87471e75532f47e5117830c1efdc021f.ppt

- Количество слайдов: 58

ABE 223 ABE Principles – Machine systems Pumps and Actuators Tony Grift Dept. of Agricultural & Biological Engineering University of Illinois 1

Agenda • Units, Pumps, Pressure Relief Valve • Cylinders • Double acting/ Single acting • Single rod, Double rod • • • Cylinder construction Pressure, Flow, Work and Power in cylinders Pressure, Flow, Torque and Power in pump/motors Volumetric and Torque efficiency of pump/motors Pump implementations 2

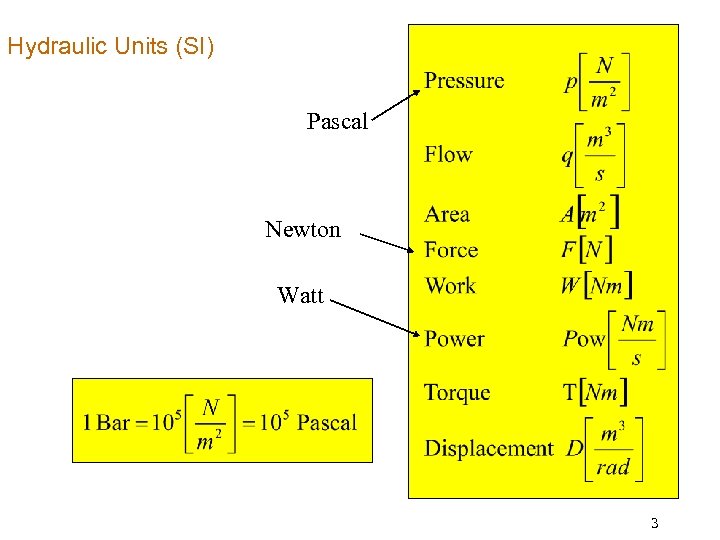

Hydraulic Units (SI) Pascal Newton Watt 3

Hydraulic drive unit 4

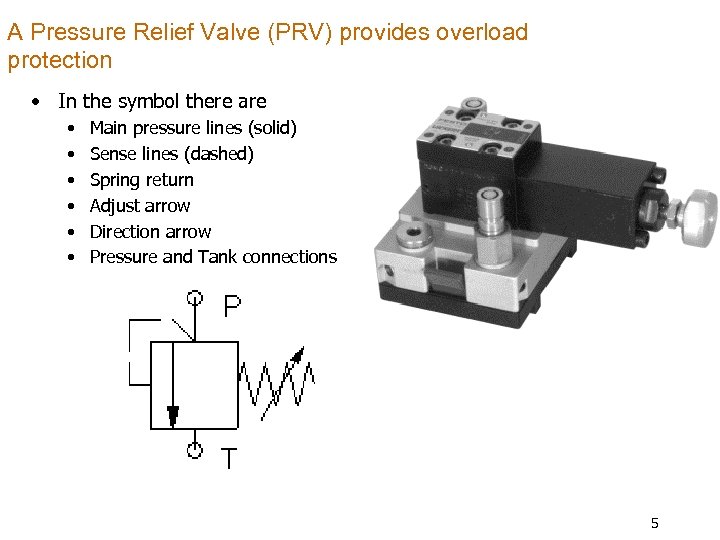

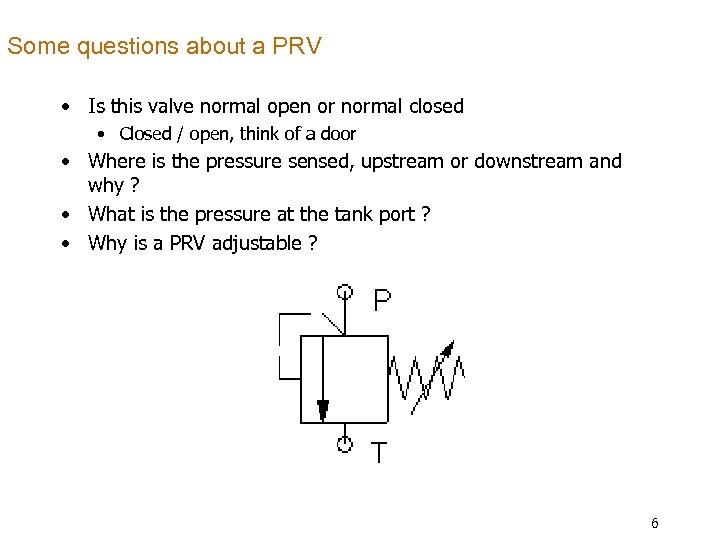

A Pressure Relief Valve (PRV) provides overload protection • In the symbol there are • • • Main pressure lines (solid) Sense lines (dashed) Spring return Adjust arrow Direction arrow Pressure and Tank connections 5

Some questions about a PRV • Is this valve normal open or normal closed • Closed / open, think of a door • Where is the pressure sensed, upstream or downstream and why ? • What is the pressure at the tank port ? • Why is a PRV adjustable ? 6

Cylinders 7

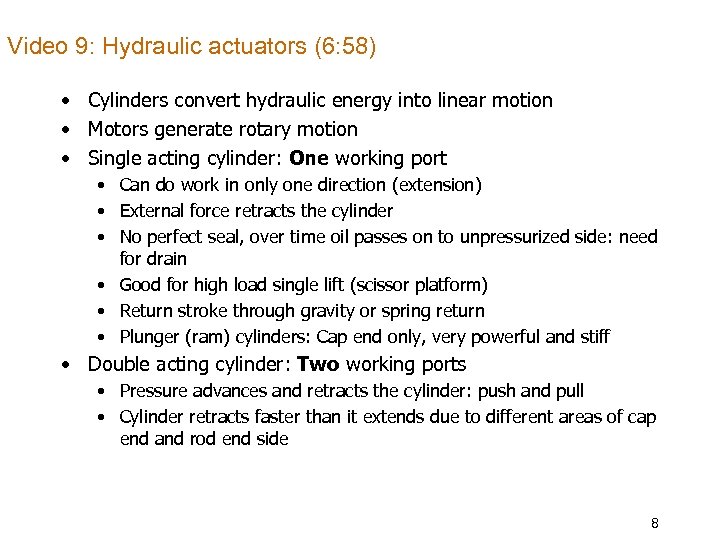

Video 9: Hydraulic actuators (6: 58) • Cylinders convert hydraulic energy into linear motion • Motors generate rotary motion • Single acting cylinder: One working port • Can do work in only one direction (extension) • External force retracts the cylinder • No perfect seal, over time oil passes on to unpressurized side: need for drain • Good for high load single lift (scissor platform) • Return stroke through gravity or spring return • Plunger (ram) cylinders: Cap end only, very powerful and stiff • Double acting cylinder: Two working ports • Pressure advances and retracts the cylinder: push and pull • Cylinder retracts faster than it extends due to different areas of cap end and rod end side 8

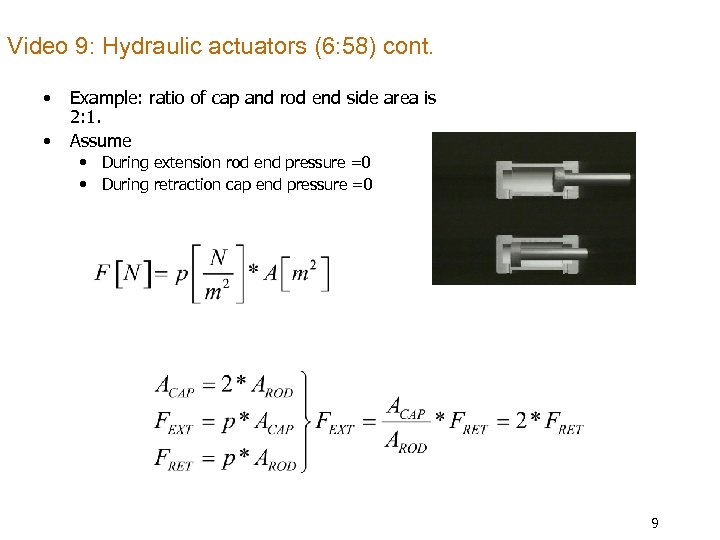

Video 9: Hydraulic actuators (6: 58) cont. • • Example: ratio of cap and rod end side area is 2: 1. Assume • During extension rod end pressure =0 • During retraction cap end pressure =0 9

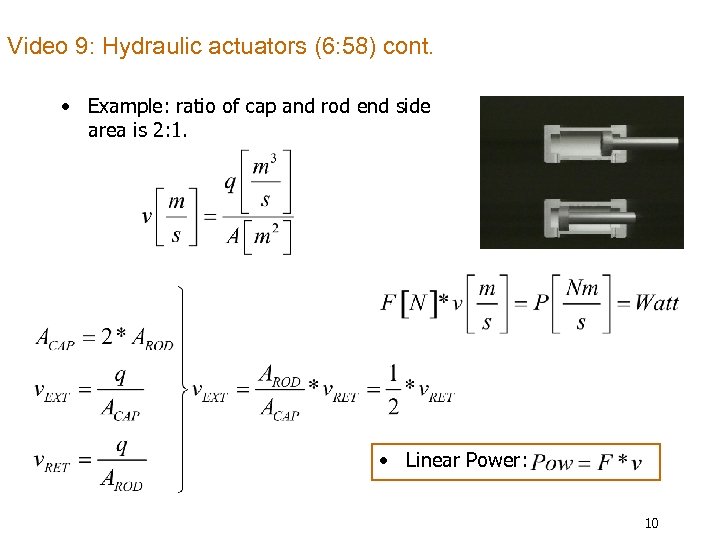

Video 9: Hydraulic actuators (6: 58) cont. • Example: ratio of cap and rod end side area is 2: 1. • Linear Power: 10

Hydraulic Cylinder 11

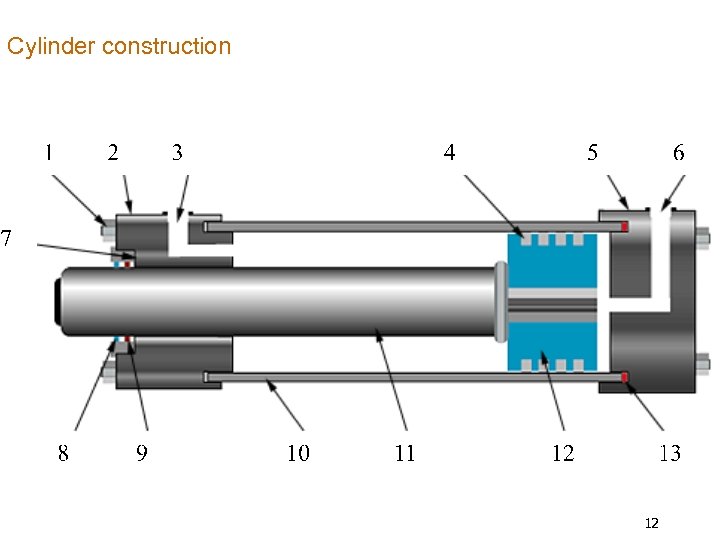

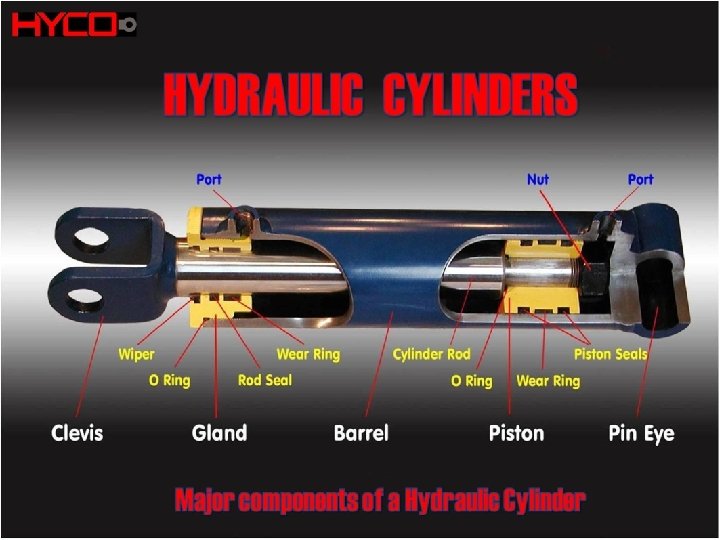

Cylinder construction 12

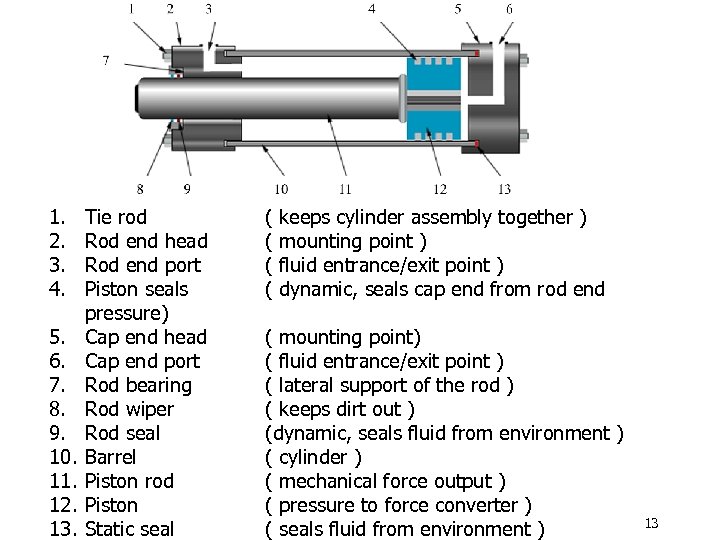

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. Tie rod Rod end head Rod end port Piston seals pressure) Cap end head Cap end port Rod bearing Rod wiper Rod seal Barrel Piston rod Piston Static seal ( ( keeps cylinder assembly together ) mounting point ) fluid entrance/exit point ) dynamic, seals cap end from rod end ( mounting point) ( fluid entrance/exit point ) ( lateral support of the rod ) ( keeps dirt out ) (dynamic, seals fluid from environment ) ( cylinder ) ( mechanical force output ) ( pressure to force converter ) ( seals fluid from environment ) 13

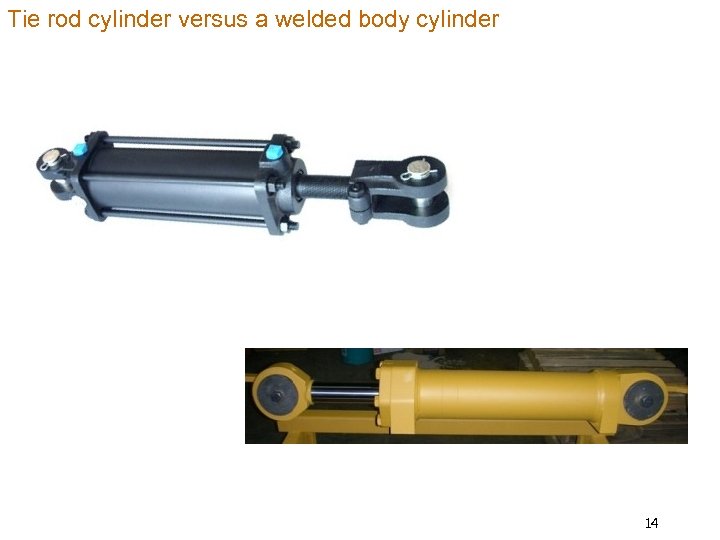

Tie rod cylinder versus a welded body cylinder 14

15

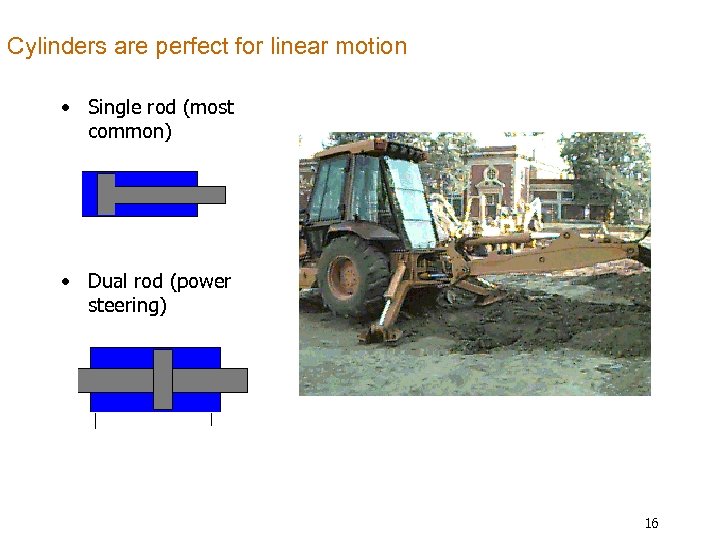

Cylinders are perfect for linear motion • Single rod (most common) • Dual rod (power steering) 16

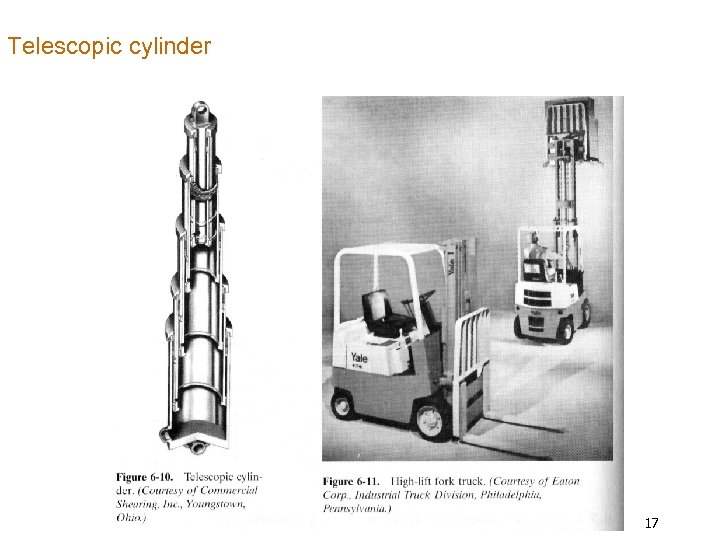

Telescopic cylinder 17

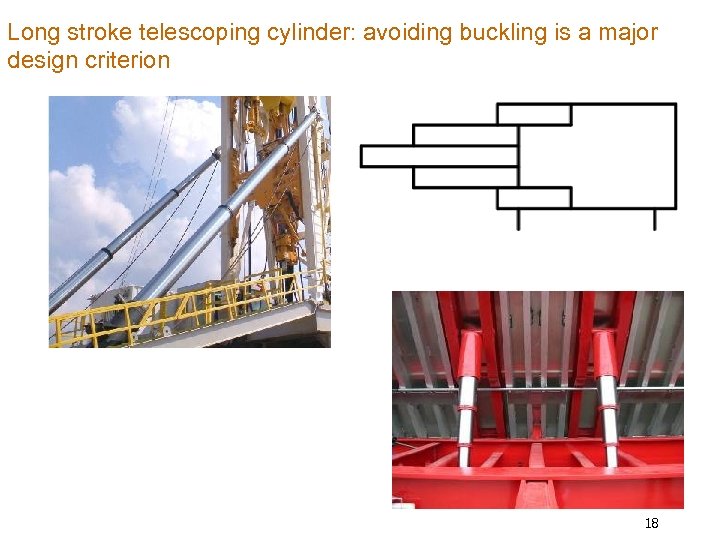

Long stroke telescoping cylinder: avoiding buckling is a major design criterion 18

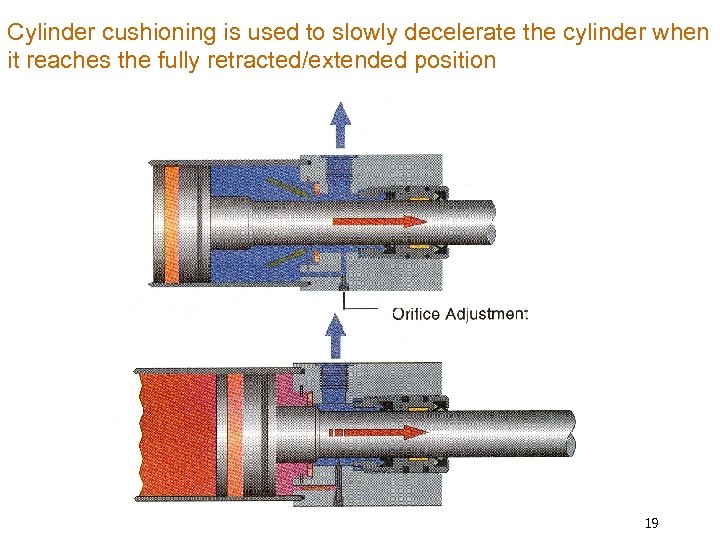

Cylinder cushioning is used to slowly decelerate the cylinder when it reaches the fully retracted/extended position 19

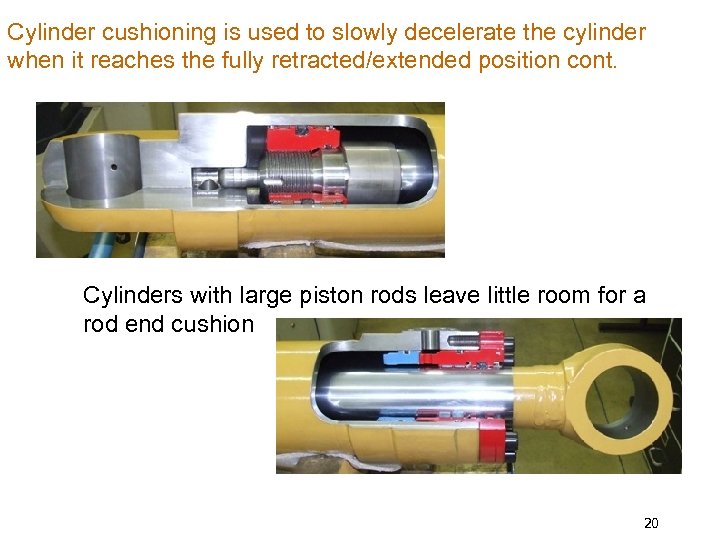

Cylinder cushioning is used to slowly decelerate the cylinder when it reaches the fully retracted/extended position cont. Cylinders with large piston rods leave little room for a rod end cushion 20

Cylinder mounting options Head flange mount Double spherical eye mount Clevis mount 21

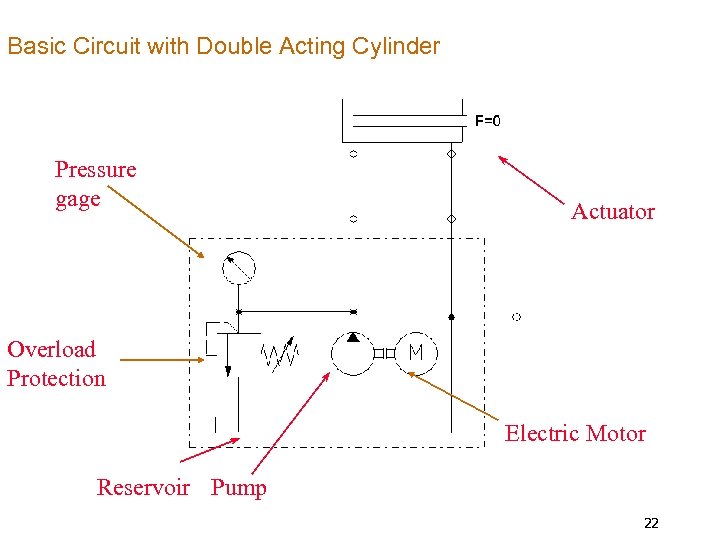

Basic Circuit with Double Acting Cylinder Pressure gage Actuator Overload Protection Electric Motor Reservoir Pump 22

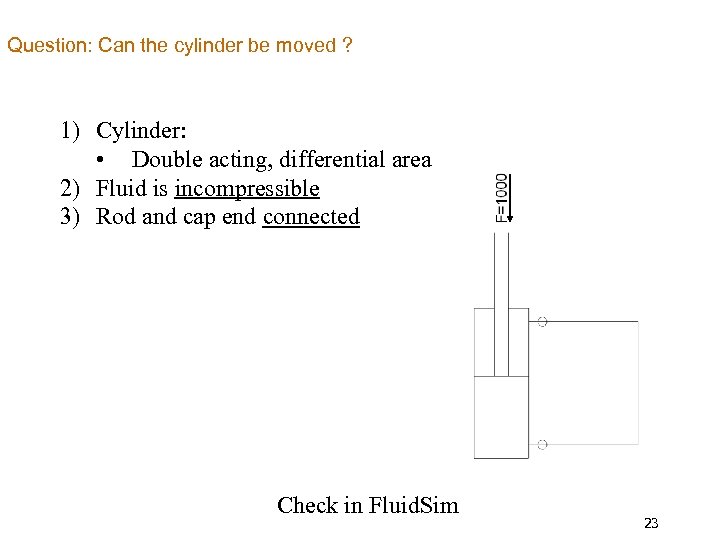

Question: Can the cylinder be moved ? 1) Cylinder: • Double acting, differential area 2) Fluid is incompressible 3) Rod and cap end connected Check in Fluid. Sim 23

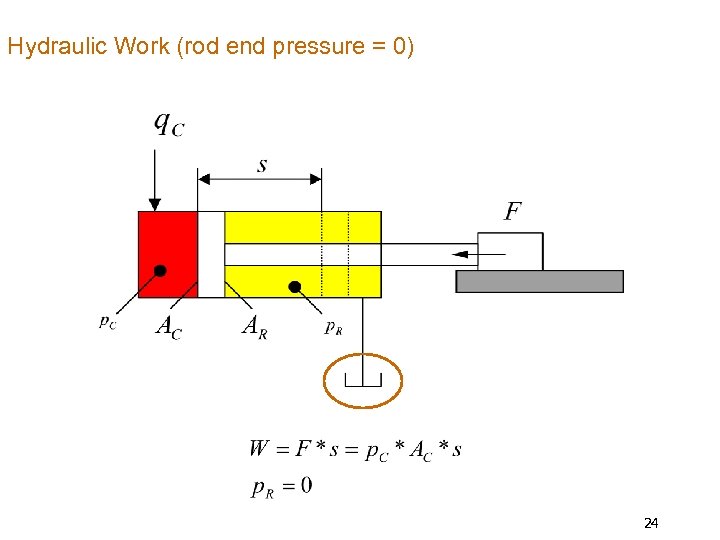

Hydraulic Work (rod end pressure = 0) 24

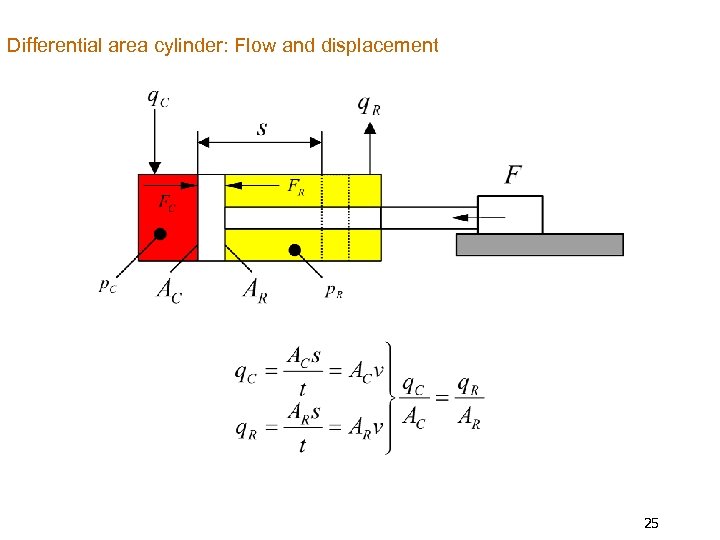

Differential area cylinder: Flow and displacement 25

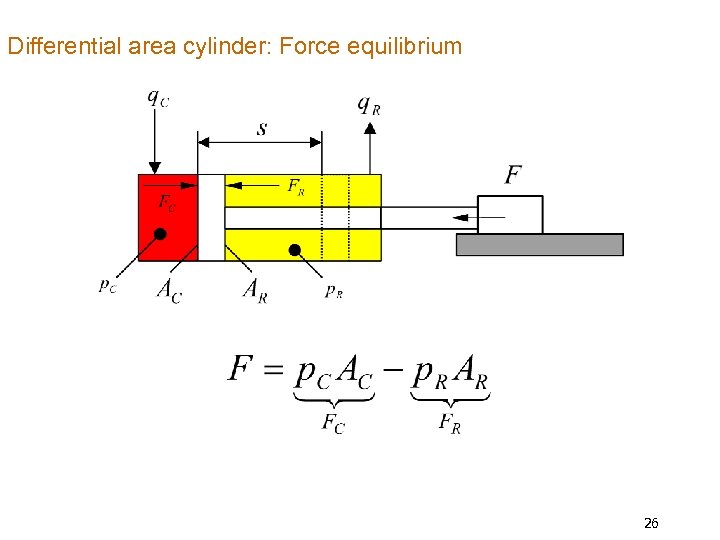

Differential area cylinder: Force equilibrium 26

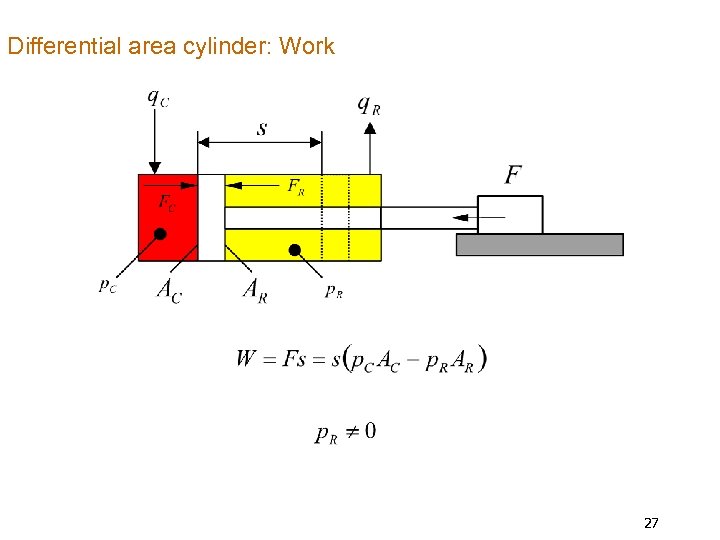

Differential area cylinder: Work 27

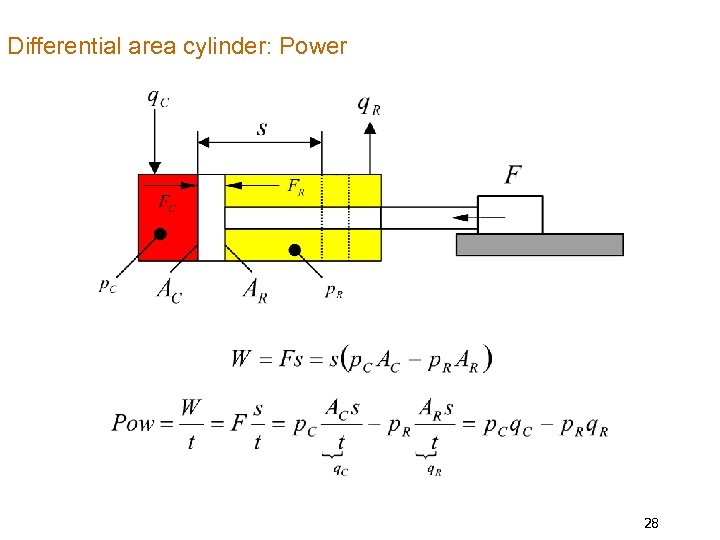

Differential area cylinder: Power 28

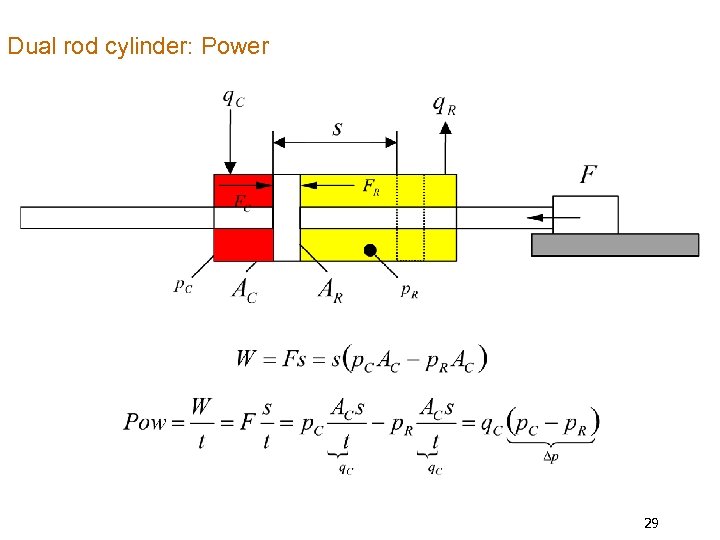

Dual rod cylinder: Power 29

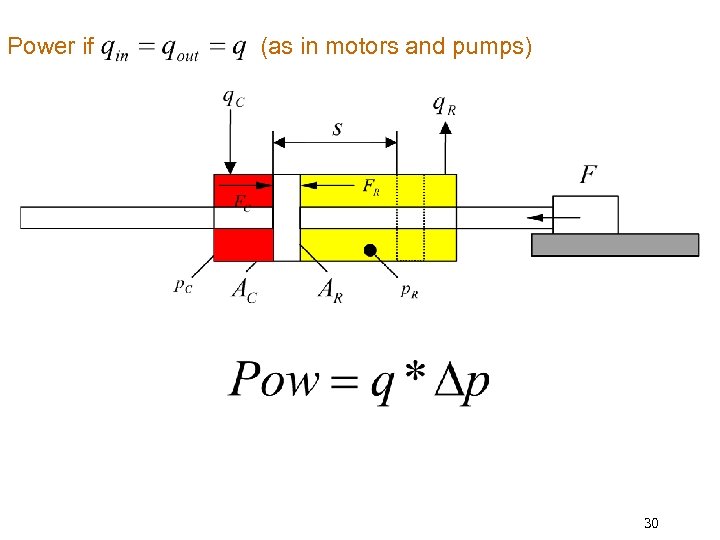

Power if (as in motors and pumps) 30

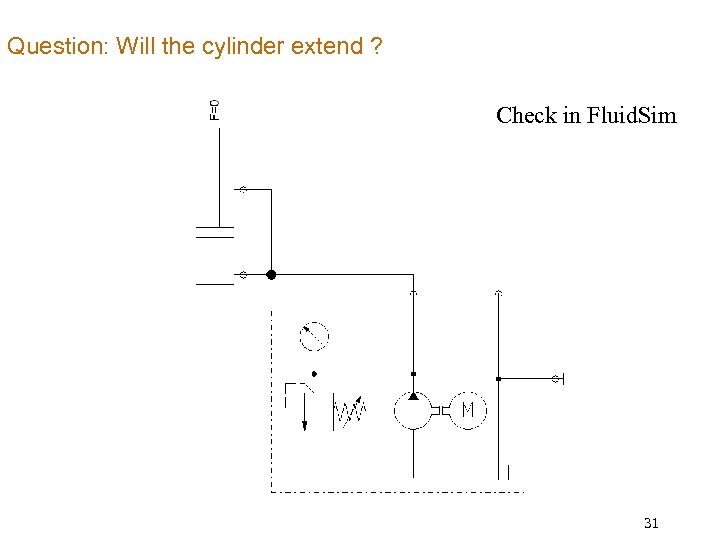

Question: Will the cylinder extend ? Check in Fluid. Sim 31

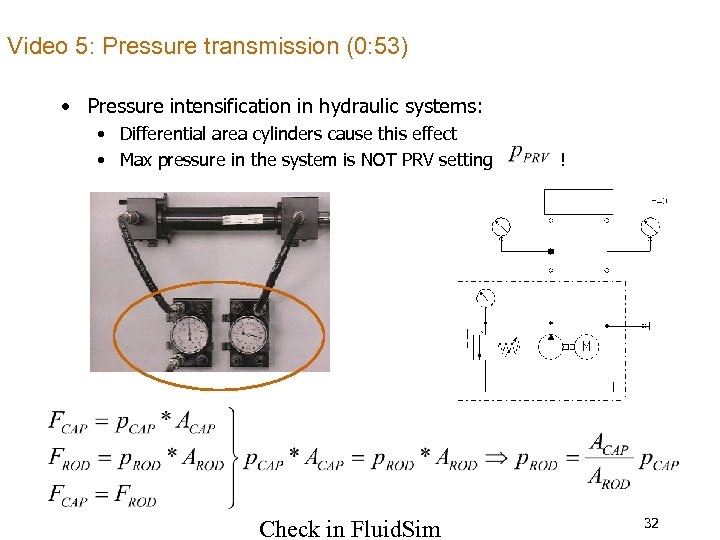

Video 5: Pressure transmission (0: 53) • Pressure intensification in hydraulic systems: • Differential area cylinders cause this effect • Max pressure in the system is NOT PRV setting Check in Fluid. Sim ! 32

Pumps and Motors 33

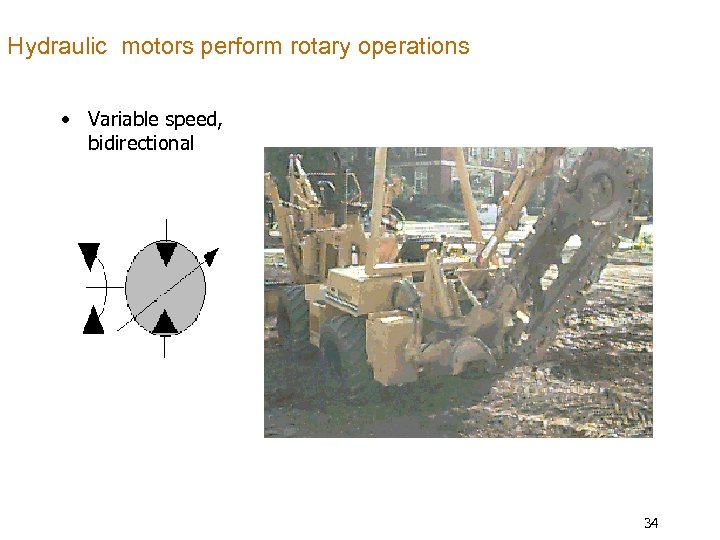

Hydraulic motors perform rotary operations • Variable speed, bidirectional 34

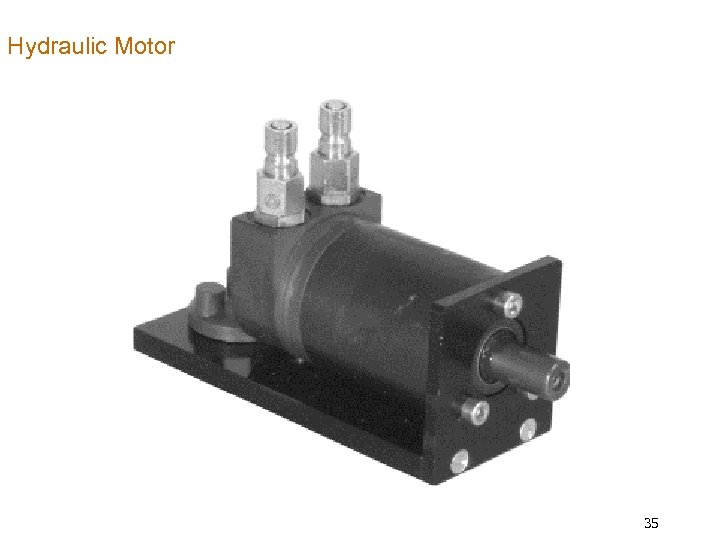

Hydraulic Motor 35

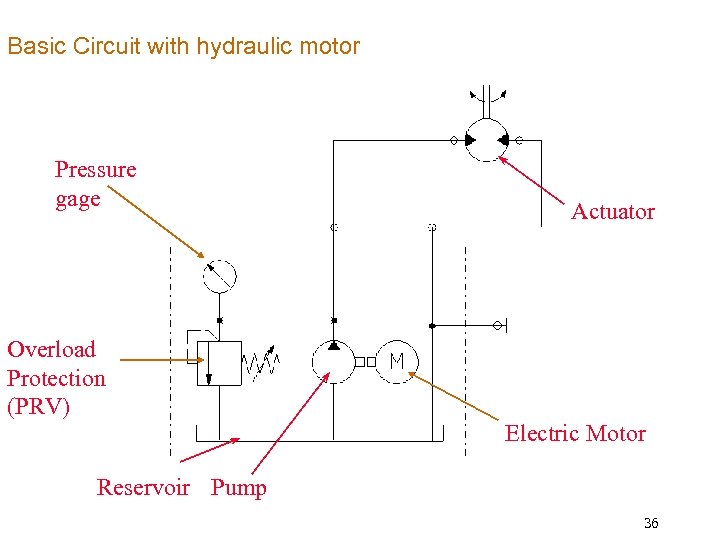

Basic Circuit with hydraulic motor Pressure gage Overload Protection (PRV) Actuator Electric Motor Reservoir Pump 36

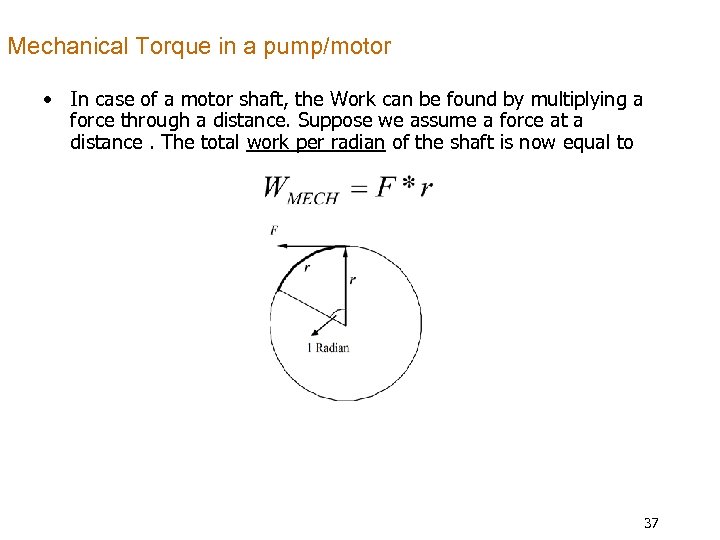

Mechanical Torque in a pump/motor • In case of a motor shaft, the Work can be found by multiplying a force through a distance. Suppose we assume a force at a distance. The total work per radian of the shaft is now equal to 37

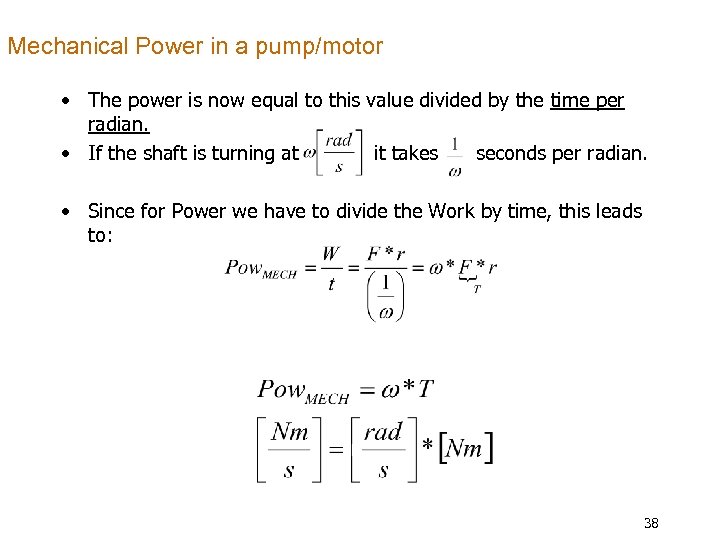

Mechanical Power in a pump/motor • The power is now equal to this value divided by the time per radian. • If the shaft is turning at it takes seconds per radian. • Since for Power we have to divide the Work by time, this leads to: 38

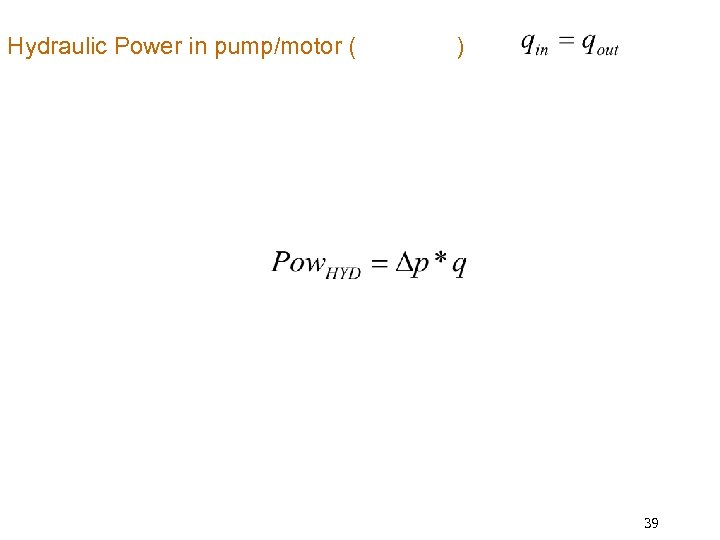

Hydraulic Power in pump/motor ( ) 39

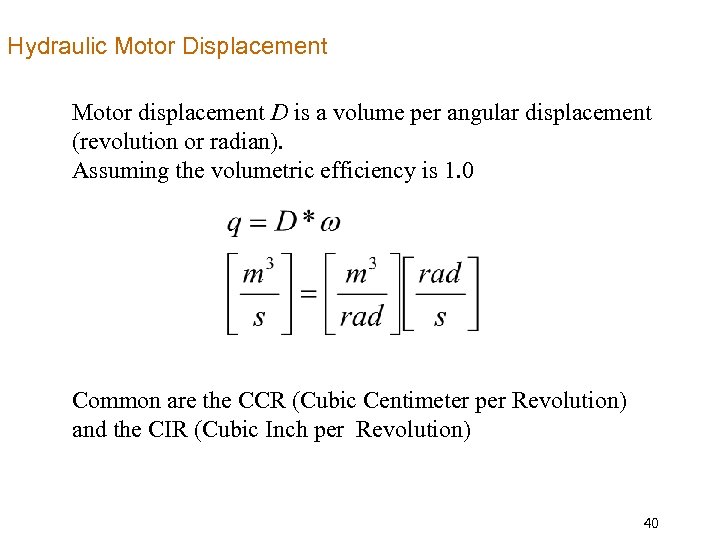

Hydraulic Motor Displacement Motor displacement D is a volume per angular displacement (revolution or radian). Assuming the volumetric efficiency is 1. 0 Common are the CCR (Cubic Centimeter per Revolution) and the CIR (Cubic Inch per Revolution) 40

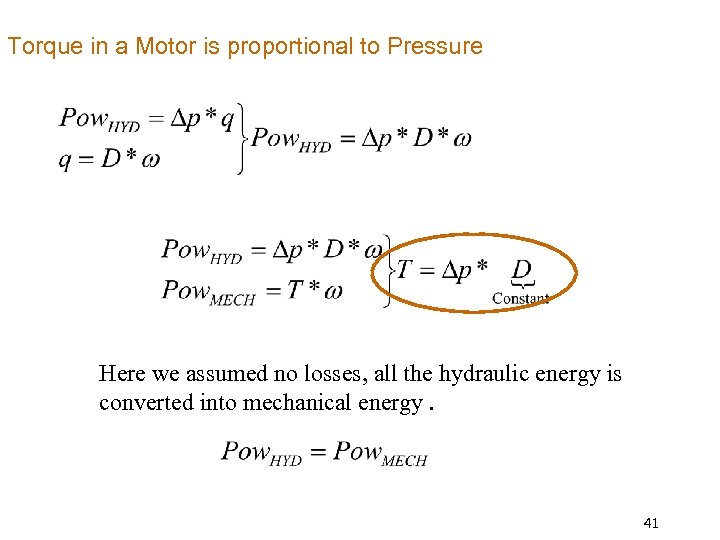

Torque in a Motor is proportional to Pressure Here we assumed no losses, all the hydraulic energy is converted into mechanical energy. 41

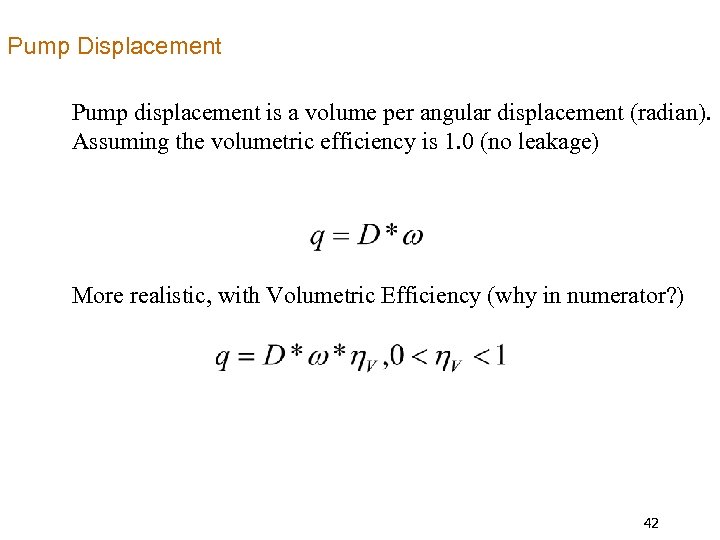

Pump Displacement Pump displacement is a volume per angular displacement (radian). Assuming the volumetric efficiency is 1. 0 (no leakage) More realistic, with Volumetric Efficiency (why in numerator? ) 42

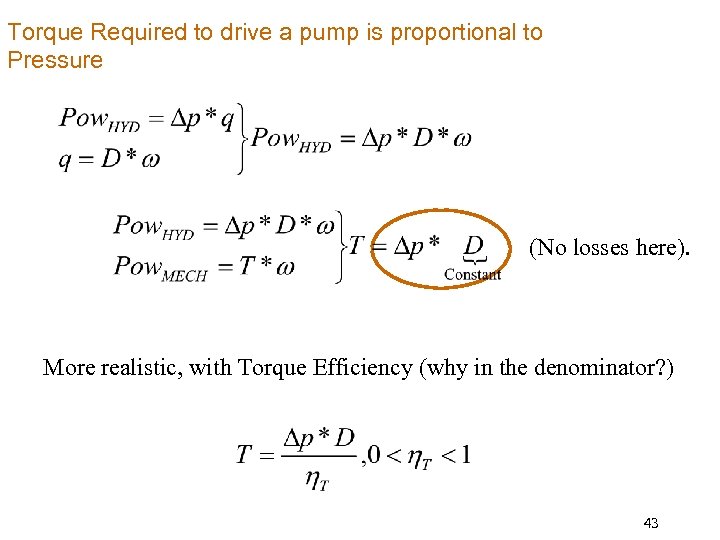

Torque Required to drive a pump is proportional to Pressure (No losses here). More realistic, with Torque Efficiency (why in the denominator? ) 43

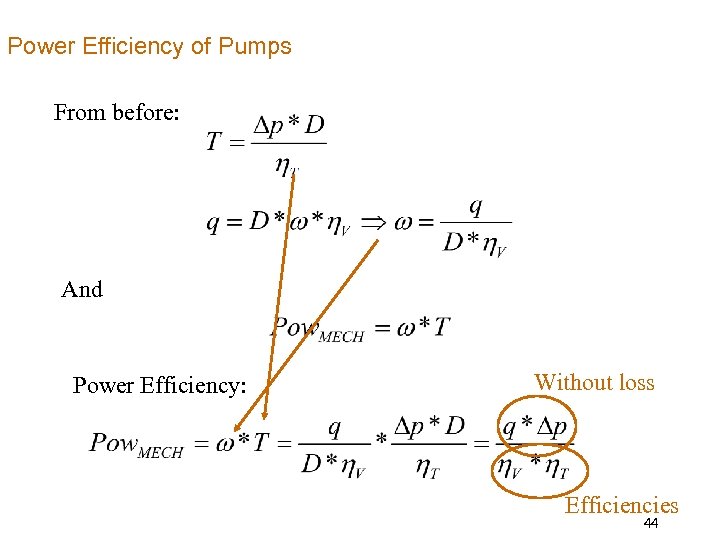

Power Efficiency of Pumps From before: And Power Efficiency: Without loss Efficiencies 44

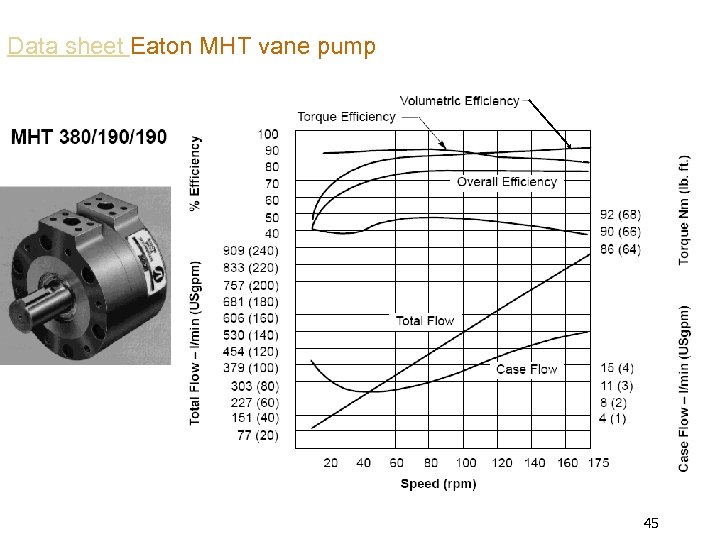

Data sheet Eaton MHT vane pump 45

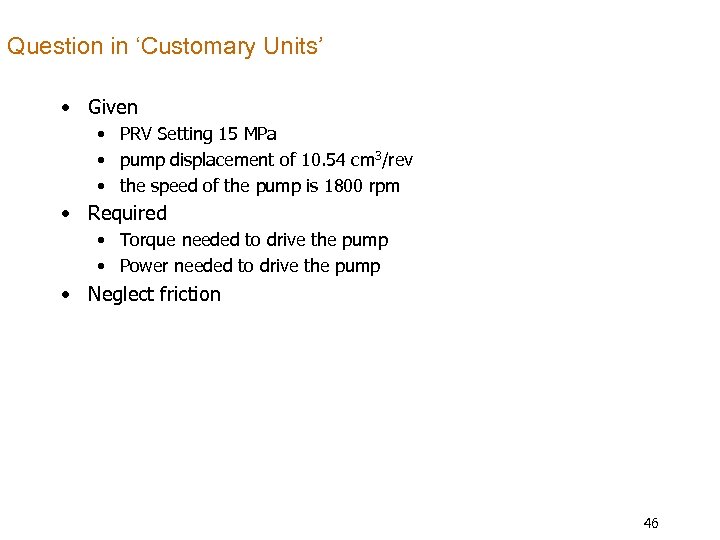

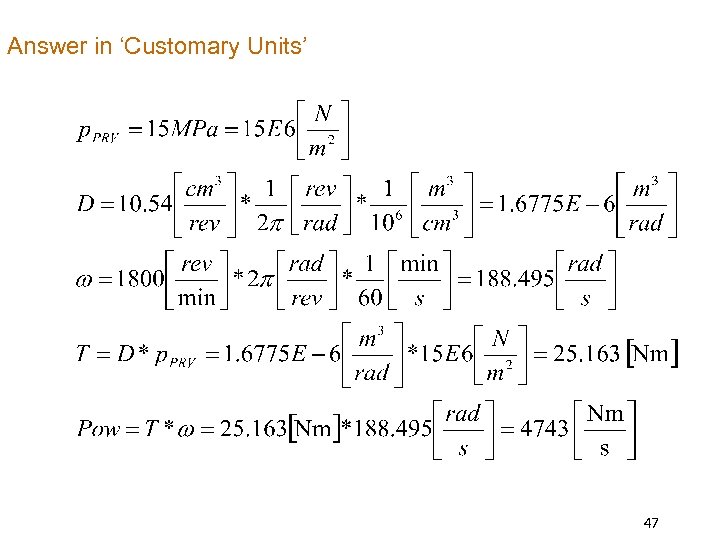

Question in ‘Customary Units’ • Given • PRV Setting 15 MPa • pump displacement of 10. 54 cm 3/rev • the speed of the pump is 1800 rpm • Required • Torque needed to drive the pump • Power needed to drive the pump • Neglect friction 46

Answer in ‘Customary Units’ 47

Question in ‘Customary Units’ • Given • PRV Setting • pump displacement of • the speed of the pump • Required • Torque needed to drive the pump • Power needed to drive the pump. • Neglect friction 48

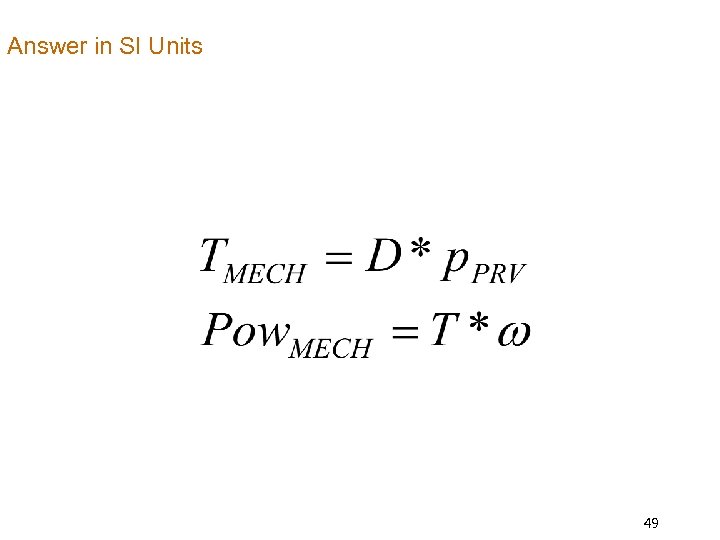

Answer in SI Units 49

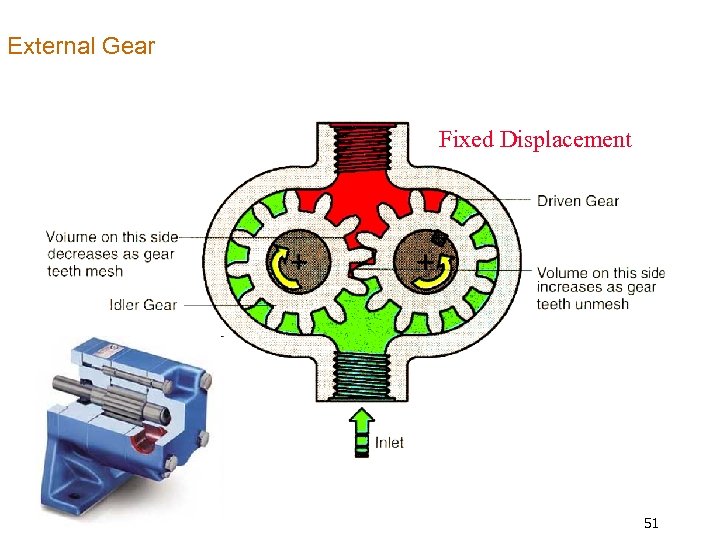

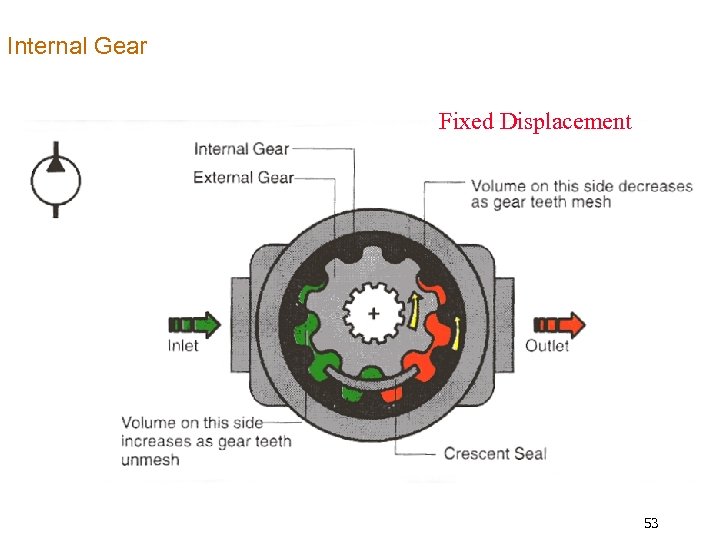

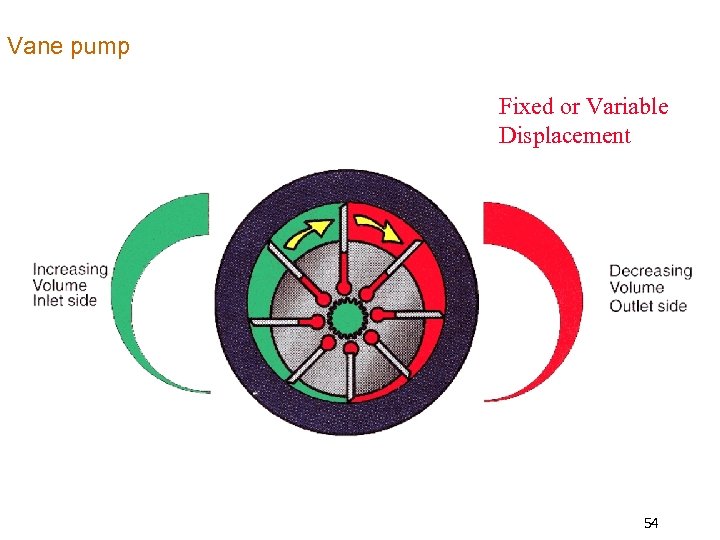

Types of Pumps and Motors • • • External Gear Internal Gear Vane Axial Piston Radial Piston 50

External Gear Fixed Displacement 51

Video 8: Power units (3: 26) • Power supply unit • Converts Mechanical energy into hydraulic energy • Hydraulic Fluid is conditioned (cooled, cleaned) • Components • • • Drive motor Safety valve Oil reservoir Pump External Gear pump function (constant delivery) • Where teeth unmesh, volume increases, oil enters • Where teeth mesh, volume decreases, oil leaves • • Pressure only builds when there is a resistance (load) Safety valve needed to prevent failure when cylinder stalls • Pressure Relief Valve diverts flow back to tank when cylinders are stalled • Reservoir • • Cools oil Cleans oil from suspended particles, water and air which takes time (Capacity) Filters trap impurities 70% of all malfunctions are due to impurities 52

Internal Gear Fixed Displacement 53

Vane pump Fixed or Variable Displacement 54

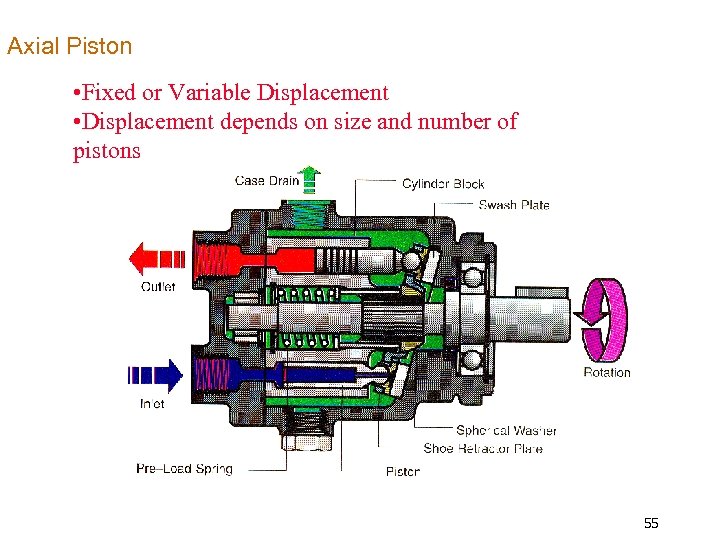

Axial Piston • Fixed or Variable Displacement • Displacement depends on size and number of pistons 55

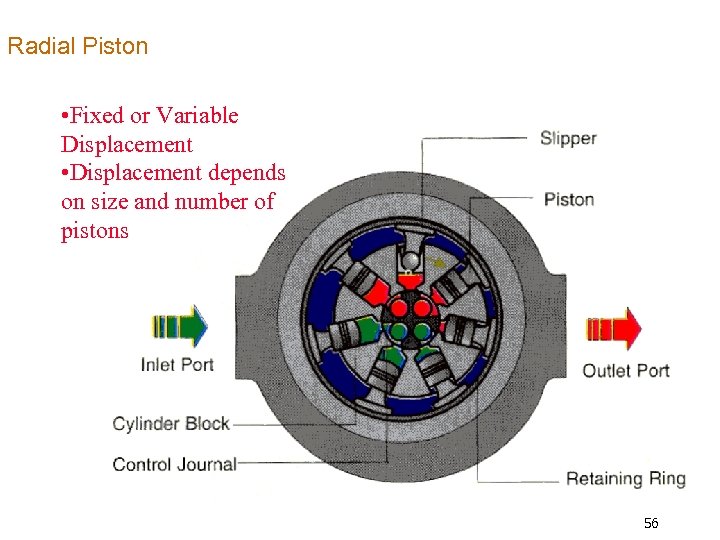

Radial Piston • Fixed or Variable Displacement • Displacement depends on size and number of pistons 56

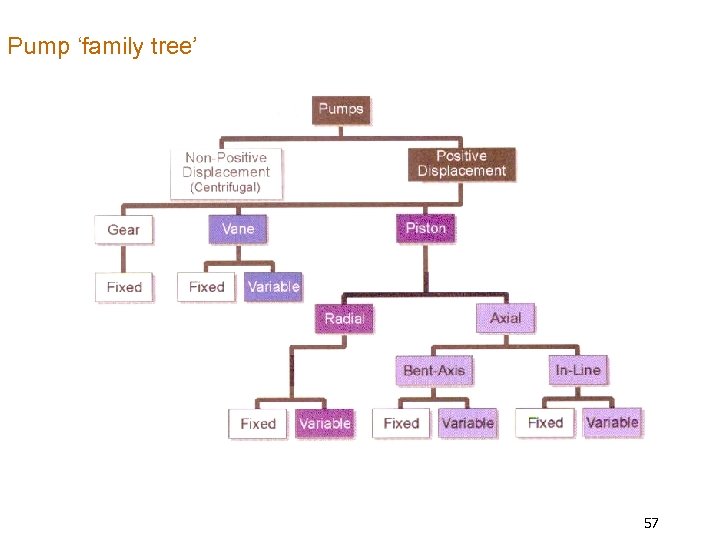

Pump ‘family tree’ 57

Pumps and Actuators: The End 58

87471e75532f47e5117830c1efdc021f.ppt