886e15322078ddc1fb026a87c1a6725b.ppt

- Количество слайдов: 28

Accounting Information Systems: Essential Concepts and Applications Fourth Edition by Wilkinson, Cerullo, Raval, and Wong-On-Wing Module 3: The Conversion Cycle Slides Authored by Somnath Florida Atlantic University Bhattacharya, Ph. D.

Accounting Information Systems: Essential Concepts and Applications Fourth Edition by Wilkinson, Cerullo, Raval, and Wong-On-Wing Module 3: The Conversion Cycle Slides Authored by Somnath Florida Atlantic University Bhattacharya, Ph. D.

Objectives of the Conversion Cycle - I z The major purpose of the Conversion Cycle is to transform raw materials into finished goods z Specifically, the objective is to ensure that: y 1) Adequate raw materials and other resources are available for production, while the investment in such resources is minimized y 2) Production costs are minimized through high labor productivity, full utilization of production equipment, low levels of scrap and rework, and optimal design of production layouts and procedures y 3) WIP inventories are transformed into finished goods, which are then either warehoused or shipped on schedule

Objectives of the Conversion Cycle - I z The major purpose of the Conversion Cycle is to transform raw materials into finished goods z Specifically, the objective is to ensure that: y 1) Adequate raw materials and other resources are available for production, while the investment in such resources is minimized y 2) Production costs are minimized through high labor productivity, full utilization of production equipment, low levels of scrap and rework, and optimal design of production layouts and procedures y 3) WIP inventories are transformed into finished goods, which are then either warehoused or shipped on schedule

Objectives of the Conversion Cycle - II y 4) Establish levels of product quality and after-sales service are attained y 5) Costs for each order or process are accumulated fully and accurately

Objectives of the Conversion Cycle - II y 4) Establish levels of product quality and after-sales service are attained y 5) Costs for each order or process are accumulated fully and accurately

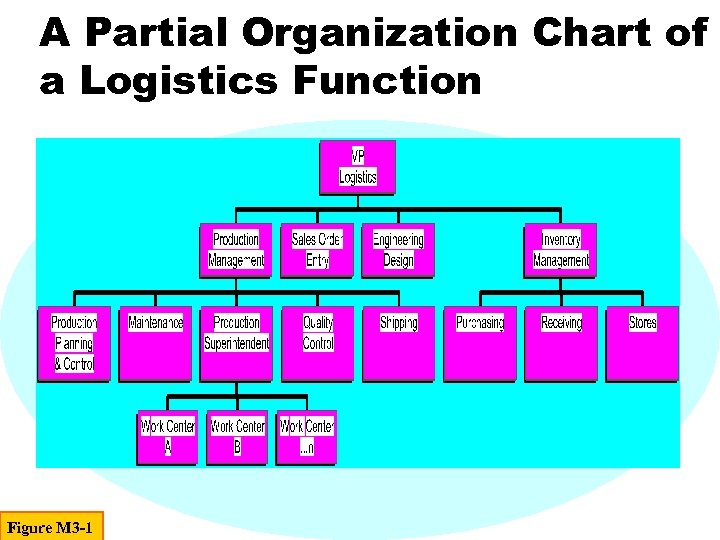

A Partial Organization Chart of a Logistics Function Figure M 3 -1

A Partial Organization Chart of a Logistics Function Figure M 3 -1

Forms of Data Input z. Customer order z. Bill of materials z. Operations list/Routing slip z. Production schedule z. Production order z. Materials issue slip/Materials requisition z. Labor job-time ticket z. Move ticket/traveler z. Inspection report(s)

Forms of Data Input z. Customer order z. Bill of materials z. Operations list/Routing slip z. Production schedule z. Production order z. Materials issue slip/Materials requisition z. Labor job-time ticket z. Move ticket/traveler z. Inspection report(s)

Computerized Data Entry z Data are captured via terminals or micro-based work-stations using such techniques as keyed-in alphanumeric codes, inserted badges or cards, scanned bar codes, or touched monitor screens. z Preformatted documents are automatically generated using application software and on-line data bases. z Electronic copies of the documents are maintained in on-line files, and hard-copy forms are printed only as needed and requested.

Computerized Data Entry z Data are captured via terminals or micro-based work-stations using such techniques as keyed-in alphanumeric codes, inserted badges or cards, scanned bar codes, or touched monitor screens. z Preformatted documents are automatically generated using application software and on-line data bases. z Electronic copies of the documents are maintained in on-line files, and hard-copy forms are printed only as needed and requested.

Data Processing z. The conversion cycle encompasses three major processing steps: y. Production planning y. Production operations y. Accounting for production costs

Data Processing z. The conversion cycle encompasses three major processing steps: y. Production planning y. Production operations y. Accounting for production costs

Advantages of Computer Integrated Manufacturing Systems - I z 1) The materials requirements relating to demands for products are determined beforehand, so that the materials are transferred to the production areas in time for production starts z 2) Production orders are scheduled to accommodate the manufacturing capacity z 3) Data are validated upon online entry, so that errors are detected more quickly and reprocessing delays due to undetected errors are reduced

Advantages of Computer Integrated Manufacturing Systems - I z 1) The materials requirements relating to demands for products are determined beforehand, so that the materials are transferred to the production areas in time for production starts z 2) Production orders are scheduled to accommodate the manufacturing capacity z 3) Data are validated upon online entry, so that errors are detected more quickly and reprocessing delays due to undetected errors are reduced

Advantages of Computer Integrated Manufacturing Systems - II z 4) Inventory and production order records are updated in a timely manner from materials requisitions, labor-time entries, and move tickets z 5) Accounting-related processing is simplified, since transactions are posted without sorting to online files z 6) Control reports such as cost variance analyses are prepared for managers

Advantages of Computer Integrated Manufacturing Systems - II z 4) Inventory and production order records are updated in a timely manner from materials requisitions, labor-time entries, and move tickets z 5) Accounting-related processing is simplified, since transactions are posted without sorting to online files z 6) Control reports such as cost variance analyses are prepared for managers

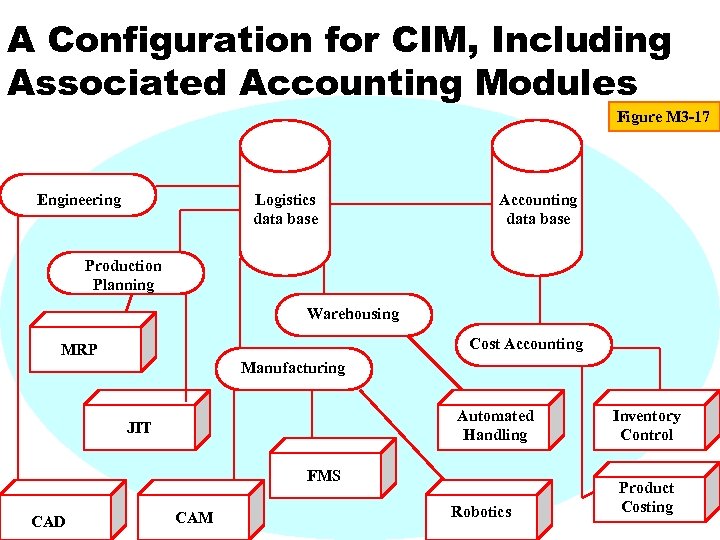

A Configuration for CIM, Including Associated Accounting Modules Figure M 3 -17 Engineering Logistics data base Accounting data base Production Planning Warehousing Cost Accounting MRP Manufacturing Automated Handling JIT FMS CAD CAM Robotics Inventory Control Product Costing

A Configuration for CIM, Including Associated Accounting Modules Figure M 3 -17 Engineering Logistics data base Accounting data base Production Planning Warehousing Cost Accounting MRP Manufacturing Automated Handling JIT FMS CAD CAM Robotics Inventory Control Product Costing

Benefits of CIM Systems - I z. Greater flexibility in meeting the changing needs of customers z. Savings in the material inventory investment z. Increased quality in products z. Optimal scheduling of production, with dynamic adjustments as conditions change or new orders are received

Benefits of CIM Systems - I z. Greater flexibility in meeting the changing needs of customers z. Savings in the material inventory investment z. Increased quality in products z. Optimal scheduling of production, with dynamic adjustments as conditions change or new orders are received

Benefits of CIM Systems - II z. Shorter production cycle times z. Improved productivity of employees and hence reduced labor costs z. Continuous monitoring of production operations, with immediate feedback of control problems as they arise

Benefits of CIM Systems - II z. Shorter production cycle times z. Improved productivity of employees and hence reduced labor costs z. Continuous monitoring of production operations, with immediate feedback of control problems as they arise

Benefits of CIM Systems - III z. Savings in paperwork costs, since most interactions are performed via computer and records are stored electronically z. Better utilization of all production facilities z. Greater accessibility of information, including the ability to provide ad hoc reports for planning and control

Benefits of CIM Systems - III z. Savings in paperwork costs, since most interactions are performed via computer and records are stored electronically z. Better utilization of all production facilities z. Greater accessibility of information, including the ability to provide ad hoc reports for planning and control

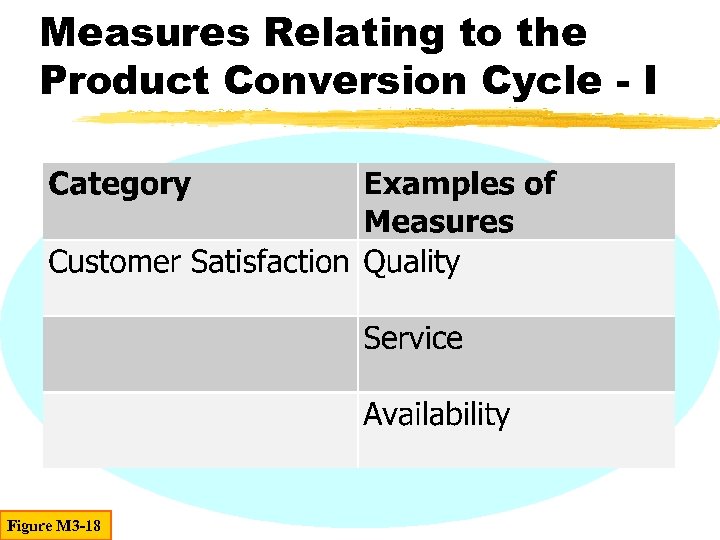

Measures Relating to the Product Conversion Cycle - I Figure M 3 -18

Measures Relating to the Product Conversion Cycle - I Figure M 3 -18

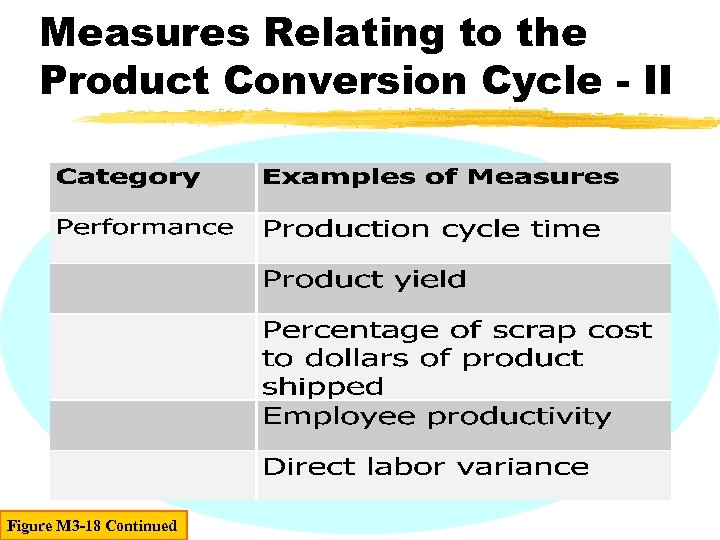

Measures Relating to the Product Conversion Cycle - II Figure M 3 -18 Continued

Measures Relating to the Product Conversion Cycle - II Figure M 3 -18 Continued

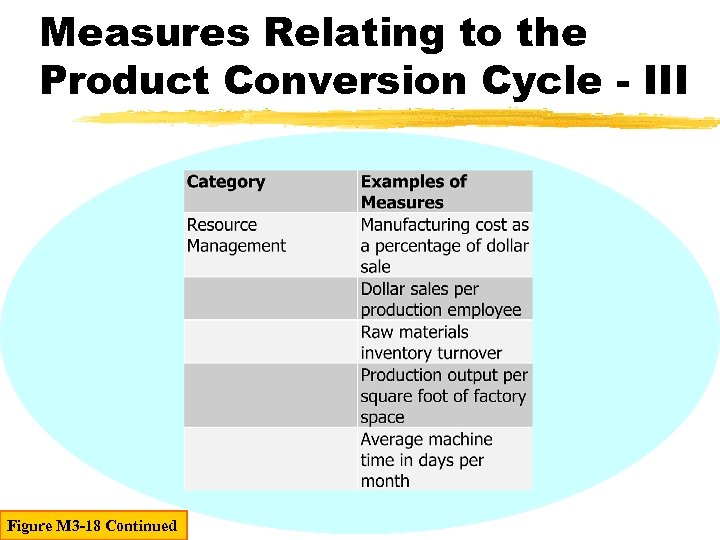

Measures Relating to the Product Conversion Cycle - III Figure M 3 -18 Continued

Measures Relating to the Product Conversion Cycle - III Figure M 3 -18 Continued

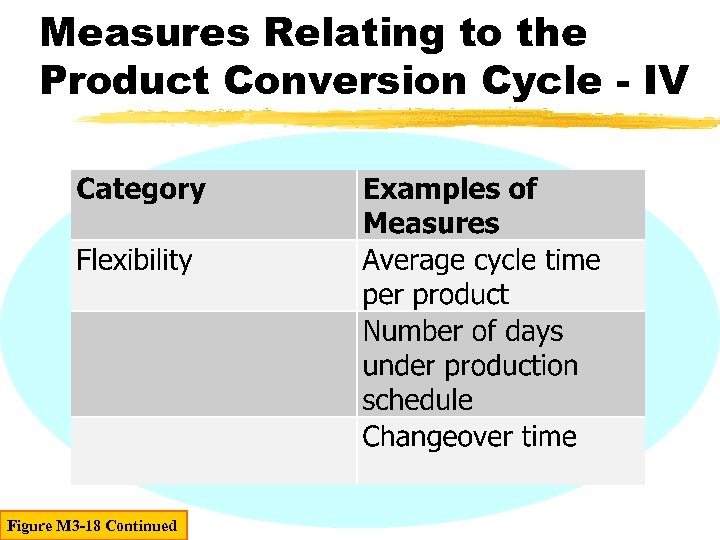

Measures Relating to the Product Conversion Cycle - IV Figure M 3 -18 Continued

Measures Relating to the Product Conversion Cycle - IV Figure M 3 -18 Continued

Scheduled Managerial Reports z Employee productivity reports that compare the output of the operations work center employees against standard levels of production z Work center performance reports that reflect the efficiency of each work center z Open production order status reports that show which orders are behind schedule and by how much z Equipment utilization reports that show the percentage of downtime for each piece of factory equipment z Waste reports that show the percentages of scrap, rework, and rejects for the production orders currently in process

Scheduled Managerial Reports z Employee productivity reports that compare the output of the operations work center employees against standard levels of production z Work center performance reports that reflect the efficiency of each work center z Open production order status reports that show which orders are behind schedule and by how much z Equipment utilization reports that show the percentage of downtime for each piece of factory equipment z Waste reports that show the percentages of scrap, rework, and rejects for the production orders currently in process

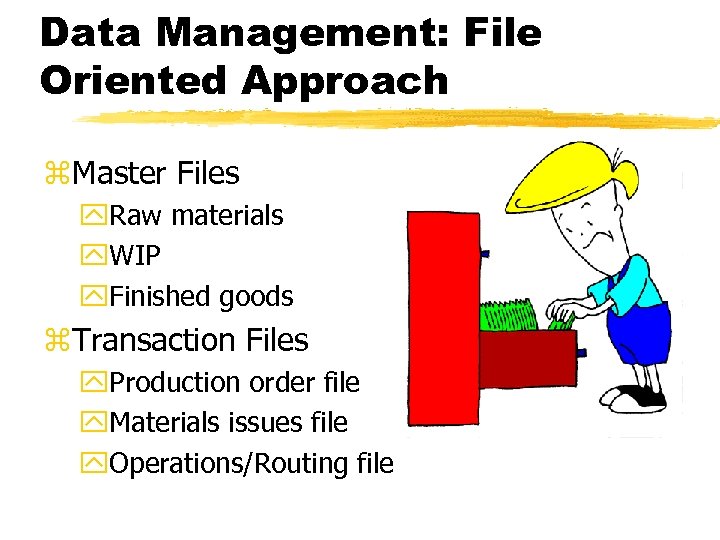

Data Management: File Oriented Approach z. Master Files y. Raw materials y. WIP y. Finished goods z. Transaction Files y. Production order file y. Materials issues file y. Operations/Routing file

Data Management: File Oriented Approach z. Master Files y. Raw materials y. WIP y. Finished goods z. Transaction Files y. Production order file y. Materials issues file y. Operations/Routing file

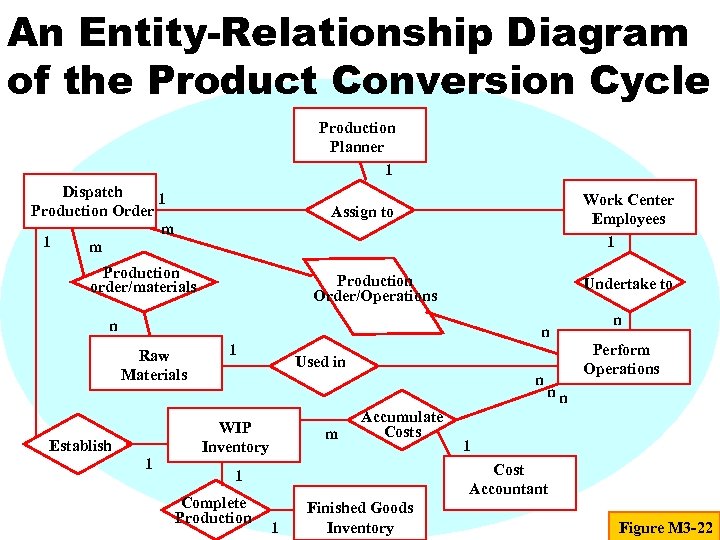

An Entity-Relationship Diagram of the Product Conversion Cycle Production Planner 1 Dispatch 1 Production Order m 1 m Work Center Employees 1 Assign to Production order/materials Production Order/Operations Undertake to n n Raw Materials Establish 1 1 WIP Inventory m Accumulate Costs nn 1 Cost Accountant 1 Complete Production Perform Operations Used in n n 1 Finished Goods Inventory Figure M 3 -22

An Entity-Relationship Diagram of the Product Conversion Cycle Production Planner 1 Dispatch 1 Production Order m 1 m Work Center Employees 1 Assign to Production order/materials Production Order/Operations Undertake to n n Raw Materials Establish 1 1 WIP Inventory m Accumulate Costs nn 1 Cost Accountant 1 Complete Production Perform Operations Used in n n 1 Finished Goods Inventory Figure M 3 -22

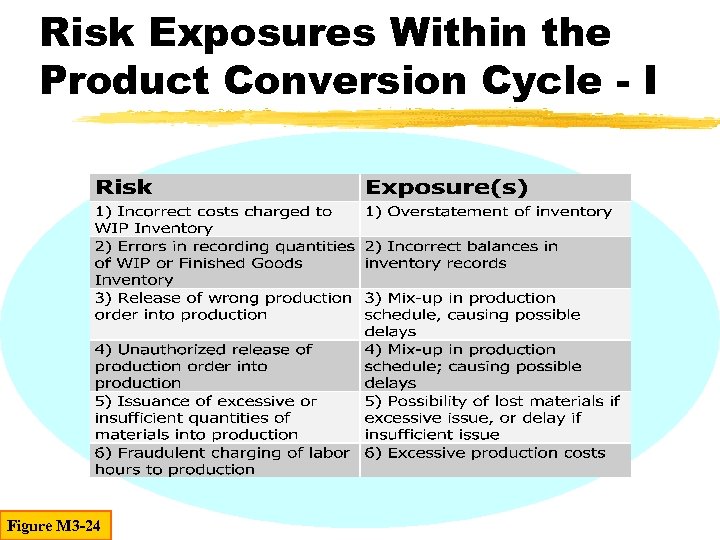

Risk Exposures Within the Product Conversion Cycle - I Figure M 3 -24

Risk Exposures Within the Product Conversion Cycle - I Figure M 3 -24

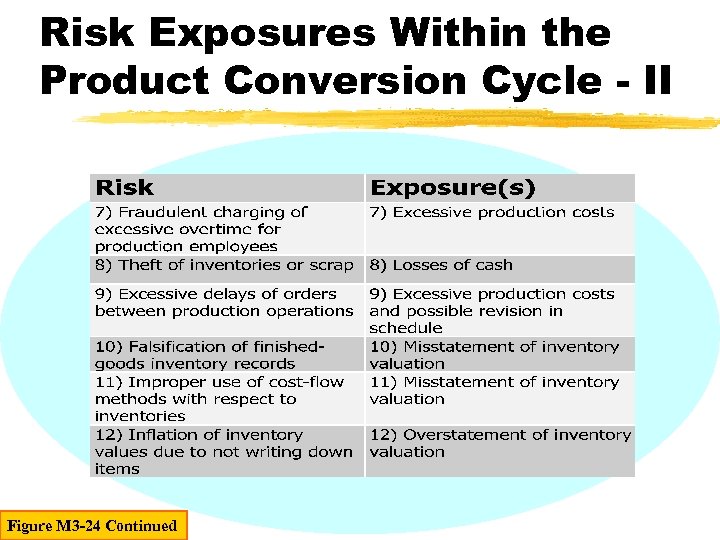

Risk Exposures Within the Product Conversion Cycle - II Figure M 3 -24 Continued

Risk Exposures Within the Product Conversion Cycle - II Figure M 3 -24 Continued

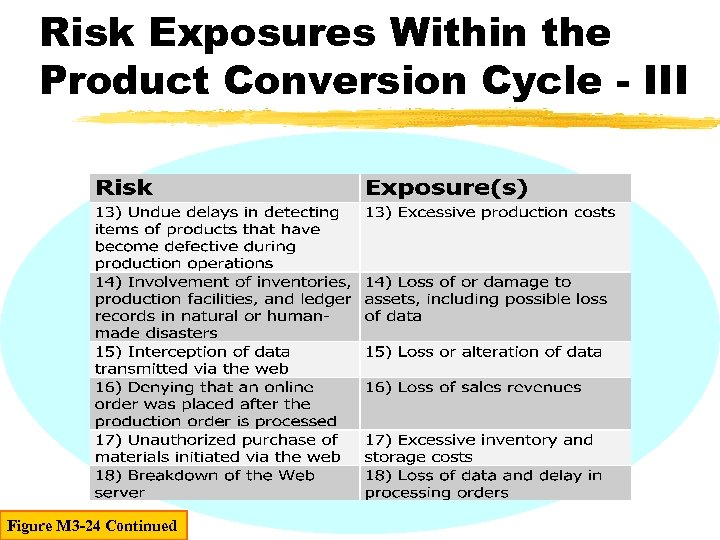

Risk Exposures Within the Product Conversion Cycle - III Figure M 3 -24 Continued

Risk Exposures Within the Product Conversion Cycle - III Figure M 3 -24 Continued

Control Objectives z To ensure that: y. All production orders are properly authorized and scheduled y. All needed raw materials and other resources are assigned to production orders promptly and accurately, and the related costs are accumulated fully in accordance with the established system of cost accounting y. All movements of production orders through the production process are reflected by acknowledgements at the various work centers y. All finished goods are valued properly y. All inventories are adequately safeguarded

Control Objectives z To ensure that: y. All production orders are properly authorized and scheduled y. All needed raw materials and other resources are assigned to production orders promptly and accurately, and the related costs are accumulated fully in accordance with the established system of cost accounting y. All movements of production orders through the production process are reflected by acknowledgements at the various work centers y. All finished goods are valued properly y. All inventories are adequately safeguarded

General Controls z. Organizational z. Documentation z. Asset Accountability z. Management Practices z. Authorization z. Access

General Controls z. Organizational z. Documentation z. Asset Accountability z. Management Practices z. Authorization z. Access

Application Controls z. Input Controls z. Processing Controls z. Output Controls

Application Controls z. Input Controls z. Processing Controls z. Output Controls

Web Security Procedures z. Authentication z. Authorization z. Accountability z. Data Transmission z. Disaster Contingency and Recovery Plan

Web Security Procedures z. Authentication z. Authorization z. Accountability z. Data Transmission z. Disaster Contingency and Recovery Plan

Accounting Information Systems: Essential Concepts and Applications Fourth Edition by Wilkinson, Cerullo, Raval, and Wong-On-Wing Copyright © 2000 John Wiley & Sons, Inc. All rights reserved. Reproduction or translation of this work beyond that permitted in Section 117 of the 1976 United States Copyright Act without the express written permission of the copyright owner is unlawful. Request for further information should be addressed to the Permissions Department, John Wiley & Sons, Inc. The purchaser may make back-up copies for his/her own use only and not for distribution or resale. The publisher assumes no responsibility for errors, omissions, or damages, caused by the use of these programs or from the use of the information contained herein.

Accounting Information Systems: Essential Concepts and Applications Fourth Edition by Wilkinson, Cerullo, Raval, and Wong-On-Wing Copyright © 2000 John Wiley & Sons, Inc. All rights reserved. Reproduction or translation of this work beyond that permitted in Section 117 of the 1976 United States Copyright Act without the express written permission of the copyright owner is unlawful. Request for further information should be addressed to the Permissions Department, John Wiley & Sons, Inc. The purchaser may make back-up copies for his/her own use only and not for distribution or resale. The publisher assumes no responsibility for errors, omissions, or damages, caused by the use of these programs or from the use of the information contained herein.