6bcfa1d422734ff259934415cd7b2960.ppt

- Количество слайдов: 15

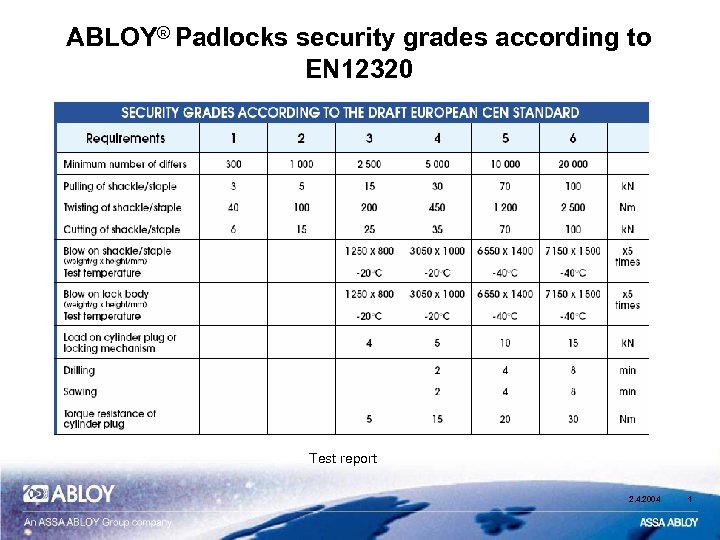

ABLOY® Padlocks security grades according to EN 12320 Test report 2. 4. 2004 1

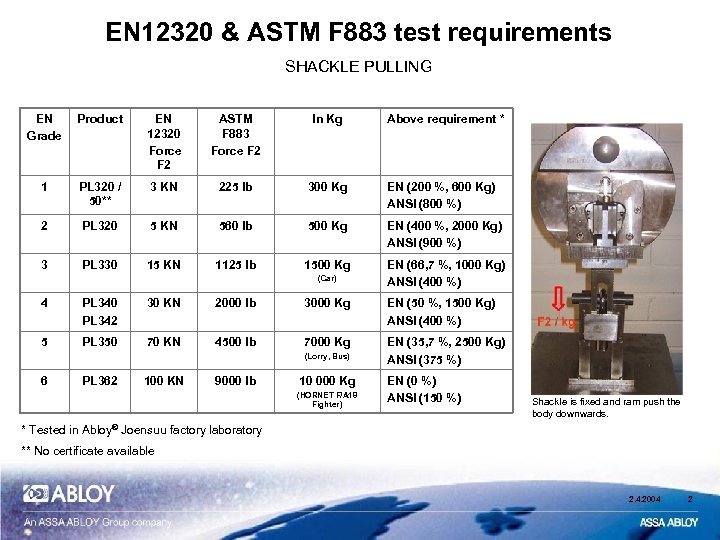

EN 12320 & ASTM F 883 test requirements SHACKLE PULLING EN Grade Product EN 12320 Force F 2 ASTM F 883 Force F 2 In Kg 1 PL 320 / 50** 3 KN 225 lb 300 Kg EN (200 %, 600 Kg) ANSI (800 %) 2 PL 320 5 KN 560 lb 500 Kg EN (400 %, 2000 Kg) ANSI (900 %) 3 PL 330 15 KN 1125 lb 1500 Kg EN (66, 7 %, 1000 Kg) ANSI (400 %) (Car) Above requirement * 4 PL 340 PL 342 30 KN 2000 lb 3000 Kg EN (50 %, 1500 Kg) ANSI (400 %) 5 PL 350 70 KN 4500 lb 7000 Kg EN (35, 7 %, 2500 Kg) ANSI (375 %) (Lorry, Bus) 6 PL 362 100 KN 9000 lb 10 000 Kg (HORNET F/A 18 Fighter) EN (0 %) ANSI (150 %) Shackle is fixed and ram push the body downwards. * Tested in Abloy® Joensuu factory laboratory ** No certificate available 2. 4. 2004 2

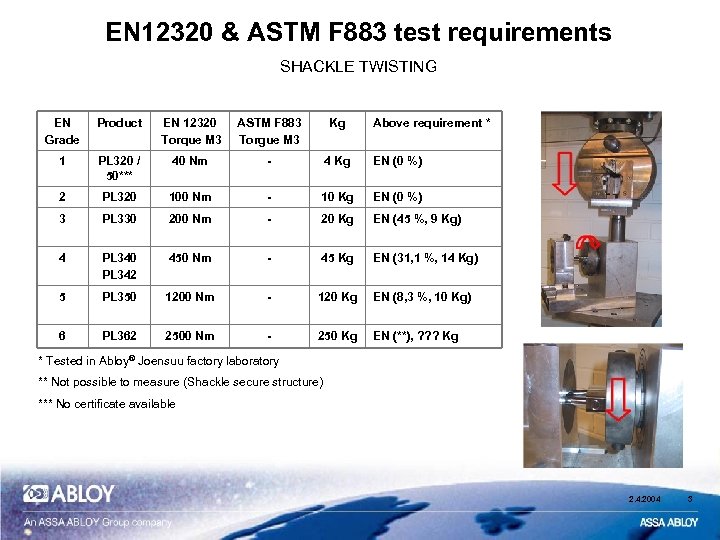

EN 12320 & ASTM F 883 test requirements SHACKLE TWISTING EN Grade Product EN 12320 Torque M 3 ASTM F 883 Torgue M 3 Kg Above requirement * 1 PL 320 / 50*** 40 Nm - 4 Kg EN (0 %) 2 PL 320 100 Nm - 10 Kg EN (0 %) 3 PL 330 200 Nm - 20 Kg EN (45 %, 9 Kg) 4 PL 340 PL 342 450 Nm - 45 Kg EN (31, 1 %, 14 Kg) 5 PL 350 1200 Nm - 120 Kg EN (8, 3 %, 10 Kg) 6 PL 362 2500 Nm - 250 Kg EN (**), ? ? ? Kg * Tested in Abloy® Joensuu factory laboratory ** Not possible to measure (Shackle secure structure) *** No certificate available 2. 4. 2004 3

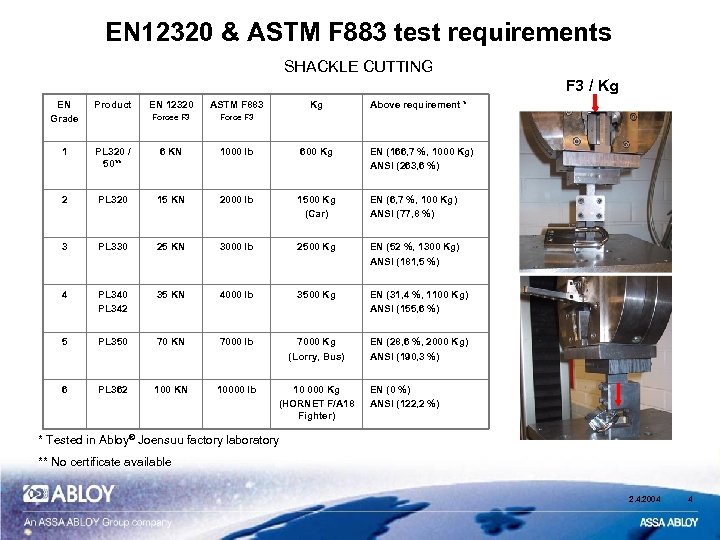

EN 12320 & ASTM F 883 test requirements SHACKLE CUTTING F 3 / Kg EN Grade Product EN 12320 ASTM F 883 Forcee F 3 Force F 3 1 Kg Above requirement * PL 320 / 50** 6 KN 1000 lb 600 Kg EN (166, 7 %, 1000 Kg) ANSI (263, 6 %) 2 PL 320 15 KN 2000 lb 1500 Kg (Car) EN (6, 7 %, 100 Kg) ANSI (77, 8 %) 3 PL 330 25 KN 3000 lb 2500 Kg EN (52 %, 1300 Kg) ANSI (181, 5 %) 4 PL 340 PL 342 35 KN 4000 lb 3500 Kg EN (31, 4 %, 1100 Kg) ANSI (155, 6 %) 5 PL 350 70 KN 7000 lb 7000 Kg (Lorry, Bus) EN (28, 6 %, 2000 Kg) ANSI (190, 3 %) 6 PL 362 100 KN 10000 lb 10 000 Kg (HORNET F/A 18 Fighter) EN (0 %) ANSI (122, 2 %) * Tested in Abloy® Joensuu factory laboratory ** No certificate available 2. 4. 2004 4

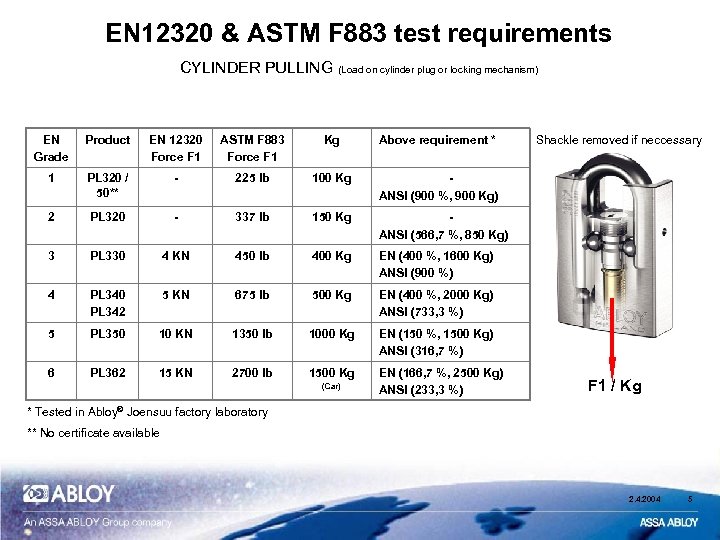

EN 12320 & ASTM F 883 test requirements CYLINDER PULLING (Load on cylinder plug or locking mechanism) EN Grade Product EN 12320 Force F 1 ASTM F 883 Force F 1 Kg Above requirement * 1 PL 320 / 50** - 225 lb 100 Kg ANSI (900 %, 900 Kg) 2 PL 320 - 337 lb 150 Kg ANSI (566, 7 %, 850 Kg) 3 PL 330 4 KN 450 lb 400 Kg EN (400 %, 1600 Kg) ANSI (900 %) 4 PL 340 PL 342 5 KN 675 lb 500 Kg EN (400 %, 2000 Kg) ANSI (733, 3 %) 5 PL 350 10 KN 1350 lb 1000 Kg EN (150 %, 1500 Kg) ANSI (316, 7 %) 6 PL 362 15 KN 2700 lb 1500 Kg EN (166, 7 %, 2500 Kg) ANSI (233, 3 %) (Car) Shackle removed if neccessary F 1 / Kg * Tested in Abloy® Joensuu factory laboratory ** No certificate available 2. 4. 2004 5

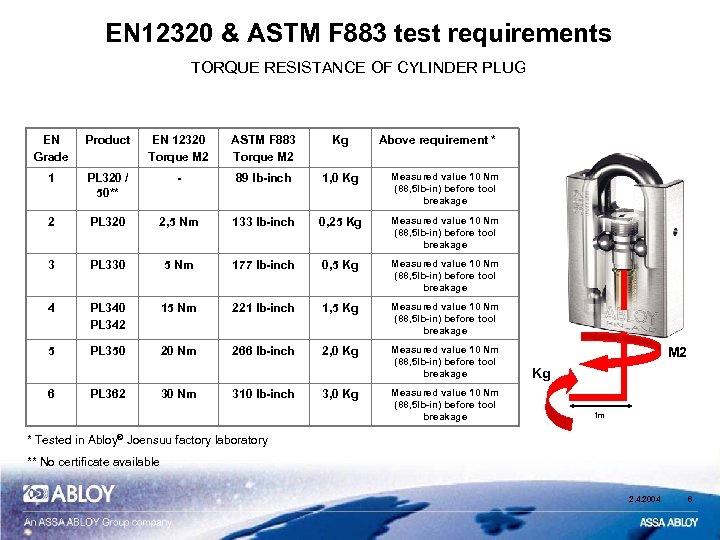

EN 12320 & ASTM F 883 test requirements TORQUE RESISTANCE OF CYLINDER PLUG EN Grade Product EN 12320 Torque M 2 ASTM F 883 Torque M 2 Kg 1 PL 320 / 50** - 89 lb-inch 1, 0 Kg Measured value 10 Nm (88, 5 lb-in) before tool breakage 2 PL 320 2, 5 Nm 133 lb-inch 0, 25 Kg Measured value 10 Nm (88, 5 lb-in) before tool breakage 3 PL 330 5 Nm 177 lb-inch 0, 5 Kg Measured value 10 Nm (88, 5 lb-in) before tool breakage 4 PL 340 PL 342 15 Nm 221 lb-inch 1, 5 Kg Measured value 10 Nm (88, 5 lb-in) before tool breakage 5 PL 350 20 Nm 266 lb-inch 2, 0 Kg Measured value 10 Nm (88, 5 lb-in) before tool breakage 6 PL 362 30 Nm 310 lb-inch 3, 0 Kg Above requirement * Measured value 10 Nm (88, 5 lb-in) before tool breakage M 2 Kg 1 m * Tested in Abloy® Joensuu factory laboratory ** No certificate available 2. 4. 2004 6

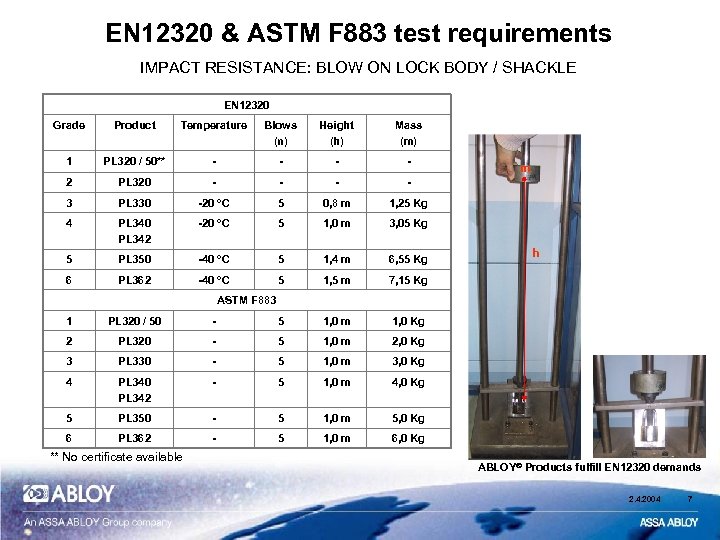

EN 12320 & ASTM F 883 test requirements IMPACT RESISTANCE: BLOW ON LOCK BODY / SHACKLE EN 12320 Grade Product Temperature Blows (n) Height (h) Mass (m) 1 PL 320 / 50** - - 2 PL 320 - - 3 PL 330 -20 °C 5 0, 8 m 1, 25 Kg 4 PL 340 PL 342 -20 °C 5 1, 0 m 3, 05 Kg 5 PL 350 -40 °C 5 1, 4 m 6, 55 Kg 6 PL 362 -40 °C 5 1, 5 m 7, 15 Kg m h ASTM F 883 1 PL 320 / 50 - 5 1, 0 m 1, 0 Kg 2 PL 320 - 5 1, 0 m 2, 0 Kg 3 PL 330 - 5 1, 0 m 3, 0 Kg 4 PL 340 PL 342 - 5 1, 0 m 4, 0 Kg 5 PL 350 - 5 1, 0 m 5, 0 Kg 6 PL 362 - 5 1, 0 m 6, 0 Kg ** No certificate available ABLOY® Products fulfill EN 12320 demands 2. 4. 2004 7

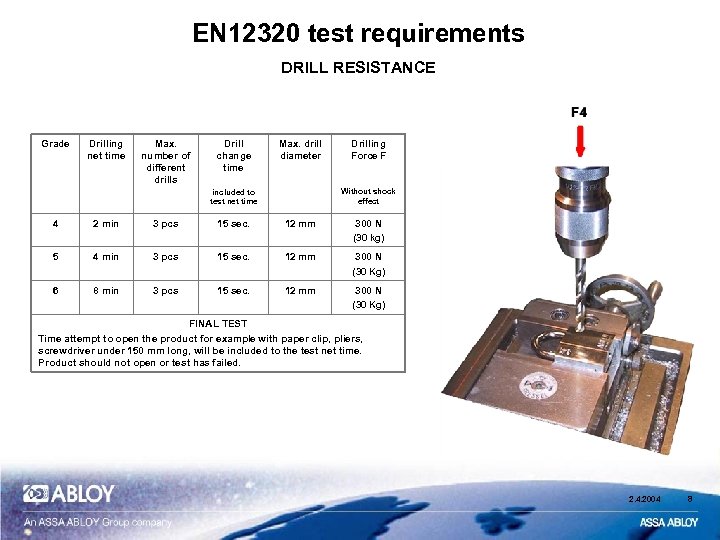

EN 12320 test requirements DRILL RESISTANCE Grade Drilling net time Max. number of different drills Drill change time Max. drill diameter Drilling Force F Without shock effect included to test net time 4 2 min 3 pcs 15 sec. 12 mm 300 N (30 kg) 5 4 min 3 pcs 15 sec. 12 mm 300 N (30 Kg) 6 8 min 3 pcs 15 sec. 12 mm 300 N (30 Kg) FINAL TEST Time attempt to open the product for example with paper clip, pliers, screwdriver under 150 mm long, will be included to the test net time. Product should not open or test has failed. 2. 4. 2004 8

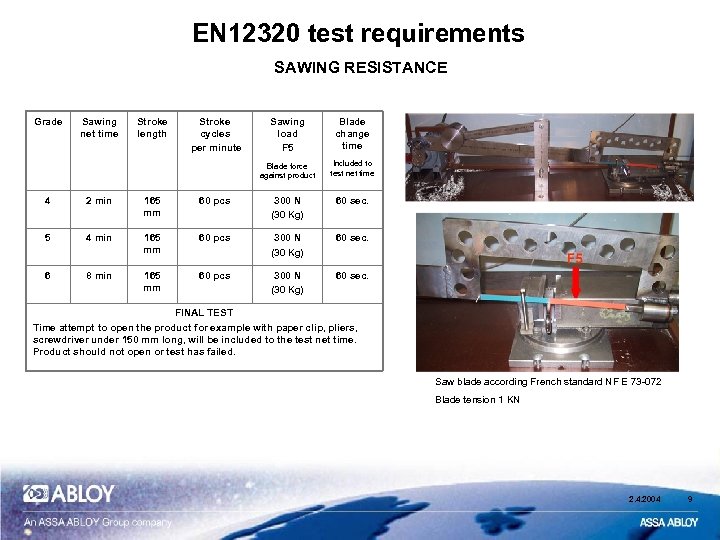

EN 12320 test requirements SAWING RESISTANCE Grade Sawing net time Stroke length Stroke cycles per minute Sawing load F 5 Blade change time Blade force against product Included to test net time 4 2 min 165 mm 60 pcs 300 N (30 Kg) 60 sec. 5 4 min 165 mm 60 pcs 300 N (30 Kg) 60 sec. 6 8 min 165 mm 60 pcs 300 N (30 Kg) 60 sec. FINAL TEST Time attempt to open the product for example with paper clip, pliers, screwdriver under 150 mm long, will be included to the test net time. Product should not open or test has failed. Saw blade according French standard NF E 73 -072 Blade tension 1 KN 2. 4. 2004 9

Padlocks BRASS PADLOCKS: PL 321 Discontinued PL 320 GRADE 2 PL 343 PL 330 PL 341 GRADE 3 2. 4. 2004 10

Padlocks STEEL PADLOCKS: PL 340 PL 342 PL 350 PL 362 GRADE 4 GRADE 5 GRADE 6 2. 4. 2004 11

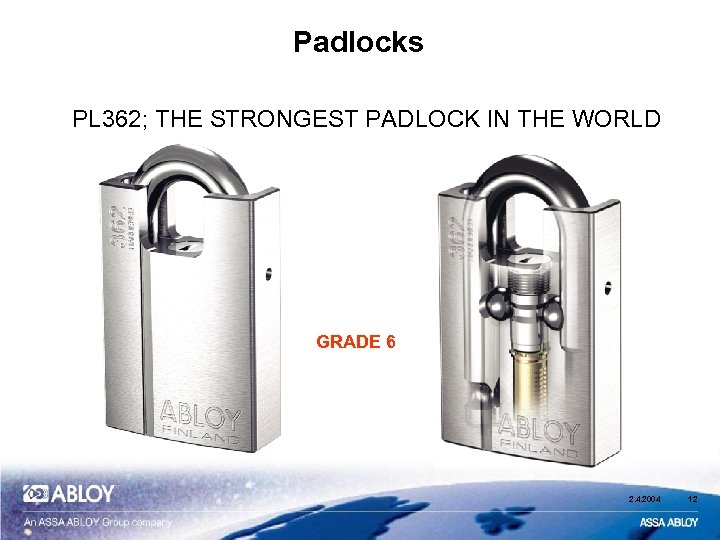

Padlocks PL 362; THE STRONGEST PADLOCK IN THE WORLD GRADE 6 2. 4. 2004 12

Accessories ADVANCED FEATURES: • New design • Coding • Chamfers • Attachment chains • Dust covers for whole range 2. 4. 2004 13

Accessories, locking plates PL 204: PL 200, 202: • 12 mm shackle hole • Non-handed • CEN grade 3 • For frame fixing • PL 200 for right handed doors • Zinc-plated, polyester coated • PL 202 for left handed doors • Case-hardened steel • For frame fixing • Fixing screws included • Zinc-plated, polyester coated • Case-hardened steel • Fixing screws included PL 201, 203: • 18 mm shackle hole • CEN grade 4 • PL 201 for right handed doors • PL 203 for left handed doors • For frame fixing • Zinc-plated, polyester coated • Case-hardened steel • Fixing screws included 2. 4. 2004 14

EN 12320 CERTIFICATES 6 PL 362 5 4 PL 342 PL 340 3 PL 330 EN GRADE PL 350 PL 341 2 3020 PL 320 1 PRODUCTS 2. 4. 2004 15

6bcfa1d422734ff259934415cd7b2960.ppt