25b2fa31c1ea34929764429a3c384a55.ppt

- Количество слайдов: 31

ADAPT IT SMART SUMMIT DURBAN KENYA SUGAR INDUSTRY PROFILE Presented by Francis K. Ingara Engineering Department KENYA SUGAR BOARD ISO 9001: 2008 Certified

OUTLINE Kenyan Sugar Industry – at a glance Industry Performance New Projects Milestones Challenges Required interventions ISO 9001: 2008 Certified

KENYAN SUGAR INDUSTRY (At a Glance) Number of growers Number of mills Average capacity (TCD) Area under cane (Ha) >250, 000 11 3, 000 213, 710 ISO 9001: 2008 Certified

KENYAN SUGAR INDUSTRY (At a Glance) Cane yield (t/ha) Cane Delivered (MT) TC/TS Sugar Produced(MT) 51. 67 5, 822, 633 10. 23 493, 937 ISO 9001: 2008 Certified

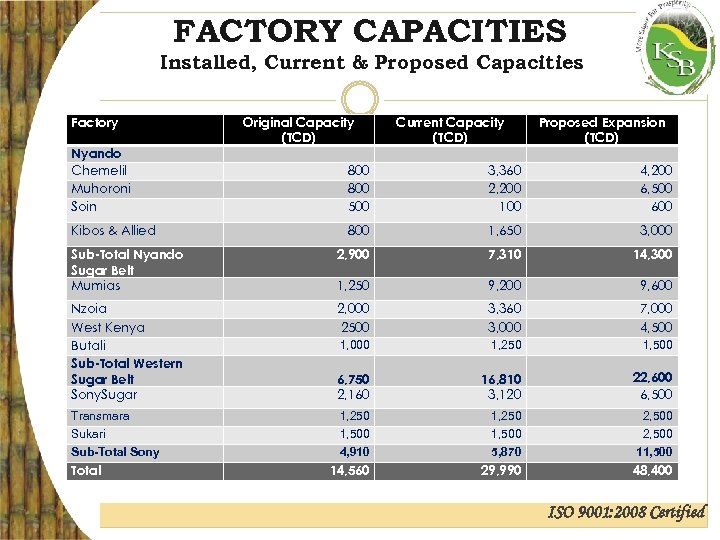

FACTORY CAPACITIES Installed, Current & Proposed Capacities Factory Nyando Chemelil Muhoroni Soin Original Capacity (TCD) Current Capacity (TCD) Proposed Expansion (TCD) 800 500 3, 360 2, 200 100 4, 200 6, 500 600 800 1, 650 3, 000 Sub-Total Nyando Sugar Belt Mumias 2, 900 7, 310 14, 300 1, 250 9, 200 9, 600 Nzoia West Kenya Butali Sub-Total Western Sugar Belt Sony. Sugar 2, 000 2500 3, 360 3, 000 7, 000 4, 500 1, 000 1, 250 1, 500 6, 750 2, 160 16, 810 3, 120 22, 600 6, 500 Transmara Sukari Sub-Total Sony 1, 250 1, 500 4, 910 1, 250 1, 500 5, 870 2, 500 11, 500 14, 560 29, 990 48, 400 Kibos & Allied Total Move table here ISO 9001: 2008 Certified

JAGGERY OPERATORS Lubao Jaggery Shajanand Ltd. Homalime Co. Farm Industries Ltd Over 300 informal including mobile jaggeries. Total cane crushed: 1. 45 Million tonnes ISO 9001: 2008 Certified

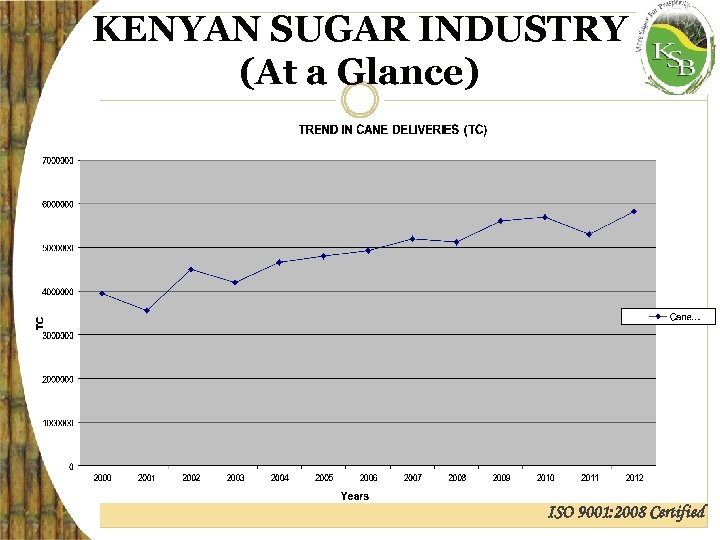

KENYAN SUGAR INDUSTRY (At a Glance) ISO 9001: 2008 Certified

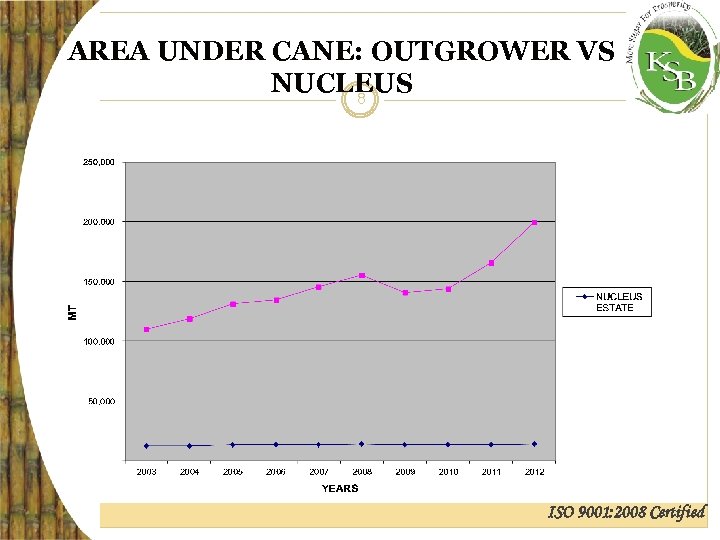

AREA UNDER CANE: OUTGROWER VS NUCLEUS 8 graph ISO 9001: 2008 Certified

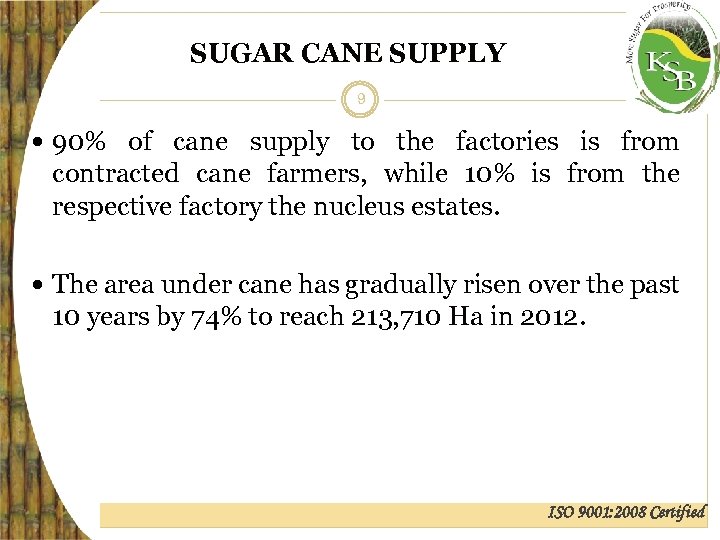

SUGAR CANE SUPPLY 9 90% of cane supply to the factories is from contracted cane farmers, while 10% is from the respective factory the nucleus estates. The area under cane has gradually risen over the past 10 years by 74% to reach 213, 710 Ha in 2012. ISO 9001: 2008 Certified

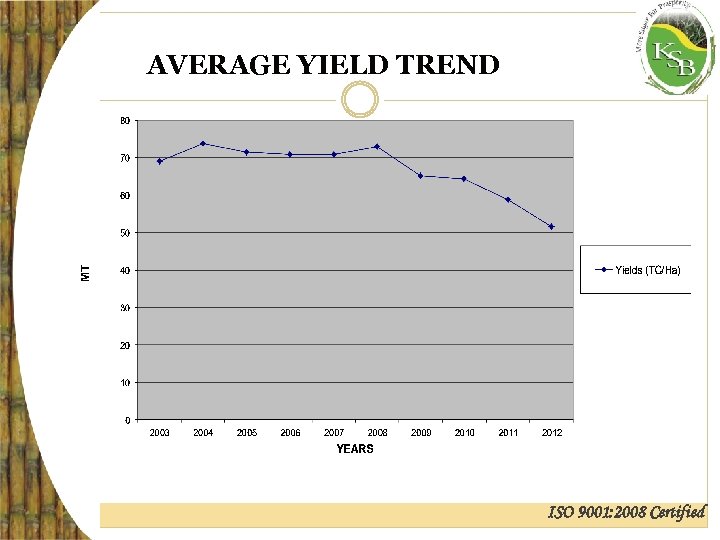

AVERAGE YIELD TREND ISO 9001: 2008 Certified

CANE YIELD The cane yields have been declining owing to continuous land use. The high cane demand has also led to occasional harvest of younger cane, reducing the yield. To mitigate this, we are currently undertaking research on soil management in the various agroecological zones, aimed at improving soil fertility. We have also embarked on a cane development program that will ensure adequate cane supply to all factories ISO 9001: 2008 Certified

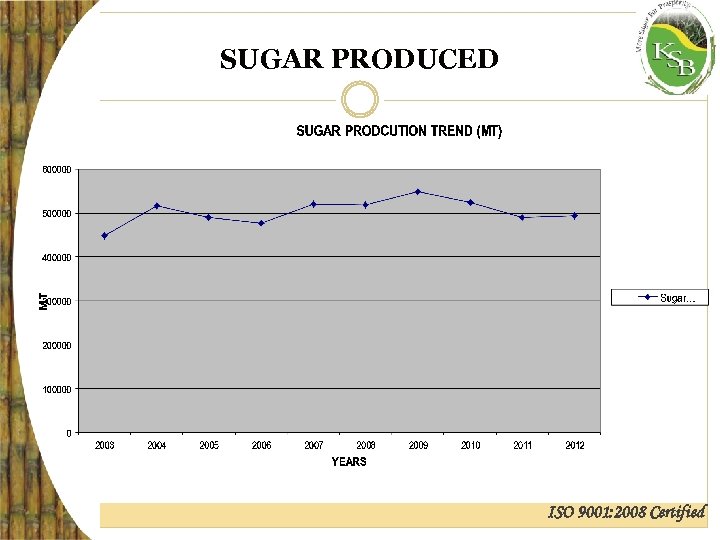

SUGAR PRODUCED ISO 9001: 2008 Certified

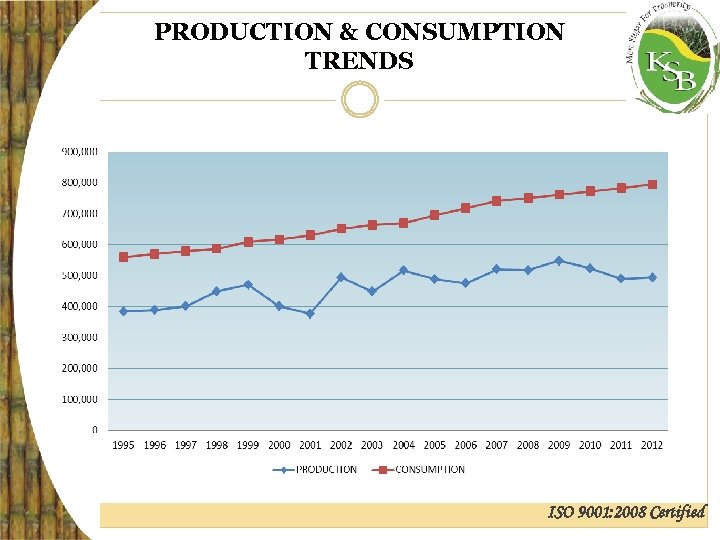

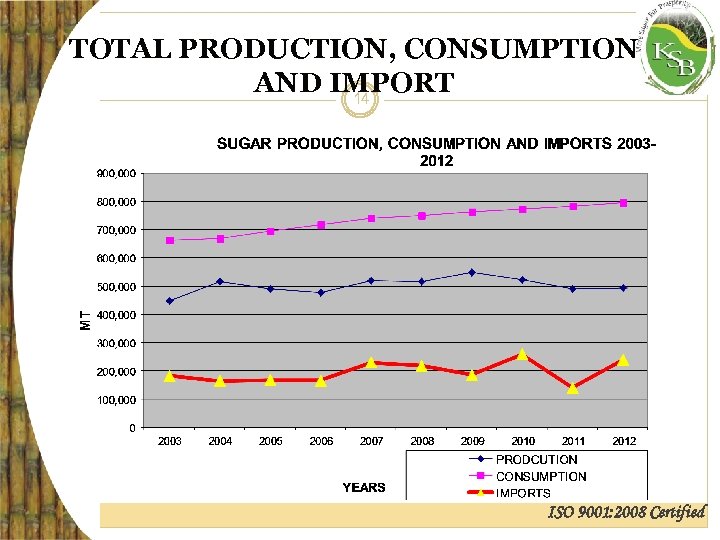

PRODUCTION & CONSUMPTION TRENDS ISO 9001: 2008 Certified

TOTAL PRODUCTION, CONSUMPTION AND IMPORT 14 ISO 9001: 2008 Certified

MILESTONES ISO 9001: 2008 Certified

MILESTONES 1. Co-generation The industry has potential to generate up to 190 MW of electricity from this source, which is currently under-exploited. Currently, only Mumias Sugar Company produces electricity for commercial use, having installed modern power generation equipment at a feed in tariff of 10 US cents per mw. The rest of the factories produce at a lower scale for consumption by the respective factories. ISO 9001: 2008 Certified

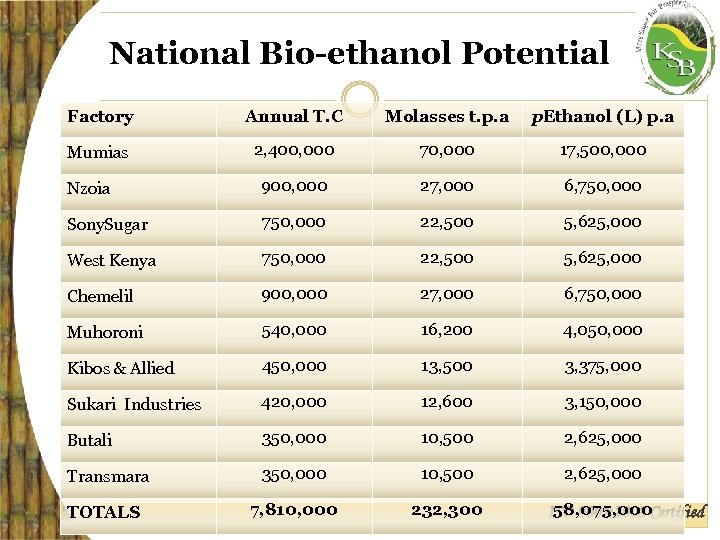

MILESTONES 2. Ethanol Production The National Bio-fuel Policy has been developed, which allows for 10% blending of ethanol with petrol. Mumias has already developed an ethanol plant, currently being commissioned. ISO 9001: 2008 Certified

National Bio-ethanol Potential Factory Annual T. C Molasses t. p. a p. Ethanol (L) p. a Mumias 2, 400, 000 70, 000 17, 500, 000 Nzoia 900, 000 27, 000 6, 750, 000 Sony. Sugar 750, 000 22, 500 5, 625, 000 West Kenya 750, 000 22, 500 5, 625, 000 Chemelil 900, 000 27, 000 6, 750, 000 Muhoroni 540, 000 16, 200 4, 050, 000 Kibos & Allied 450, 000 13, 500 3, 375, 000 Sukari Industries 420, 000 12, 600 3, 150, 000 Butali 350, 000 10, 500 2, 625, 000 Transmara 350, 000 10, 500 2, 625, 000 TOTALS 7, 810, 000 232, 300 58, 075, 000 ISO 9001: 2008 Certified

CHALLENGES ISO 9001: 2008 Certified

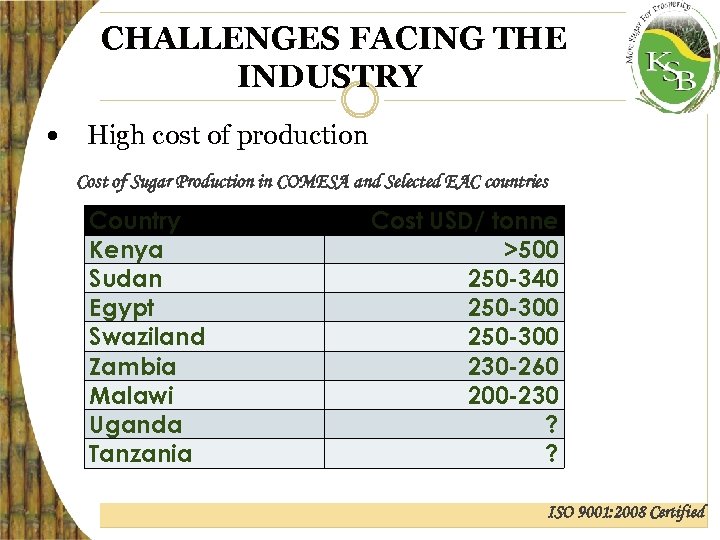

CHALLENGES FACING THE INDUSTRY High cost of production Cost of Sugar Production in COMESA and Selected EAC countries Country Kenya Sudan Egypt Swaziland Zambia Malawi Uganda Tanzania Cost USD/ tonne >500 250 -340 250 -300 230 -260 200 -230 ? ? ISO 9001: 2008 Certified

CHALLENGES FACING THE INDUSTRY High Cost of Inputs Punitive taxation regime Diminishing land sizes Reliance on rain-fed cane production Inadequate capital for operations, factory rehabilitation, maintenance of infrastructure, modernization and expansion ISO 9001: 2008 Certified

CHALLENGES FACING THE INDUSTRY Weak Research and Extension linkages Cane Fires Challenging regulatory framework with slow pace of amendment of laws and gazettement of regulations ISO 9001: 2008 Certified

CHALLENGES FACING THE INDUSTRY Changing farmer attitudes to view sugarcane production as a business Motivation of farmers to produce higher quality cane Reduced levels of factory efficiencies ISO 9001: 2008 Certified

REQUIRED INTERVENTIONS ISO 9001: 2008 Certified

Improved Productivity Introduction of cane quality monitoring processes Introduction of quality based cane purchase system to motivate farmers to deliver higher sucrose tonnages opposed to higher cane tonnages Improved factory performance management and reporting for easy benchmarking ISO 9001: 2008 Certified

Pilot Cane Testing Project at Nzoia Sugar The project scope includes the construction and equiping of a laboratory with cane sampling and testing equipment, installation of a cane payment IMS for capturing data from the weighbridge, cane testing laboratory and compilation of growers cane proceeds on the basis of the current legal cane payment fomula. Installation was through a turn-key project in which Bosch and Adapt IT were responsible for all project delivery activities. ISO 9001: 2008 Certified

Pilot Cane Testing Project at Nzoia Sugar ISO 9001: 2008 Certified

Pilot Cane Testing Project at Nzoia Sugar ISO 9001: 2008 Certified

Pilot Cane Testing Project at Nzoia Sugar ISO 9001: 2008 Certified

Pilot Cane Testing Project at Nzoia Sugar Project installation delivered successfully last December to KSB Kenya Sugar Research Foundation is currently undertaking trials on the economic feasibility of changing the countries cane payment system from that based on weight to one based on quality. To date over 1170 samples have been tested in the research phase of the project. ISO 9001: 2008 Certified

THANK YOU ISO 9001: 2008 Certified

25b2fa31c1ea34929764429a3c384a55.ppt