06ab121cece2b919ea7b32e564697465.ppt

- Количество слайдов: 48

A Systems Approach to Safety Engineering Nancy G. Leveson Aero/Astro Engineering Systems

A Systems Approach to Safety Engineering Nancy G. Leveson Aero/Astro Engineering Systems

Types of Accidents • Component Failure Accidents – Single or multiple component failures – Usually assume random failure • System Accidents – Arise in interactions among components – Related to interactive complexity and tight coupling – Exacerbated by introduction of computers and software © Copyright Nancy Leveson, Aug. 2006

Types of Accidents • Component Failure Accidents – Single or multiple component failures – Usually assume random failure • System Accidents – Arise in interactions among components – Related to interactive complexity and tight coupling – Exacerbated by introduction of computers and software © Copyright Nancy Leveson, Aug. 2006

Chain-of-Events Model • Explains accidents in terms of multiple events, sequenced as a forward chain over time. – Simple, direct relationship between events in chain – Contrapositive (if A had not occurred, then B would not have) • Events almost always involve component failure, human error, or energy-related event • Forms the basis for most safety-engineering and reliability engineering analysis: e, g, FTA, PRA, FMECA, Event Trees, etc. and design: e. g. , redundancy, overdesign, safety margins, …. © Copyright Nancy Leveson, Aug. 2006

Chain-of-Events Model • Explains accidents in terms of multiple events, sequenced as a forward chain over time. – Simple, direct relationship between events in chain – Contrapositive (if A had not occurred, then B would not have) • Events almost always involve component failure, human error, or energy-related event • Forms the basis for most safety-engineering and reliability engineering analysis: e, g, FTA, PRA, FMECA, Event Trees, etc. and design: e. g. , redundancy, overdesign, safety margins, …. © Copyright Nancy Leveson, Aug. 2006

Limitations of Chain-of-Events Model • Social and organizational factors in accidents • System accidents • Software • Human error • Adaptation – Systems are continually changing – Systems and organizations migrate toward accidents (states of high risk) under cost and productivity pressures in an aggressive, competitive environment © Copyright Nancy Leveson, Aug. 2006

Limitations of Chain-of-Events Model • Social and organizational factors in accidents • System accidents • Software • Human error • Adaptation – Systems are continually changing – Systems and organizations migrate toward accidents (states of high risk) under cost and productivity pressures in an aggressive, competitive environment © Copyright Nancy Leveson, Aug. 2006

STAMP • Systems-Theoretic Accident Model and Processes – Accidents are not simply an event or chain of events but involve a complex, dynamic process – Based on systems and control theory • Accidents arise from interactions among humans, machines, and the environment Not simply linear causality, but more complex types of causal connections

STAMP • Systems-Theoretic Accident Model and Processes – Accidents are not simply an event or chain of events but involve a complex, dynamic process – Based on systems and control theory • Accidents arise from interactions among humans, machines, and the environment Not simply linear causality, but more complex types of causal connections

STAMP (2) • Safety is an emergent property that arises when system components interact with each other within a larger environment – A set of safety constraints related to behavior of system components enforces that property – Accidents occur when interactions violate those constraints (a lack of appropriate constraints on the interactions) – “Controllers” embody or enforce those constraints – Goal of system safety engineering is to identify the safety constraints and enforce them in the system design

STAMP (2) • Safety is an emergent property that arises when system components interact with each other within a larger environment – A set of safety constraints related to behavior of system components enforces that property – Accidents occur when interactions violate those constraints (a lack of appropriate constraints on the interactions) – “Controllers” embody or enforce those constraints – Goal of system safety engineering is to identify the safety constraints and enforce them in the system design

A Broad View of “Control” Note: • Does not imply need for a “controller” Component failures and dysfunctional interactions may be “controlled” through design (e. g. , redundancy, interlocks, fail-safe design) or through process • Manufacturing processes and procedures • Maintenance processes • Operations • Does imply the need to enforce the safety constraints in some way • New model includes what do now and more

A Broad View of “Control” Note: • Does not imply need for a “controller” Component failures and dysfunctional interactions may be “controlled” through design (e. g. , redundancy, interlocks, fail-safe design) or through process • Manufacturing processes and procedures • Maintenance processes • Operations • Does imply the need to enforce the safety constraints in some way • New model includes what do now and more

STAMP (3) • Systems are not treated as a static design – A socio-technical system is a dynamic process continually adapting to achieve its ends and to react to changes in itself and its environment – Migration toward states of high risk – Preventing accidents requires designing a control structure to enforce constraints on system behavior and adaptation

STAMP (3) • Systems are not treated as a static design – A socio-technical system is a dynamic process continually adapting to achieve its ends and to react to changes in itself and its environment – Migration toward states of high risk – Preventing accidents requires designing a control structure to enforce constraints on system behavior and adaptation

STAMP (4) • Views accidents as a control problem O-ring did not control propellant gas release by sealing gap in field joint Software did not adequately control descent speed of Mars Polar Lander • Events are the result of the inadequate control Result from lack of enforcement of safety constraints

STAMP (4) • Views accidents as a control problem O-ring did not control propellant gas release by sealing gap in field joint Software did not adequately control descent speed of Mars Polar Lander • Events are the result of the inadequate control Result from lack of enforcement of safety constraints

STAMP (5) • To understand accidents, need to examine safety control structure itself to determine why inadequate to maintain safety constraints and why events occurred • To prevent accidents, need to create an effective safety control structure to enforce the system safety constraints • Not a “blame” model but a “why” model

STAMP (5) • To understand accidents, need to examine safety control structure itself to determine why inadequate to maintain safety constraints and why events occurred • To prevent accidents, need to create an effective safety control structure to enforce the system safety constraints • Not a “blame” model but a “why” model

Accident Causality • Accidents occur when – Control structure or control actions do not enforce safety constraints • Unhandled environmental disturbances or conditions • Unhandled or uncontrolled component failures • Dysfunctional (unsafe) interactions among components – Control structure degrades over time (asynchronous evolution) – Control actions inadequately coordinated among multiple controllers

Accident Causality • Accidents occur when – Control structure or control actions do not enforce safety constraints • Unhandled environmental disturbances or conditions • Unhandled or uncontrolled component failures • Dysfunctional (unsafe) interactions among components – Control structure degrades over time (asynchronous evolution) – Control actions inadequately coordinated among multiple controllers

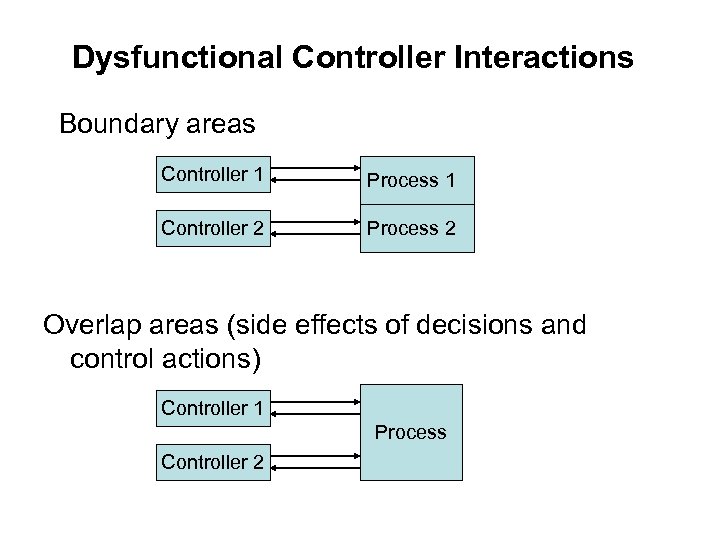

Dysfunctional Controller Interactions Boundary areas Controller 1 Process 1 Controller 2 Process 2 Overlap areas (side effects of decisions and control actions) Controller 1 Process Controller 2

Dysfunctional Controller Interactions Boundary areas Controller 1 Process 1 Controller 2 Process 2 Overlap areas (side effects of decisions and control actions) Controller 1 Process Controller 2

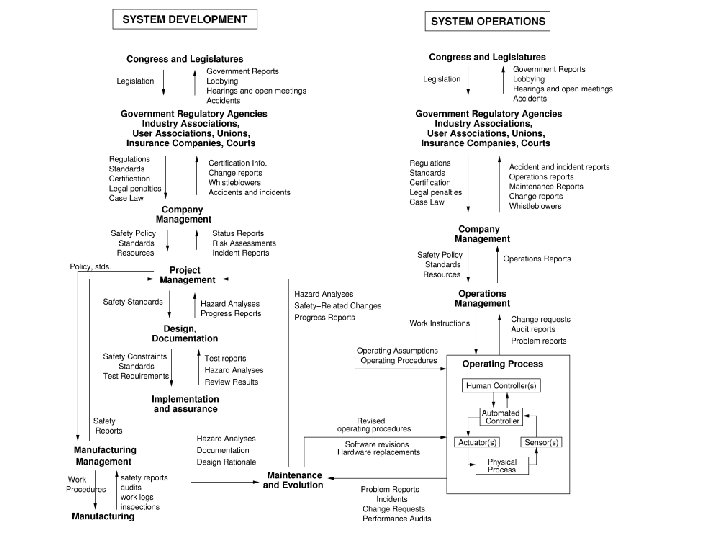

Modeling Accidents Using STAMP Two types of models are used: 1. Static safety control structure 2. Behavioral dynamics (system dynamics) Dynamic processes behind change in the safety control structure, i. e. , why it may change (e. g. , degrade) over time © Copyright Nancy Leveson, Aug. 2006

Modeling Accidents Using STAMP Two types of models are used: 1. Static safety control structure 2. Behavioral dynamics (system dynamics) Dynamic processes behind change in the safety control structure, i. e. , why it may change (e. g. , degrade) over time © Copyright Nancy Leveson, Aug. 2006

Uses for STAMP • Basis for new, more powerful hazard analysis techniques (STPA) • Safety-driven design • More comprehensive accident/incident investigation and root cause analysis • Organizational and cultural risk analysis – Defining safety metrics and performance audits – Designing and evaluating potential policy and structural improvements – Identifying leading indicators of increasing risk (“canary in the coal mine”) • New risk management tools – Policy analysis and evaluation – Risk analysis and control • New holistic approaches to security © Copyright Nancy Leveson, Aug. 2006

Uses for STAMP • Basis for new, more powerful hazard analysis techniques (STPA) • Safety-driven design • More comprehensive accident/incident investigation and root cause analysis • Organizational and cultural risk analysis – Defining safety metrics and performance audits – Designing and evaluating potential policy and structural improvements – Identifying leading indicators of increasing risk (“canary in the coal mine”) • New risk management tools – Policy analysis and evaluation – Risk analysis and control • New holistic approaches to security © Copyright Nancy Leveson, Aug. 2006

STAMP-Based Hazard Analysis (STPA) • Supports a safety-driven design process where – Hazard analysis influences and shapes early design decisions – Hazard analysis iterated and refined as design evolves • Goals (same as any hazard analysis) – Identification of system hazards and related safety constraints necessary to ensure acceptable risk – Accumulation of information about how hazards can be violated, which is used to eliminate, reduce and control hazards in system design, development, manufacturing, and operations

STAMP-Based Hazard Analysis (STPA) • Supports a safety-driven design process where – Hazard analysis influences and shapes early design decisions – Hazard analysis iterated and refined as design evolves • Goals (same as any hazard analysis) – Identification of system hazards and related safety constraints necessary to ensure acceptable risk – Accumulation of information about how hazards can be violated, which is used to eliminate, reduce and control hazards in system design, development, manufacturing, and operations

STPA (2) • Safety-Driven Design Process – Start with identifying system requirements and design constraints necessary to maintain safety. – STPA assists in top-down refinement into requirements and safety constraints on individual components. – STPA used to identify scenarios in which safety constraints can be violated. Use results to eliminate or control them in design, operations, etc.

STPA (2) • Safety-Driven Design Process – Start with identifying system requirements and design constraints necessary to maintain safety. – STPA assists in top-down refinement into requirements and safety constraints on individual components. – STPA used to identify scenarios in which safety constraints can be violated. Use results to eliminate or control them in design, operations, etc.

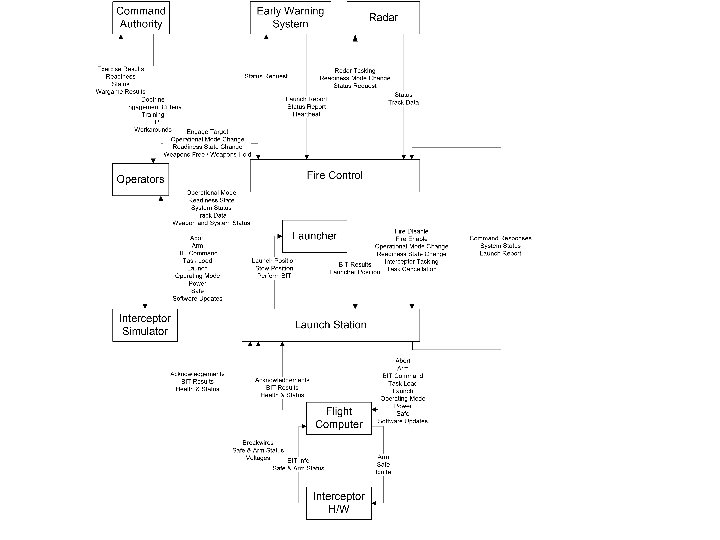

Missile Defense • A large system-of-systems • Non-advocate safety assessment of inadvertent launch • STPA was the only technique they could find that would work on such a complex, software-intensive system • Have found a large number of potential safety problems that had to be fixed before the system could be deployed.

Missile Defense • A large system-of-systems • Non-advocate safety assessment of inadvertent launch • STPA was the only technique they could find that would work on such a complex, software-intensive system • Have found a large number of potential safety problems that had to be fixed before the system could be deployed.

Recent and Current Uses of STAMP • Aerospace – NASA Independent Technical Authority (ITA) risk analysis (operations) – NASA Exploration Systems risk management tools (development) Built STAMP and SD models and analyzed effects of things like: hiring constraints management reserves independence of safety decision-making requirements changes on schedule, cost, safety, and performance – Crew Exploration Vehicle (hazard analysis)

Recent and Current Uses of STAMP • Aerospace – NASA Independent Technical Authority (ITA) risk analysis (operations) – NASA Exploration Systems risk management tools (development) Built STAMP and SD models and analyzed effects of things like: hiring constraints management reserves independence of safety decision-making requirements changes on schedule, cost, safety, and performance – Crew Exploration Vehicle (hazard analysis)

Recent and Current Uses of STAMP (2) • Defense – Non-advocate safety assessment of the Ballistic Missile Defense System – Singapore department of defense • Security (bioterrorism, internet worms) • Others are using it but I only hear indirectly

Recent and Current Uses of STAMP (2) • Defense – Non-advocate safety assessment of the Ballistic Missile Defense System – Singapore department of defense • Security (bioterrorism, internet worms) • Others are using it but I only hear indirectly

In Work or Planned • Corporate fraud (e. g. , Enron) • NGATS (Next Generation Air Transportation System) for FAA/NASA JPDO • Medical Electronic Health Records (and perhaps other medical applications) • Pharmaceutical testing • Railroads (Maglev) • Forest Fires (Department of the Interior) • Process industry (? ? ) • Security (NGATS)

In Work or Planned • Corporate fraud (e. g. , Enron) • NGATS (Next Generation Air Transportation System) for FAA/NASA JPDO • Medical Electronic Health Records (and perhaps other medical applications) • Pharmaceutical testing • Railroads (Maglev) • Forest Fires (Department of the Interior) • Process industry (? ? ) • Security (NGATS)

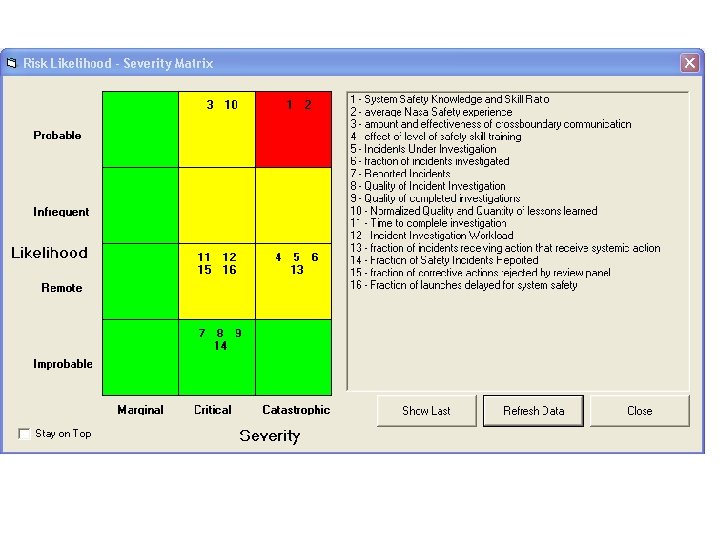

Modeling the New NASA Independent Technical Authority (ITA) • Built structural and dynamic models of ITA • Identified system-level requirements to reduce poor engineering and management decision-making that leads to an accident • Identified gaps and omissions in ITA program design • Performed a rigorous risk analysis on resulting structure to determine: – Factors involved in successful or unsuccessful implementations – Leading indicators and metrics to identify increasing risk – Suggested policy changes in ITA design

Modeling the New NASA Independent Technical Authority (ITA) • Built structural and dynamic models of ITA • Identified system-level requirements to reduce poor engineering and management decision-making that leads to an accident • Identified gaps and omissions in ITA program design • Performed a rigorous risk analysis on resulting structure to determine: – Factors involved in successful or unsuccessful implementations – Leading indicators and metrics to identify increasing risk – Suggested policy changes in ITA design

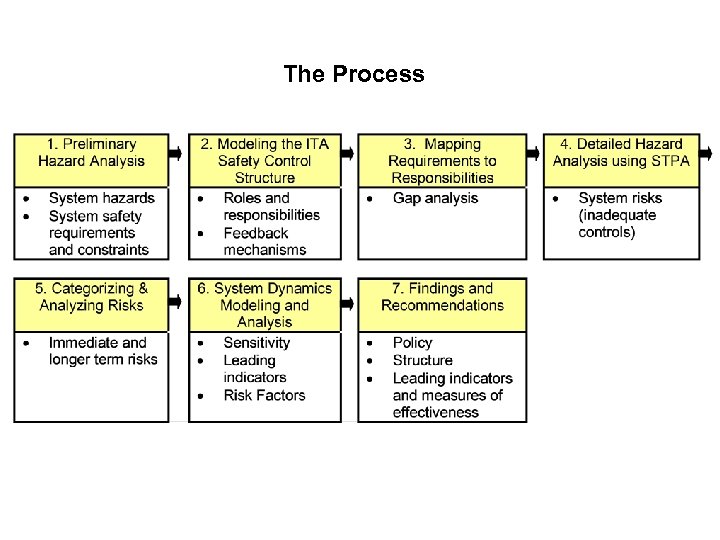

The Process

The Process

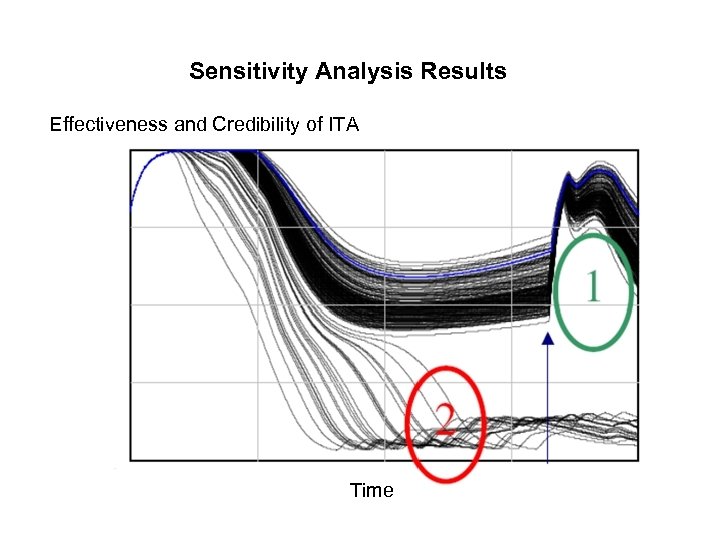

Sensitivity Analysis Results Effectiveness and Credibility of ITA Time

Sensitivity Analysis Results Effectiveness and Credibility of ITA Time

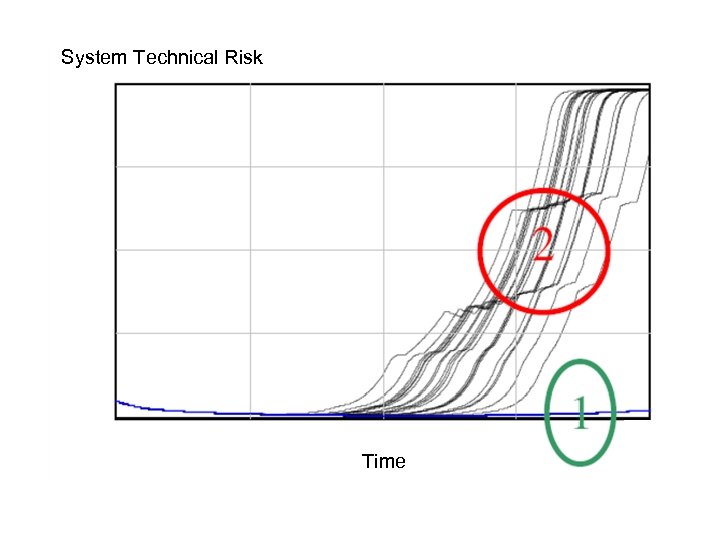

System Technical Risk Time

System Technical Risk Time

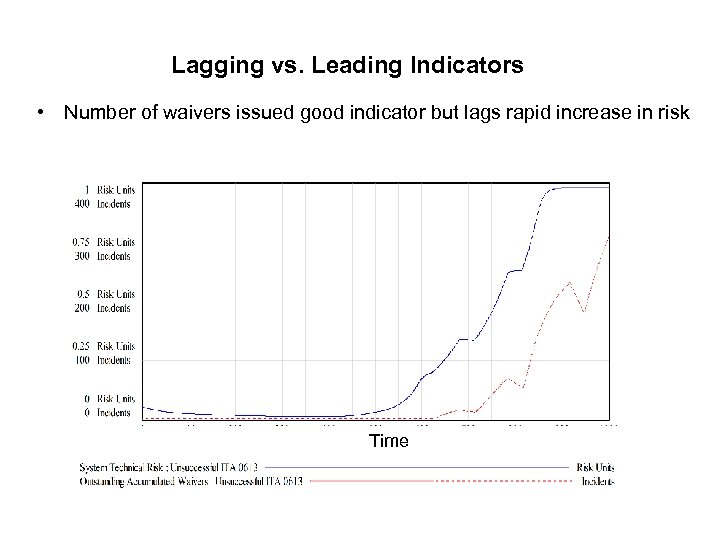

Lagging vs. Leading Indicators • Number of waivers issued good indicator but lags rapid increase in risk Time

Lagging vs. Leading Indicators • Number of waivers issued good indicator but lags rapid increase in risk Time

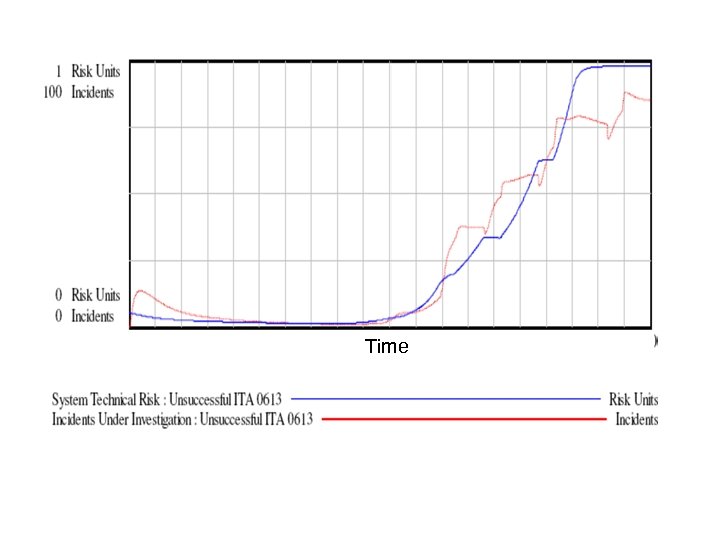

Time

Time

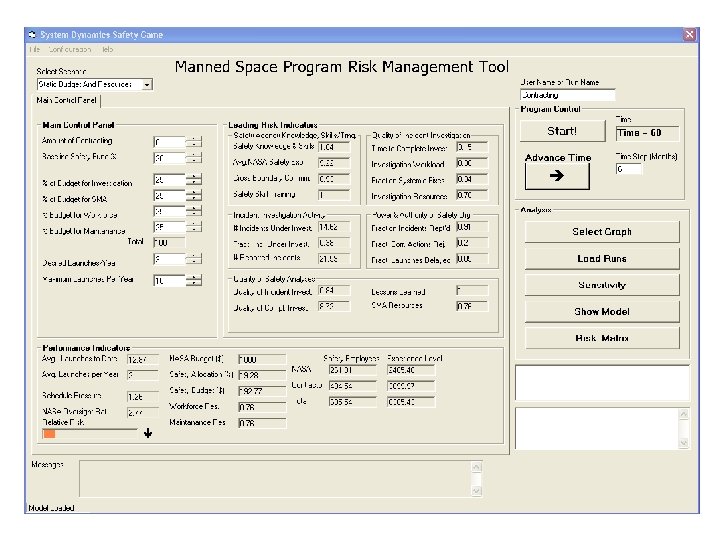

Risk Management in NASA’s New Exploration Systems Mission Directorate • Created an executable model, using input from the NASA workforce, to analyze relative effects of management strategies on schedule, cost, safety & performance • Developed scenarios to analyze risks identified by the Agency’s workforce – Performed preliminary analysis on the effects of hiring constraints, management reserves, independence of safety decision-making, requirements changes, etc. • Derived preliminary recommendations to mitigate & monitor program-level risks

Risk Management in NASA’s New Exploration Systems Mission Directorate • Created an executable model, using input from the NASA workforce, to analyze relative effects of management strategies on schedule, cost, safety & performance • Developed scenarios to analyze risks identified by the Agency’s workforce – Performed preliminary analysis on the effects of hiring constraints, management reserves, independence of safety decision-making, requirements changes, etc. • Derived preliminary recommendations to mitigate & monitor program-level risks

ESMD Risk Management • Interview data for validation of the model was collected from 44 NASA employees at HQ, MSFC, JSC, & La. RC in the following offices & directorates: – – – – Office of the Administrator Office of the Chief Engineer (OCE) Office of Safety & Mission Assurance (OSMA) Office of Program Analysis & Evaluation (PA&E) Office of Institutions & Management ESMD Directorate Offices Program Offices Project Offices NASA Engineering & Safety Center (NESC) Center Safety & Mission Assurance Directorates Center Engineering Directorates Center Mission Operations Directorates The Astronaut Office

ESMD Risk Management • Interview data for validation of the model was collected from 44 NASA employees at HQ, MSFC, JSC, & La. RC in the following offices & directorates: – – – – Office of the Administrator Office of the Chief Engineer (OCE) Office of Safety & Mission Assurance (OSMA) Office of Program Analysis & Evaluation (PA&E) Office of Institutions & Management ESMD Directorate Offices Program Offices Project Offices NASA Engineering & Safety Center (NESC) Center Safety & Mission Assurance Directorates Center Engineering Directorates Center Mission Operations Directorates The Astronaut Office

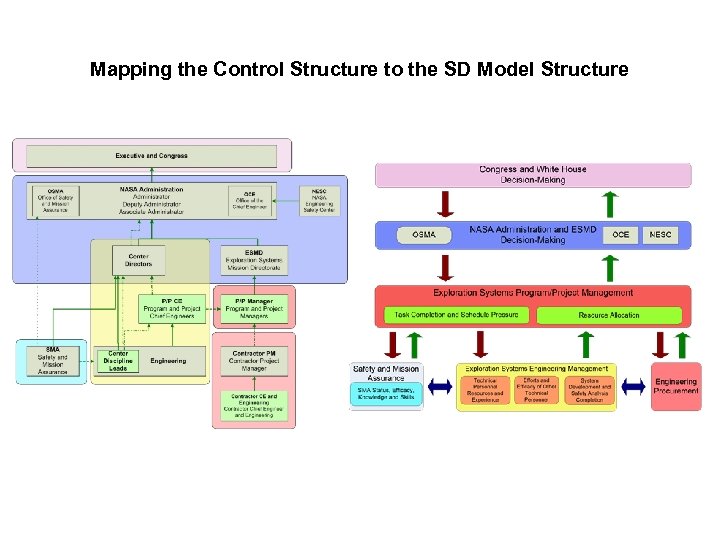

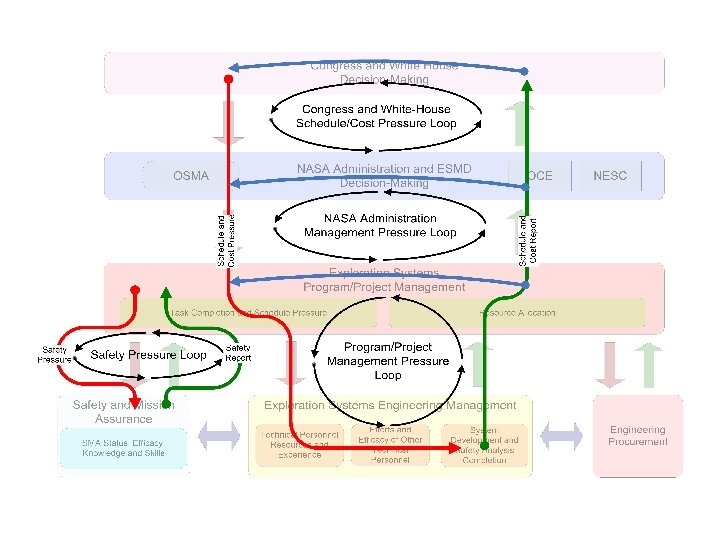

Mapping the Control Structure to the SD Model Structure

Mapping the Control Structure to the SD Model Structure

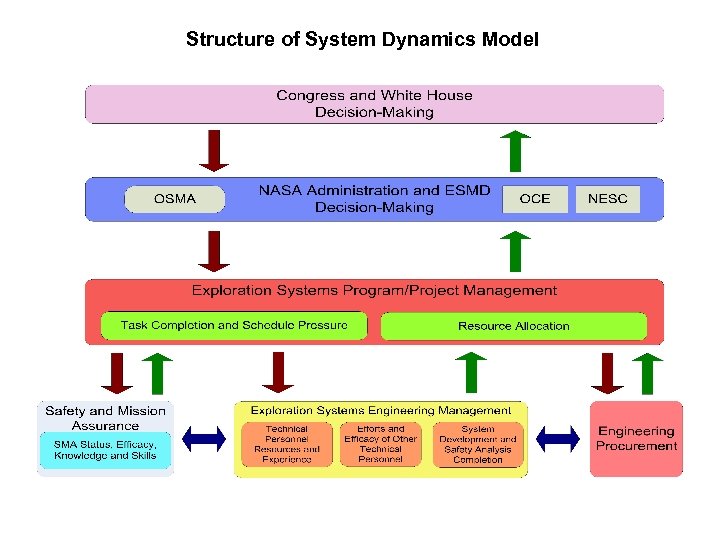

Structure of System Dynamics Model

Structure of System Dynamics Model

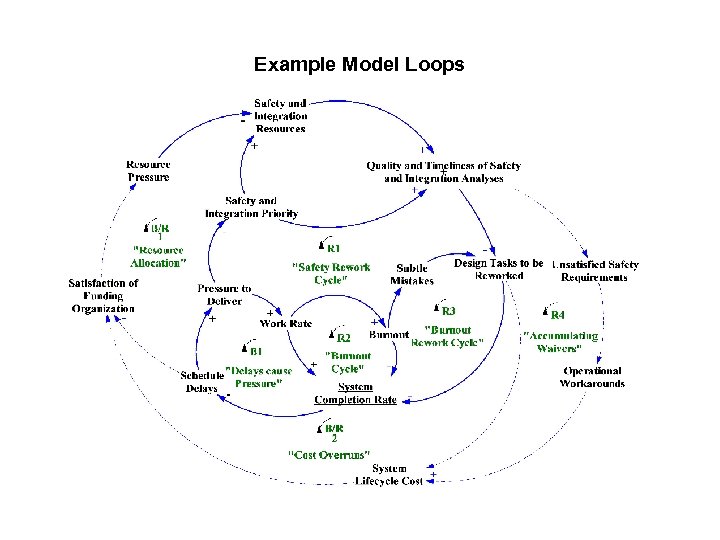

Example Model Loops

Example Model Loops

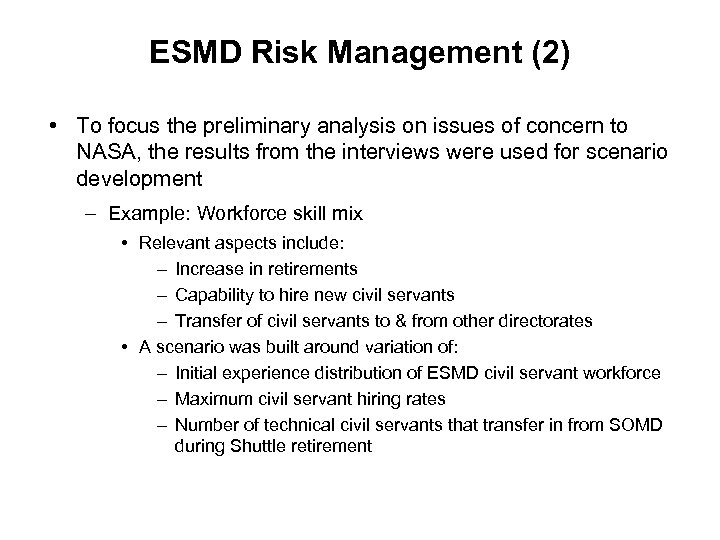

ESMD Risk Management (2) • To focus the preliminary analysis on issues of concern to NASA, the results from the interviews were used for scenario development – Example: Workforce skill mix • Relevant aspects include: – Increase in retirements – Capability to hire new civil servants – Transfer of civil servants to & from other directorates • A scenario was built around variation of: – Initial experience distribution of ESMD civil servant workforce – Maximum civil servant hiring rates – Number of technical civil servants that transfer in from SOMD during Shuttle retirement

ESMD Risk Management (2) • To focus the preliminary analysis on issues of concern to NASA, the results from the interviews were used for scenario development – Example: Workforce skill mix • Relevant aspects include: – Increase in retirements – Capability to hire new civil servants – Transfer of civil servants to & from other directorates • A scenario was built around variation of: – Initial experience distribution of ESMD civil servant workforce – Maximum civil servant hiring rates – Number of technical civil servants that transfer in from SOMD during Shuttle retirement

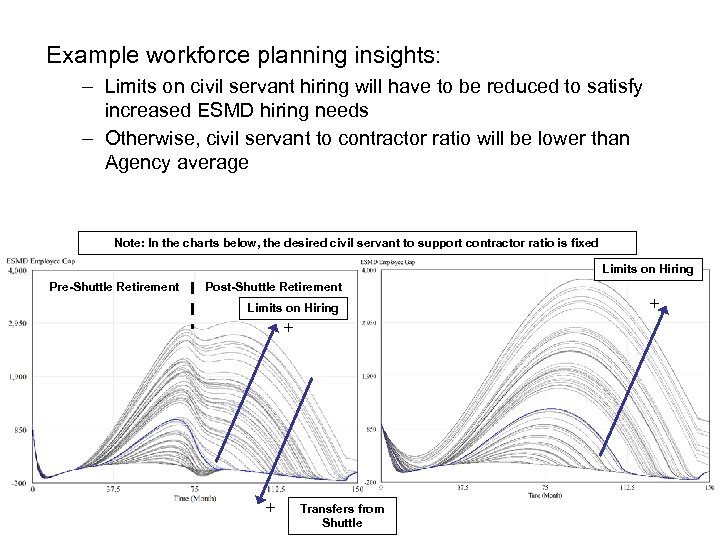

Example workforce planning insights: – Limits on civil servant hiring will have to be reduced to satisfy increased ESMD hiring needs – Otherwise, civil servant to contractor ratio will be lower than Agency average Note: In the charts below, the desired civil servant to support contractor ratio is fixed Limits on Hiring Pre-Shuttle Retirement Post-Shuttle Retirement Limits on Hiring + + Transfers from Shuttle +

Example workforce planning insights: – Limits on civil servant hiring will have to be reduced to satisfy increased ESMD hiring needs – Otherwise, civil servant to contractor ratio will be lower than Agency average Note: In the charts below, the desired civil servant to support contractor ratio is fixed Limits on Hiring Pre-Shuttle Retirement Post-Shuttle Retirement Limits on Hiring + + Transfers from Shuttle +

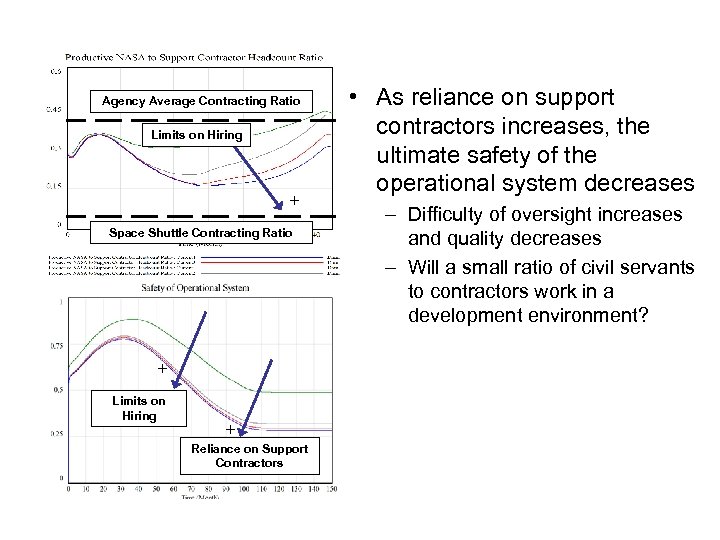

Agency Average Contracting Ratio Limits on Hiring + Space Shuttle Contracting Ratio + Limits on Hiring + Reliance on Support Contractors • As reliance on support contractors increases, the ultimate safety of the operational system decreases – Difficulty of oversight increases and quality decreases – Will a small ratio of civil servants to contractors work in a development environment?

Agency Average Contracting Ratio Limits on Hiring + Space Shuttle Contracting Ratio + Limits on Hiring + Reliance on Support Contractors • As reliance on support contractors increases, the ultimate safety of the operational system decreases – Difficulty of oversight increases and quality decreases – Will a small ratio of civil servants to contractors work in a development environment?

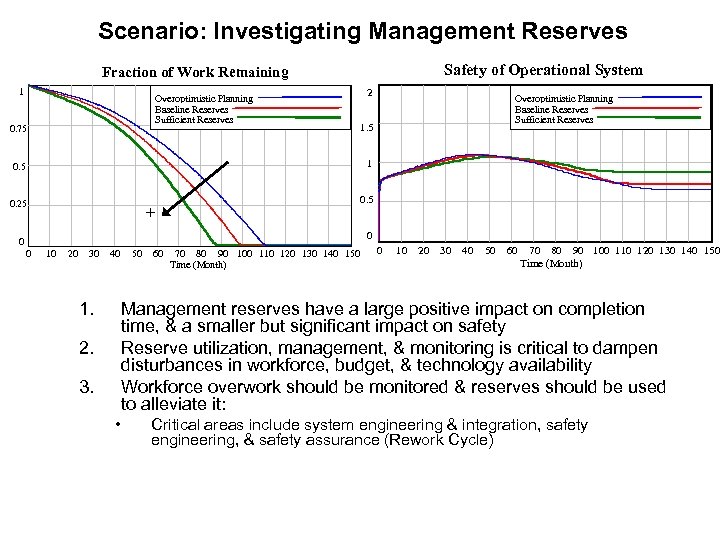

Scenario: Investigating Management Reserves Safety of Operational System Fraction of Work Remaining 1 2 Overoptimistic Planning Baseline Reserves Sufficient Reserves 0. 75 Overoptimistic Planning Baseline Reserves Sufficient Reserves 1. 5 0. 5 1 0. 25 0. 5 + 0 0 0 10 20 30 40 1. 50 60 70 80 90 100 110 120 130 140 150 Time (Month) 0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 Time (Month) Management reserves have a large positive impact on completion time, & a smaller but significant impact on safety Reserve utilization, management, & monitoring is critical to dampen disturbances in workforce, budget, & technology availability Workforce overwork should be monitored & reserves should be used to alleviate it: 2. 3. • Critical areas include system engineering & integration, safety engineering, & safety assurance (Rework Cycle)

Scenario: Investigating Management Reserves Safety of Operational System Fraction of Work Remaining 1 2 Overoptimistic Planning Baseline Reserves Sufficient Reserves 0. 75 Overoptimistic Planning Baseline Reserves Sufficient Reserves 1. 5 0. 5 1 0. 25 0. 5 + 0 0 0 10 20 30 40 1. 50 60 70 80 90 100 110 120 130 140 150 Time (Month) 0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 Time (Month) Management reserves have a large positive impact on completion time, & a smaller but significant impact on safety Reserve utilization, management, & monitoring is critical to dampen disturbances in workforce, budget, & technology availability Workforce overwork should be monitored & reserves should be used to alleviate it: 2. 3. • Critical areas include system engineering & integration, safety engineering, & safety assurance (Rework Cycle)

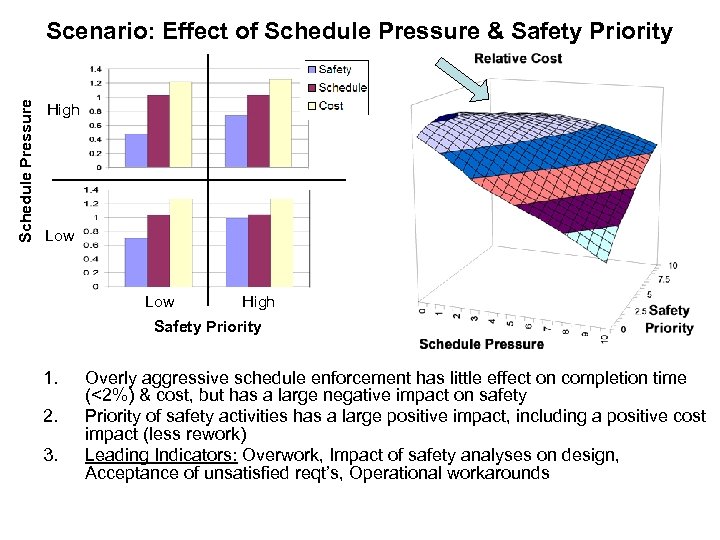

Schedule Pressure Scenario: Effect of Schedule Pressure & Safety Priority High Low High Safety Priority 1. 2. 3. Overly aggressive schedule enforcement has little effect on completion time (<2%) & cost, but has a large negative impact on safety Priority of safety activities has a large positive impact, including a positive cost impact (less rework) Leading Indicators: Overwork, Impact of safety analyses on design, Acceptance of unsatisfied reqt’s, Operational workarounds

Schedule Pressure Scenario: Effect of Schedule Pressure & Safety Priority High Low High Safety Priority 1. 2. 3. Overly aggressive schedule enforcement has little effect on completion time (<2%) & cost, but has a large negative impact on safety Priority of safety activities has a large positive impact, including a positive cost impact (less rework) Leading Indicators: Overwork, Impact of safety analyses on design, Acceptance of unsatisfied reqt’s, Operational workarounds

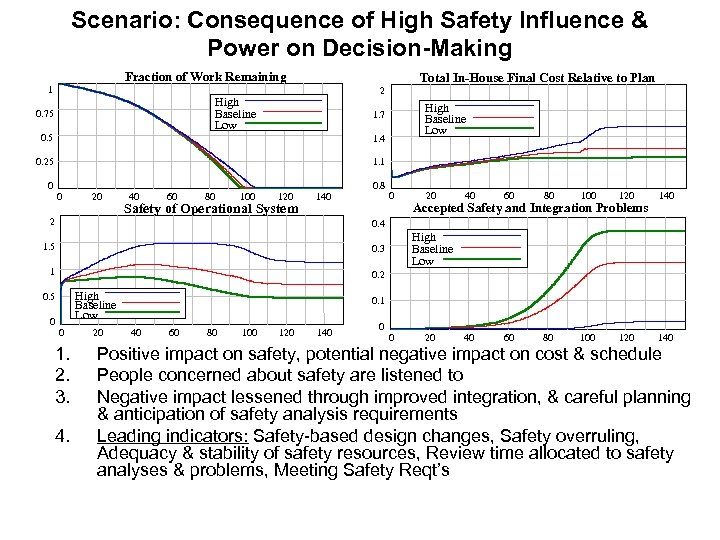

Scenario: Consequence of High Safety Influence & Power on Decision-Making Fraction of Work Remaining Total In-House Final Cost Relative to Plan 1 2 High Baseline Low 0. 75 High Baseline Low 1. 7 0. 5 1. 4 0. 25 1. 1 0 0 20 2 40 60 80 100 120 Safety of Operational System 140 0. 8 0 20 40 60 80 100 120 140 Accepted Safety and Integration Problems 0. 4 1. 5 1 High Baseline Low 0. 3 0. 2 High Baseline Low 0. 5 0 0 1. 2. 3. 4. 20 0. 1 40 60 80 100 120 140 0 0 20 Positive impact on safety, potential negative impact on cost & schedule People concerned about safety are listened to Negative impact lessened through improved integration, & careful planning & anticipation of safety analysis requirements Leading indicators: Safety-based design changes, Safety overruling, Adequacy & stability of safety resources, Review time allocated to safety analyses & problems, Meeting Safety Reqt’s

Scenario: Consequence of High Safety Influence & Power on Decision-Making Fraction of Work Remaining Total In-House Final Cost Relative to Plan 1 2 High Baseline Low 0. 75 High Baseline Low 1. 7 0. 5 1. 4 0. 25 1. 1 0 0 20 2 40 60 80 100 120 Safety of Operational System 140 0. 8 0 20 40 60 80 100 120 140 Accepted Safety and Integration Problems 0. 4 1. 5 1 High Baseline Low 0. 3 0. 2 High Baseline Low 0. 5 0 0 1. 2. 3. 4. 20 0. 1 40 60 80 100 120 140 0 0 20 Positive impact on safety, potential negative impact on cost & schedule People concerned about safety are listened to Negative impact lessened through improved integration, & careful planning & anticipation of safety analysis requirements Leading indicators: Safety-based design changes, Safety overruling, Adequacy & stability of safety resources, Review time allocated to safety analyses & problems, Meeting Safety Reqt’s

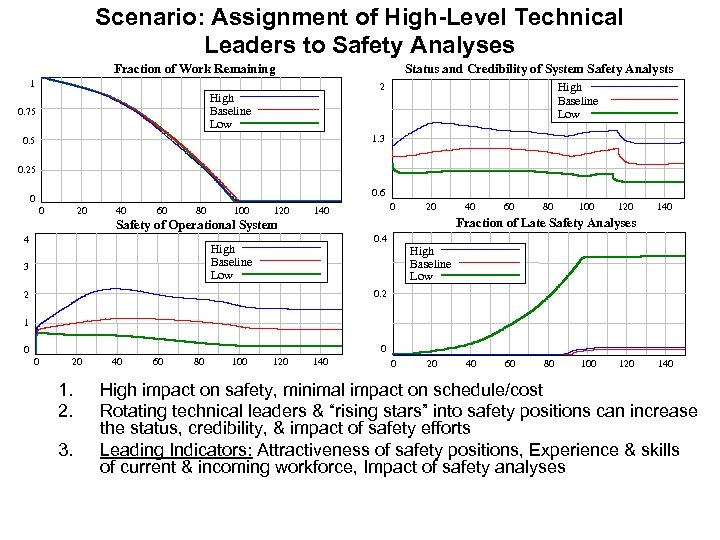

Scenario: Assignment of High-Level Technical Leaders to Safety Analyses Fraction of Work Remaining Status and Credibility of System Safety Analysts 1 0. 75 High Baseline Low 2 High Baseline Low 1. 3 0. 5 0. 25 0. 6 0 0 20 40 60 80 100 120 0 140 20 0. 4 High Baseline Low 3 60 80 100 120 140 Fraction of Late Safety Analyses Safety of Operational System 4 40 High Baseline Low 0. 2 2 1 + 0 0 0 20 1. 2. 3. 40 60 80 100 120 140 0 20 40 60 80 100 120 140 High impact on safety, minimal impact on schedule/cost Rotating technical leaders & “rising stars” into safety positions can increase the status, credibility, & impact of safety efforts Leading Indicators: Attractiveness of safety positions, Experience & skills of current & incoming workforce, Impact of safety analyses

Scenario: Assignment of High-Level Technical Leaders to Safety Analyses Fraction of Work Remaining Status and Credibility of System Safety Analysts 1 0. 75 High Baseline Low 2 High Baseline Low 1. 3 0. 5 0. 25 0. 6 0 0 20 40 60 80 100 120 0 140 20 0. 4 High Baseline Low 3 60 80 100 120 140 Fraction of Late Safety Analyses Safety of Operational System 4 40 High Baseline Low 0. 2 2 1 + 0 0 0 20 1. 2. 3. 40 60 80 100 120 140 0 20 40 60 80 100 120 140 High impact on safety, minimal impact on schedule/cost Rotating technical leaders & “rising stars” into safety positions can increase the status, credibility, & impact of safety efforts Leading Indicators: Attractiveness of safety positions, Experience & skills of current & incoming workforce, Impact of safety analyses

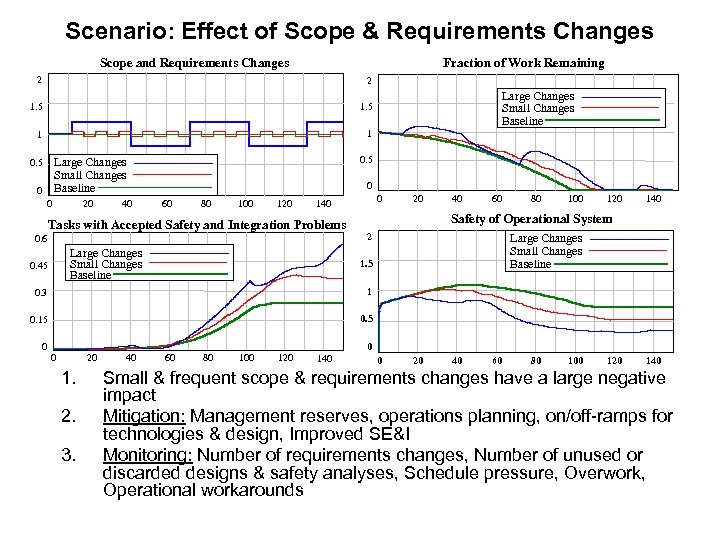

Scenario: Effect of Scope & Requirements Changes Fraction of Work Remaining Scope and Requirements Changes 2 2 1. 5 1 1 0. 5 Large Changes Small Changes Baseline 0. 5 0 0 20 40 0 60 80 100 120 0 140 Tasks with Accepted Safety and Integration Problems 0. 6 Large Changes Small Changes Baseline 0. 45 Large Changes Small Changes Baseline 20 40 60 80 100 120 140 Safety of Operational System 2 Large Changes Small Changes Baseline 1. 5 0. 3 1 0. 15 0. 5 0 0 0 20 1. 2. 3. 40 60 80 100 120 140 0 20 40 60 80 100 120 140 Small & frequent scope & requirements changes have a large negative impact Mitigation: Management reserves, operations planning, on/off-ramps for technologies & design, Improved SE&I Monitoring: Number of requirements changes, Number of unused or discarded designs & safety analyses, Schedule pressure, Overwork, Operational workarounds

Scenario: Effect of Scope & Requirements Changes Fraction of Work Remaining Scope and Requirements Changes 2 2 1. 5 1 1 0. 5 Large Changes Small Changes Baseline 0. 5 0 0 20 40 0 60 80 100 120 0 140 Tasks with Accepted Safety and Integration Problems 0. 6 Large Changes Small Changes Baseline 0. 45 Large Changes Small Changes Baseline 20 40 60 80 100 120 140 Safety of Operational System 2 Large Changes Small Changes Baseline 1. 5 0. 3 1 0. 15 0. 5 0 0 0 20 1. 2. 3. 40 60 80 100 120 140 0 20 40 60 80 100 120 140 Small & frequent scope & requirements changes have a large negative impact Mitigation: Management reserves, operations planning, on/off-ramps for technologies & design, Improved SE&I Monitoring: Number of requirements changes, Number of unused or discarded designs & safety analyses, Schedule pressure, Overwork, Operational workarounds

Resources and Opportunities • New book on the model (about 300 pages written) http: //sunnyday. mit. edu/book 2. html • Commercial tools are being developed by Safeware Engineering Corp.

Resources and Opportunities • New book on the model (about 300 pages written) http: //sunnyday. mit. edu/book 2. html • Commercial tools are being developed by Safeware Engineering Corp.

Summary • A new, more inclusive model of accident causation (STAMP) allows more powerful: – Hazard analysis techniques – Accident/incident investigation and root cause analysis – Design for safety starting in concept development – Project and organizational risk analysis and risk management tools – New, holistic approaches to security

Summary • A new, more inclusive model of accident causation (STAMP) allows more powerful: – Hazard analysis techniques – Accident/incident investigation and root cause analysis – Design for safety starting in concept development – Project and organizational risk analysis and risk management tools – New, holistic approaches to security