63f635c38fab36cf5d2ec1723734a1d9.ppt

- Количество слайдов: 19

Abqaiq Plants Experience in Implementing Lean Six Sigma by: Nayef S. Al-Utaibi Abqaiq Plants

Introduction § Abqaiq Plants Initiated the in-house Lean Six Sigma Projects in 2005 § Lean Six Sigma Training was Provided by OCD 2

Background Lean Six Sigma is a data-driven business process optimization methodology which aims to reduce variation, eliminate non-value added activities, and significantly improve process quality. § 1 st Introduced by Motorola in 1980’s 3

Background Total Quality Lean Process Reengineering Management Sigma Six 4

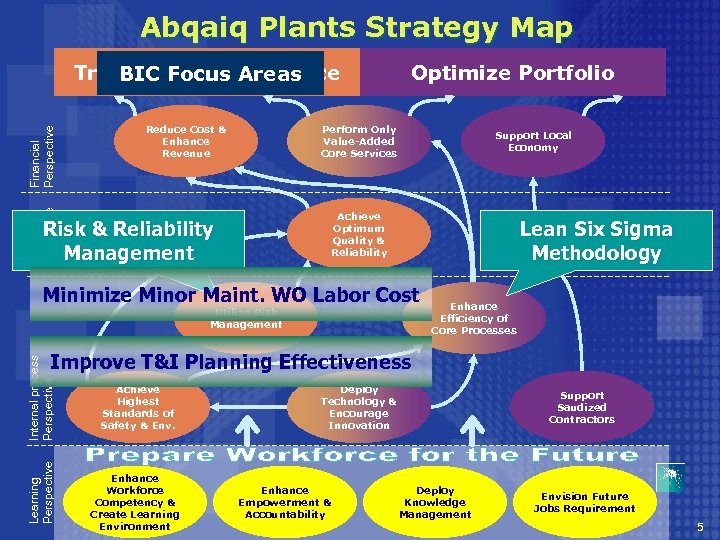

Abqaiq Plants Strategy Map Reduce Cost & Enhance Revenue Optimize Portfolio Perform Only Value-Added Core Services Customer Perspective Financial Perspective Transform Performance BIC Focus Areas Support Local Economy Achieve Optimum Quality & Reliability Risk & Reliability Management Lean Six Sigma Methodology Minimize Minor Maint. WO Labor Cost Utilize Risk Management Enhance Efficiency of Core Processes Learning Perspective Internal process Perspective Improve T&I Planning Effectiveness Achieve Highest Standards of Safety & Env. Enhance Workforce Competency & Create Learning Environment Deploy Technology & Encourage Innovation Enhance Empowerment & Accountability Support Saudized Contractors Deploy Knowledge Management Envision Future Jobs Requirement 5

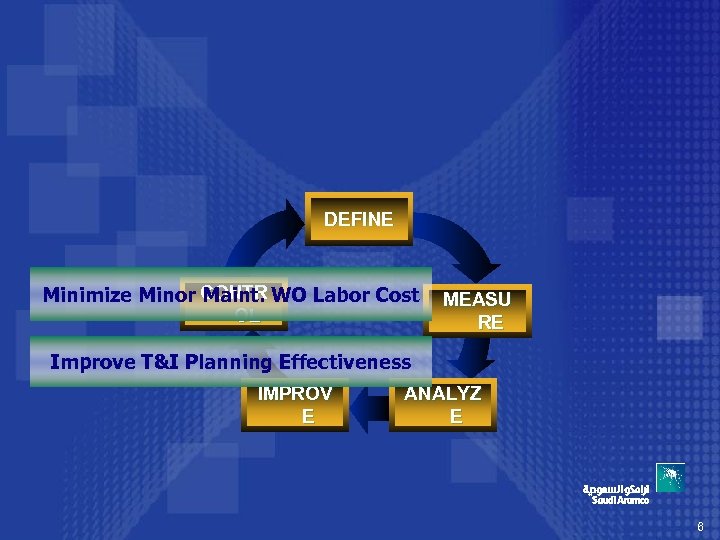

DEFINE Minimize Minor CONTR WO Labor Cost Maint. OL MEASU RE Improve T&I Planning Effectiveness IMPROV E ANALYZ E 6

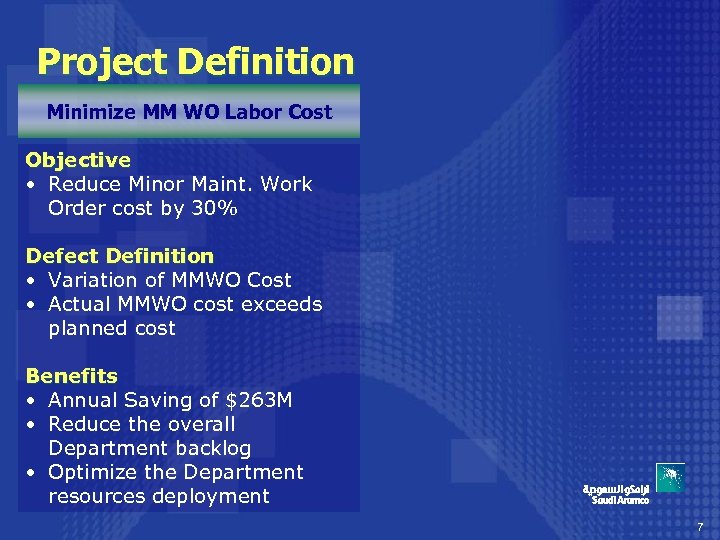

Project Definition Minimize MM WO Labor Cost Objective • Reduce Minor Maint. Work Order cost by 30% Defect Definition • Variation of MMWO Cost • Actual MMWO cost exceeds planned cost Benefits • Annual Saving of $263 M • Reduce the overall Department backlog • Optimize the Department resources deployment 7

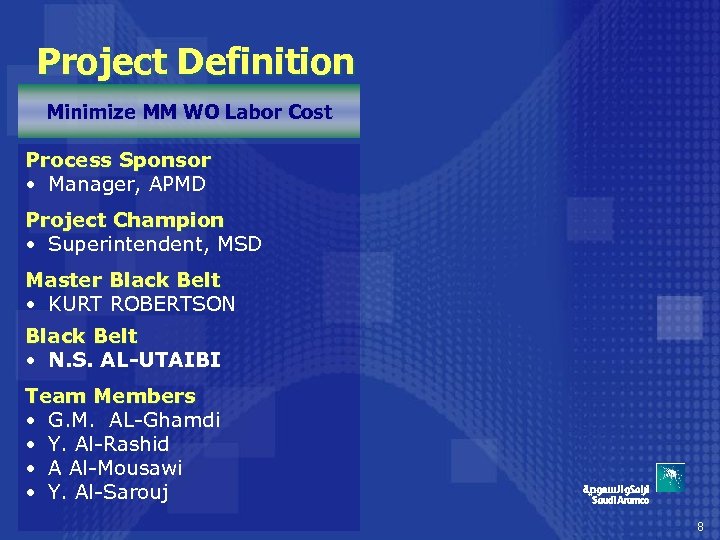

Project Definition Minimize MM WO Labor Cost Process Sponsor • Manager, APMD Project Champion • Superintendent, MSD Master Black Belt • KURT ROBERTSON Black Belt • N. S. AL-UTAIBI Team Members • G. M. AL-Ghamdi • Y. Al-Rashid • A Al-Mousawi • Y. Al-Sarouj 8

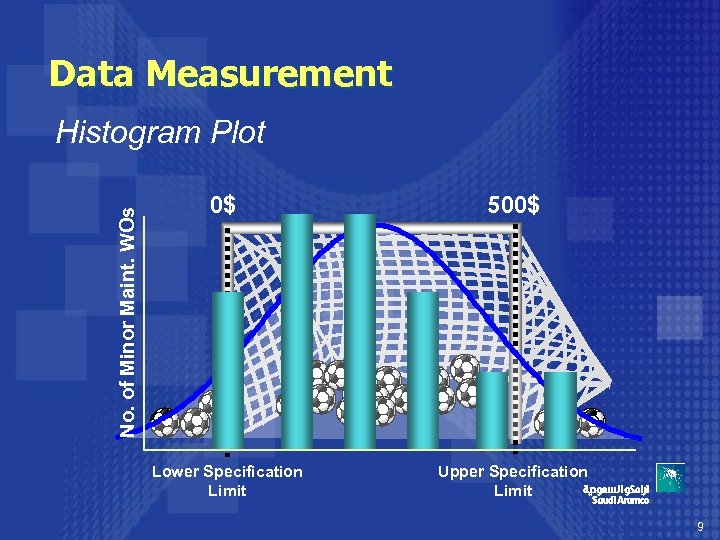

Data Measurement No. of Minor Maint. WOs Histogram Plot 0$ 500$ Lower Specification Limit Upper Specification Limit 9

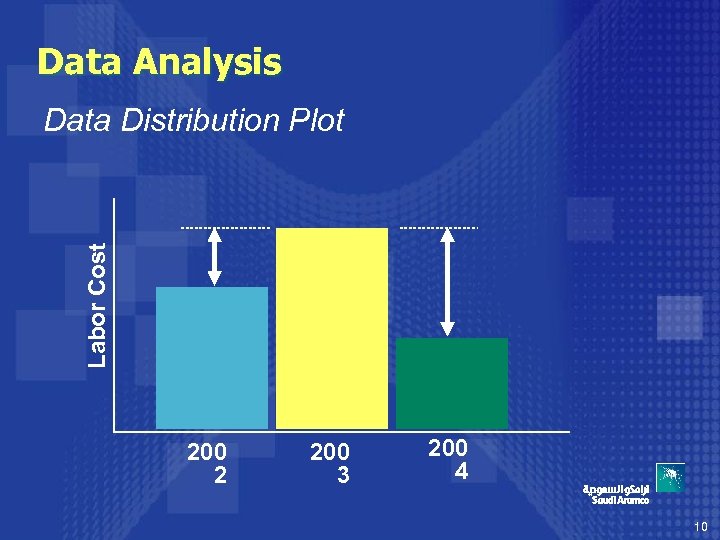

Data Analysis Labor Cost Data Distribution Plot 200 2 200 3 200 4 10

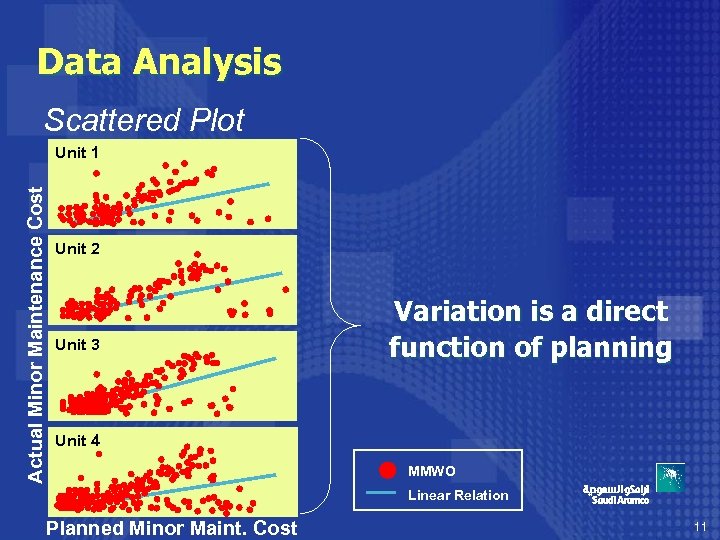

Data Analysis Scattered Plot Actual Minor Maintenance Cost Unit 1 Unit 2 Unit 3 Variation is a direct function of planning Unit 4 MMWO Linear Relation Planned Minor Maint. Cost 11

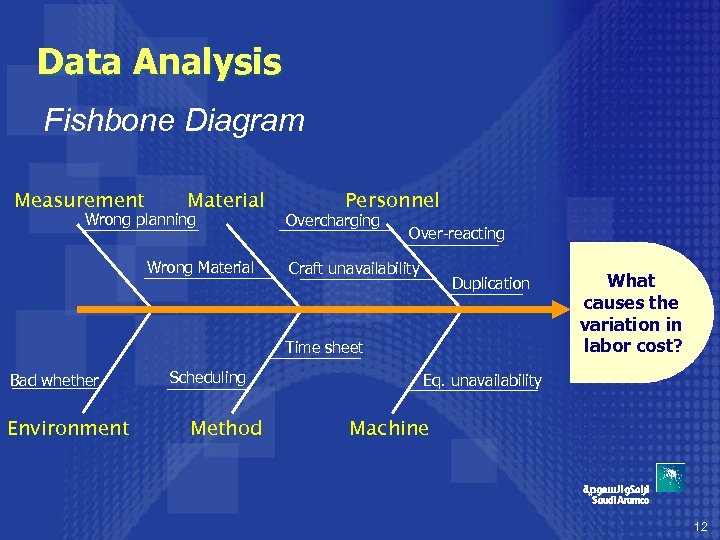

Data Analysis Fishbone Diagram Measurement Material Wrong planning Wrong Material Personnel Overcharging Over-reacting Craft unavailability Duplication Time sheet Bad whether Environment Scheduling Method What causes the variation in labor cost? Eq. unavailability Machine 12

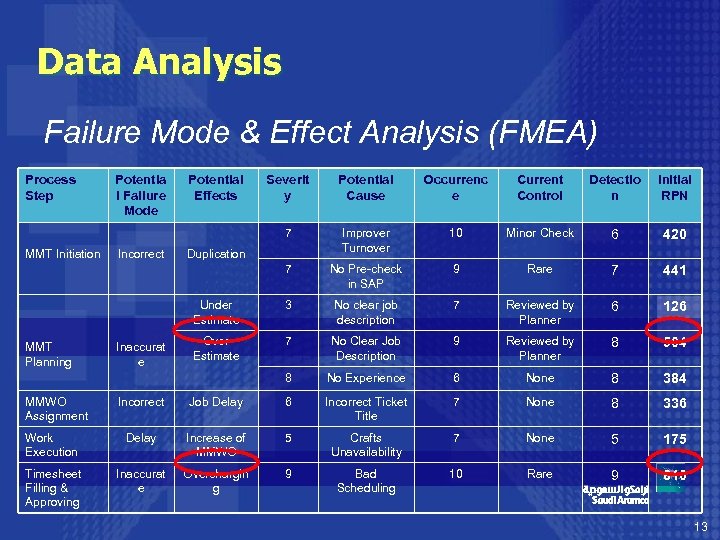

Data Analysis Failure Mode & Effect Analysis (FMEA) Process Step MMWO Assignment Current Control Detectio n Initial RPN Improver Turnover 10 Minor Check 6 420 No Pre-check in SAP 9 Rare 7 441 3 No clear job description 7 Reviewed by Planner 6 126 Over Estimate 7 No Clear Job Description 9 Reviewed by Planner 8 504 8 Inaccurat e Occurrenc e Under Estimate MMT Planning Potential Cause 7 Incorrect Severit y 7 MMT Initiation Potentia l Failure Mode Potential Effects No Experience 6 None 8 384 Duplication Incorrect Job Delay 6 Incorrect Ticket Title 7 None 8 336 Work Execution Delay Increase of MMWO 5 Crafts Unavailability 7 None 5 175 Timesheet Filling & Approving Inaccurat e Overchargin g 9 Bad Scheduling 10 Rare 9 810 13

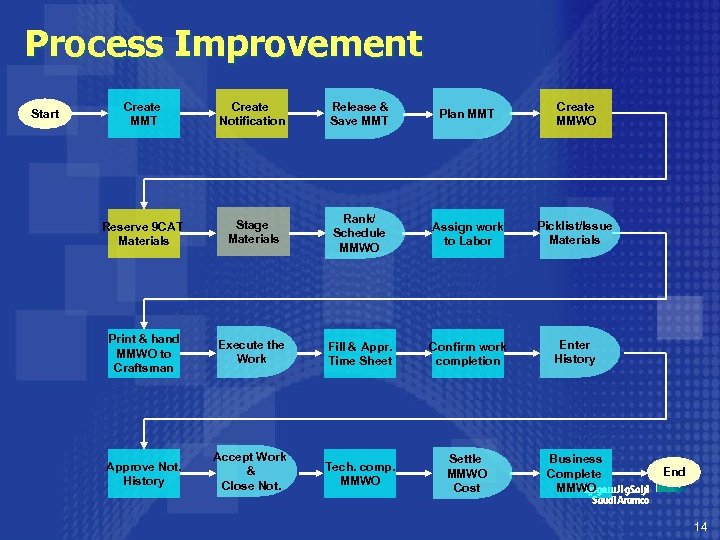

Process Improvement Start Create MMT Create Notification Release & Save MMT Plan MMT Create MMWO Reserve 9 CAT Materials Stage Materials Rank/ Schedule MMWO Assign work to Labor Picklist/Issue Materials Print & hand MMWO to Craftsman Execute the Work Fill & Appr. Time Sheet Confirm work completion Enter History Approve Not. History Accept Work & Close Not. Tech. comp. MMWO Settle MMWO Cost Business Complete MMWO End 14

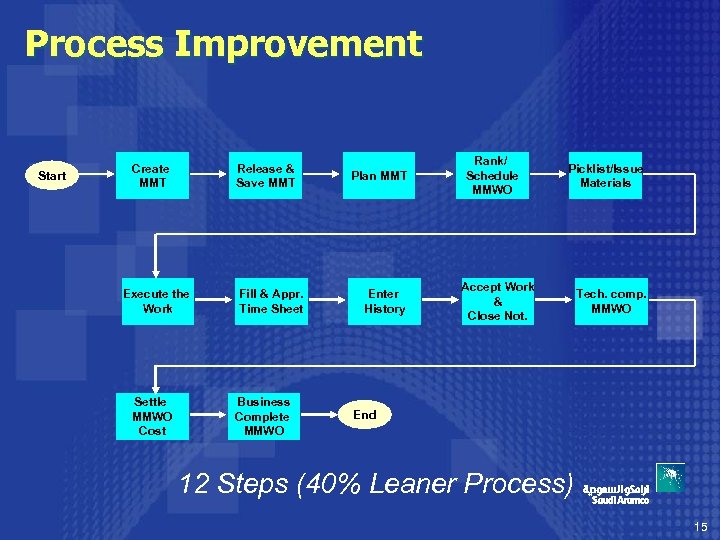

Process Improvement Start Create MMT Release & Save MMT Execute the Work Settle MMWO Cost Fill & Appr. Time Sheet Business Complete MMWO Plan MMT Enter History Rank/ Schedule MMWO Picklist/Issue Materials Accept Work & Close Not. Tech. comp. MMWO End 12 Steps (40% Leaner Process) 15

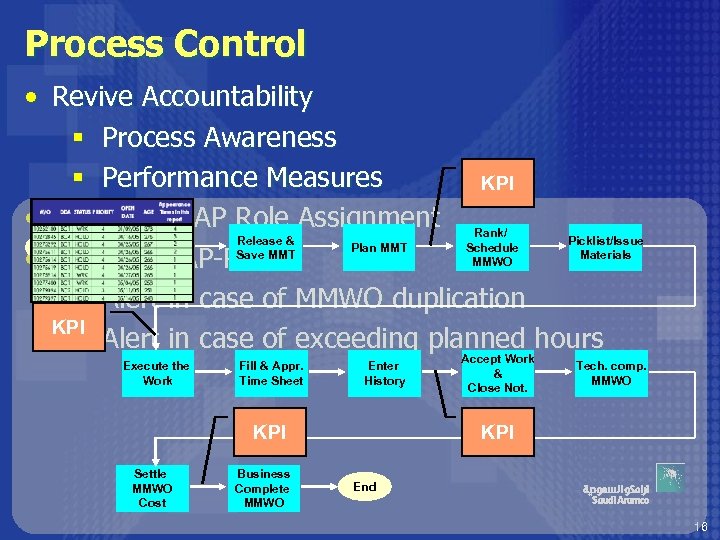

Process Control • Revive Accountability § Process Awareness § Performance Measures KPI • Re-define SAP Role Assignment Rank/ Create Release & Picklist/Issue Plan MMT Start Schedule MMT Save MMT Materials MMWO • Enhance SAP-PM 04 § Alert in case of MMWO duplication KPI § Alert in case of exceeding planned hours Accept Work Execute the Work Fill & Appr. Time Sheet Enter History KPI Settle MMWO Cost Business Complete MMWO & Close Not. Tech. comp. MMWO KPI End 16

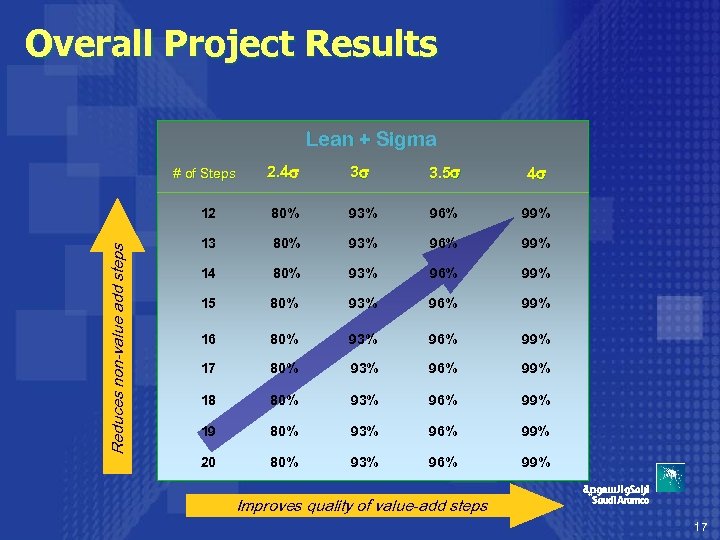

Overall Project Results Lean + Sigma 2. 4 3 3. 5 4 12 Reduces non-value add steps # of Steps 80% 93% 96% 99% 13 80% 93% 96% 99% 14 80% 93% 96% 99% 15 80% 93% 96% 99% 16 80% 93% 96% 99% 17 80% 93% 96% 99% 18 80% 93% 96% 99% 19 80% 93% 96% 99% 20 80% 93% 96% 99% Improves quality of value-add steps 17

Summary • Lean Sigma is an effective work processes enhancement tool • Promising results are guaranteed with proper implementation • Knowledge gain and individual development is an added benefit 18

Thank You 19

63f635c38fab36cf5d2ec1723734a1d9.ppt