3baee47e728b1755c3fd7091f9a31c80.ppt

- Количество слайдов: 27

© ABB Utilities - 1 2001 -01/SPIDER MR 9 Process Communication Unit PCU 400

© ABB Utilities - 2 - PCU 400 Product Presentation

PCU 400 Presentation Agenda Presentation by Mattias Gustin for Market Release 9: History n Protocols n PCU 400 concept and configuration n Documentation n Data flows n Tools n Ordering n © ABB Utilities - 3 - n H/W

PCU 400 Requirements for the product n Flexible enough to build systems solutions n Possible to work standalone n Suitable also for non-SCADA systems n Minimal configuration n Component thinking n Support of open interfaces n Modern development tools n Easy to adapt new protocols n Easy debugging and fault tracing Windows NT based n © ABB Utilities - 4 - n Standard PC type Hardware

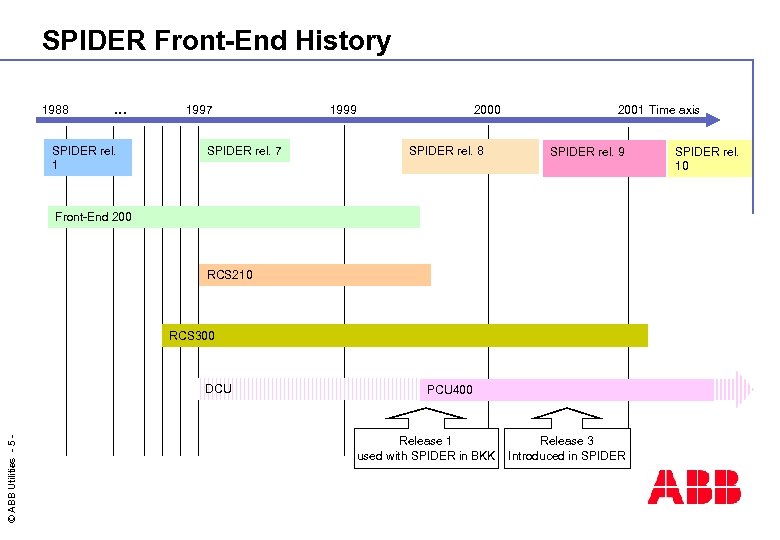

SPIDER Front-End History 1988 . . . SPIDER rel. 1 1997 SPIDER rel. 7 1999 2000 SPIDER rel. 8 2001 Time axis SPIDER rel. 9 Front-End 200 RCS 210 RCS 300 © ABB Utilities - 5 - DCU PCU 400 Release 1 used with SPIDER in BKK Release 3 Introduced in SPIDER rel. 10

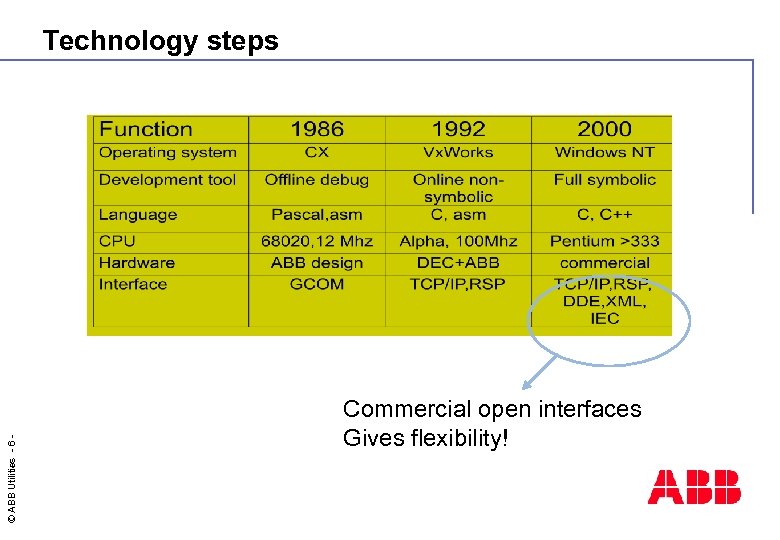

© ABB Utilities - 6 - Technology steps Commercial open interfaces Gives flexibility!

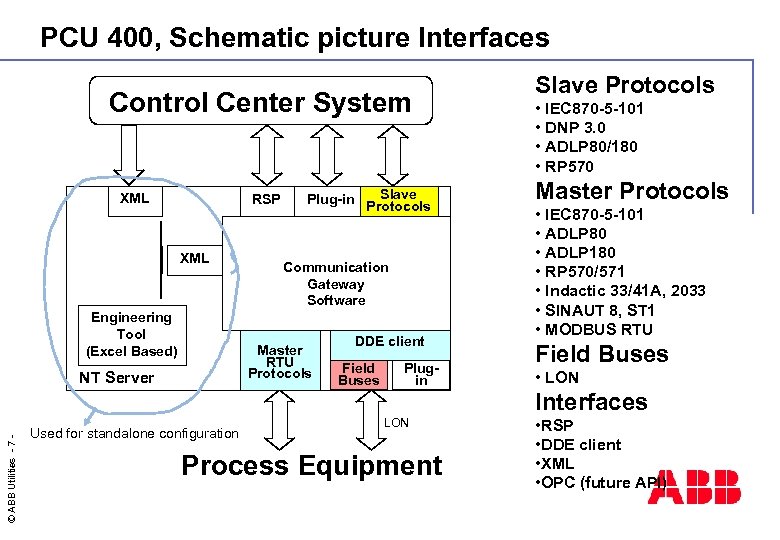

PCU 400, Schematic picture Interfaces Control Center System XML RSP XML Engineering Tool (Excel Based) Slave Plug-in Protocols Communication Gateway Software Master RTU Protocols NT Server DDE client Field Buses Plugin Slave Protocols • IEC 870 -5 -101 • DNP 3. 0 • ADLP 80/180 • RP 570 Master Protocols • IEC 870 -5 -101 • ADLP 80 • ADLP 180 • RP 570/571 • Indactic 33/41 A, 2033 • SINAUT 8, ST 1 • MODBUS RTU Field Buses • LON © ABB Utilities - 7 - Interfaces Used for standalone configuration LON Process Equipment • RSP • DDE client • XML • OPC (future API)

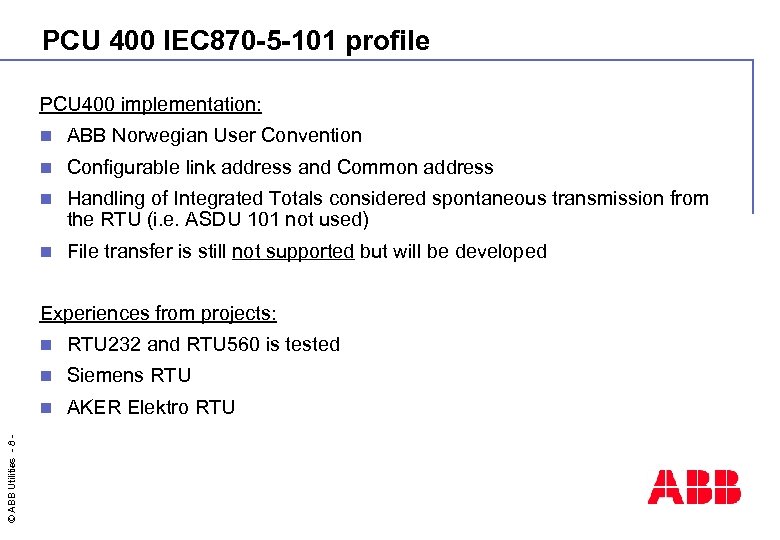

PCU 400 IEC 870 -5 -101 profile PCU 400 implementation: n ABB Norwegian User Convention n Configurable link address and Common address n Handling of Integrated Totals considered spontaneous transmission from the RTU (i. e. ASDU 101 not used) n File transfer is still not supported but will be developed Experiences from projects: RTU 232 and RTU 560 is tested n Siemens RTU n © ABB Utilities - 8 - n AKER Elektro RTU

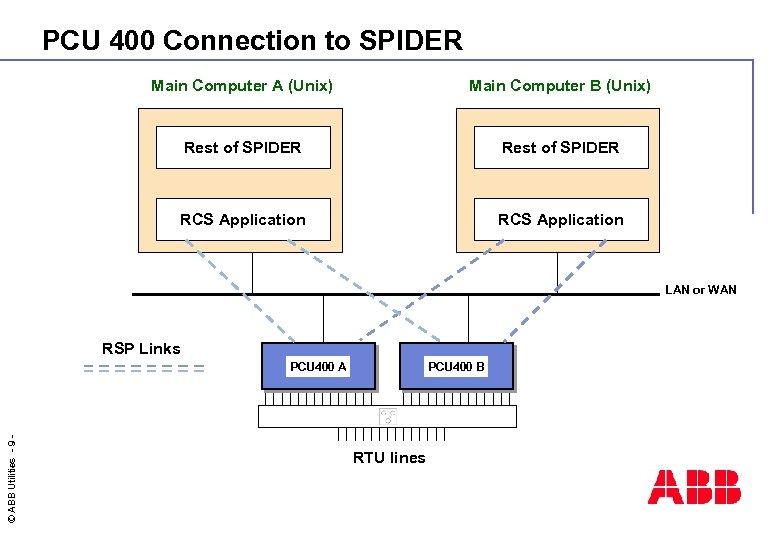

PCU 400 Connection to SPIDER Main Computer A (Unix) Main Computer B (Unix) Rest of SPIDER RCS Application LAN or WAN RSP Links © ABB Utilities - 9 - PCU 400 A PCU 400 B RTU lines

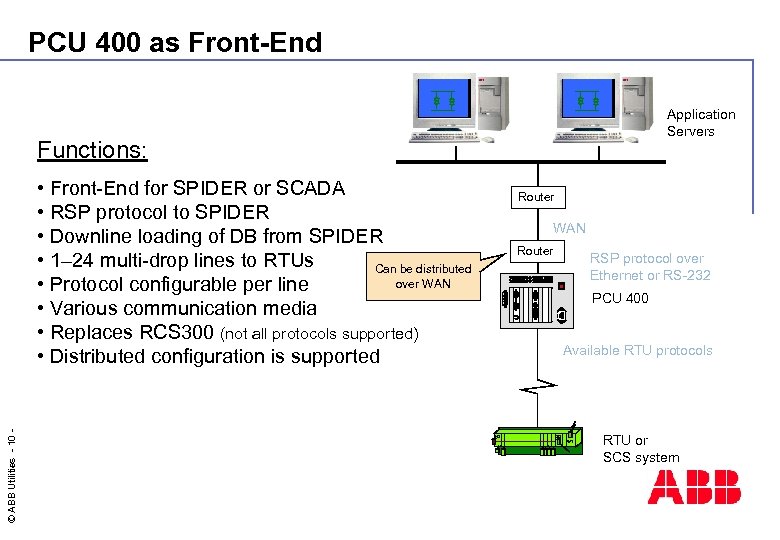

PCU 400 as Front-End Application Servers Functions: © ABB Utilities - 10 - • Front-End for SPIDER or SCADA • RSP protocol to SPIDER • Downline loading of DB from SPIDER • 1– 24 multi-drop lines to RTUs Can be distributed over WAN • Protocol configurable per line • Various communication media • Replaces RCS 300 (not all protocols supported) • Distributed configuration is supported Router WAN Router RSP protocol over Ethernet or RS-232 PCU 400 Available RTU protocols NG ZG WT 15 1 RTU or SCS system

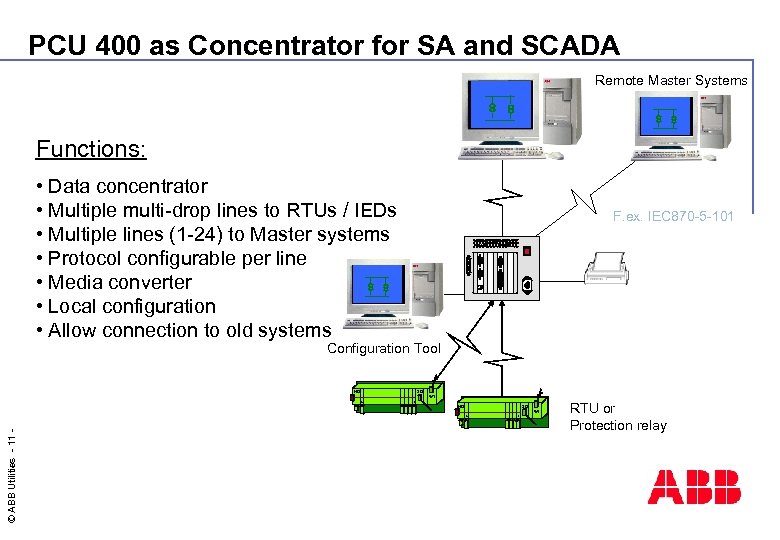

PCU 400 as Concentrator for SA and SCADA Remote Master Systems Functions: • Data concentrator • Multiple multi-drop lines to RTUs / IEDs • Multiple lines (1 -24) to Master systems • Protocol configurable per line • Media converter • Local configuration • Allow connection to old systems F. ex. IEC 870 -5 -101 Configuration Tool NG ZG WT 15 1 NG ZG WT © ABB Utilities - 11 - 15 1 RTU or Protection relay

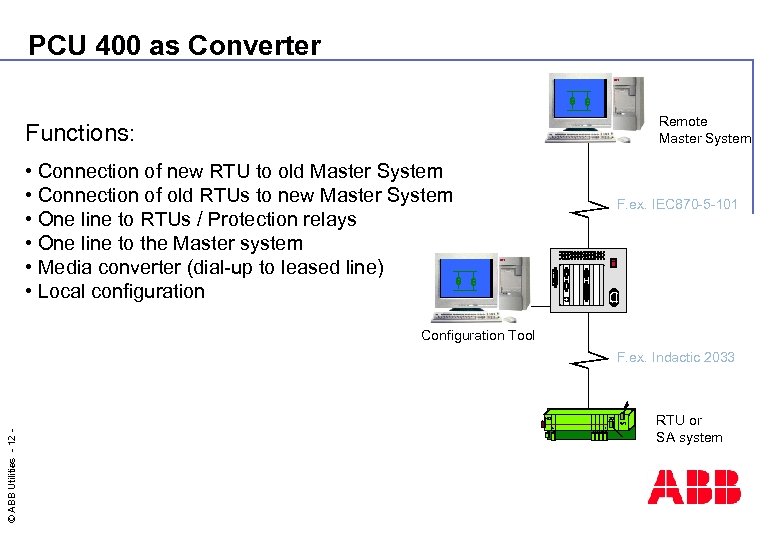

PCU 400 as Converter Remote Master System Functions: • Connection of new RTU to old Master System • Connection of old RTUs to new Master System • One line to RTUs / Protection relays • One line to the Master system • Media converter (dial-up to leased line) • Local configuration F. ex. IEC 870 -5 -101 Configuration Tool F. ex. Indactic 2033 NG ZG © ABB Utilities - 12 - WT 15 1 RTU or SA system

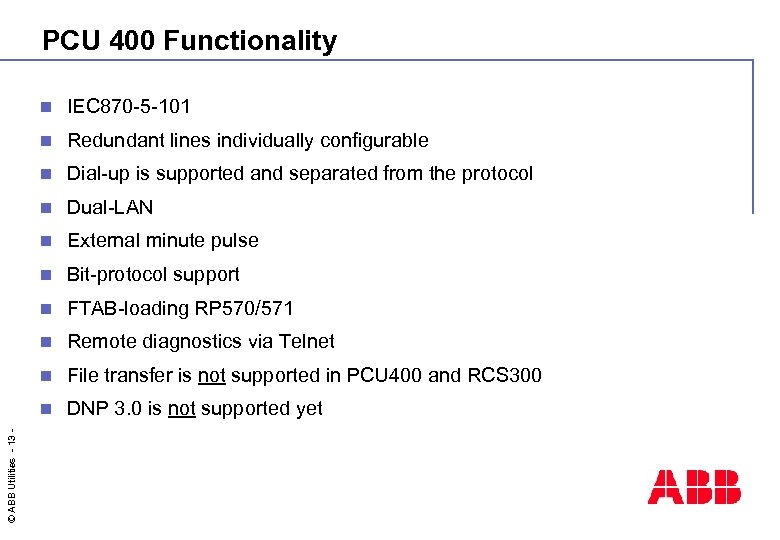

PCU 400 Functionality IEC 870 -5 -101 n Redundant lines individually configurable n Dial-up is supported and separated from the protocol n Dual-LAN n External minute pulse n Bit-protocol support n FTAB-loading RP 570/571 n Remote diagnostics via Telnet n File transfer is not supported in PCU 400 and RCS 300 n © ABB Utilities - 13 - n DNP 3. 0 is not supported yet

Aftersales opportunities Flexible solutions both for SCADA, Substation Automation and Standalone protocol converting n Add new functionality to old systems n Extend old systems with more lines and new protocols n Selling communication solutions to other competitors n © ABB Utilities - 14 - n Integrate new functionality in old systems

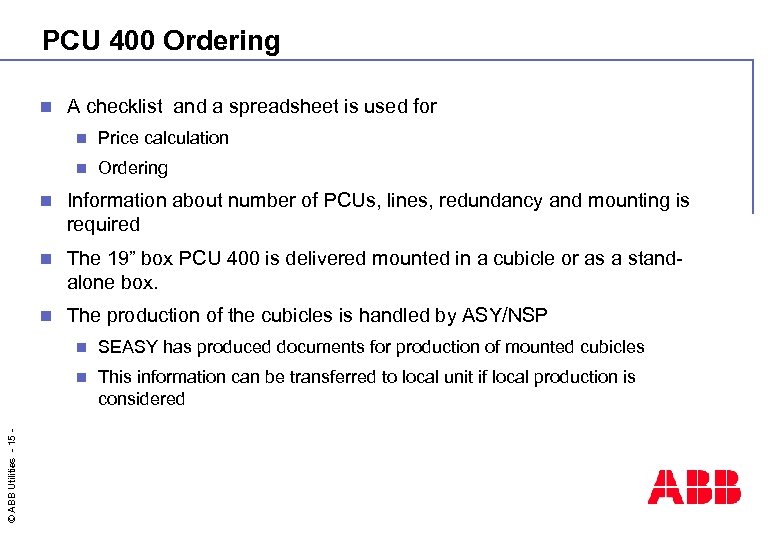

PCU 400 Ordering n A checklist and a spreadsheet is used for n Price calculation n Ordering n Information about number of PCUs, lines, redundancy and mounting is required n The 19” box PCU 400 is delivered mounted in a cubicle or as a standalone box. n The production of the cubicles is handled by ASY/NSP SEASY has produced documents for production of mounted cubicles n © ABB Utilities - 15 - n This information can be transferred to local unit if local production is considered

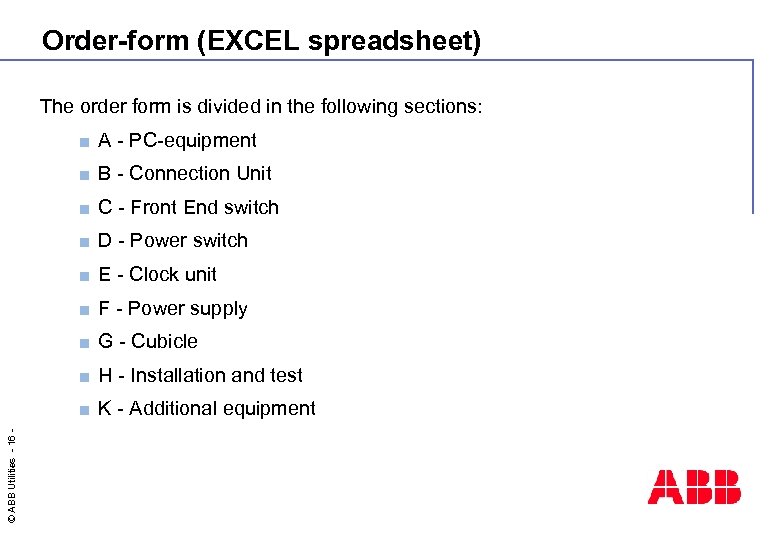

Order-form (EXCEL spreadsheet) The order form is divided in the following sections: A - PC-equipment < B - Connection Unit < C - Front End switch < D - Power switch < E - Clock unit < F - Power supply < G - Cubicle < H - Installation and test < © ABB Utilities - 16 - < K - Additional equipment

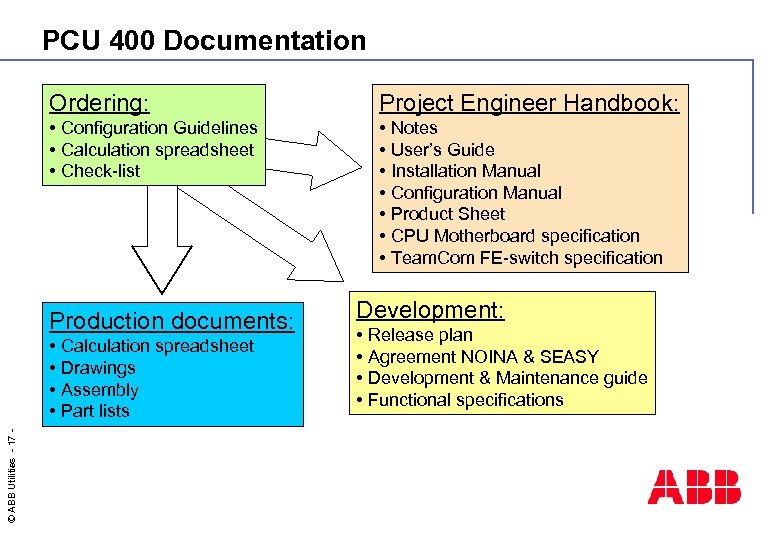

PCU 400 Documentation Ordering: Project Engineer Handbook: • Configuration Guidelines • Calculation spreadsheet • Check-list • Notes • User’s Guide • Installation Manual • Configuration Manual • Product Sheet • CPU Motherboard specification • Team. Com FE-switch specification Production documents: © ABB Utilities - 17 - • Calculation spreadsheet • Drawings • Assembly • Part lists Development: • Release plan • Agreement NOINA & SEASY • Development & Maintenance guide • Functional specifications

Training n SEASY has developed a PCU 400 course called F 96. The training is handled by ABB University (contact Lars Garpemyr). The course is useful both for customers and ABB personnel for learning the functions and the tools of PCU 400. n We plan to make a special marketing tour for DEUTA and USTRA for promoting the PCU 400 product. The seminar includes: Sales training n Technical description n © ABB Utilities - 18 - n DEMO of the product.

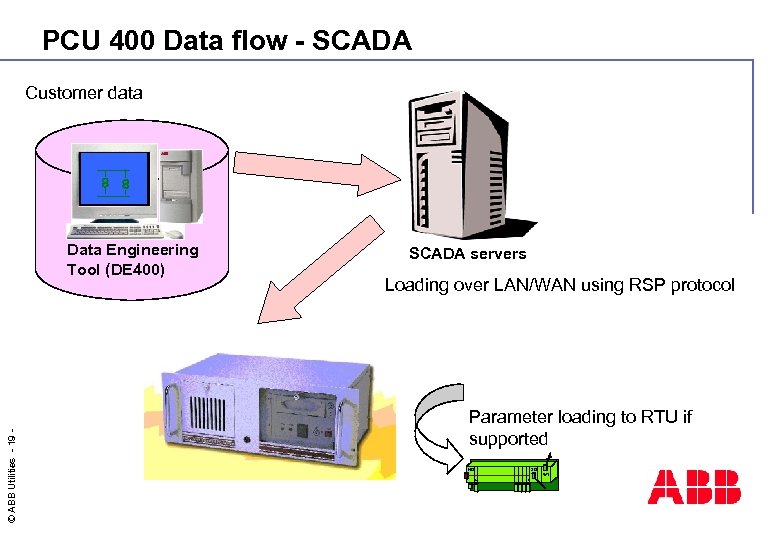

PCU 400 Data flow - SCADA Customer data © ABB Utilities - 19 - Data Engineering Tool (DE 400) SCADA servers Loading over LAN/WAN using RSP protocol Parameter loading to RTU if supported NG ZG WT 15 1

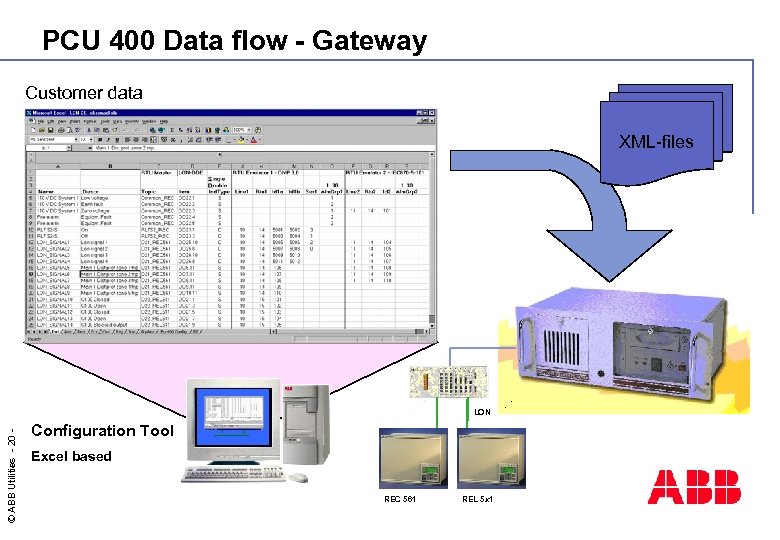

PCU 400 Data flow - Gateway Customer data XML-files © ABB Utilities - 20 - LON Configuration Tool Excel based REC 561 REL 5 x 1

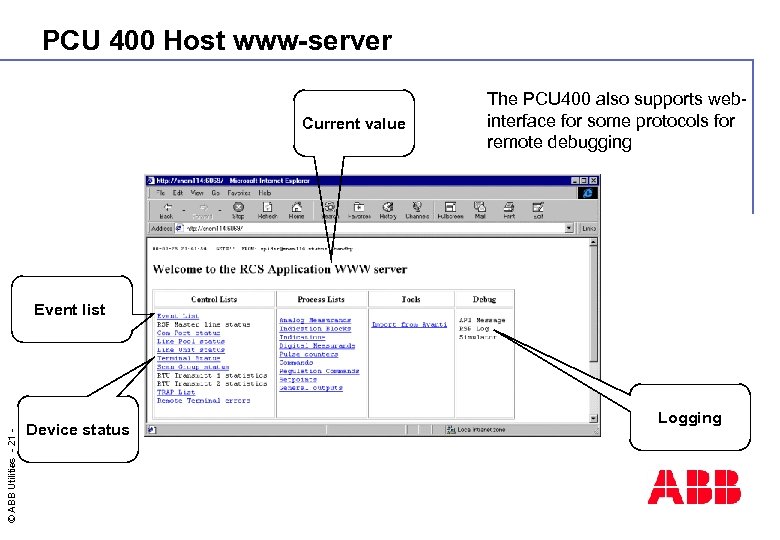

PCU 400 Host www-server Current value The PCU 400 also supports webinterface for some protocols for remote debugging © ABB Utilities - 21 - Event list Device status Logging

PCU 400 Development tool • Standard software • Microsoft Development Studio 6. 0 • Language C and C++ • Visual Source Safe • PC based © ABB Utilities - 22 - • portable for site assistance

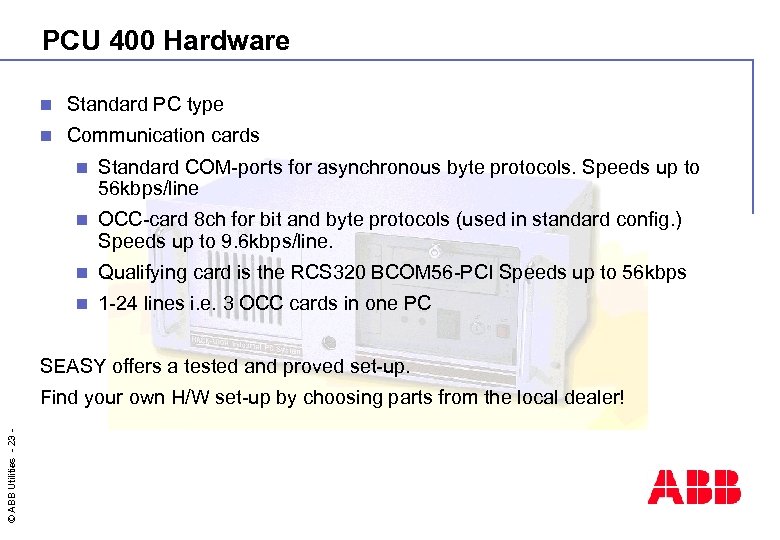

PCU 400 Hardware n Standard PC type n Communication cards n Standard COM-ports for asynchronous byte protocols. Speeds up to 56 kbps/line n OCC-card 8 ch for bit and byte protocols (used in standard config. ) Speeds up to 9. 6 kbps/line. n Qualifying card is the RCS 320 BCOM 56 -PCI Speeds up to 56 kbps n 1 -24 lines i. e. 3 OCC cards in one PC SEASY offers a tested and proved set-up. © ABB Utilities - 23 - Find your own H/W set-up by choosing parts from the local dealer!

PCU 400 Protocol Development n Developed as “e. Xternal”-modules. n n n No interference with other system components Private database structures Template as a base for new protocols available for: n RSP interface n API for internal functions Media and Low level drivers available n © ABB Utilities - 24 - n Or use DDE protocol interface. This will gain access to many already developed protocols.

Customer benefits PCU 400 is flexible n Different configurations are supported n Standard non-ABB hardware is used n Standard Windows NT 4. 0 n Open interfaces available e. g. DDE, XML n Protocols can be bought as 3 rd part products e. g. LON n Protocols are run as separate processes in NT n Remote diagnostics via LAN or Modem n © ABB Utilities - 25 - n Adds functionality as new protocols to old systems

Customer benefits (cont. ) © ABB Utilities - 26 - PCU 400 replaces RCS 3 xx PCU 400 covers SCADA, SA and standalone configurations PCU 400 is a component in the SPIDER system PCU 400 has potential to grow as Gateway Reduced maintenance cost New markets gives bigger volumes

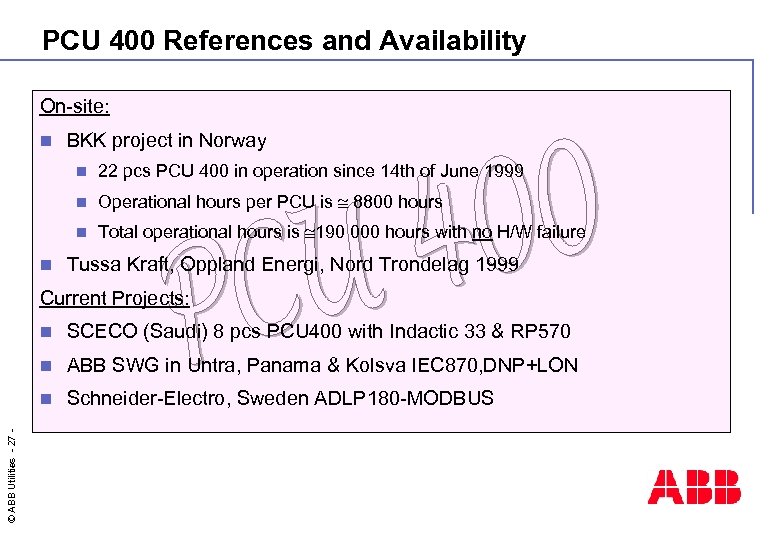

PCU 400 References and Availability On-site: n BKK project in Norway n n Operational hours per PCU is 8800 hours n n 22 pcs PCU 400 in operation since 14 th of June 1999 Total operational hours is 190 000 hours with no H/W failure Tussa Kraft, Oppland Energi, Nord Trondelag 1999 Current Projects: SCECO (Saudi) 8 pcs PCU 400 with Indactic 33 & RP 570 n ABB SWG in Untra, Panama & Kolsva IEC 870, DNP+LON n © ABB Utilities - 27 - n Schneider-Electro, Sweden ADLP 180 -MODBUS

3baee47e728b1755c3fd7091f9a31c80.ppt