0af9ad0f1edb29c18d8944c39eb15e00.ppt

- Количество слайдов: 10

© ABB Ltd - Page 1 Quintin Thom Service for increased productivity ABB

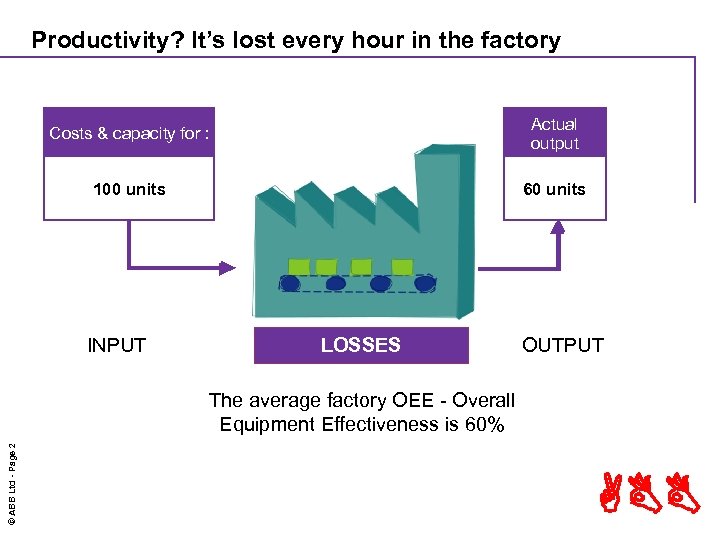

Productivity? It’s lost every hour in the factory Costs & capacity for : Actual output 100 units 60 units INPUT LOSSES OUTPUT © ABB Ltd - Page 2 The average factory OEE - Overall Equipment Effectiveness is 60% ABB

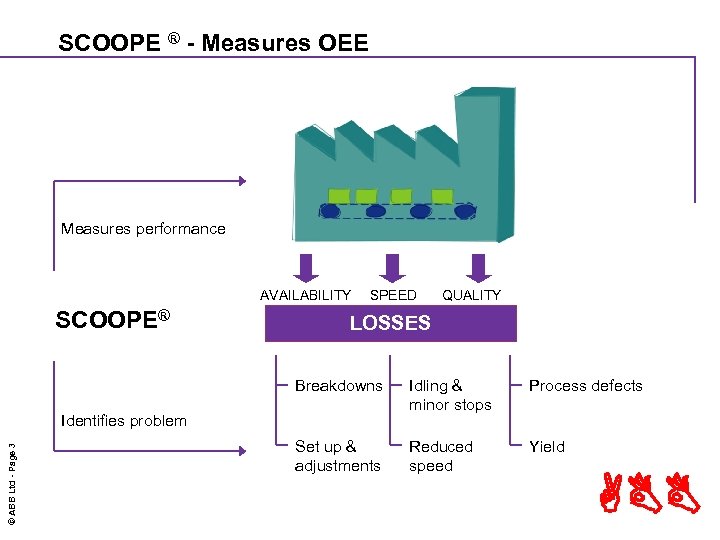

SCOOPE ® - Measures OEE Measures performance AVAILABILITY SCOOPE® SPEED QUALITY LOSSES Breakdowns Idling & minor stops Process defects Set up & adjustments Reduced speed Yield © ABB Ltd - Page 3 Identifies problem ABB

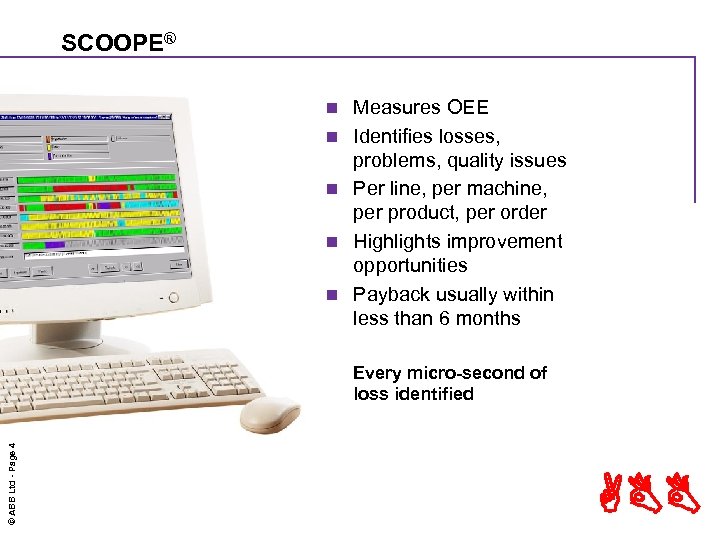

SCOOPE® n n n Measures OEE Identifies losses, problems, quality issues Per line, per machine, per product, per order Highlights improvement opportunities Payback usually within less than 6 months © ABB Ltd - Page 4 Every micro-second of loss identified ABB

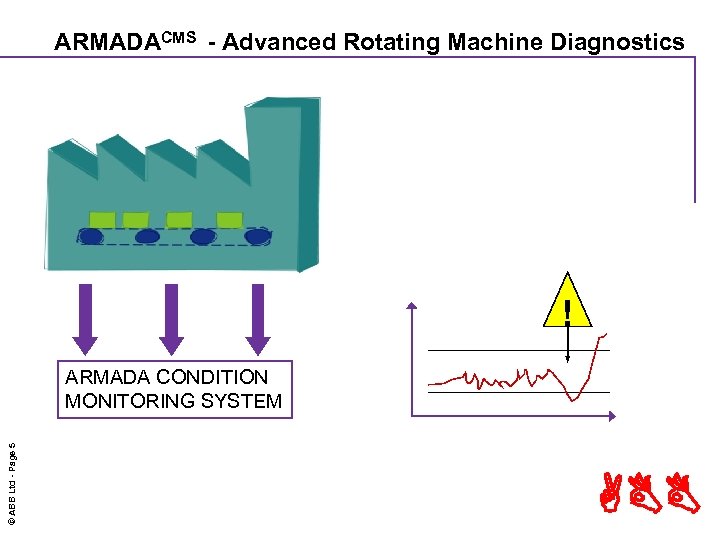

ARMADACMS - Advanced Rotating Machine Diagnostics ! © ABB Ltd - Page 5 ARMADA CONDITION MONITORING SYSTEM ABB

ARMADACMS - Knowledge in advance 80% of rotating machine problems can be detected before breakdown Mechanical § bearing § misalignment § looseness n © ABB Ltd - Page 6 n Electrical § contamination § aging § coil looseness ABB

maintenance-tv. com for knowledge A public Web site best practices n maintenance information n tools, products, software n database, benchmarking n remote diagnostics n © ABB Ltd - Page 7 n root cause analysis ABB

Centers of excellence generate and deploy knowledge ABB An Intranet for MMC’s Maintenance Methodology Centers Knowledge factories n Experts n © ABB Ltd - Page 8 n ABB System databases ABB ABB

3 ways to reduce losses and increase productivity SCOOPE® LOSSES Measures OEE ARMADACMS Predicts maintenance levels maintenance-tv. com + MMC’s © ABB Ltd - Page 9 knowledge, benchmarks, best practices ABB

© ABB Ltd - Page 10 ABB

0af9ad0f1edb29c18d8944c39eb15e00.ppt