3d549c34d7f8f6dba0132413258cbb8b.ppt

- Количество слайдов: 14

Abstracts: 344, 350, 646 Precision Drift Chambers for the ATLAS Muon Spectrometer Susanne Mohrdieck Max-Planck-Institut f. Physik, Munich for the ATLAS Muon Collaboration International Europhysics Conference on High-Energy Physics 17. -23. 7. 2003 Outline: Ø Introduction - ATLAS and the muon spectrometer Ø Precision chamber production Ø Monitoring and measurement of chamber quality/accuracy Ø Performance test of precision chambers under LHC operating conditions

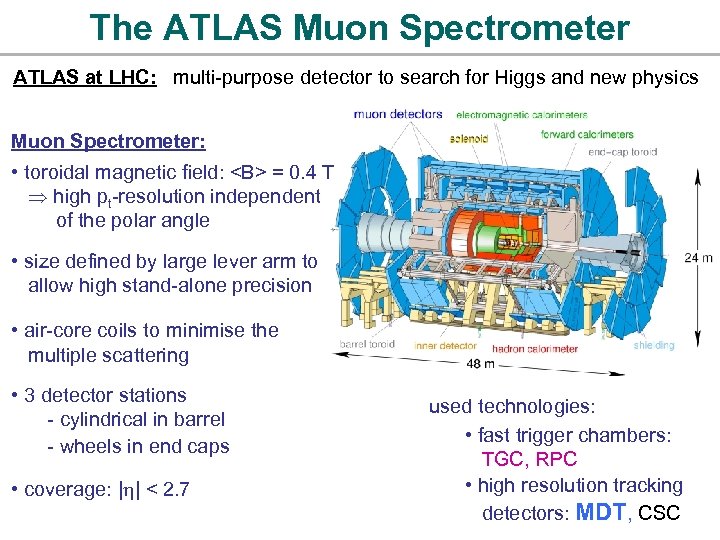

The ATLAS Muon Spectrometer ATLAS at LHC: multi-purpose detector to search for Higgs and new physics Muon Spectrometer: • toroidal magnetic field: <B> = 0. 4 T high pt-resolution independent of the polar angle • size defined by large lever arm to allow high stand-alone precision • air-core coils to minimise the multiple scattering • 3 detector stations - cylindrical in barrel - wheels in end caps • coverage: | | < 2. 7 used technologies: • fast trigger chambers: TGC, RPC • high resolution tracking detectors: MDT, CSC

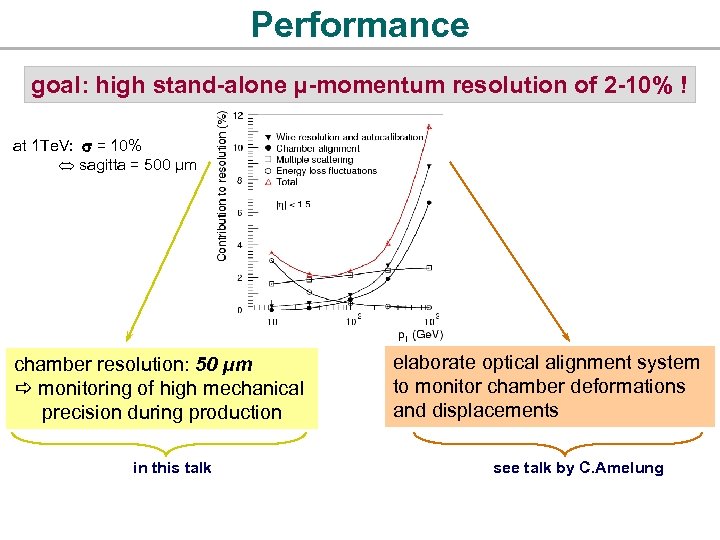

Performance goal: high stand-alone µ-momentum resolution of 2 -10% ! at 1 Te. V: = 10% sagitta = 500 µm chamber resolution: 50 µm monitoring of high mechanical precision during production in this talk elaborate optical alignment system to monitor chamber deformations and displacements see talk by C. Amelung

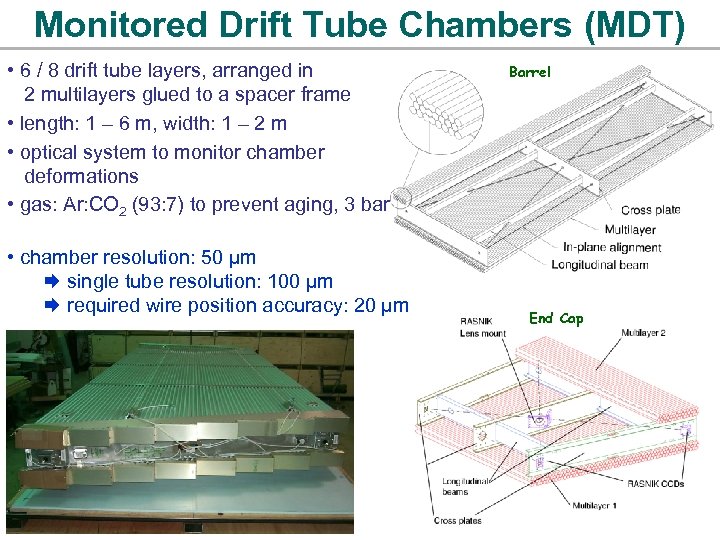

Monitored Drift Tube Chambers (MDT) • 6 / 8 drift tube layers, arranged in 2 multilayers glued to a spacer frame • length: 1 – 6 m, width: 1 – 2 m • optical system to monitor chamber deformations • gas: Ar: CO 2 (93: 7) to prevent aging, 3 bar • chamber resolution: 50 µm single tube resolution: 100 µm required wire position accuracy: 20 µm Barrel End Cap

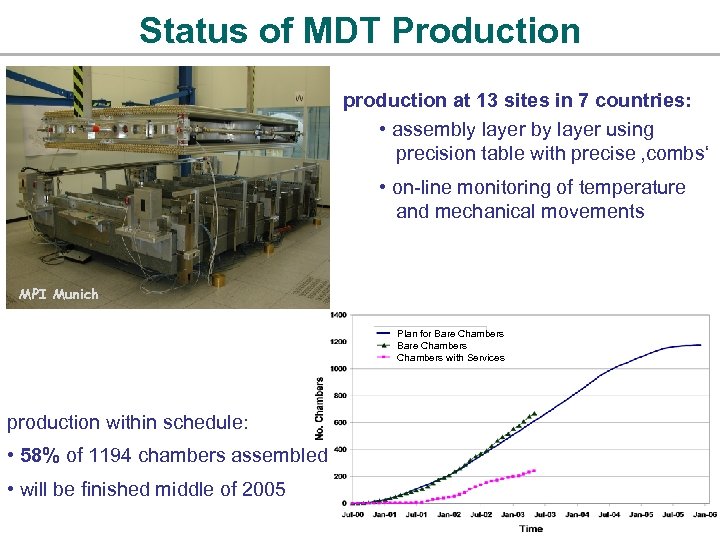

Status of MDT Production production at 13 sites in 7 countries: • assembly layer by layer using precision table with precise ‚combs‘ • on-line monitoring of temperature and mechanical movements MPI Munich Plan for Bare Chambers with Services production within schedule: • 58% of 1194 chambers assembled • will be finished middle of 2005

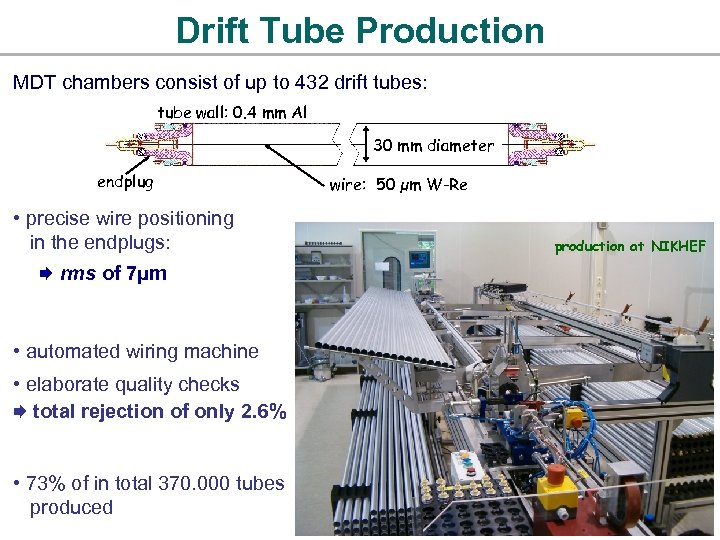

Drift Tube Production MDT chambers consist of up to 432 drift tubes: tube wall: 0. 4 mm Al 30 mm diameter endplug • precise wire positioning in the endplugs: rms of 7µm • automated wiring machine • elaborate quality checks total rejection of only 2. 6% • 73% of in total 370. 000 tubes produced wire: 50 µm W-Re production at NIKHEF

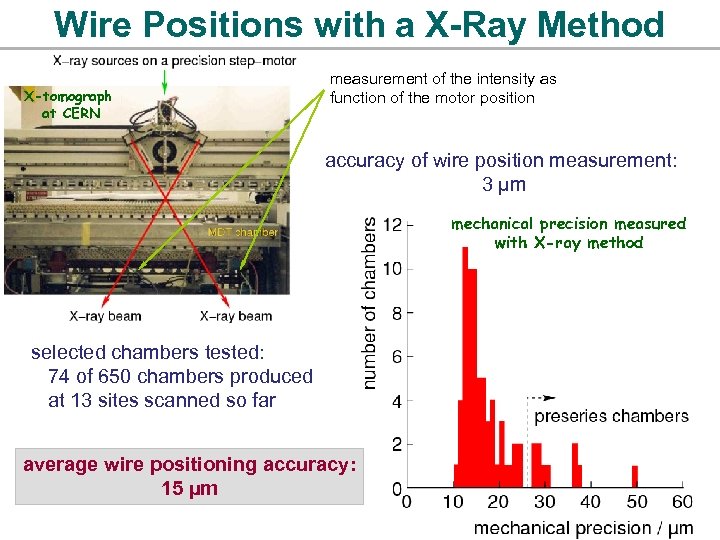

Wire Positions with a X-Ray Method X-tomograph at CERN measurement of the intensity as function of the motor position accuracy of wire position measurement: 3 µm mechanical precision measured with X-ray method selected chambers tested: 74 of 650 chambers produced at 13 sites scanned so far average wire positioning accuracy: 15 µm

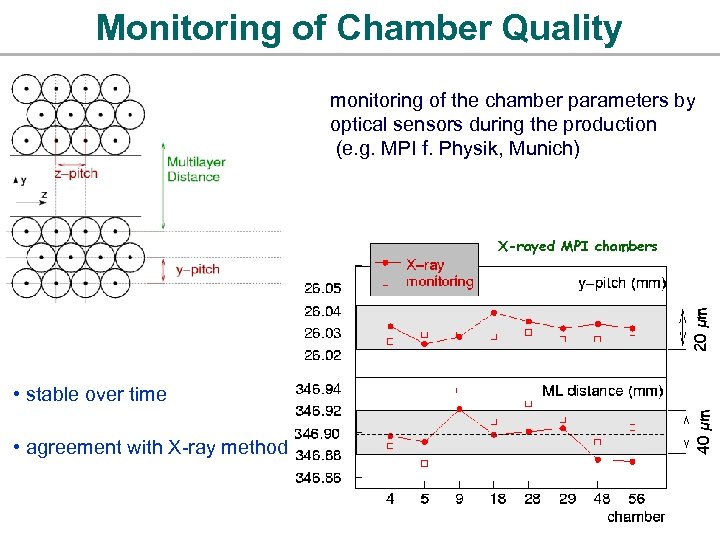

Monitoring of Chamber Quality monitoring of the chamber parameters by optical sensors during the production (e. g. MPI f. Physik, Munich) 20 µm X-rayed MPI chambers • agreement with X-ray method 40 µm • stable over time

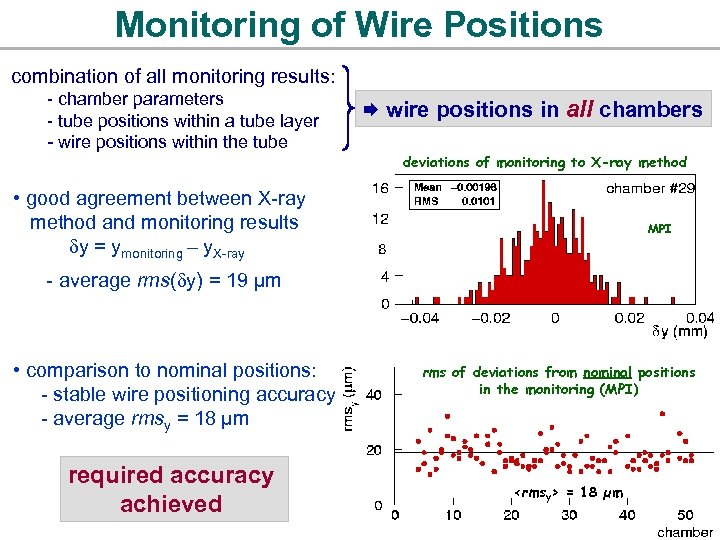

Monitoring of Wire Positions combination of all monitoring results: - chamber parameters - tube positions within a tube layer - wire positions within the tube wire positions in all chambers deviations of monitoring to X-ray method • good agreement between X-ray method and monitoring results y = ymonitoring – y. X-ray MPI - average rms( y) = 19 µm • comparison to nominal positions: - stable wire positioning accuracy - average rmsy = 18 µm required accuracy achieved rms of deviations from nominal positions in the monitoring (MPI) <rmsy> = 18 µm

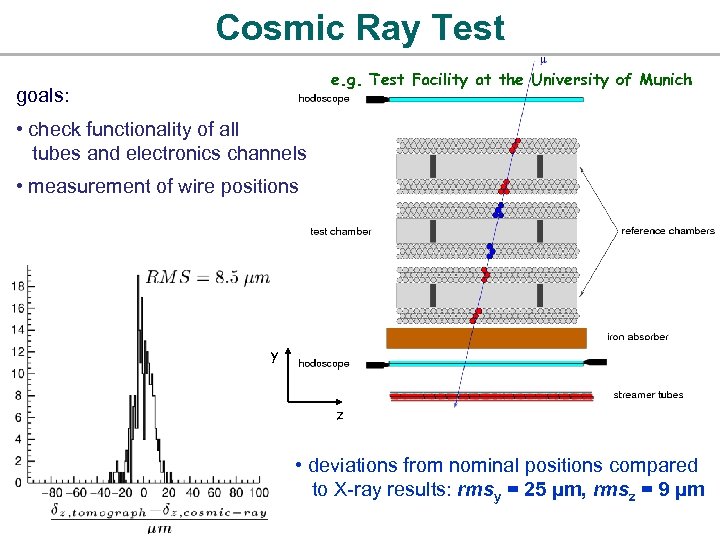

Cosmic Ray Test e. g. Test Facility at the University of Munich goals: • check functionality of all tubes and electronics channels • measurement of wire positions y z • deviations from nominal positions compared to X-ray results: rmsy = 25 µm, rmsz = 9 µm

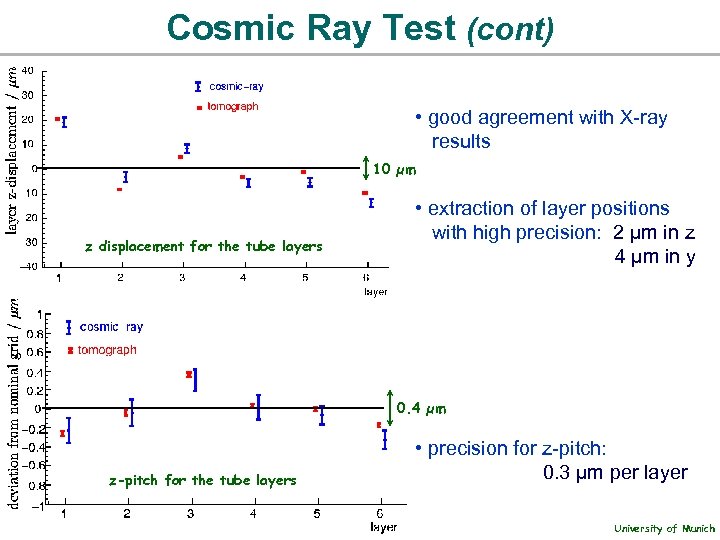

Cosmic Ray Test (cont) • good agreement with X-ray results 10 µm z displacement for the tube layers • extraction of layer positions with high precision: 2 µm in z 4 µm in y 0. 4 µm z-pitch for the tube layers • precision for z-pitch: 0. 3 µm per layer University of Munich

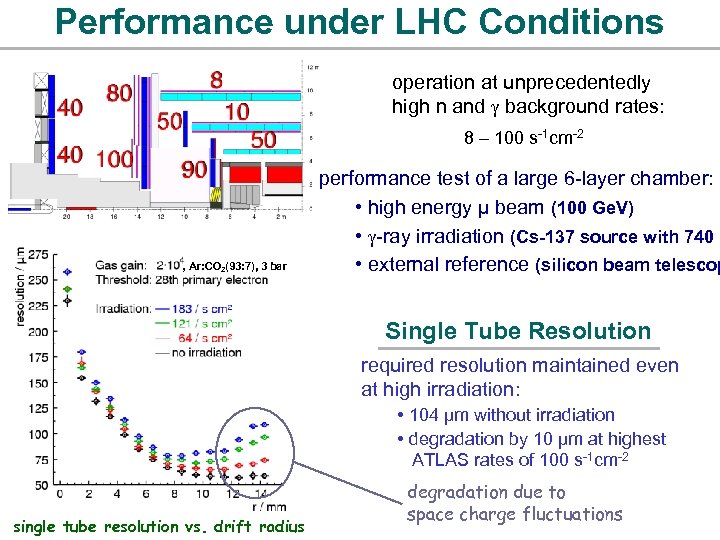

Performance under LHC Conditions operation at unprecedentedly high n and background rates: 8 – 100 s-1 cm-2 , Ar: CO 2(93: 7), 3 bar performance test of a large 6 -layer chamber: • high energy µ beam (100 Ge. V) • -ray irradiation (Cs-137 source with 740 G • external reference (silicon beam telescop Single Tube Resolution required resolution maintained even at high irradiation: • 104 µm without irradiation • degradation by 10 µm at highest ATLAS rates of 100 s-1 cm-2 single tube resolution vs. drift radius degradation due to space charge fluctuations

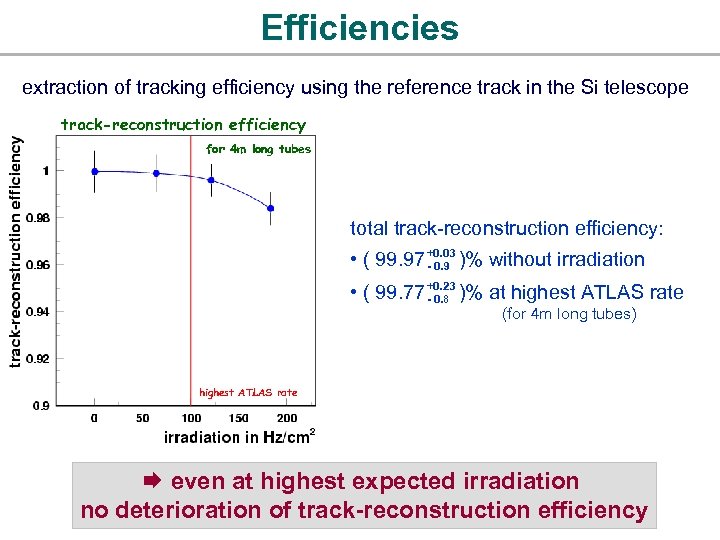

Efficiencies extraction of tracking efficiency using the reference track in the Si telescope track-reconstruction efficiency for 4 m long tubes total track-reconstruction efficiency: • ( 99. 97 +0. 03 )% without irradiation - 0. 9 • ( 99. 77 +0. 23 )% at highest ATLAS rate - 0. 8 (for 4 m long tubes) highest ATLAS rate even at highest expected irradiation no deterioration of track-reconstruction efficiency

Conclusions • Precision MDT chamber production within schedule (58% assembled) • Wire positioning measured with several methods during production required accuracy of 20 µm achieved • Performance under LHC conditions tested at highest background rates chamber resolution of 50 µm maintained no deterioration of track-reconstruction efficiency

3d549c34d7f8f6dba0132413258cbb8b.ppt