Quickly eliminate undesirable designs State space reachability analysis 10^4 10^3 designs ica Relational Abstraction tin So g ftw ar e Ph ys Linear Differential Equation Models pu A Co m • Auto code generation • Generation of hardwarespecific timing models • Monte Carlo simulation sampling to co-verify • Hybrid model checking under investigation • • • l Embedded Software Synthesis Static constraint application Manufacturability constraints Structural complexity metrics Info entropy complexity metrics Identify Pareto-dominant designs 10^10 10^4 designs CAD & Partial Differential Equation Models • Generate composed CAD geometry for i. FAB • Generate structured & unstructured grids • Provide constraints and input data to PDE solvers • Couple to existing FEA, CFD, EMI, & blast codes • 10 1 design B • Models are fully composable • Simulation trace sampling to verify correctness probability • Application of probabilistic model checking under investigation • 10^2 10 designs • • • Relational abstraction of dynamics Discretization of continuous state space Enables formal model checking State-space reachability analysis 10^3 10^2 designs 38

Verification of design correctness Qualitative Reasoning Static Trade Space Exploration Component Models Modelica State Flow Bond Graphs XML Geometry Semantic Integration • • • Qualitative abstraction of dynamics Computationally inexpensive Quickly eliminate undesirable designs State space reachability analysis 10^4 10^3 designs ica Relational Abstraction tin So g ftw ar e Ph ys Linear Differential Equation Models pu A Co m • Auto code generation • Generation of hardwarespecific timing models • Monte Carlo simulation sampling to co-verify • Hybrid model checking under investigation • • • l Embedded Software Synthesis Static constraint application Manufacturability constraints Structural complexity metrics Info entropy complexity metrics Identify Pareto-dominant designs 10^10 10^4 designs CAD & Partial Differential Equation Models • Generate composed CAD geometry for i. FAB • Generate structured & unstructured grids • Provide constraints and input data to PDE solvers • Couple to existing FEA, CFD, EMI, & blast codes • 10 1 design B • Models are fully composable • Simulation trace sampling to verify correctness probability • Application of probabilistic model checking under investigation • 10^2 10 designs • • • Relational abstraction of dynamics Discretization of continuous state space Enables formal model checking State-space reachability analysis 10^3 10^2 designs 38

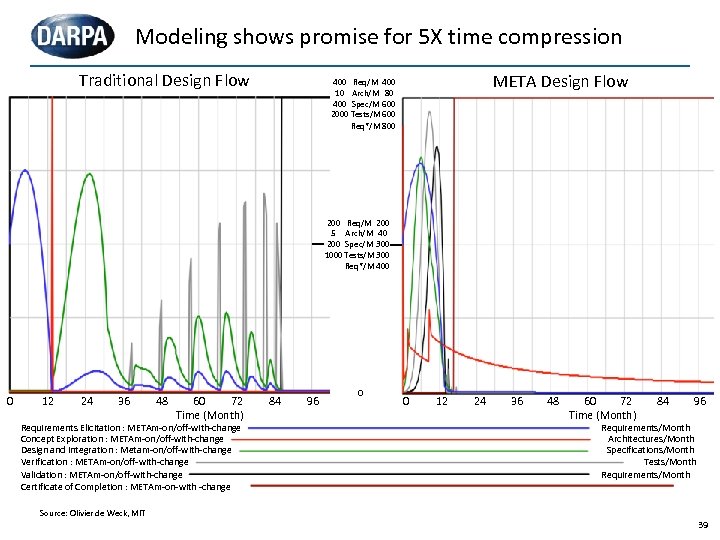

Modeling shows promise for 5 X time compression Traditional Design Flow META Design Flow 400 Req/M 400 10 Arch/M 80 400 Spec/M 600 2000 Tests/M 600 Req*/M 800 200 Req/M 200 5 Arch/M 40 200 Spec/M 300 1000 Tests/M 300 Req*/M 400 0 12 24 36 48 60 72 Time (Month) Requirements Elicitation : METAm-on/off-with-change Concept Exploration : METAm-on/off-with-change Design and Integration : Metam-on/off-with-change Verification : METAm-on/off-with-change Validation : METAm-on/off-with-change Certificate of Completion : METAm-on-with -change 84 96 0 0 12 24 36 48 60 72 Time (Month) 84 96 Requirements/Month Architectures/Month Specifications/Month Tests/Month Requirements/Month Source: Olivier de Weck, MIT 39

Modeling shows promise for 5 X time compression Traditional Design Flow META Design Flow 400 Req/M 400 10 Arch/M 80 400 Spec/M 600 2000 Tests/M 600 Req*/M 800 200 Req/M 200 5 Arch/M 40 200 Spec/M 300 1000 Tests/M 300 Req*/M 400 0 12 24 36 48 60 72 Time (Month) Requirements Elicitation : METAm-on/off-with-change Concept Exploration : METAm-on/off-with-change Design and Integration : Metam-on/off-with-change Verification : METAm-on/off-with-change Validation : METAm-on/off-with-change Certificate of Completion : METAm-on-with -change 84 96 0 0 12 24 36 48 60 72 Time (Month) 84 96 Requirements/Month Architectures/Month Specifications/Month Tests/Month Requirements/Month Source: Olivier de Weck, MIT 39

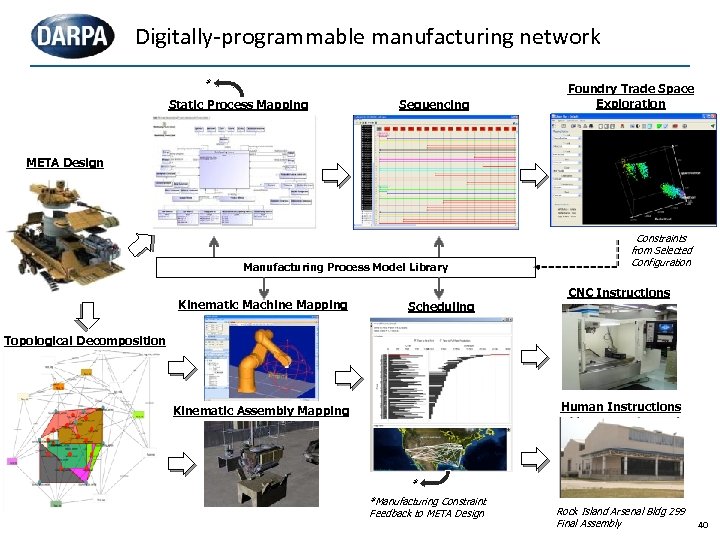

Digitally-programmable manufacturing network * Static Process Mapping Sequencing Foundry Trade Space Exploration META Design Manufacturing Process Model Library Kinematic Machine Mapping Scheduling Constraints from Selected Configuration CNC Instructions Topological Decomposition Human Instructions Kinematic Assembly Mapping * *Manufacturing Constraint Feedback to META Design Rock Island Arsenal Bldg 299 Final Assembly 40

Digitally-programmable manufacturing network * Static Process Mapping Sequencing Foundry Trade Space Exploration META Design Manufacturing Process Model Library Kinematic Machine Mapping Scheduling Constraints from Selected Configuration CNC Instructions Topological Decomposition Human Instructions Kinematic Assembly Mapping * *Manufacturing Constraint Feedback to META Design Rock Island Arsenal Bldg 299 Final Assembly 40

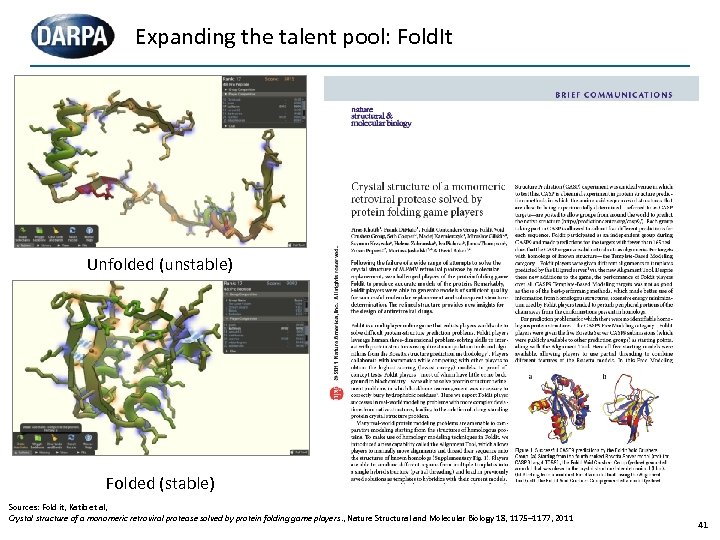

Expanding the talent pool: Fold. It Unfolded (unstable) Folded (stable) Sources: Fold it, Katib et al, Crystal structure of a monomeric retroviral protease solved by protein folding game players. , Nature Structural and Molecular Biology 18, 1175– 1177, 2011 41

Expanding the talent pool: Fold. It Unfolded (unstable) Folded (stable) Sources: Fold it, Katib et al, Crystal structure of a monomeric retroviral protease solved by protein folding game players. , Nature Structural and Molecular Biology 18, 1175– 1177, 2011 41

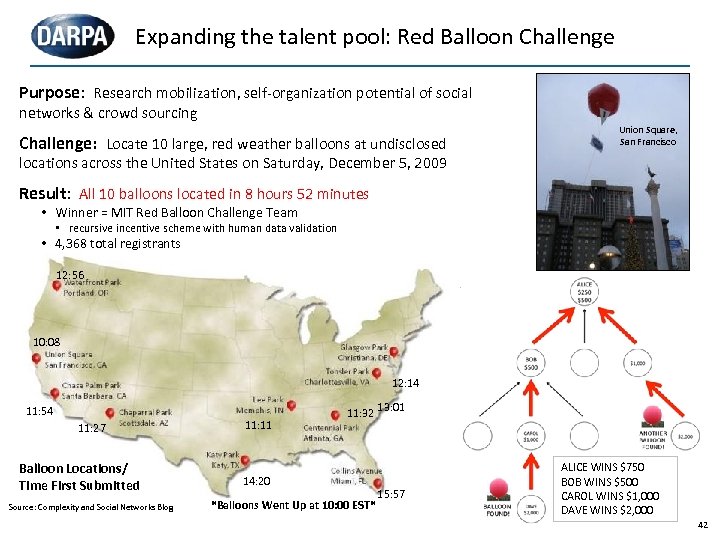

Expanding the talent pool: Red Balloon Challenge Purpose: Research mobilization, self-organization potential of social networks & crowd sourcing Challenge: Locate 10 large, red weather balloons at undisclosed Union Square, San Francisco locations across the United States on Saturday, December 5, 2009 Result: All 10 balloons located in 8 hours 52 minutes • Winner = MIT Red Balloon Challenge Team • recursive incentive scheme with human data validation • 4, 368 total registrants 12: 56 10: 08 12: 14 11: 54 11: 27 Balloon Locations/ Time First Submitted Source: Complexity and Social Networks Blog 11: 11 11: 32 14: 20 *Balloons Went Up at 10: 00 EST* 13: 01 15: 57 ALICE WINS $750 BOB WINS $500 CAROL WINS $1, 000 DAVE WINS $2, 000 42

Expanding the talent pool: Red Balloon Challenge Purpose: Research mobilization, self-organization potential of social networks & crowd sourcing Challenge: Locate 10 large, red weather balloons at undisclosed Union Square, San Francisco locations across the United States on Saturday, December 5, 2009 Result: All 10 balloons located in 8 hours 52 minutes • Winner = MIT Red Balloon Challenge Team • recursive incentive scheme with human data validation • 4, 368 total registrants 12: 56 10: 08 12: 14 11: 54 11: 27 Balloon Locations/ Time First Submitted Source: Complexity and Social Networks Blog 11: 11 11: 32 14: 20 *Balloons Went Up at 10: 00 EST* 13: 01 15: 57 ALICE WINS $750 BOB WINS $500 CAROL WINS $1, 000 DAVE WINS $2, 000 42

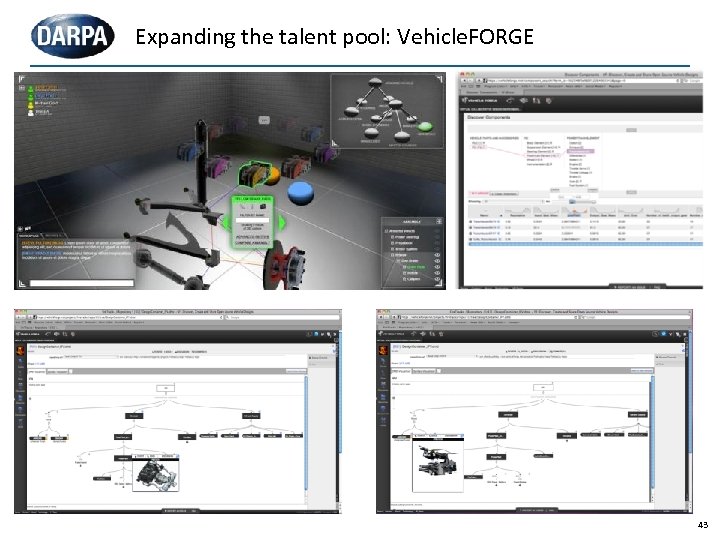

Expanding the talent pool: Vehicle. FORGE 43

Expanding the talent pool: Vehicle. FORGE 43

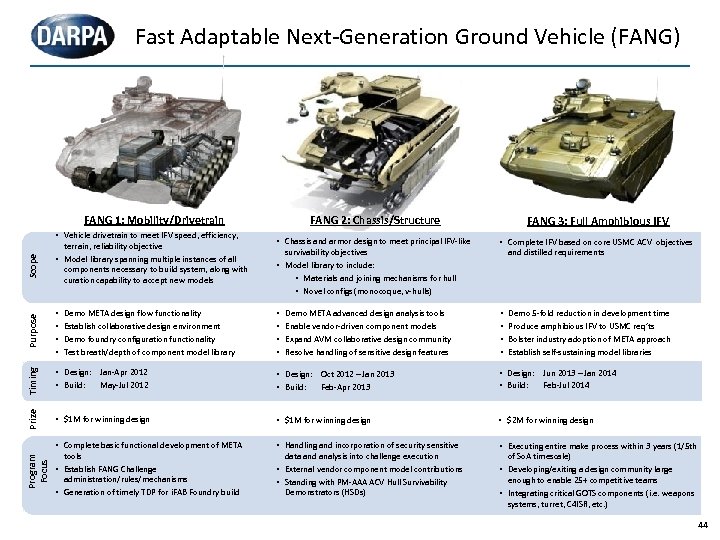

Fast Adaptable Next-Generation Ground Vehicle (FANG) FANG 1: Mobility/Drivetrain • Complete IFV based on core USMC ACV objectives • • • Design: Jan-Apr 2012 • Build: May-Jul 2012 • Design: Oct 2012 – Jan 2013 • Build: Feb-Apr 2013 • Design: Jun 2013 – Jan 2014 • Build: Feb-Jul 2014 • $1 M for winning design • $2 M for winning design • Complete basic functional development of META • Handling and incorporation of security sensitive • Executing entire make process within 3 years (1/5 th Program Focus Scope • Chassis and armor design to meet principal IFV-like terrain, reliability objective • Model library spanning multiple instances of all components necessary to build system, along with curation capability to accept new models Purpose FANG 3: Full Amphibious IFV Timing FANG 2: Chassis/Structure Prize • Vehicle drivetrain to meet IFV speed, efficiency, Demo META design flow functionality Establish collaborative design environment Demo foundry configuration functionality Test breath/depth of component model library tools • Establish FANG Challenge administration/rules/mechanisms • Generation of timely TDP for i. FAB Foundry build survivability objectives • Model library to include: • Materials and joining mechanisms for hull • Novel configs (monocoque, v-hulls) • • Demo META advanced design analysis tools Enable vendor-driven component models Expand AVM collaborative design community Resolve handling of sensitive design features data and analysis into challenge execution • External vendor component model contributions • Standing with PM-AAA ACV Hull Survivability Demonstrators (HSDs) and distilled requirements • • Demo 5 -fold reduction in development time Produce amphibious IFV to USMC req’ts Bolster industry adoption of META approach Establish self-sustaining model libraries of So. A timescale) • Developing/exiting a design community large enough to enable 25+ competitive teams • Integrating critical GOTS components (i. e. weapons systems, turret, C 4 ISR, etc. ) 44

Fast Adaptable Next-Generation Ground Vehicle (FANG) FANG 1: Mobility/Drivetrain • Complete IFV based on core USMC ACV objectives • • • Design: Jan-Apr 2012 • Build: May-Jul 2012 • Design: Oct 2012 – Jan 2013 • Build: Feb-Apr 2013 • Design: Jun 2013 – Jan 2014 • Build: Feb-Jul 2014 • $1 M for winning design • $2 M for winning design • Complete basic functional development of META • Handling and incorporation of security sensitive • Executing entire make process within 3 years (1/5 th Program Focus Scope • Chassis and armor design to meet principal IFV-like terrain, reliability objective • Model library spanning multiple instances of all components necessary to build system, along with curation capability to accept new models Purpose FANG 3: Full Amphibious IFV Timing FANG 2: Chassis/Structure Prize • Vehicle drivetrain to meet IFV speed, efficiency, Demo META design flow functionality Establish collaborative design environment Demo foundry configuration functionality Test breath/depth of component model library tools • Establish FANG Challenge administration/rules/mechanisms • Generation of timely TDP for i. FAB Foundry build survivability objectives • Model library to include: • Materials and joining mechanisms for hull • Novel configs (monocoque, v-hulls) • • Demo META advanced design analysis tools Enable vendor-driven component models Expand AVM collaborative design community Resolve handling of sensitive design features data and analysis into challenge execution • External vendor component model contributions • Standing with PM-AAA ACV Hull Survivability Demonstrators (HSDs) and distilled requirements • • Demo 5 -fold reduction in development time Produce amphibious IFV to USMC req’ts Bolster industry adoption of META approach Establish self-sustaining model libraries of So. A timescale) • Developing/exiting a design community large enough to enable 25+ competitive teams • Integrating critical GOTS components (i. e. weapons systems, turret, C 4 ISR, etc. ) 44

www. darpa. mil 45

www. darpa. mil 45