fd9084047f69ac0faa700cd99976491e.ppt

- Количество слайдов: 58

© ABB Oy - 1 - Petri Torniainen 12. 5. 2009 ACS 850 -04 New Industrial Drive Module

ACS 850 -04 Table of Contents What is ACS 850 -04 n HW features n SW features n Control connections n Options n PC Tools n Documents n © ABB Oy - 2 n Sales arguments

ACS 850 -04 ABB Industrial Drive Very flexible drives that are easy to be configured to meet the needs of various industries and applications n ABB Industrial drives are designed especially for applications in process industries such as: n n n n Examples of applications: n n n © ABB Oy - 3 Pulp & paper Metals Mining Cement Chemical Oil & gas n n Cranes Winders Extruders Mixers Wire drawing machines Separators …

ACS 850 -04 © ABB Oy - 4 n Drive modules ACS 850 -04 is a drive module designed to be built into a customer’s own cabinet

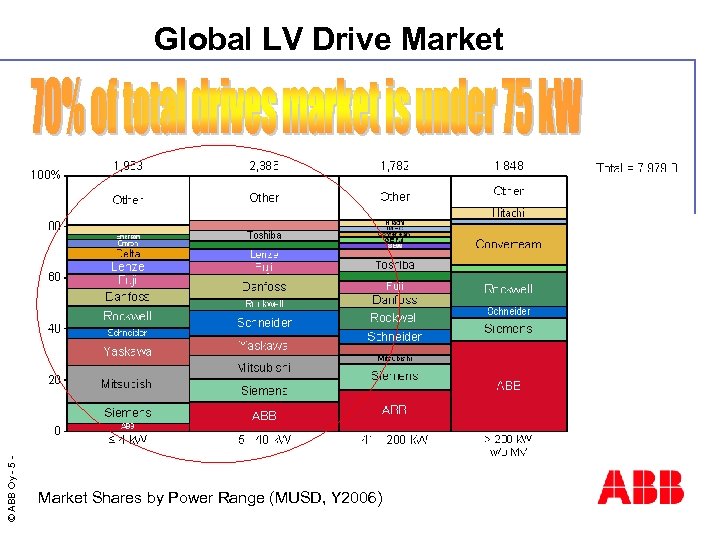

© ABB Oy - 5 Global LV Drive Market Shares by Power Range (MUSD, Y 2006)

ACS 850 -04 n Market strategy - targets Growth n n © ABB Oy - 6 Low power market n n In the new industries and applications In the module market Strengthen position in the existing markets

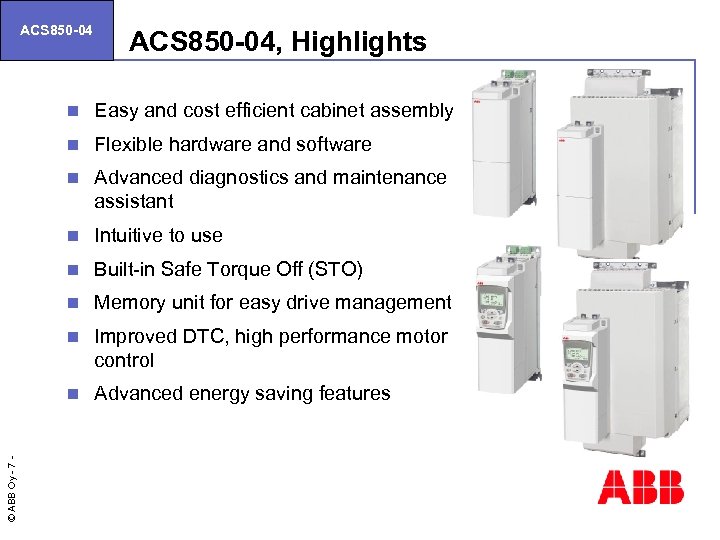

ACS 850 -04, Highlights Easy and cost efficient cabinet assembly n Flexible hardware and software n Advanced diagnostics and maintenance assistant n Intuitive to use n Built-in Safe Torque Off (STO) n Memory unit for easy drive management n Improved DTC, high performance motor control n © ABB Oy - 7 n Advanced energy saving features

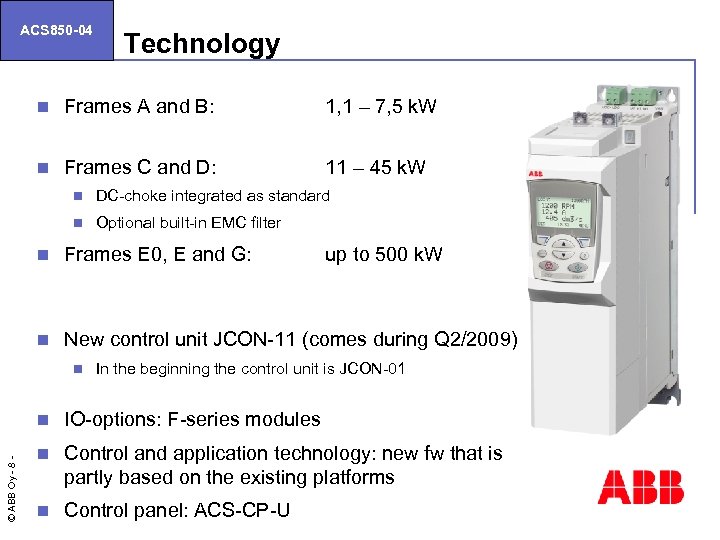

ACS 850 -04 Technology n Frames A and B: 1, 1 – 7, 5 k. W n Frames C and D: 11 – 45 k. W n n n DC-choke integrated as standard Optional built-in EMC filter Frames E 0, E and G: up to 500 k. W + n New control unit JCON-11 (comes during Q 2/2009) n In the beginning the control unit is JCON-01 © ABB Oy - 8 n IO-options: F-series modules n Control and application technology: new fw that is partly based on the existing platforms n Control panel: ACS-CP-U

© ABB Oy - 9 HARDWARE

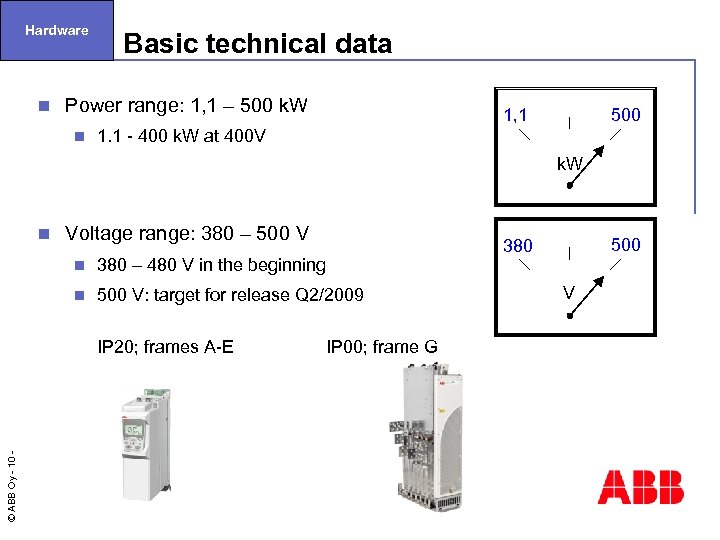

Hardware n Basic technical data Power range: 1, 1 – 500 k. W n 500 1, 1 1. 1 - 400 k. W at 400 V k. W n Voltage range: 380 – 500 V n 380 – 480 V in the beginning n 500 V: target for release Q 2/2009 © ABB Oy - 10 IP 20; frames A-E 500 380 IP 00; frame G V

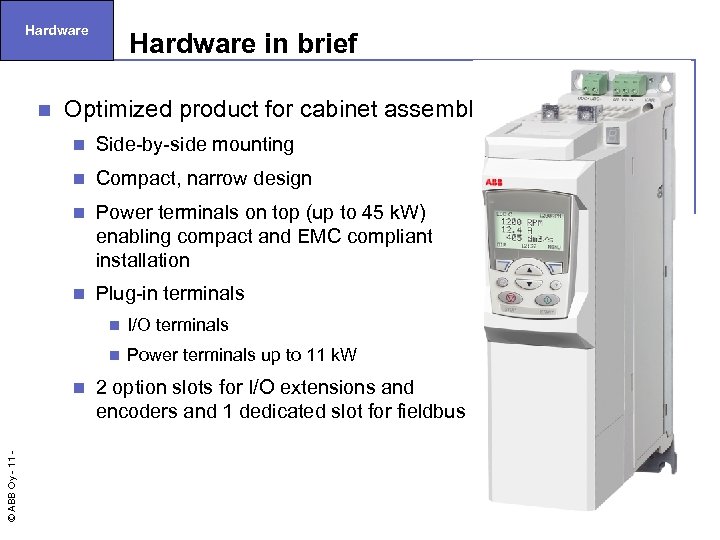

Hardware n Hardware in brief Optimized product for cabinet assembly n Side-by-side mounting n Compact, narrow design n Power terminals on top (up to 45 k. W) enabling compact and EMC compliant installation n Plug-in terminals n n © ABB Oy - 11 n I/O terminals Power terminals up to 11 k. W 2 option slots for I/O extensions and encoders and 1 dedicated slot for fieldbus

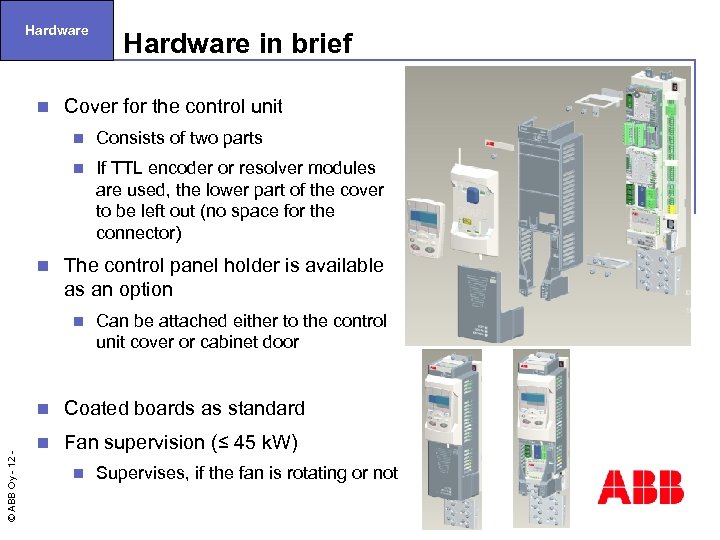

Hardware n Hardware in brief Cover for the control unit n n n Consists of two parts If TTL encoder or resolver modules are used, the lower part of the cover to be left out (no space for the connector) The control panel holder is available as an option n Can be attached either to the control unit cover or cabinet door © ABB Oy - 12 n Coated boards as standard n Fan supervision (≤ 45 k. W) n Supervises, if the fan is rotating or not

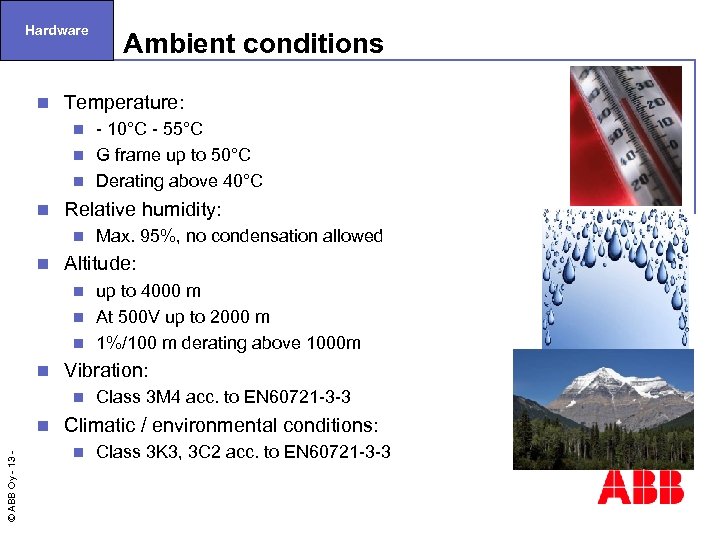

Hardware n Ambient conditions Temperature: - 10°C - 55°C n G frame up to 50°C n Derating above 40°C n n Relative humidity: n n Max. 95%, no condensation allowed Altitude: up to 4000 m n At 500 V up to 2000 m n 1%/100 m derating above 1000 m n n Vibration: n © ABB Oy - 13 n Class 3 M 4 acc. to EN 60721 -3 -3 Climatic / environmental conditions: n Class 3 K 3, 3 C 2 acc. to EN 60721 -3 -3

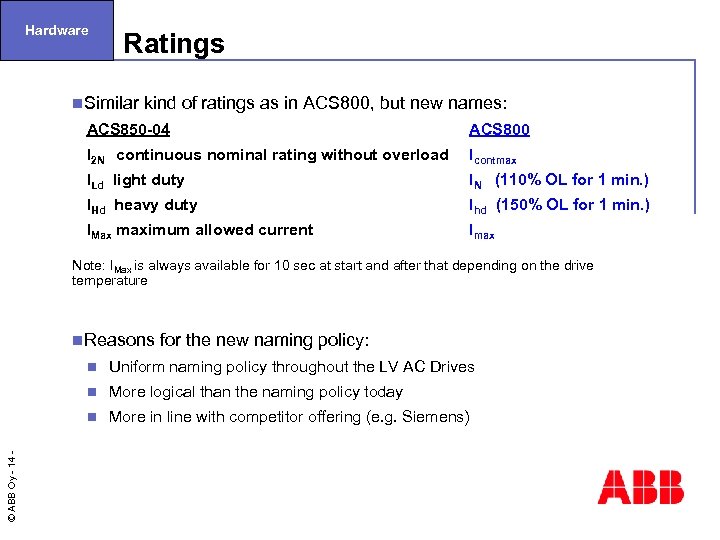

Hardware Ratings n. Similar kind of ratings as in ACS 800, but new names: ACS 850 -04 ACS 800 I 2 N continuous nominal rating without overload Icontmax ILd light duty IN (110% OL for 1 min. ) IHd heavy duty Ihd (150% OL for 1 min. ) IMax maximum allowed current Imax Note: IMax is always available for 10 sec at start and after that depending on the drive temperature n. Reasons for the new naming policy: Uniform naming policy throughout the LV AC Drives n More logical than the naming policy today n © ABB Oy - 14 n More in line with competitor offering (e. g. Siemens)

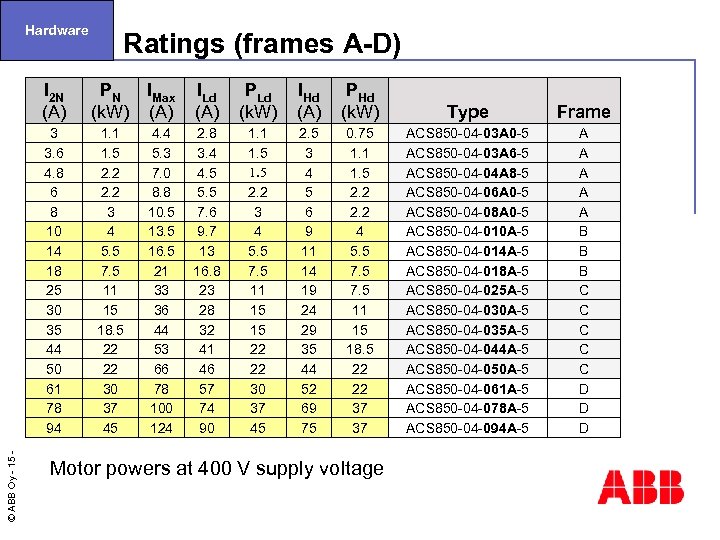

Hardware I 2 N (A) © ABB Oy - 15 3 3. 6 4. 8 6 8 10 14 18 25 30 35 44 50 61 78 94 Ratings (frames A-D) PN IMax ILd PLd (k. W) (A) (k. W) 1. 1 1. 5 2. 2 3 4 5. 5 7. 5 11 15 18. 5 22 22 30 37 45 4. 4 5. 3 7. 0 8. 8 10. 5 13. 5 16. 5 21 33 36 44 53 66 78 100 124 2. 8 3. 4 4. 5 5. 5 7. 6 9. 7 13 16. 8 23 28 32 41 46 57 74 90 1. 1 1. 5 2. 2 3 4 5. 5 7. 5 11 15 15 22 22 30 37 45 IHd PHd (A) (k. W) 2. 5 3 4 5 6 9 11 14 19 24 29 35 44 52 69 75 0. 75 1. 1 1. 5 2. 2 4 5. 5 7. 5 11 15 18. 5 22 22 37 37 Motor powers at 400 V supply voltage Type Frame ACS 850 -04 -03 A 0 -5 ACS 850 -04 -03 A 6 -5 ACS 850 -04 -04 A 8 -5 ACS 850 -04 -06 A 0 -5 ACS 850 -04 -08 A 0 -5 ACS 850 -04 -010 A-5 ACS 850 -04 -014 A-5 ACS 850 -04 -018 A-5 ACS 850 -04 -025 A-5 ACS 850 -04 -030 A-5 ACS 850 -04 -035 A-5 ACS 850 -04 -044 A-5 ACS 850 -04 -050 A-5 ACS 850 -04 -061 A-5 ACS 850 -04 -078 A-5 ACS 850 -04 -094 A-5 A A A B B B C C C D D D

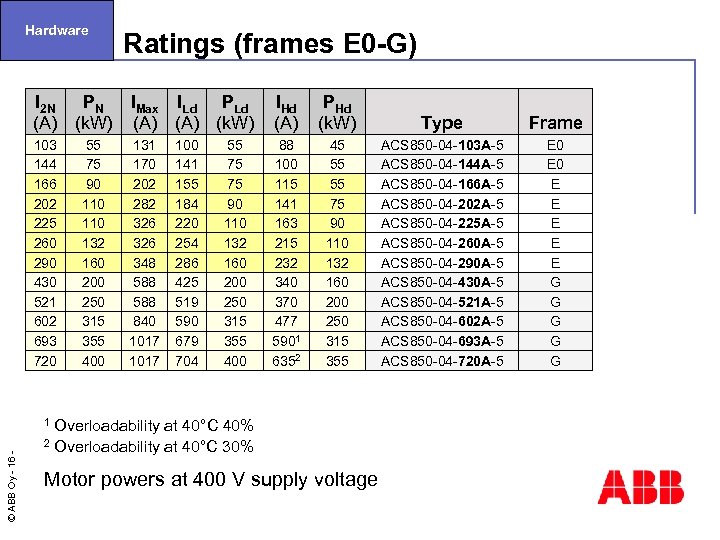

Hardware Ratings (frames E 0 -G) I 2 N PN (A) (k. W) IMax ILd PLd (A) (k. W) IHd PHd (A) (k. W) 103 144 166 202 225 260 290 430 521 602 693 720 131 170 202 282 326 348 588 840 1017 88 100 115 141 163 215 232 340 370 477 5901 6352 55 75 90 110 132 160 200 250 315 355 400 141 155 184 220 254 286 425 519 590 679 704 55 75 75 90 110 132 160 200 250 315 355 400 © ABB Oy - 16 1 Overloadability at 40°C 40% 2 Overloadability at 40°C 30% 45 55 55 75 90 110 132 160 200 250 315 355 Motor powers at 400 V supply voltage Type Frame ACS 850 -04 -103 A-5 ACS 850 -04 -144 A-5 ACS 850 -04 -166 A-5 ACS 850 -04 -202 A-5 ACS 850 -04 -225 A-5 ACS 850 -04 -260 A-5 ACS 850 -04 -290 A-5 ACS 850 -04 -430 A-5 ACS 850 -04 -521 A-5 ACS 850 -04 -602 A-5 ACS 850 -04 -693 A-5 ACS 850 -04 -720 A-5 E 0 E E E G G G

Hardware Derating Voltage derating: no derating needed from 400 V to 500 V n Temperature derating: 1%/1°C n © ABB Oy - 17 n Altitude derating: 1%/100 m

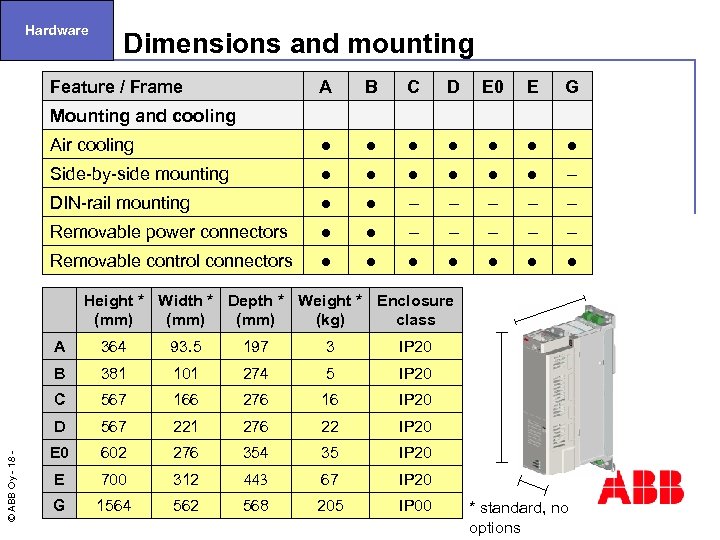

Hardware Dimensions and mounting Feature / Frame A B C D E 0 E G Mounting and cooling Air cooling ● ● ● ● Side-by-side mounting ● ● ● – DIN-rail mounting ● ● – – – Removable power connectors ● ● – – – Removable control connectors ● ● ● ● Height * Width * Depth * Weight * Enclosure (mm) (kg) class 364 93. 5 197 3 IP 20 B 381 101 274 5 IP 20 C 567 166 276 16 IP 20 D © ABB Oy - 18 A 567 221 276 22 IP 20 E 0 602 276 354 35 IP 20 E 700 312 443 67 IP 20 G 1564 562 568 205 IP 00 * standard, no options

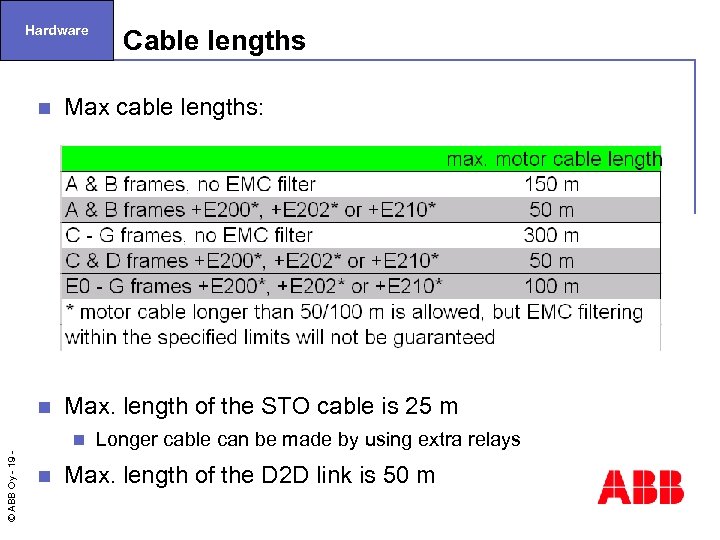

Hardware Cable lengths n Max cable lengths: n Max. length of the STO cable is 25 m © ABB Oy - 19 n n Longer cable can be made by using extra relays Max. length of the D 2 D link is 50 m

© ABB Oy - 20 SOFTWARE

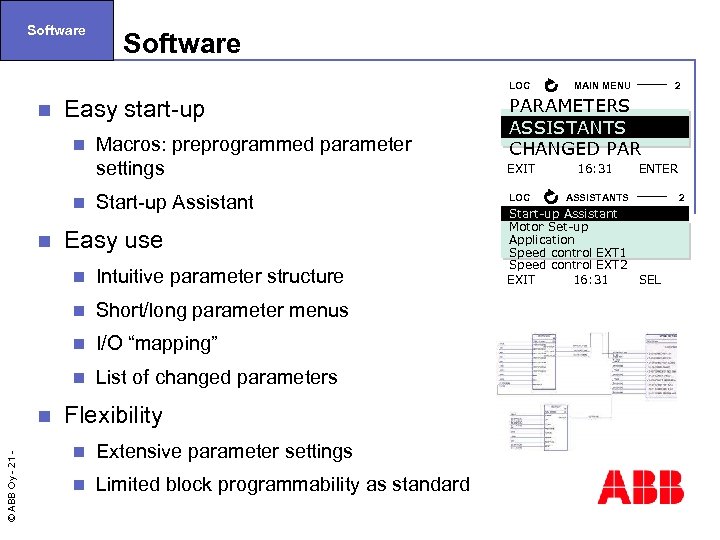

Software LOC n Easy start-up n n n Macros: preprogrammed parameter settings Start-up Assistant Easy use n n I/O “mapping” n © ABB Oy - 21 Short/long parameter menus n n Intuitive parameter structure List of changed parameters Flexibility n Extensive parameter settings n Limited block programmability as standard MAIN MENU 2 PARAMETERS ASSISTANTS CHANGED PAR EXIT 16: 31 LOC ENTER ASSISTANTS Start-up Assistant Motor Set-up Application Speed control EXT 1 Speed control EXT 2 EXIT 16: 31 SEL 2

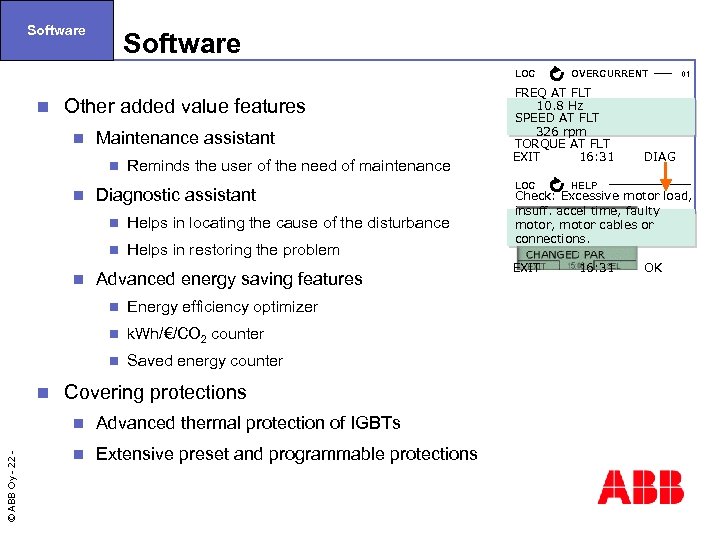

Software LOC n Other added value features n Maintenance assistant n n Reminds the user of the need of maintenance Diagnostic assistant n n n Helps in locating the cause of the disturbance Helps in restoring the problem Advanced energy saving features n n k. Wh/€/CO 2 counter n n Energy efficiency optimizer Saved energy counter Covering protections © ABB Oy - 22 n Advanced thermal protection of IGBTs n Extensive preset and programmable protections OVERCURRENT FREQ AT FLT 10. 8 Hz SPEED AT FLT 326 rpm TORQUE AT FLT EXIT 16: 31 LOC 01 DIAG HELP Check: Excessive motor load, insuff. accel time, faulty motor, motor cables or connections. EXIT 16: 31 OK

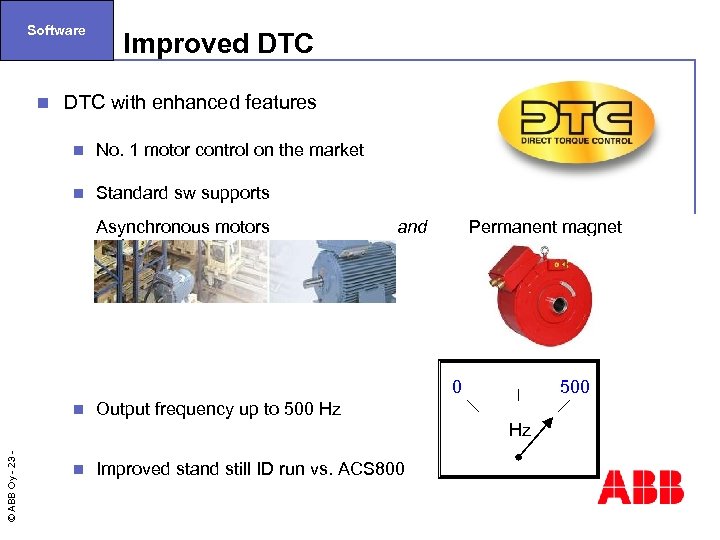

Software n Improved DTC with enhanced features n No. 1 motor control on the market n Standard sw supports Asynchronous motors and Permanent magnet 500 0 n Output frequency up to 500 Hz © ABB Oy - 23 Hz n Improved stand still ID run vs. ACS 800

© ABB Oy - 24 CONTROL CONNECTIONS

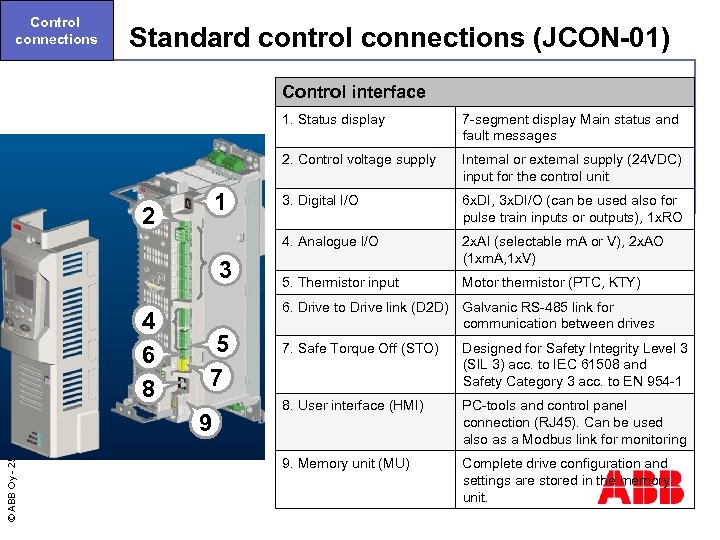

Control connections Standard control connections (JCON-01) Control interface 1. Status display 2. Control voltage supply 3 4 6 8 5 7 © ABB Oy - 25 9 3. Digital I/O 6 x. DI, 3 x. DI/O (can be used also for pulse train inputs or outputs), 1 x. RO 2 x. AI (selectable m. A or V), 2 x. AO (1 xm. A, 1 x. V) 5. Thermistor input Motor thermistor (PTC, KTY) 6. Drive to Drive link (D 2 D) 2 Internal or external supply (24 VDC) input for the control unit 4. Analogue I/O 1 7 -segment display Main status and fault messages Galvanic RS-485 link for communication between drives 7. Safe Torque Off (STO) Designed for Safety Integrity Level 3 (SIL 3) acc. to IEC 61508 and Safety Category 3 acc. to EN 954 -1 8. User interface (HMI) PC-tools and control panel connection (RJ 45). Can be used also as a Modbus link for monitoring 9. Memory unit (MU) Complete drive configuration and settings are stored in the memory unit.

Control connections New control board Some features needed for Industrial drive market are missing in JCON-01 new control board (JCON-11) n Sets the standard for the I/O and terminal numbering for the next generation Industrial drive products n Target for sales release: Q 2/2009 © ABB Oy - 26 n

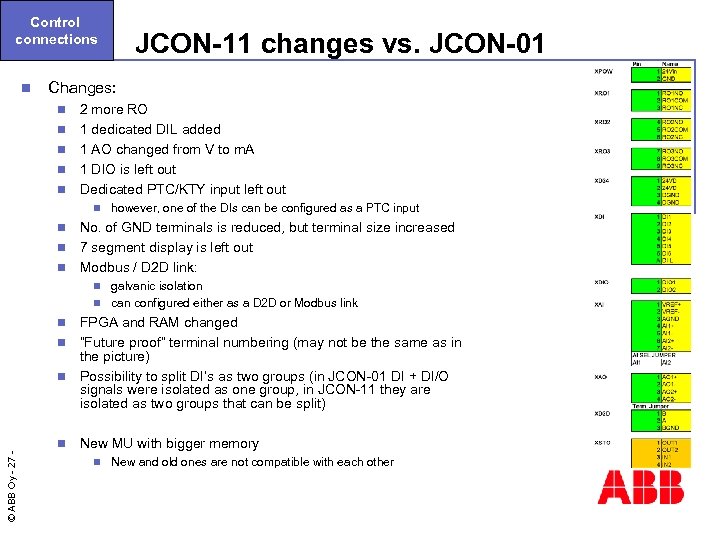

Control connections n JCON-11 changes vs. JCON-01 Changes: n n n 2 more RO 1 dedicated DIL added 1 AO changed from V to m. A 1 DIO is left out Dedicated PTC/KTY input left out n however, one of the DIs can be configured as a PTC input No. of GND terminals is reduced, but terminal size increased n 7 segment display is left out n Modbus / D 2 D link: n galvanic isolation n can configured either as a D 2 D or Modbus link n FPGA and RAM changed n “Future proof” terminal numbering (may not be the same as in the picture) n Possibility to split DI’s as two groups (in JCON-01 DI + DI/O signals were isolated as one group, in JCON-11 they are isolated as two groups that can be split) n © ABB Oy - 27 n New MU with bigger memory n New and old ones are not compatible with each other

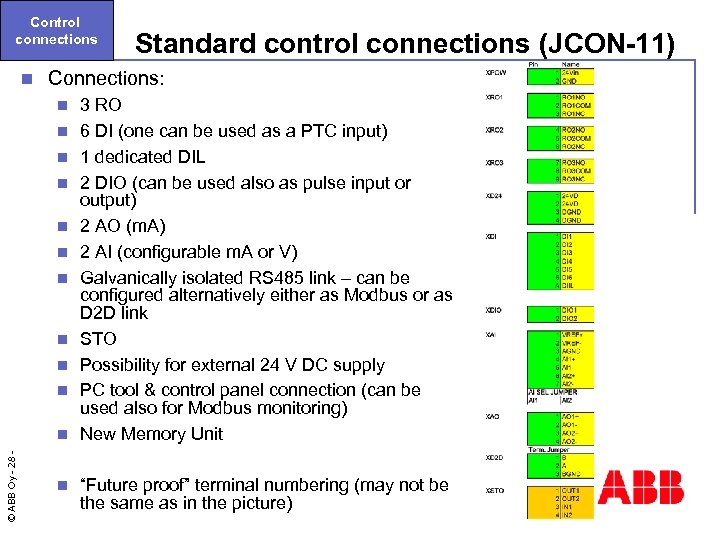

Control connections n Connections: n n n © ABB Oy - 28 Standard control connections (JCON-11) n 3 RO 6 DI (one can be used as a PTC input) 1 dedicated DIL 2 DIO (can be used also as pulse input or output) 2 AO (m. A) 2 AI (configurable m. A or V) Galvanically isolated RS 485 link – can be configured alternatively either as Modbus or as D 2 D link STO Possibility for external 24 V DC supply PC tool & control panel connection (can be used also for Modbus monitoring) New Memory Unit “Future proof” terminal numbering (may not be the same as in the picture)

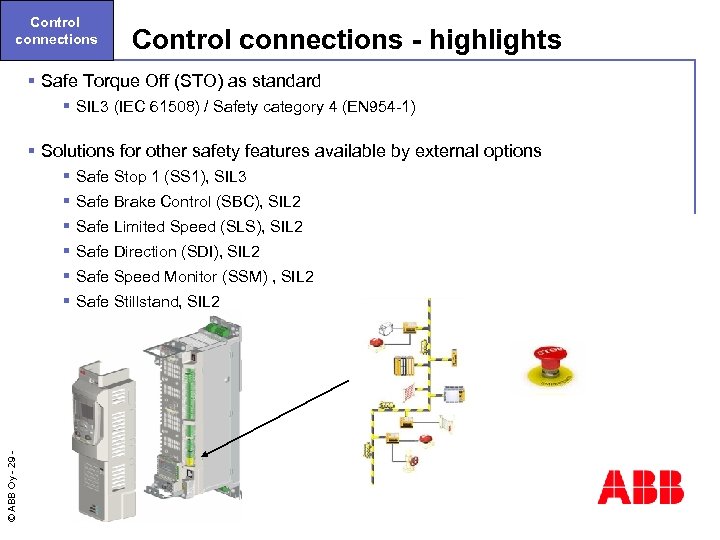

Control connections - highlights § Safe Torque Off (STO) as standard § SIL 3 (IEC 61508) / Safety category 4 (EN 954 -1) § Solutions for other safety features available by external options § Safe Stop 1 (SS 1), SIL 3 § Safe Brake Control (SBC), SIL 2 § Safe Limited Speed (SLS), SIL 2 § Safe Direction (SDI), SIL 2 § Safe Speed Monitor (SSM) , SIL 2 © ABB Oy - 29 § Safe Stillstand, SIL 2

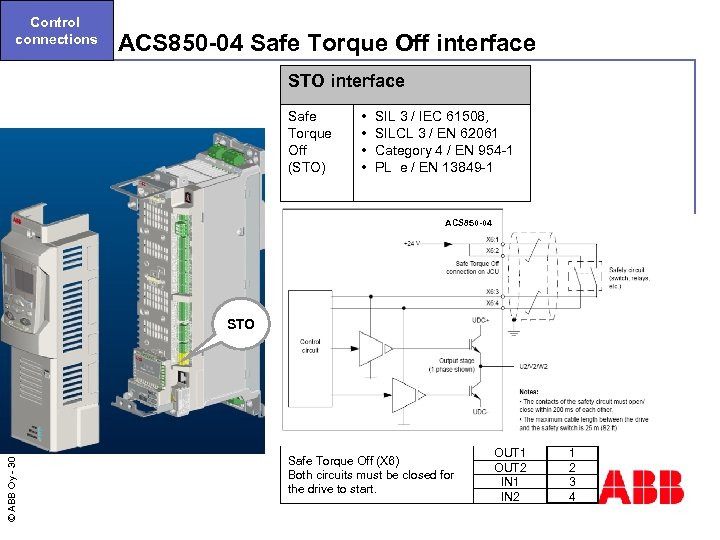

Control connections ACS 850 -04 Safe Torque Off interface STO interface Safe Torque Off (STO) • • SIL 3 / IEC 61508, SILCL 3 / EN 62061 Category 4 / EN 954 -1 PL e / EN 13849 -1 ACS 850 -04 © ABB Oy - 30 STO Safe Torque Off (X 6) Both circuits must be closed for the drive to start. OUT 1 OUT 2 IN 1 IN 2 1 2 3 4

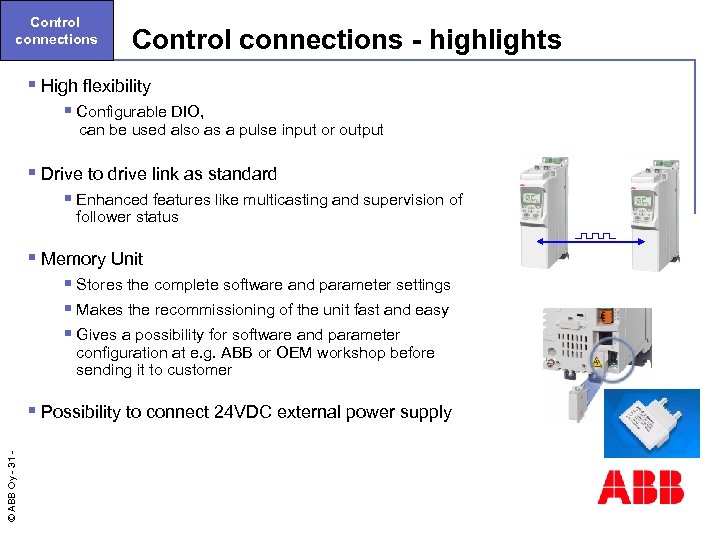

Control connections - highlights § High flexibility § Configurable DIO, can be used also as a pulse input or output § Drive to drive link as standard § Enhanced features like multicasting and supervision of follower status § Memory Unit § Stores the complete software and parameter settings § Makes the recommissioning of the unit fast and easy § Gives a possibility for software and parameter configuration at e. g. ABB or OEM workshop before sending it to customer © ABB Oy - 31 § Possibility to connect 24 VDC external power supply

© ABB Oy - 32 OPTIONS

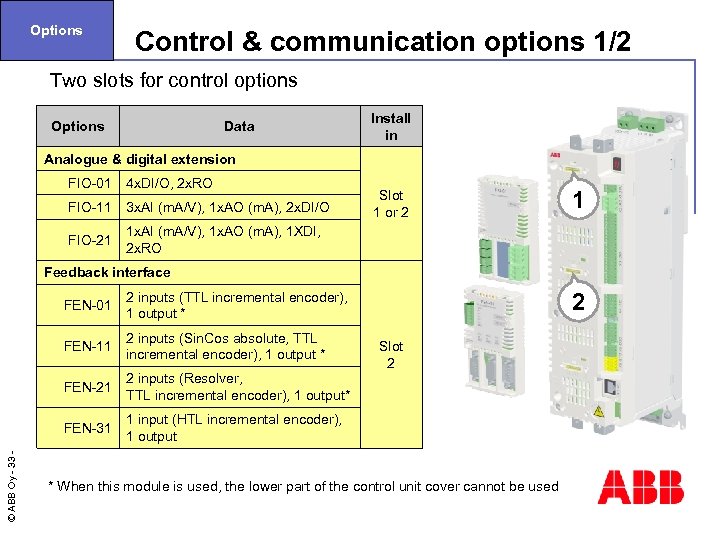

Options Control & communication options 1/2 Two slots for control options Options Data Install in Analogue & digital extension FIO-01 4 x. DI/O, 2 x. RO FIO-11 3 x. AI (m. A/V), 1 x. AO (m. A), 2 x. DI/O FIO-21 1 x. AI (m. A/V), 1 x. AO (m. A), 1 XDI, 2 x. RO Slot 1 or 2 1 Feedback interface 2 inputs (Sin. Cos absolute, TTL incremental encoder), 1 output * FEN-21 2 inputs (Resolver, TTL incremental encoder), 1 output* FEN-31 2 2 inputs (TTL incremental encoder), 1 output * FEN-11 © ABB Oy - 33 FEN-01 1 input (HTL incremental encoder), 1 output Slot 2 * When this module is used, the lower part of the control unit cover cannot be used

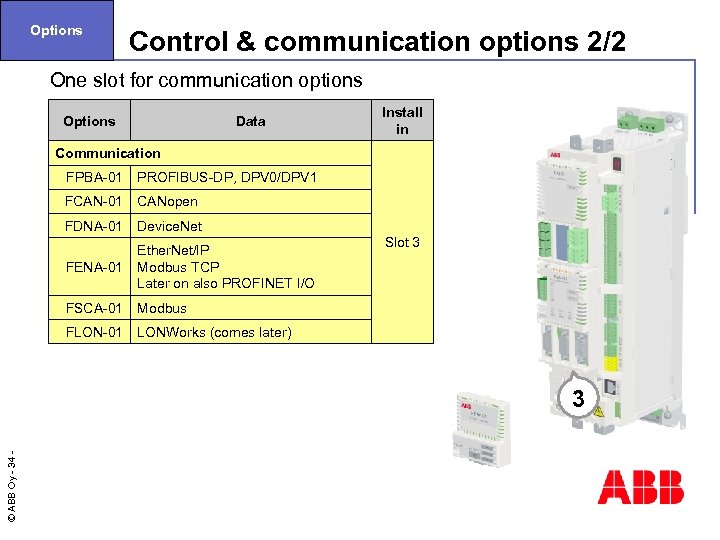

Options Control & communication options 2/2 One slot for communication options Options Data Install in Communication FPBA-01 PROFIBUS-DP, DPV 0/DPV 1 FCAN-01 CANopen FDNA-01 Device. Net FENA-01 Ether. Net/IP Modbus TCP Later on also PROFINET I/O FSCA-01 Modbus FLON-01 LONWorks (comes later) Slot 3 © ABB Oy - 34 3

Options Main circuit options Flexibility with different main circuit options Mains choke • EMC filter C 3 • EMC filter C 2 • Braking chopper (standard in frames A – D) • Braking resistor • Common mode filters • d. U/dt filter • © ABB Oy - 35 • DC connection

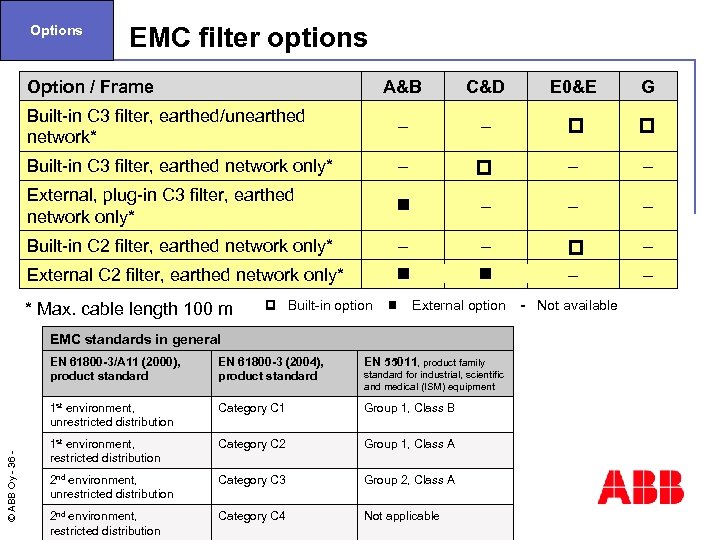

Options EMC filter options Option / Frame A&B C&D E 0&E G Built-in C 3 filter, earthed/unearthed network* – – Built-in C 3 filter, earthed network only* – – – External, plug-in C 3 filter, earthed network only* – – – Built-in C 2 filter, earthed network only* – – – External C 2 filter, earthed network only* – * Max. cable length 100 m Built-in option External option - Not available EMC standards in general EN 61800 -3 (2004), product standard EN 55011, product family 1 st environment, unrestricted distribution © ABB Oy - 36 EN 61800 -3/A 11 (2000), product standard Category C 1 Group 1, Class B 1 st environment, restricted distribution Category C 2 Group 1, Class A 2 nd environment, unrestricted distribution Category C 3 Group 2, Class A 2 nd environment, restricted distribution Category C 4 Not applicable standard for industrial, scientific and medical (ISM) equipment –

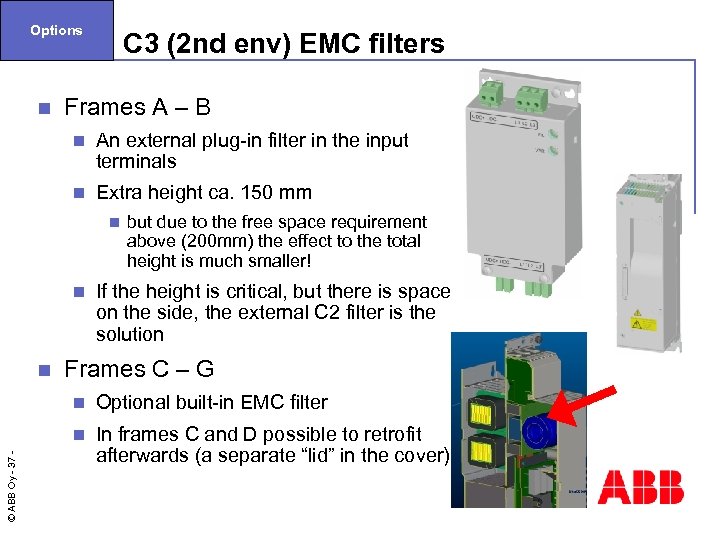

Options n C 3 (2 nd env) EMC filters Frames A – B n An external plug-in filter in the input terminals n Extra height ca. 150 mm n n n but due to the free space requirement above (200 mm) the effect to the total height is much smaller! If the height is critical, but there is space on the side, the external C 2 filter is the solution Frames C – G Optional built-in EMC filter n © ABB Oy - 37 n In frames C and D possible to retrofit afterwards (a separate “lid” in the cover)

Options n Frames A – D n n Optional built-in EMC filter Frame G n © ABB Oy - 38 An external filter (same filters as in ACSM 1) Frames E 0 & E n n C 2 (1 st env) EMC filters Not available

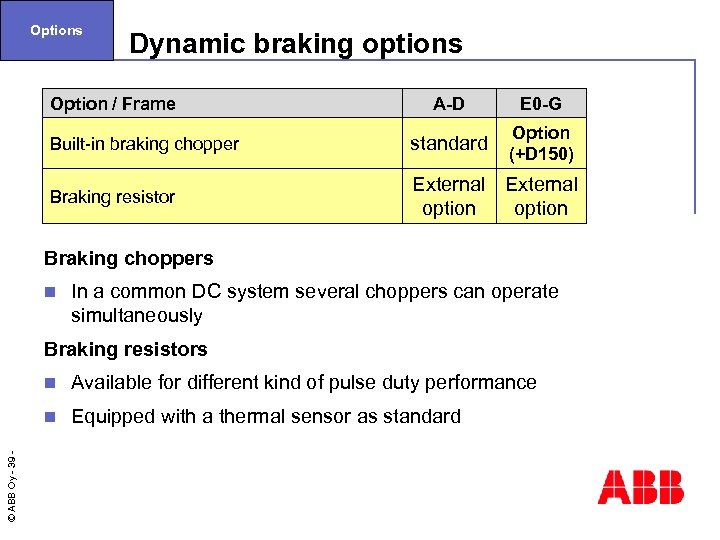

Options Dynamic braking options Option / Frame A-D E 0 -G Built-in braking chopper standard Option (+D 150) Braking resistor External option Braking choppers n In a common DC system several choppers can operate simultaneously Braking resistors Available for different kind of pulse duty performance n © ABB Oy - 39 n Equipped with a thermal sensor as standard

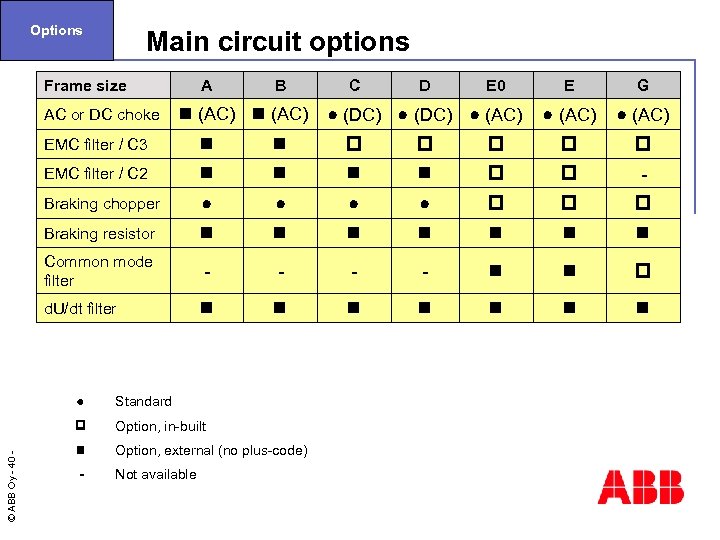

Options Main circuit options Frame size A B (AC) EMC filter / C 3 EMC filter / C 2 Braking chopper Braking resistor Common mode filter d. U/dt filter AC or DC choke E G (AC) - - Standard © ABB Oy - 40 Option, in-built Option, external (no plus-code) - Not available C D E 0 (DC) (AC)

Options User interface – control panel Standard delivery © ABB Oy - 41 n No control panel

Options User interface – control panel Assistant control panel n Option + J 400 n With real time clock n Incl. Control panel holder in the unit © ABB Oy - 42 n The same holder can be used also in the cabinet door

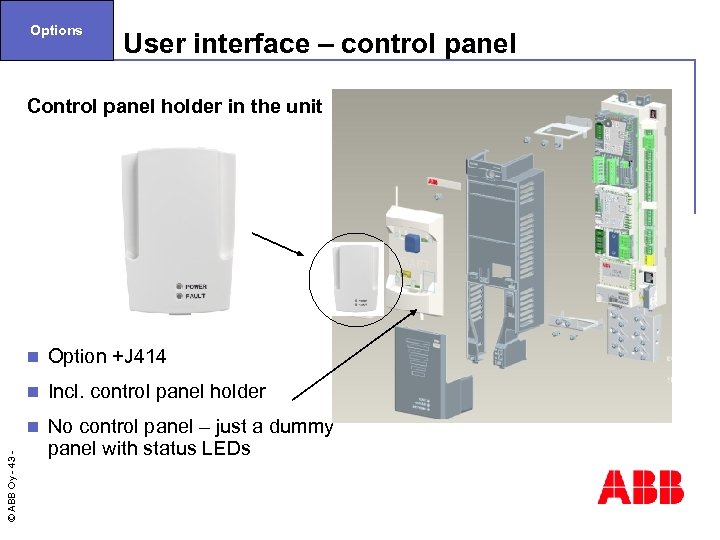

Options User interface – control panel Control panel holder in the unit Option +J 414 n Incl. control panel holder n No control panel – just a dummy panel with status LEDs © ABB Oy - 43 n

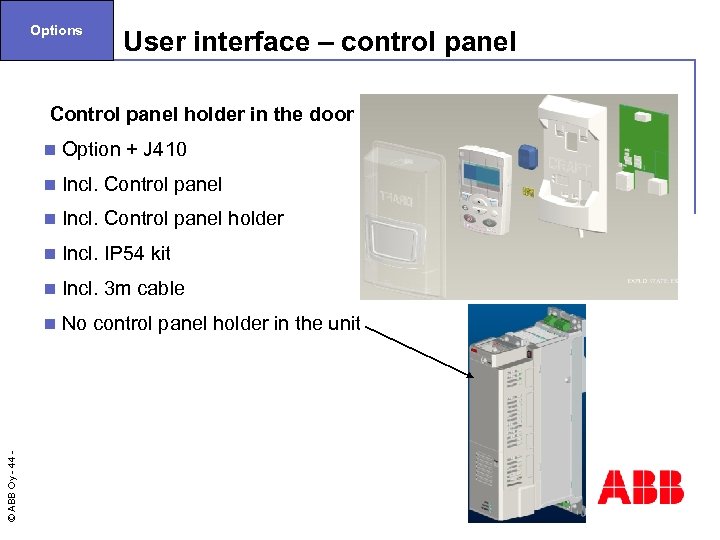

Options User interface – control panel Control panel holder in the door n Option + J 410 n Incl. Control panel holder n Incl. IP 54 kit n Incl. 3 m cable © ABB Oy - 44 n No control panel holder in the unit

Options User interface – control panel Without control unit cover n Option + 0 C 103 n No control panel © ABB Oy - 45 n No control panel holder

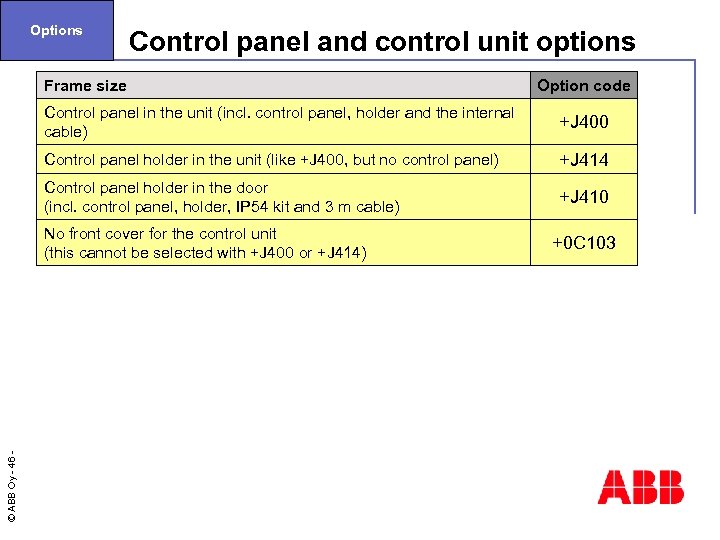

Options Control panel and control unit options Frame size Option code Control panel in the unit (incl. control panel, holder and the internal cable) +J 400 Control panel holder in the unit (like +J 400, but no control panel) +J 414 Control panel holder in the door (incl. control panel, holder, IP 54 kit and 3 m cable) +J 410 © ABB Oy - 46 No front cover for the control unit (this cannot be selected with +J 400 or +J 414) +0 C 103

© ABB Oy - 47 PC TOOLS

PC tools Drive. Studio Commissioning, tuning and monitoring tool Parameters setting and signal monitoring n Data logger and on-line signal monitoring n Backup and restore n Context sensitive helps n © ABB Oy - 48 n Start-up and Diagnostic Assistants

PC tools Sizing tool Drive. Size © ABB Oy - 49 n PC tool for sizing the motor and drive

© ABB Oy - 50 DOCUMENTATION

Documentation n Documentation As standard with every drive n n n Quick installation and start-up guides CD with full documentation Full paper format manuals available as an option To be ordered either with a pluscode or as a separate item n © ABB Oy - 51 n Many customers are serial manufacturers or users and do not need / want piles of paper manuals

© ABB Oy - 52 APPROVALS

Approvals n CE n A – D frames: UL & c. UL n Pending: Frames E 0 – G: UL & c. UL n CSA n C-Tick n GOST R n © ABB Oy - 53 n TÜV approval for STO

© ABB Oy - 54 SALES ARGUMENTS

Sales arguments n Sales arguments Optimized for cabinet assembly n n Side-by-side installation n n Compact size Optimal location for power terminals Flexible software n n n Extensive, but simple parameter settings Some block programming possibilities Flexible hardware Extensive and configurable I/O n © ABB Oy - 55 n Wide selection of options – “order what you need”

Sales arguments n Sales arguments Maximized runtime n Maintenance assistant – helps to reduce unexpected downtime n Diagnostic assistant – helps in fixing disturbances n Design for reliability and long life time Coated boards as standard n Advanced thermal protection of power semiconductors n Fast and advanced over/under voltage and load protections n DC circuit capacitor life time at least 100000 h (at 30 C average ambient temperature) n Cooling fan supervision (up to 55 k. W) n © ABB Oy - 56 n Memory unit making recommissioning of the drive fast and easy

Sales arguments n Sales arguments In-built easiness of use n Application macros n Intelligent, interactive assistants n Several other user friendly features n Short / long menus n Easy I/O “mapping” showing the use of different I/Os n List of the latest changed parameters n Safety as standard n High performance n n n DTC with enhanced features Drive to drive link as standard Advanced energy saving features © ABB Oy - 57 n Energy optimizer n Energy saving calculator

fd9084047f69ac0faa700cd99976491e.ppt